Multiple helmholtz resonator parallel cellular sandwich wood sound absorption plate

A technology of sound-absorbing panels and resonators, applied in covering/lining, layered products, buildings, etc., can solve the problems of narrow sound-absorbing frequency band, poor sound-absorbing effect, small chamber volume ratio, etc., and achieve broadening of sound-absorbing frequency band , low cost, and high chamber volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

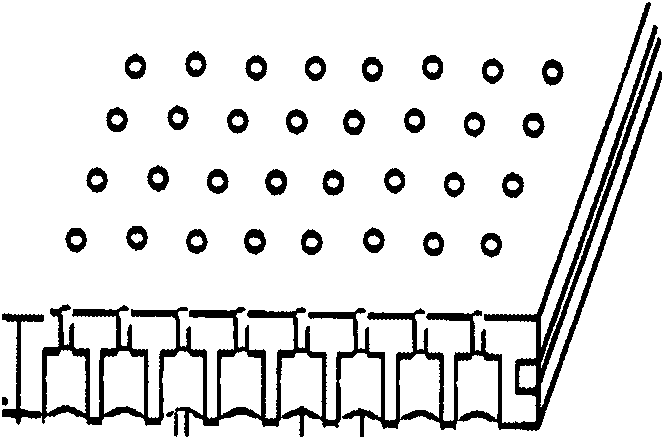

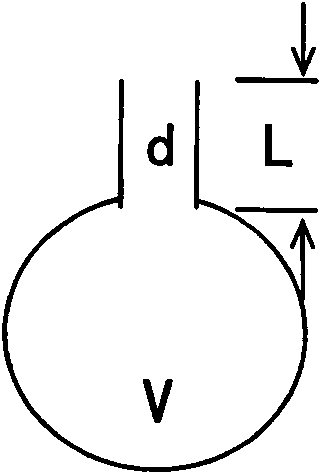

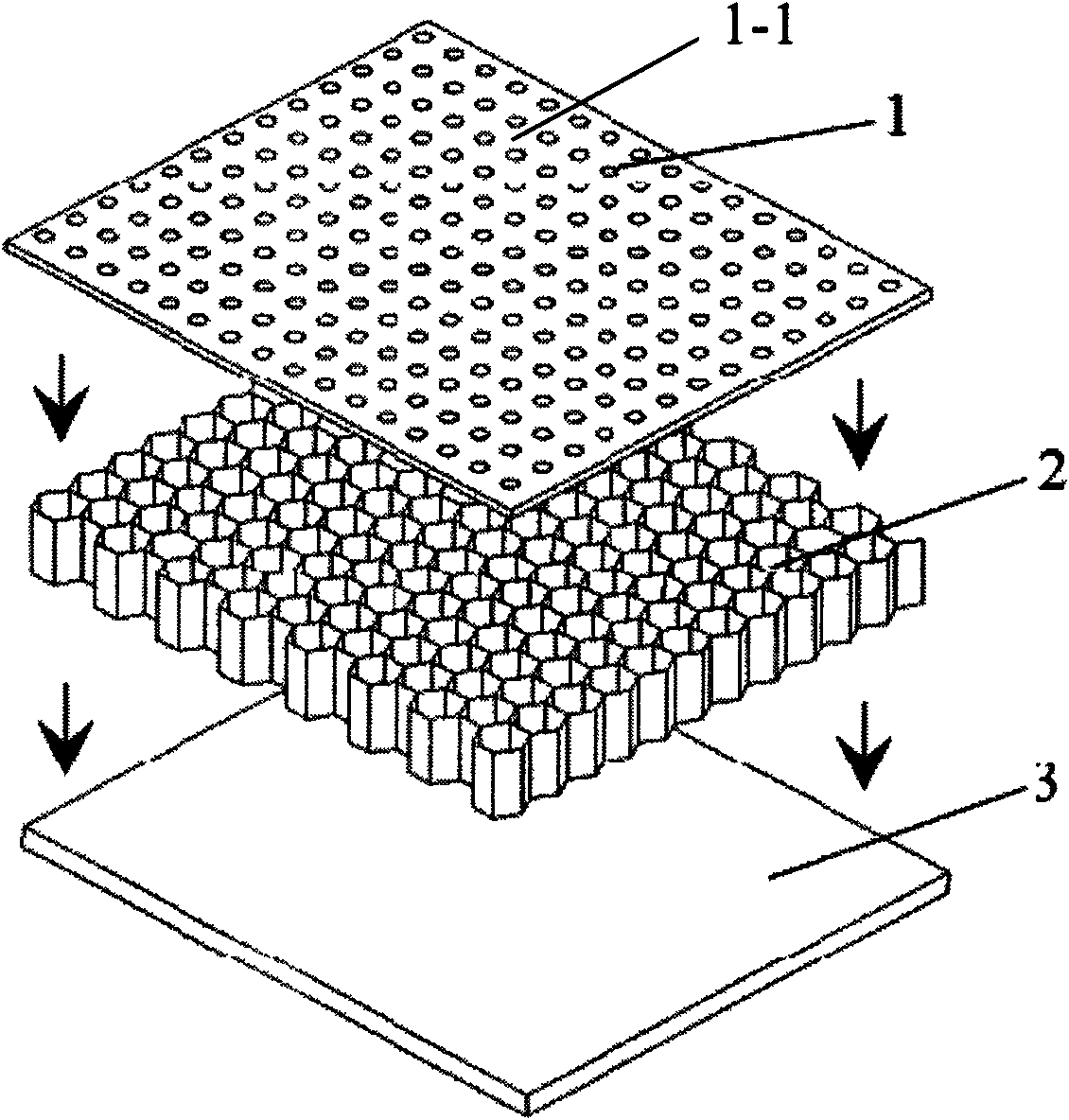

[0013] Specific implementation mode one: as Figure 2a , Figure 2b , image 3 and Figure 4 As shown, the multi-Helmholtz resonator parallel honeycomb sandwich wooden sound-absorbing panel in this embodiment includes a panel 1, a core layer 2 and a back panel 3, and the core layer 2 is sandwiched between the panel 1 and the back panel 3 And the three are connected together; the core layer 2 is a honeycomb core layer (honeycomb core material). The section is that the inner cavity of the hexagonal cylinder is a honeycomb chamber; the chamber volume ratio of the core layer 2 (the chamber volume ratio is equal to the percentage of the volume sum of all cavities in the core layer accounting for the core layer volume) is greater than 90%, several perforations (small through holes) 1-1 are opened on the panel 1, and the area of the perforation shape surrounded by the outline of each perforation 1-1 is smaller than the hexagonal area on the corresponding core layer 2 1 / 4 of the...

specific Embodiment approach 2

[0015] Embodiment 2: The perforation rate (percentage of the hole area in the panel area) of the panel 1 in this embodiment is 3-10%. , has been proved by countless experiments that the combination of the two technical parameters of the core layer 2 with a chamber volume ratio greater than 90% and the panel 1 with a perforation rate of 3-10% greatly improves the sound absorption rate. When the core layer 2 remains unchanged, the combination of the two technical parameters of the core layer 2 with a chamber volume ratio greater than 90% and the panel 1 with a perforation rate of 3 to 10% can increase the sound absorption rate by 8% to 10%. %. The panel 1 can be perforated according to a certain pattern. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: as image 3 As shown, in this embodiment, each perforation 1-1 is a circular hole, and the aperture (diameter) of the circular hole is 1-10 mm. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com