Patents

Literature

77results about How to "Achieve torque transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

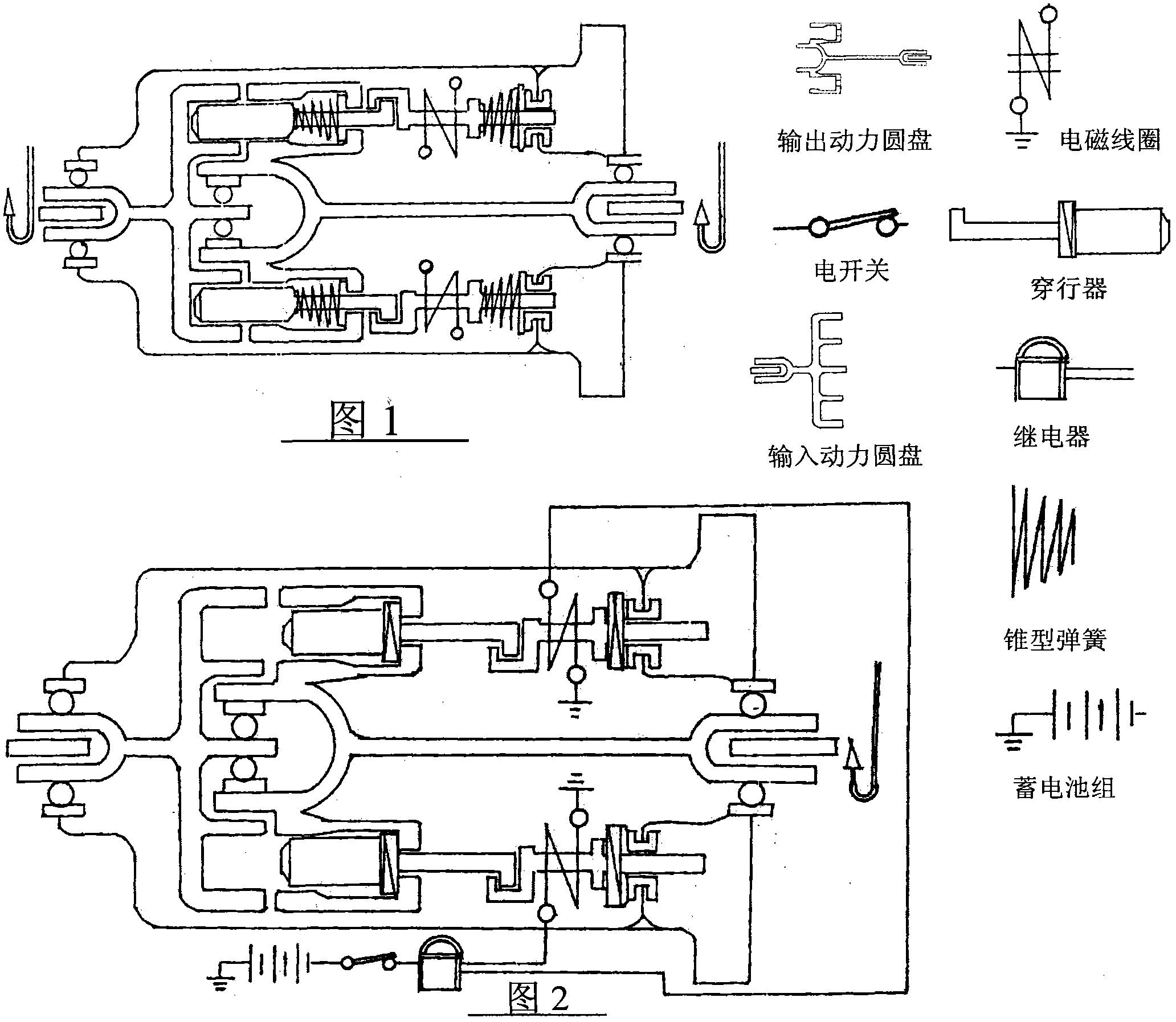

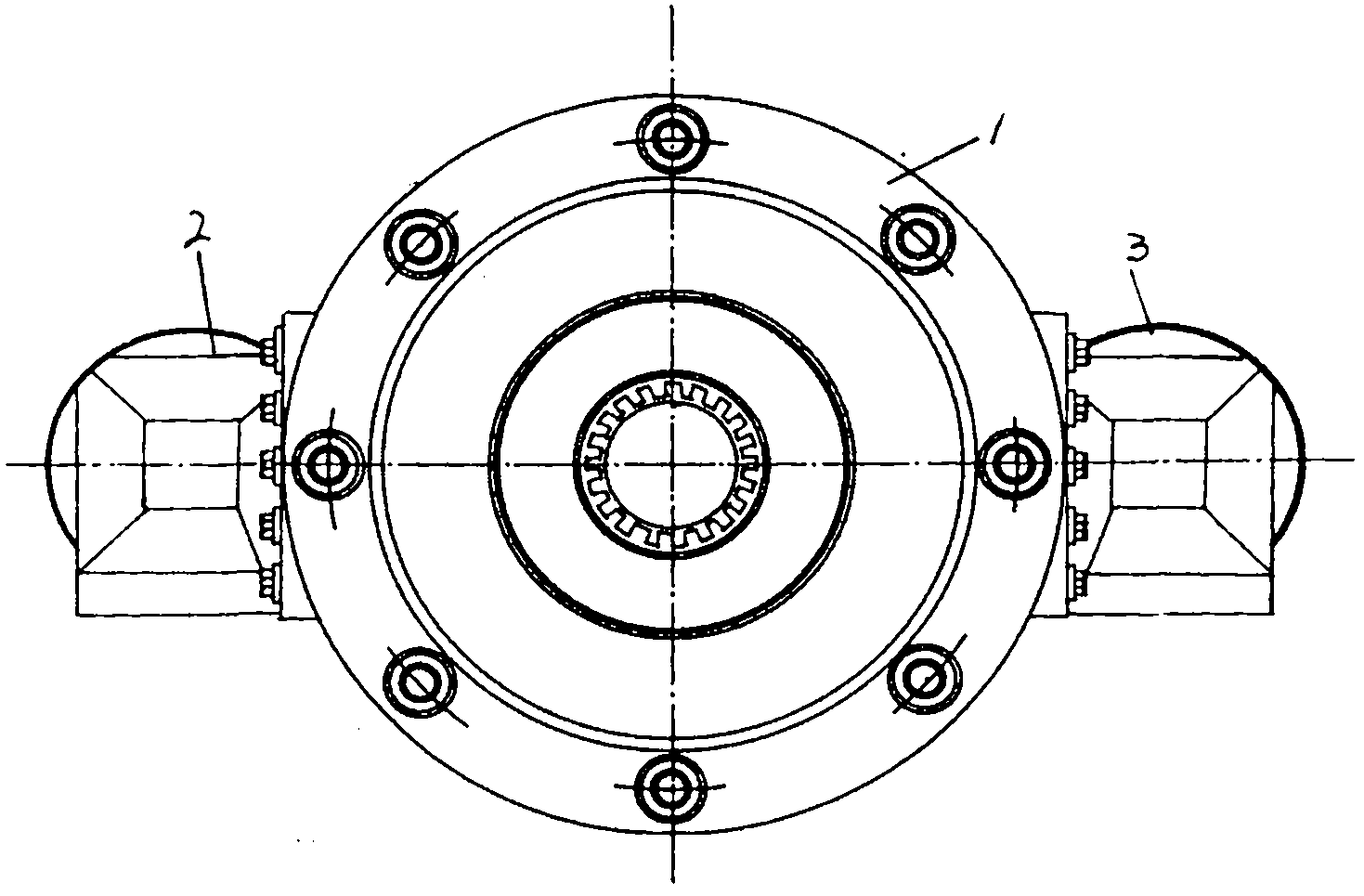

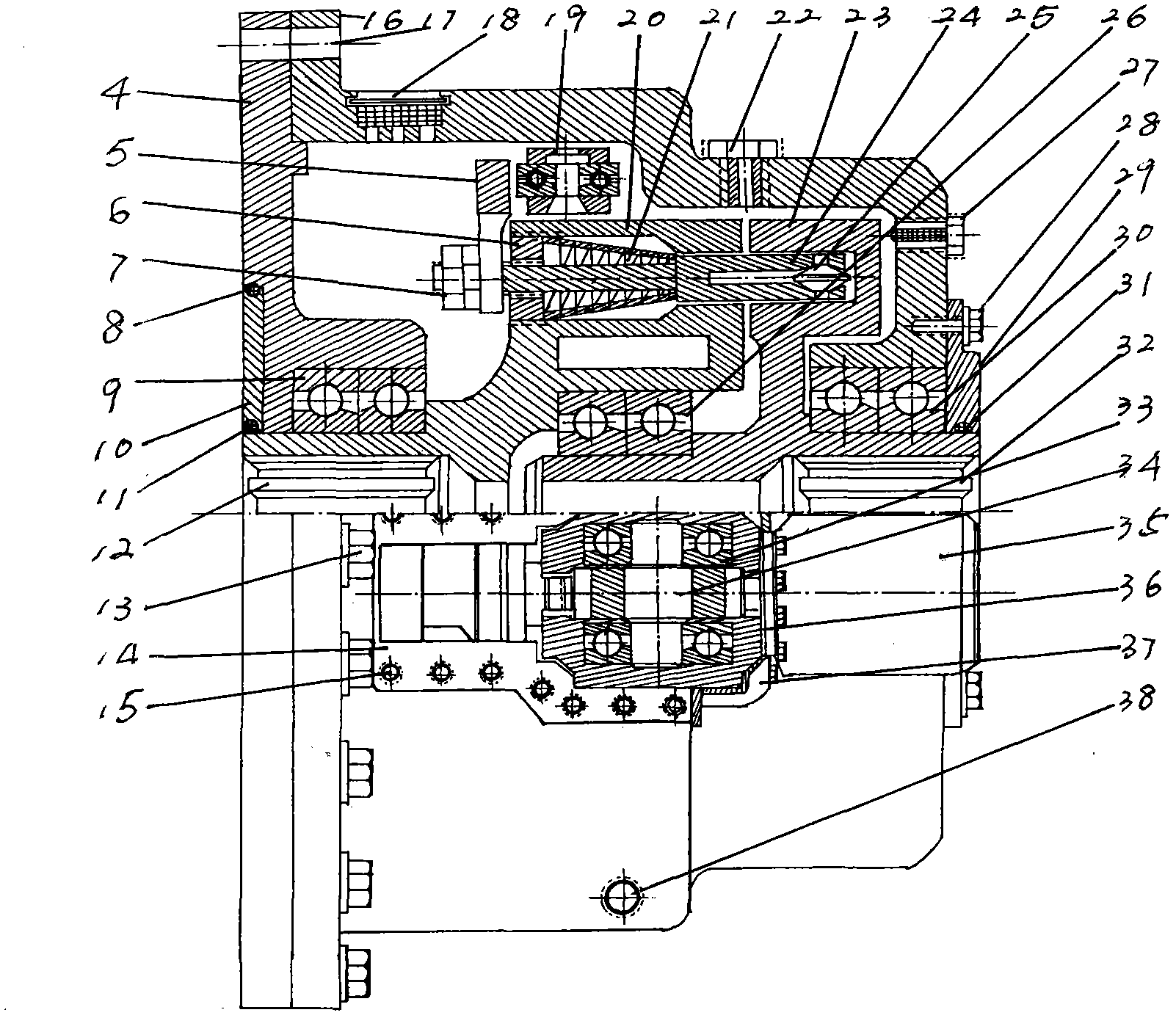

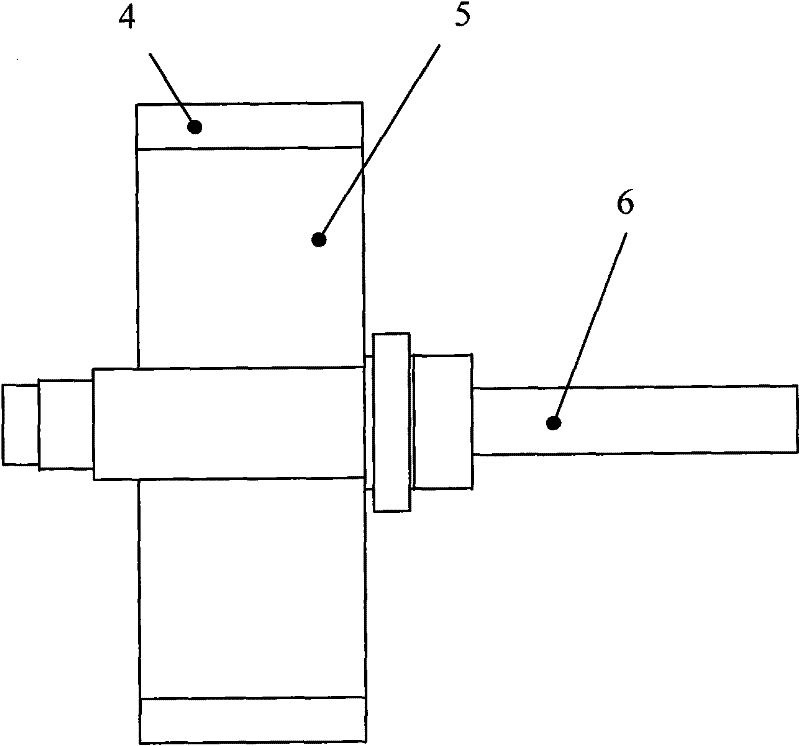

