Method of correcting printer spectrum characterization model

A spectral feature and printer technology, applied in color/spectral feature measurement, printing, computer parts, etc., can solve the problems of waste of consumables such as ink and paper, reduced accuracy of spectral characterization models, and inconformity with energy conservation and environmental protection. Effects of waste and inconvenience, compensation for loss of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Taking a CMYK (cyan, magenta, yellow, black) four-ink printer as an example, the specific implementation method of the above characterization model correction method is described. It should be noted that the present invention is not limited to four-ink printers, and is applicable to correction of spectrum-based characterization models of various multi-ink printers.

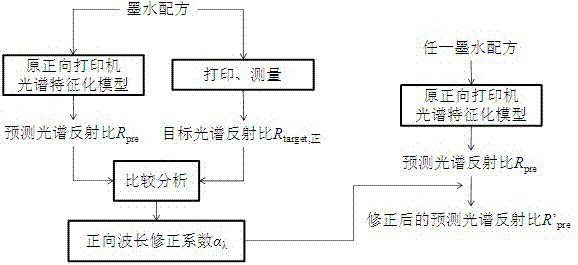

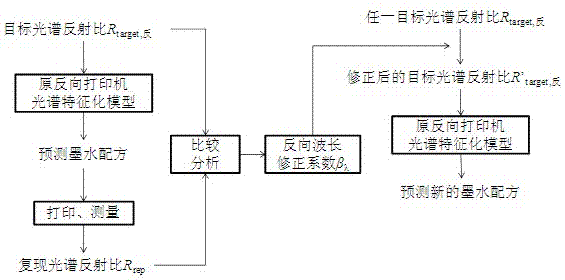

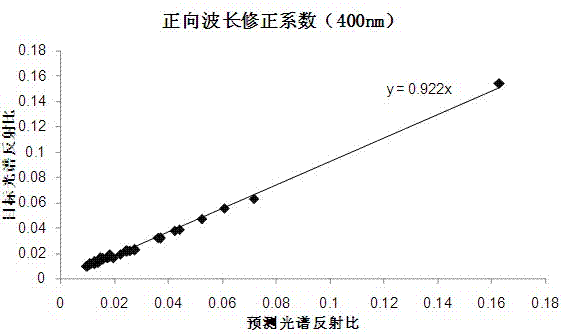

[0032] The establishment of a printer spectral characterization model based on a certain printing environment is a prerequisite for model correction. There are two types of forward spectral characterization models for printers: model method and empirical method. The model method is to simulate the coloring mechanism of the equipment through a physical model, and establish the corresponding relationship between the ink formula and the spectral reflectance, such as the Kubelka-Munk model, the Clapper-Yule model, the Neugebauer model, and the Cellular Yule-Nielsen Neugebauer model. Orientation models are ofte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com