Hydraulic bushing device for chassis swing arm and chassis swing arm system

A hydraulic bushing and chassis technology, applied in the direction of gas-hydraulic shock absorbers, springs, shock absorbers, etc., can solve the problems of not meeting the requirements of vibration and noise reduction, unsatisfactory, low rigidity, etc., and achieve the reduction of outer frame assembly , easy assembly, and strong working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

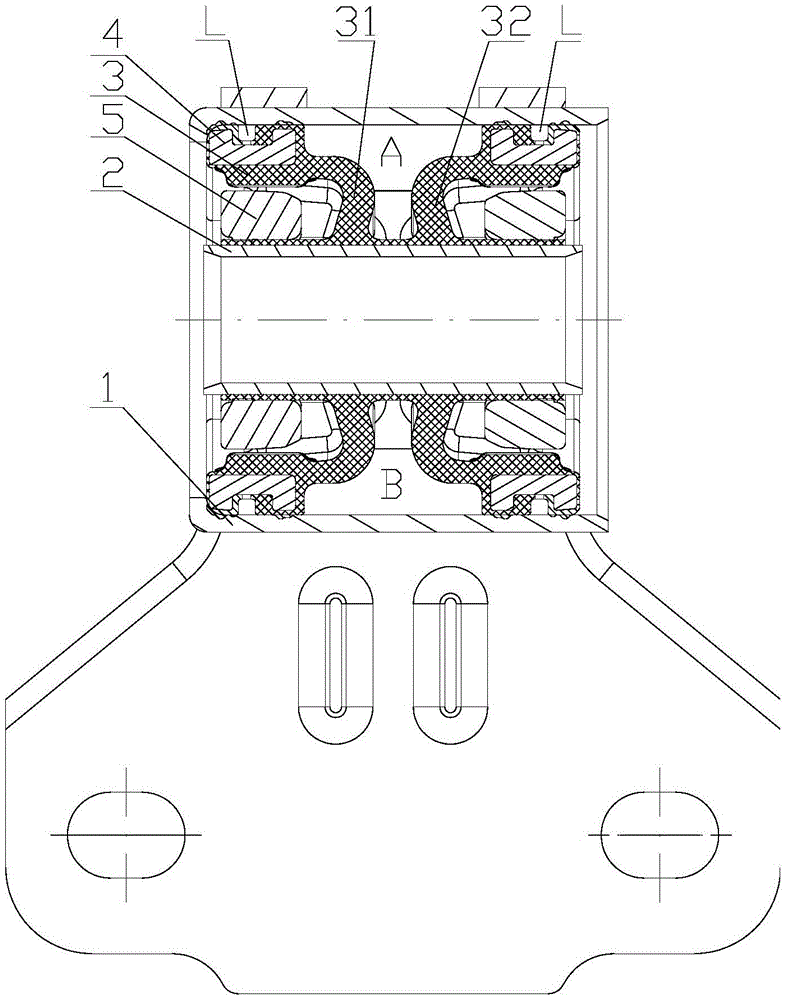

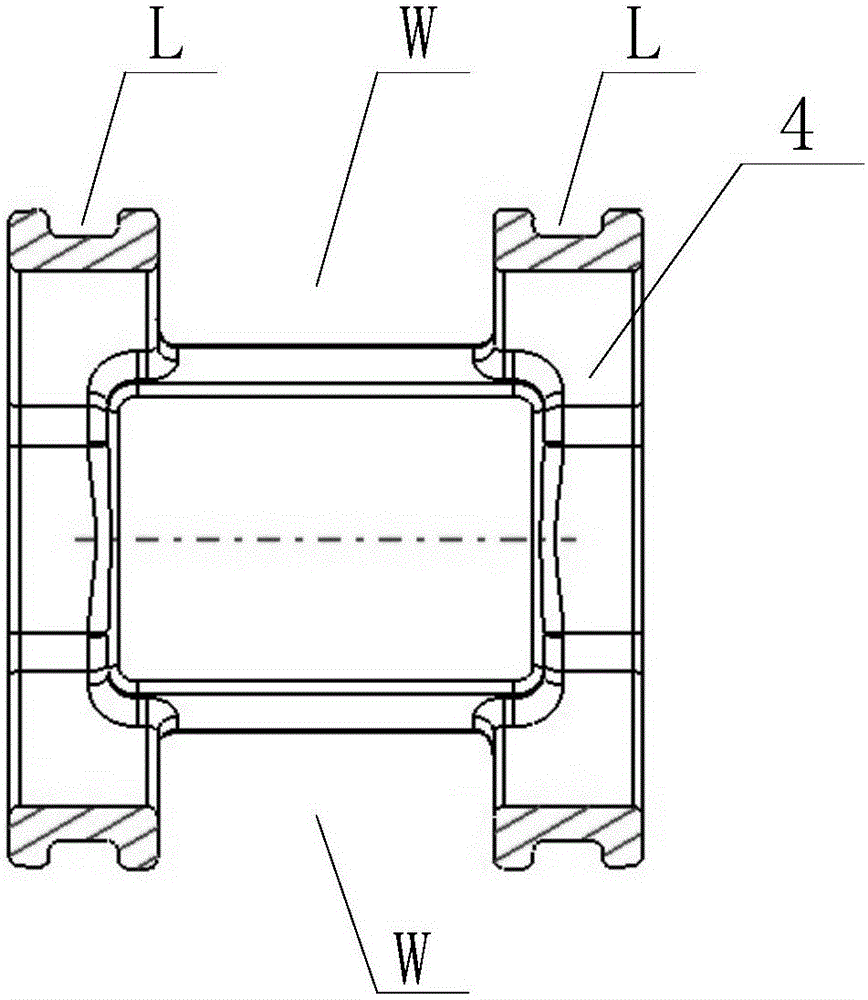

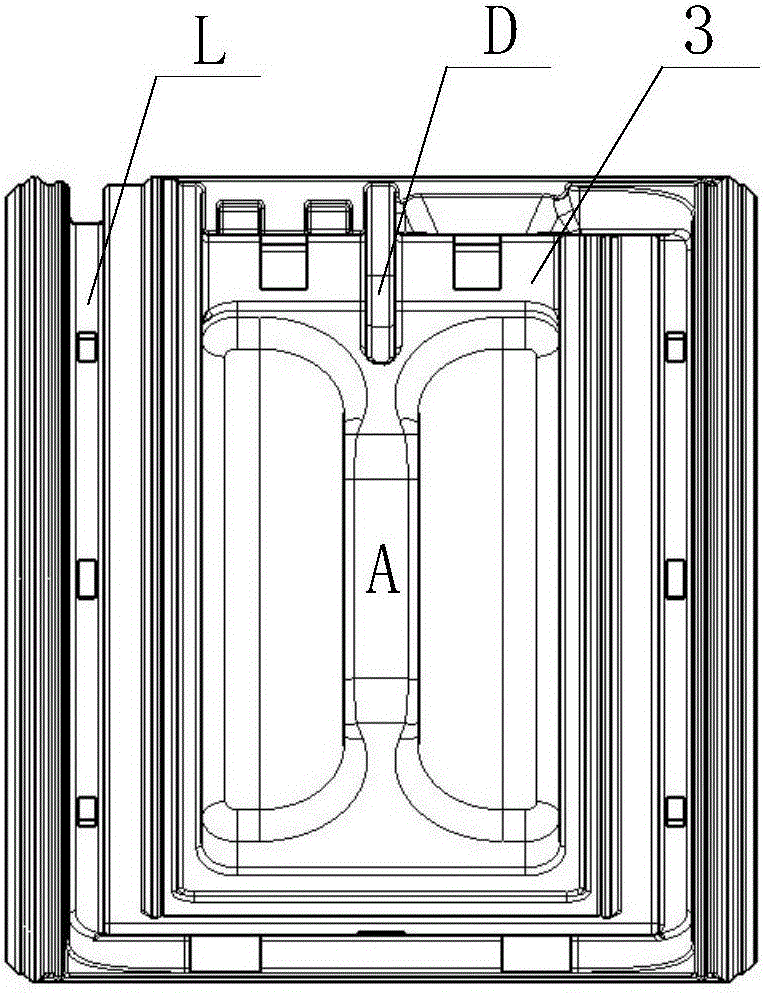

[0022] Such as Figure 1 to Figure 3 as shown, figure 1 It is a structural schematic diagram of a chassis swing arm hydraulic bushing device proposed by the present invention, figure 2 for figure 1 Schematic diagram of the structure of the barrel holder, image 3 for figure 1 Schematic diagram of the structure of the bushing components.

[0023] refer to Figure 1 to Figure 3 , the present invention proposes a chassis swing arm hydraulic bushing device, comprising: a mounting bracket 1, a core barrel 2, a rubber main spring 3, a barrel frame 4 and a limit frame 5;

[0024] Two windows W are symmetrically arranged in the middle of the barrel holder 4, and the unfolded shape of the window W is a rectangle. Cover part; in the bushing part, the rubber main spring 3 is wrapped on the outer periphery of the core tube 2, and the rubber main spring 3 extends outward from the middle of the core tube 2 to form a rib frame and passes through two windows to cover the tube frame 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com