Polyolefin/graphene nanocomposite and preparation method thereof

A nanocomposite material and graphene technology are applied in the field of polyolefin/graphene nanocomposite materials and their preparation, which can solve the problems of large amount of organic solvent, difficulty in dispersing graphene, serious environmental pollution, etc., and improve compatibility. , Improve dispersion, overcome the effect of high wrinkle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

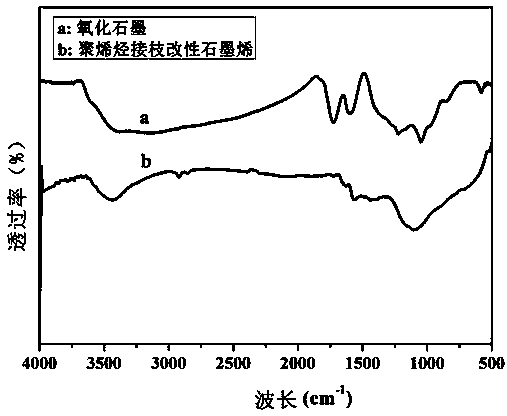

[0036] (1) Functional modification of graphene: mix 1g of graphite oxide and 200ml of ethanol, ultrasonically disperse for 1h, and the ultrasonic frequency is 70Hz to obtain a uniformly dispersed suspension; under stirring conditions, add 100ml of ethanol solution containing 10g of hexamethylenediamine , and then at N 2 Reflux reaction was carried out under protection for 12 hours, and the reaction temperature was 80°C; then 12 g of hydrazine hydrate solution with a mass concentration of 50% was added for reduction reaction, and the reaction time was 6 hours; finally, cooling, suction filtration, and repeated washing of the product with deionized water and ethanol alternately , and the obtained solid product was dried in a vacuum oven at 60° C. to obtain graphene modified by surface functionalization.

[0037] (2) Preparation of polypropylene grafted modified graphene: Take 0.5g of the above-mentioned functionalized modified graphene and disperse it in 200ml of xylene, ultraso...

Embodiment 2

[0046] (1) Functional modification of graphene: mix 1g of graphite oxide and 200ml of ethanol, ultrasonically disperse for 1h, and the ultrasonic frequency is 70Hz, to obtain a uniformly dispersed suspension; under stirring conditions, add 150ml of ethanol containing 15g of p-phenylenediamine solution, followed by N 2 Reflux reaction was carried out under protection for 8 hours, and the reaction temperature was 100°C; then 7g of hydrobromic acid solution with a mass concentration of 60% was added for reduction reaction, and the reaction time was 10 hours; finally, cooling and suction filtration were carried out, and the product was alternately used with deionized water and ethanol repeatedly After washing, the obtained solid product was dried in a vacuum oven at 80°C to obtain surface functionalized modified graphene.

[0047] (2) Preparation of polypropylene grafted modified graphene: Take 0.5g of the above-mentioned functionalized modified graphene and disperse it in 200ml o...

Embodiment 3

[0052] (1) Functional modification of graphene: mix 1g of graphite oxide and 200ml of ethanol, disperse by ultrasonic for 1h, and the ultrasonic frequency is 70Hz to obtain a uniformly dispersed suspension; under stirring conditions, add 50ml of diaminodiphenylmethane ethanol solution, followed by N 2 Reflux reaction was carried out under protection for 2 hours, and the reaction temperature was 120°C; then 20 g of sodium borohydride solution with a mass concentration of 40% was added for reduction reaction, and the reaction time was 2 hours; finally, cooling and suction filtration were performed, and the product was alternately used with deionized water and ethanol repeatedly After washing, the obtained solid product was dried in a vacuum oven at 50°C to obtain surface functionalized modified graphene.

[0053] (2) Preparation of polyethylene grafted modified graphene: Take 0.5g of the above-mentioned functionalized modified graphene and disperse it in 200ml of xylene, ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com