Sintering and cooling integrated method for efficiently recovering and utilizing waste heat resources and device thereof

A waste heat and resource technology, applied in the field of efficient recovery and utilization of waste heat resources in the sintering process, can solve the problems of low cooling recovery efficiency, waste of sensible heat, environmental pollution, etc., and achieve the effect of simple and easy operation of equipment and reasonable methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

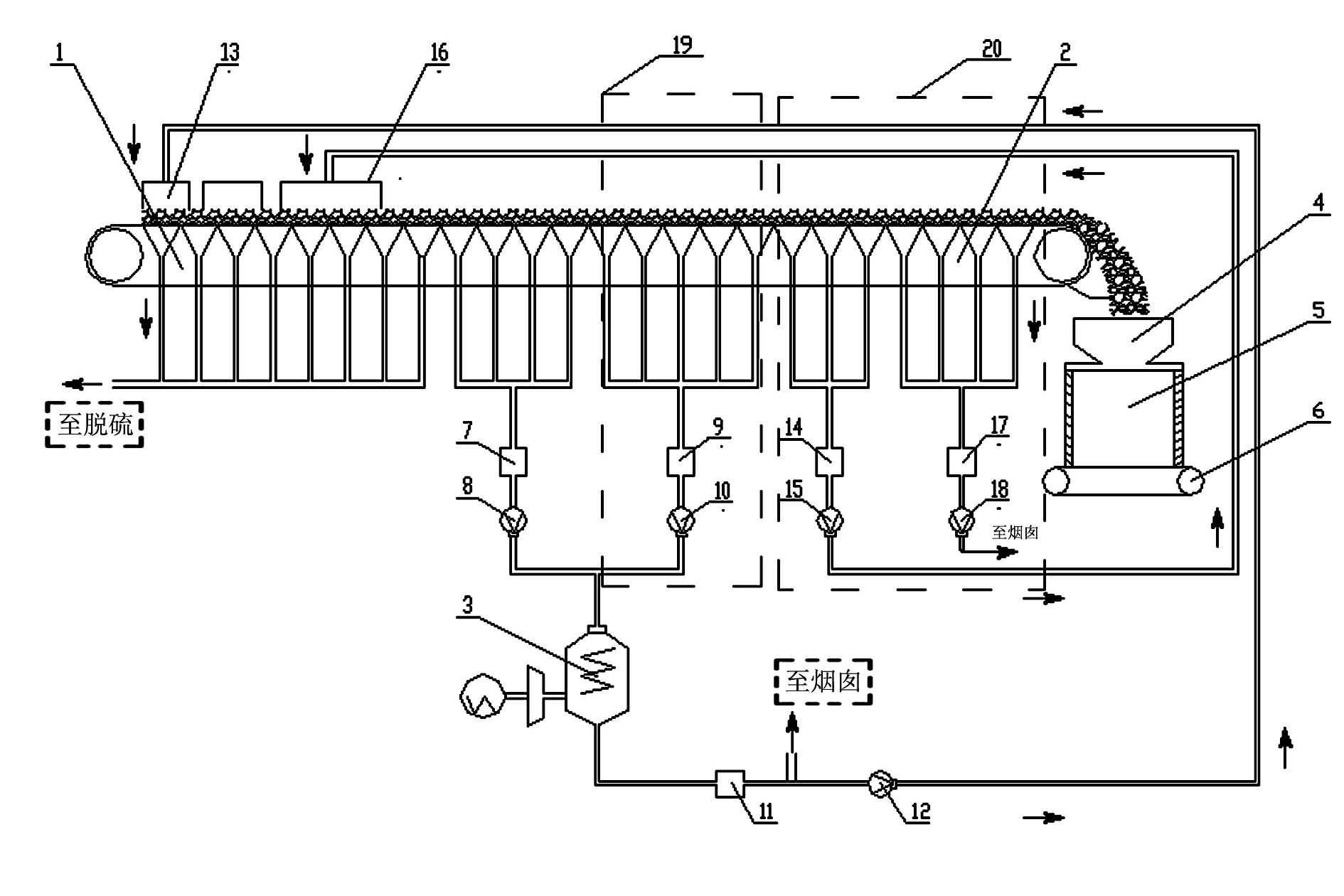

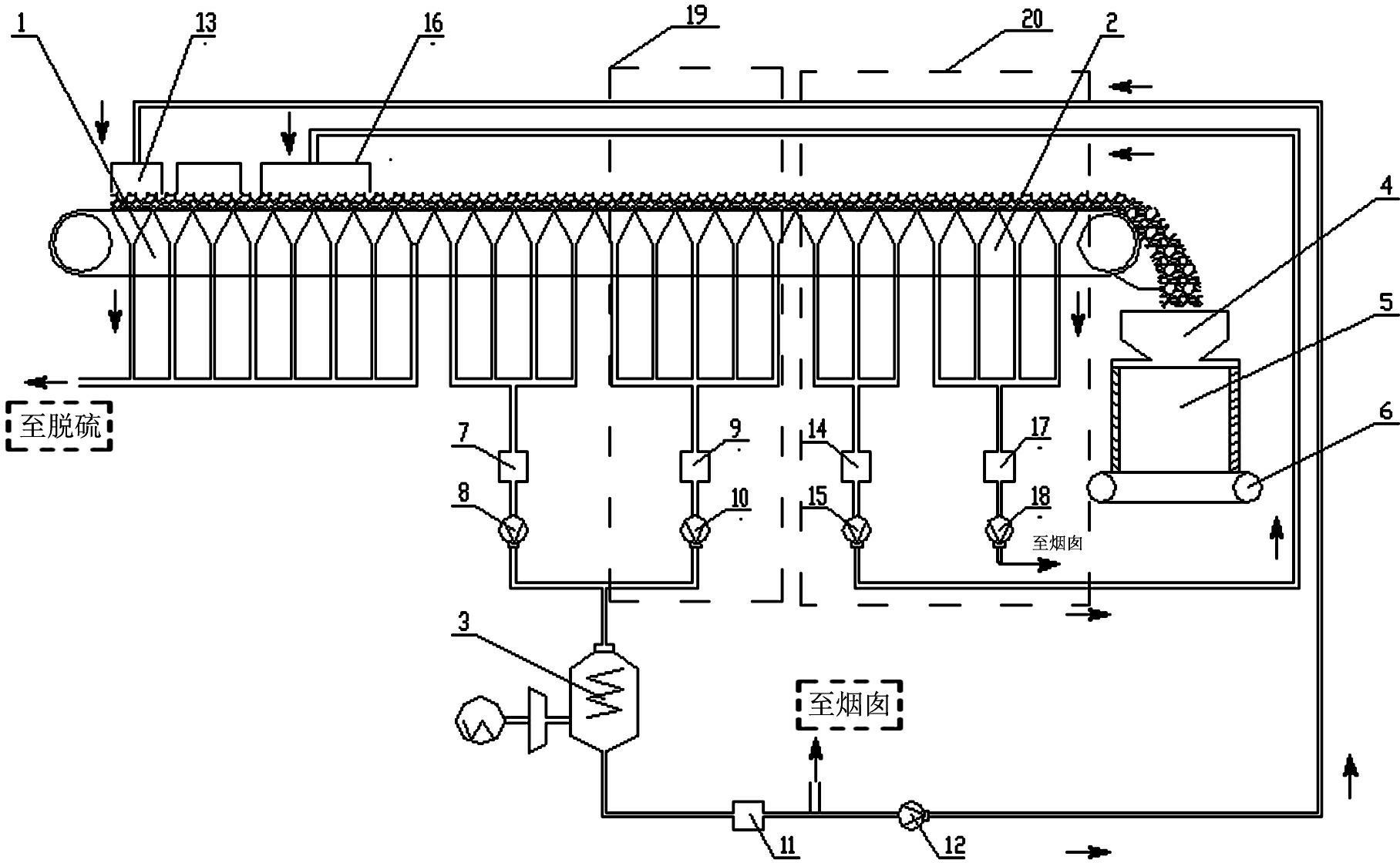

[0030] Implementation method: The present invention will be further described below in conjunction with accompanying drawing:

