Three-dimensional phonon functional material structure comprising resonance units and manufacturing method thereof

A technology of resonant units and functional materials, applied in the field of acoustics, can solve problems such as difficulty in generating a complete band gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

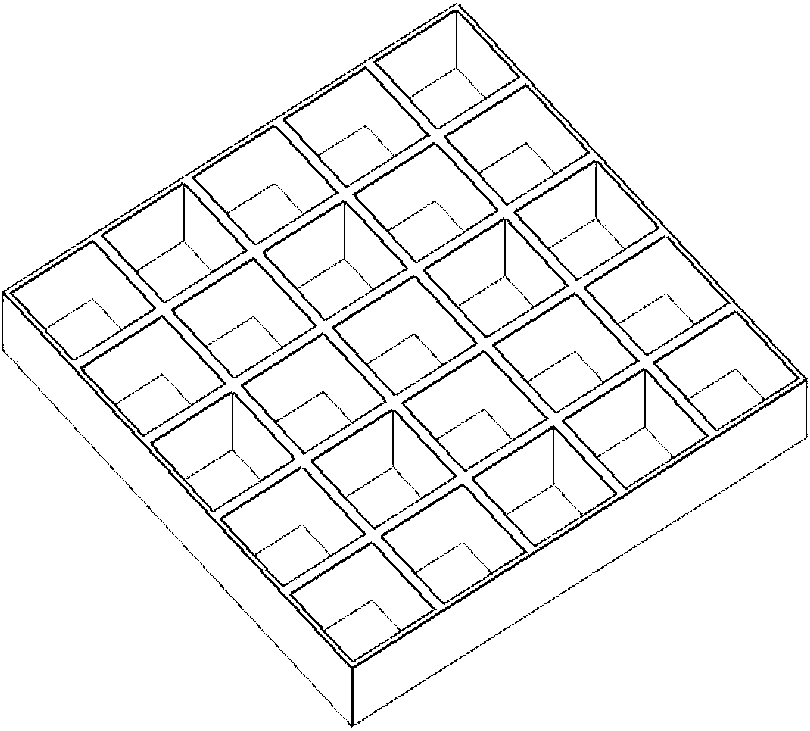

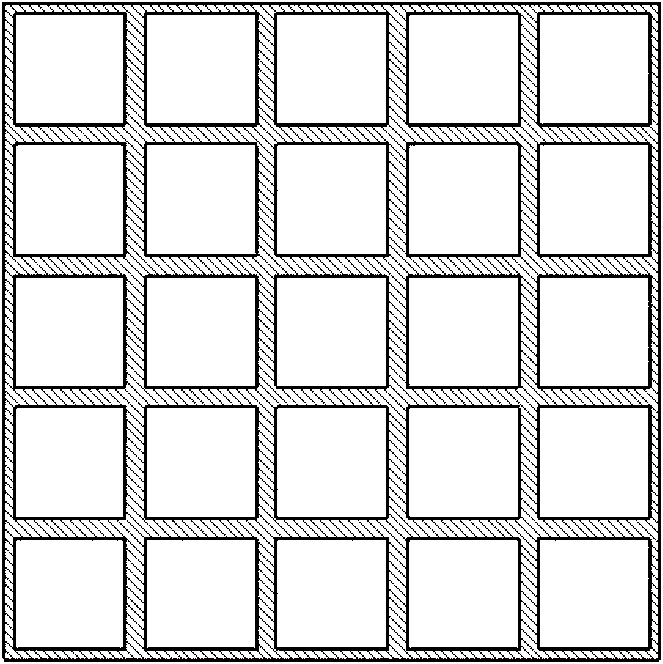

[0045] The structure of the three-dimensional phonon functional material containing resonant units is a closed honeycomb material containing resonant units in a square lattice arrangement from the first layer to the Nth layer, which are sequentially bonded to form a three-dimensional phonon functional material structure containing resonant units in a simple cubic lattice arrangement. .

[0046] The first layer of the three-dimensional phonon functional material structure of the closed honeycomb material containing the square lattice arrangement resonance unit is: the first layer of honeycomb core is bonded to the first layer of flat plate 1, and the first layer of honeycomb core is A mass block is placed in a honeycomb, and it is connected to the first layer of flat plate 1 or the honeycomb wall and the first layer of flat plate 1 through one to six connecting bodies; the second layer of flat plate 2 is bonded on the upper surface of the first layer of honeycomb core to make the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com