Underground construction constructed in assembled mode and construction method of underground construction

A technology of underground construction and construction method, which is applied in construction, artificial islands, water conservancy projects, etc. It can solve the problems of unguaranteed project quality, waste of construction materials, and low operating efficiency, so as to save temporary construction materials, reduce noise and dust Pollution, the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

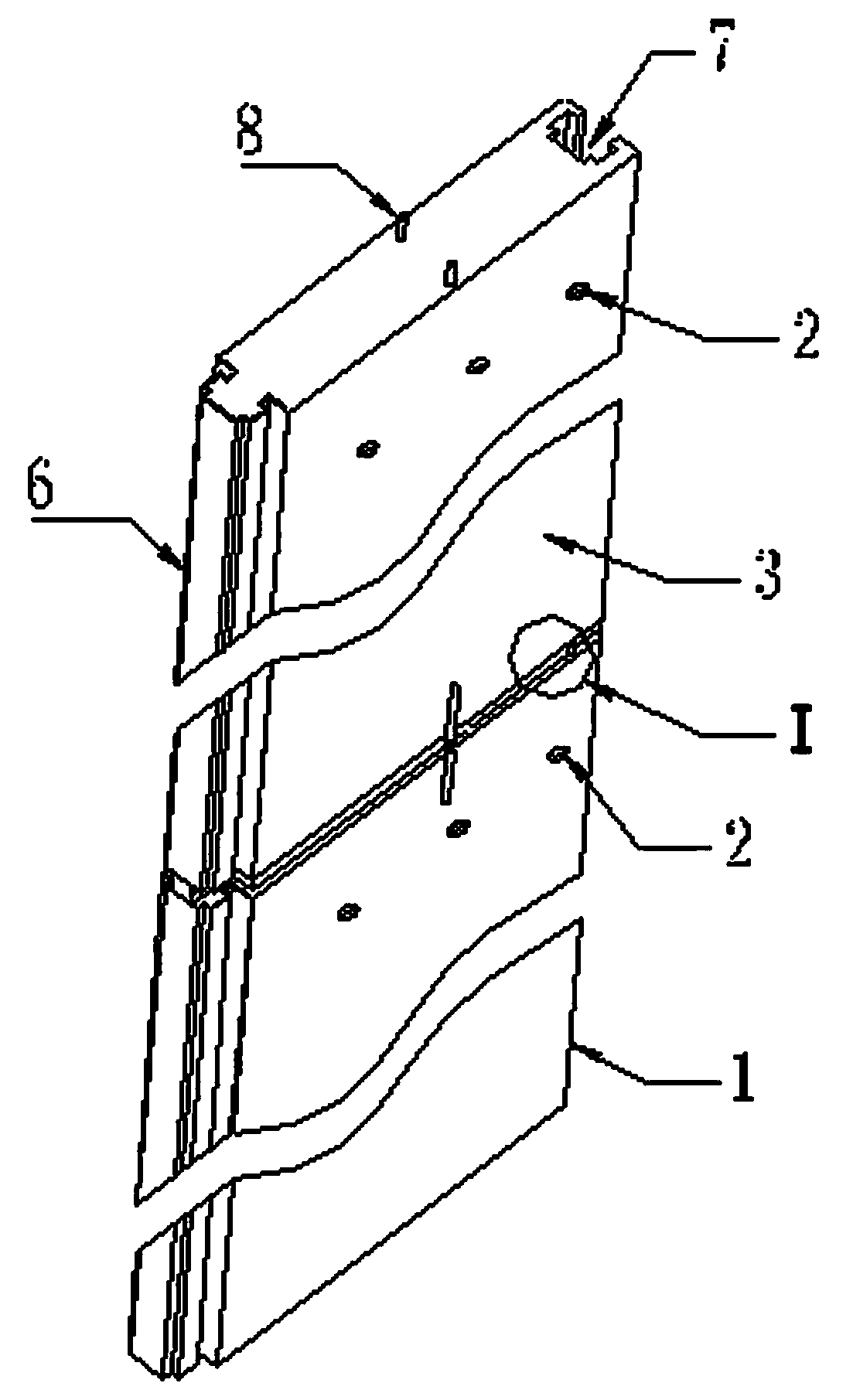

