Construction method for wall-body constructional column joint bar

A construction method and a technology of structural columns, which are applied in building construction, formwork/formwork/work frame, preparation of building components on site, etc., can solve the problems of difficulty in ensuring the accuracy of the drilling position of planting bars, formwork damage, dust pollution, etc. problems, to achieve the effect of saving the cost of planting reinforcement construction, ensuring the construction quality, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments, where the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

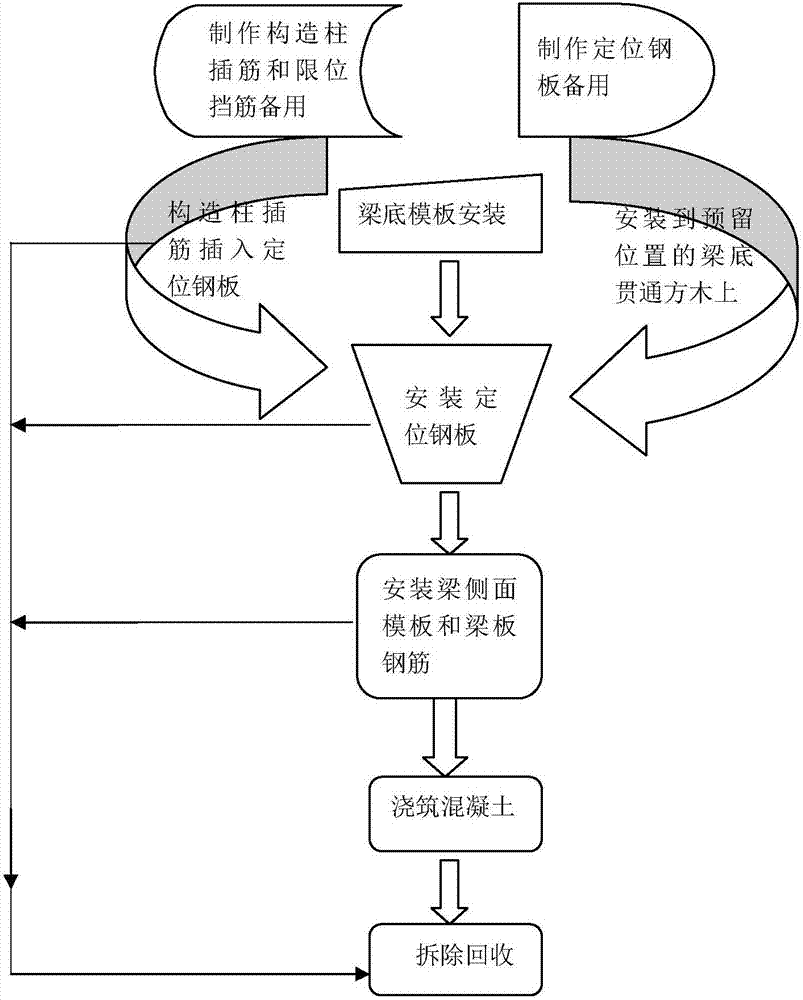

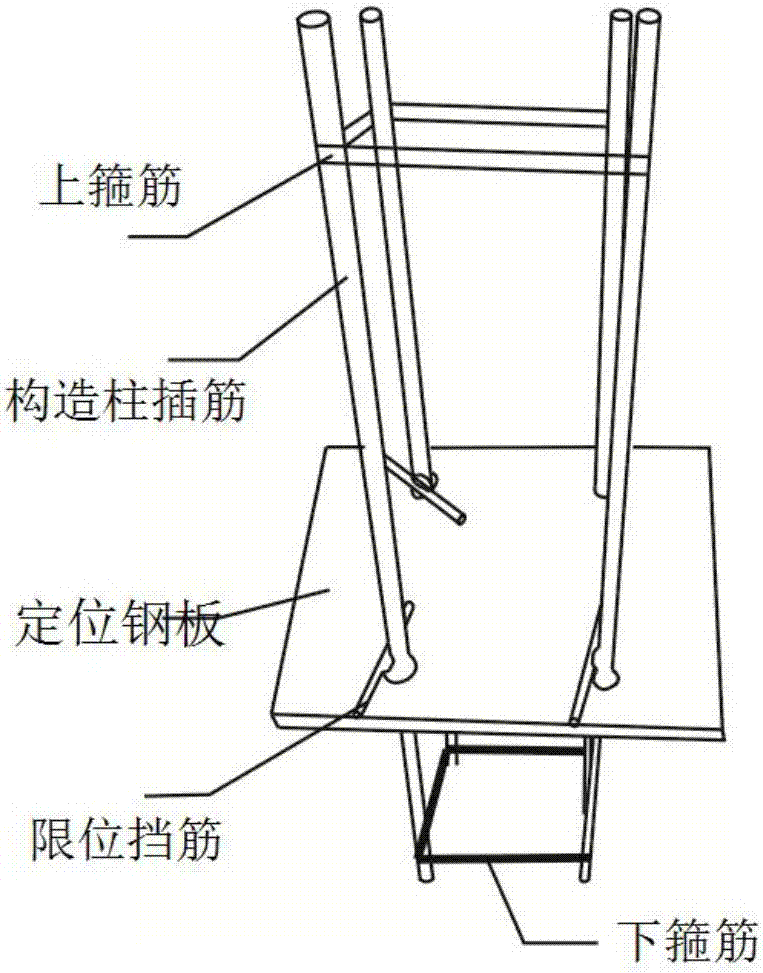

[0022] refer to Figure 1 to Figure 2 A construction method for inserting ribs in structural columns of a wall, the method is to replace the cast-in-place beam slab concrete bottom form at the position of the structural columns with a positioning steel plate whose plane size is the width of the main structural beam×the section width of the structural column×the thickness of the main structural beam bottom formwork Methods.

[0023] Specifically: this method is used in the construction process of the main structure of the wall structure of the construction project. The positioning steel plate is used as the concrete pouring bottom form, and the pre-embedded structural column inserting holes are uniformly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com