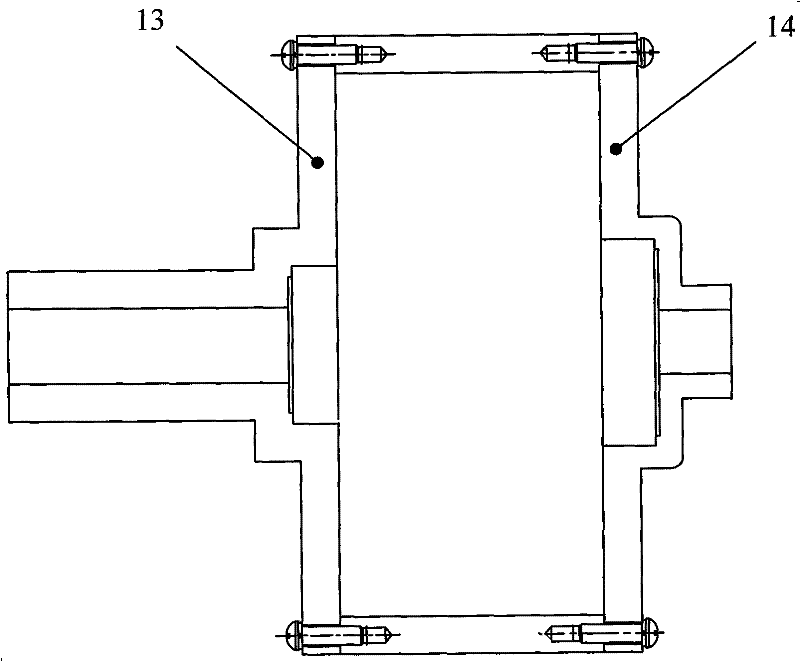

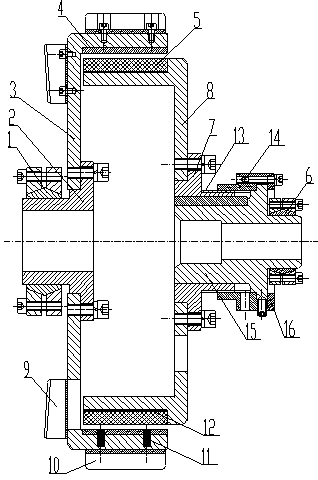

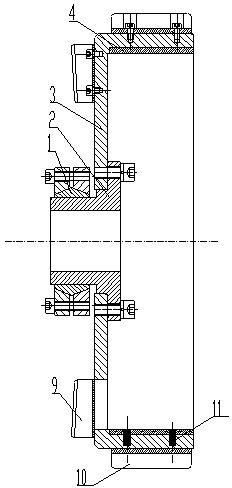

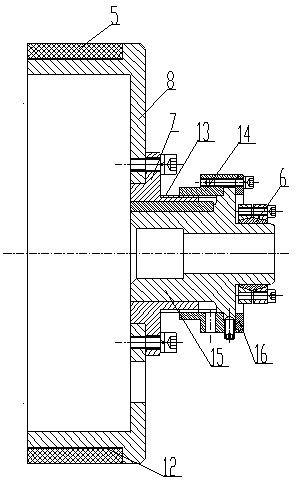

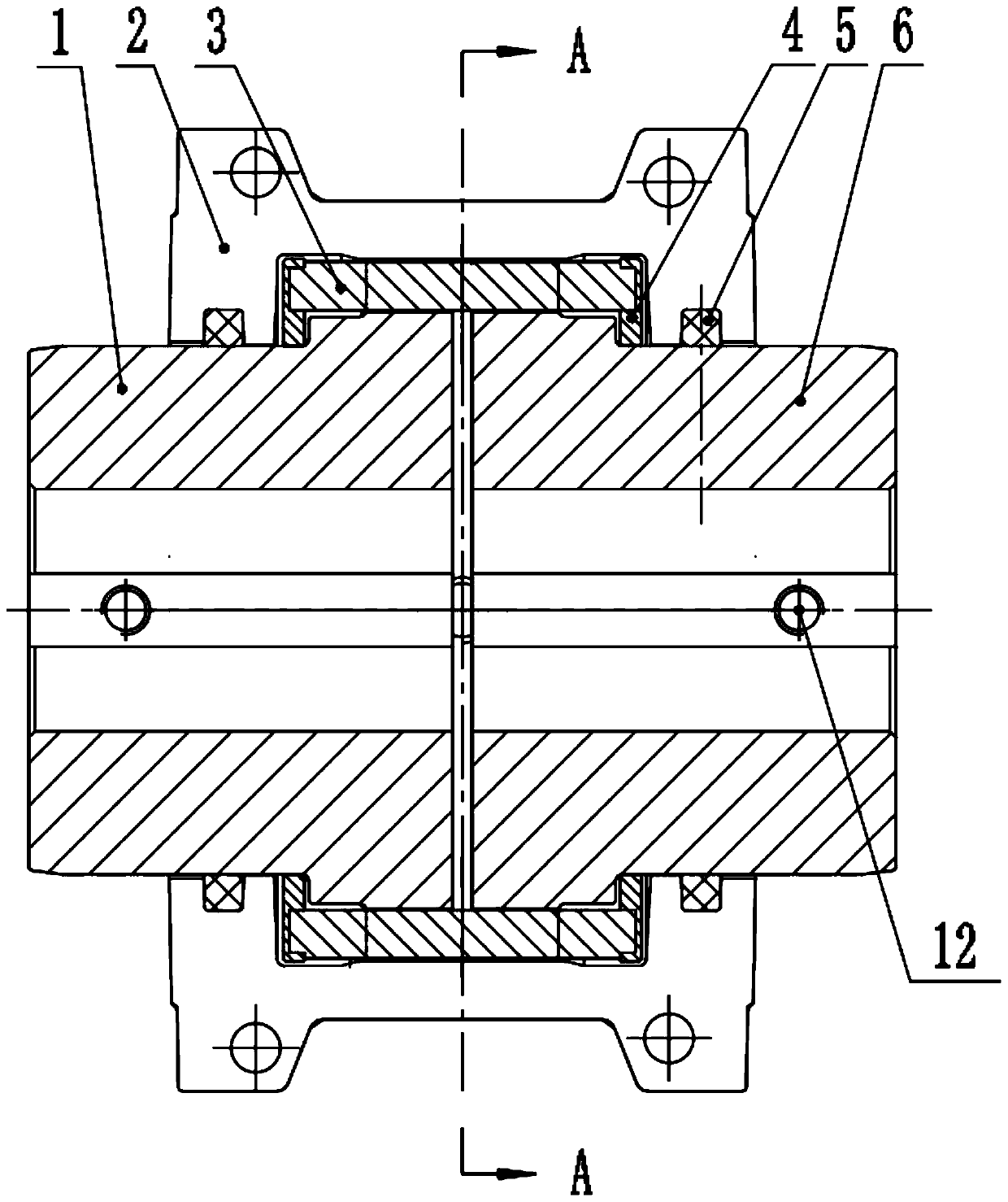

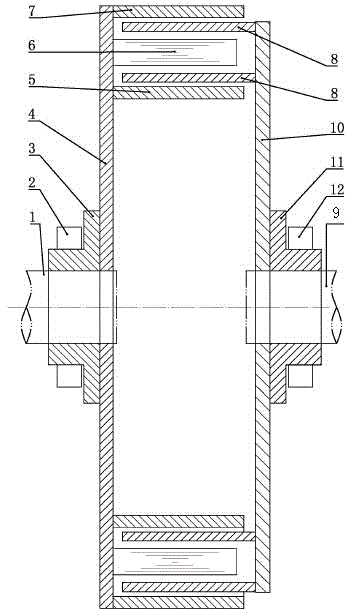

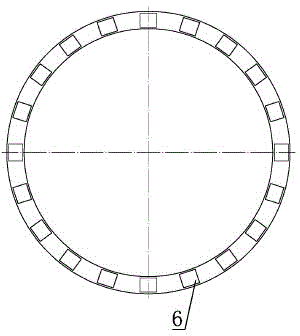