[0031] The invention provides a method for efficient recovery and utilization of waste heat resources integrated with sintering and cooling, the steps of the method are as follows:

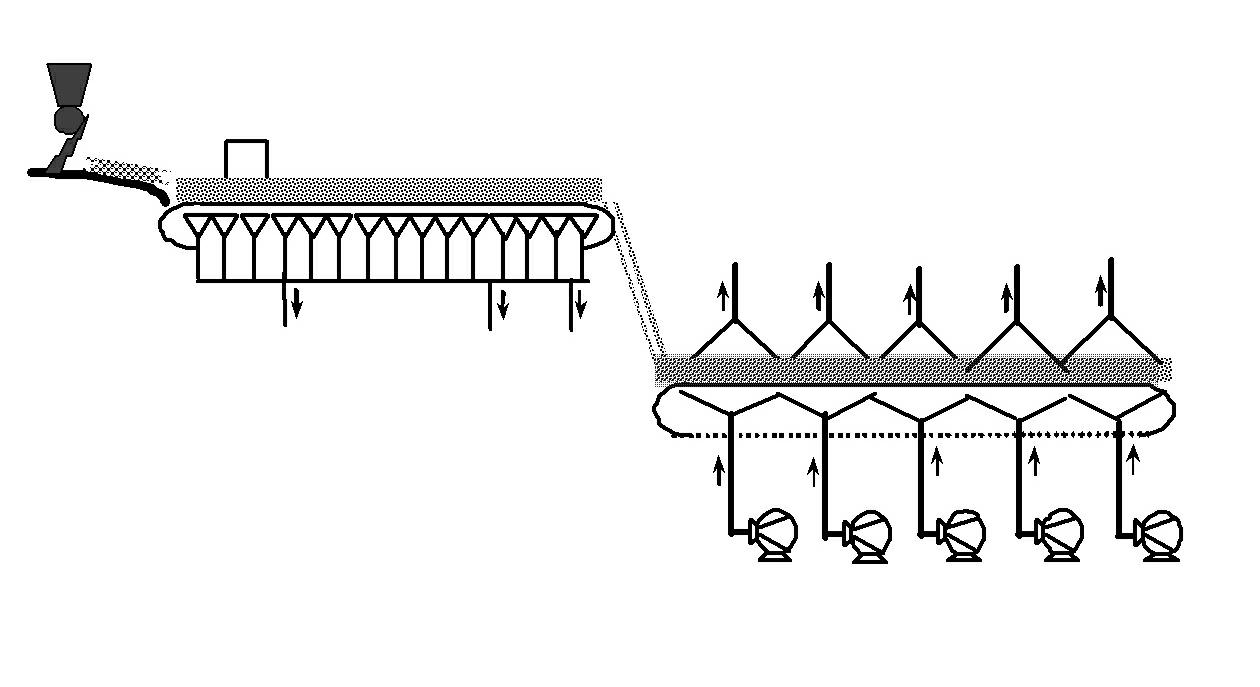

[0032] (1) The length of the sintering machine is doubled. The extension part has the same structure as the sintering machine. The extension part is used as the sinter cooling section, and the cooling section is divided into two sections. The first half is the cooling section 19, and the second half is Cooling stage 2 20;

[0033] (2), set the flow rate to 300,000 m 3 / h, temperature 300 ℃ ~ 350 ℃, oxygen volume content above 20%, sulfur dioxide below 300ppm, the flue gas at the end of sintering and the cooling section 19 have a flow rate of 500,000 m 3 / h, flue gas at a temperature of 420°C to 470°C is introduced into the waste heat boiler through a circulating fan t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com