Inserted type outer frame L-type steel wall connecting piece structure free of scaffold hole and construction method thereof

A wall-connecting and plug-in technology, which is applied to the scaffold-free and eye-plug-in L-shaped steel connecting wall structure and its construction field, can solve the problems affecting the progress and quality of railing installation, external window installation and external wall decoration, and affecting the normal operation of the project. Construction and safety performance are not high enough to achieve the effect of improving the quality of decoration projects, convenient and fast construction, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

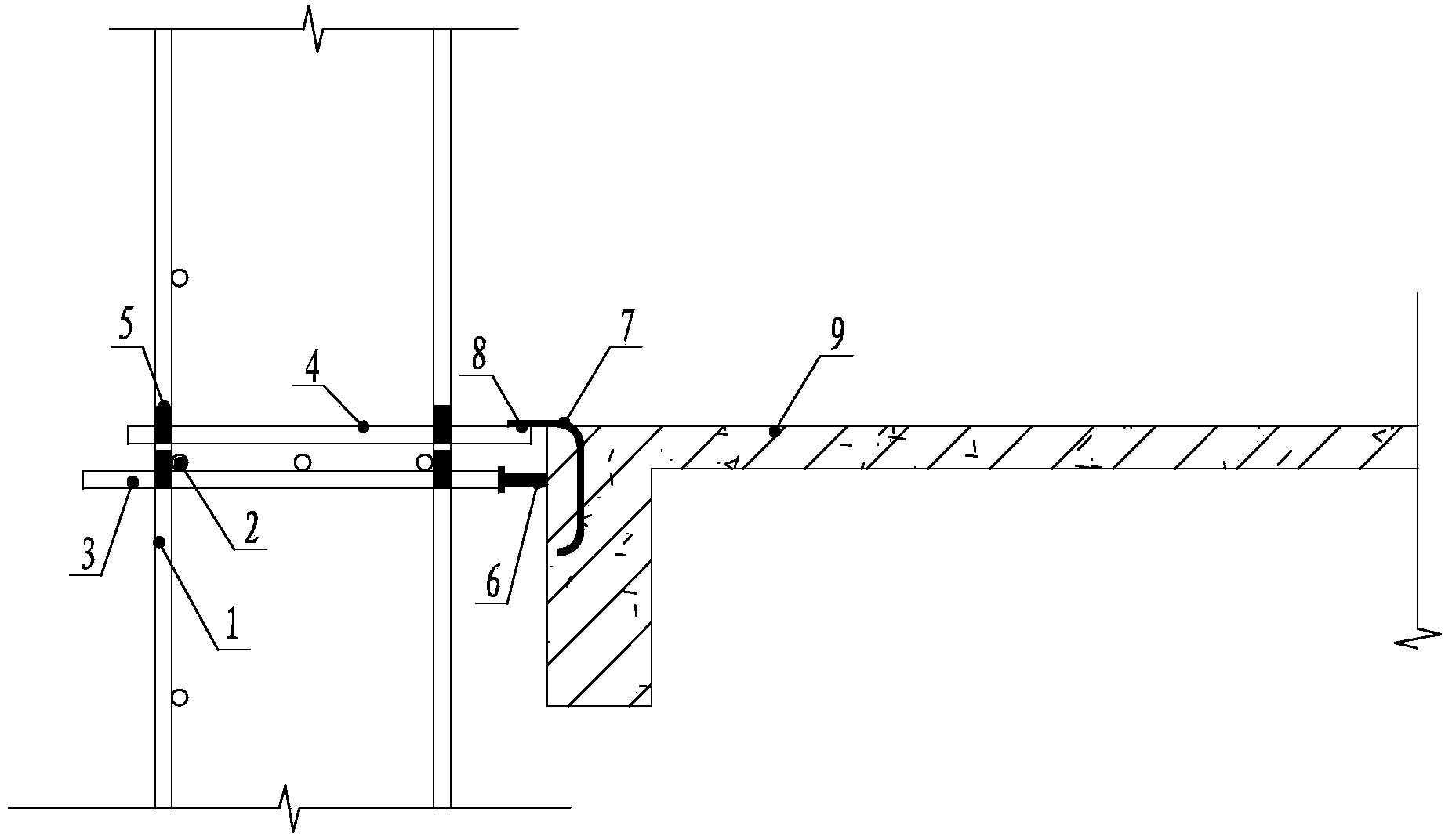

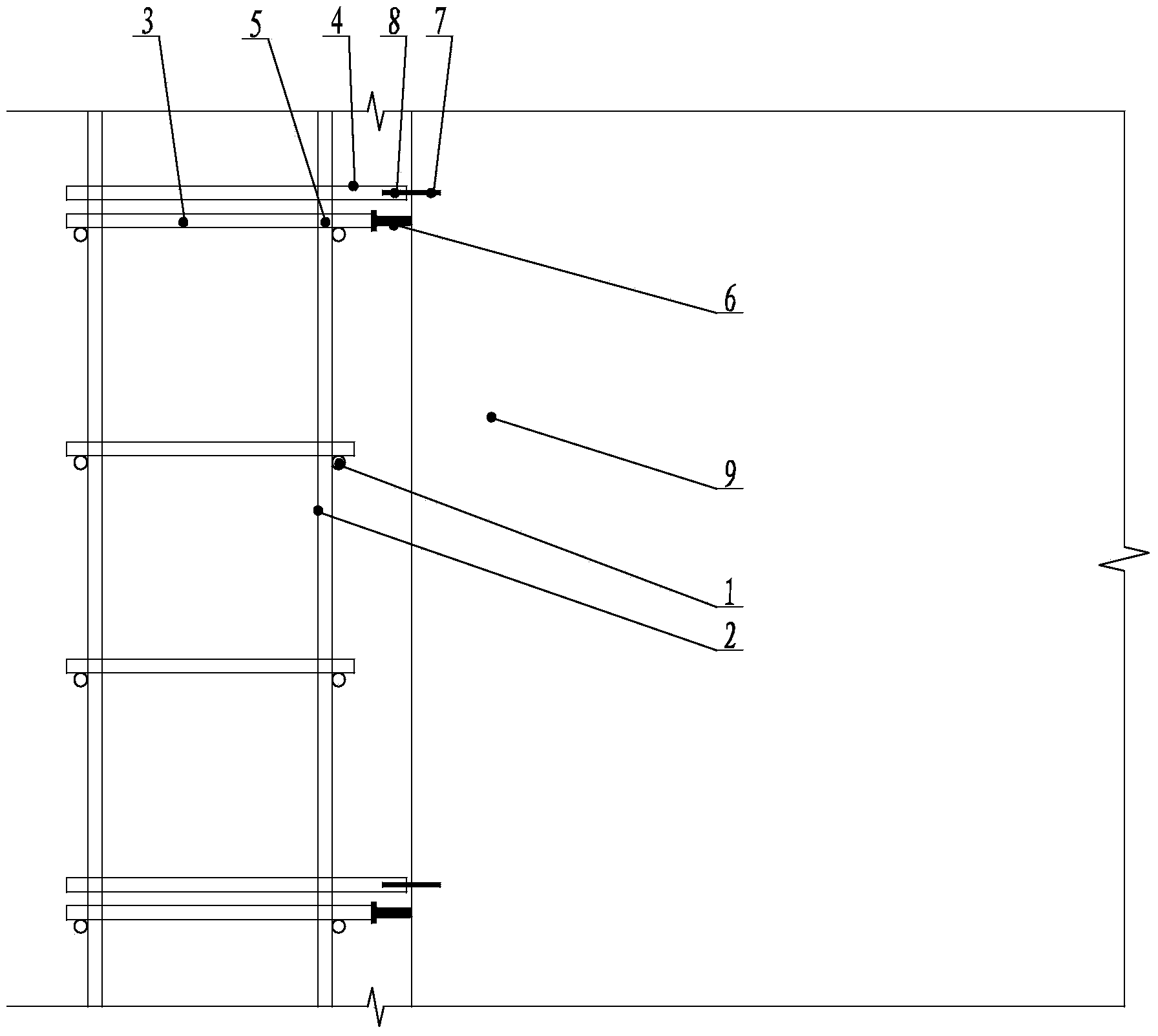

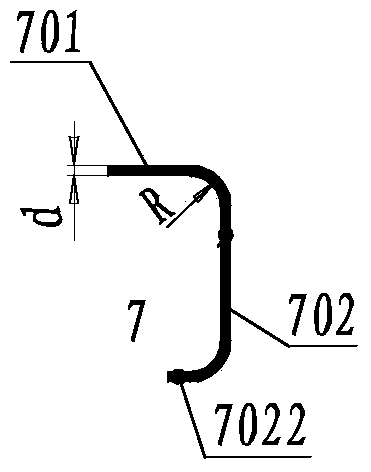

[0080] A hand-eye-free plug-in type outer frame L-shaped steel wall connection structure installed on the side beam of the balcony of a building, including the outer frame and the wall connection part. The outer frame is mainly composed of a vertical rod 1, a large horizontal rod The crossbar 3 is formed, and the wall connecting piece includes a wall connecting rod 4 and an L-shaped steel 7. The L-shaped steel 7 is composed of a short side 701 and a long side 702, and