Series type fastening assembly and impact device using same

A technology for fastening components and impact devices, applied in the field of impact devices, can solve the problems of time-consuming, inconvenient, and unfavorable for large-scale construction, and achieve the effect of improving the installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable examiners to further understand the purpose, features and achieved effects of the present invention, several preferred embodiments of the present invention will be described in detail below with illustrations.

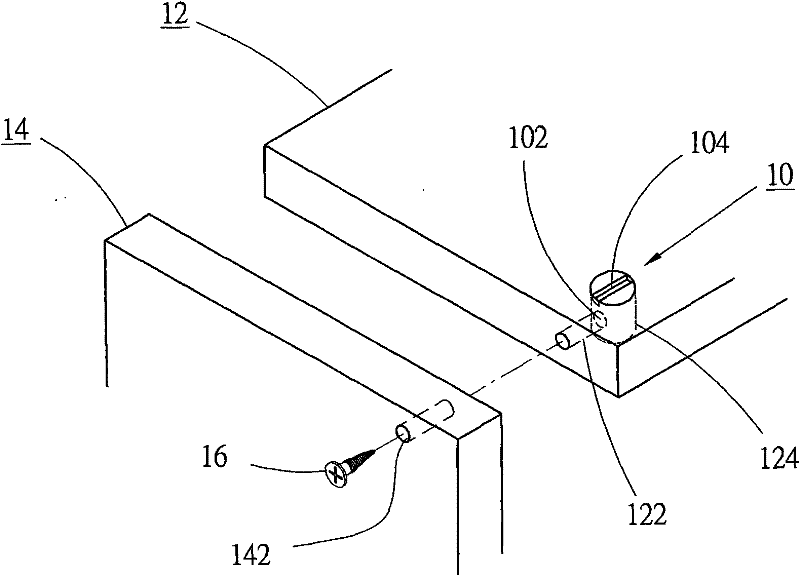

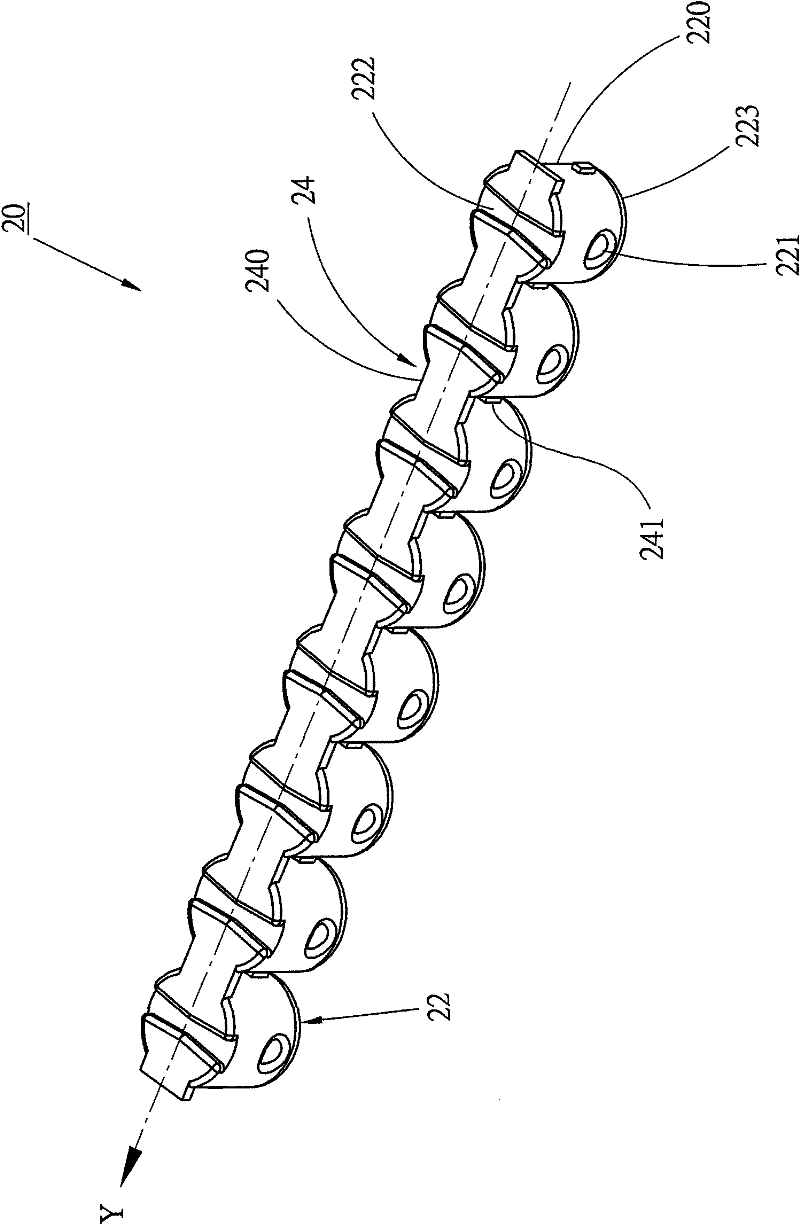

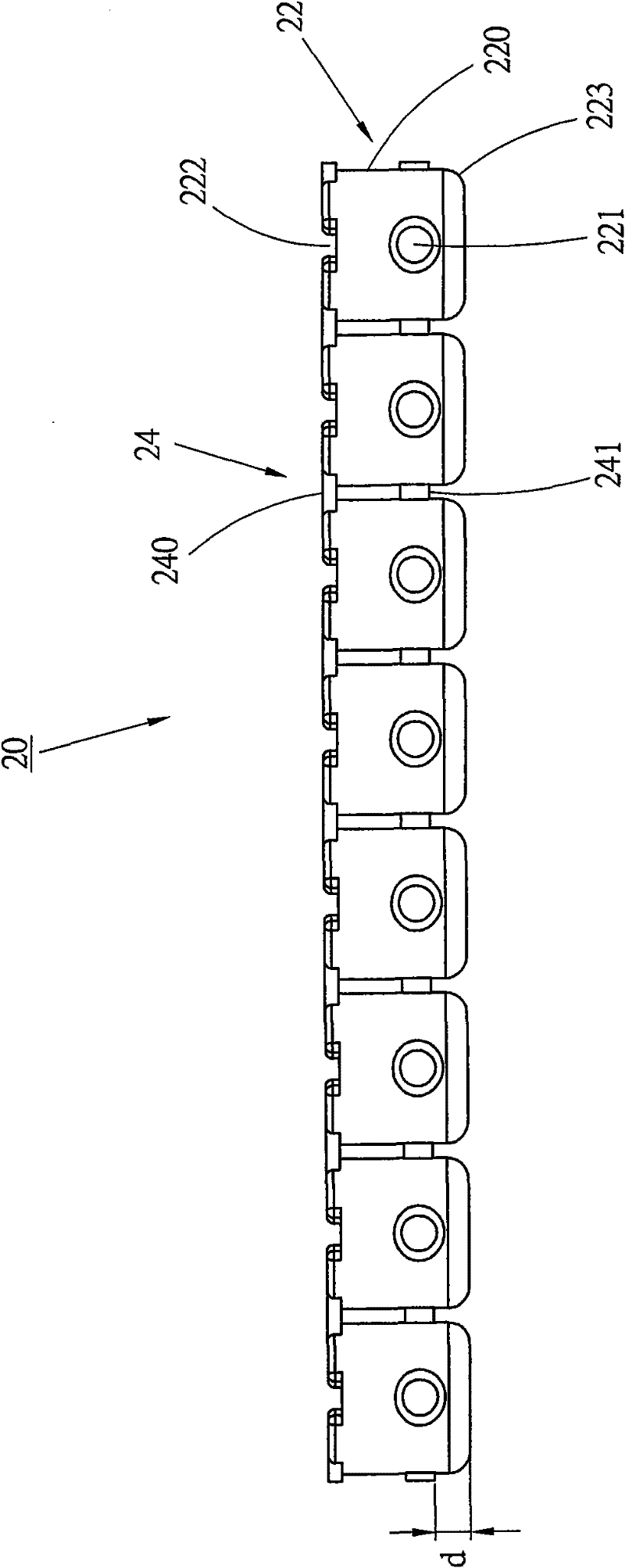

[0023] figure 2 , image 3 It is a preferred embodiment of a serial fastening assembly 20 disclosed in the present invention. The serial fastening assembly 20 includes a plurality of fasteners 22 and a plurality of connecting components 24 . The connecting members 24 and the fasteners 22 are arranged alternately; the two sides of each connecting member 24 are connected to two adjacent fasteners 22 respectively; thereby, the fasteners 22 achieve a series effect through the connecting members 24 and are arranged in a straight line . In addition, the fastener 22 and the connecting member 24 can be integrally formed by stamping or injection; the fastening component 20 can be made of an injection-molded elastic material.

[0024] Each fastener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com