Transportation and assembling equipment system for prefabricated components and construction method of transportation and assembling equipment system

A technology of prefabricated components and assembly equipment, which is applied in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve the problems of high labor intensity in alignment assembly operations, large hoisting operations, and heavy hoisting workloads. The effect of alleviating the shortage of labor resources, improving construction efficiency and reducing labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

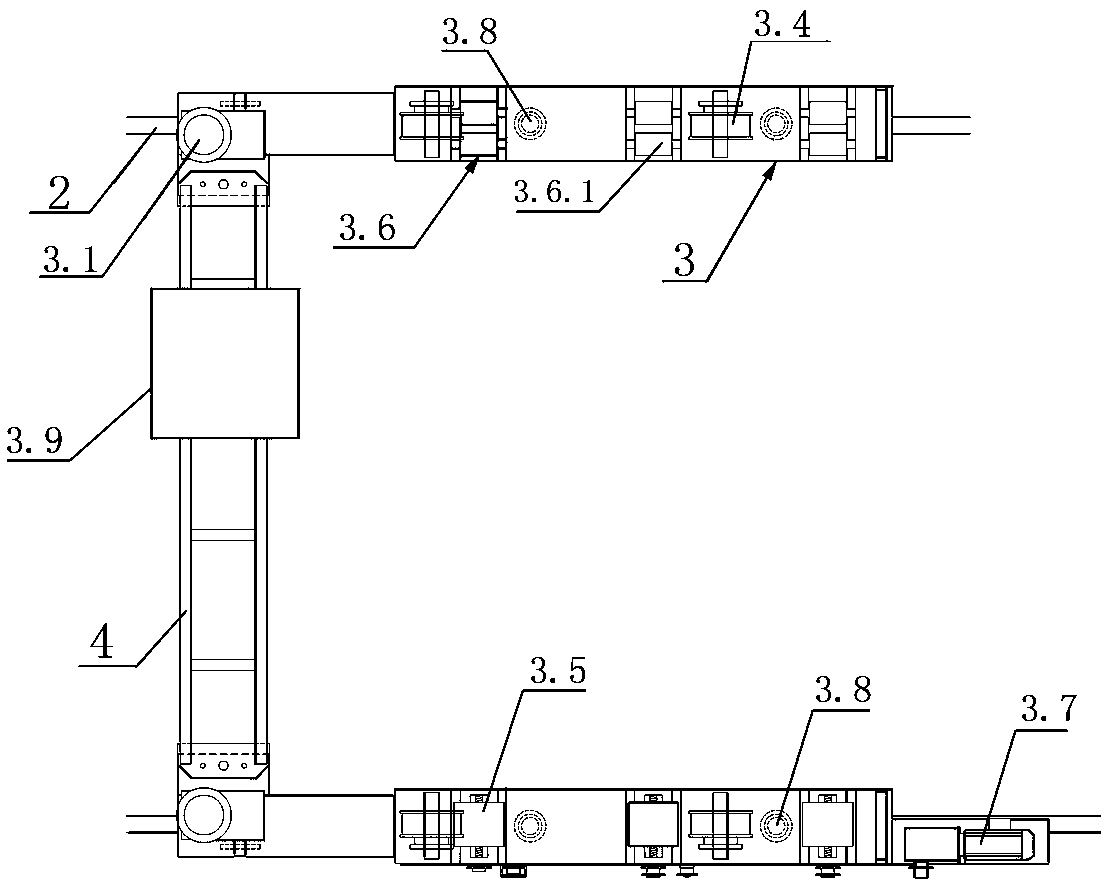

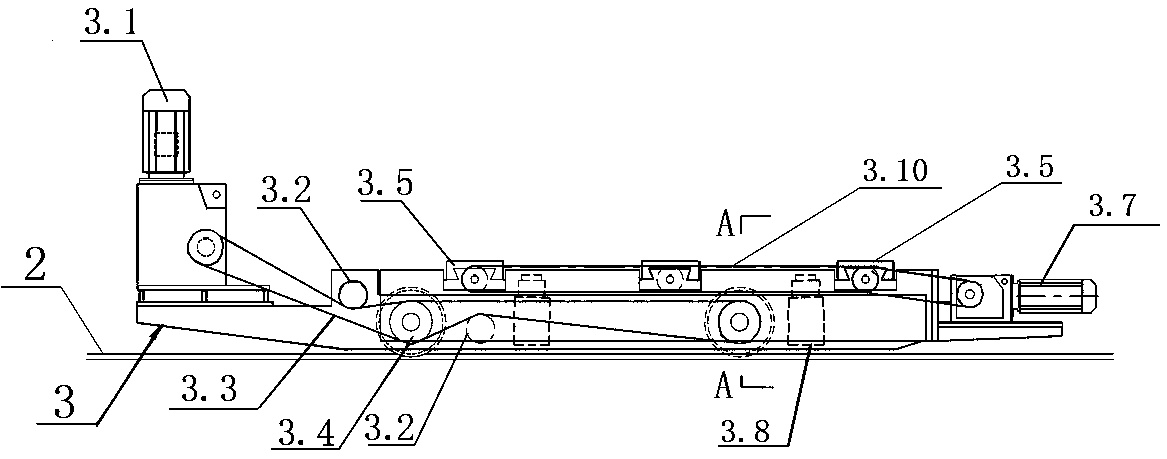

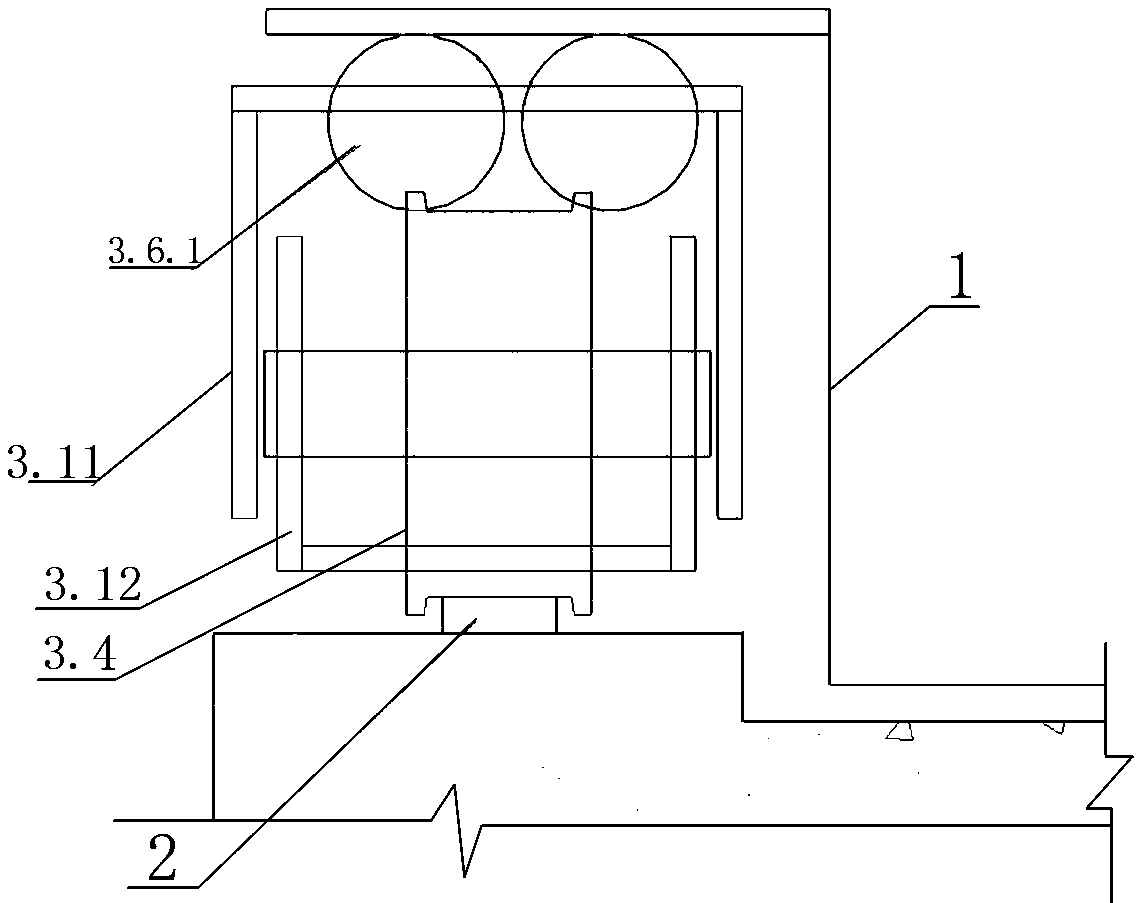

[0039] Example 1: Such as Figure 1-7 As shown, this prefabricated component transportation assembly equipment system is used for the transportation and installation of the prefabricated component 1. The equipment system includes a guide rail 2 and transportation assembly equipment; the transportation assembly equipment includes at least two car bodies 3 and connecting phases. The connecting beam 4 adjacent to the car body 3; wherein, each car body 3 is rolling connected to the guide rail 2; the car body 3 includes a car body structure, a walking system and an alignment system; the car body structure includes a top gusset 3.11 and The bottom gusset plate 3.12, and the top gusset plate 3.11 and the bottom gusset plate 3.12 are assembled together to form a hollow box with a rectangular cross section; the walking system is installed on the body structure to drive the body structure to move along the guide rail 2; The positioning system is installed on the body structure to adjust t...

Embodiment 2

[0049] Example 2: Such as Figure 1-6 As shown in 8, this prefabricated component transportation assembly equipment system is used for the transportation and installation of the prefabricated component 1; the equipment system includes a guide rail 2 and transportation assembly equipment; the transportation assembly equipment includes at least two car bodies 3 and Connecting beams 4 connecting adjacent car bodies 3; wherein, each car body 3 is roll-connected to the guide rail 2; the car body 3 includes a car body structure, a walking system, and an alignment system; the car body structure includes a top buckle plate 3.11 and the bottom gusset 3.12, and the top gusset 3.11 and the bottom gusset 3.12 are assembled together to form a hollow box with a rectangular cross section; the walking system is installed on the body structure to drive the body structure to move along the guide rail 2; The alignment system is installed on the body structure to adjust the vertical and lateral di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com