Mechanical agitation type body-expanding anti-floating anchor construction method

A technology of anti-floating anchor and mechanical stirring, which is used in infrastructure engineering, sheet pile walls, protection devices, etc., to increase the anti-pulling capacity, protect the environment, and reduce the amount of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

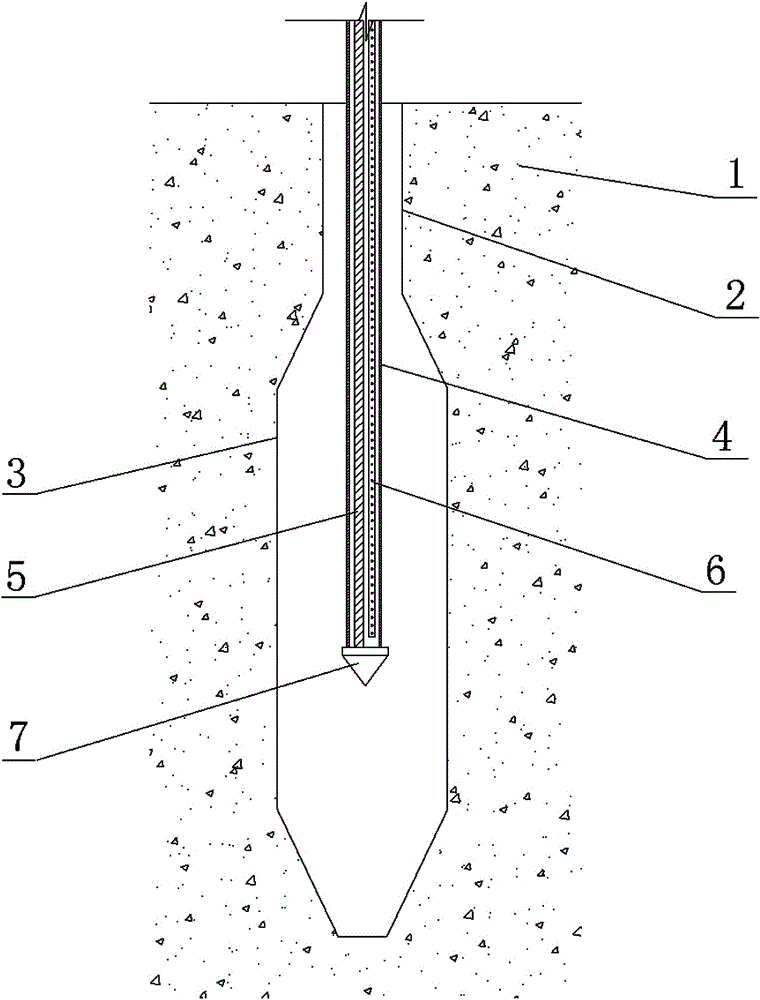

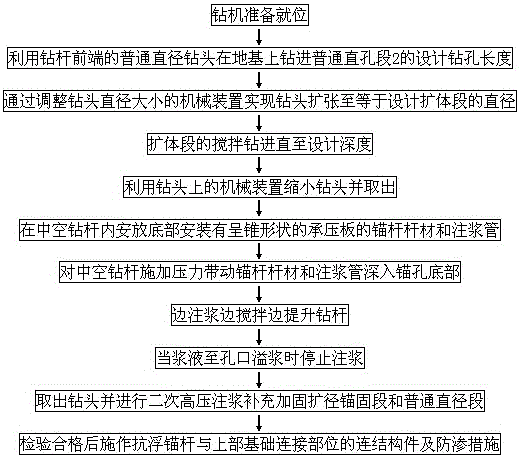

[0028] Such as figure 1 and figure 2 Shown, the construction method of mechanical agitation type expansion body anti-floating anchor rod, it comprises the following steps:

[0029] S1. The drilling rig is ready to be in place;

[0030] S2, using the common diameter drill bit at the front end of the drill rod to drill into the designed drilling length of the common straight hole section 2 on the foundation 1;

[0031] S3. Through the mechanical device for adjusting the diameter of the drill bit, the drill bit can be expanded to the diameter equal to the designed expansion section 3, and mechanically stirred to form holes without dust, which protects the environment and realizes green construction;

[0032] S4, use the drill bit to complete the stirring and drilling of the expansion section 3 until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com