Patents

Literature

352 results about "Latticework" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Latticework is an openwork framework consisting of a criss-crossed pattern of strips of building material, typically wood or metal. The design is created by crossing the strips to form a grid or weave. Latticework may be functional – for example, to allow airflow to or through an area; structural, as a truss in a lattice girder; used to add privacy, as through a lattice screen; purely decorative; or some combination of these.

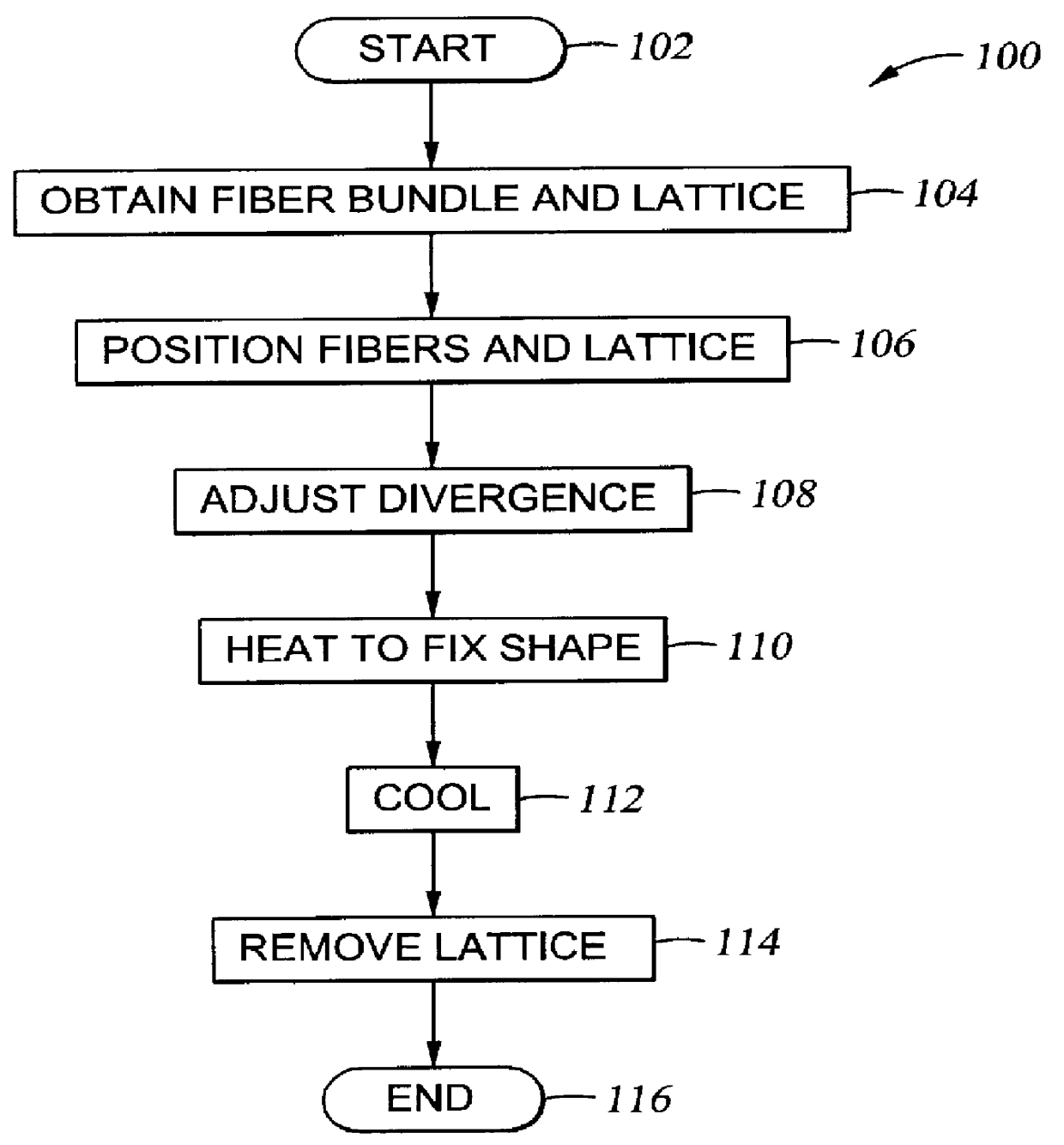

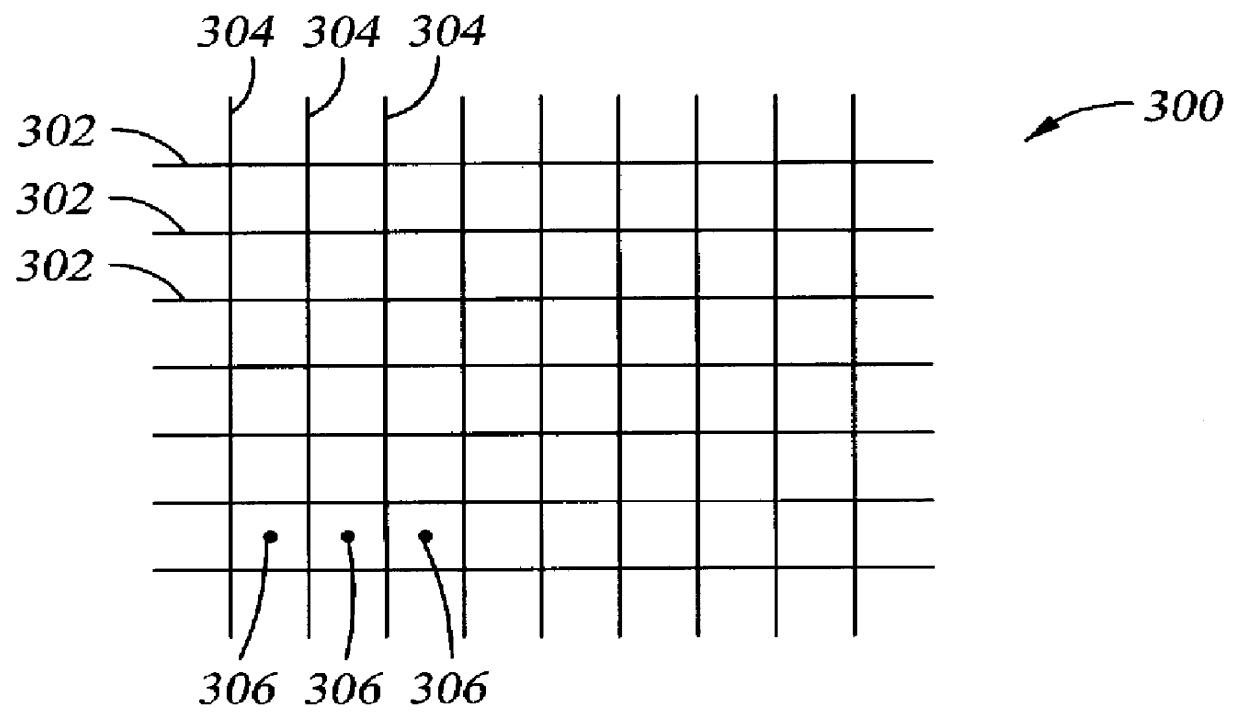

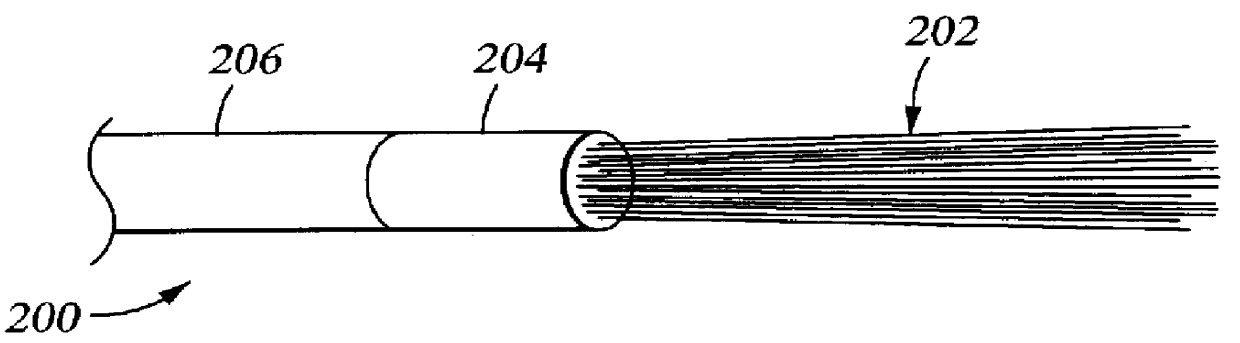

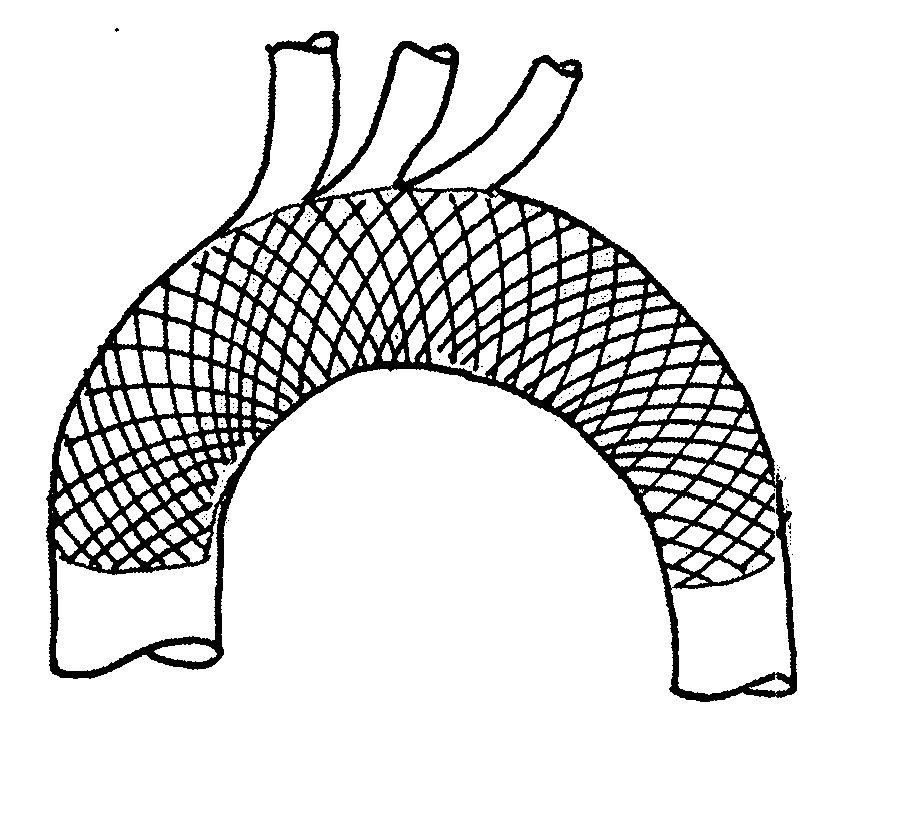

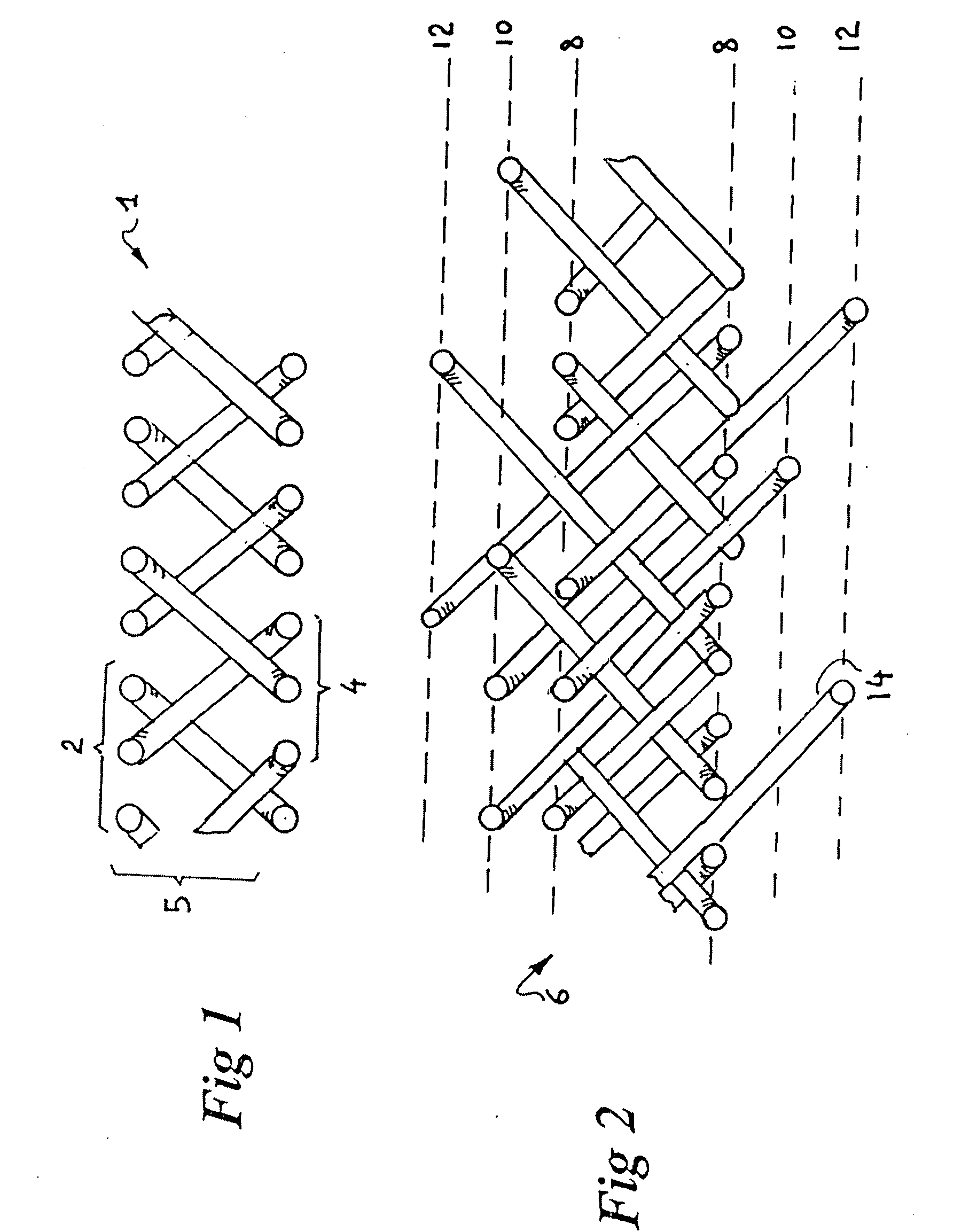

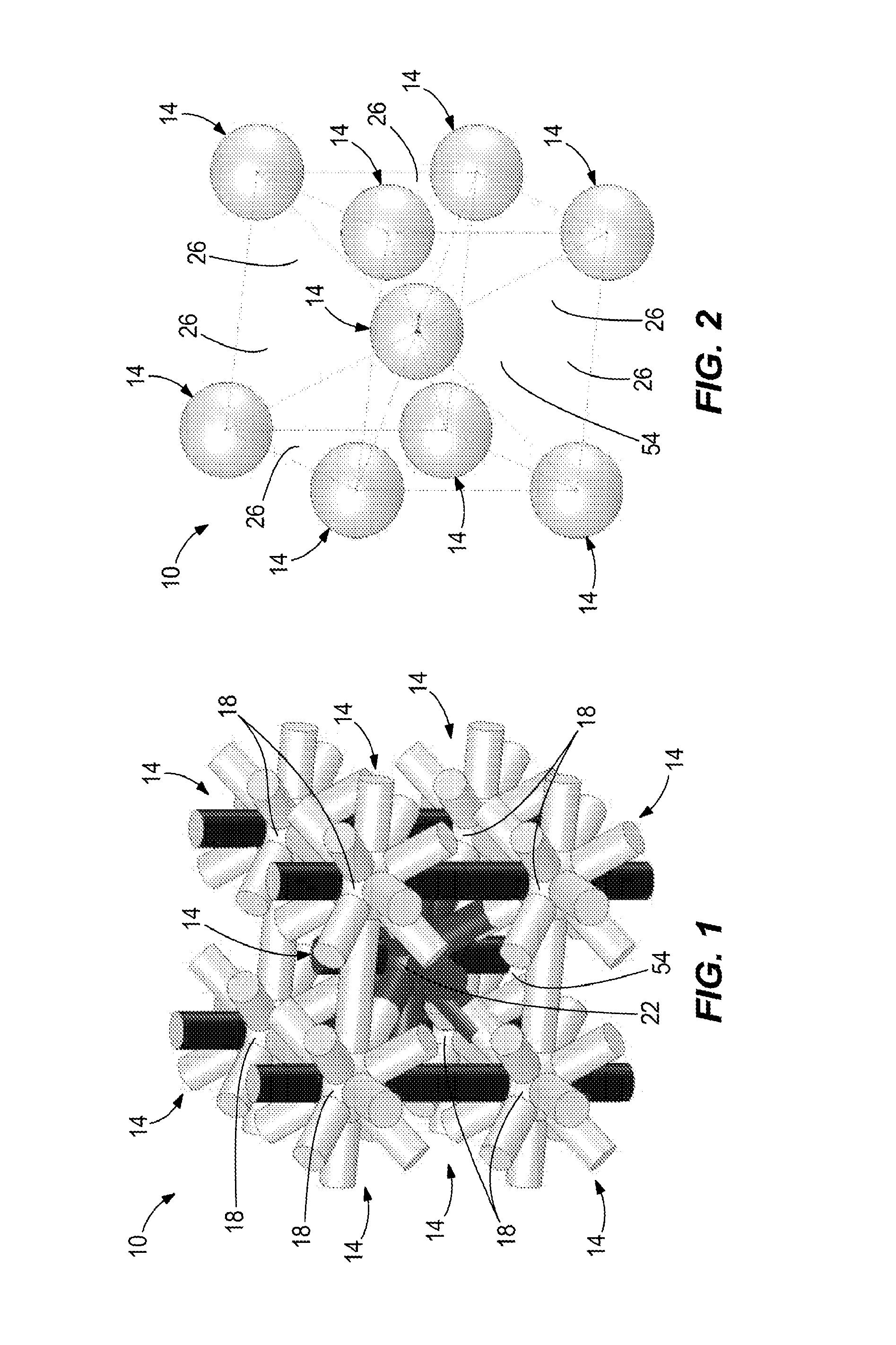

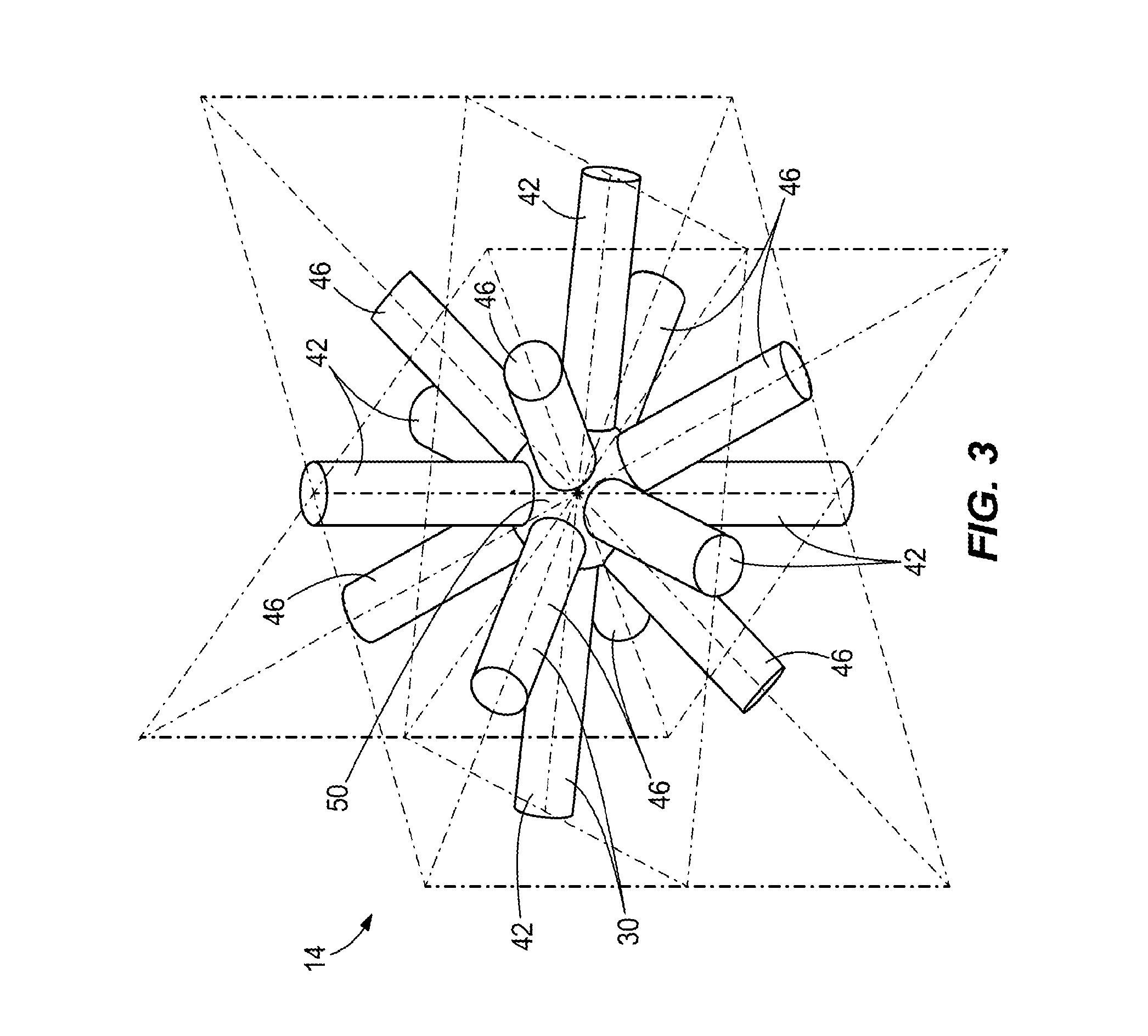

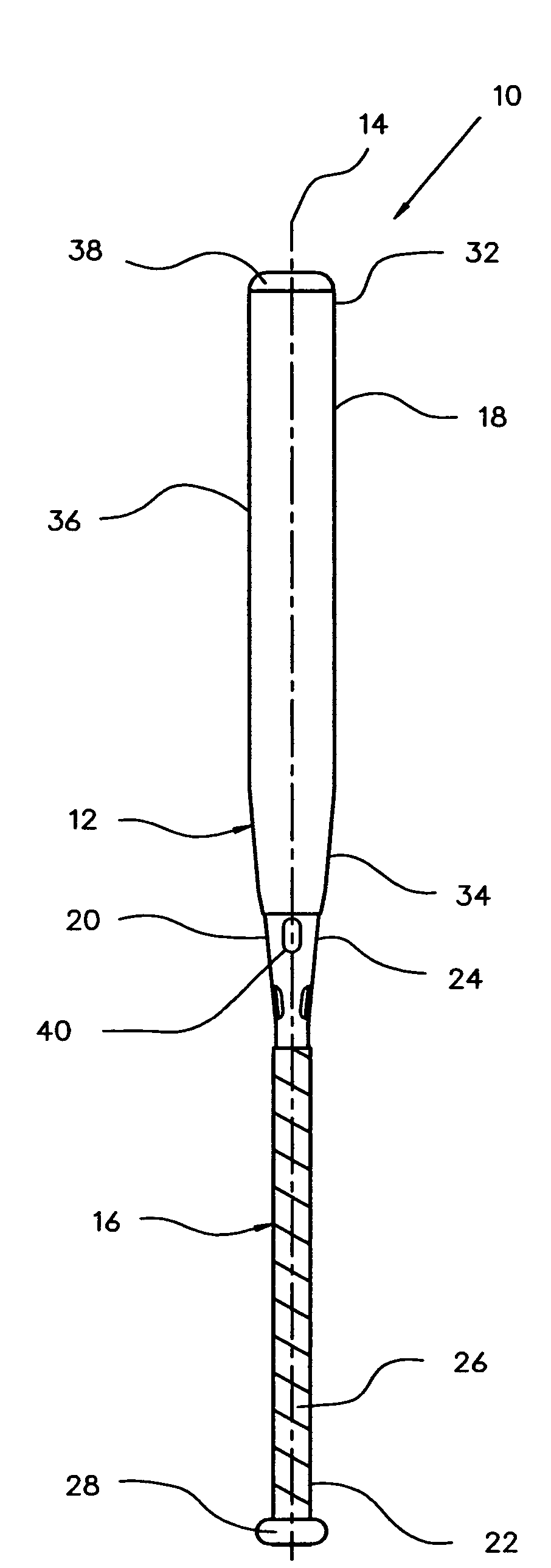

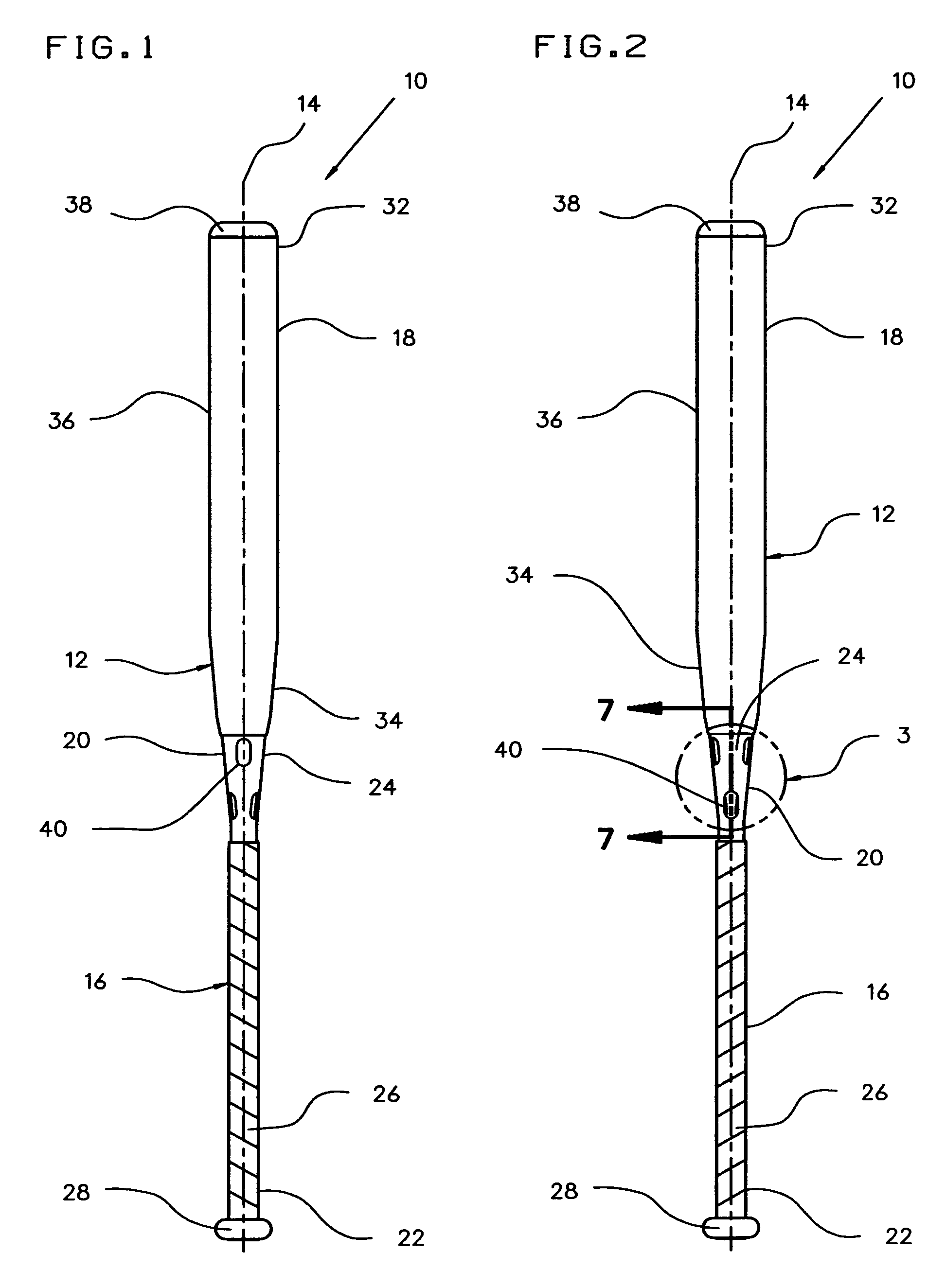

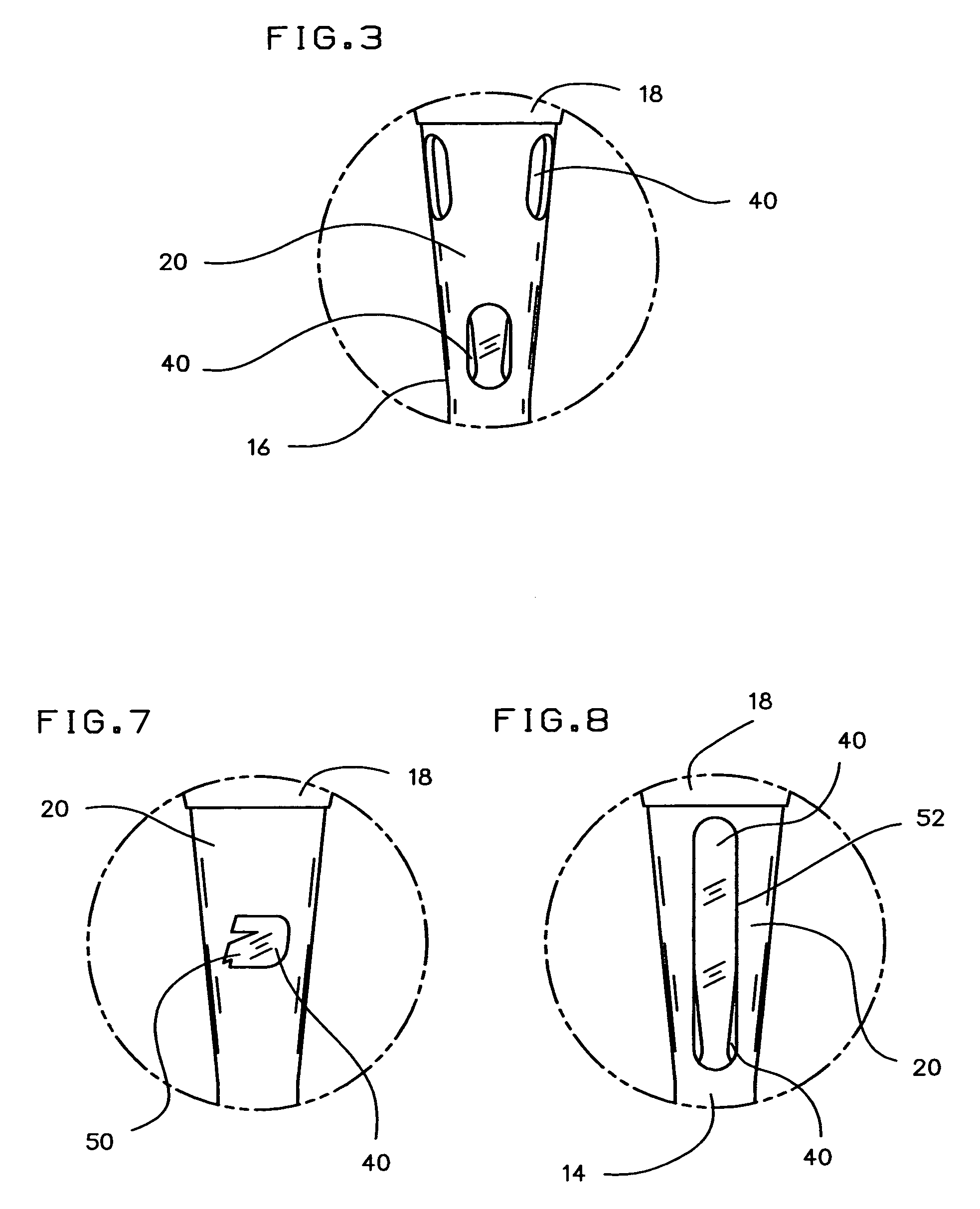

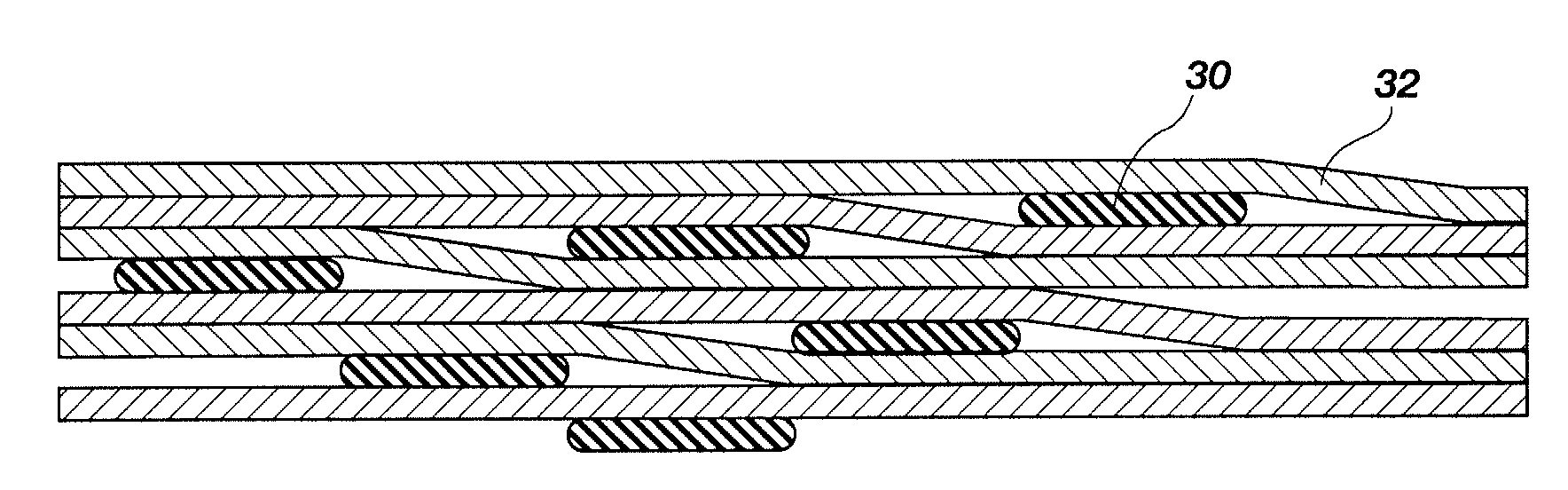

Method of selectively shaping hollow fibers of heat exchange catheter

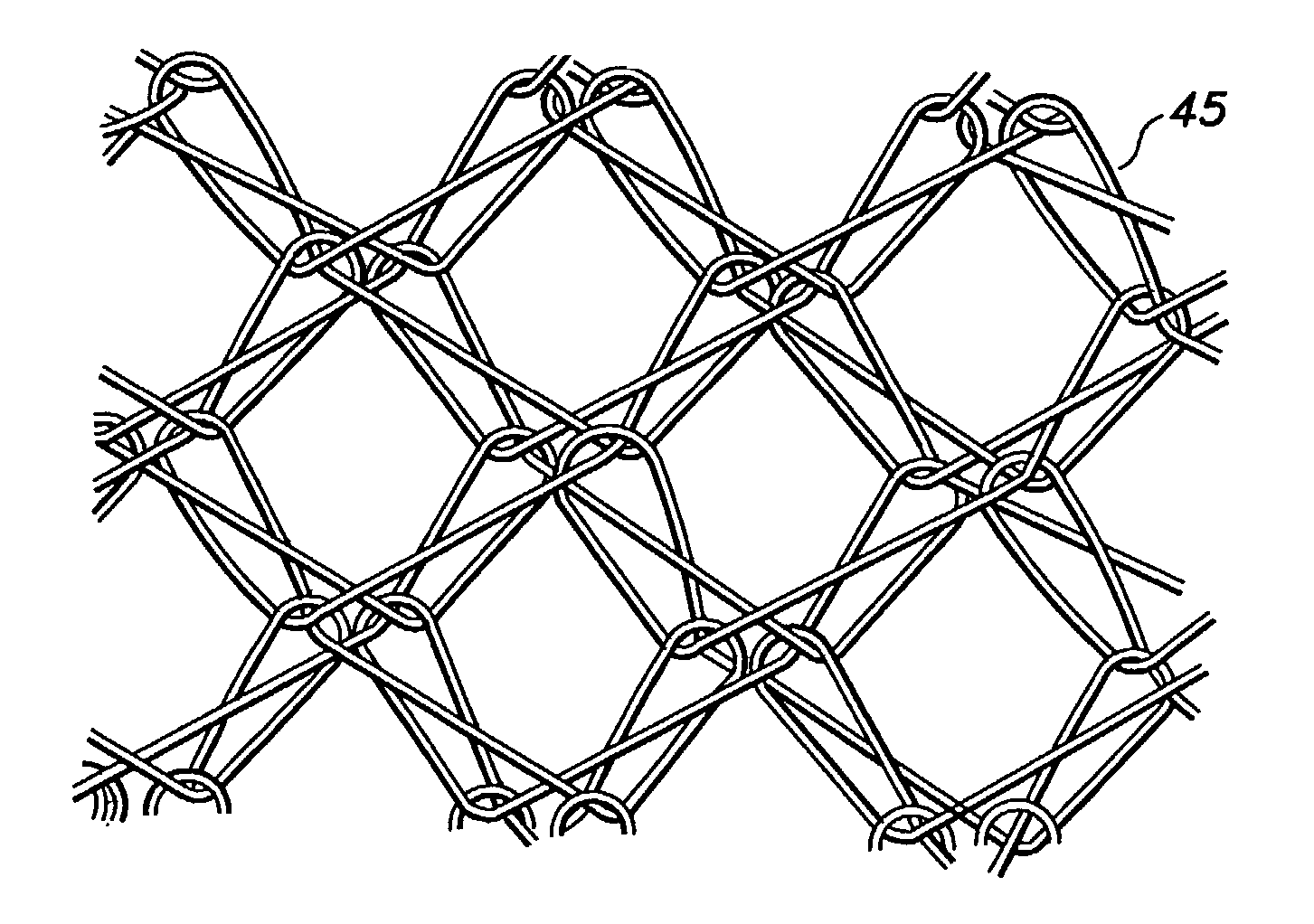

A group of multiple hollow fibers may be shaped to introduce angular divergence among the fibers, or to introduce a selected longitudinal oscillation into the fibers. In one shaping technique, the fibers are held in parallel while upper and lower crimping assemblies of parallel crimping bars are drawn together on opposite sides of the parallel fibers. When bars of the opposing assemblies draw sufficiently close, they sandwich the fibers in between them, causing each fiber to assume a shape that oscillates as the fiber repeatedly goes over and then under successive bars. Since the crimping bars are aligned at oblique angles to the fibers, the peaks and troughs of successive fibers are offset. While in this position, the fibers are heated and then cooled to permanently retain their shapes. A different shaping technique utilizes a lattice of crisscrossing tines defining multiple apertures. In this technique, the lattice and fibers are positioned so that each fiber passes through one of the apertures. Then, the lattice and / or the fibers are slid apart or together until the lattice holds the fibers in a desired configuration, where the fibers have a prescribed outward divergence relative to each other. While in this position, the fibers are heated and then cooled to permanently retain this angular divergence.