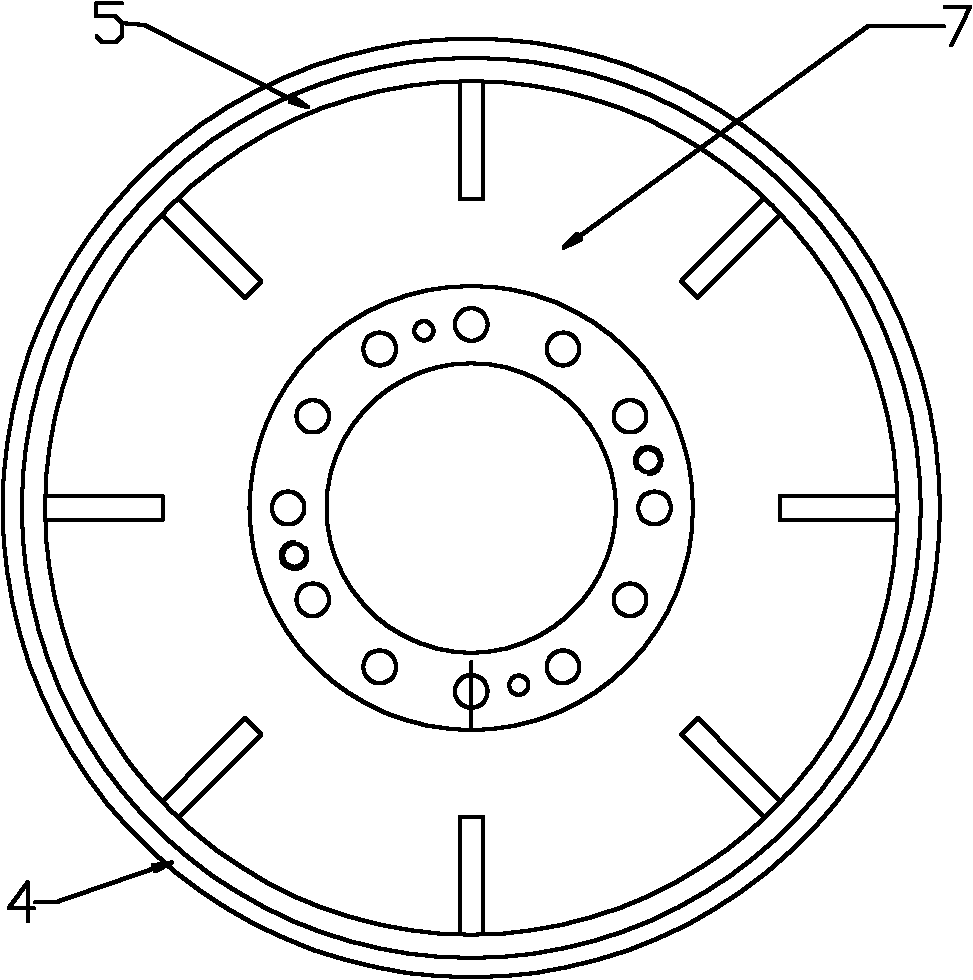

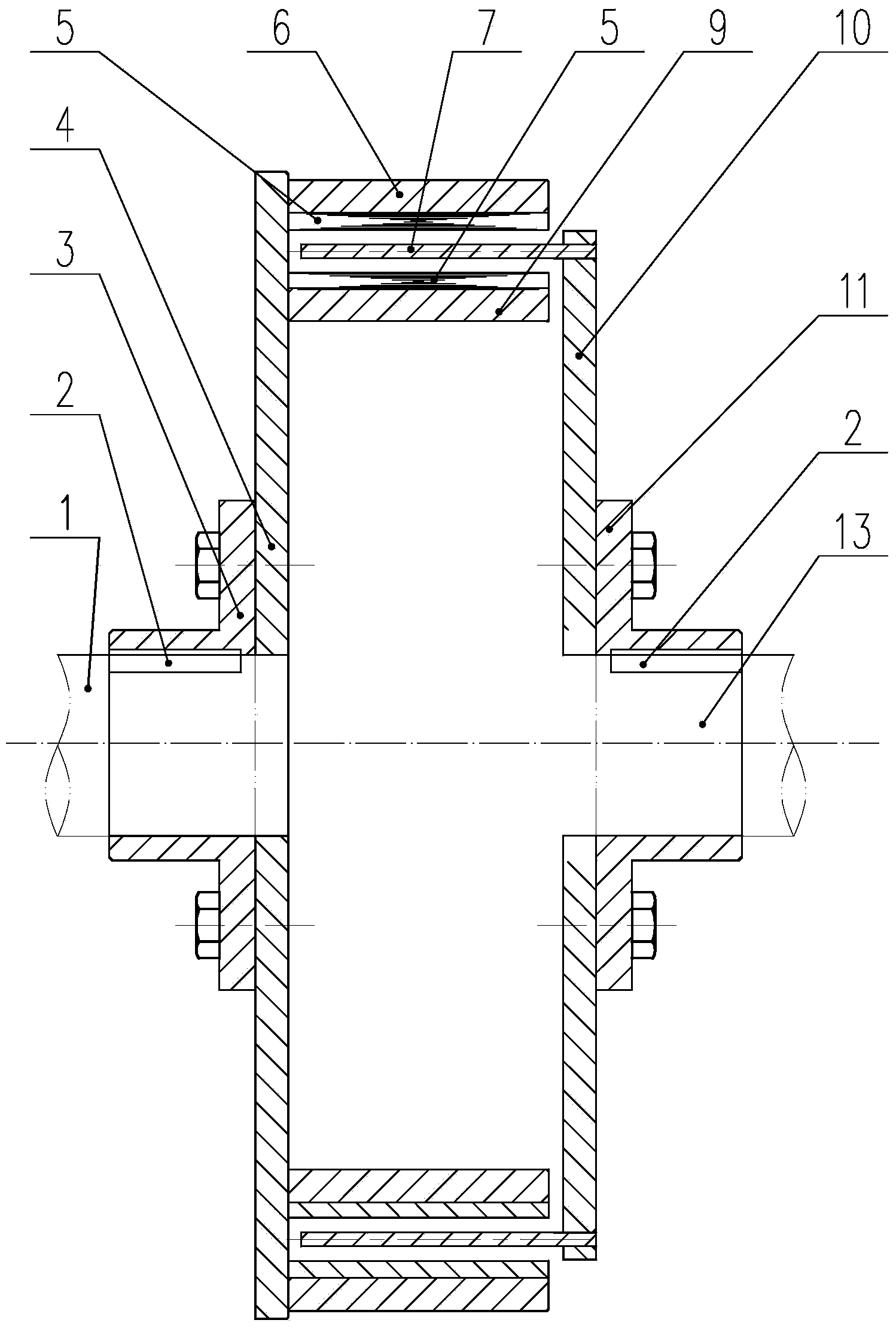

Inserter-connected electromagnetic drive clutch with spline shafts having discs and spline sleeves having discs

InactiveCN103438119AExtend your lifeAchieve torque transmissionMagnetically actuated clutchesTurbineElectromagnetic drive

