Marine gearbox body structure optimization design method

A technology for optimizing design and box structure, applied in design optimization/simulation, belt/chain/gear, transmission box, etc., can solve problems such as costly design, insufficient rigidity, impact damage, abnormal vibration, etc., to achieve The effect of meeting the requirements of lightweight design and meeting the requirements of vibration reduction and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

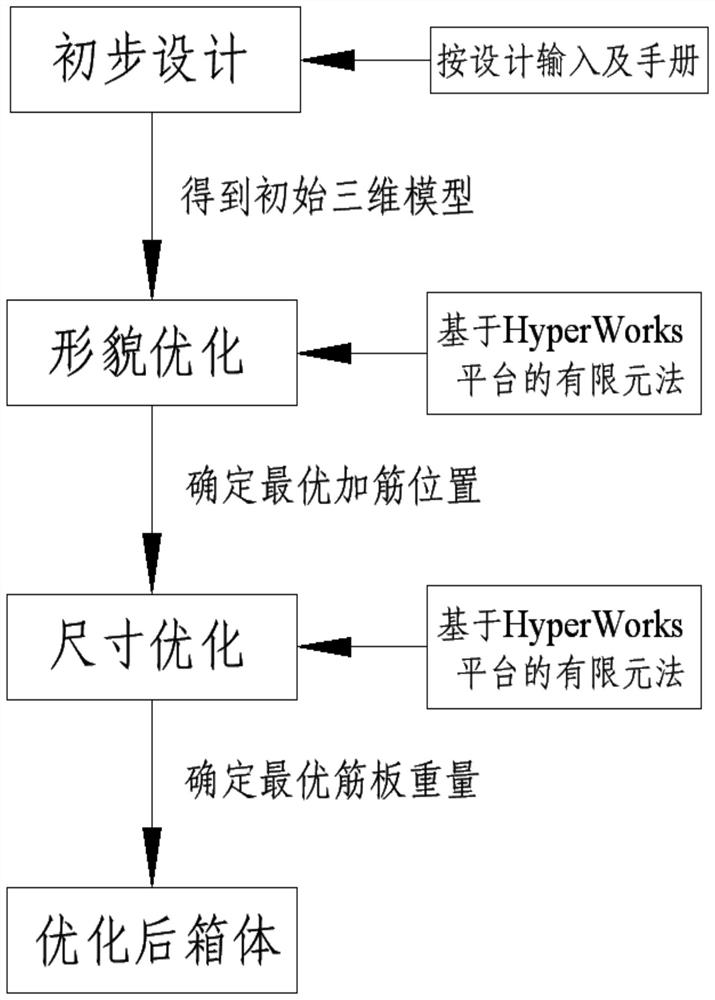

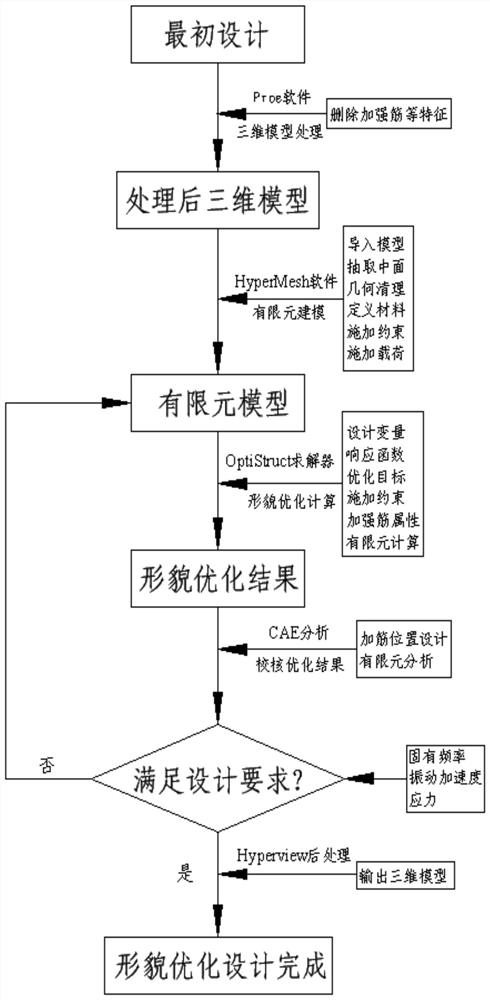

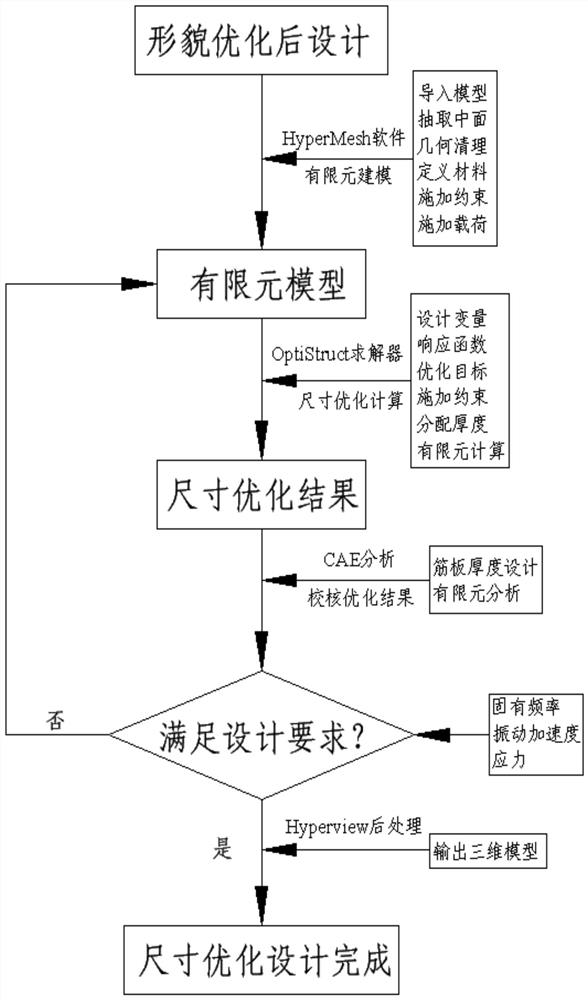

[0028] A method for optimizing the structure of a marine gearbox case of the present invention, such as figure 1 As shown, it mainly includes the following steps:

[0029] (1) Preliminary design and three-dimensional modeling of the cabinet. The preliminary design of the box mainly includes the design of the main structural parameters of the box, such as the thickness of the box wall, the thickness of the middle panel, the thickness of the bottom plate, the thickness and length of the reinforcement, the diameter of the bearing seat bolts, the diameter of the bolts of the middle panel, and the diameter of the anchor bolts. , these designs can be completed by referring to the relevant formulas in the mechanical design manual, and the three-dimensional model of the box is established according to the preliminary calculation results.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com