Owner:ZOLL CIRCULATION

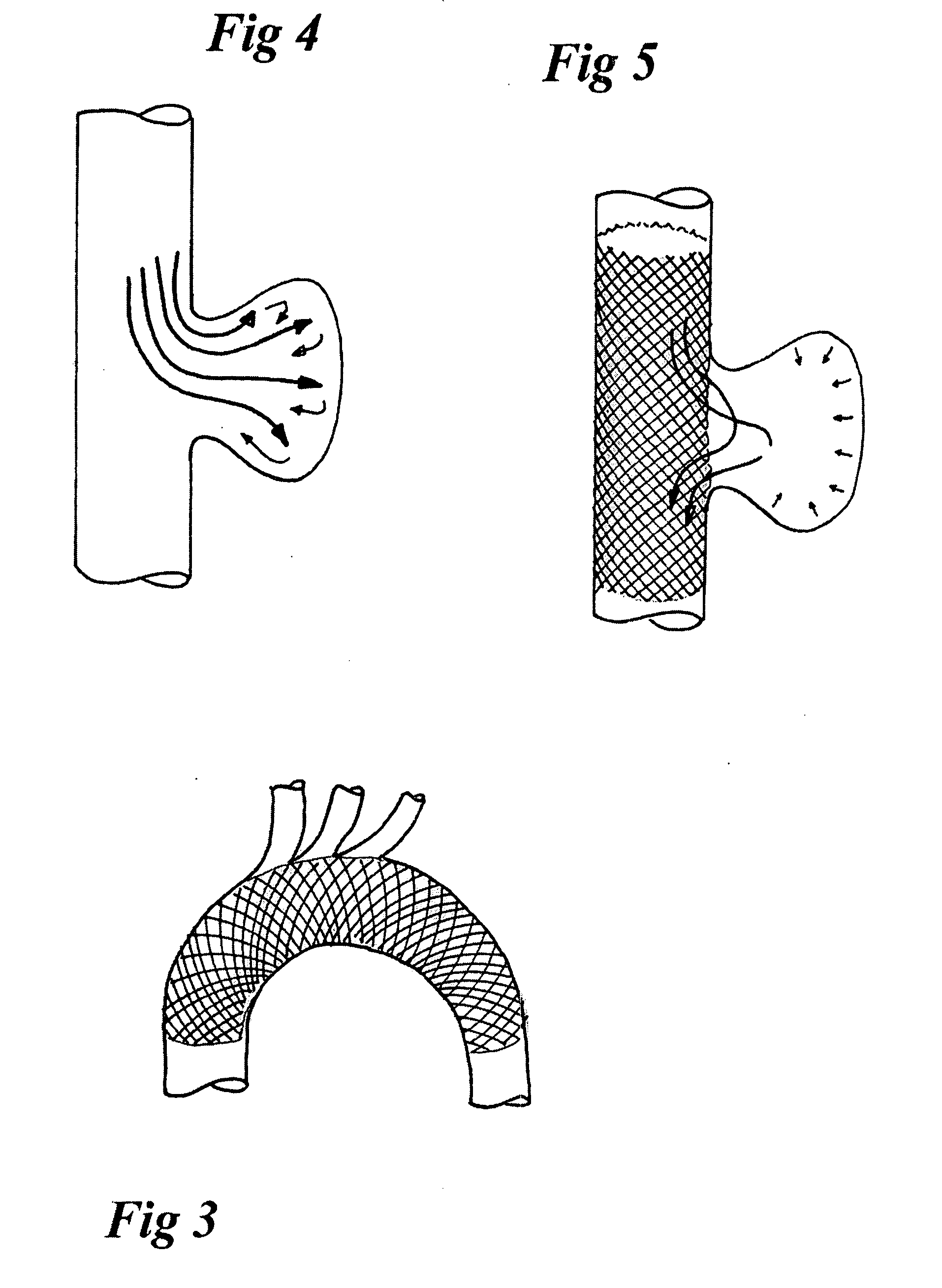

Stent for blood flow improvement

InactiveUS20070162104A1Avoids low shear stress flowInhibit hyperplasiaStentsBlood vesselsHemodynamicsBiomedical engineering

Luminal endoprosthesis formed of a multi-layer braided framework. The framework is devoid of any cover layer, and formed of a plurality of stabilized layers of biocompatible metal wires which are interlaced, forming a lattice, a plurality of wires of a given layer being integrated in the lattice of the adjacent layers. The mechanical characteristics of an outermost layer is so that when in place, the layer applies against a vessel wall, the other layers extending substantially along cylindrical surfaces distinct from the outermost layer so as to form a multi-layer mat which affects the haemodynamic of a flow of blood passing along or through this mat and preventing a growing of plaque.

Owner:CARDIATIS SA

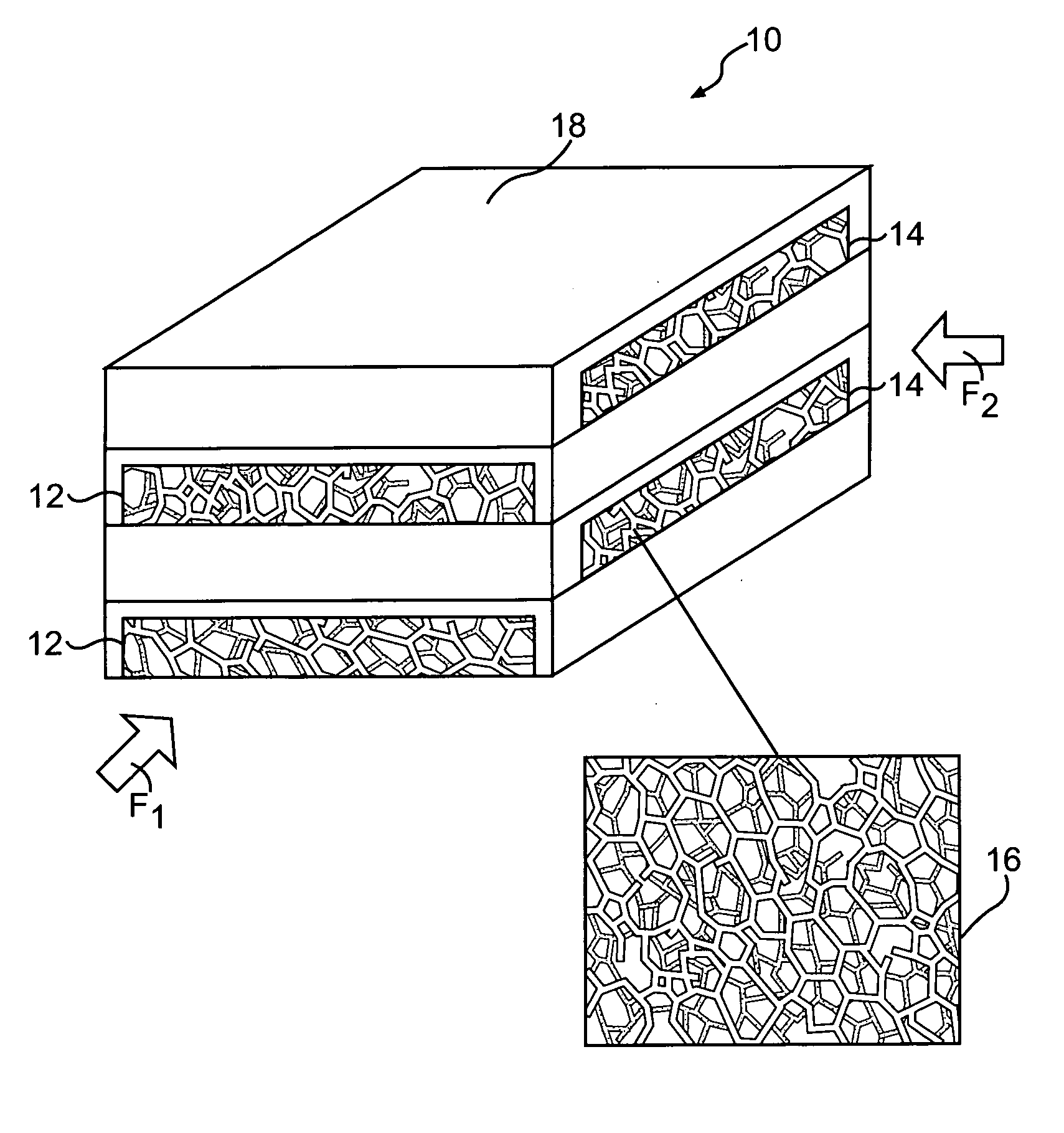

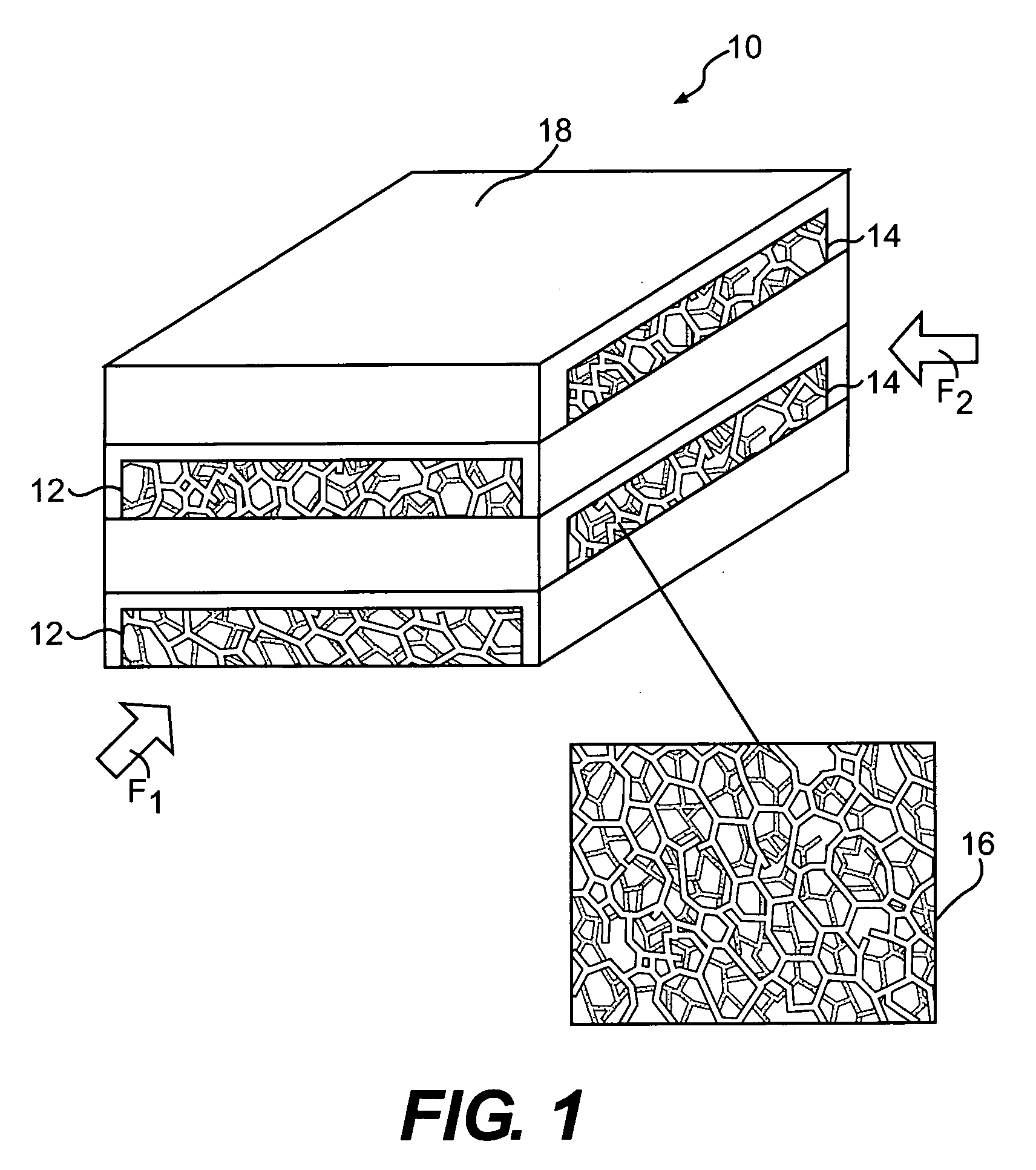

Micro heat exchanger with thermally conductive porous network

ActiveUS20060245987A1Inexpensive and efficient to manufactureGaseous chemical processesAdditive manufacturing apparatusThermal energyReticulated foam

A micro heat exchanger system includes a first flow path and a second flow path transverse thereto for transferring thermal energy between a first fluid flowing through the first flow path and a second fluid flowing through the second flow path. The first flow path and the second flow path are filled with a thermally conductive porous network which incorporate unique structures, such as tubes, honeycomb, corrugated metal, reticulated foams, woven meshes or nonwoven mats or felts, engineered lattice structures, or a combination of these structures. In another embodiment, the thermally conductive porous network is coated with catalyst to provide an integrated heat exchanger and catalytic reactors.

Owner:RTX CORP

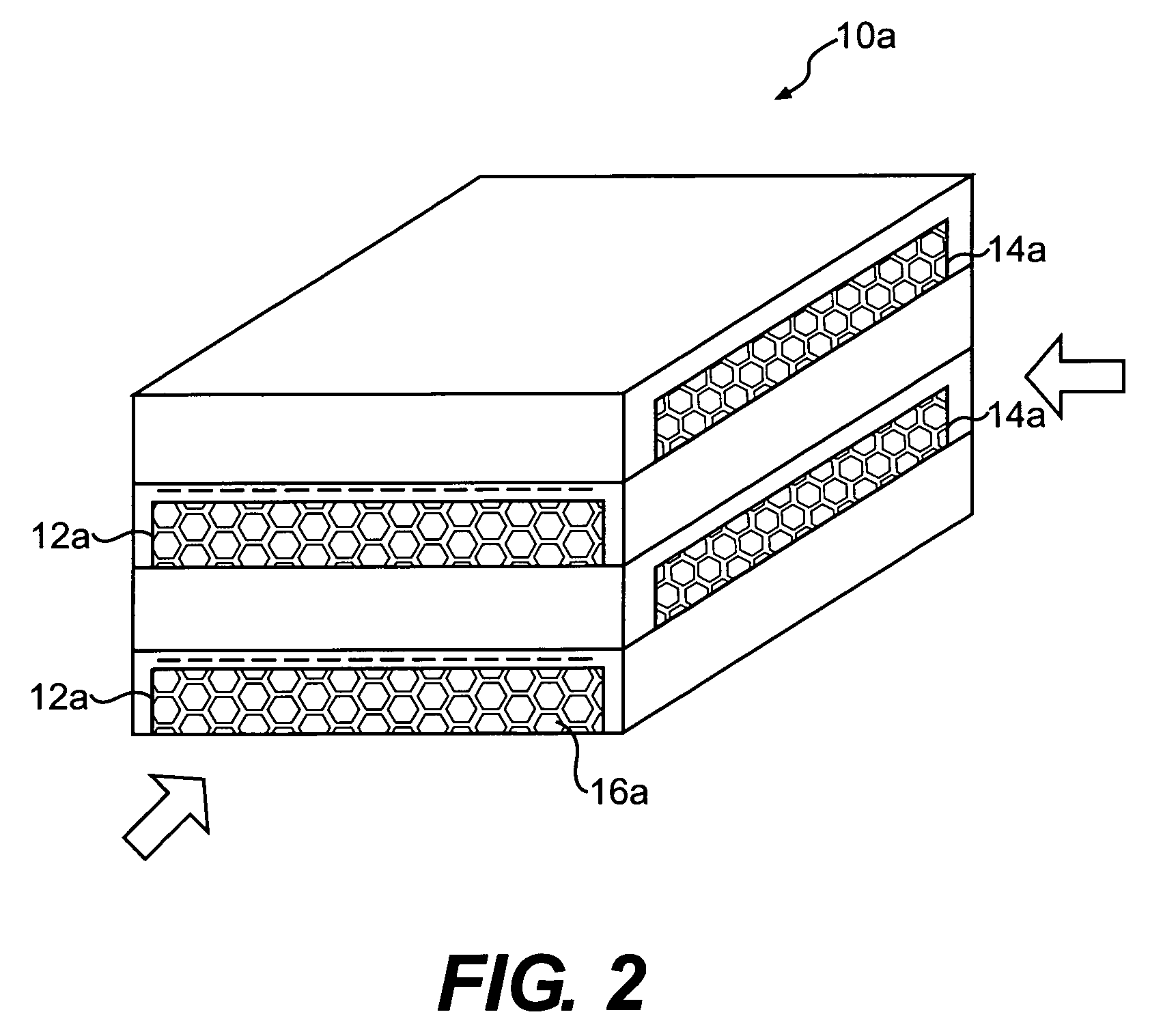

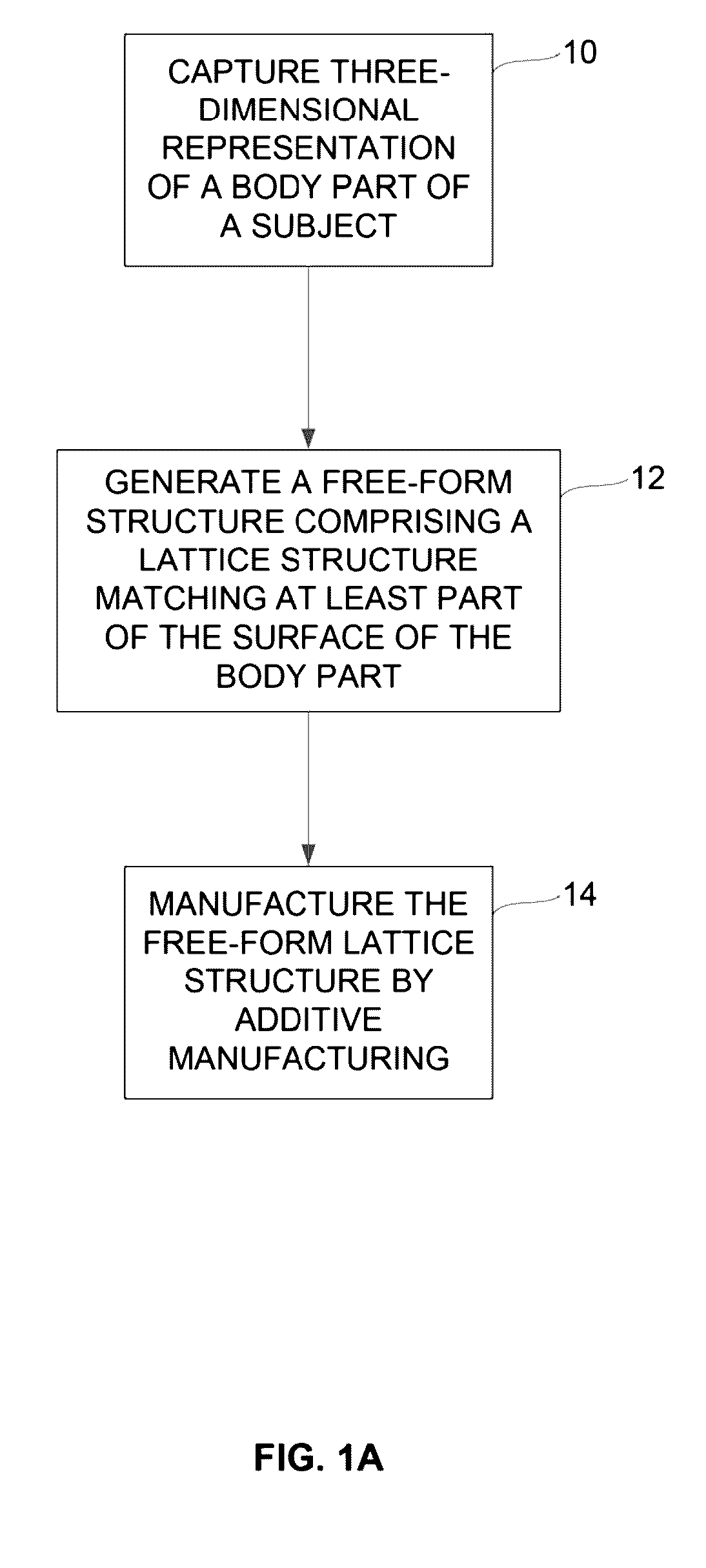

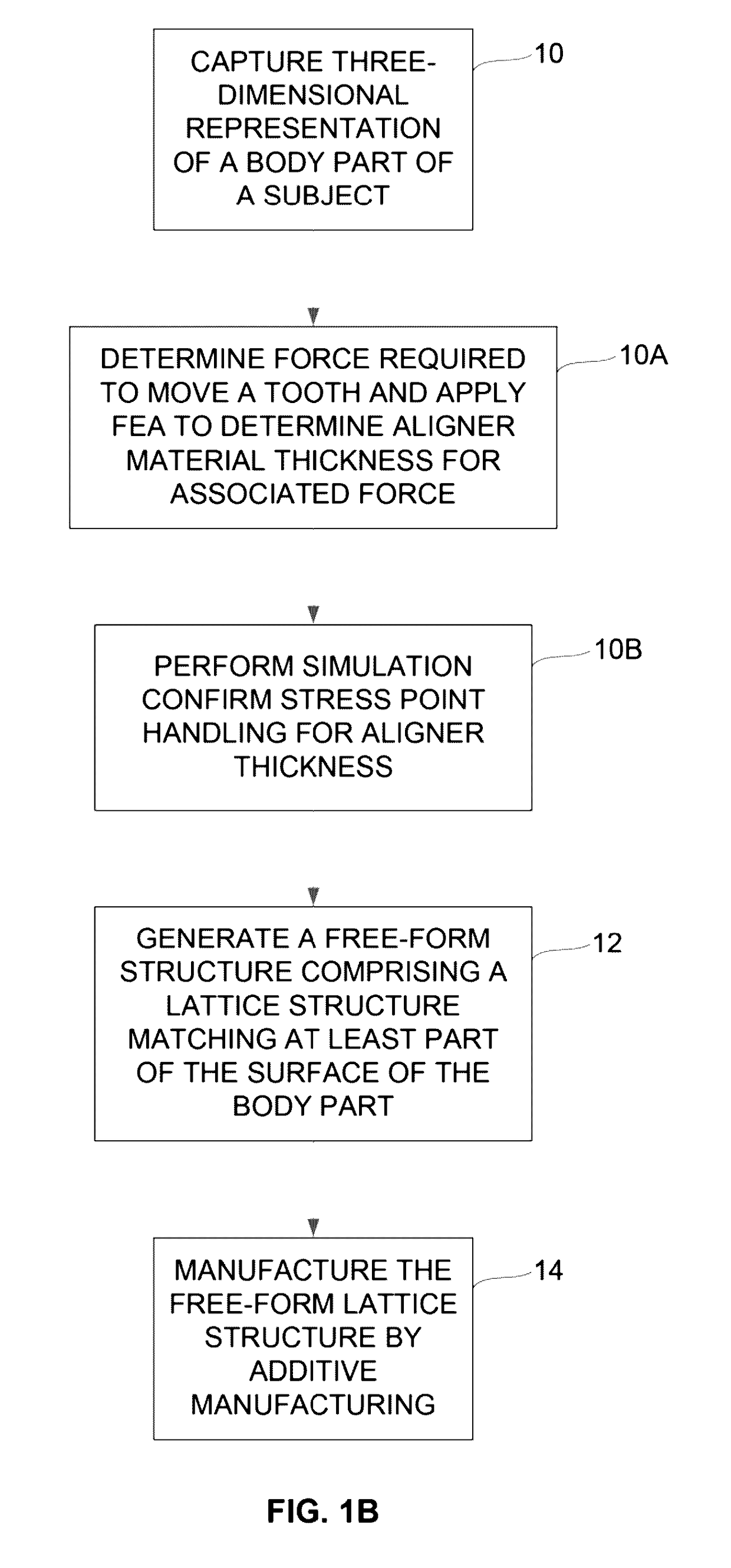

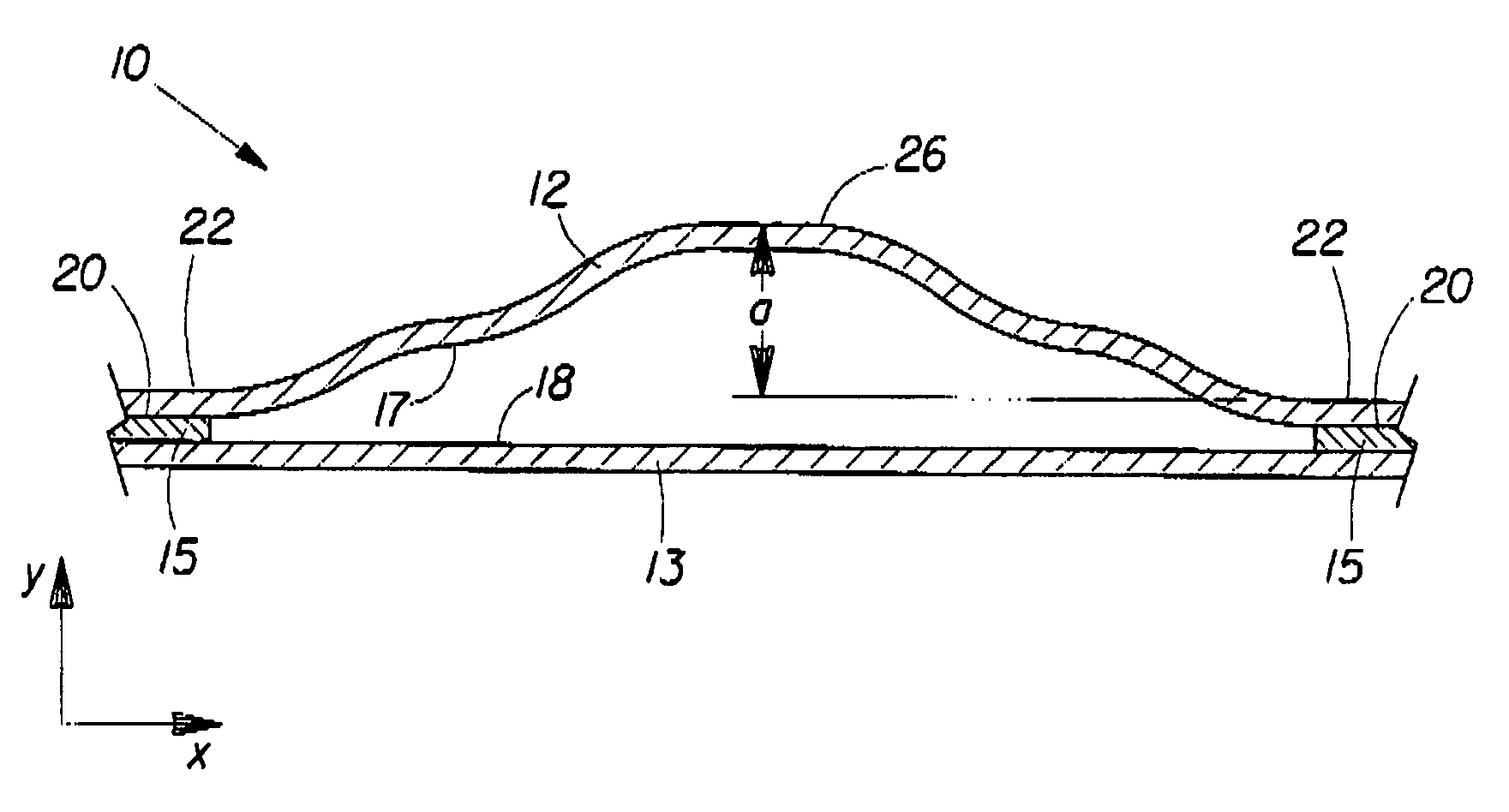

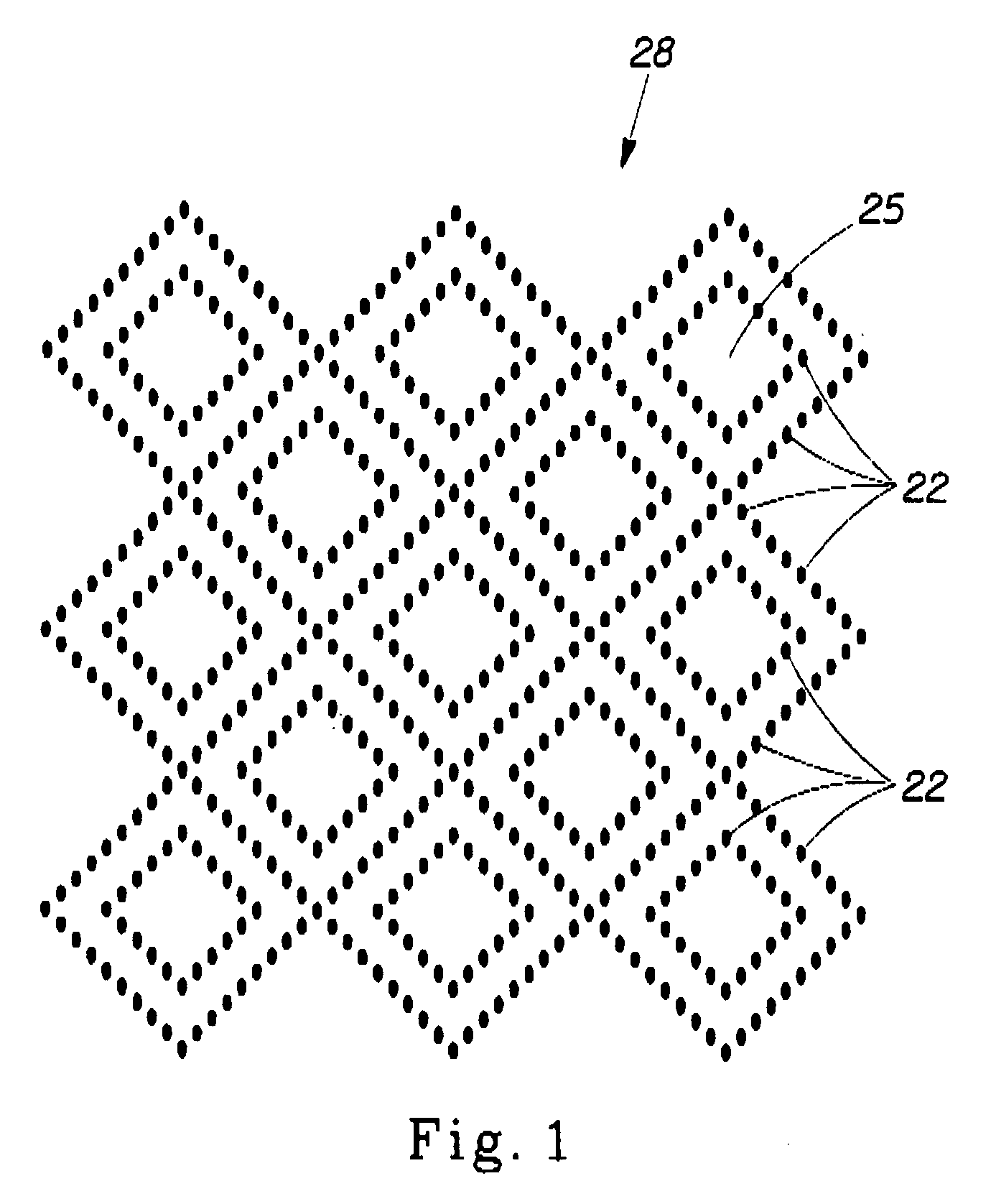

Three-dimensional printed dental appliances using lattices

Method and apparatus for fabricating an oral appliance are described for correcting malocclusions on a dentition of a subject. A three-dimensional representation of the dentition may be captured and a free-form structure having a lattice structure which matches at least part of a surface of the dentition is generated. The lattice structure defines a plurality of open spaces such that the free-form structure is at least partially transparent. The lattice structure may then be manufactured by impregnating or covering a coating into or upon the lattice structure such that the oral appliance is formed.

Owner:ULAB SYST INC

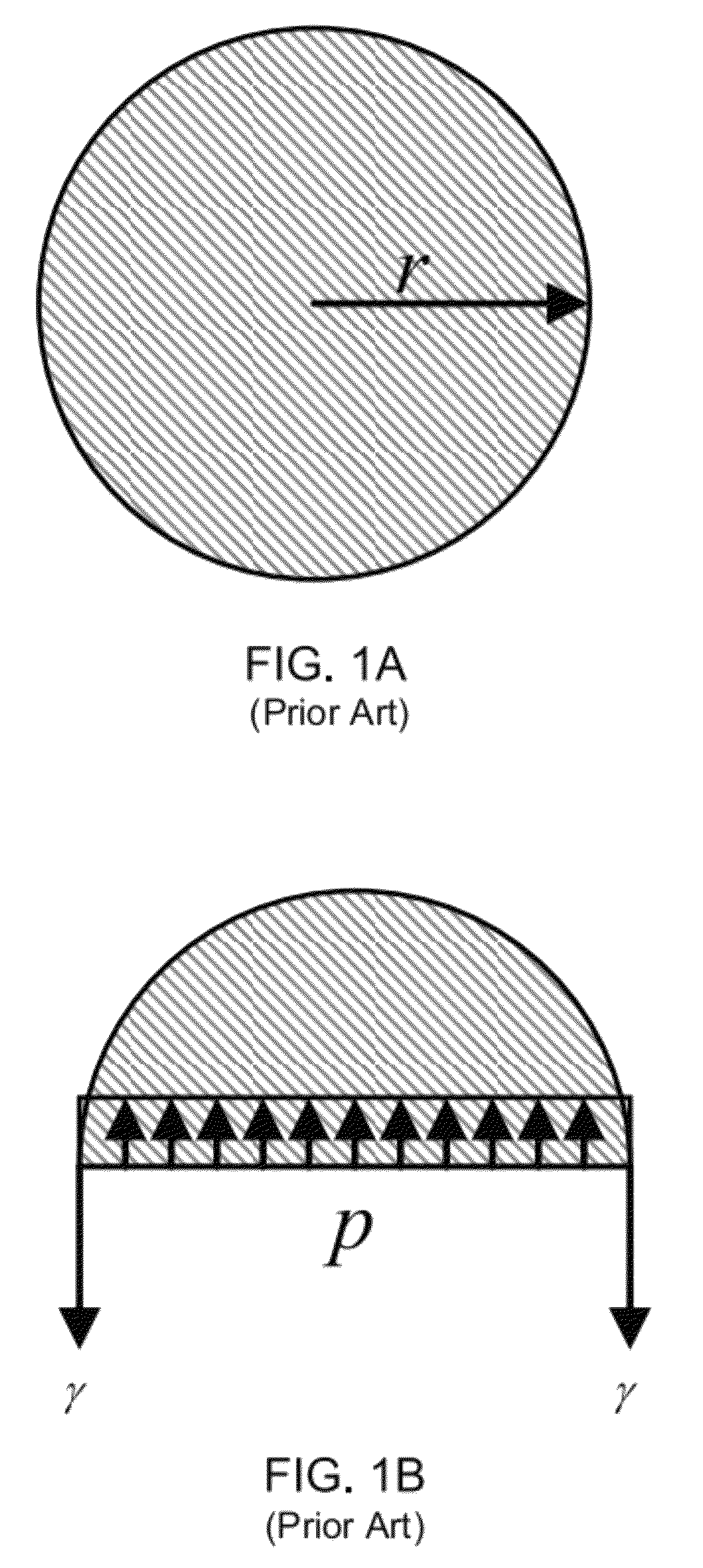

Core shell catalyst

InactiveUS8168561B2Low costImprove stabilityMolecular sieve catalystsOther chemical processesCrystal structureCore shell

