Sample storage barrel and intelligent management system

An intelligent management and sample technology, applied to instruments, time registers, individual input/output registers, etc., can solve the problems of water loss, packaging bags, sewing threads that cannot be reused, poor safety, etc., to overcome Waste, stability of sample information processing system, and effect of ensuring sample safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

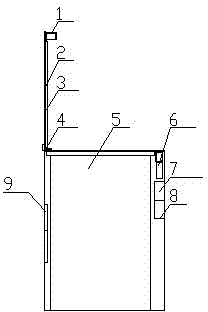

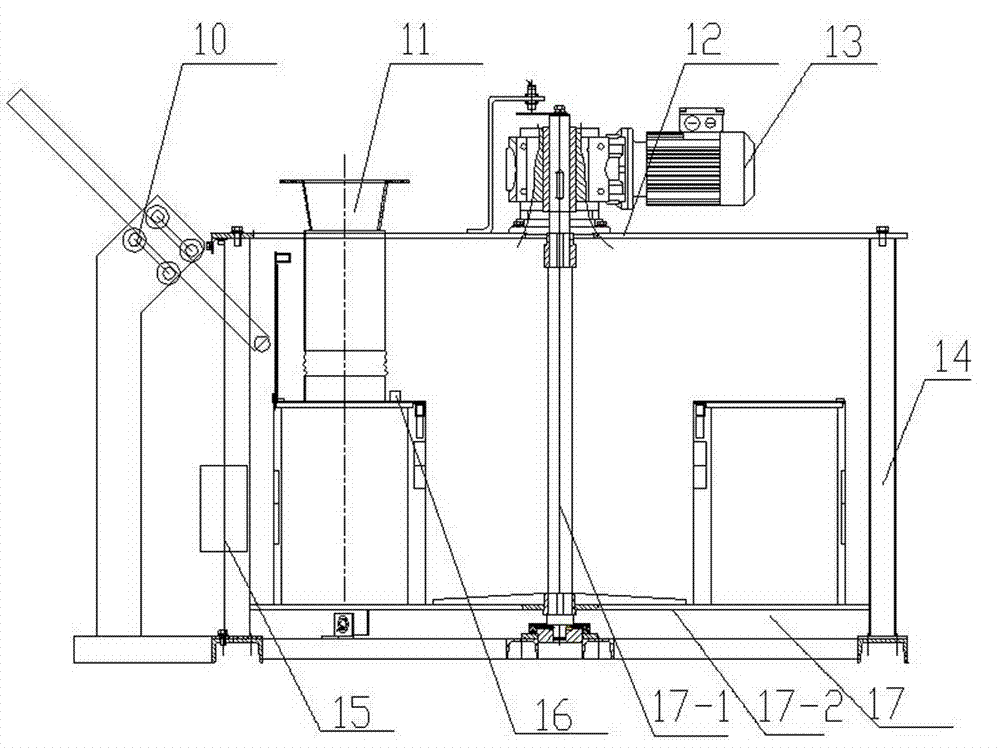

[0017] Such as figure 1 and 2 As shown, a sample storage bucket includes a barrel body 5 and a barrel cover 2 installed on the upper end of the barrel body 5 and matched with the upper port, and a connecting part for opening and closing the barrel cover is provided between one end of the barrel cover 2 and the barrel body 4. A lock hook 1 is provided on the lower surface of the other end of the bung 2, and an electromagnetic lock 6 matched with the lock hook and a control circuit are arranged on the barrel body. The control circuit includes a control module 7, which is connected with the control The module is connected with the IC card 8 used for storing article information and unlocking, and the power supply module connected with the control module. Described IC card 8 is arranged on the staving.

[0018] The barrel body 5 is composed of a shell and a detachable inner barrel installed inside the shell; the cross section of the shell and the detachable inner barrel is square...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com