the long side 702 of the L-shaped steel 7 has a Hook 7022 (see image 3 ), the hook 7022 can help to fix the position and increase the riveting degree between the wall piece and the main body, and it is easy to manufacture and install; the L-shaped steel 7 is made of a threaded steel bar head, and the steel bar diameter of the threaded steel bar head is d=25mm , bending radius R≥4 times the steel bar diameter; the length of the short side 701 of the L-shaped steel=500mm, the length of the long side 702 of the L-s...

Embodiment 2

[0099] A hand-eye-free plug-in type outer frame L-shaped steel wall connection structure installed on the side beam of the main body of the building, including the outer frame and the wall connection part. The outer frame is mainly composed of a vertical bar 1, a large horizontal bar 2, a small The crossbar 3 is formed, and the wall connecting piece includes a wall connecting rod 4 and an L-shaped steel 7. The L-shaped steel 7 is composed of a short side 701 and a long side 702, and the long side 702 of the L-shaped steel 7 has a Irregularly sloped barb 7021 (see Figure 10 ), the irregular inclined setting of the barb 7021 can help to fix the position and increase the riveting degree between the wall parts and the main body, and prevent the displacement and deformation of the buried wall end during concrete pouring; the L-shaped steel 7 is made of square steel profiles, The short side 701 of the L-shaped steel has a length of 900 mm, and the long side 702 has a length of 1200...

Embodiment 3

[0117] A hand-eye-free plug-in type outer frame L-shaped steel wall connection structure installed on concrete walls and pillars, including an outer frame and wall connection parts. The outer frame is mainly composed of vertical rods 1, large horizontal rods 2, The crossbar 3 is formed, and the wall connecting piece includes a wall connecting rod 4 and an L-shaped steel 7. The L-shaped steel 7 is composed of a short side 701 and a long side 702, and the long side 702 of the L-shaped steel 7 has a Irregularly sloped barb 7021 (see Figure 17 ), the irregularly inclined setting of the barb 7021 can help to fix the position and increase the riveting degree between the wall parts and the main body, and prevent the displacement and deformation of the buried wall end during concrete pouring; the L-shaped steel is made of flat steel or angle steel profiles , the length of the short side of the L-shaped steel = 700mm, and the length of the long side of the L-shaped steel = 1000mm. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com