Owner:UNIV OF UTAH RES FOUND

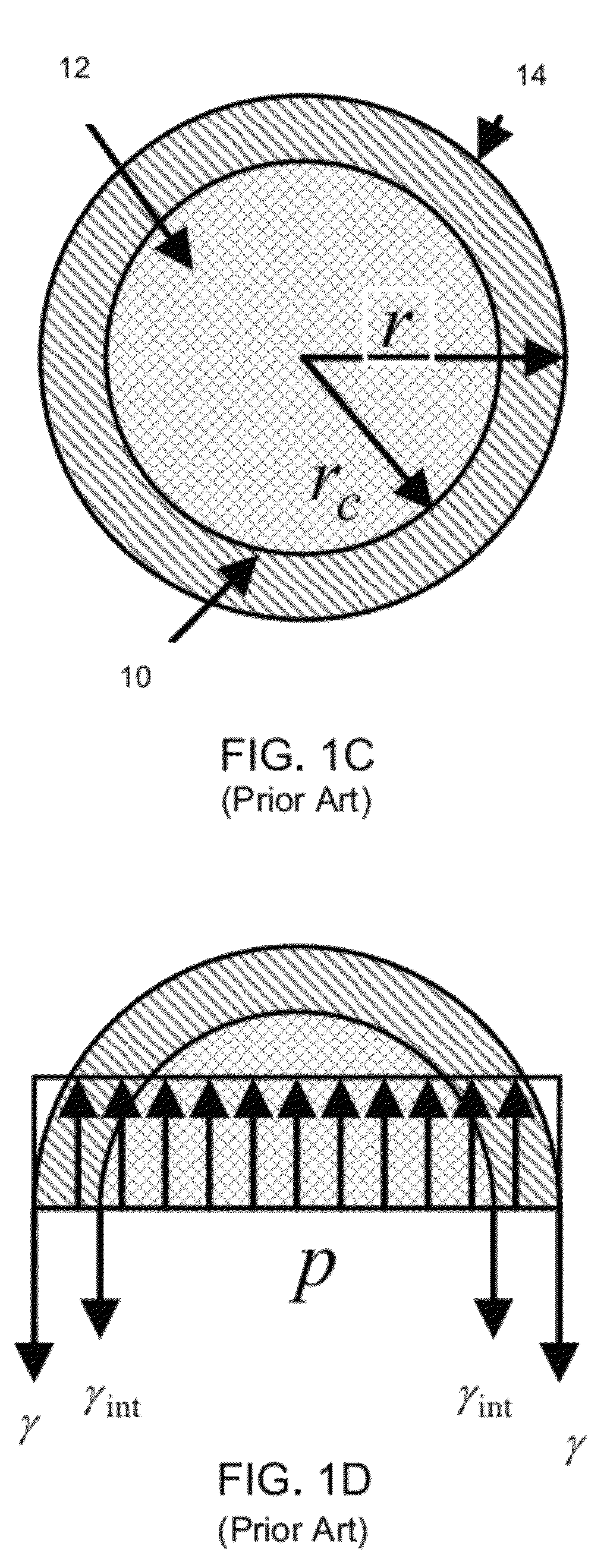

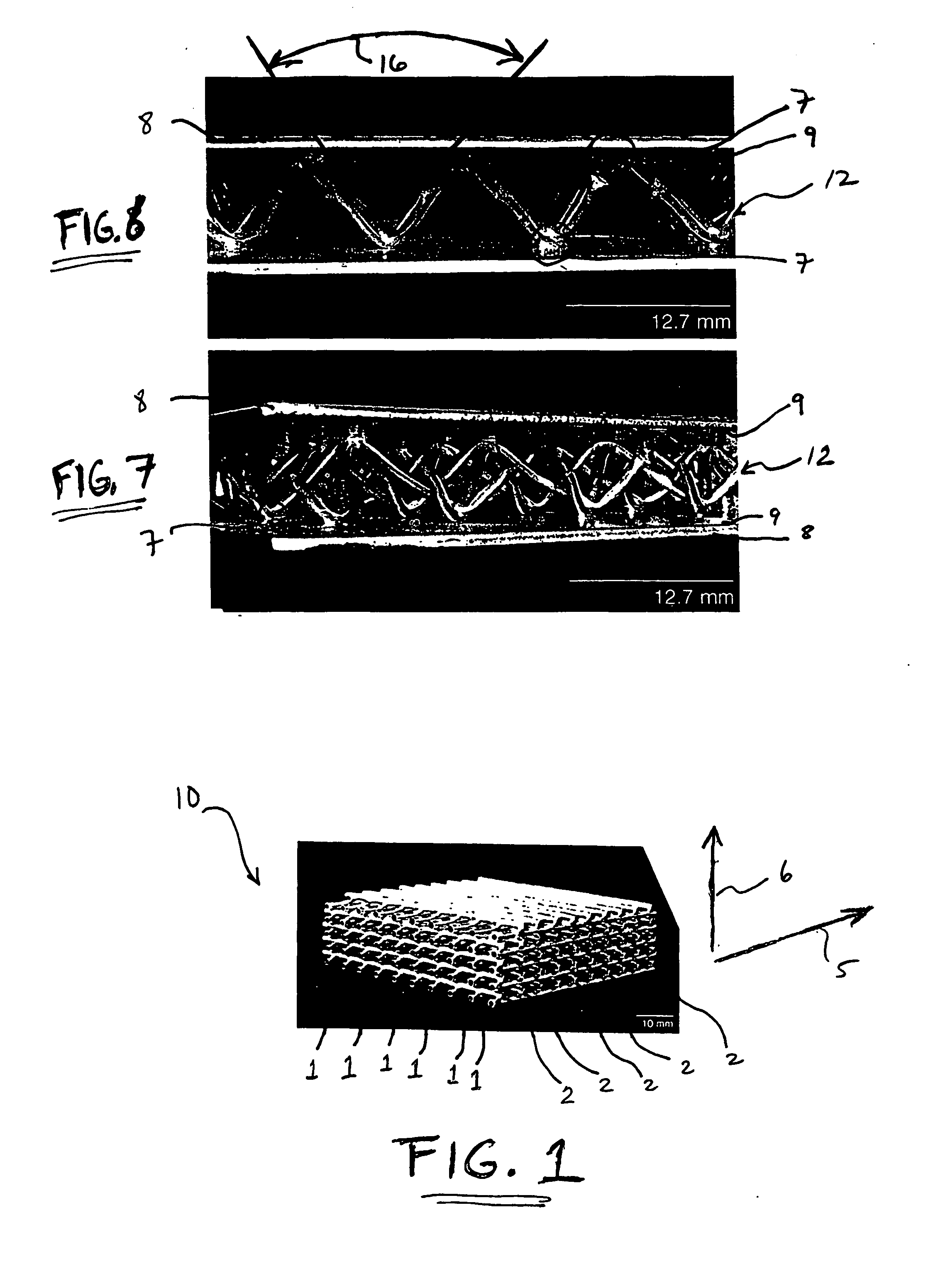

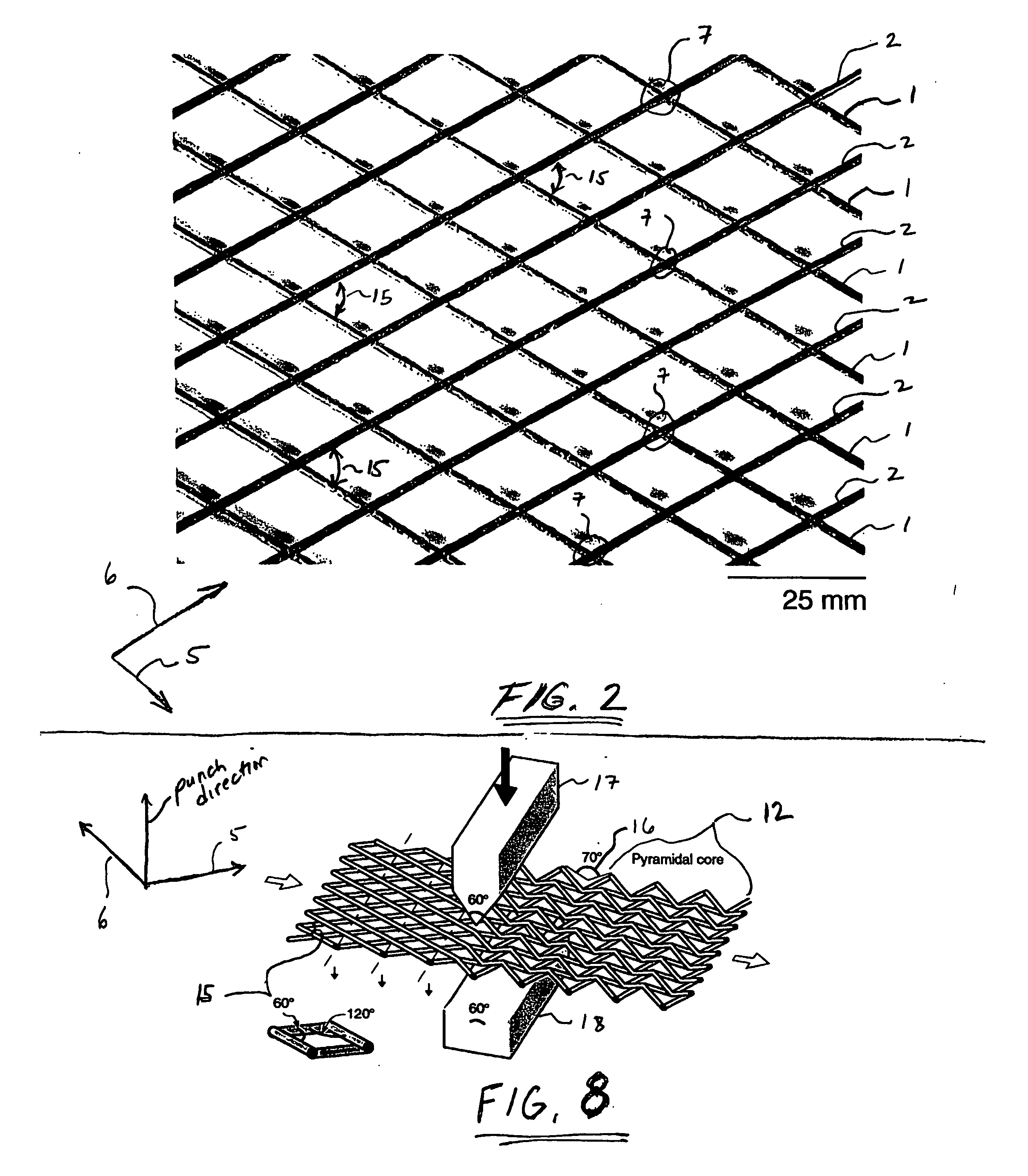

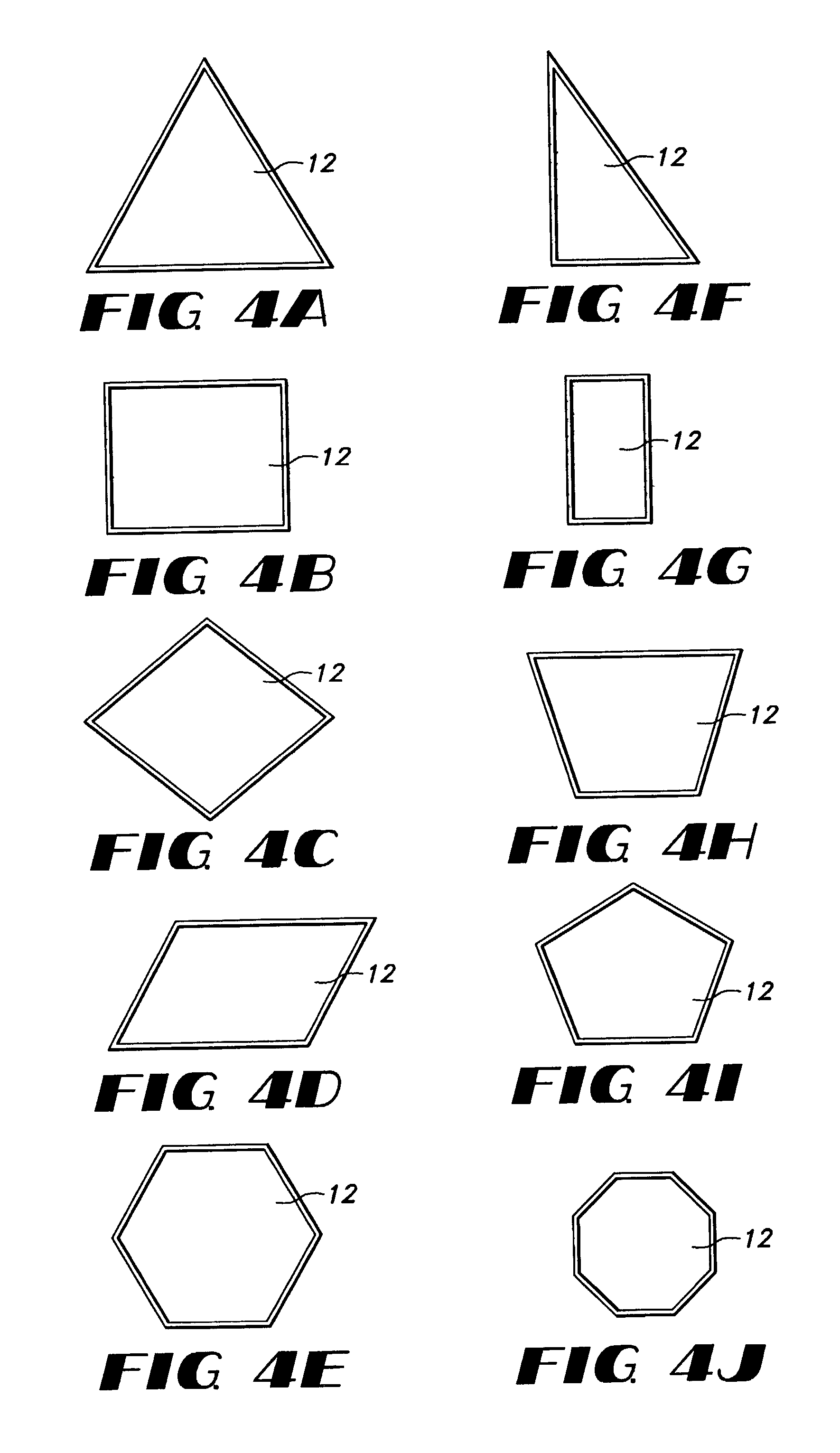

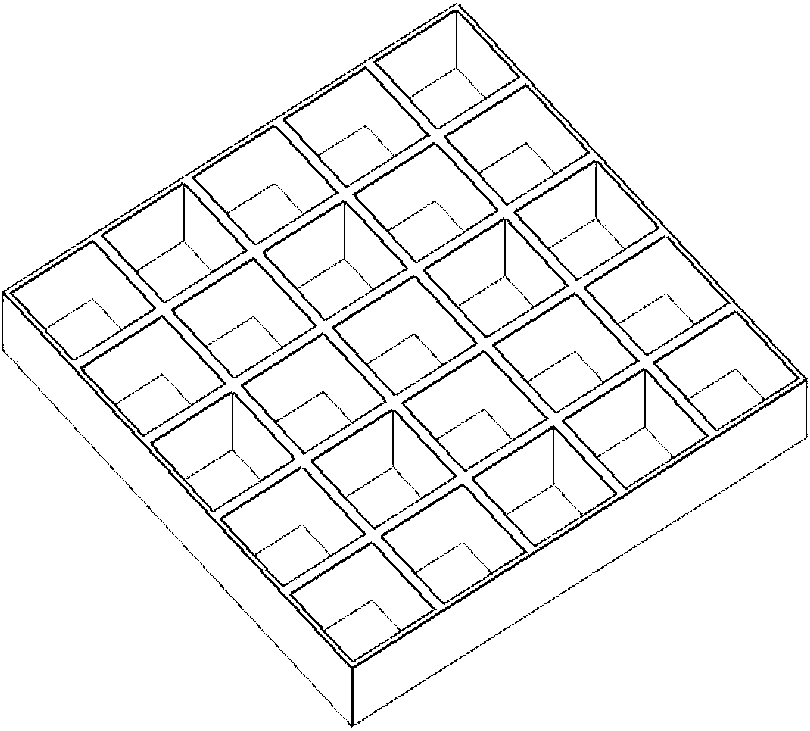

Method for manufacture of periodic cellular structure and resulting periodic cellular structure

A lightweight periodic cellular structure has a stacked array of hollow or solid structural elements that are bonded at their contact points in order to form a stacked lattice structure. Further arrays may be stacked onto the stacked lattice structure in order to form a periodic cellular structure of varying thickness and depth. Also, structural panels may be added to parallel exterior edges of the stacked lattice structure to form a structural panel. Further, the hollow structural elements are provided with wicking elements along their interior walls to facilitate heat transfer through the periodic cellular structure. Liquid may also be introduced into the hollow structural elements to further facilitate heat transfer through the periodic cellular structure. Also, the cellular structure may be utilized as light weight current collectors, such as electrodes, anodes, and cathodes. The related method of manufacturing the periodic cellular structure can accommodate a variety of cross-sectional shapes, introduce a variety of stacking offset angles to vary the lattice shape and resultant mechanical characteristics of the periodic cellular structure; and allow for the bending of the array of hollow or solid structural elements into an array of hollow pyramidal truss elements that can be used to form a stacked pyramidal.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

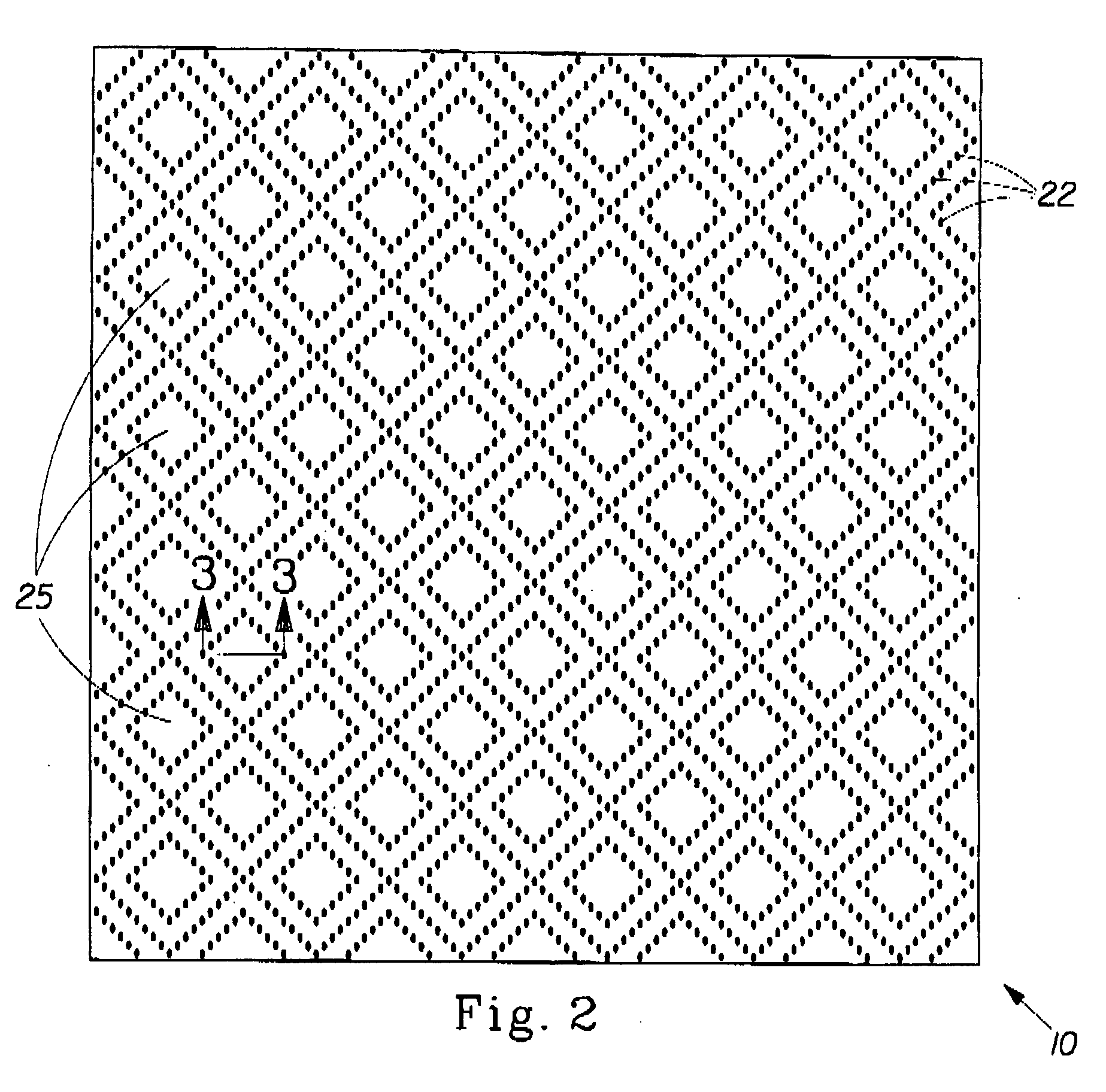

Embossed multi-ply fibrous structure product

ActiveUS20070207293A1Good lookingImprove tightnessMechanical working/deformationSynthetic resin layered productsFiberCompressibility

An embossed multi-ply fibrous structure product having enhanced quilted appearance comprising: two or more plies of fibrous structure wherein at least one of the piles has a plurality of embossments thereon having a total embossment area of from about 6% to about 16%; the embossments forming a latticework defining a plurality of unembossed cells; wherein each cell has a surface area of from about 0.5 square inches to about 6 square inches, the cells being unadhered to the adjacent ply and the embossments having a height from about about 350 μm to about 1,500 μm. Further embodiment comprise a product having a Percent Compressibility from about 1.5% to about 4.5%.

Owner:THE PROCTER & GAMBLE COMPANY

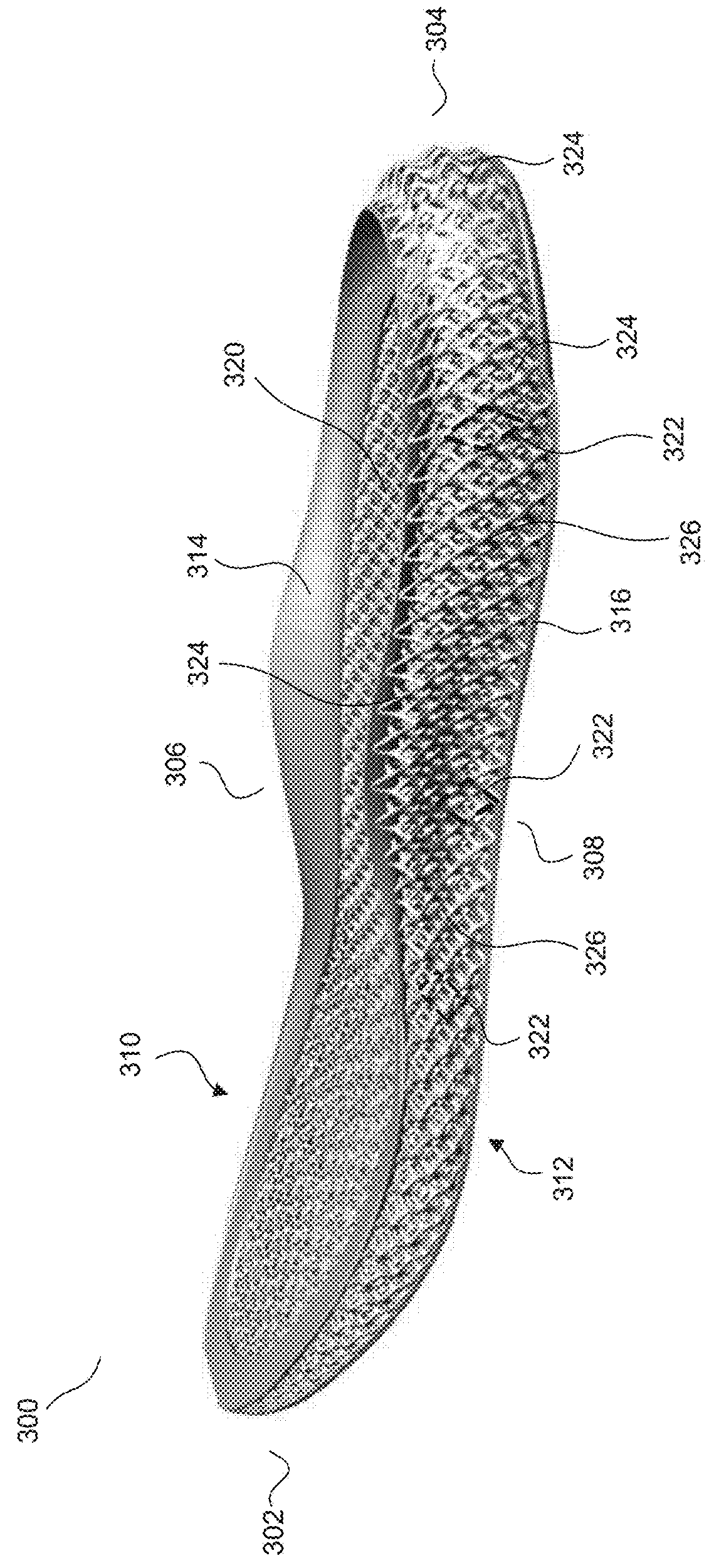

Footwear midsole with warped lattice structure and method of making the same

ActiveUS20180271211A1Foot measurement devicesAdditive manufacturing apparatusBiometric dataEngineering

A midsole for an article of footwear including a three dimensional mesh including interconnected unit cells and methods of making the same. The interconnected unit cells each include a plurality of struts defining a three dimensional shape. The interconnected unit cells are connected at nodes having a valence number defined by the number of struts connected at that node. The valence number of the nodes may vary to provide customized characteristics to zones or portions of the midsole. The plurality of interconnected unit cells may be organized in a warped cubic lattice structure. The warped cubic lattice structure and the size / shape of interconnected unit cells may vary to provide customized characteristics to zones or portions of the midsole. The three dimensional mesh may be customized based on a biometric data profile for an individual, or group of individuals. The midsole may be manufactured using an additive manufacturing process.

Owner:ADIDAS

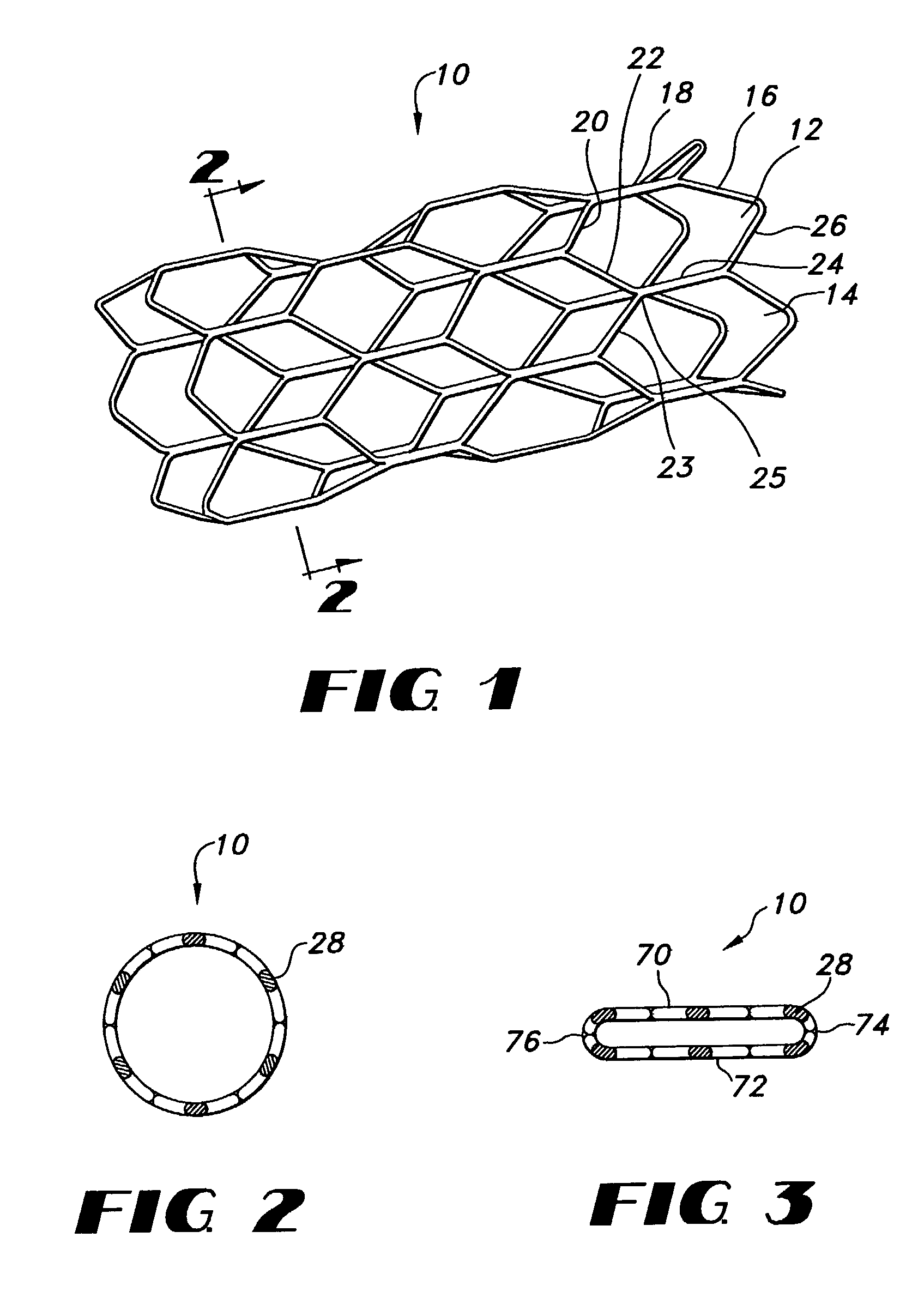

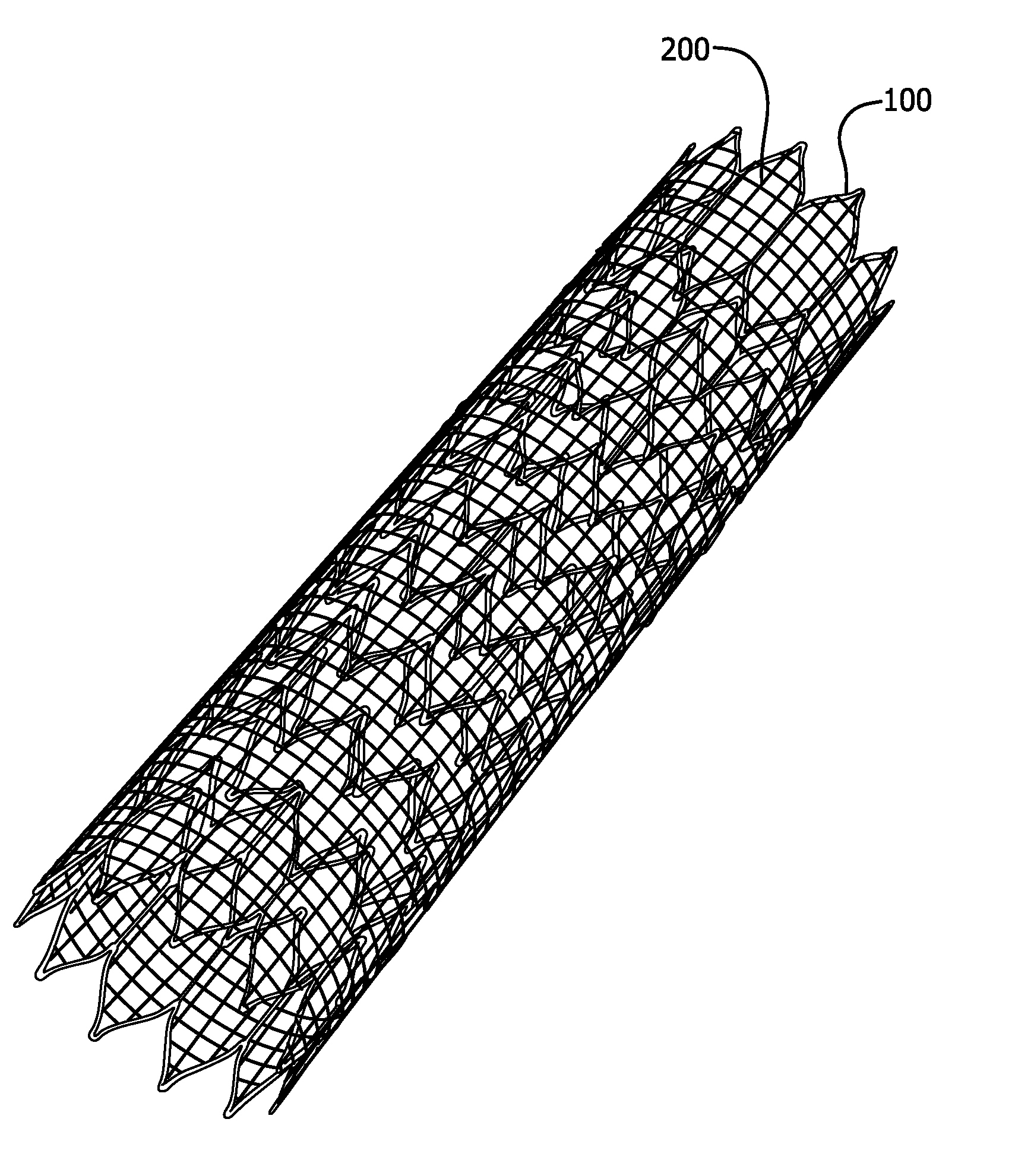

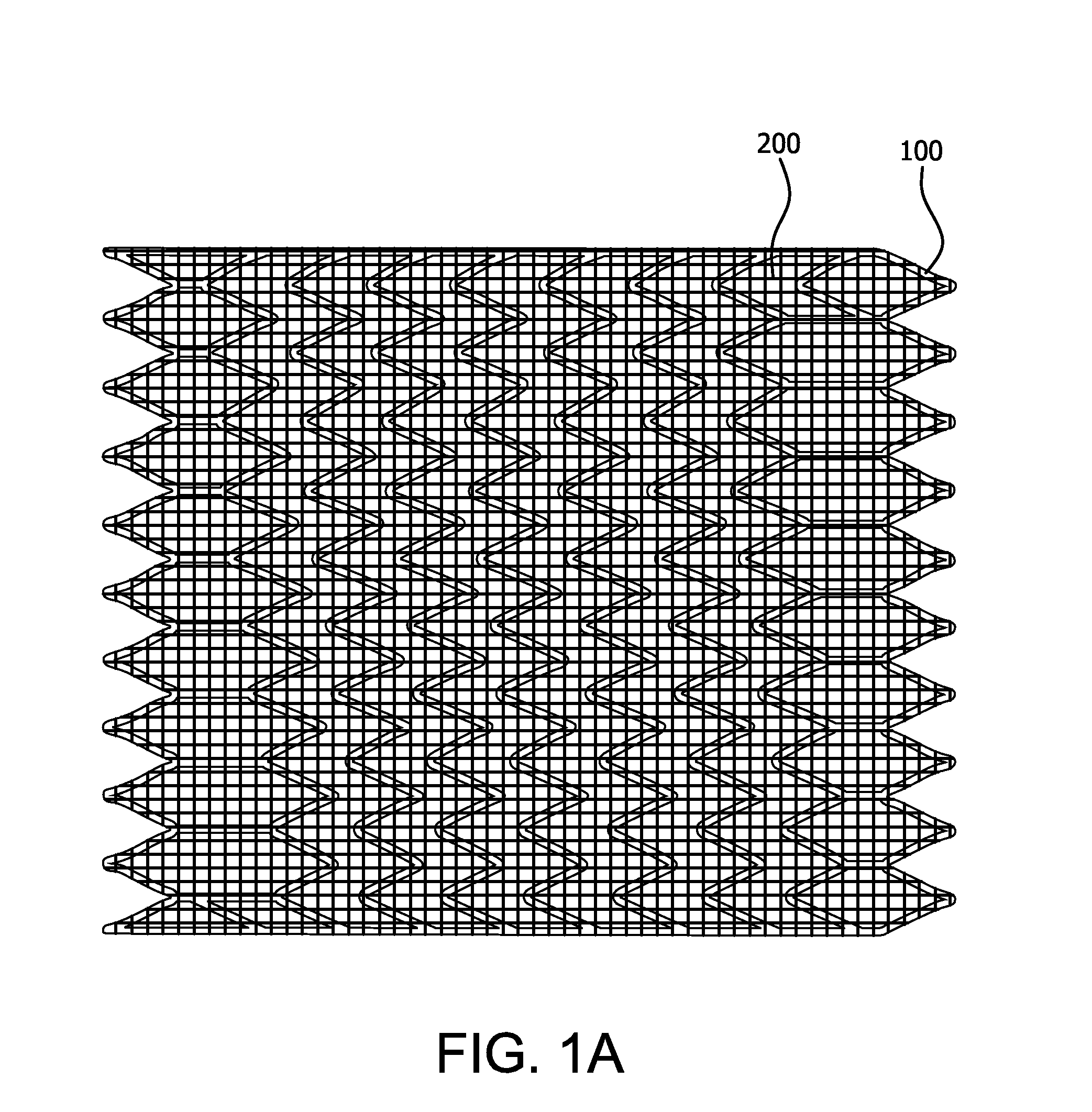

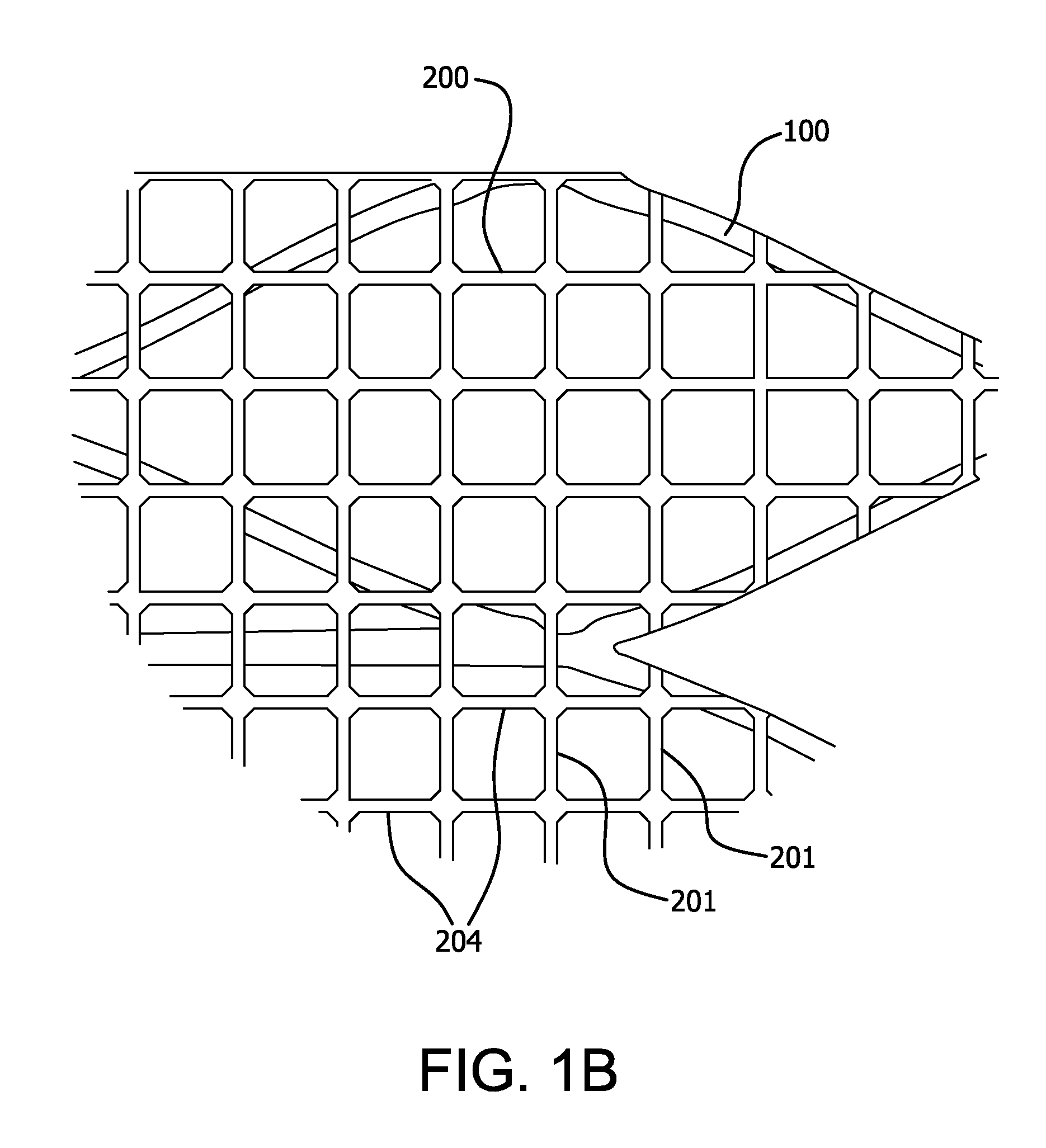

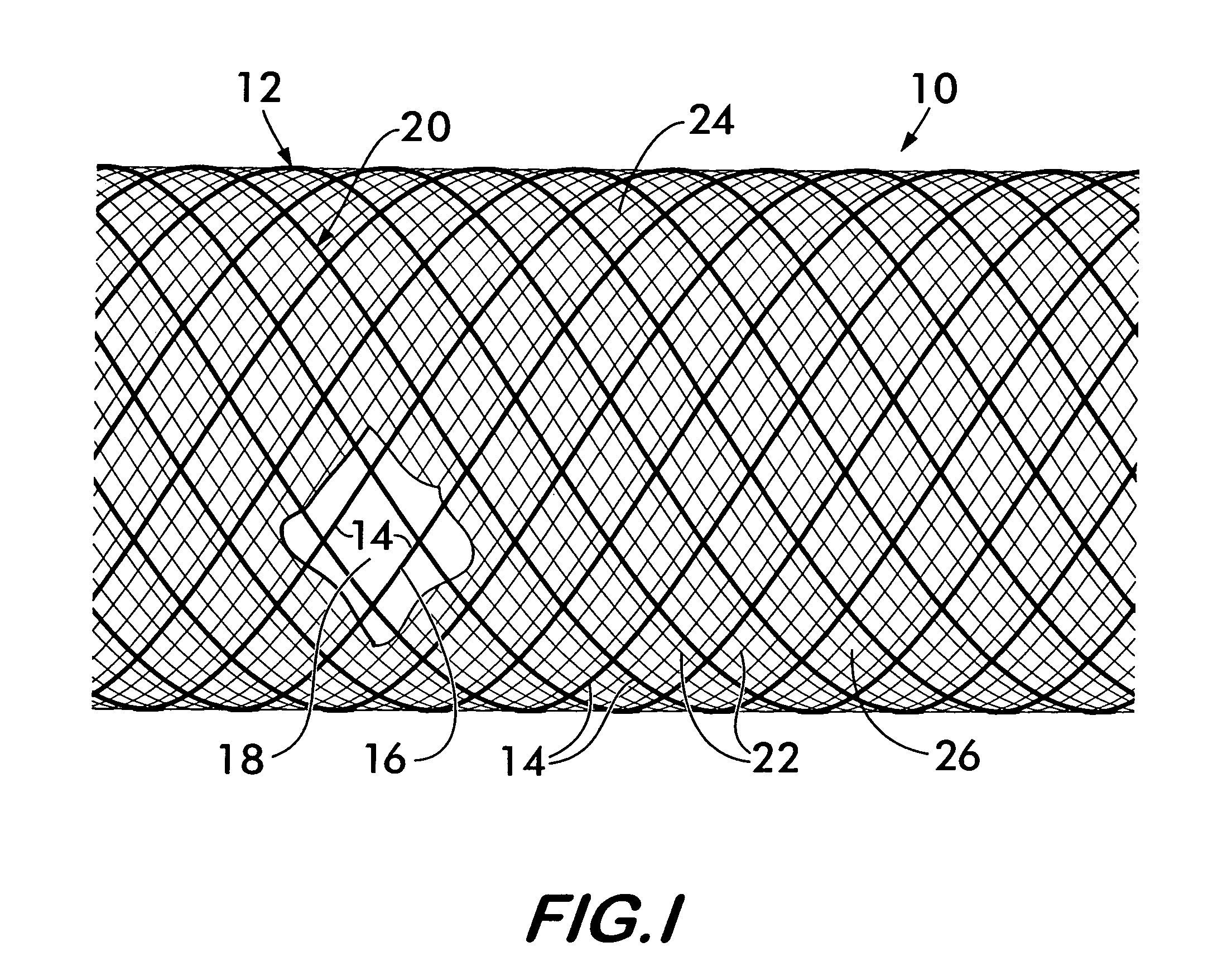

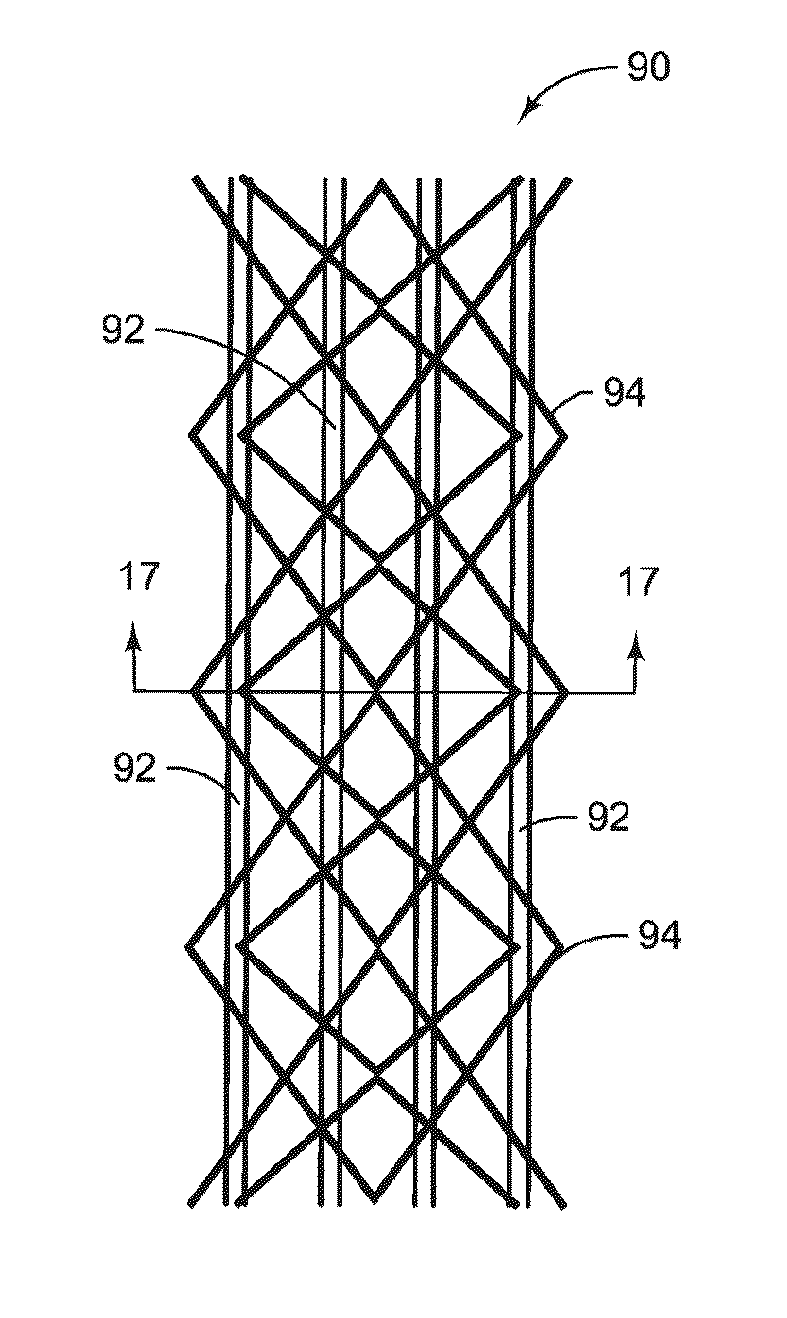

Flat knitted stent and method of making the same

A knitted implantable stent having a hollow tubular structure having opposed open ends defining a wall portion therebetween is provided. The wall portion includes an open lattice structure of a plurality of interconnected perimetrically bound cells. The cells are defined by a plurality cell segments. The cell segments are defined by at least two wires knittingly interlaced in a plurality of loops. Adjacent cell segments are knittingly interlaced with each other to form the open lattice structure of interconnected perimetrically bound cells. The stent may be a singular tubular structure or may be a bifurcated stent. Methods for producing the flat knitted stents include the use of double needle bar flat knitting machines.