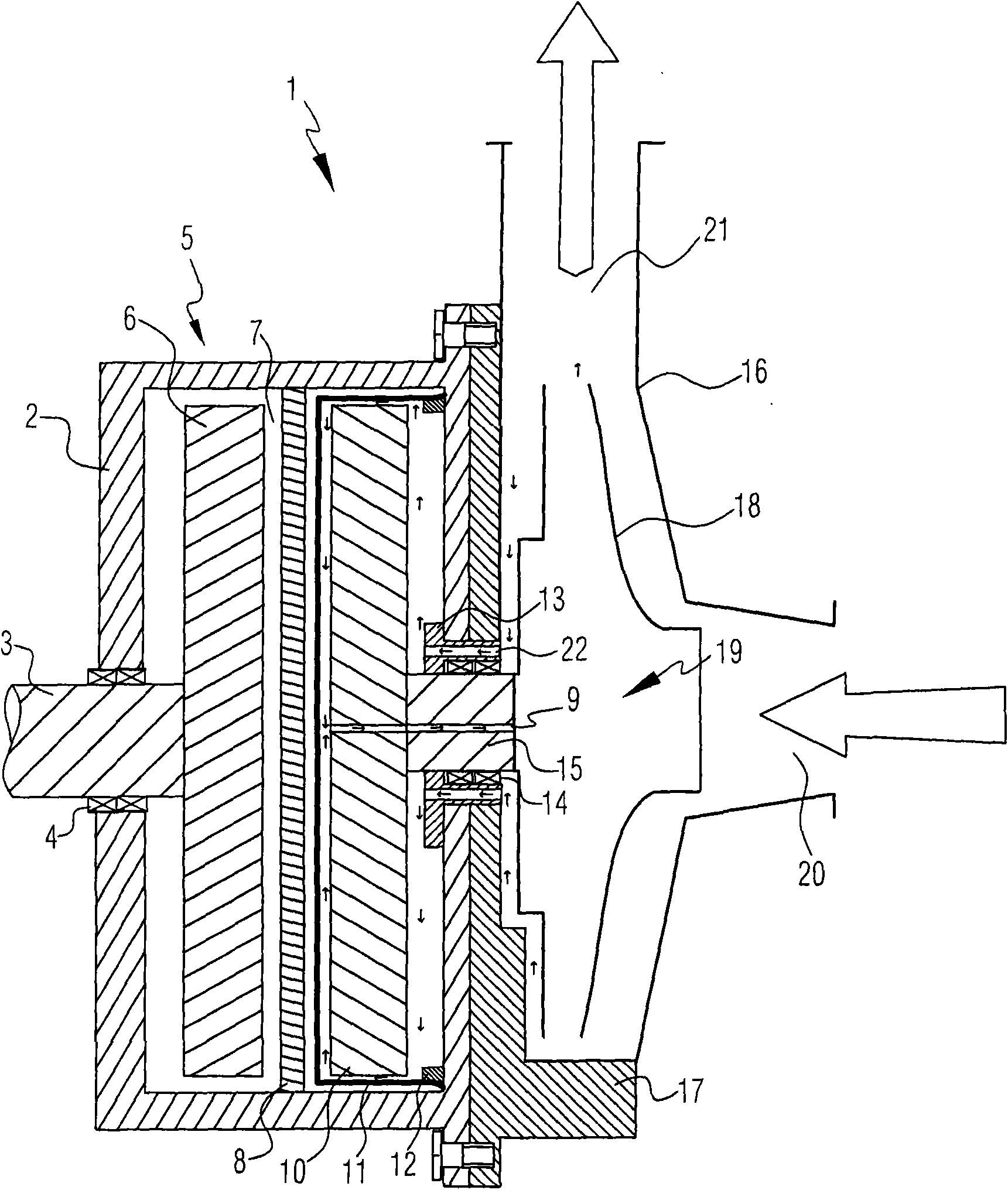

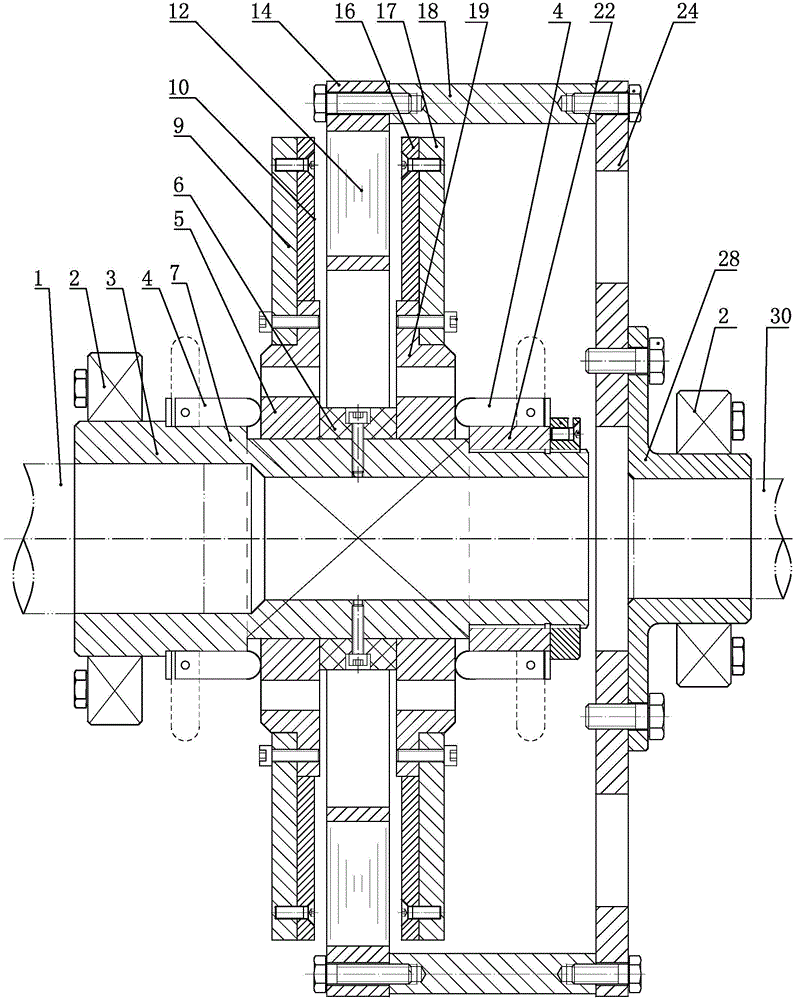

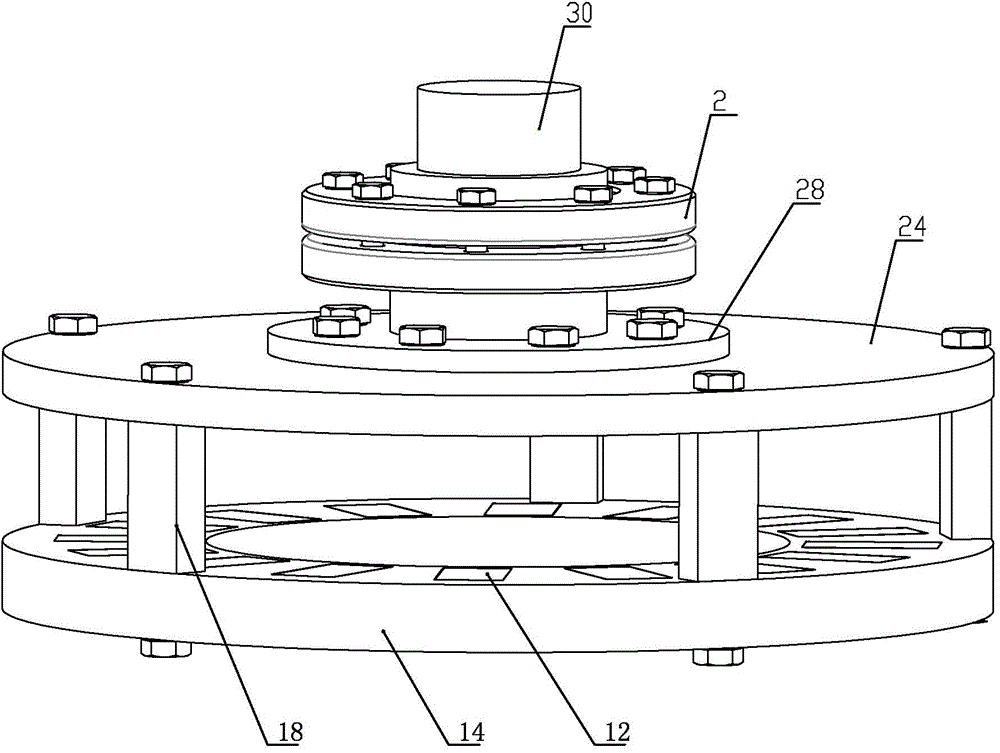

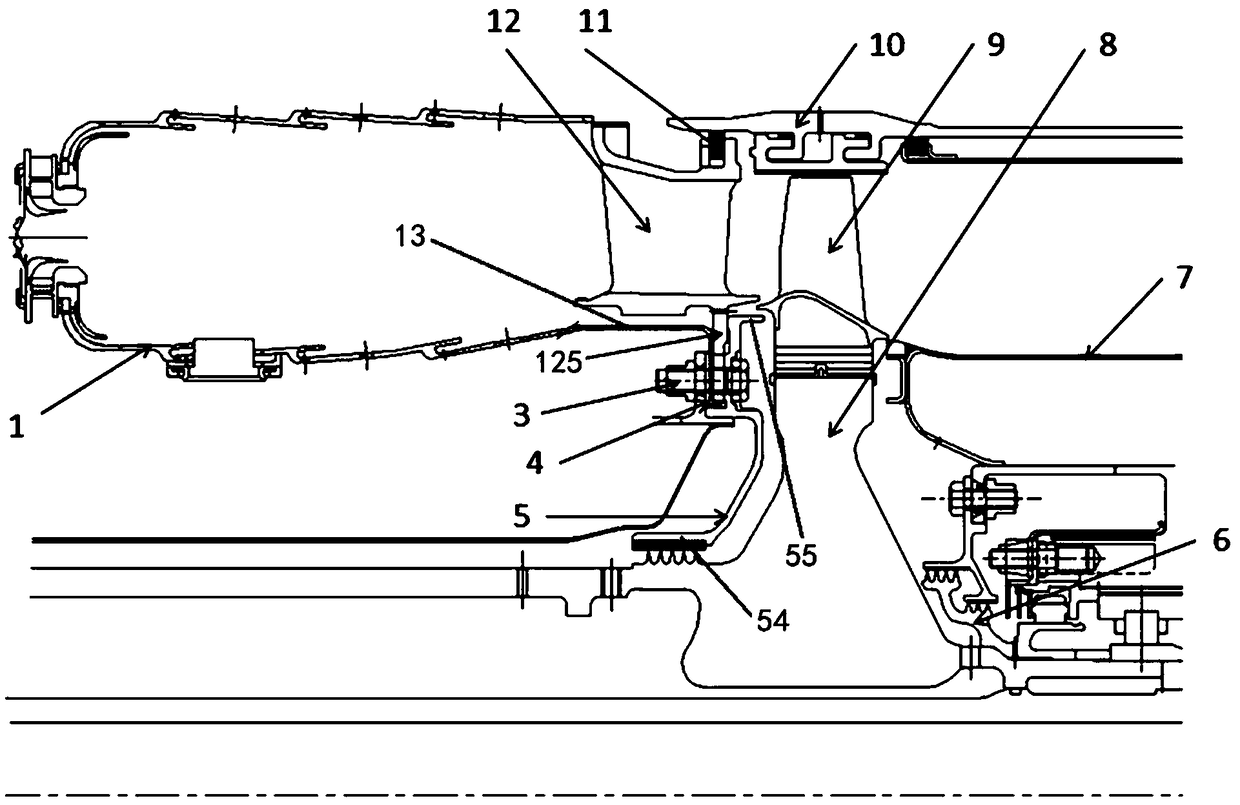

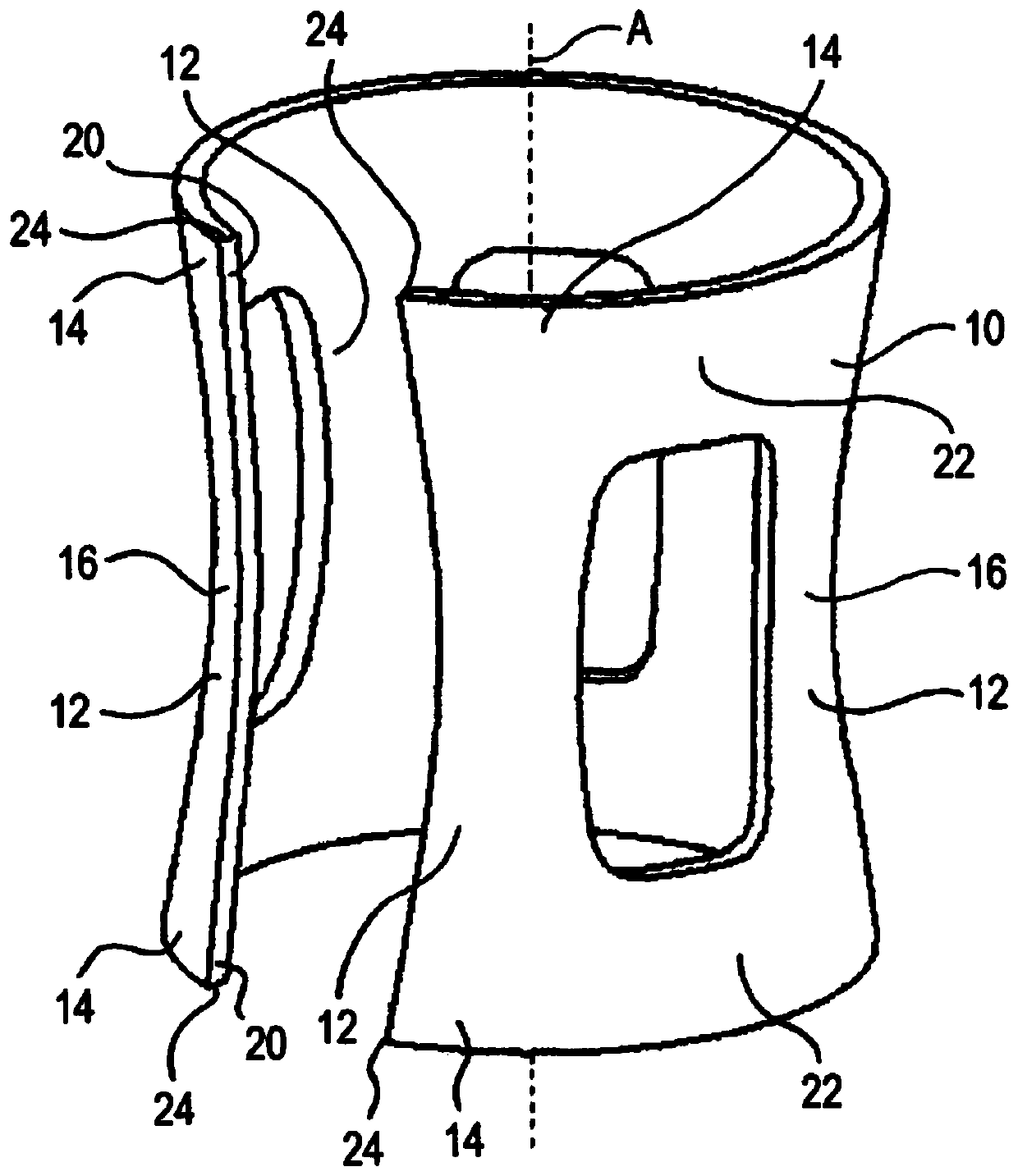

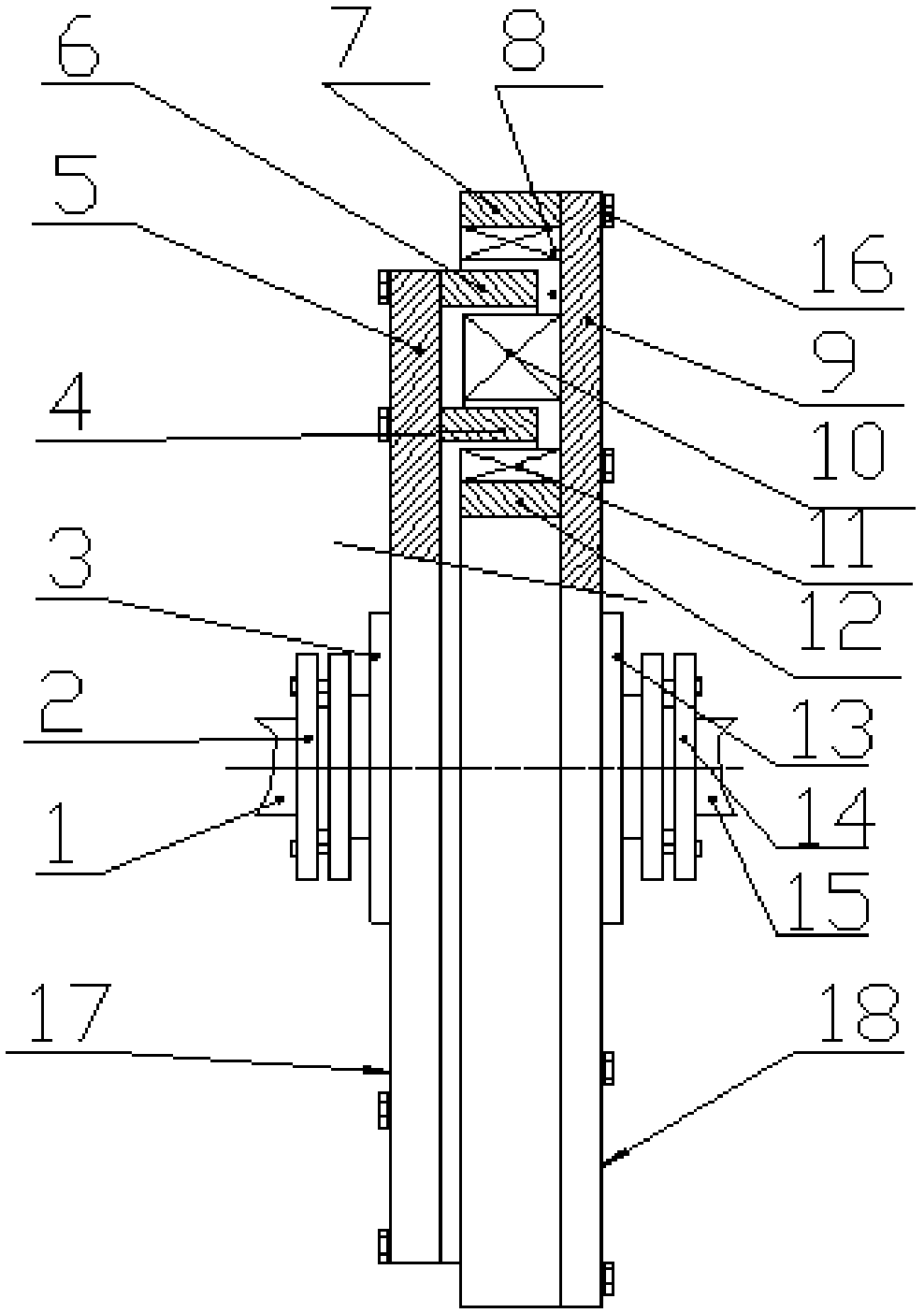

The invention relates to an inserter-connected electromagnetic drive clutch with spline shafts having discs and spline sleeves having discs. The inserter-connected electromagnetic drive clutch is stably and reliably connected with a transmission system and is temporarily and thoroughly separated from the transmission system through an input power disc (1) and an output power disc (2) by using electromagnetic drivers (4) in a manner that inserters (3) complete the torque delivery of a radial-flow turbine engine. After the radial-flow turbine engine is created, the inserter-connected electromagnetic drive clutch is a key device during use and is integrated with a rolling shaft core by using a rolling bearing so as to complete the frequently alternate operation between connection and temporary and thorough separation; according to the environmental characteristics and needs of output and input mechanisms, clutches among shafts can be of two-spline-sleeve types or two-spline-shaft types or spline shaft and spline sleeve combined types, different angles, different revolving speeds and different distances are matched by using gears so that several clutches work simultaneously, some clutches work, and some clutches do not work; at different distances, a plurality of shafts work simultaneously, some shafts work, some shafts do not work, and the shafts can be controlled simultaneously and remotely.