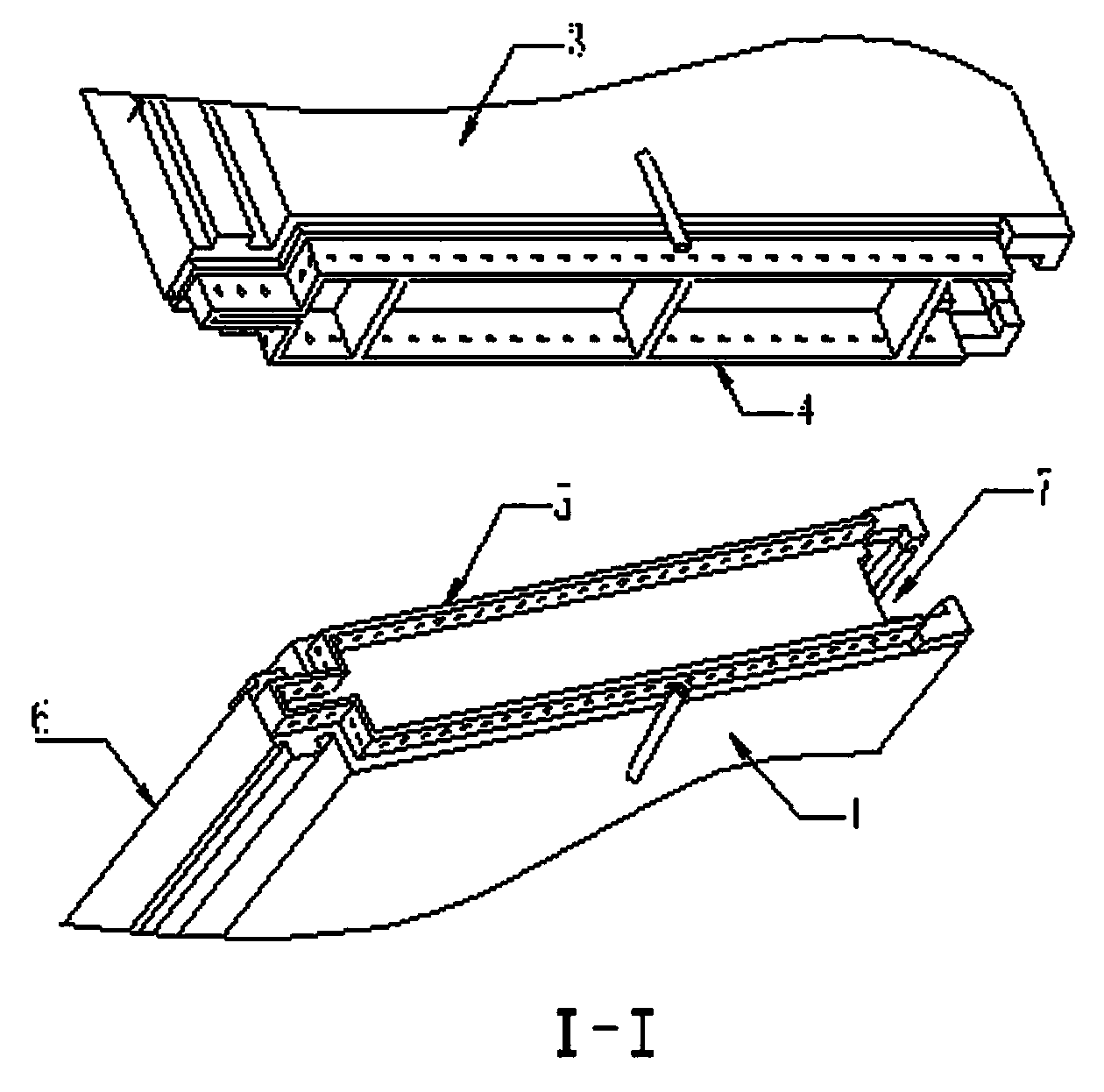

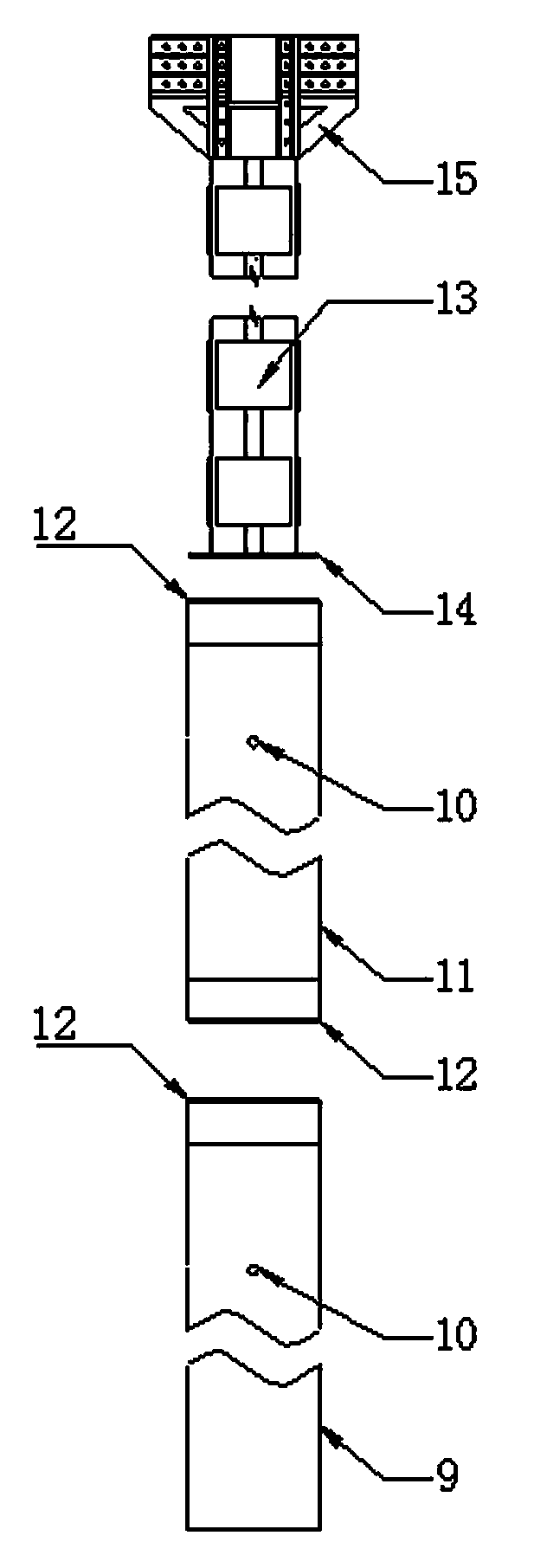

[0038] refer to Figure 1-Figure 10 , an assembly construction method for underground buildings, comprising prefabricated underground diaphragm walls (upper panel 1, lower panel 3), steel lattice columns 13, prefabricated concrete piles (upper section 11, lower section 9), prefabricated main beams 16, section steel secondary Beam 17, prefabricated prestressed floor slabs 18, 19, 20 are characterized in that:

[0039] The prefabricated components are prefabricated in a factory;

[0040] The prefabricated underground continuous wall panel 1 and the lower panel 3 are connected by bolts of the embedded steel plate combination joints 4 and 5, and painted with epoxy coal tar pitch anti-corrosion paint; the left panel and the right panel are inserted through the slots 6 and 7, and the slots 7. Paste the water-swelling water-stop strip in advance.

[0041] The prefabricated pile 11 of the upper section and the prefabricated pile 9 of the lower section are welded by the pre-embedded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com