Connector for prefabricated members

A technology of prefabricated components and connectors, which is applied in the direction of building components, structural elements, building reinforcements, etc., can solve the problems that the assembly rate of prefabricated buildings cannot be effectively increased significantly, and the construction cycle is slow, so as to improve the efficiency of assembly construction and shorten the construction period. The effect of shortening the construction period and improving the assembly rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

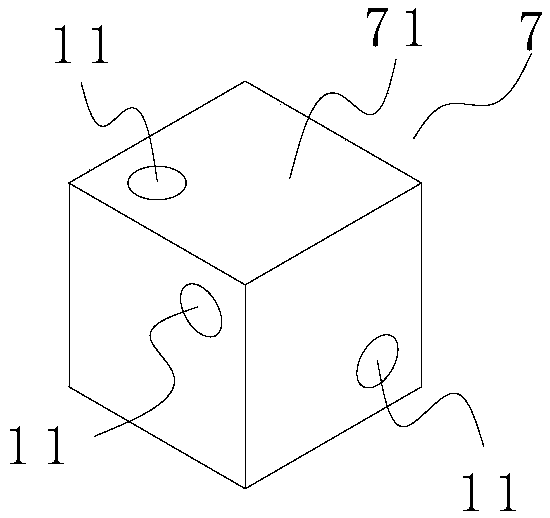

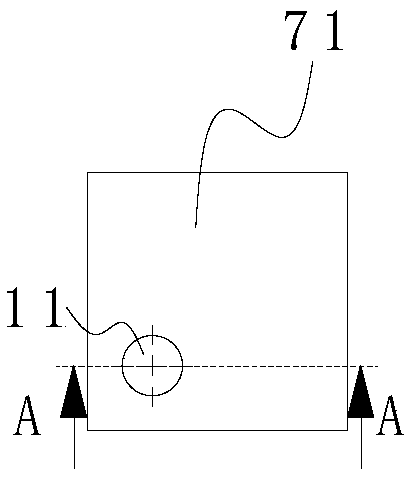

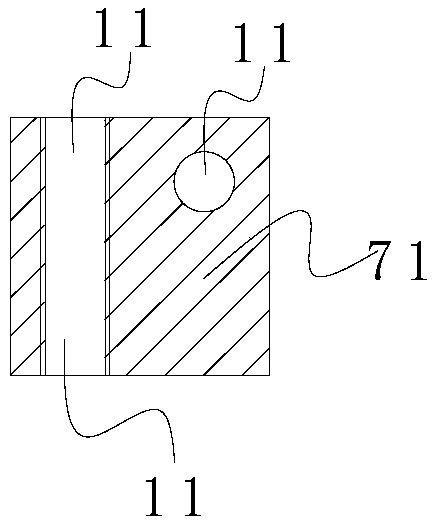

[0086] Such as Figure 1 to Figure 3 As shown, the connector 7 for prefabricated components provided in this embodiment includes a connector body 71, the connector body 71 is in the shape of a cuboid, and the connector body 71 is provided with upward, downward, left, right, forward, For the connection ends in the last 6 directions, each connection end is provided with a threaded hole 11, and each connection end corresponds to a prefabricated beam or prefabricated column, and the correspondence referred to herein refers to a one-to-one correspondence.

[0087] Specifically, the central axes of the threaded holes 11 at the upward and downward connecting ends and the central axes of the threaded holes 11 at the leftward and rightward connecting ends form a 90° angle with each other, and the central axes of the threaded holes 11 at the upward and downward connecting ends The central axis of the threaded hole 11 at the forward and backward connection ends forms a 90° angle with eac...

Embodiment 2

[0106] Such as Figure 11 to Figure 13 As shown, another connector for prefabricated components provided by this embodiment can be applied in Figure 4 In the rigid connection node between the prefabricated beam and the column shown, the connector 7 and Figure 1 to Figure 3 The provided connectors 7 are basically the same, and will not be repeated here. The difference is that, for each connector 7, the threaded holes 11 of the upward and downward connecting ends, the threaded holes 11 of the leftward and rightward connecting ends and The threaded holes 11 at the forward and backward connecting ends communicate with each other. The central axes of the threaded holes 11 at the upward and downward connecting ends, the central axes of the threaded holes 11 at the leftward and rightward connecting ends, and the central axes of the threaded holes 11 at the forward and backward connecting ends intersect each other at the same point .

[0107] Of course, for each connector 7, it m...

Embodiment 3

[0109] Such as Figure 14 to Figure 16 As shown, another connector for prefabricated components provided by this embodiment can be applied in Figure 4 In the rigid connection node between the prefabricated beam and the column shown, the connector 7 and Figure 11 to Figure 13 The provided connectors 7 are basically the same, and will not be repeated here. The difference is that the connector body 71 is provided with six cylindrical connection ends protruding in different directions, and a threaded hole 11 is provided at the center of each connection end. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com