Owner:LIFESHIELD SCI

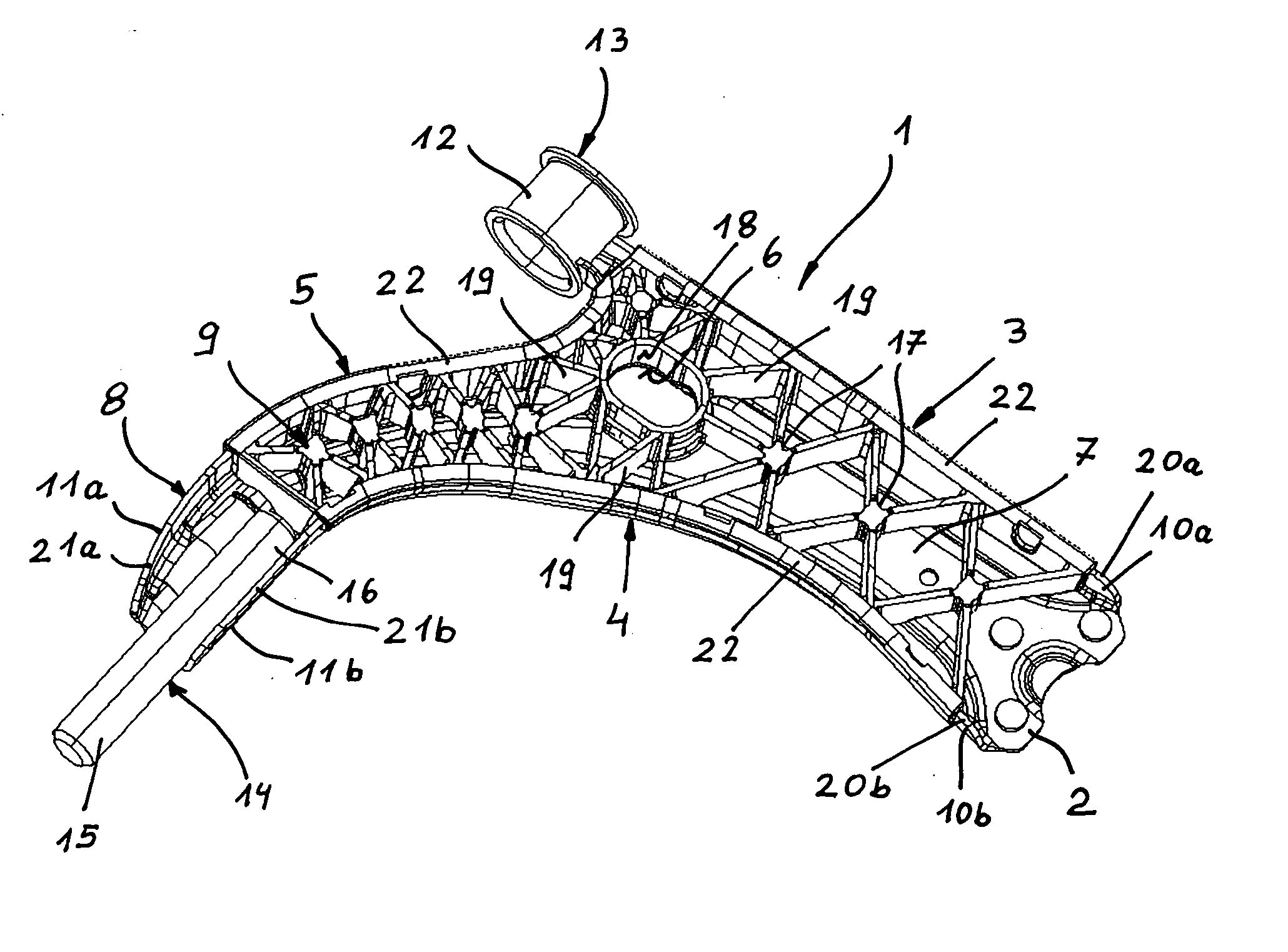

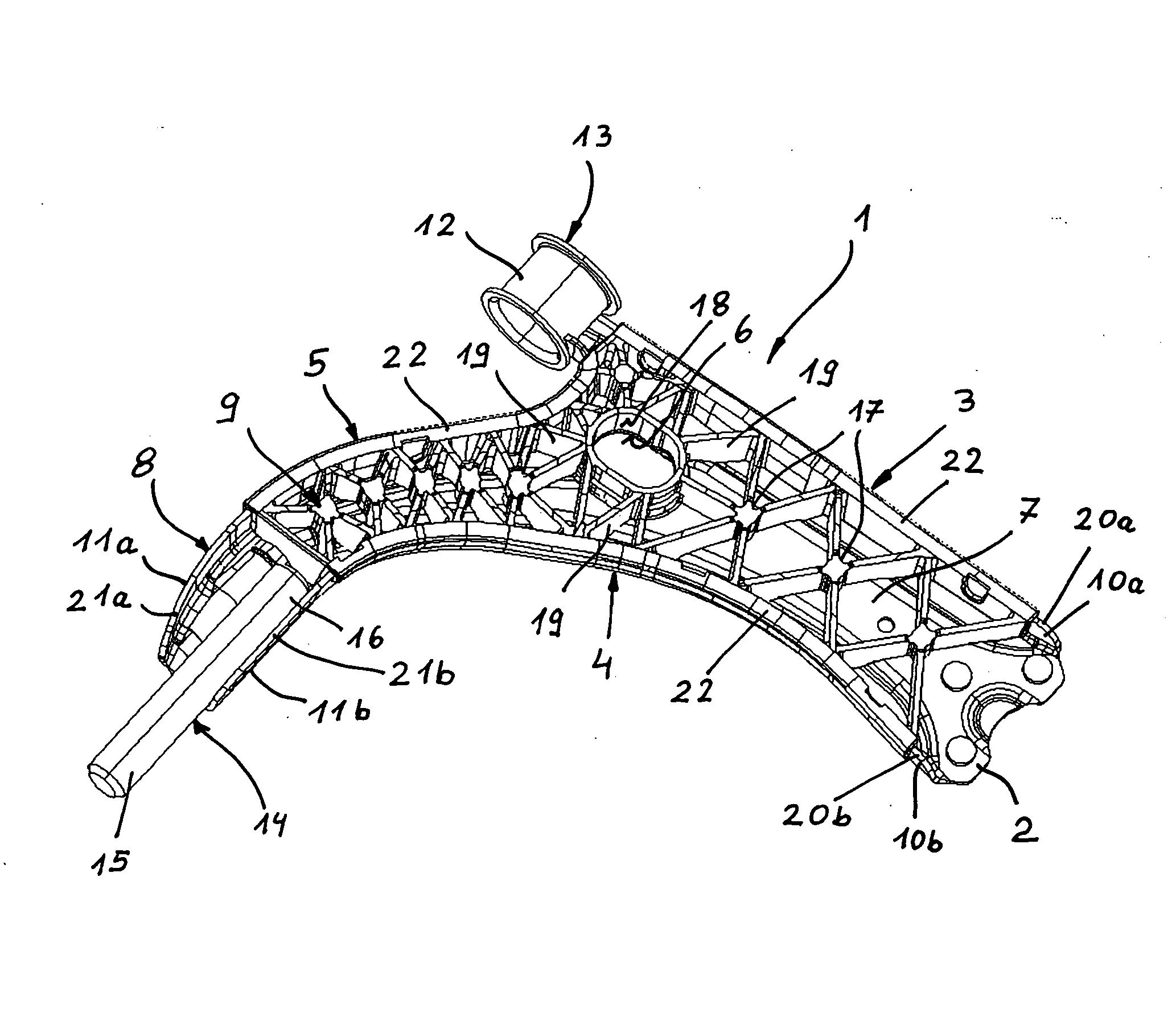

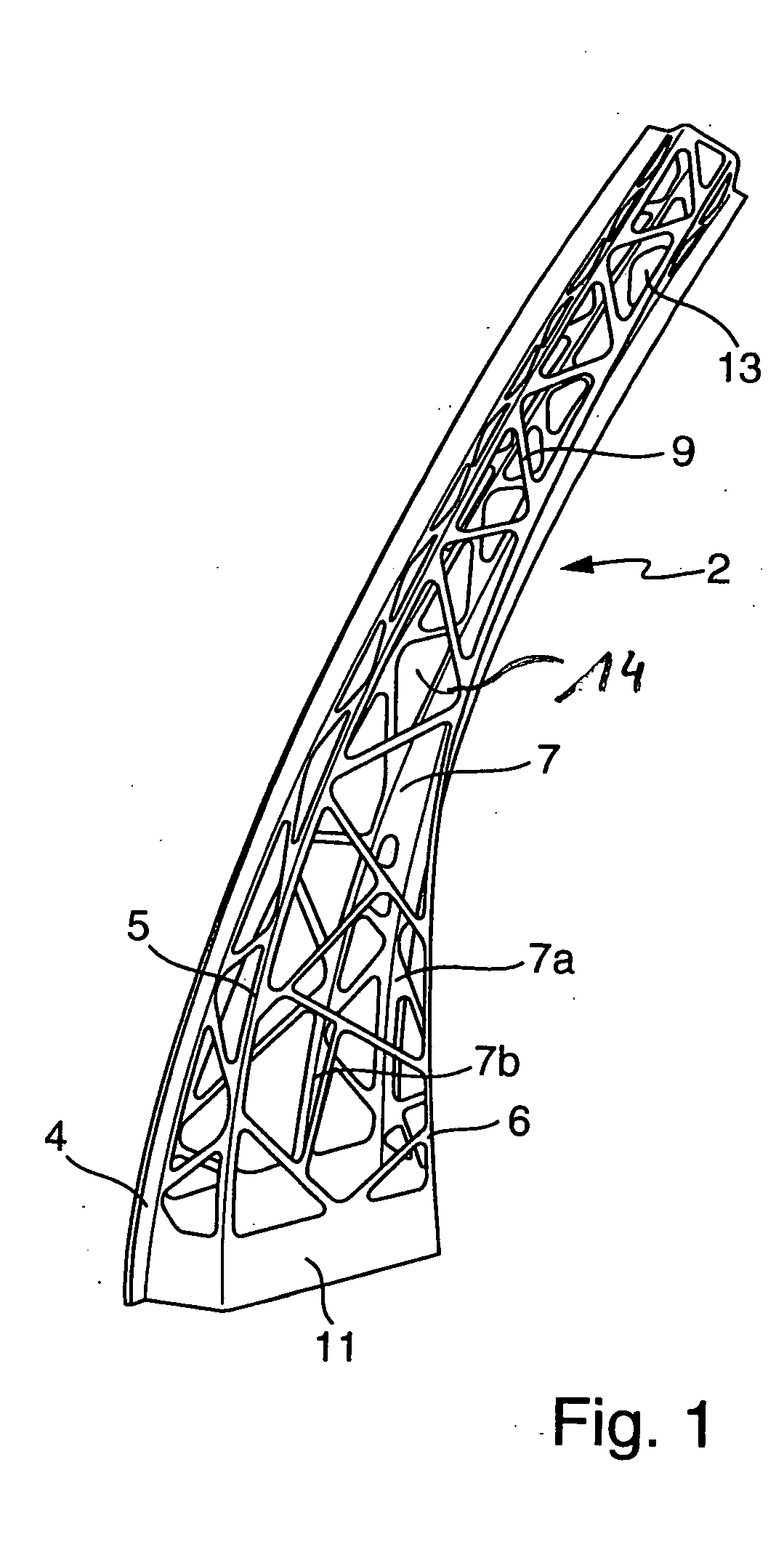

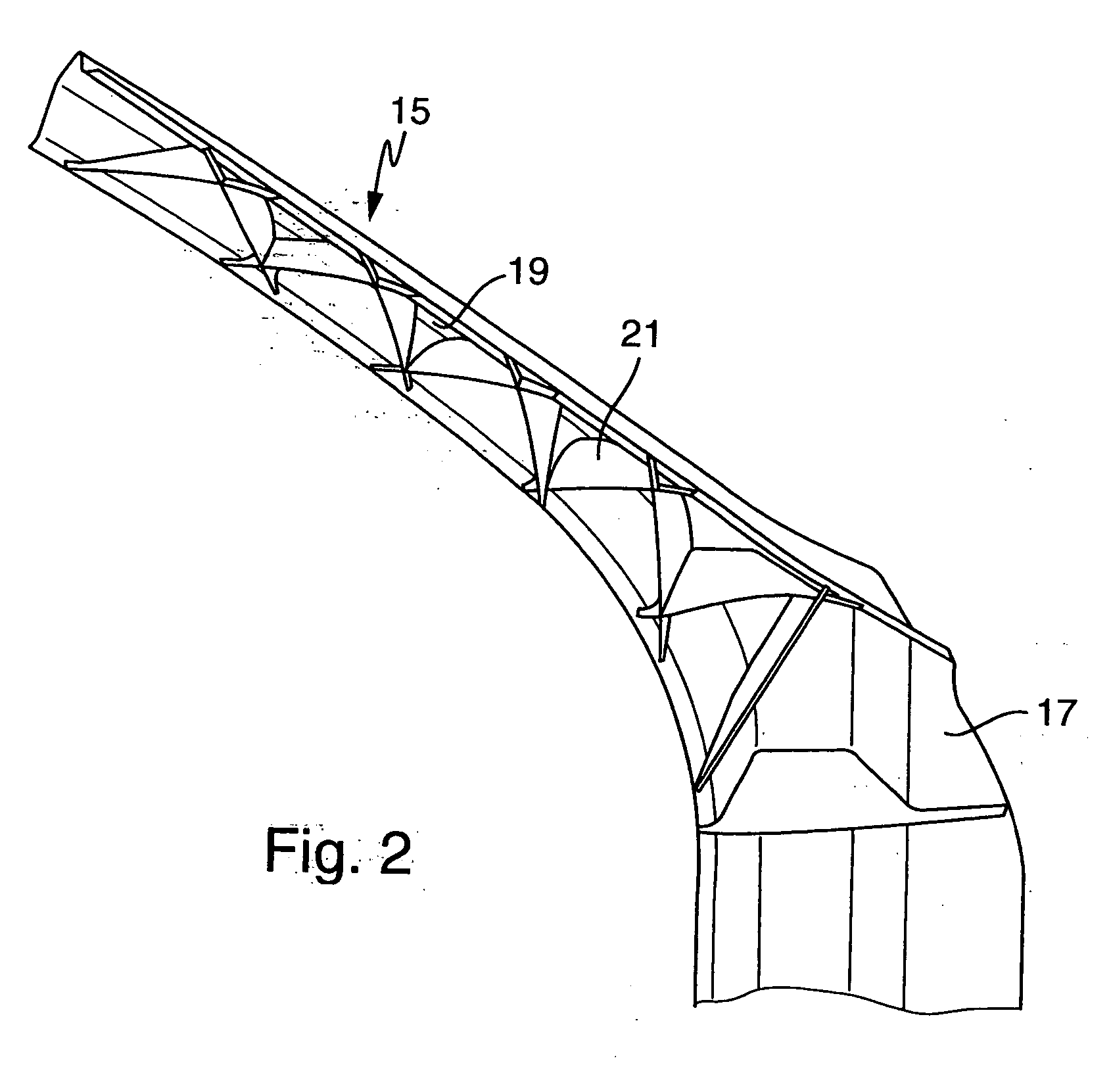

Control arm structure for wheel suspensions of motor vehicles, and method of making such a control arm structure

InactiveUS20060175786A1Low ductility potentialHigh strengthMouldsMetal-working apparatusControl armEngineering

In a method of making a control arm for a wheel suspension of a motor vehicle a blank of steel material having a tensile strength of at least 800 MPa is shaped, using a sheet metal forming process, into a shell body having a center web and plural flank portions extending from the center web in a same direction. The flank portions are connected by a latticed reinforcement made of plastic, without application of a heat treatment process.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

Lattice

The invention relates to medical devices and methods of using them. The devices are prostheses which can be percutaneously deliverable with (or on) an endovascular catheter or via other surgical or other techniques and then expanded. The prostheses are configured to have a lattice resistant to dilation and creep, which is defined by a plurality of openings. The prosthesis may also optionally have a stent disposed proximal to the lattice. In exemplary embodiments, the fluoropolymer is expanded polytetrafluoroethylene. The composite materials exhibit high elongation while substantially retaining the strength properties of the fluoropolymer membrane. In at least one embodiment, the lattice is made of a composite material that includes a least one fluoropolymer membrane including serpentine fibrils and an elastomer. A lattice including a generally tubular member formed of a composite material including a least one fluoropolymer membrane containing serpentine fibrils and an elastomer is also provided.

Owner:WL GORE & ASSOC INC

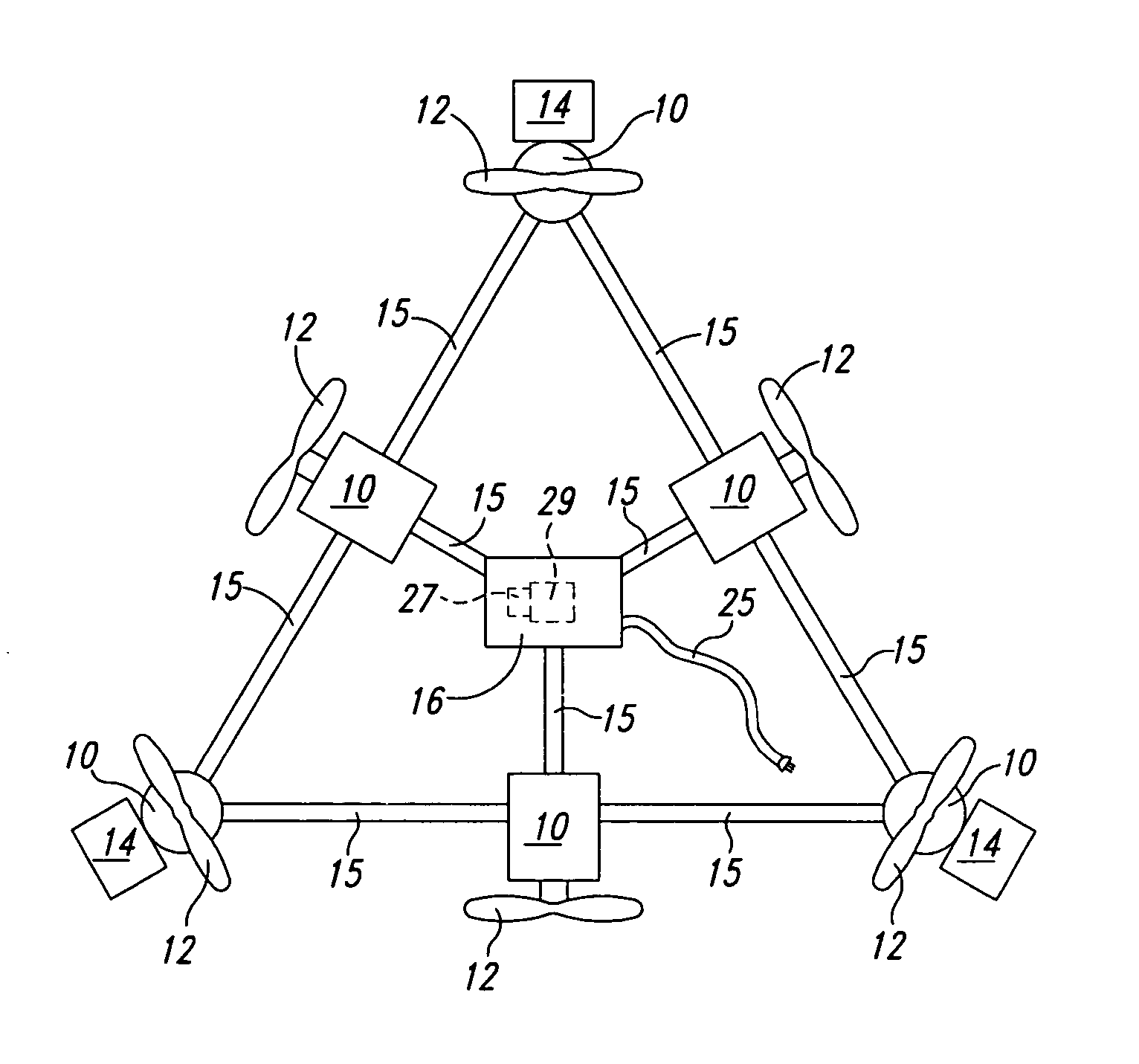

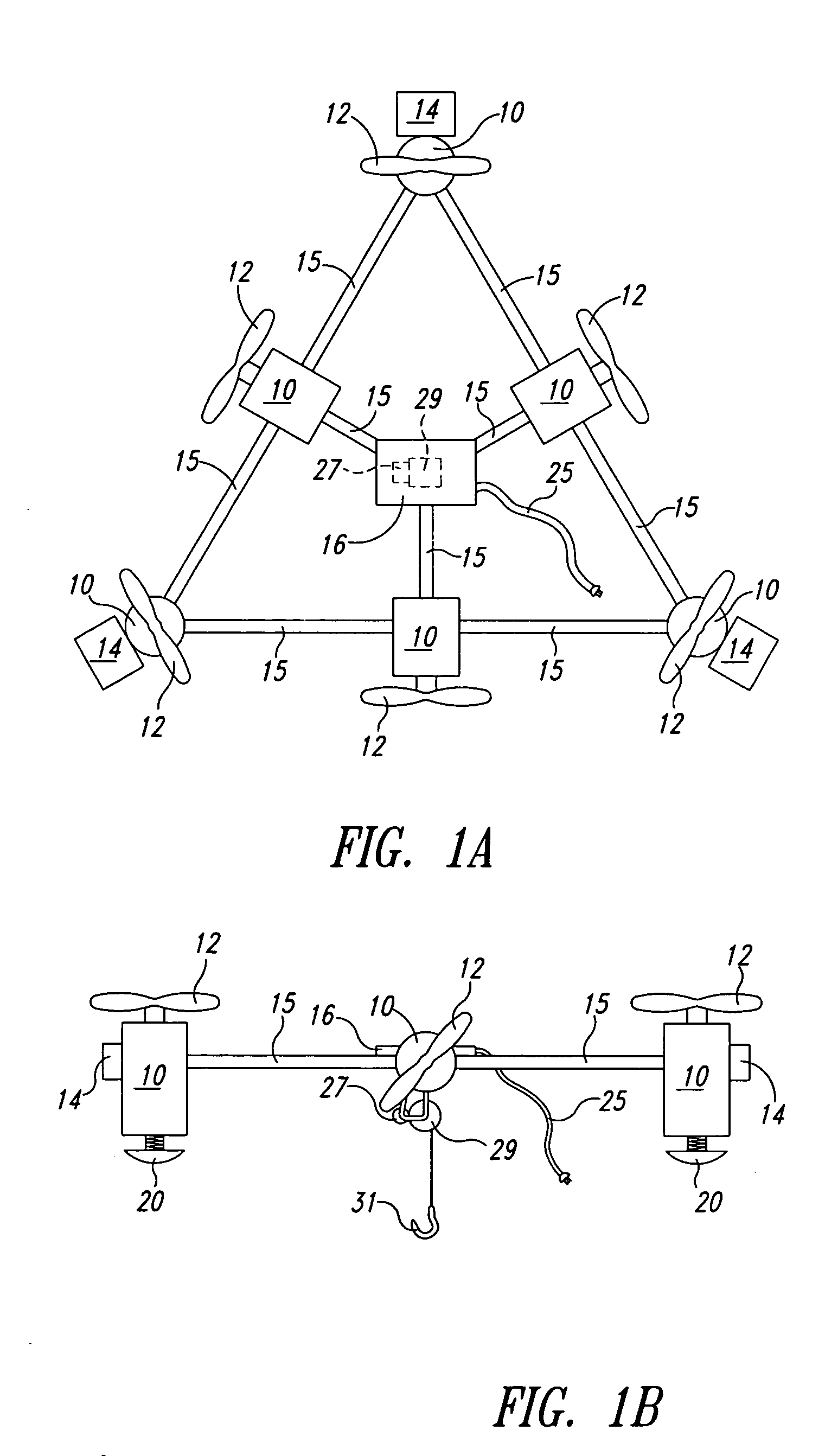

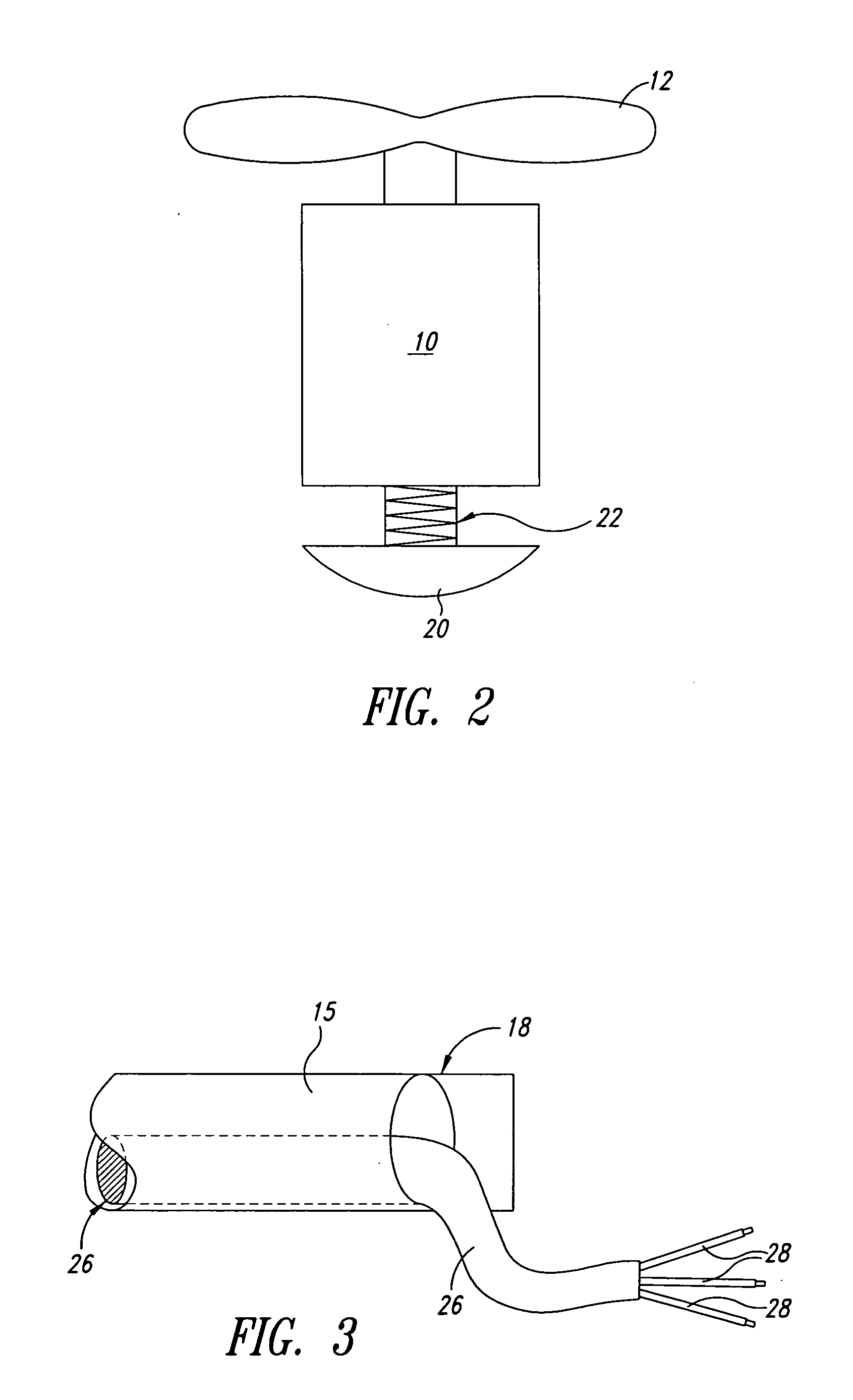

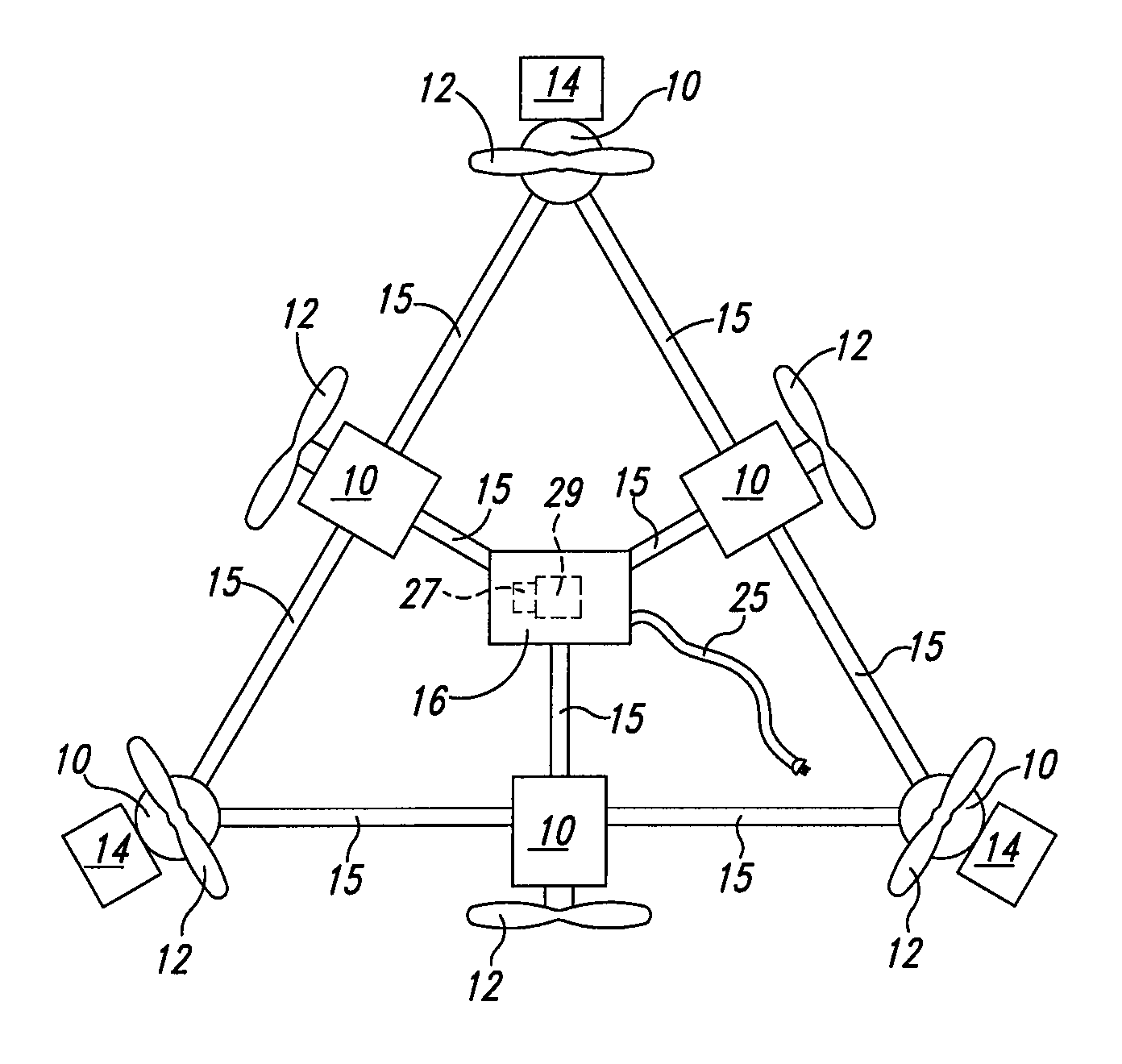

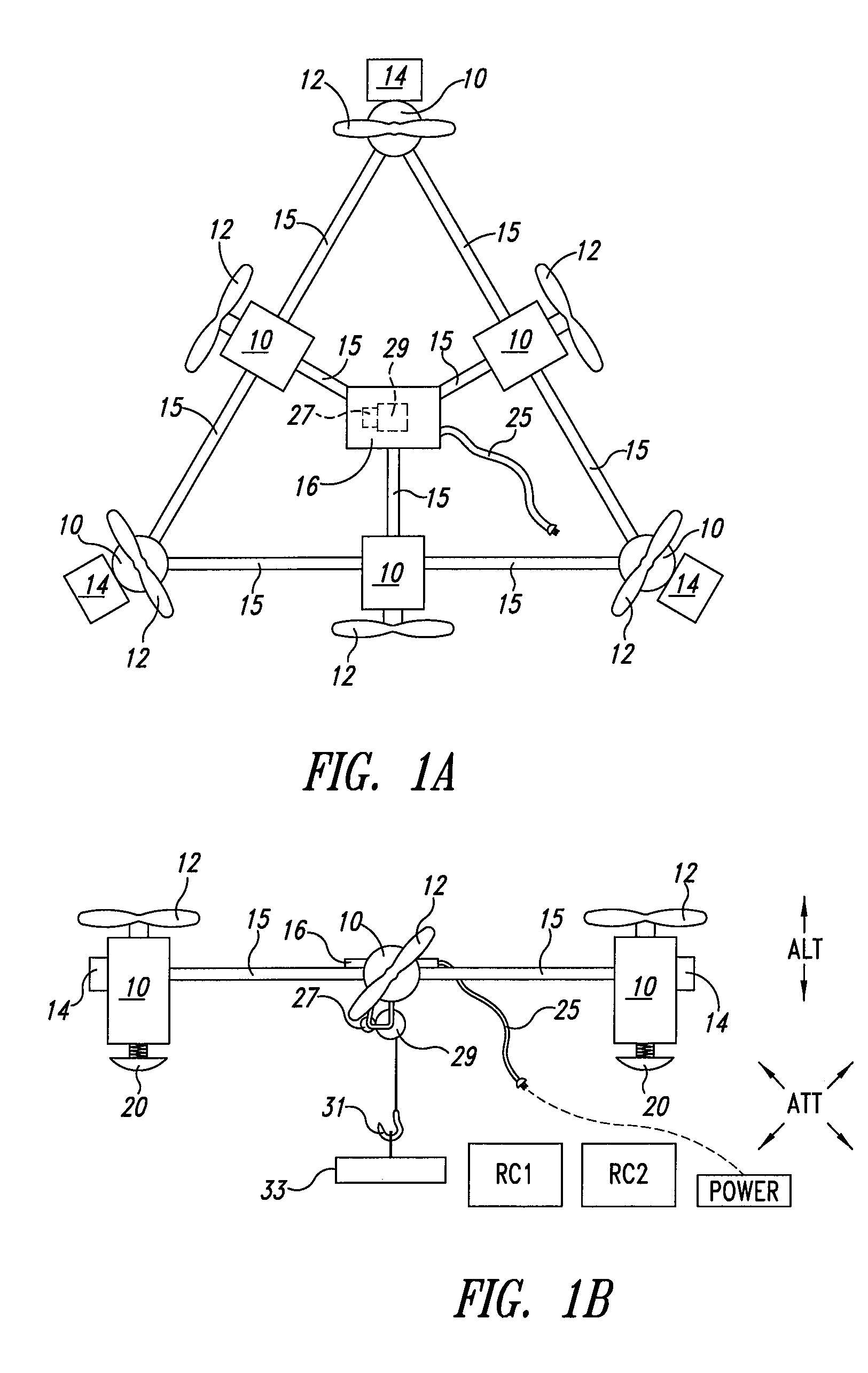

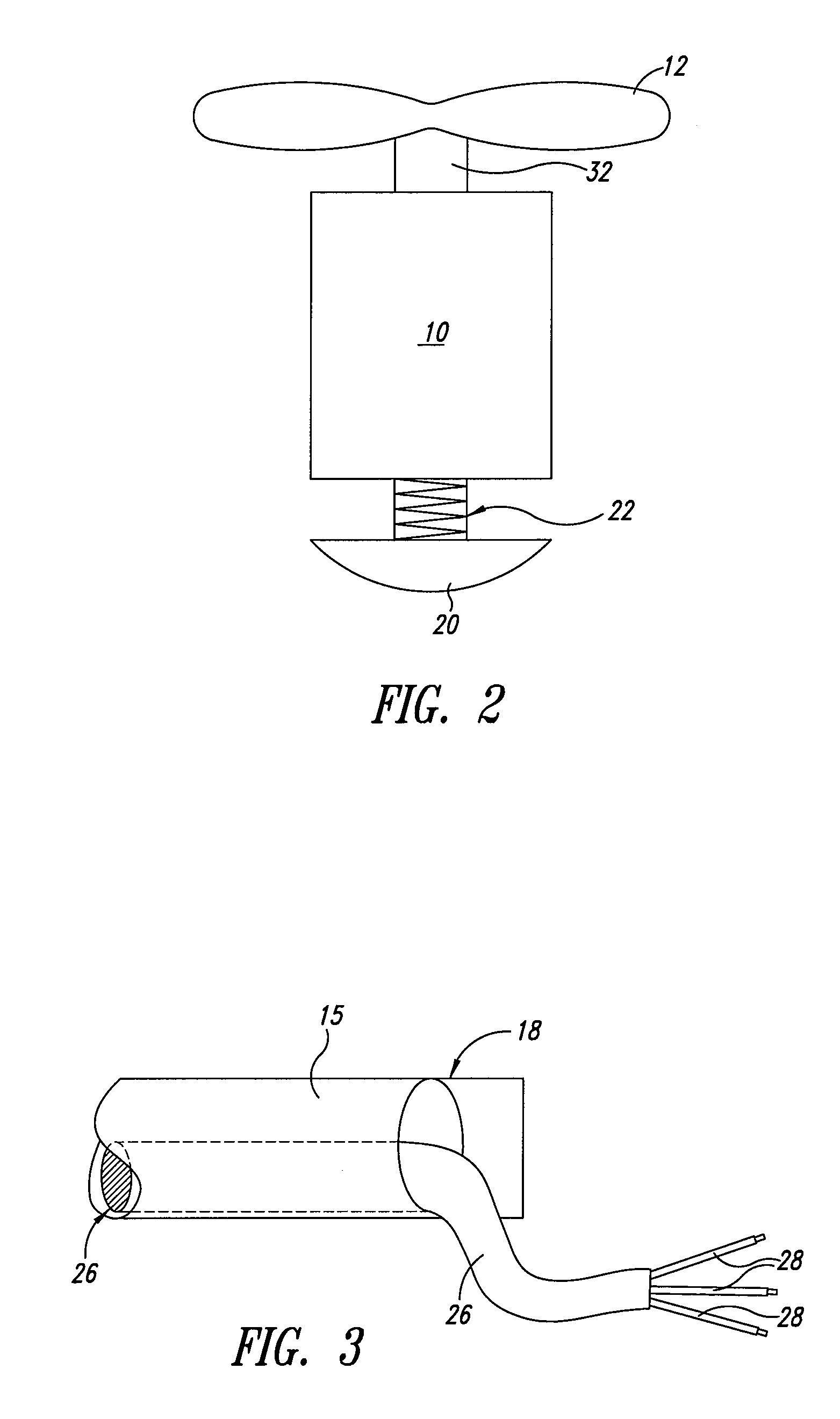

Aircraft

InactiveUS20050061910A1Reduce inherent weightLower center of gravityAircraft navigation controlTethered aircraftFlight vehicleAirplane

The present invention concerns an aircraft having a plurality of lifting and thrust rotors, with an electric motor and an inverter for each motor. In order to provide an aircraft having a greater payload, connecting bars are provided between the motors. In that respect the invention is based on the realization that, if such connecting bars are arranged in the manner of a latticework, they can provide a light but nonetheless stable structure for the aircraft, and that structure can carry correspondingly greater loads.