Owner:韩凤琳 +1

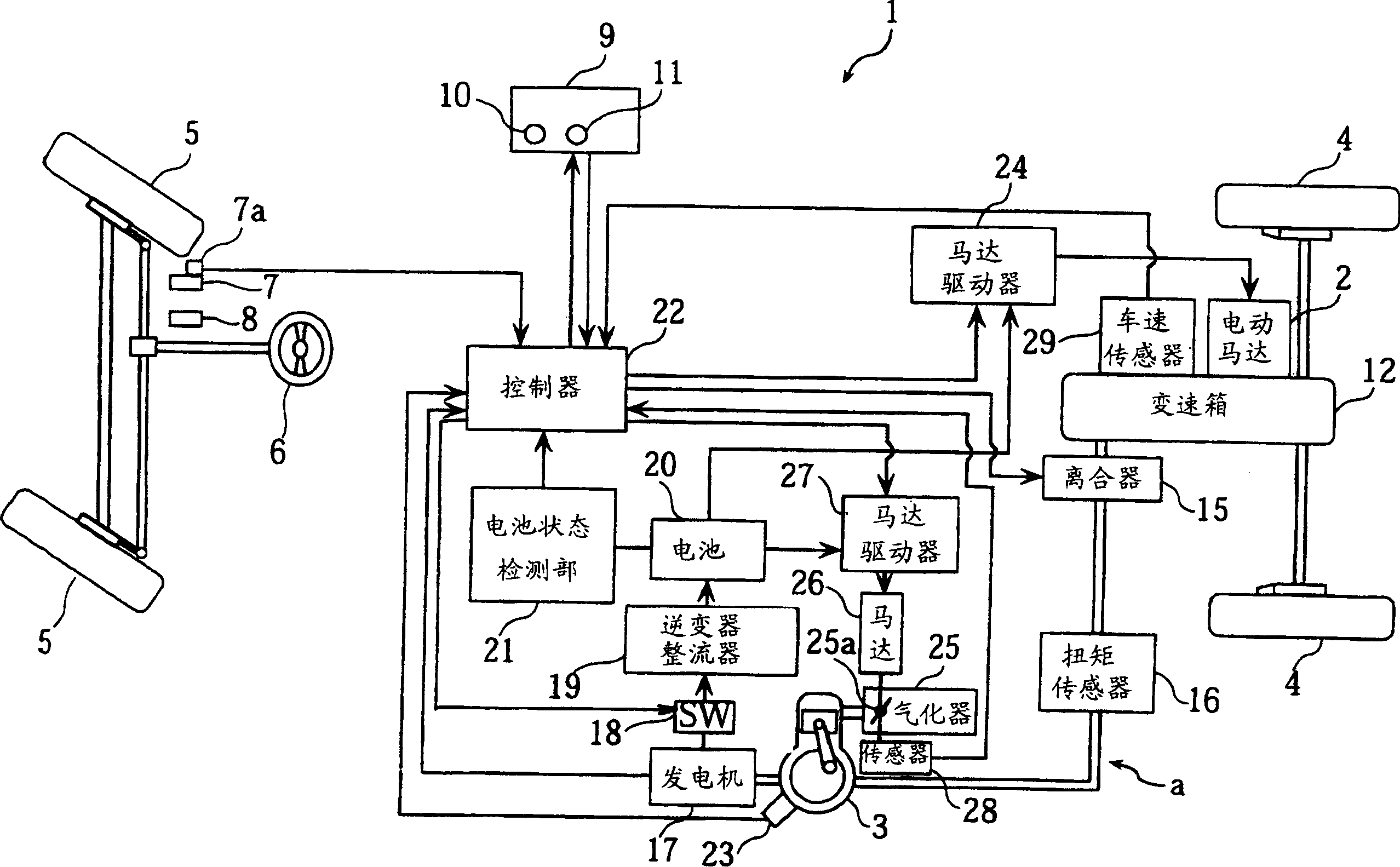

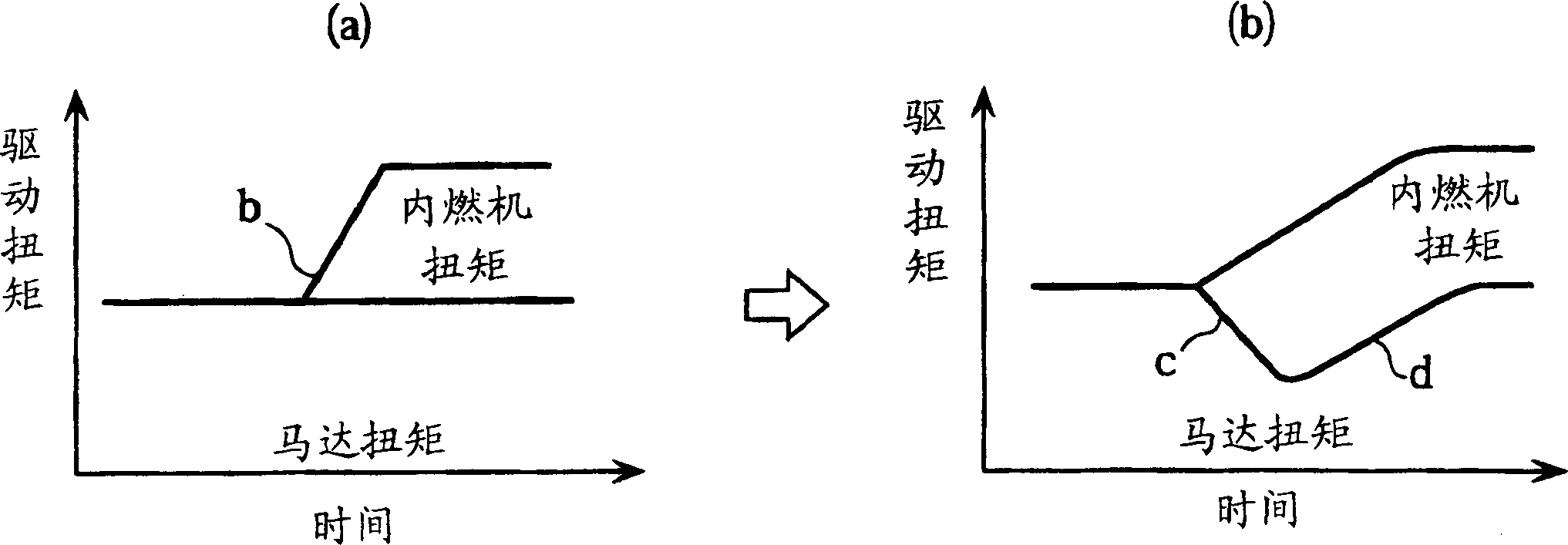

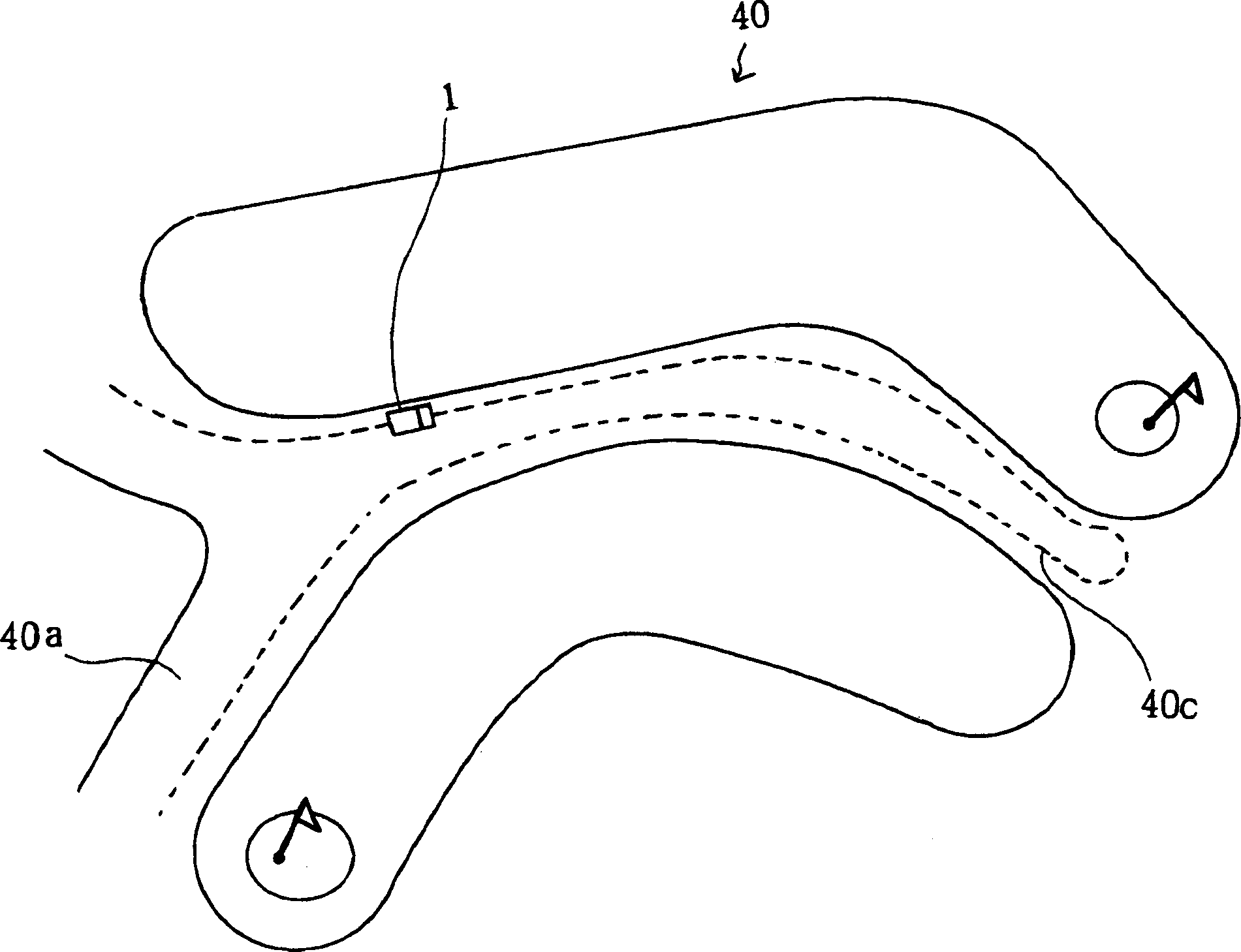

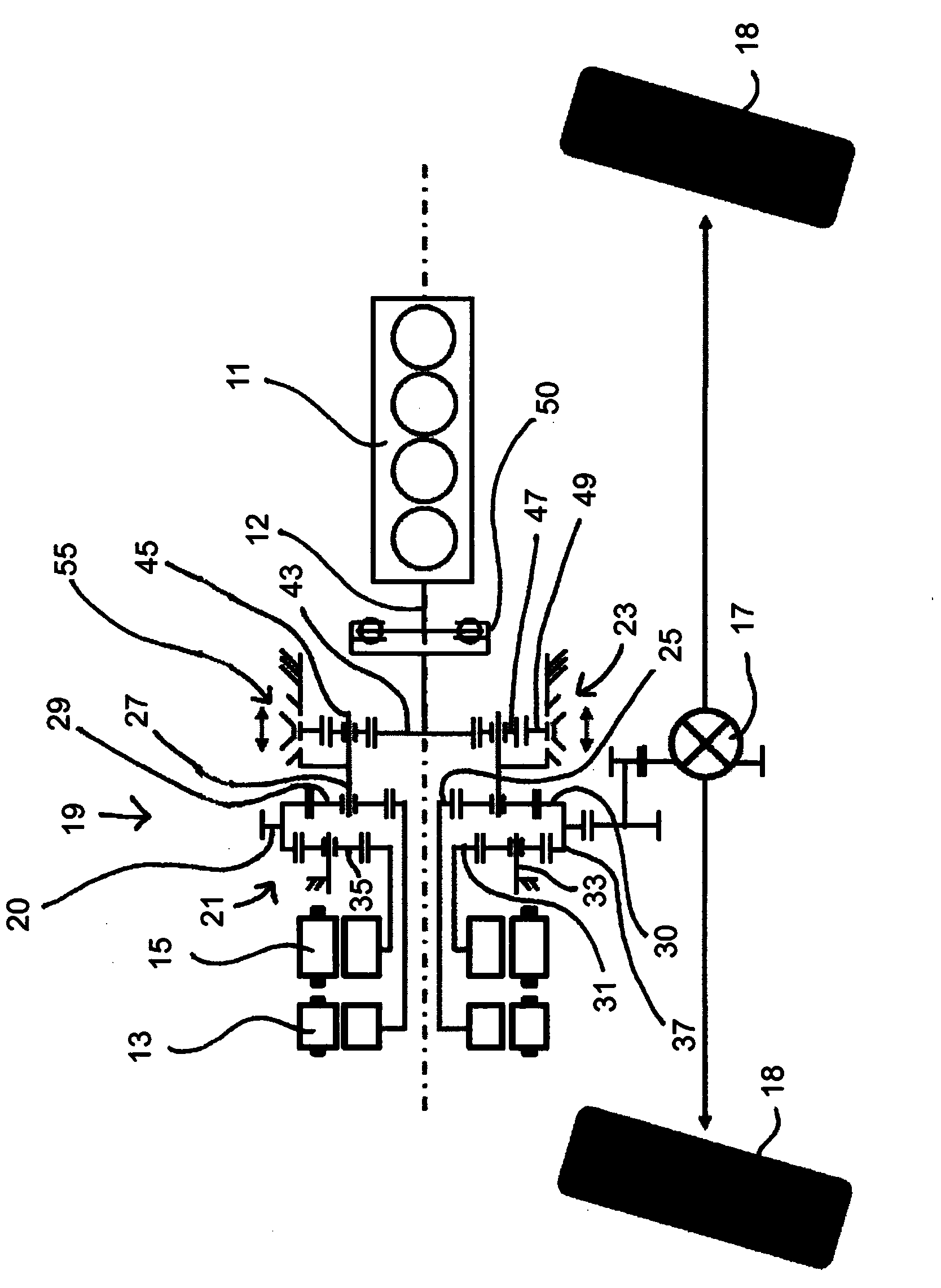

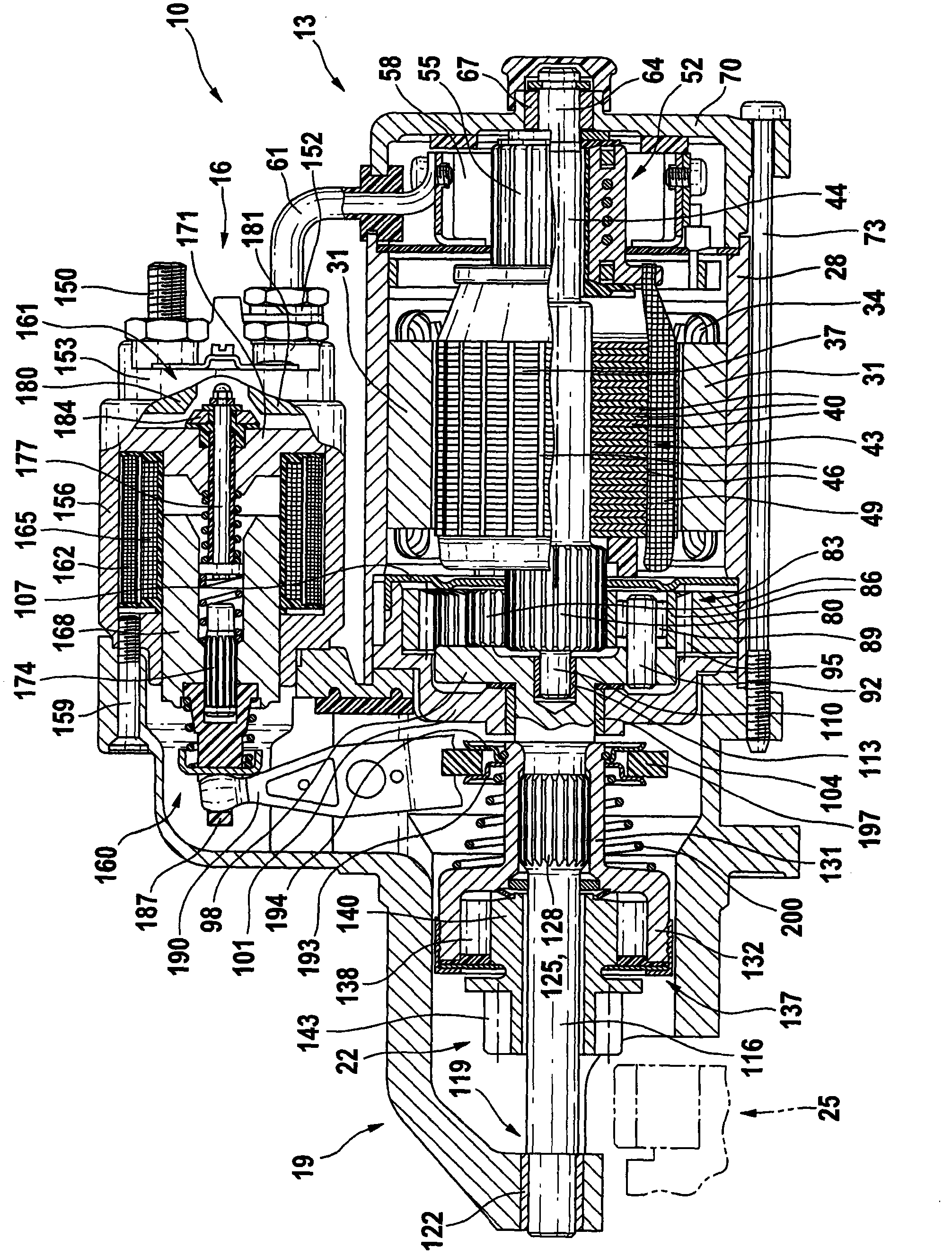

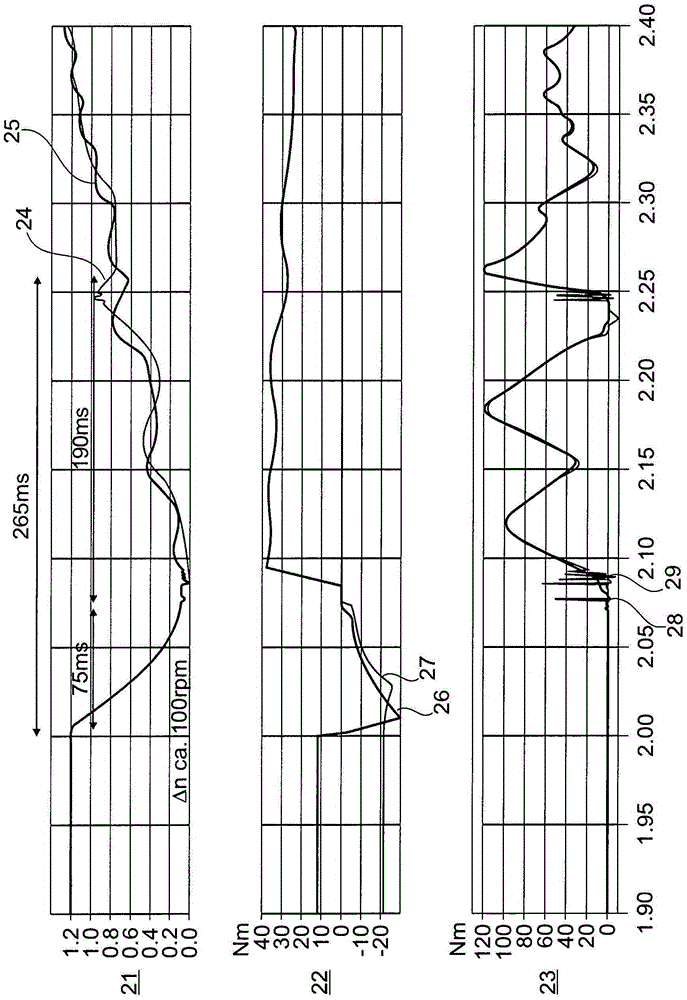

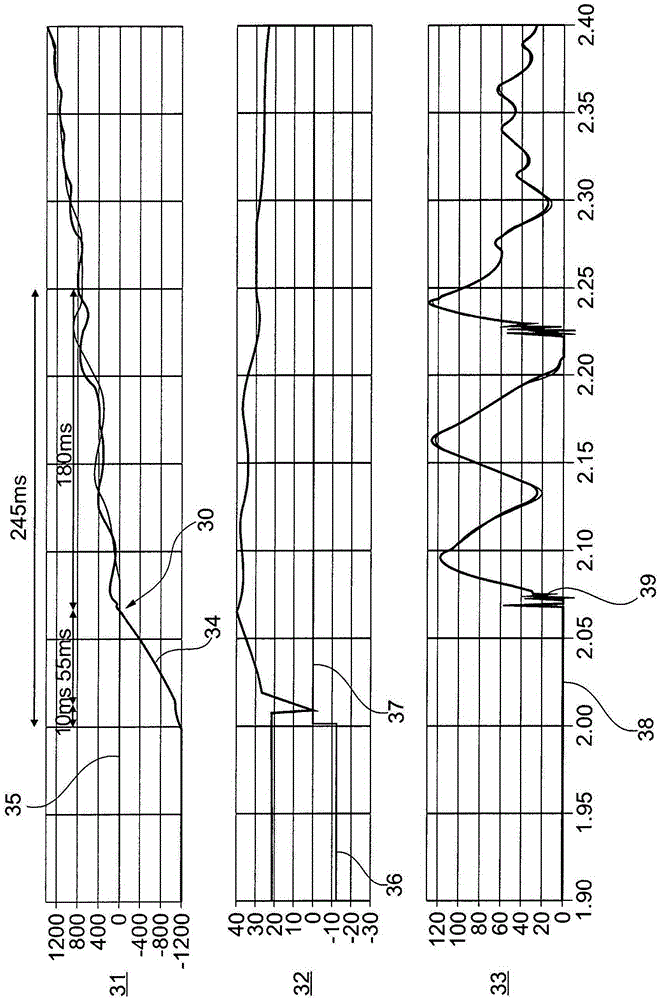

Mixed driving type vehicle running controller and vehicle thereof

InactiveCN1428256AAvoid brakingNormal state of chargeGearingRailway vehiclesDrive wheelInternal combustion engine

The invention provides a drive control device for a hybrid vehicle capable of reducing the discomfort of an occupant