High bridge pier self-lifting outer frame over-form construction technology

A construction technique and high pier technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems that formwork cannot be fully used, waste, and formwork is not a turnover material, etc., to avoid construction waste, green construction, and easier quality control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

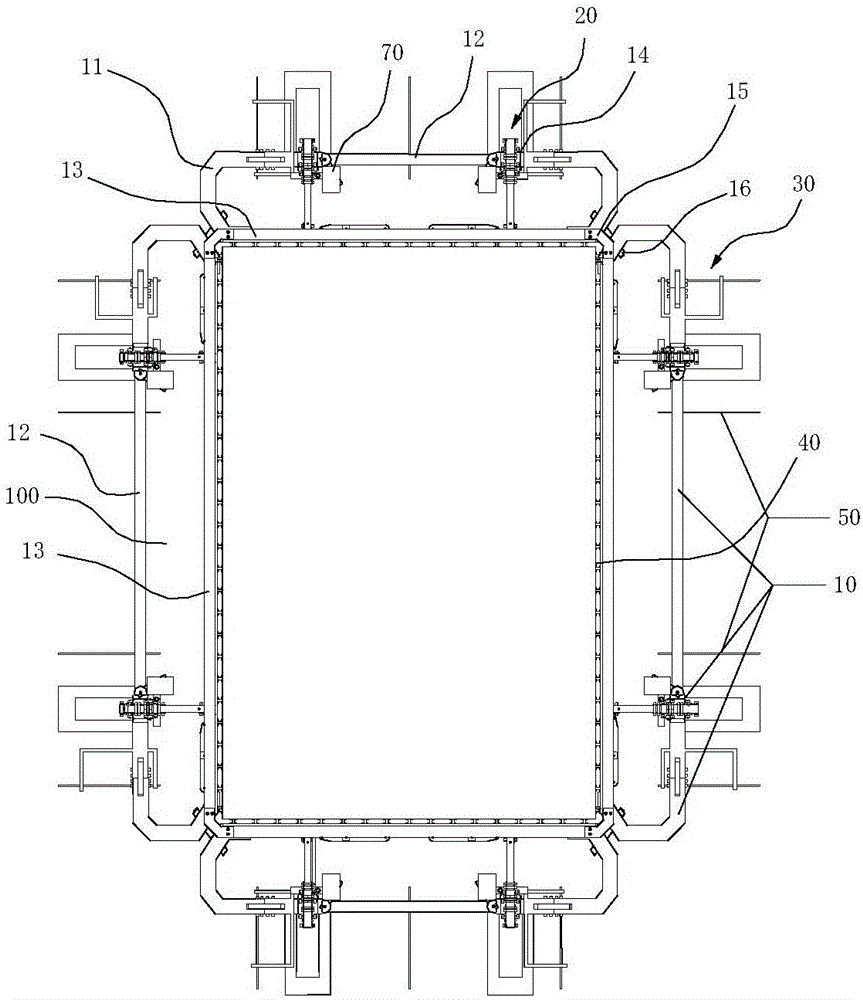

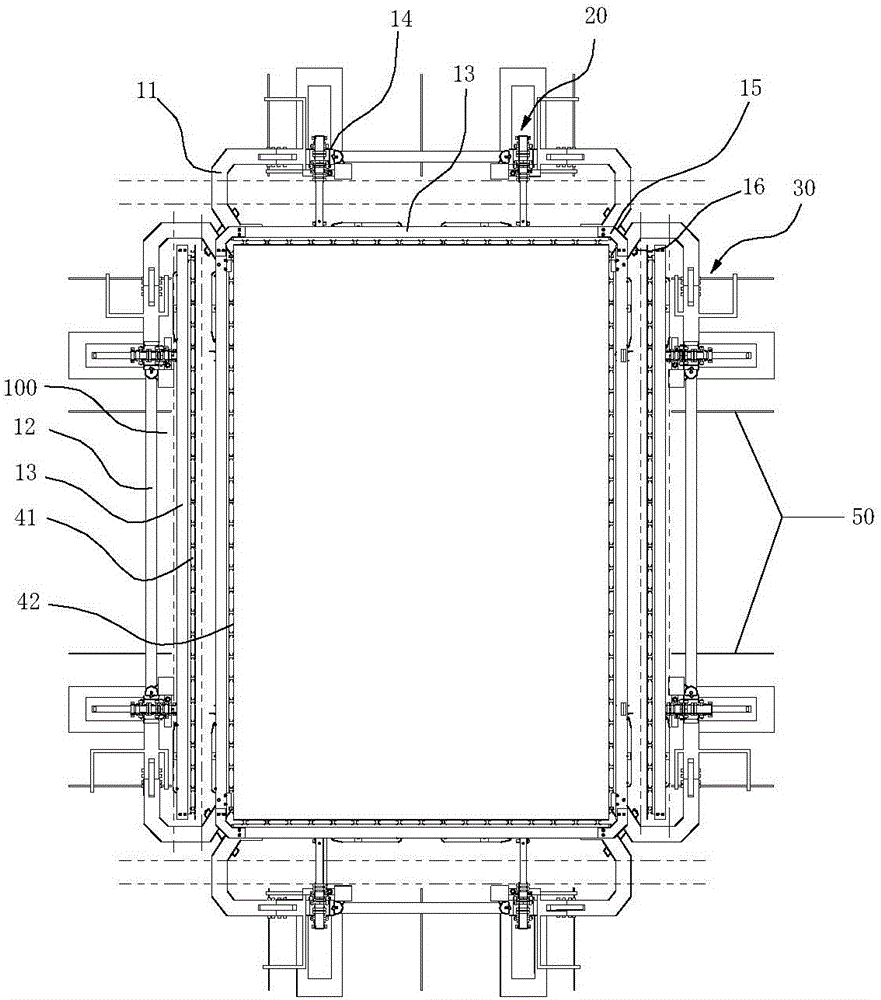

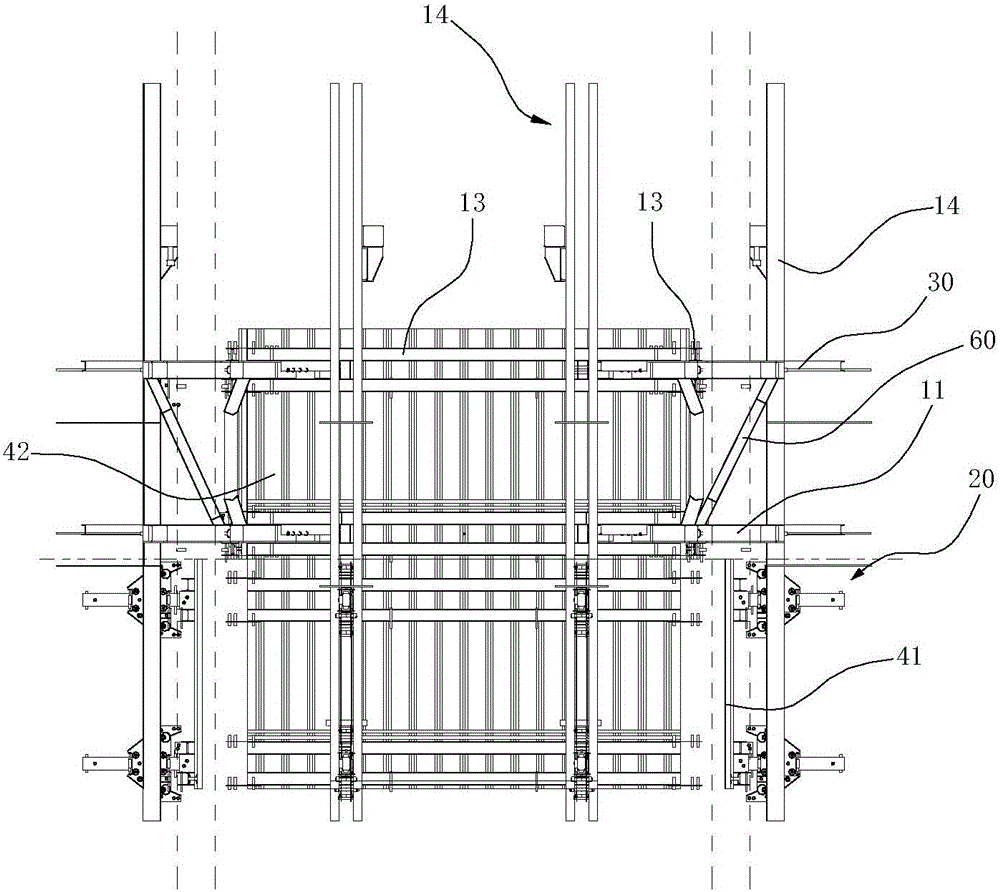

[0058] Such as Figure 1 to Figure 12 Shown, the bridge high pier self-elevating outer frame turning over construction technology of the present invention comprises the following steps:

[0059] 1) Formwork installation, pouring of upper and lower concrete;

[0060] Install a layer of formwork 40 surrounding the pouring cavity of the high pier of the bridge to form the lower formwork system 41, and pour the first layer of concrete after the installation is completed; however, install another layer of formwork 40 above the lower formwork system 41 to form the pouring cavity of the high pier of the bridge to form The upper formwork system 42; however, the pouring of the second layer of concrete is carried out;

[0061] The outer surfaces of the formwork of the upper formwork system 42 and the lower formwork system 41 are all provided with reinforced hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com