Owner:WOBBEN ALOYS

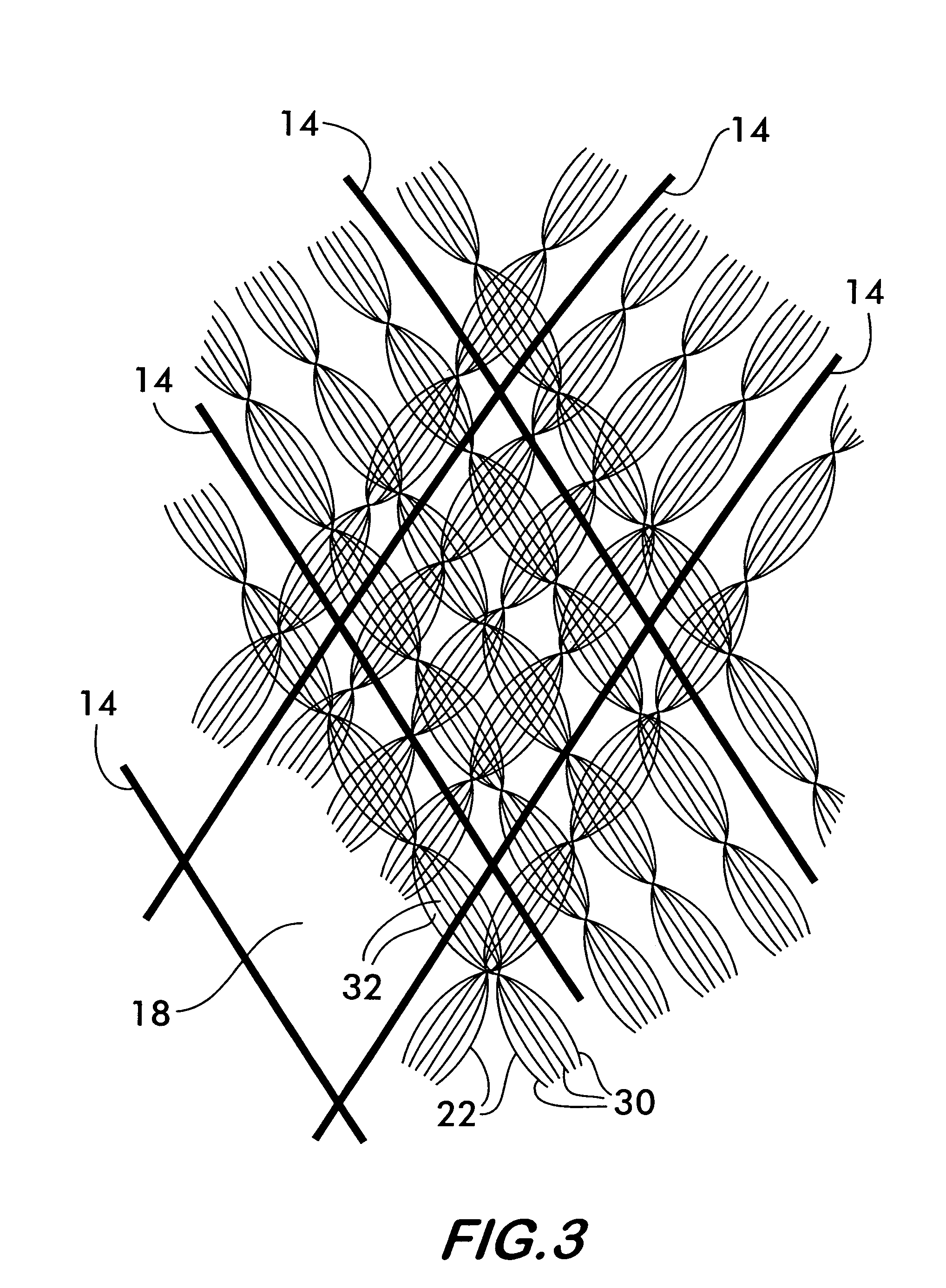

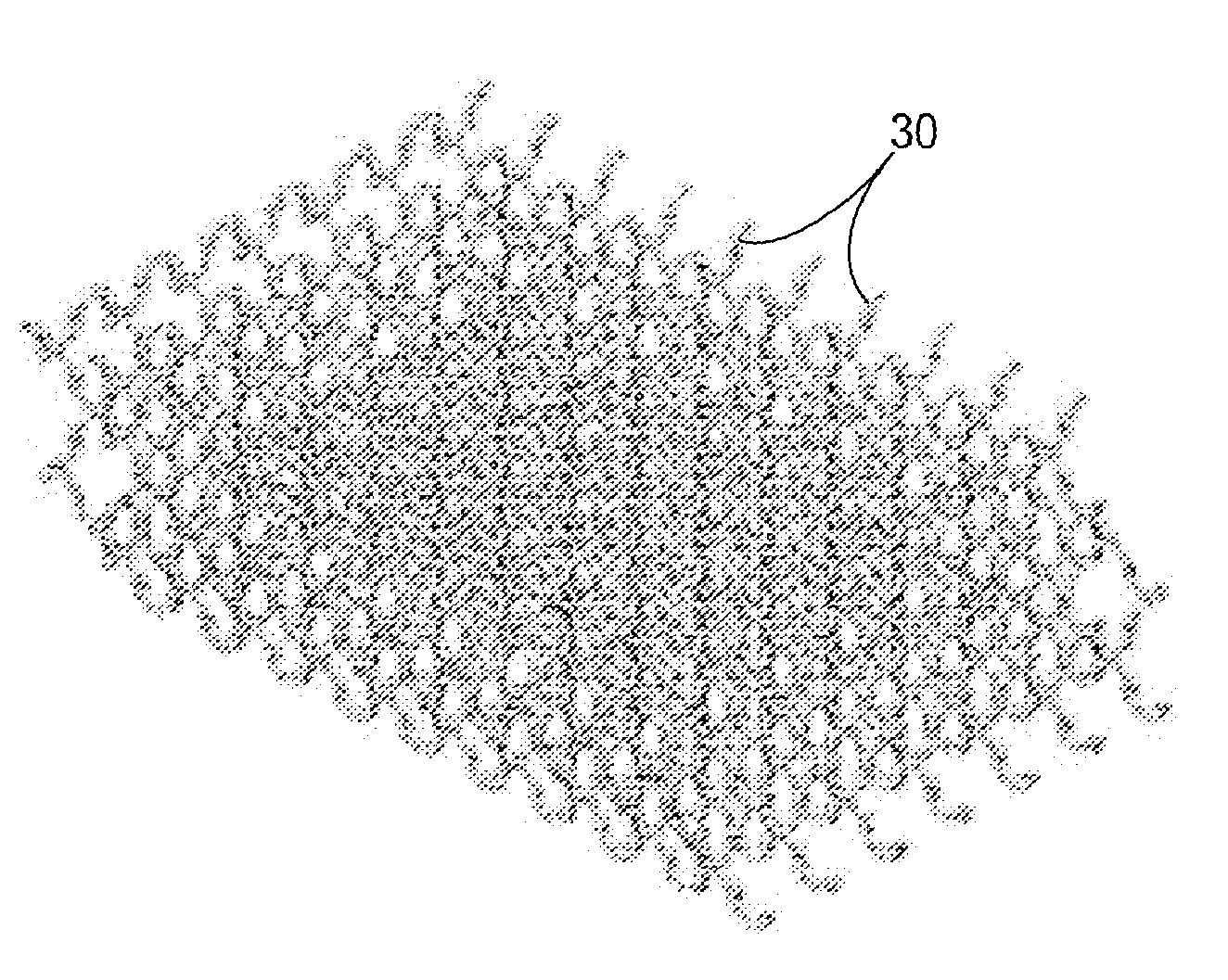

Supported lattice for cell cultivation

A supported lattice is disclosed having a support substrate formed of a plurality of resilient filamentary members braided together to yield a coarse mesh having relatively large interstices and a cell cultivation lattice formed of a plurality of flexible filamentary members braided together and with the resilient filamentary members to form a fine mesh having small interstices. The cell cultivation lattice provides a bed adapted for growing cells in a two-dimensional array across the large interstices of the support substrate to form a continuous surface of living tissue useful to form a graft.

Owner:THE SECANT GRP

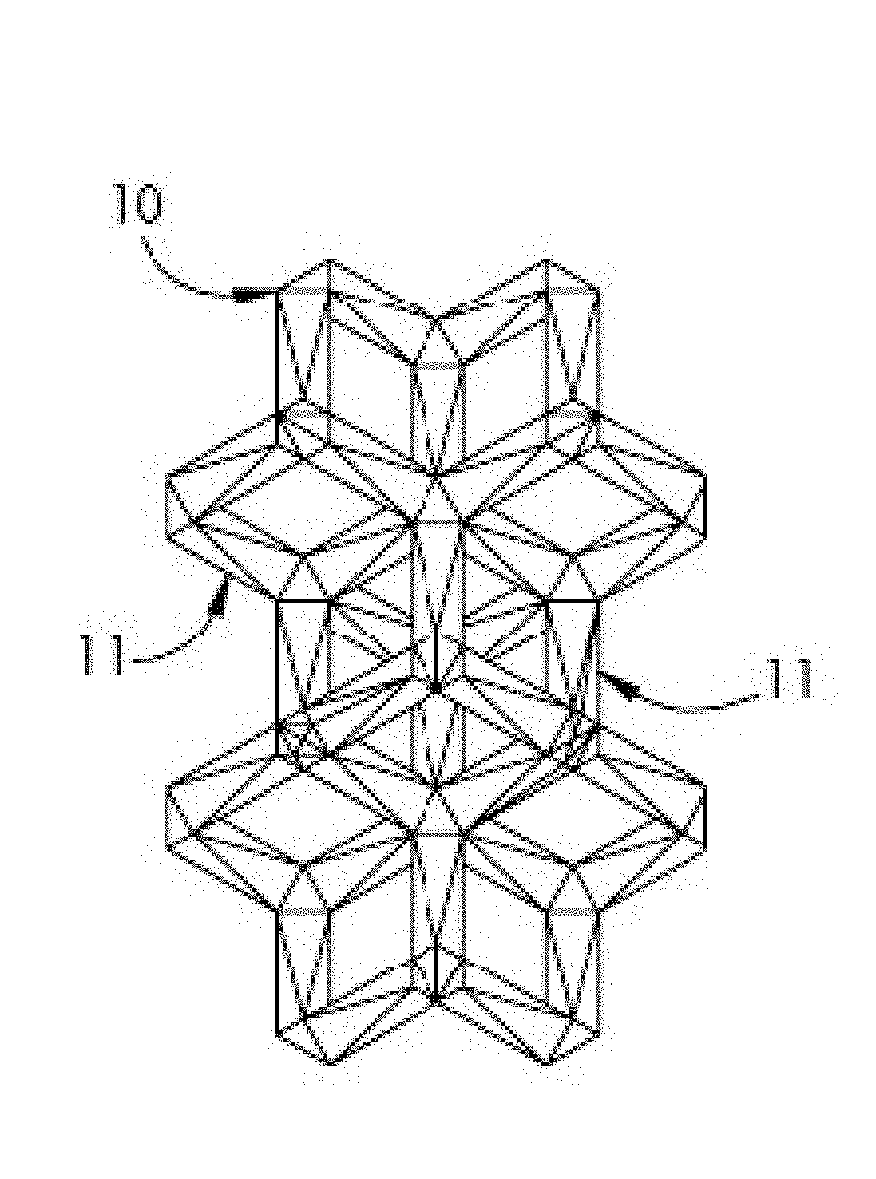

Lattice structures

A unit cell for a lattice structure includes eight unit trusses disposed at vertices of the unit cell. A single unit truss is disposed at a centroid of the unit cell. Each of the nine unit trusses includes fourteen struts. Lattice structures are commonly used to connect various loads within a volume of space. Most such structures, however, have a rigid definition for their topology, and are unable to conform to shape or load directions. Additionally, conventional lattice structures are homogeneous, having dimensions and properties that are consistent throughout. These constraints, generally imposed for ease of manufacturing and assembly, prevent the development of highly robust and efficient structures, and limit the potential for multi-functional applications.

Owner:MILWAUKEE SCHOOL OF ENGINEERING

Ball bat having windows

A bat extending along a longitudinal axis and configured for impacting a baseball or softball in competitive play includes a handle portion coupled to a barrel portion. The handle portion has a distal end and includes a tubular tapered region positioned adjacent the distal end. The tapered region has a peripheral outer surface encircling the longitudinal axis and includes at least one window formed into the outer surface. The one or more windows can be defined by a latticework.

Owner:WILSON SPORTING GOODS

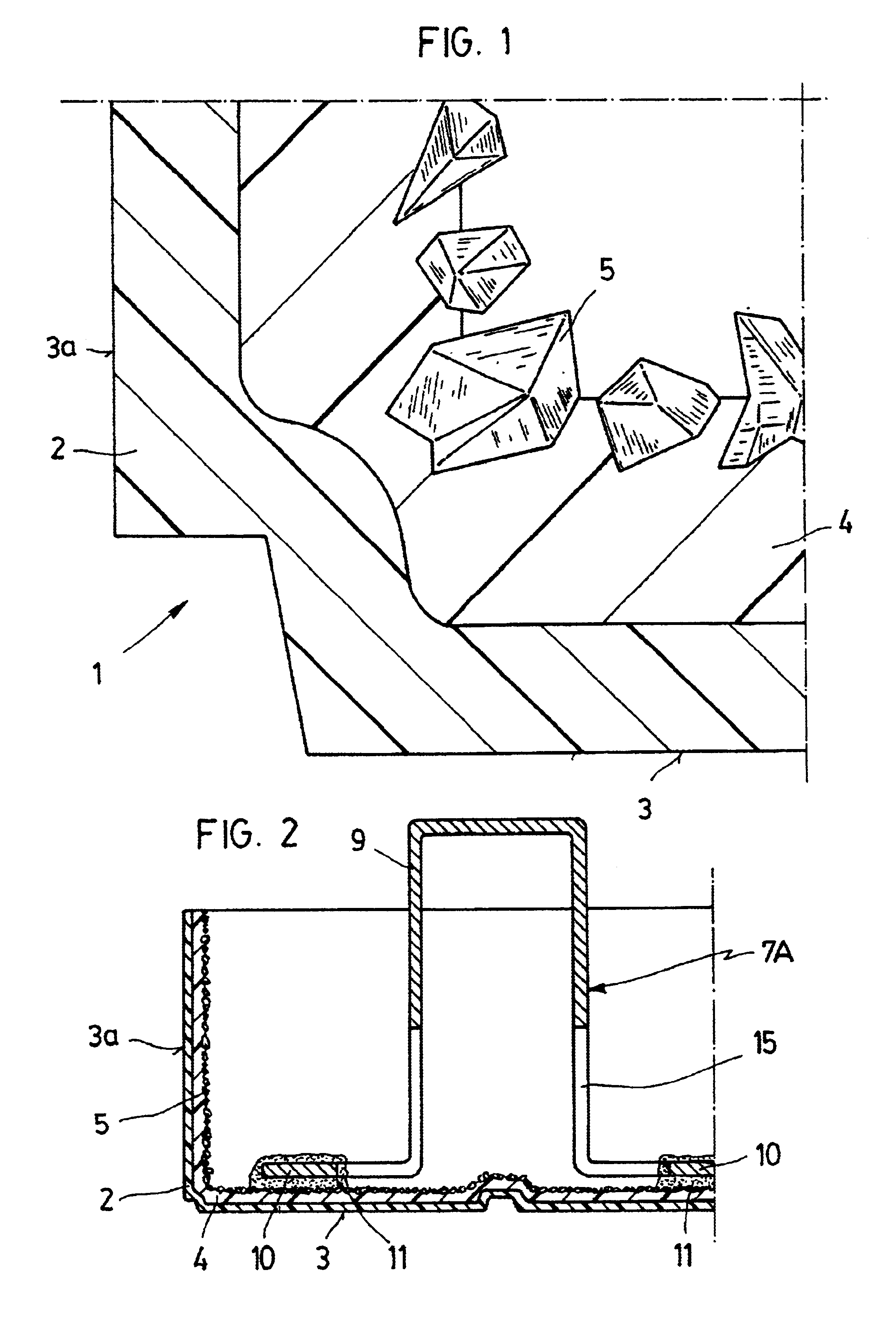

Building panel and plant for the manufacture thereof

InactiveUS6857241B1Easy to produceAccurate locationArtificial islandsConstruction materialThin layerSynthetic resin

This building panel consists of lightweight panel for external or internal closures of latticework support structures, which is constituted by slabs of air-setting resistant material. The slabs are reinforced in the facade panels for external closures and unreinforced for the dividing panels for internal closures. They are provided with a patterned surface on the visible face and are smooth or shaped at the edges. The visible face is formed by a thin layer of molded synthetic resin or fine mortar paste. When the layer is molded synthetic resin and is disposed as a shell for the panel, it comprises over the whole of the inner surface thereof an internal synthetic resin layer, the entire free surface of which is covered with a solid bulk material, the components of which firmly partially anchored in said internal layer and afford a substantial free surface for anchorage of the air-setting material forming the resistant body poured thereover. This material fills the entire volume of said panel shell, at the same time as it includes therein reinforcement means provided with points directly accessible from the outside of the concealed face of the panel.

Owner:PELLICER CARLOS FRADERA

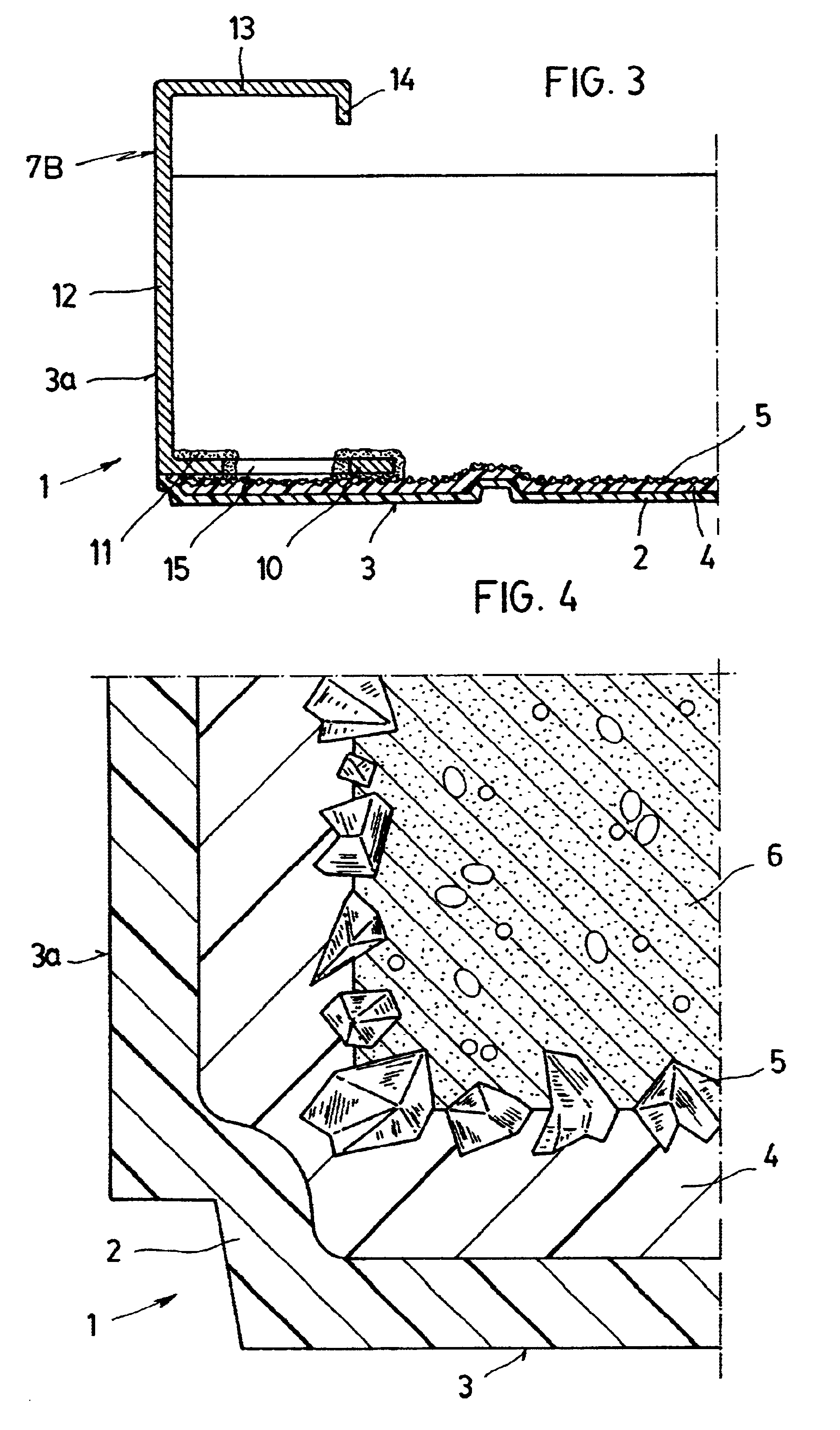

Methods of manufacturing diamond capsules

InactiveUS7309446B1Reduce temperature differenceImprove conductivityMaterial nanotechnologyPaper/cardboard articlesNanocrystalAccess port

Capsules and similar objects are made from materials having diamond (sp3) lattice structures, including diamond materials in synthetic crystalline, polycrystalline (ordered or disordered), nanocrystalline and amorphous forms. The capsules generally include a hollow shell made of a diamond material that defines an interior region that may be empty or that may contain a fluid or solid material. Some of the capsules include access ports that can be used to fill the capsule with a fluid. Capsules and similar structures can be manufactured by growing diamond on suitably shaped substrates. In some of these methods, diamond shell sections are grown on substrates, then joined together. In other methods, a nearly complete diamond shell is grown around a form substrate, and the substrate can be removed through a relatively small opening in the shell.

Owner:SUNSHELL

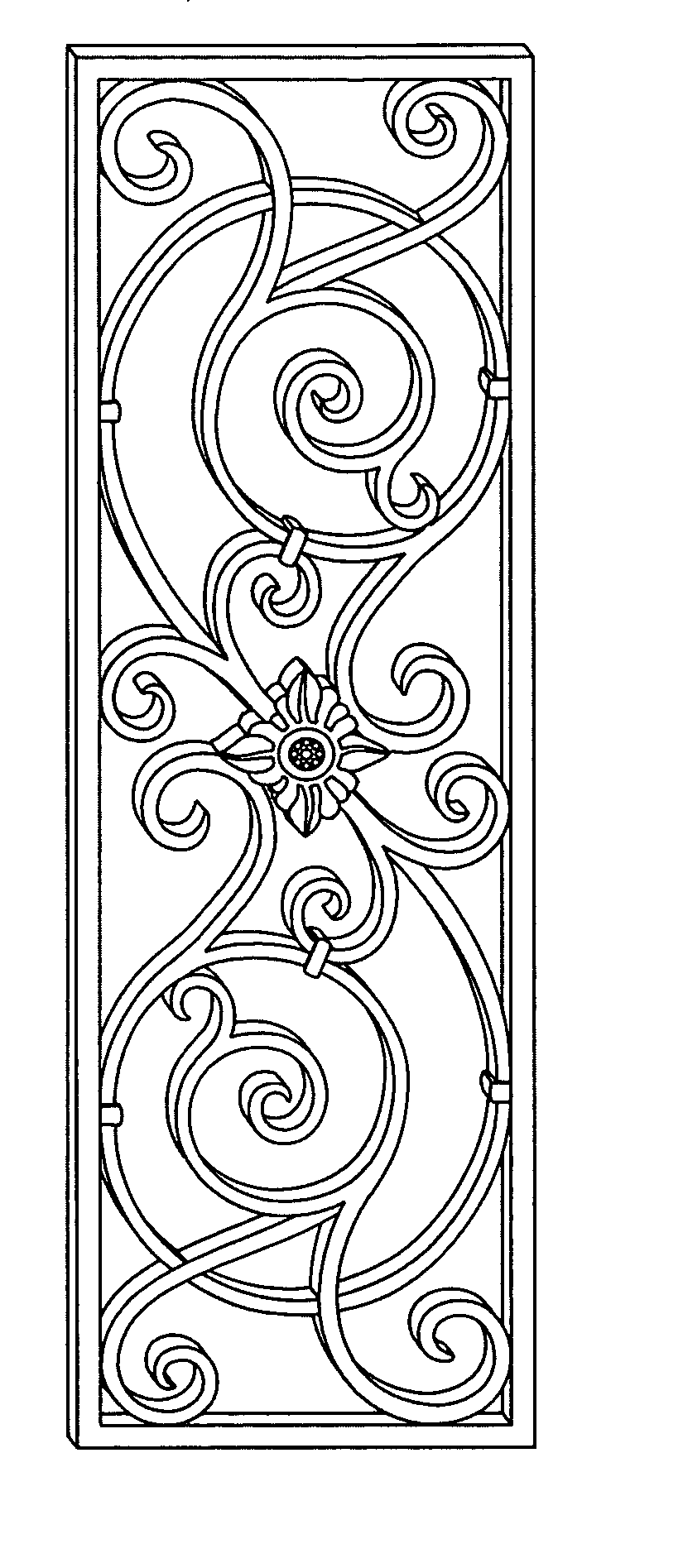

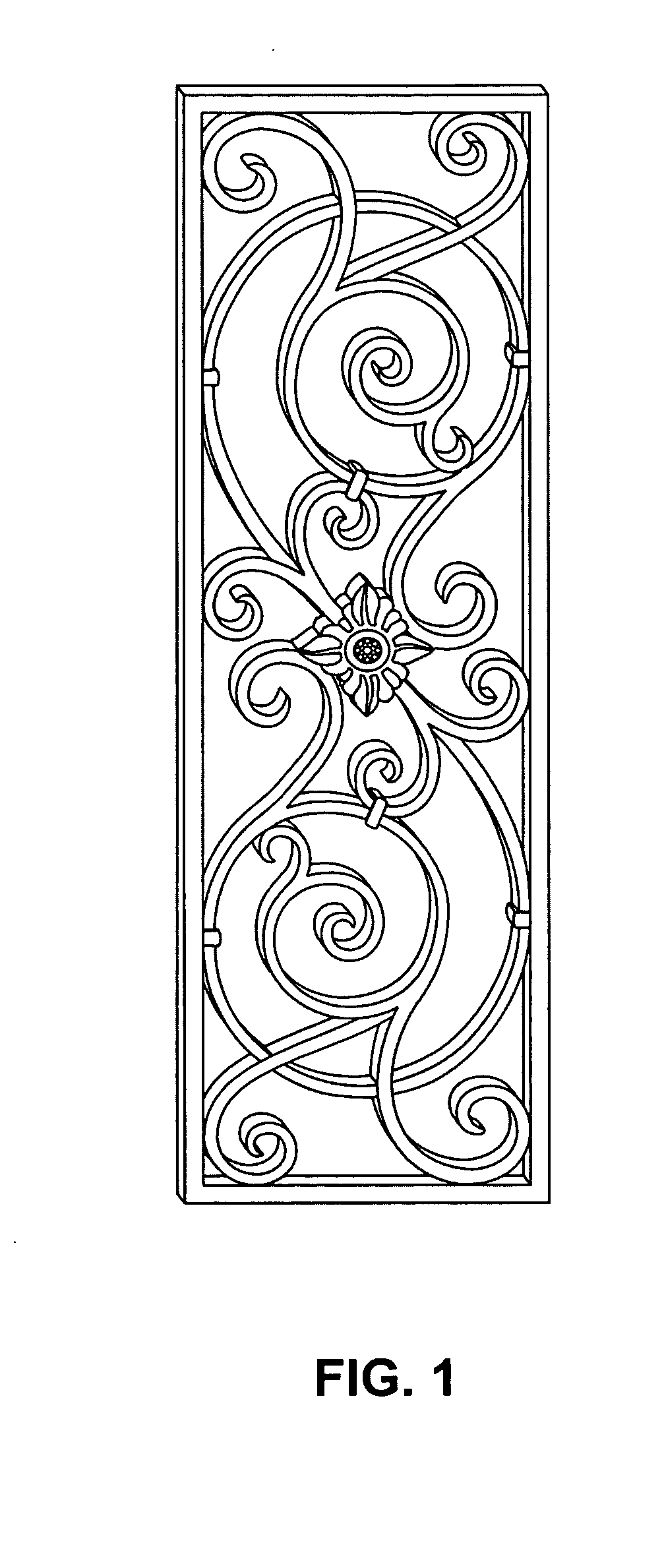

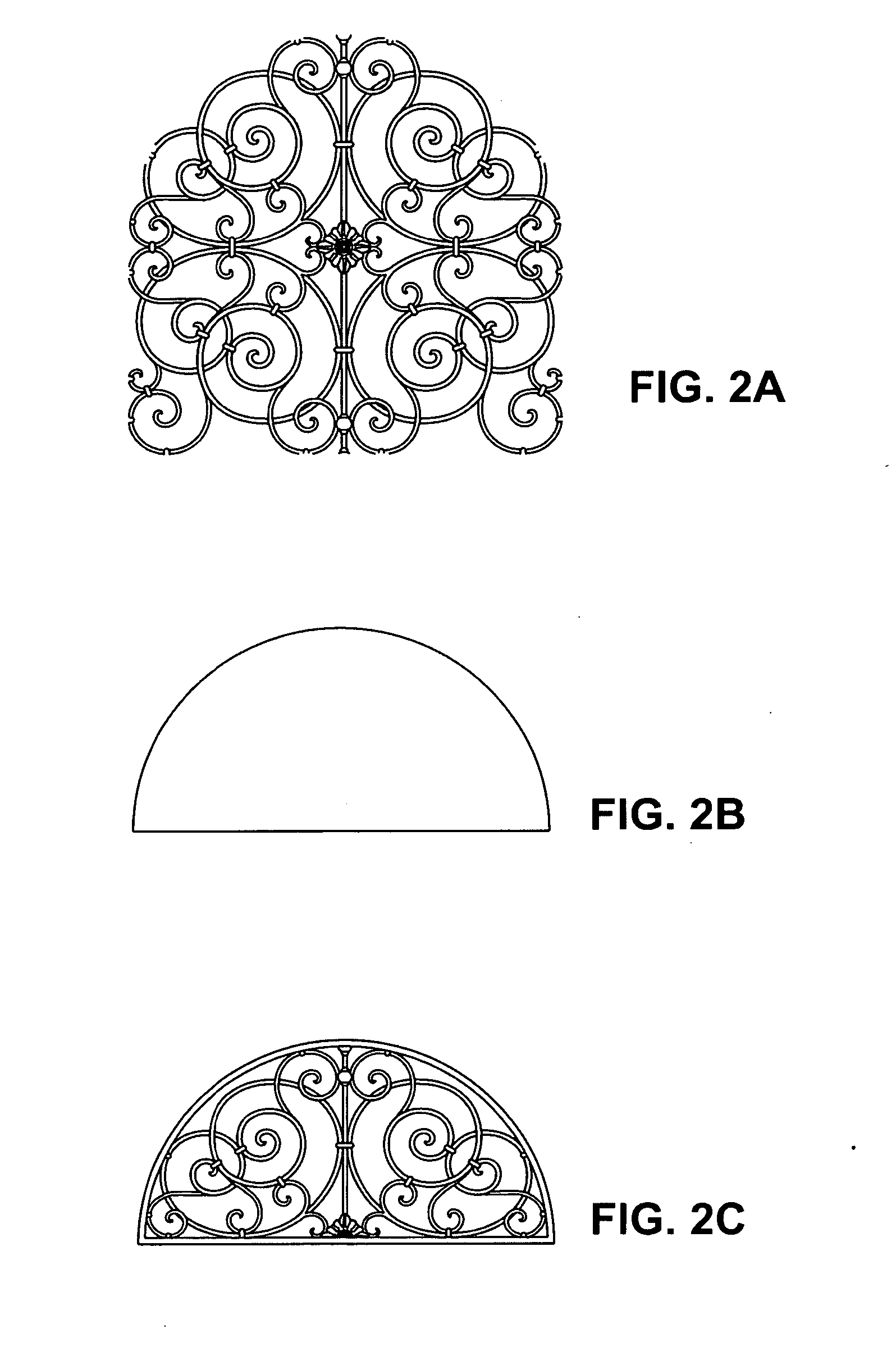

Decorative lattice structure and methods for manufacturing and installing same

InactiveUS20070000195A1High cost lookLow mass production costCovering/liningsFixed grillesFiberMass customization

A decorative lattice that simulates the look and feel of decorative ironwork by combining carving techniques and coating techniques is described. The decorative latticework is made of a sheet material such as a composite wood / fiber board material. The decorative lattice is suitable for a mass customization manufacturing processes.

Owner:LUNA PIENA

Aircraft

InactiveUS20080006737A1Accurate monitoringLower center of gravityTethered aircraftPropellersFlight vehicleAirplane

The present invention concerns an aircraft having a plurality of lifting and thrust rotors, with an electric motor and an inverter for each motor. In order to provide an aircraft having a greater payload, connecting bars are provided between the motors. In that respect the invention is based on the realization that, if such connecting bars are arranged in the manner of a latticework, they can provide a light but nonetheless stable structure for the aircraft, and that structure can carry correspondingly greater loads.

