Medium high-rise concrete modularization building structure system

A technology for concrete building and building structure, applied in building construction, construction and other directions, can solve the problem of difficult and high building assembly rate, and achieve the effect of improving building quality and construction speed, shortening construction period, and improving the degree of industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further illustrate the principle of the present invention and the concrete modular building structure, the embodiments of the present invention will now be described in detail in conjunction with the accompanying drawings.

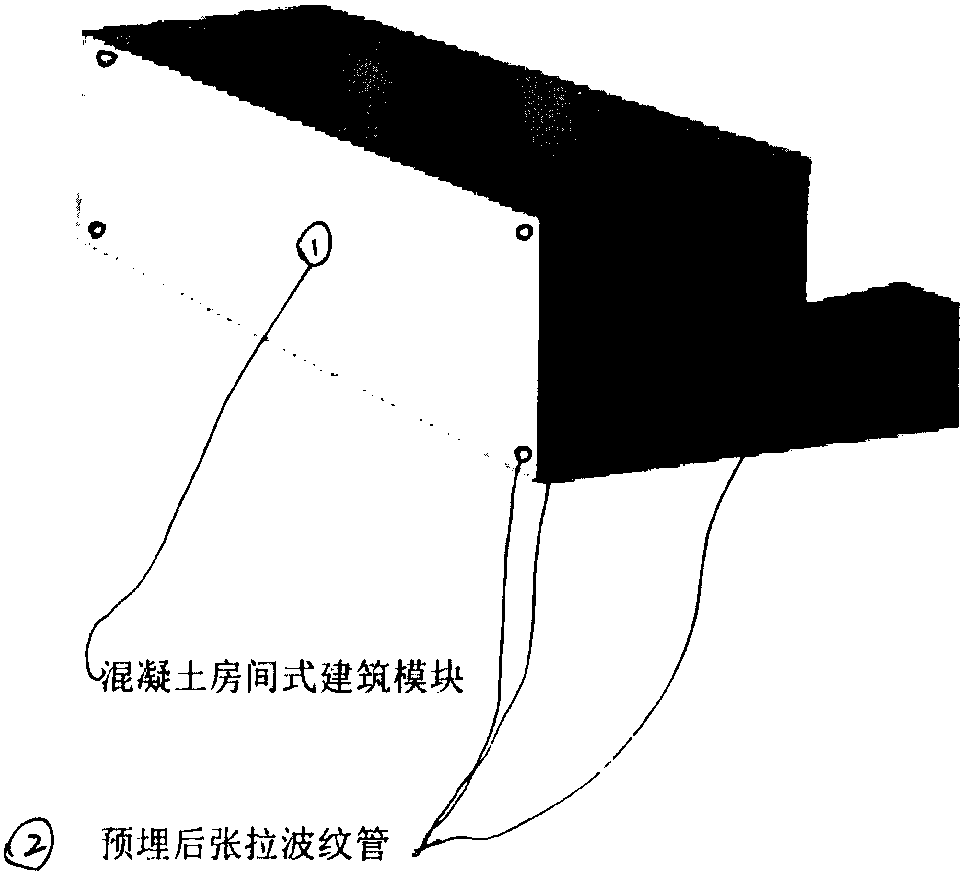

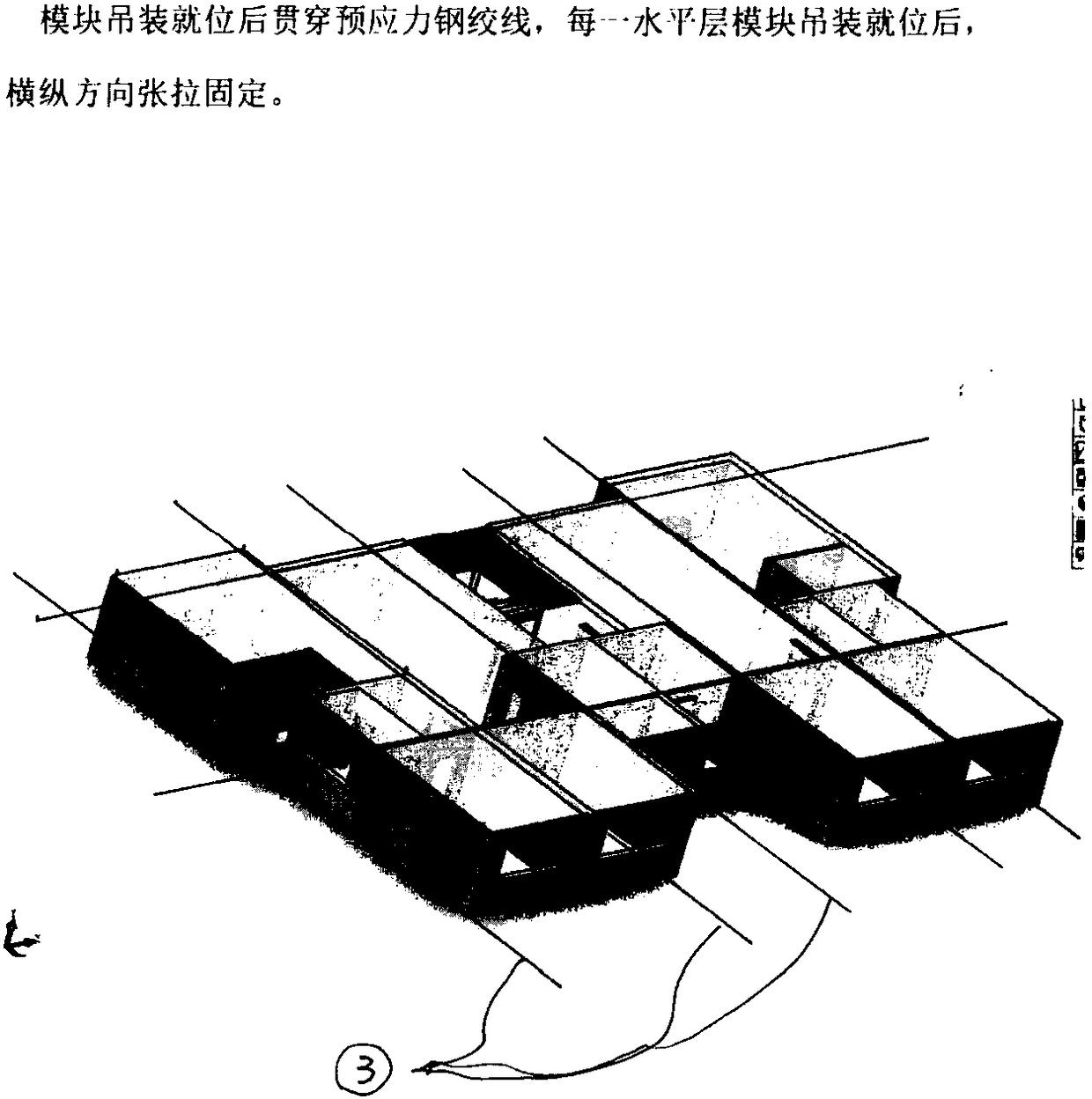

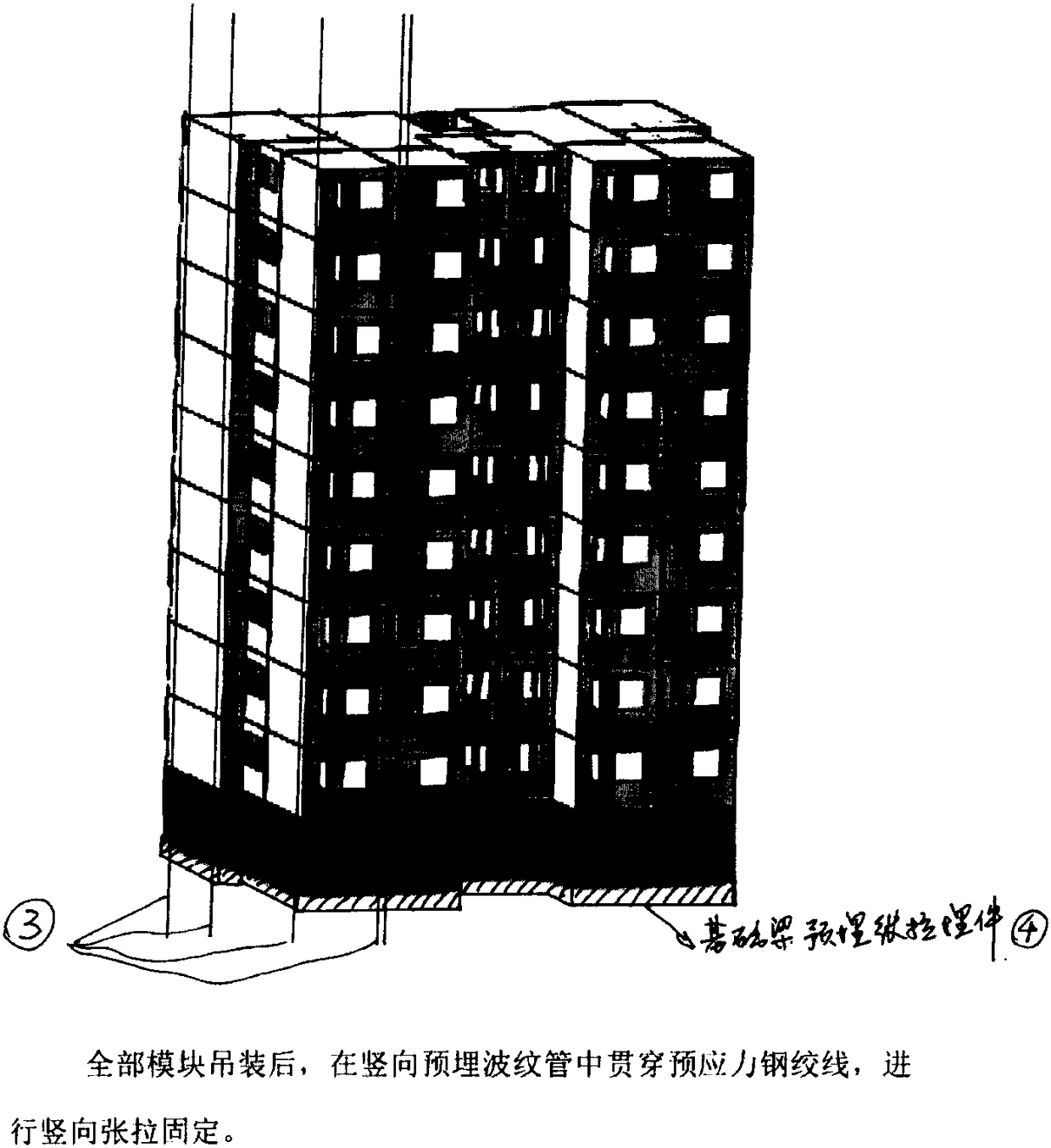

[0015] see figure 1 , this embodiment provides a concrete modular building structure system. Depend on figure 1 Several concrete room-type modules 1 embedded with post-tensioned prestressed bellows 2 form a high-rise building; several modules 1 form a figure 2 It is the flat floor of a floor, and the prestressed steel strand 3 is run through the prestressed corrugated pipe 2, and is stretched and fixed in the horizontal and vertical directions to form a whole floor. figure 2 After all the floors are hoisted and fixed in place in this order, the prestressed steel strands 3 are penetrated up and down in the vertical pre-embedded prestressed bellows 2, and the whole building is vertically tensioned and fixed. image 3 . The tension me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com