Owner:WOBBEN ALOYS

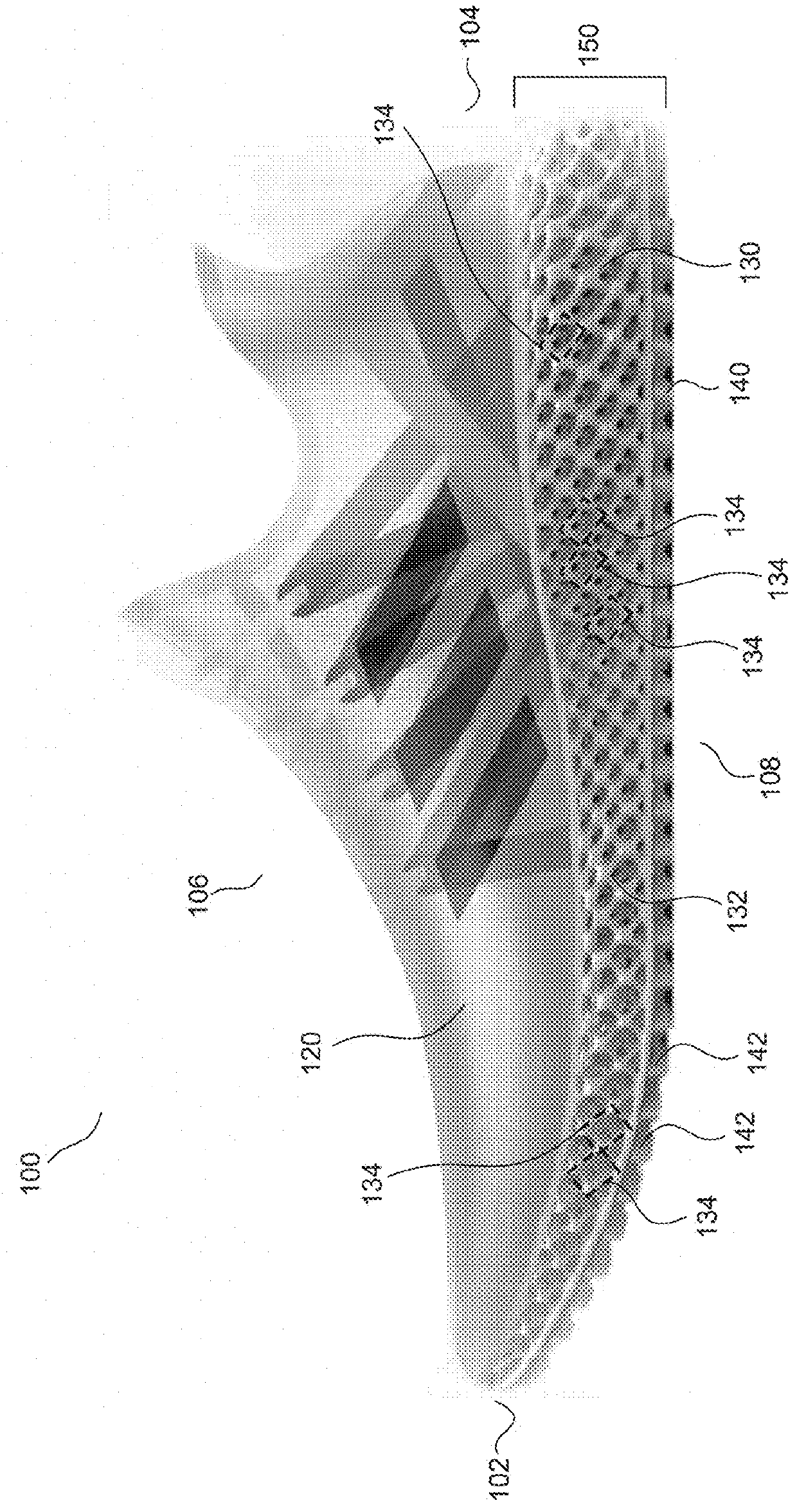

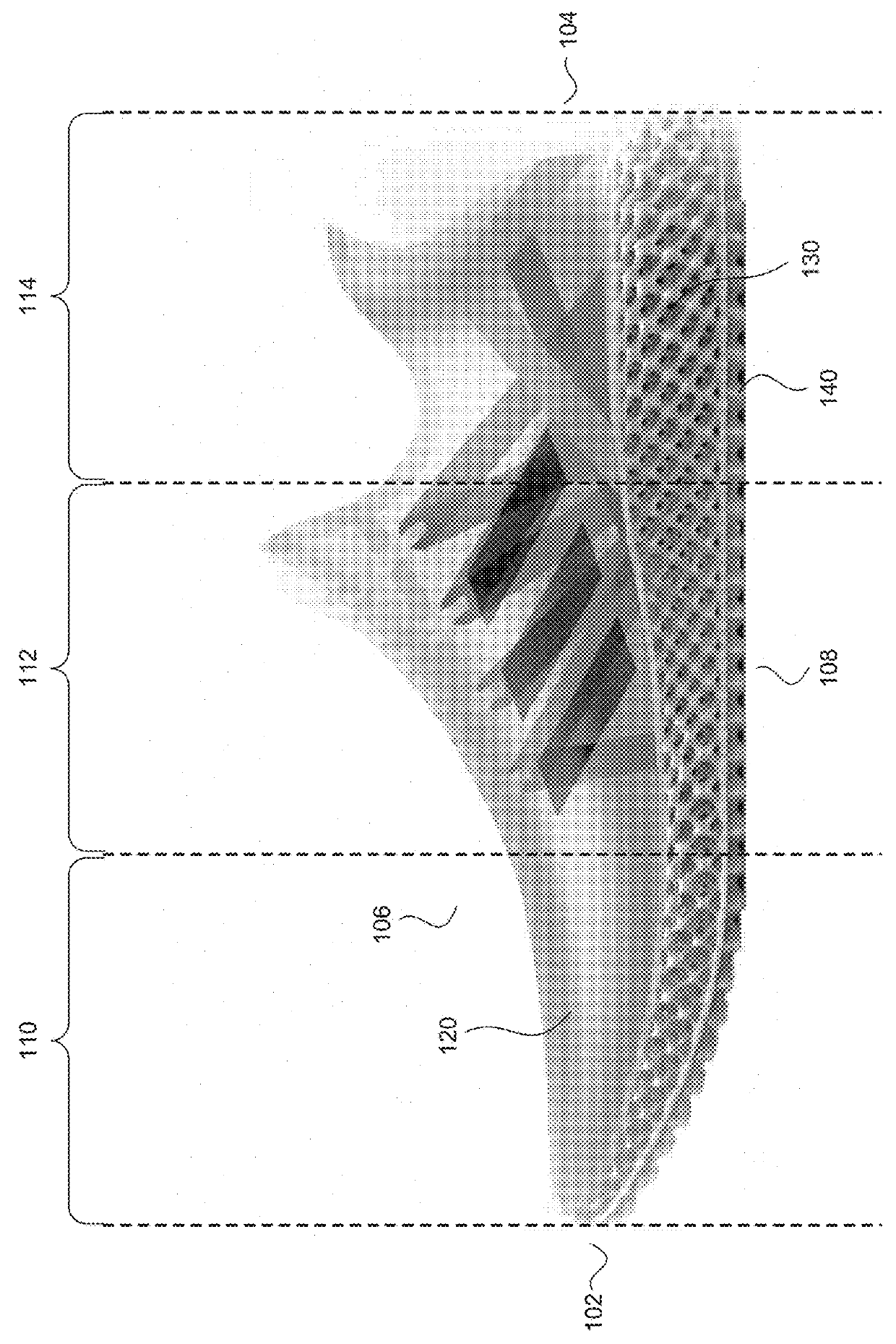

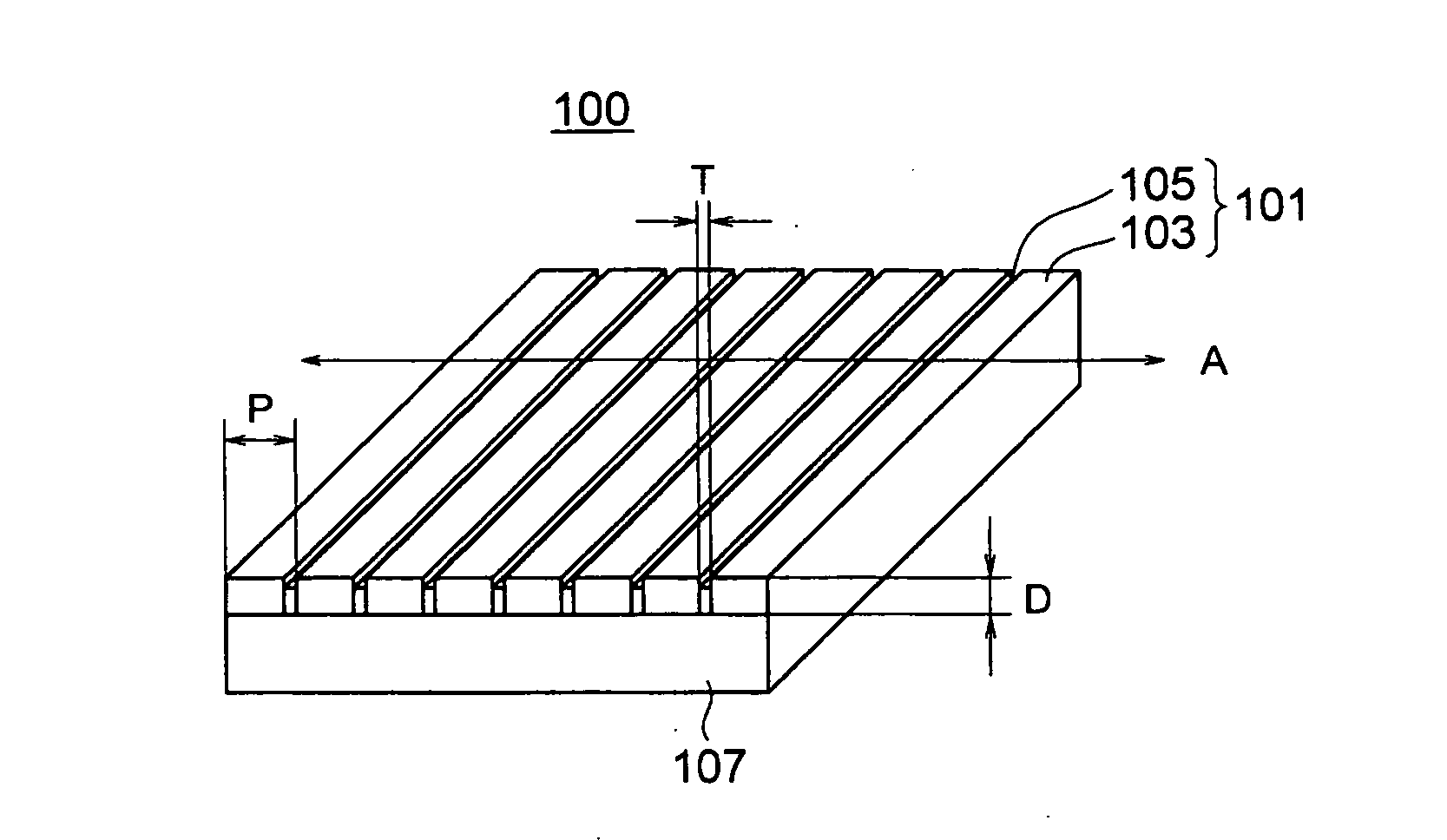

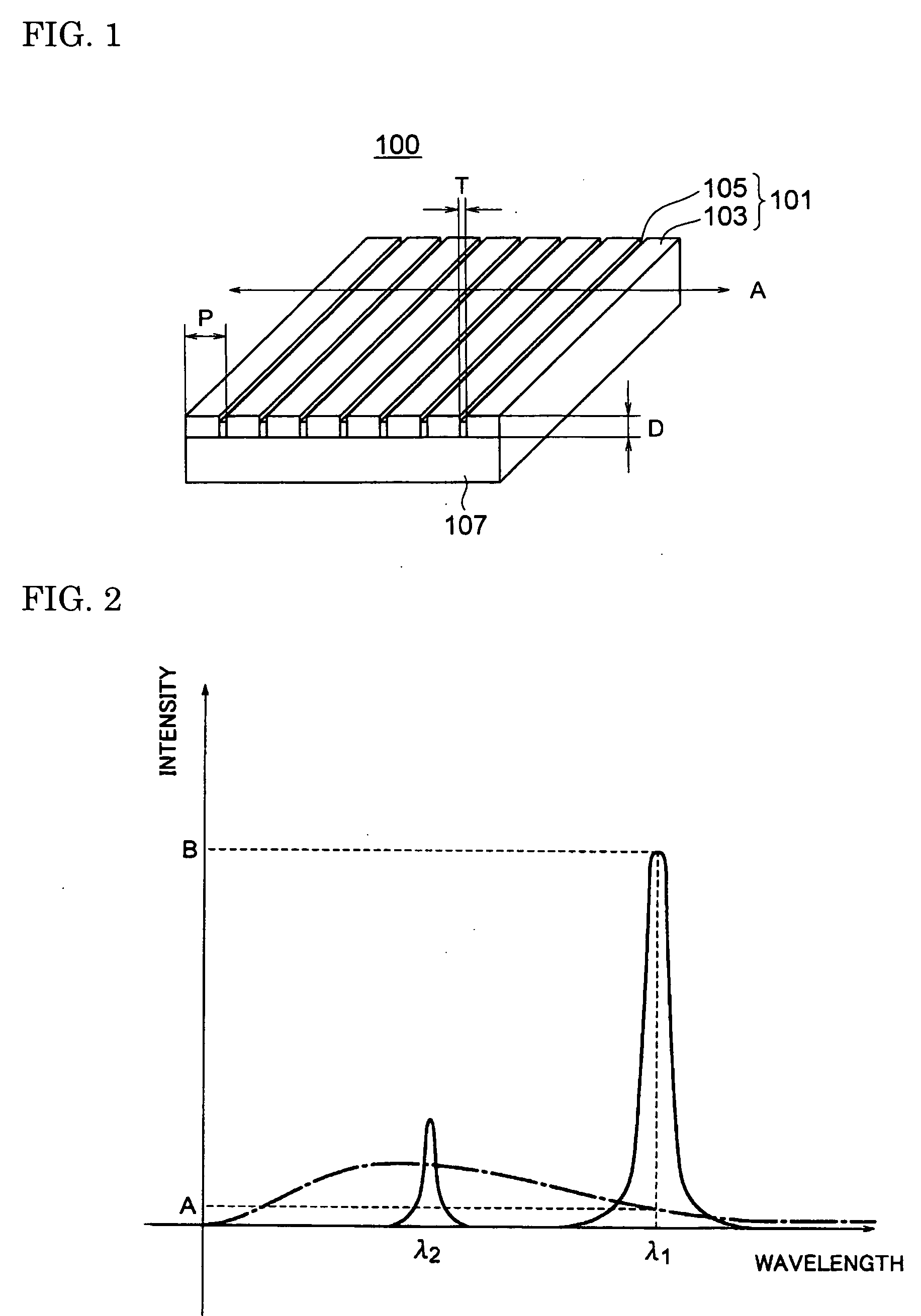

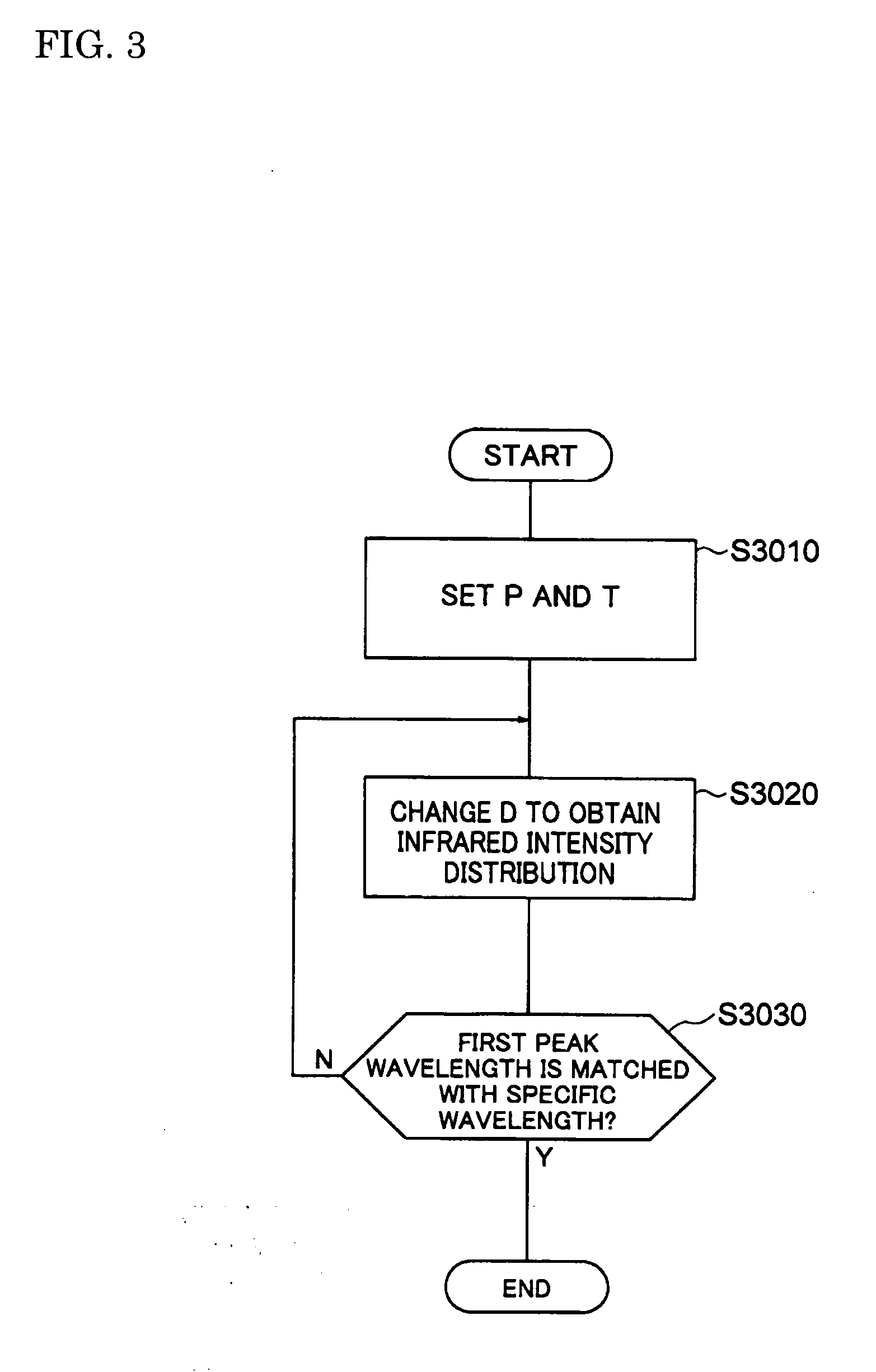

Infrared Source and Method of Manufacturing the Same

ActiveUS20090127478A1Simple structureRadiation pyrometryWave amplification devicesElectricityInfrared

There is provided an infrared light source that has a simple structure and radiates infrared rays polarized in a specific direction and having a specific wavelength. The infrared light source (100) comprises a heat generator (107) and a latticework (101) in which a dielectric part (105) and a metal part (103) are alternately formed at a constant pitch in a constant direction. The infrared rays are radiated in a direction perpendicular to the surface of the latticework and are polarized in the direction indicated by an arrow A. If the constant pitch is denoted by P, the width of the dielectric part in the constant direction by T, and the specific wavelength by λ, for arbitrary P and T that meet the inequalities 0<P≦2.0 and T≦0.5P, the depth D of the latticework is so selected that the intensity spectrum of the infrared rays radiated from the infrared light source has the peak at λ.

Owner:NALUX CO LTD +1

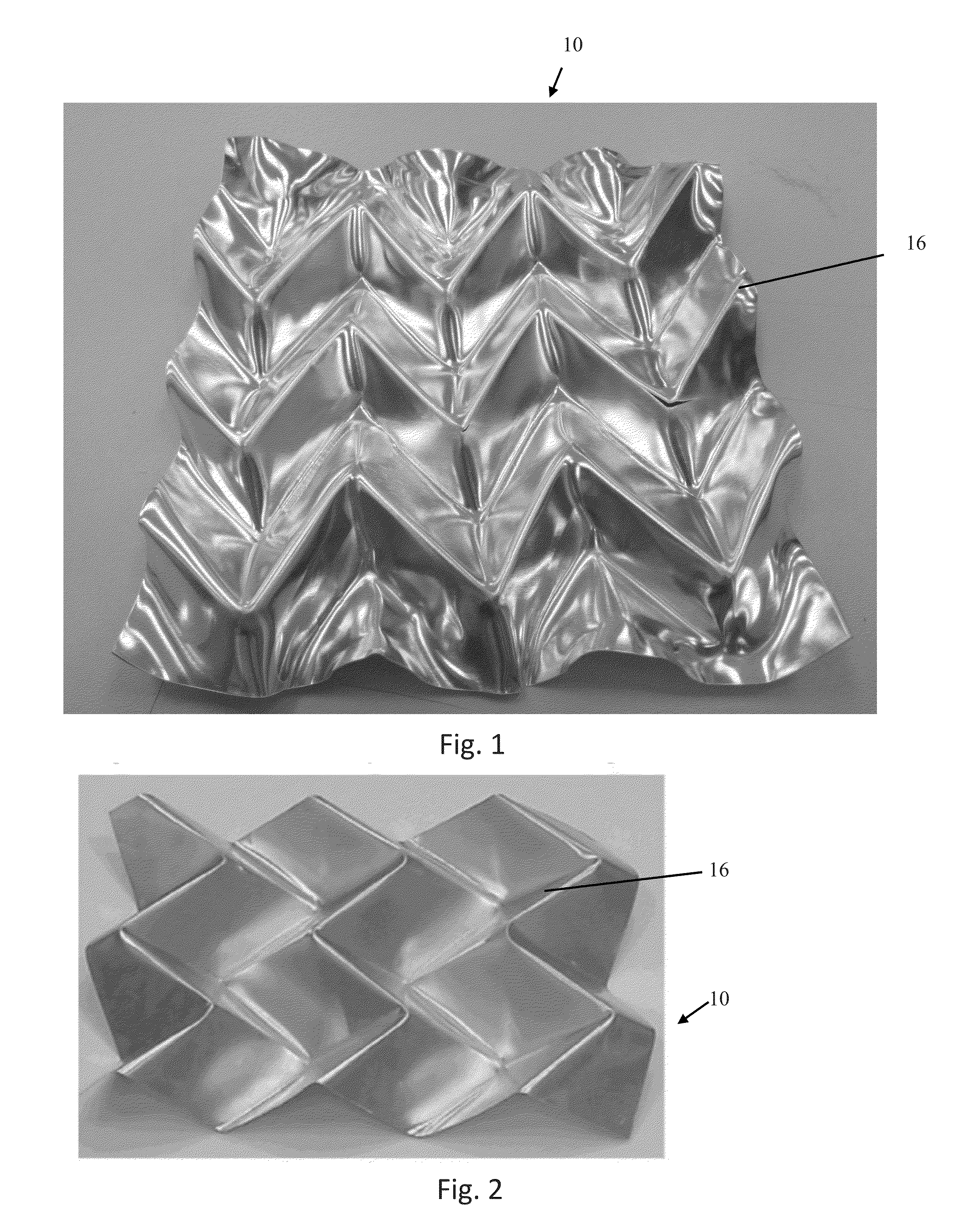

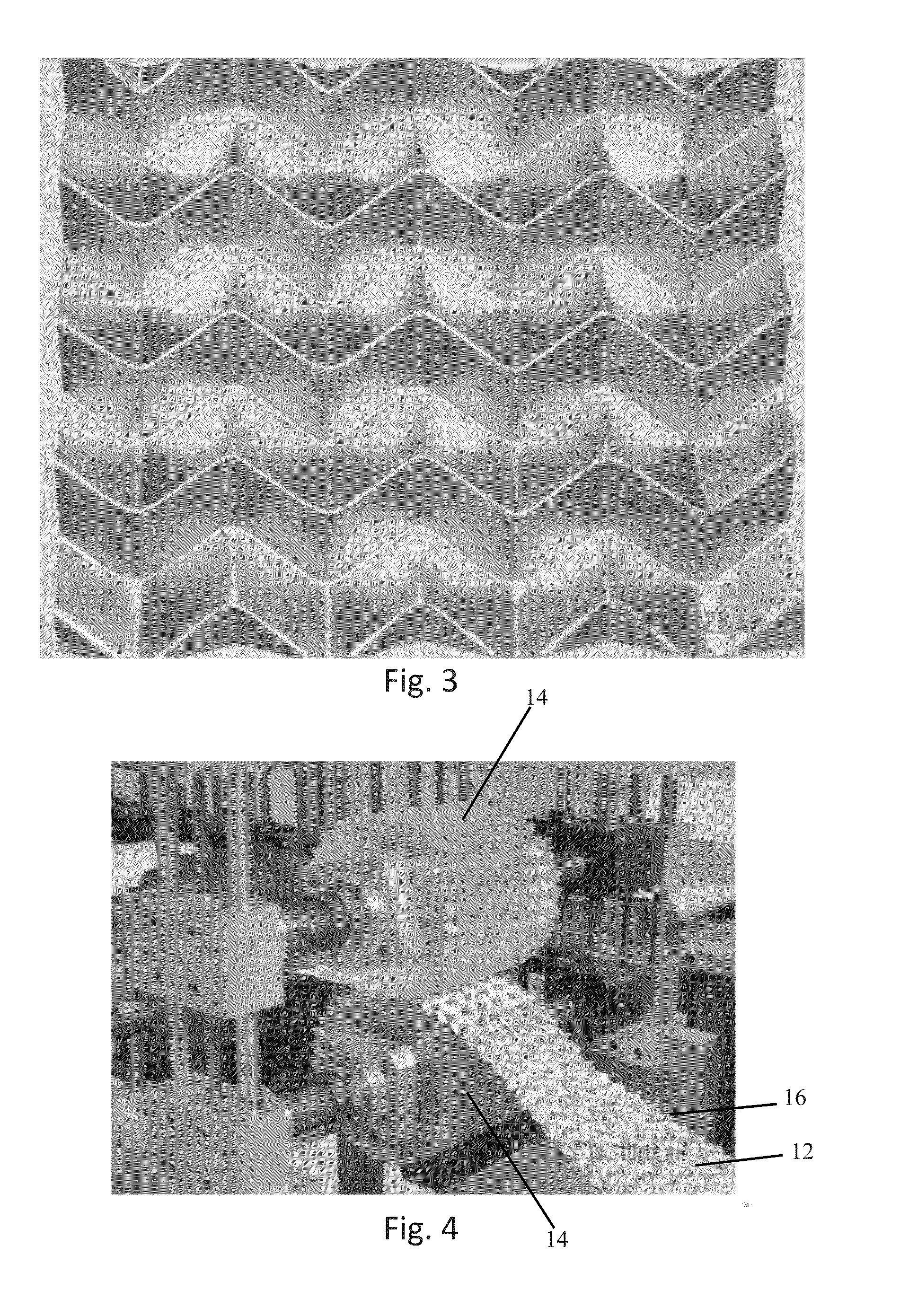

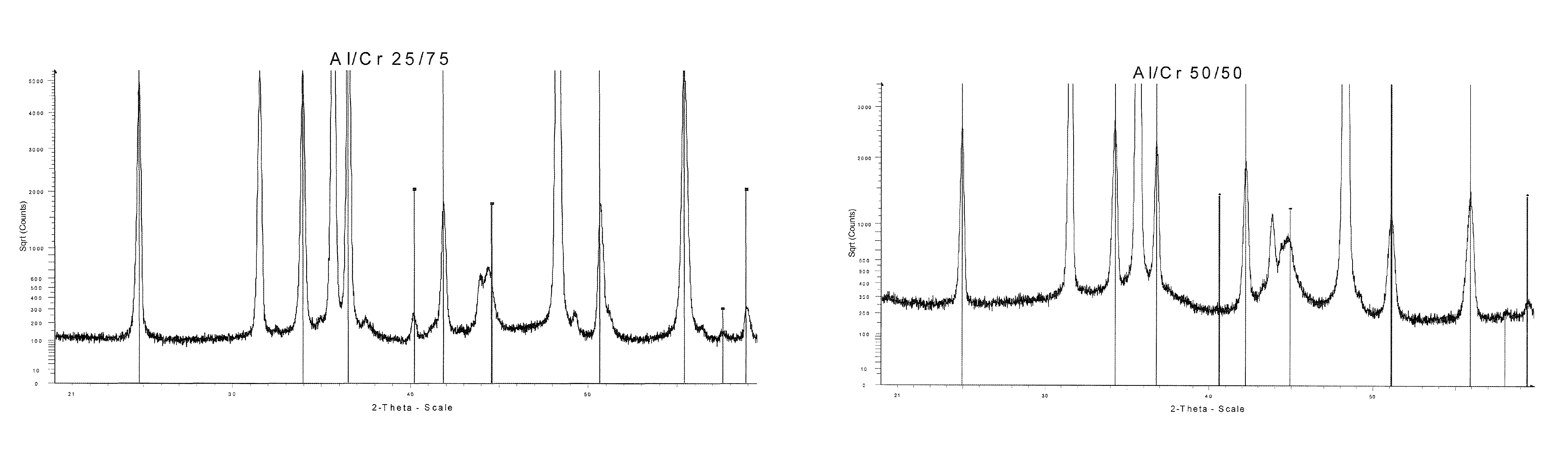

Macro-patterned materials and structures for vehicle arresting systems

Embodiments of the present disclosure relate generally to macro-patterned materials and methods of their use in connection with vehicle arresting systems. Certain embodiments provide 3-D folded materials, honeycombs, lattice structures, and other periodic cellular material structures, that can be used for arresting vehicles. The materials can be engineered to have properties that allow them to reliably crush in a predictable manner under pressure from a vehicle. The materials can be formed into various shapes and combined in various ways in order to provide the desired properties.

Owner:ENGINEERED ARRESTING SYST CORP

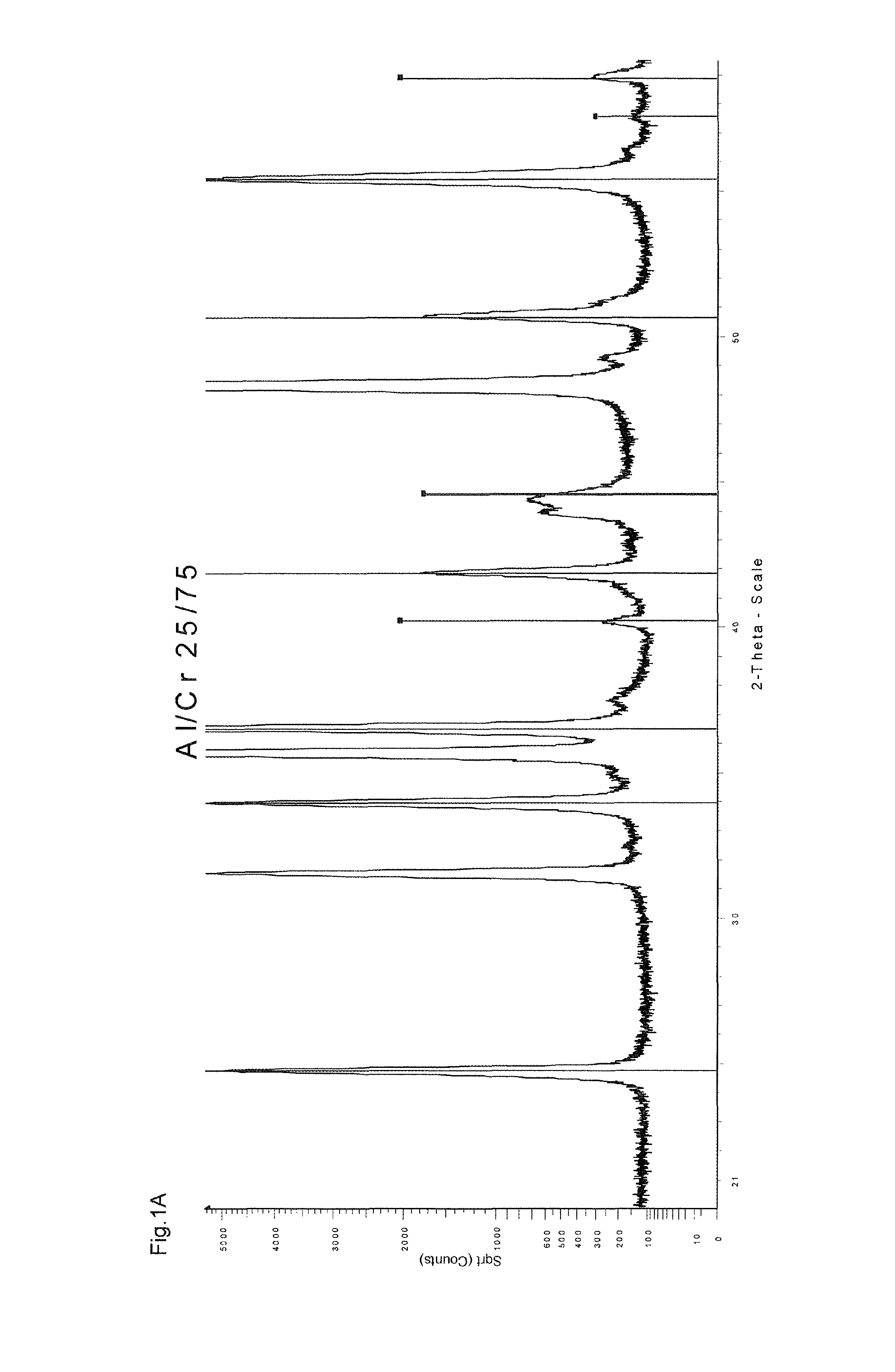

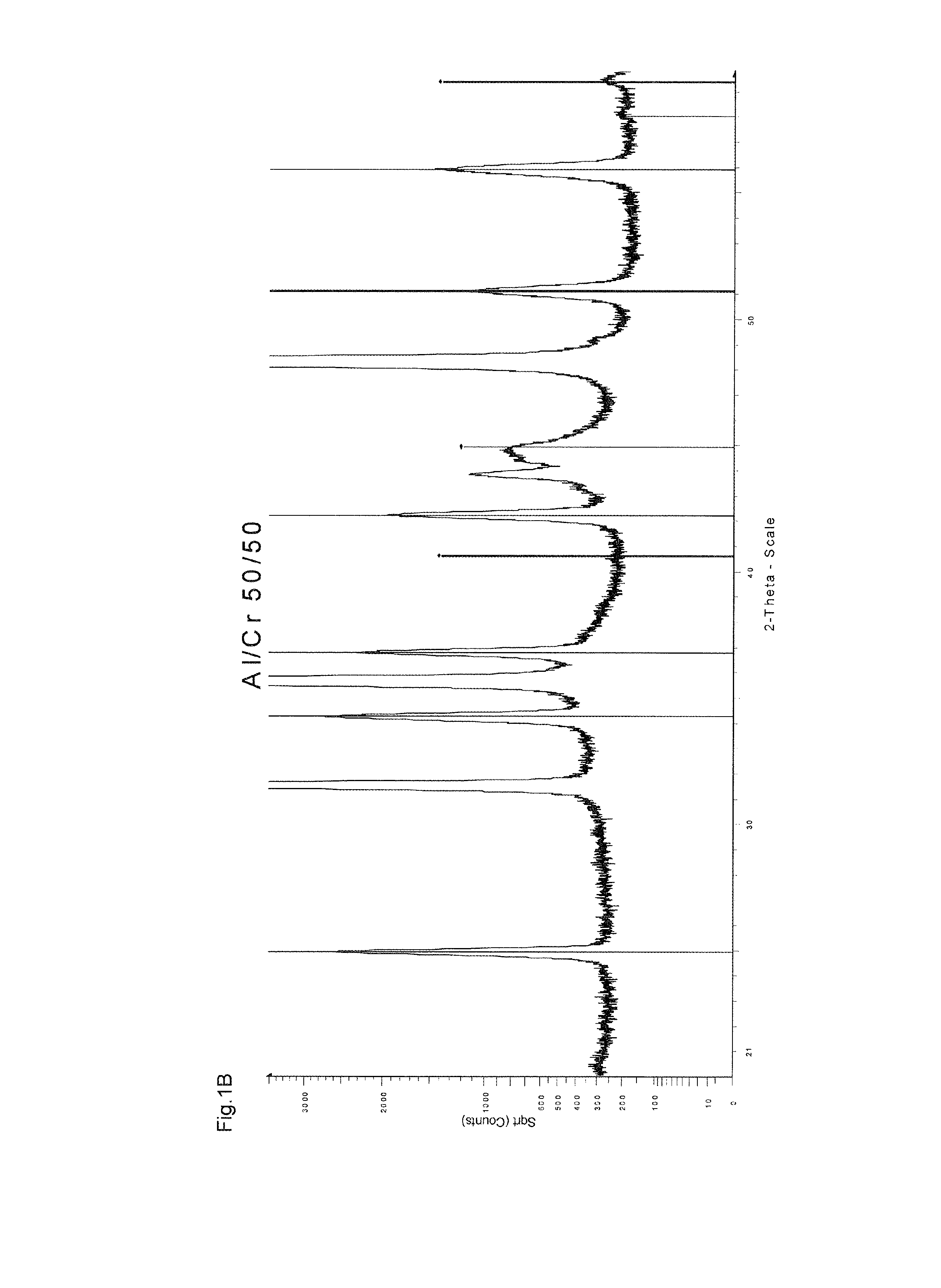

Layer system with at least one mixed crystal layer of a multi-oxide

A PVD layer system for the coating of workpieces encompasses at least one mixed-crystal layer of a multi-oxide having the following composition: (Me11-xMe2x)2O3, where Me1 and Me2 each represent at least one of the elements Al, Cr, Fe, Li, Mg, Mn, Nb, Ti, Sb or V. The elements of Me1 and Me2 differ from one another. The crystal lattice of the mixed-crystal layer in the PVD layer system has a corundum structure which in an x-ray diffractometrically analyzed spectrum of the mixed-crystal layer is characterized by at least three of the lines associated with the corundum structure. Also disclosed is a vacuum coating method for producing a mixed-crystal layer of a multi-oxide, as well as correspondingly coated tools and components.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

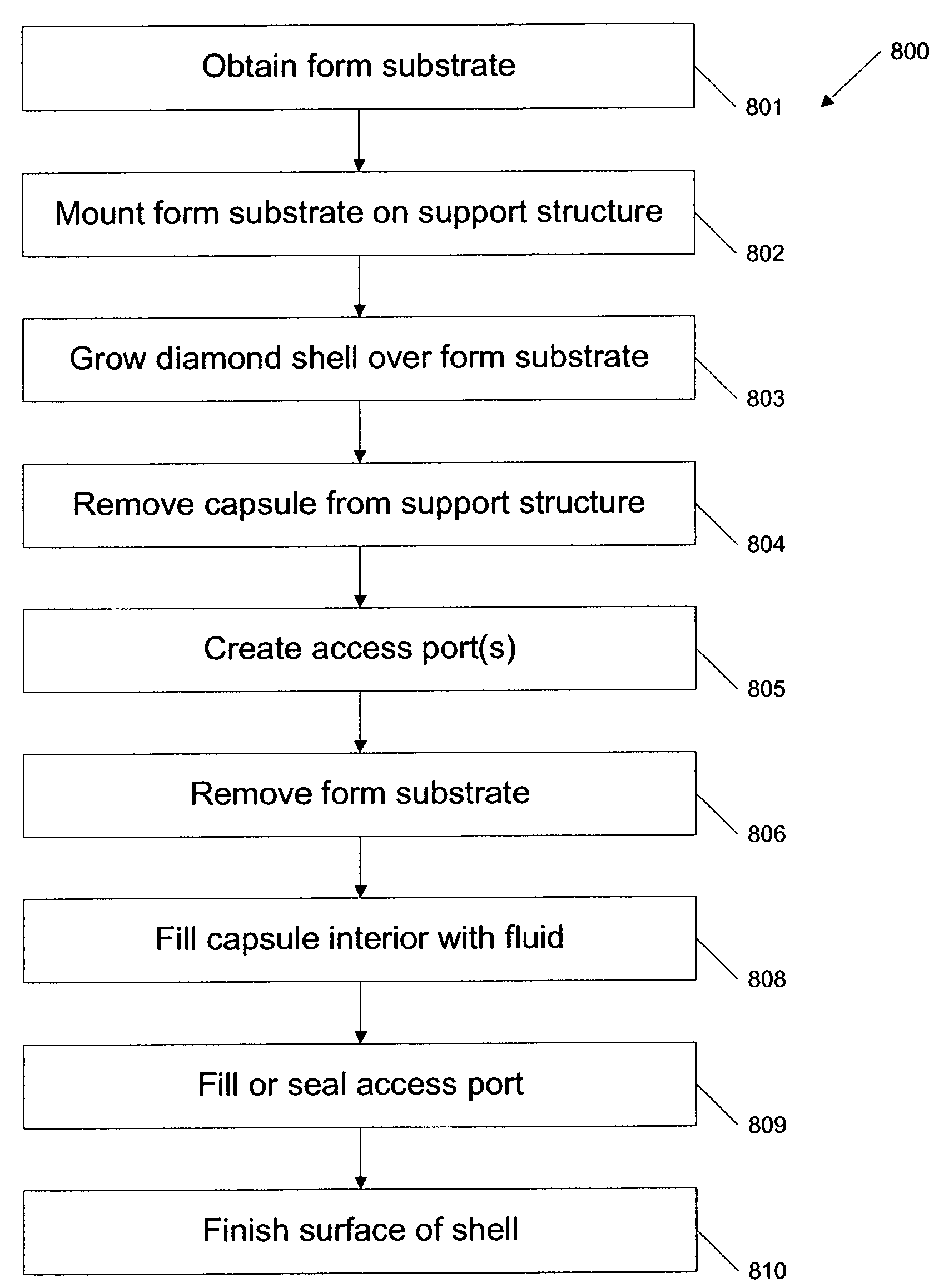

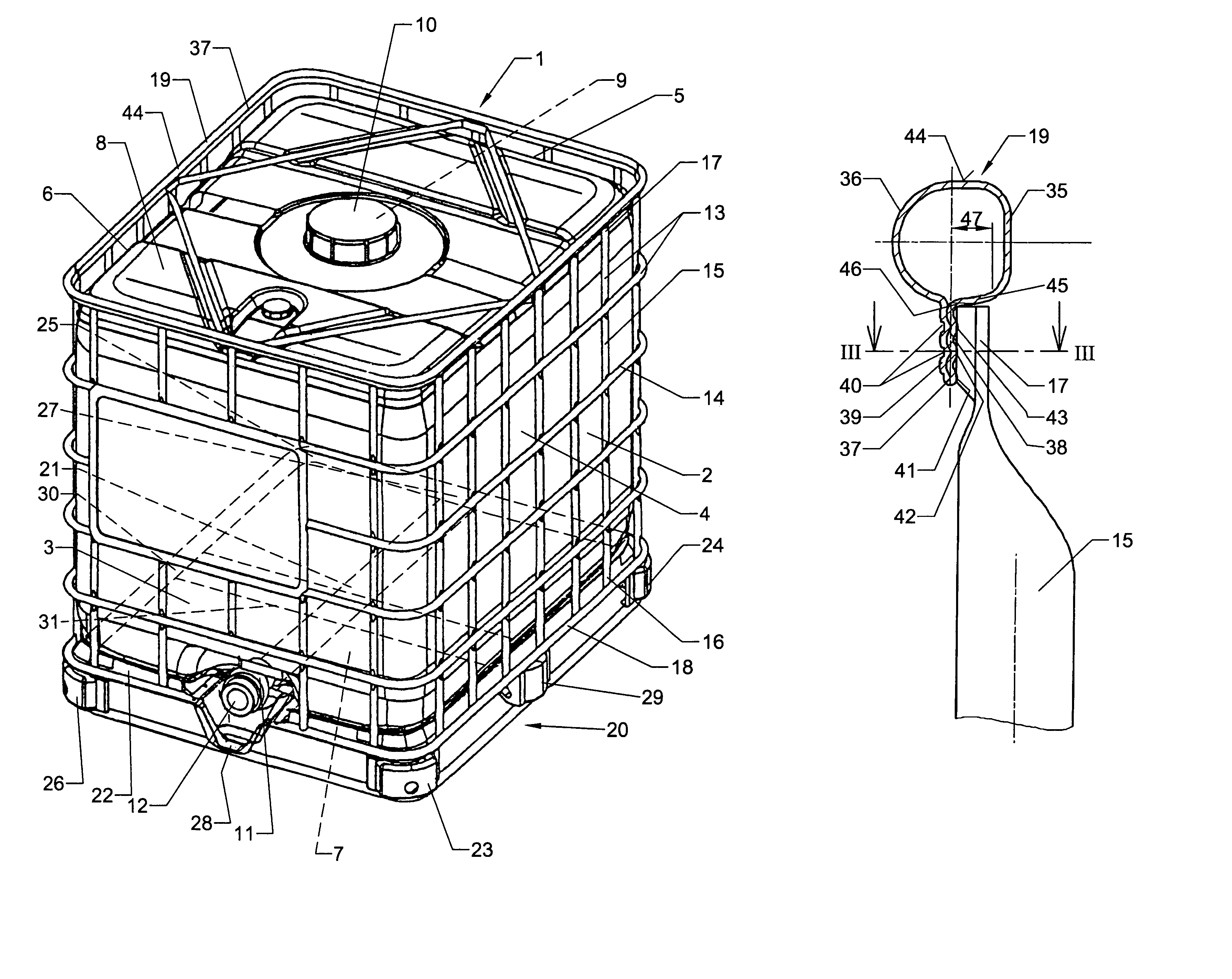

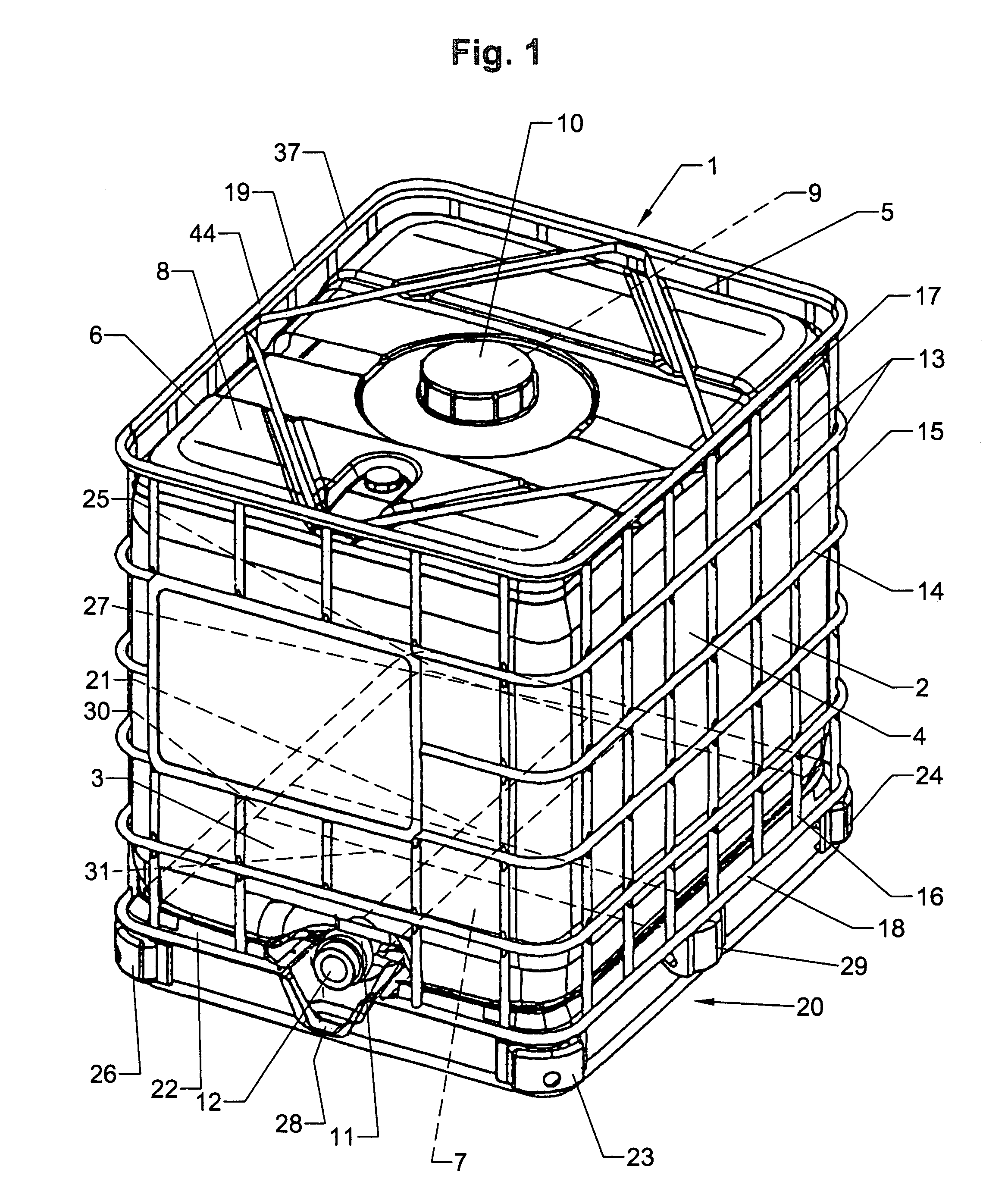

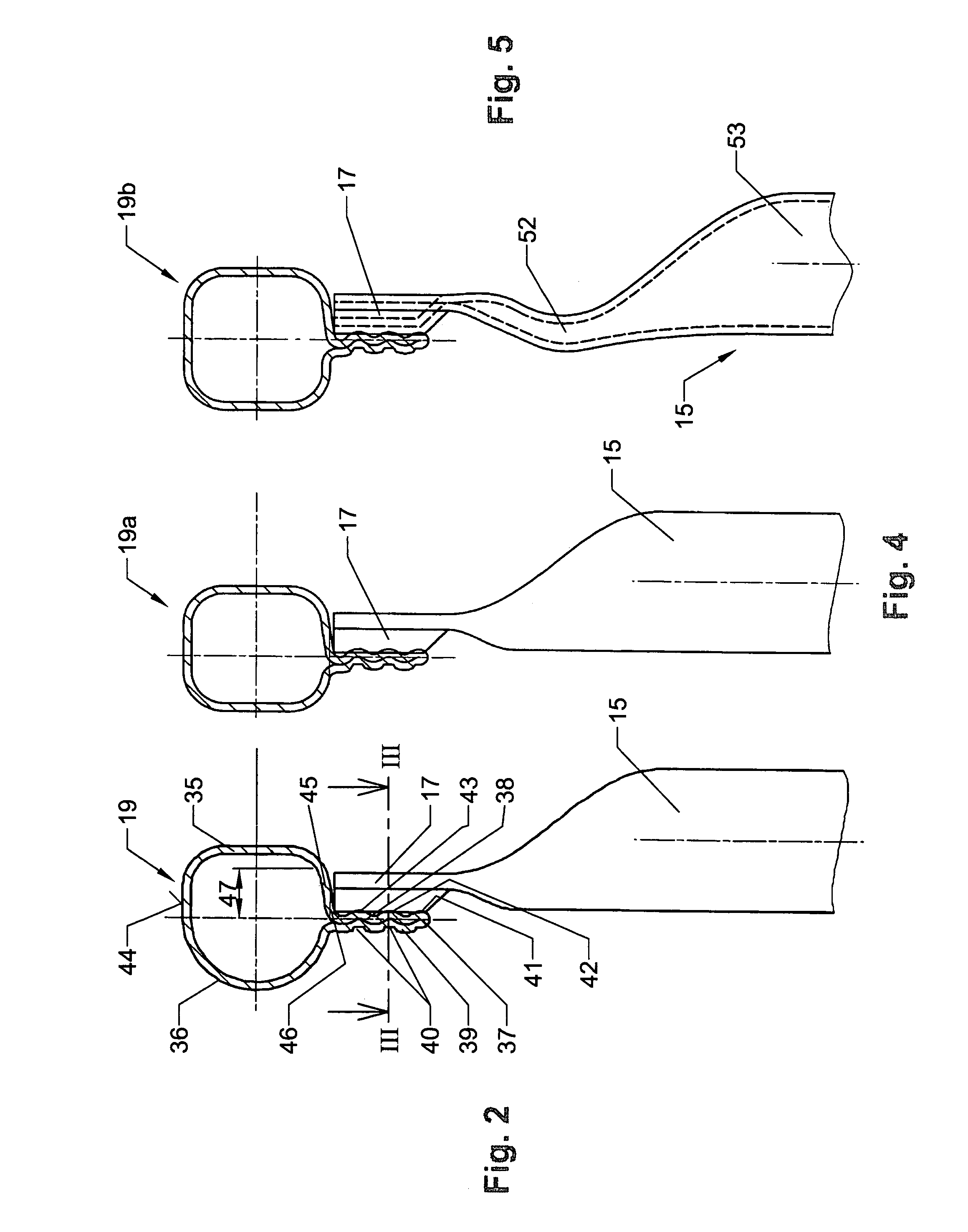

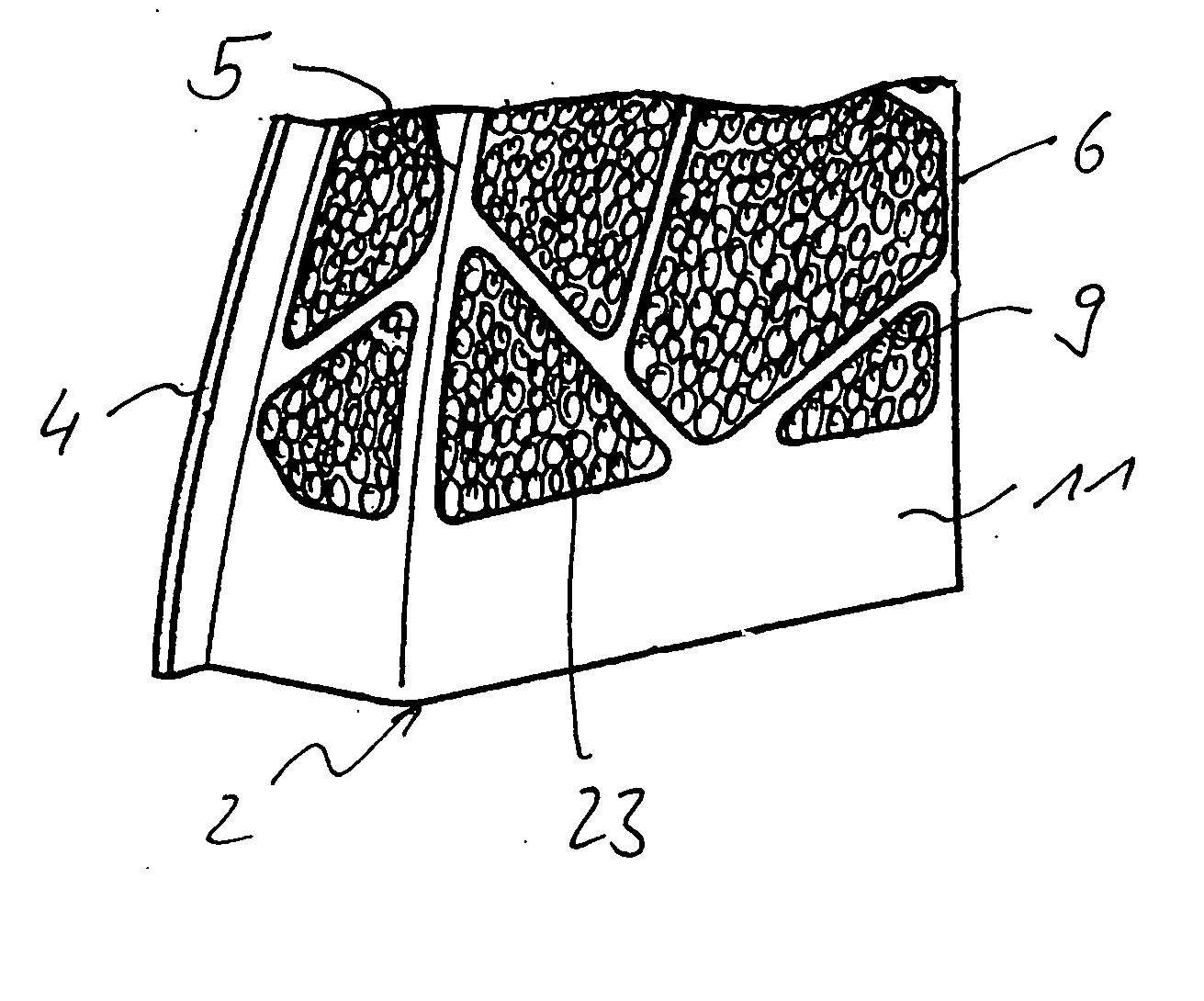

Transport and storage container for liquids

ActiveUS7036662B2Avoid damagePrevent disengagementLarge containersOther accessoriesEngineeringLatticework

A transport and storage container for liquids has a pallet bottom frame, a latticework enclosure connected to the bottom frame, and an inner container received in the enclosure. The vertical rods of the latticework enclosure are connected to upper and lower peripheral profiled edge sections. The vertical rods are hollow and have flattened upper ends shaped to a wave profile with welding projections. The upper profiled edge section is a hollow profiled section formed to a double bar that extends peripherally and transversely to the vertical rods and is shaped to have inner and outer wave profiles engaging one another. The outer wave profile has grooves, and the inner wave profile forms welding projections. The upper ends of the vertical rods and the double bar are connected by projection welding. The upper profiled edge section has a flat upper rim for supporting legs of a container stacked on top.

Owner:PROTECHNA SA

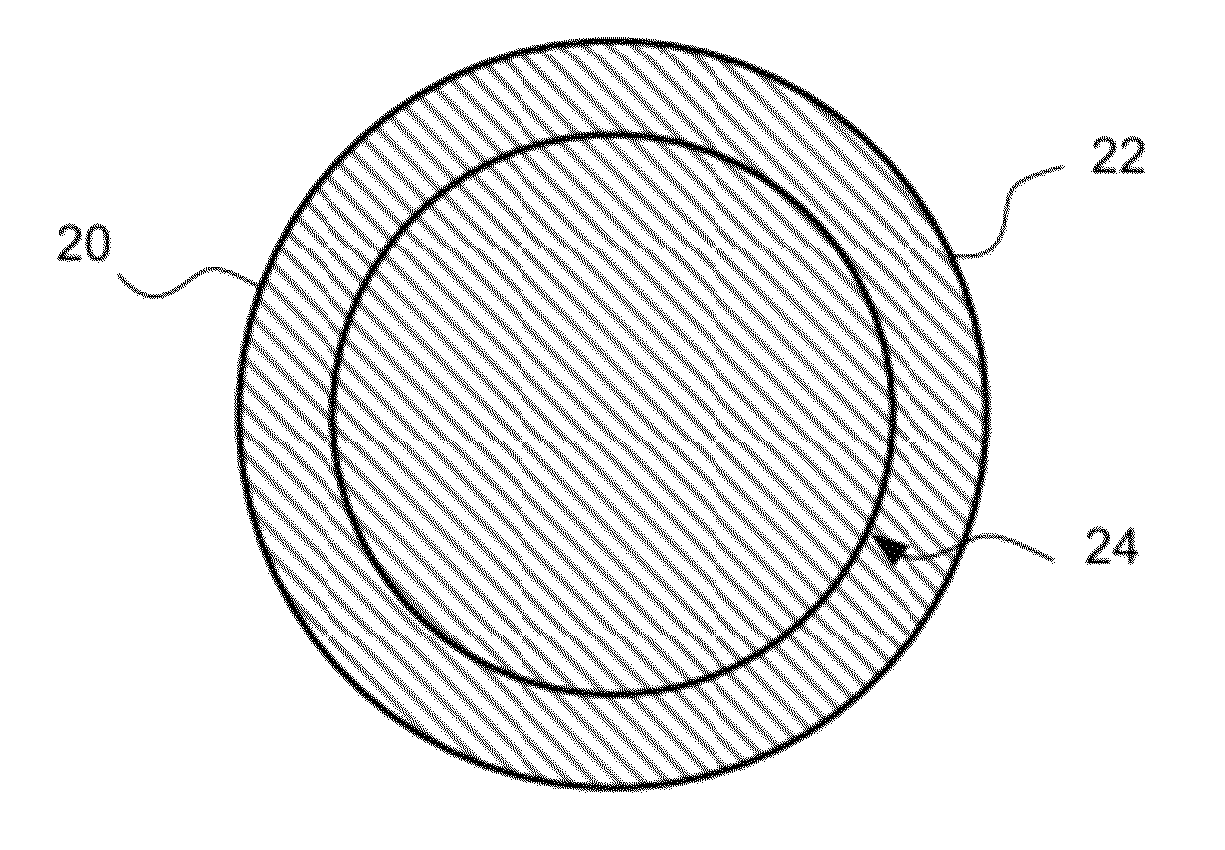

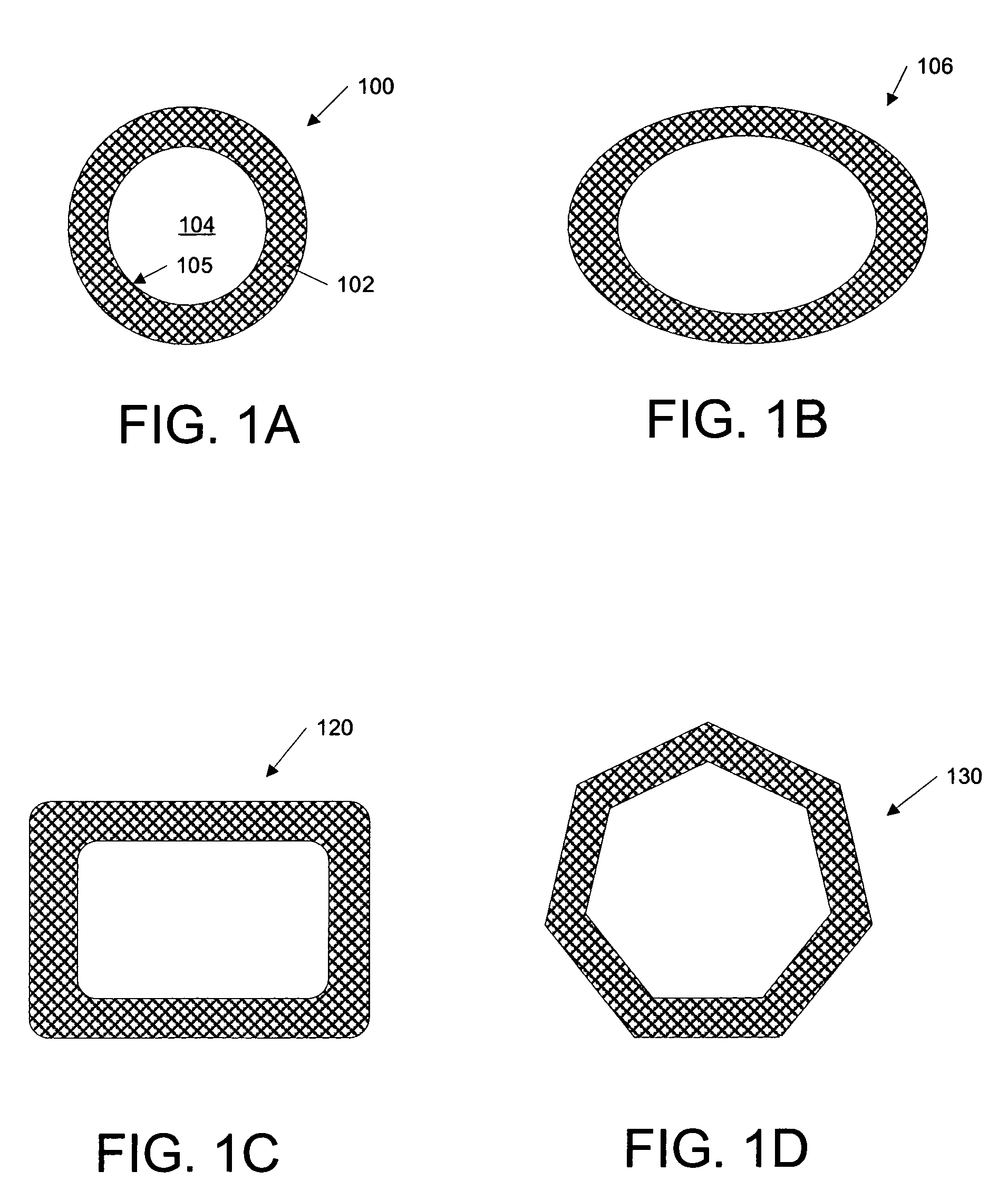

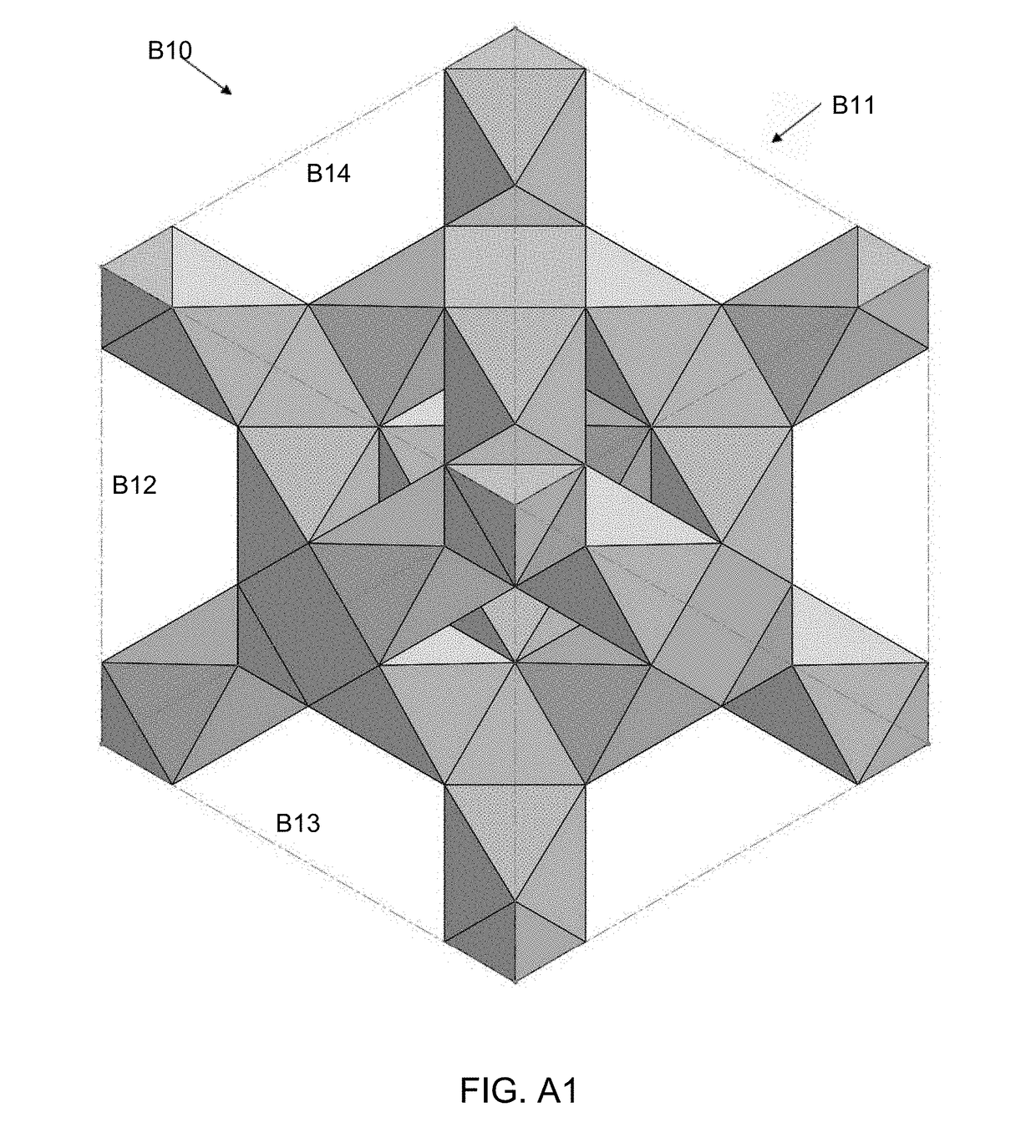

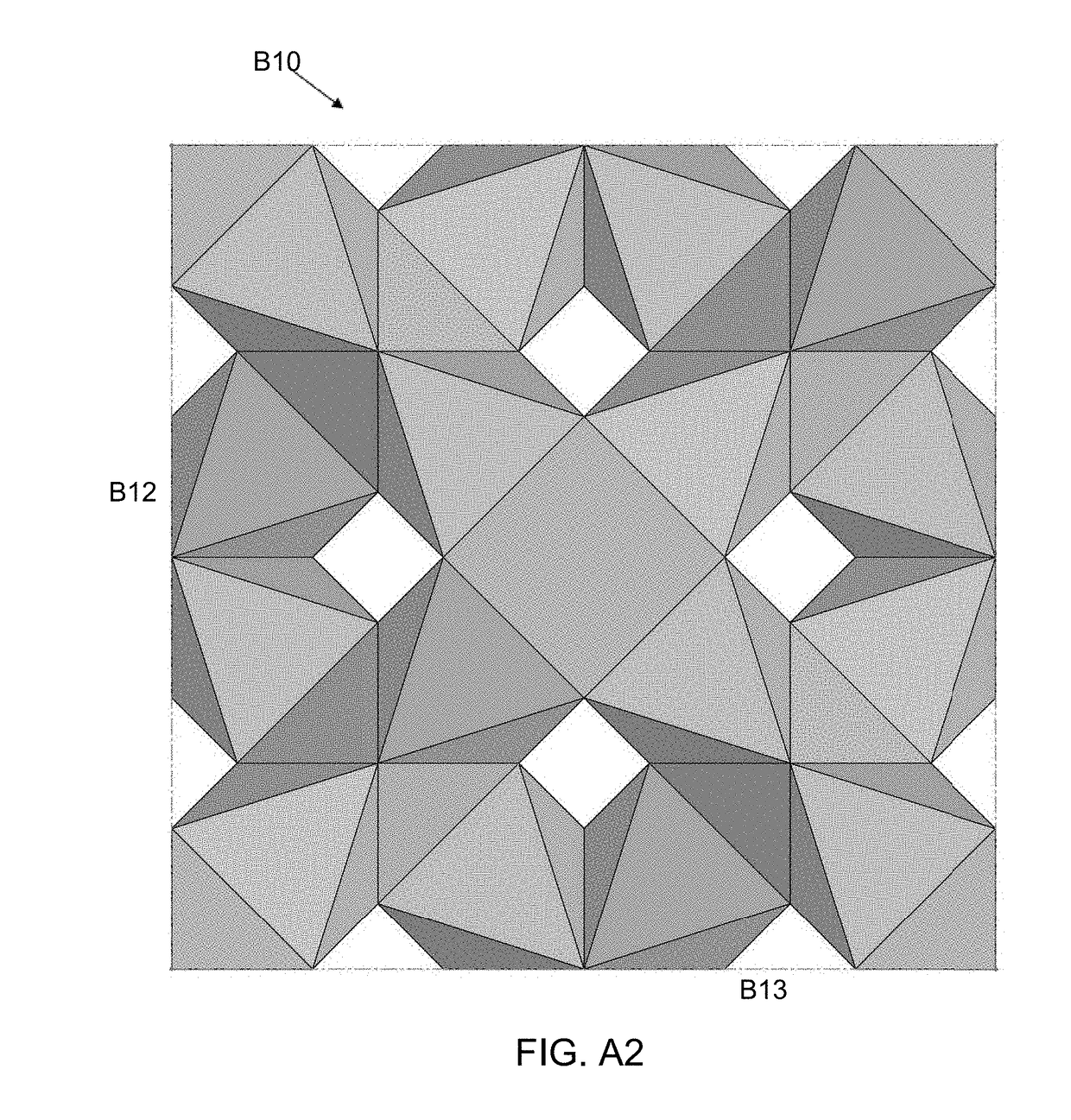

Anisotropic Biocompatible Lattice Structure

ActiveUS20180280140A1Useful applicationReduce loadDental implantsAdditive manufacturing apparatusDodecahedronRhombic dodecahedron

The three-dimensional lattice structures disclosed herein have applications including use in medical implants. Some examples of the lattice structure are structural in that they can be used to provide structural support or mechanical spacing. In some examples, the lattice can be configured as a scaffold to support bone or tissue growth. Some examples can use a repeating modified rhombic dodecahedron or radial dodeca-rhombus unit cell. The lattice structures are also capable of providing a lattice structure with anisotropic properties to better suit the lattice for its intended purpose.

Owner:NANOHIVE MEDICAL LLC

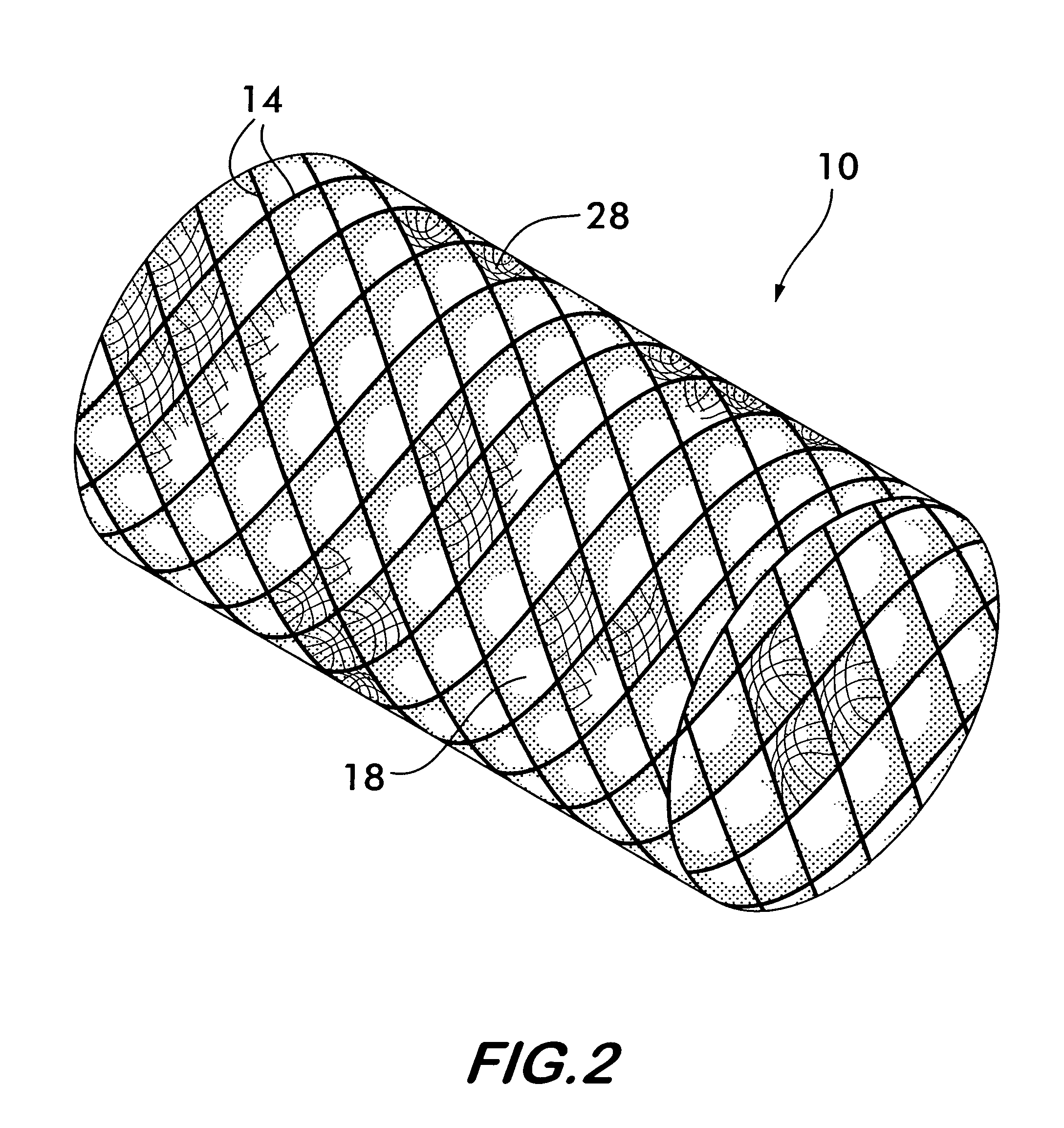

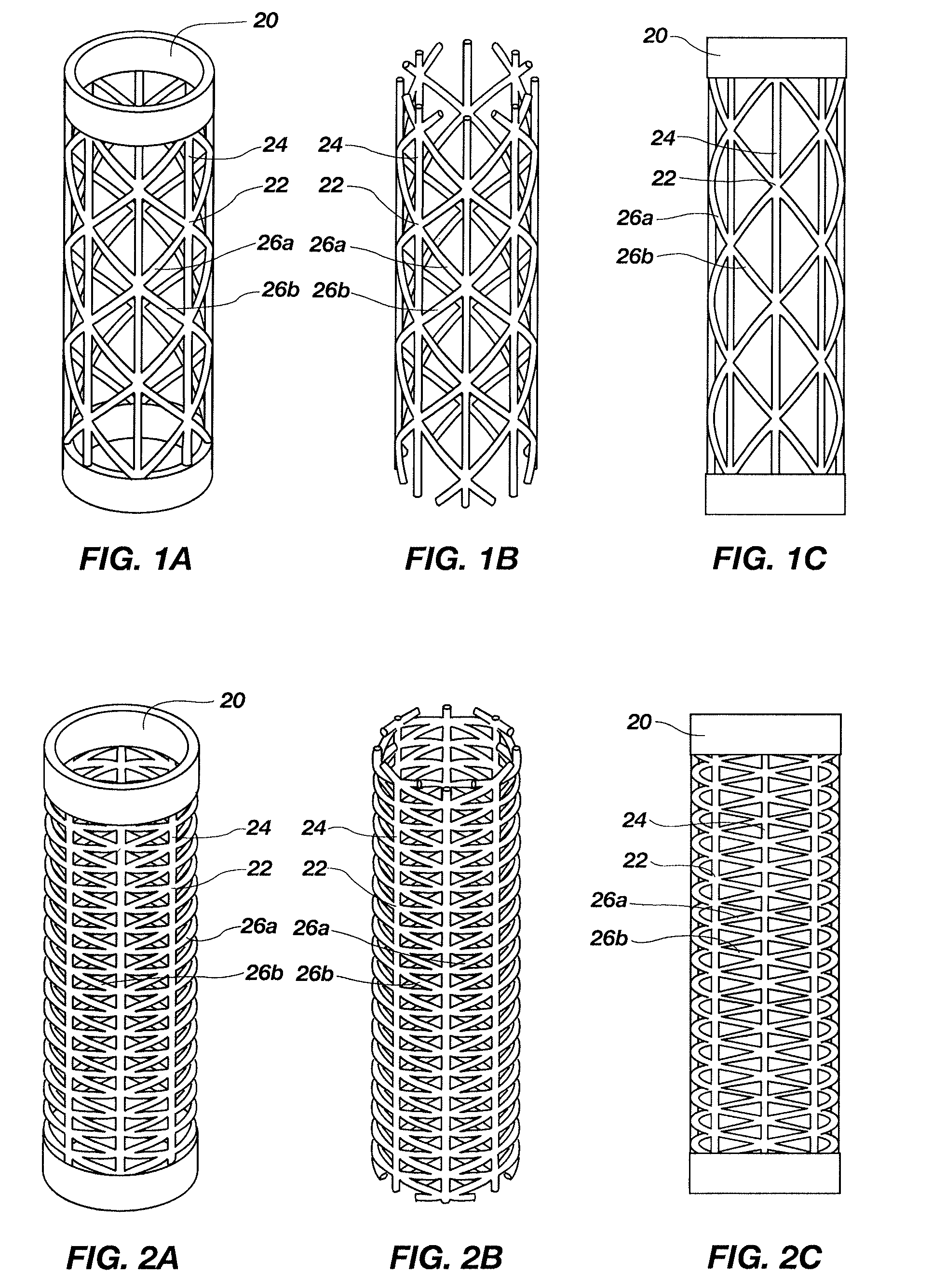

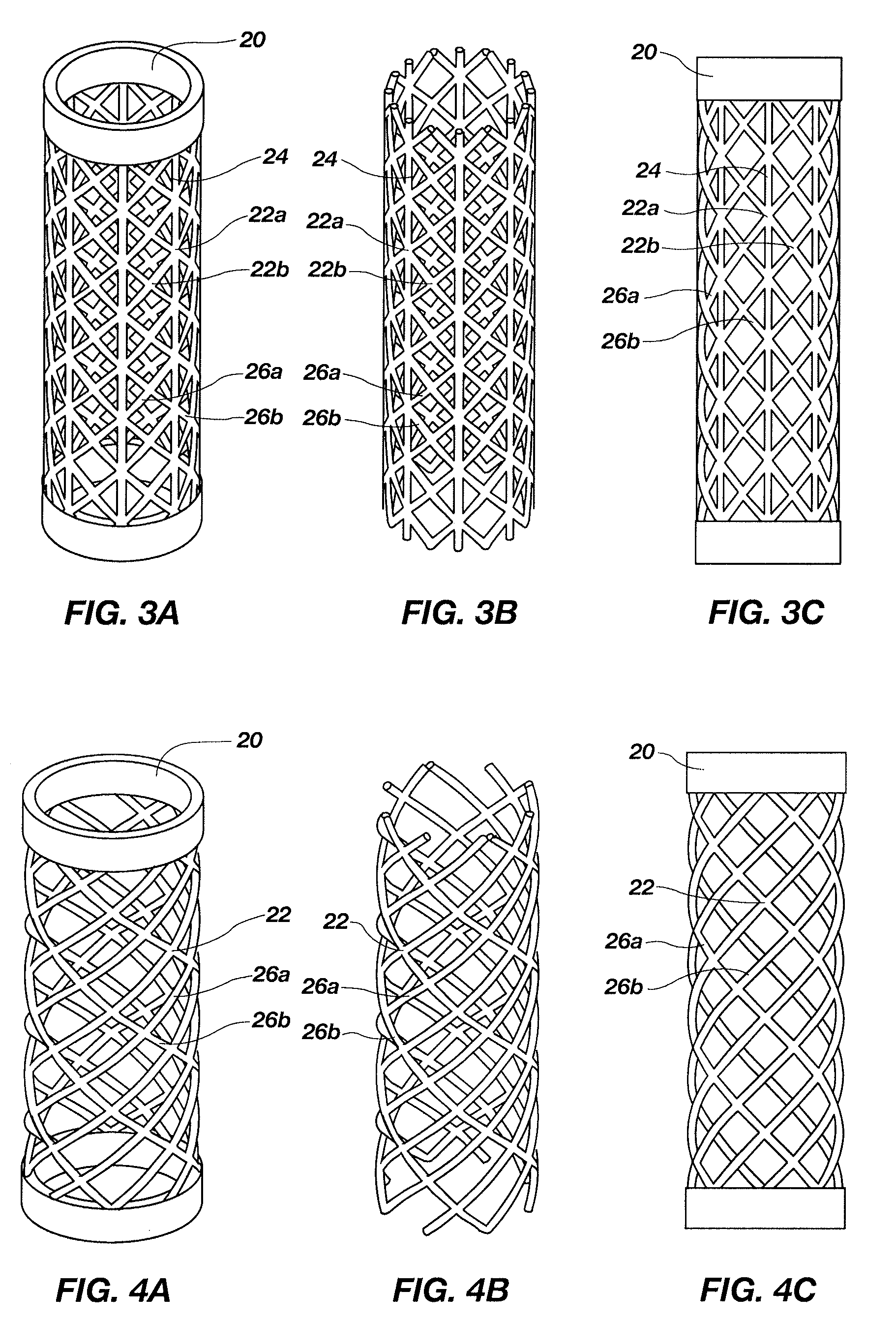

Method and system for forming composite geometric support structures

A method and system for fabricating a geometrically versatile composite lattice support structure having a seamless three-dimensional configuration. The lattice support structure is created by forming two or more cross supports, such as helical, longitudinal, circumferential and / or lateral cross supports, which intersect to form a plurality of multi-layered nodes. The lattice support structure may be designed without any protrusions extending outward from the overall geometry, thus enabling efficient tooling, and thus enabling ease of mass production. The lattice support structure may comprise a completely circumferentially closed geometry, such as a cylinder, ellipse, airfoil, etc. The method for fabricating the lattice support structure comprises laying up a fiber material, in the presence of resin, within rigid channels of a rigid mold, thus creating a green, uncured three-dimensional geometry of unconsolidated cross supports and multi-layered nodes where these intersect. Subjecting these to a curing system functions to consolidate the cross supports and multi-layered nodes to produce the composite lattice support structure.

Owner:SIGMATEK KANSAS

Cast carrier element for a vehicle body

InactiveUS20050035628A1Reduce weightHigh strengthVehicle seatsSuperstructure subunitsMaterials scienceCast iron

The invention relates to a support element for a vehicle body, in particular for supporting columns, the support element being produced from cast iron. The support element is designed, for example, as a lattice structure and is filled with metallic hollow balls for additional reinforcement.

Owner:DAIMLER AG

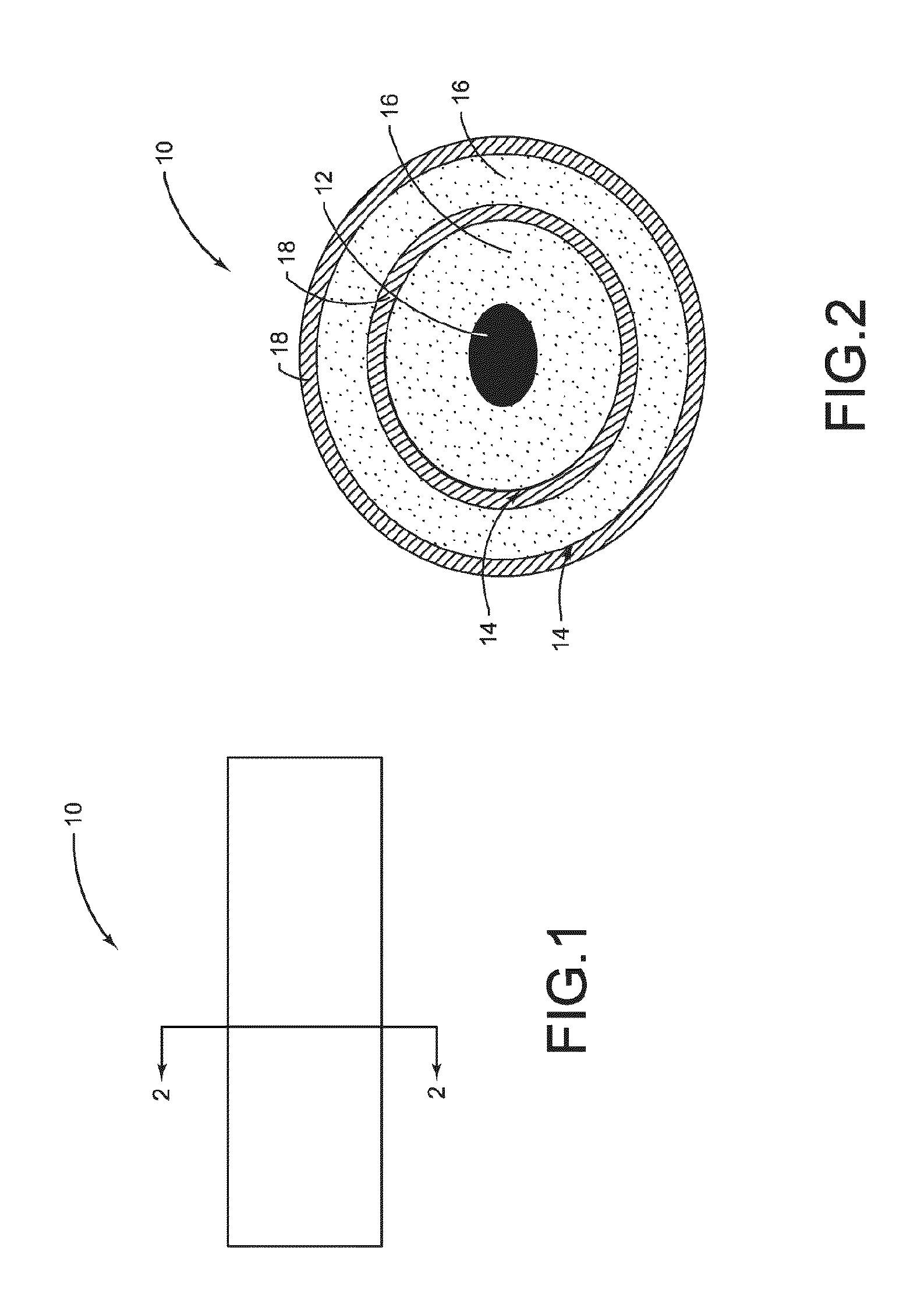

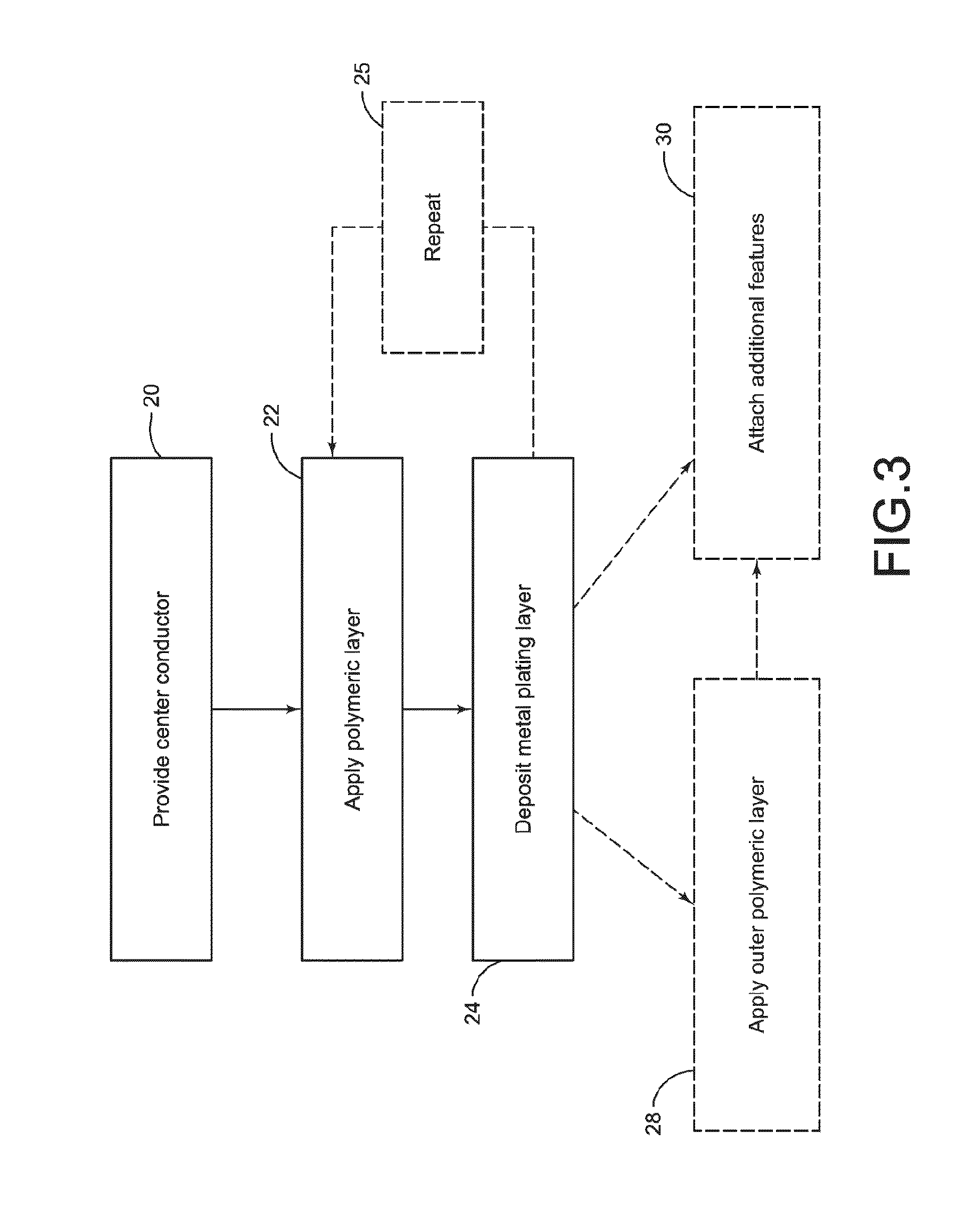

Plated tubular lattice structure

ActiveUS20160145850A1Pretreated surfacesLiquid/solution decomposition chemical coatingEngineeringMechanical engineering

A plated tubular lattice structure is described. The plated tubular lattice structure may comprise a backbone structure which may include a plurality of axial posts and a plurality of pyramidal structures extending laterally from the axial posts and connecting the axial posts at nodes. The plated tubular lattice structure may further comprise a metal plating layer plated on an outer surface of the backbone structure.

Owner:RTX CORP

Three-dimensional phonon functional material structure comprising resonance units and manufacturing method thereof

InactiveCN102708853AMeet the requirements of different acoustic characteristicsMeet the requirements of vibration reduction and noise reductionSound producing devicesResonanceHoneycomb

The invention relates to a three-dimensional phonon functional material structure comprising resonance units and a manufacturing method of the three-dimensional phonon functional material structure, which belongs to the field of acoustic materials and the like and overcomes the defect that the existing porous material structure is difficult to generate a complete band gap. The material structure is formed by arranging the resonance units according to simple cubic lattices. The manufacturing method of the material structure comprises the following steps of: making first to Nth layers of closed honeycomb materials comprising the resonance units which are arranged in a square lattice mode; and fixedly connecting the layers to form the three-dimensional phonon functional material structure comprising the resonance units which are arranged in the simple cubic lattice mode. Each resonance unit is formed by a mass block arranged in each honeycomb, one to six connecting bodies, a honeycomb wall and parts of honeycomb core upper and lower flat plates on and under each honeycomb. N is greater than or equal to 5. According to the material structure, the complete band gap can be generated; the width and the position of the band gap can be regulated by regulating the shape of the structure, the geometric dimensioning of the structure and the number of the connecting bodies; and the requirements of different acoustic characteristics are met.

Owner:BEIJING JIAOTONG UNIV

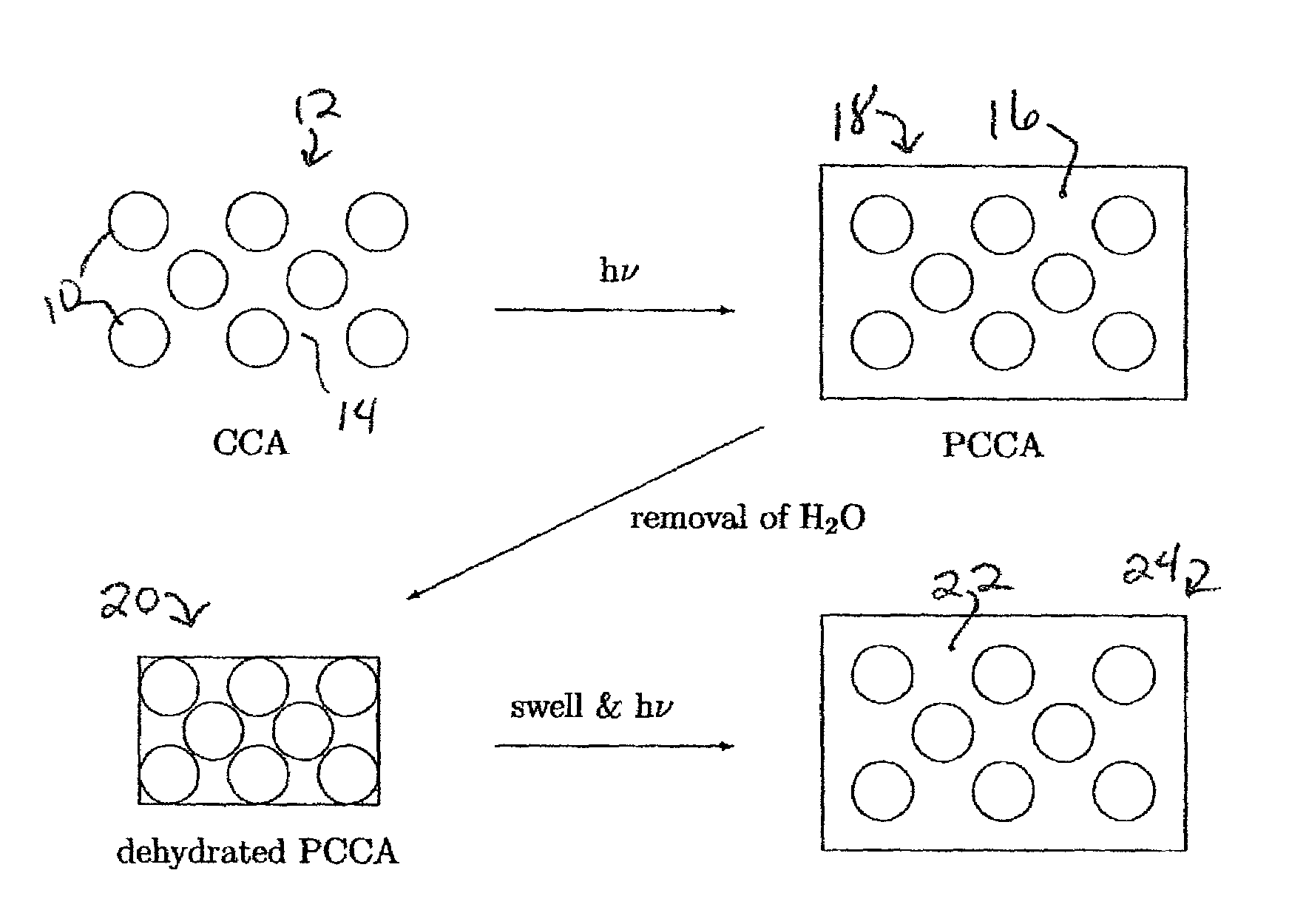

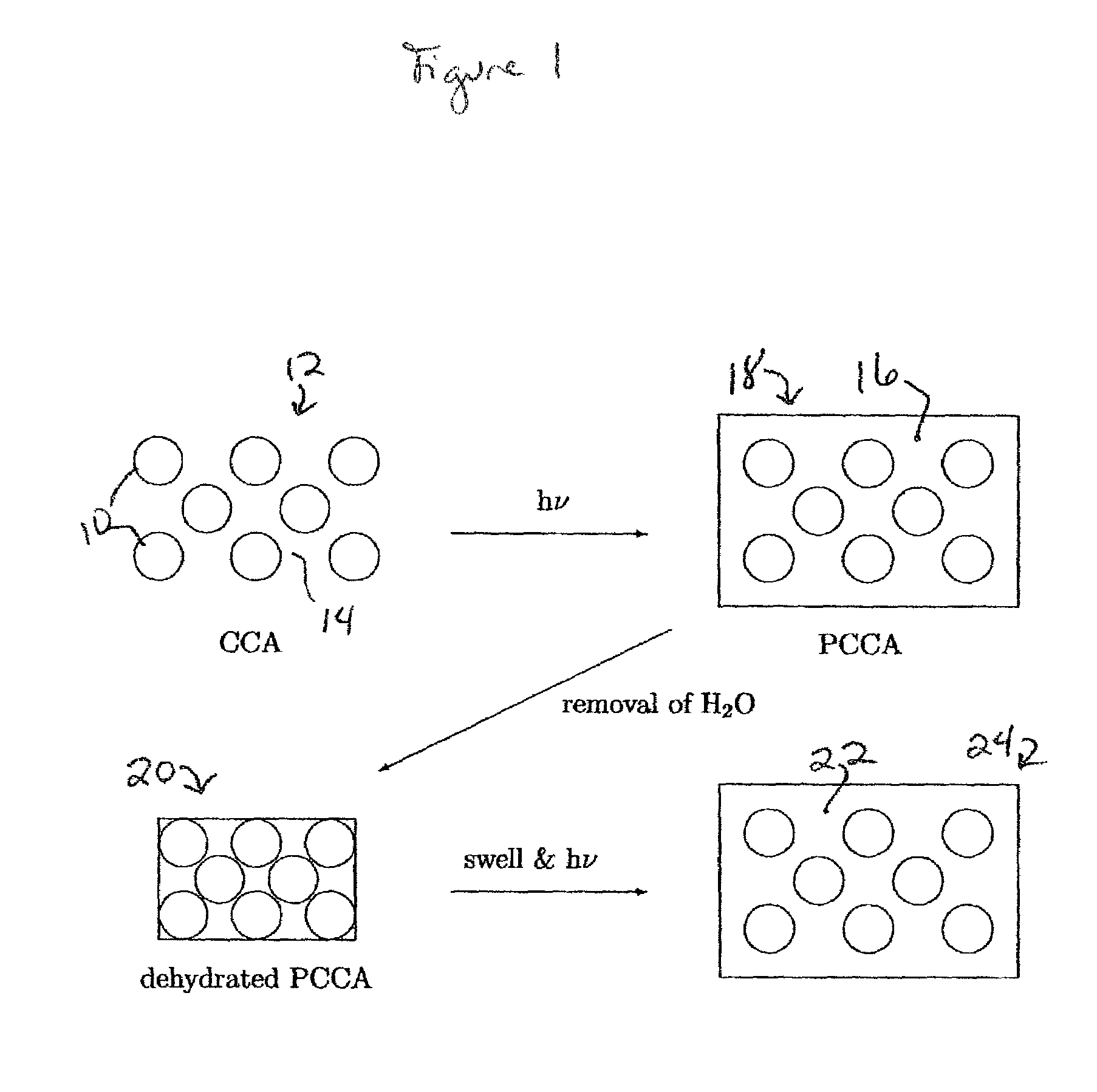

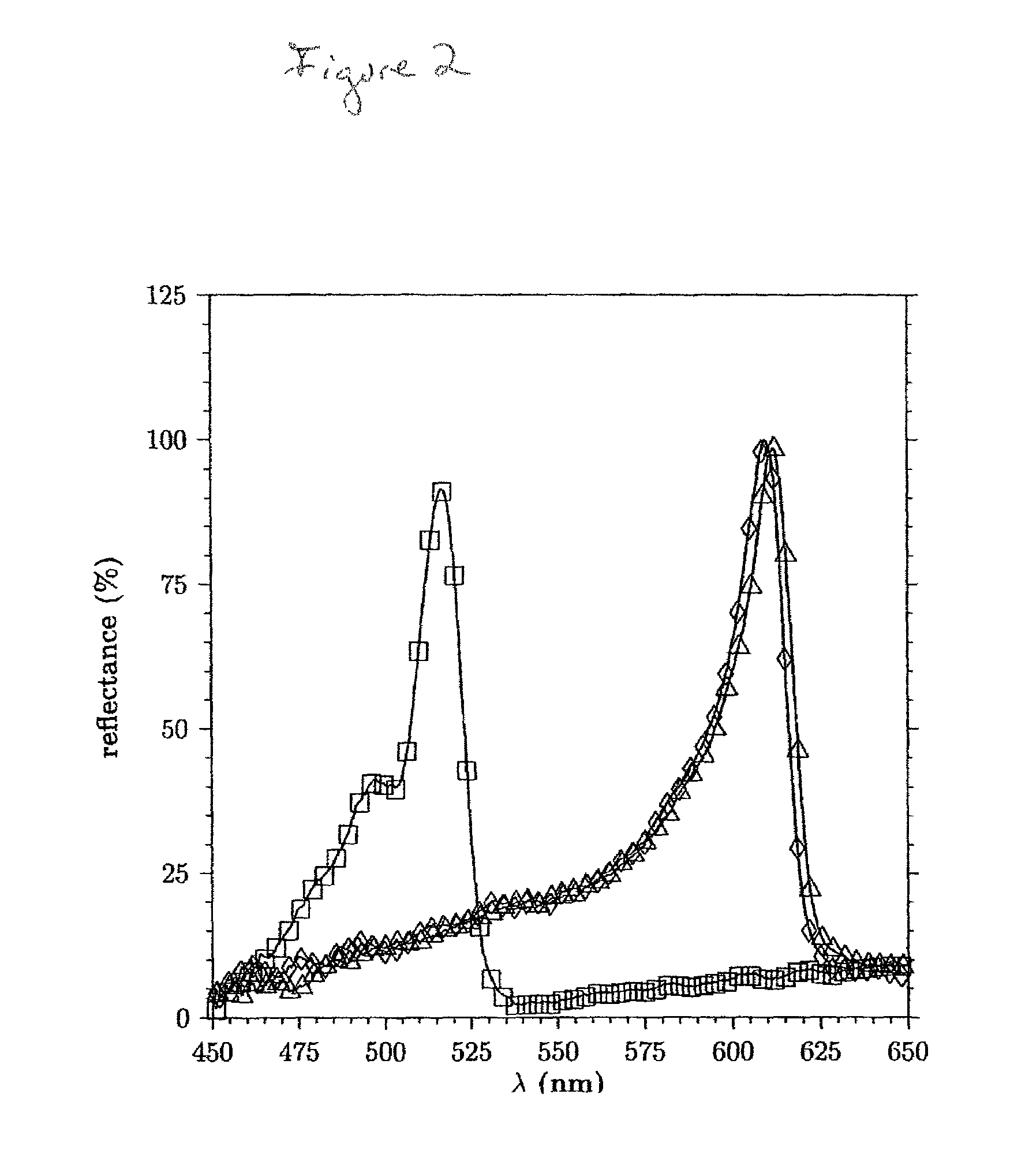

Essentially water-free polymerized crystalline colloidal array composites having tunable radiation diffracting properties and process for making

The present invention is directed to a composite having tunable radiation diffracting properties which includes a flexible, water-free polymeric matrix and a crystalline colloidal array of particles having a lattice spacing, the array being embedded in the polymeric matrix and the lattice spacing changing responsive to stress applied to the polymeric matrix, thereby causing the radiation diffracting properties to change, wherein the polymeric matrix, the lattice spacing and the radiation diffracting properties all return to their original state essentially immediately upon removal of the stress. The present inventive composite is preferably made by a process, which involves forming a preliminary hydrogel polymerized crystalline colloidal array (PCCA), dehydrating the PCCA, and then forming a final, encapsulating polymeric matrix.

Owner:CLEMSON UNIV RES FOUND

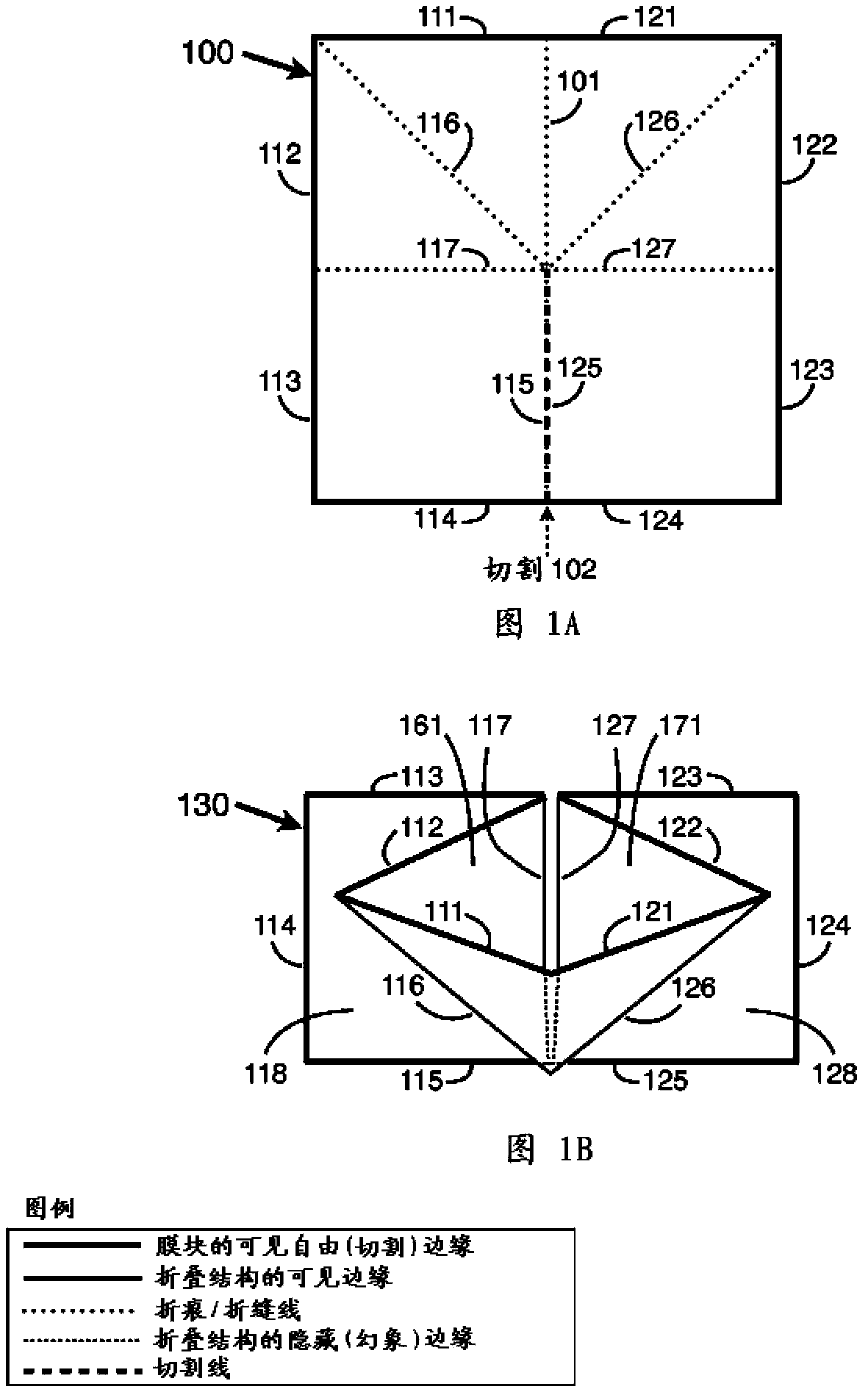

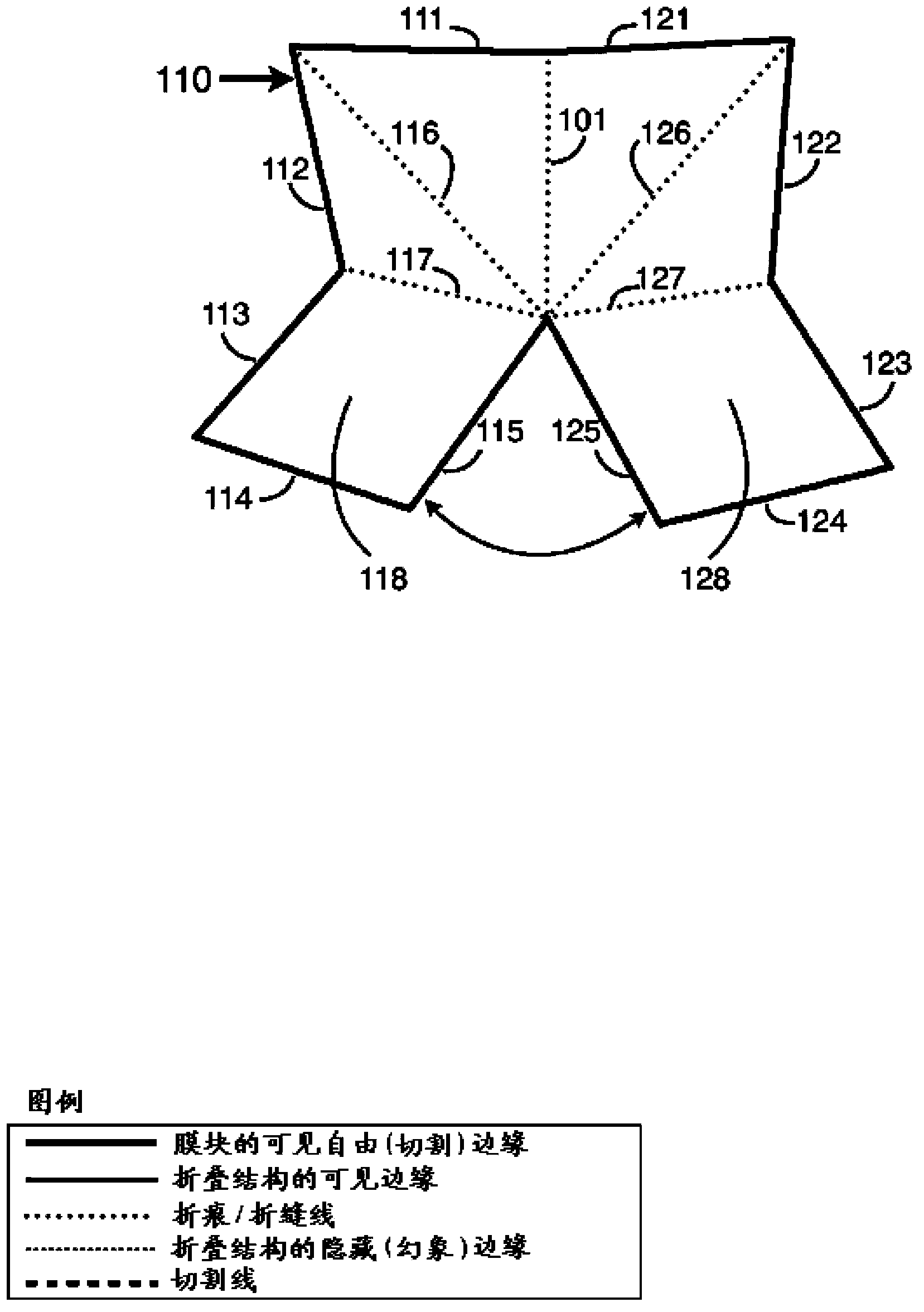

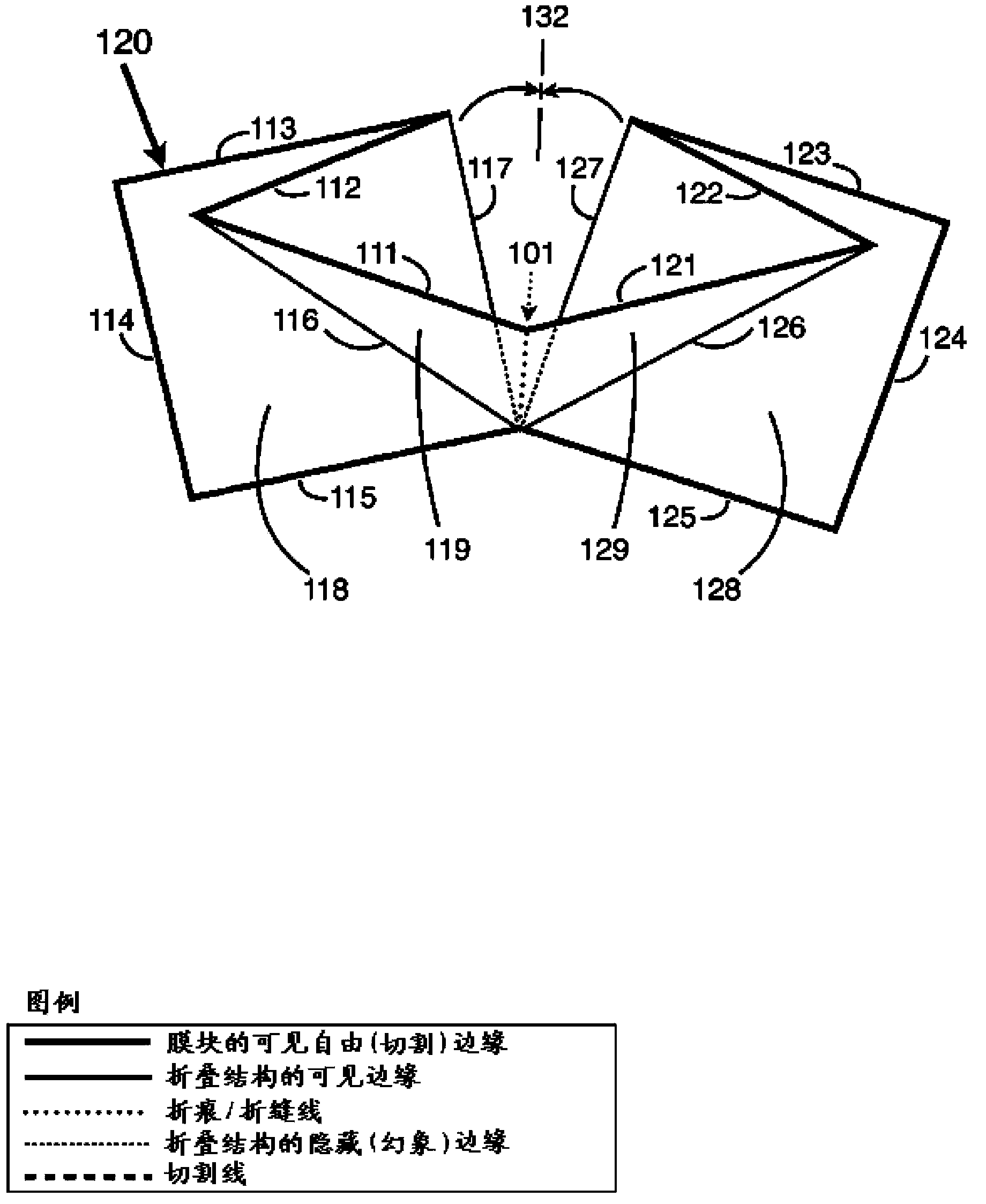

Percutaneously deliverable heart valve including folded membrane cusps with integral leaflets

A transcatheter, percutaneously implantable, prosthetic heart valve is provided that comprises a lattice frame and two or more integrated cusp and leaflet folded structures attached to the lattice frame. The two or more integrated cusp and leaflet folded structures each comprise a flat sheet of biocompatible membrane that is folded to include a substantially conical shape according to a flat folding pattern. The substantially conical shape is further formed by joining apposing sides of the substantially conical shape along a seam. The two or more integrated cusp and leaflet folded structures are each attached along their respective seams to the lattice frame in a direction substantially parallel to an axis of the lattice frame. Embodiments of valves described herein have application within the entire vascular system.

Owner:COLIBRI HEART VALVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com