by releasing a shock in applying the driving force of an internal combustion engine. In the drive control device for a hybrid vehicle including an electric motor (2) and an internal combustion engine (3), when a load is less than a predetermined reference value, the drive wheels are driven only by driving force of the electric motor (2); when the load is the reference value or more, the drive wheels are driven by driving force of both the electric motor (2) and the internal combustion engine (3). A drive force detecting sensor (16) for detecting the drive force is arranged in midway of a drive force transmission system from the internal combustion engine (3) to the drive wheel (4). During the drive wheels are driven by driving force of both the electric motor (2) and the internal combustion engine (3), the controller preferably controls the electric motor to reduce the drive force provided by the electric motor when the drive force detected by the drive force detecting sensor (16) changes to a rising direction based on a rate of change over a predetermined reference value.

Owner:YAMAHA MOTOR CO LTD

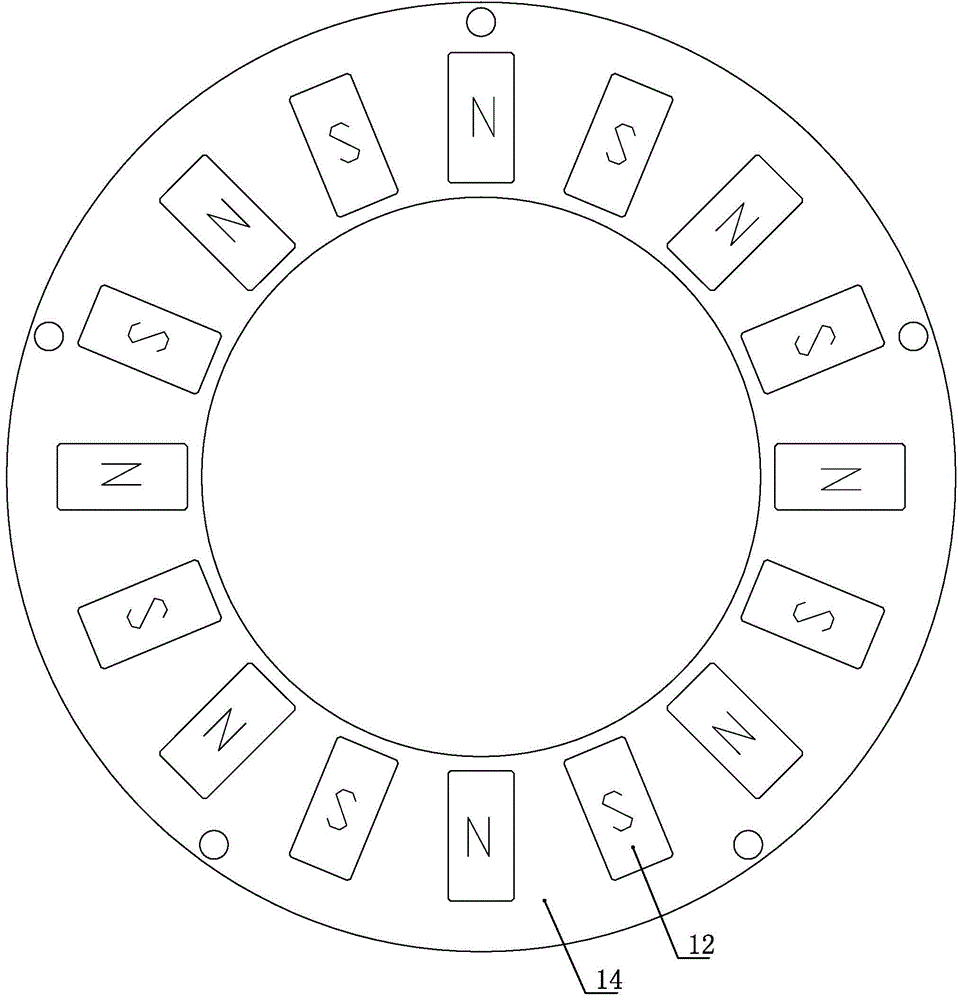

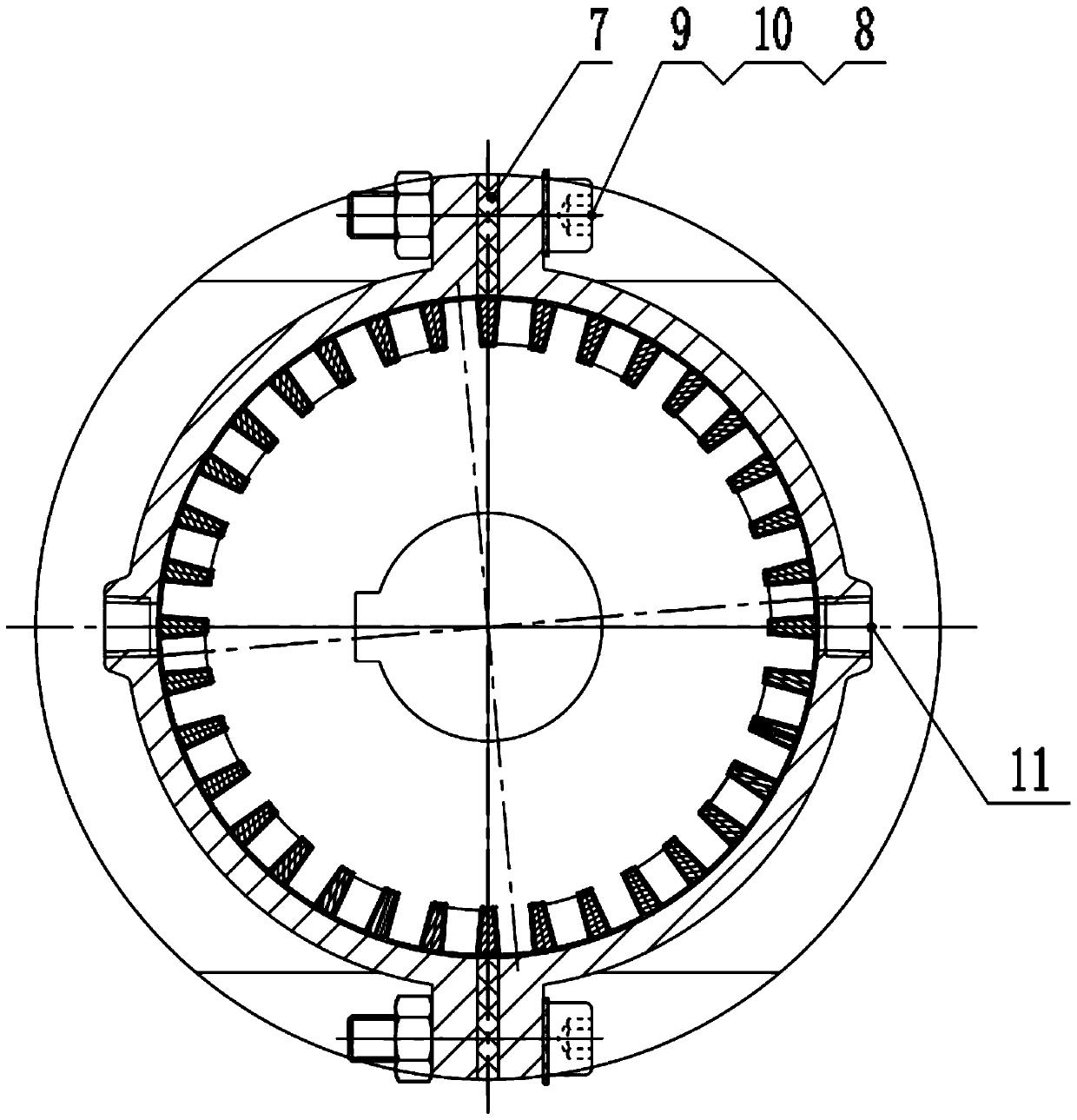

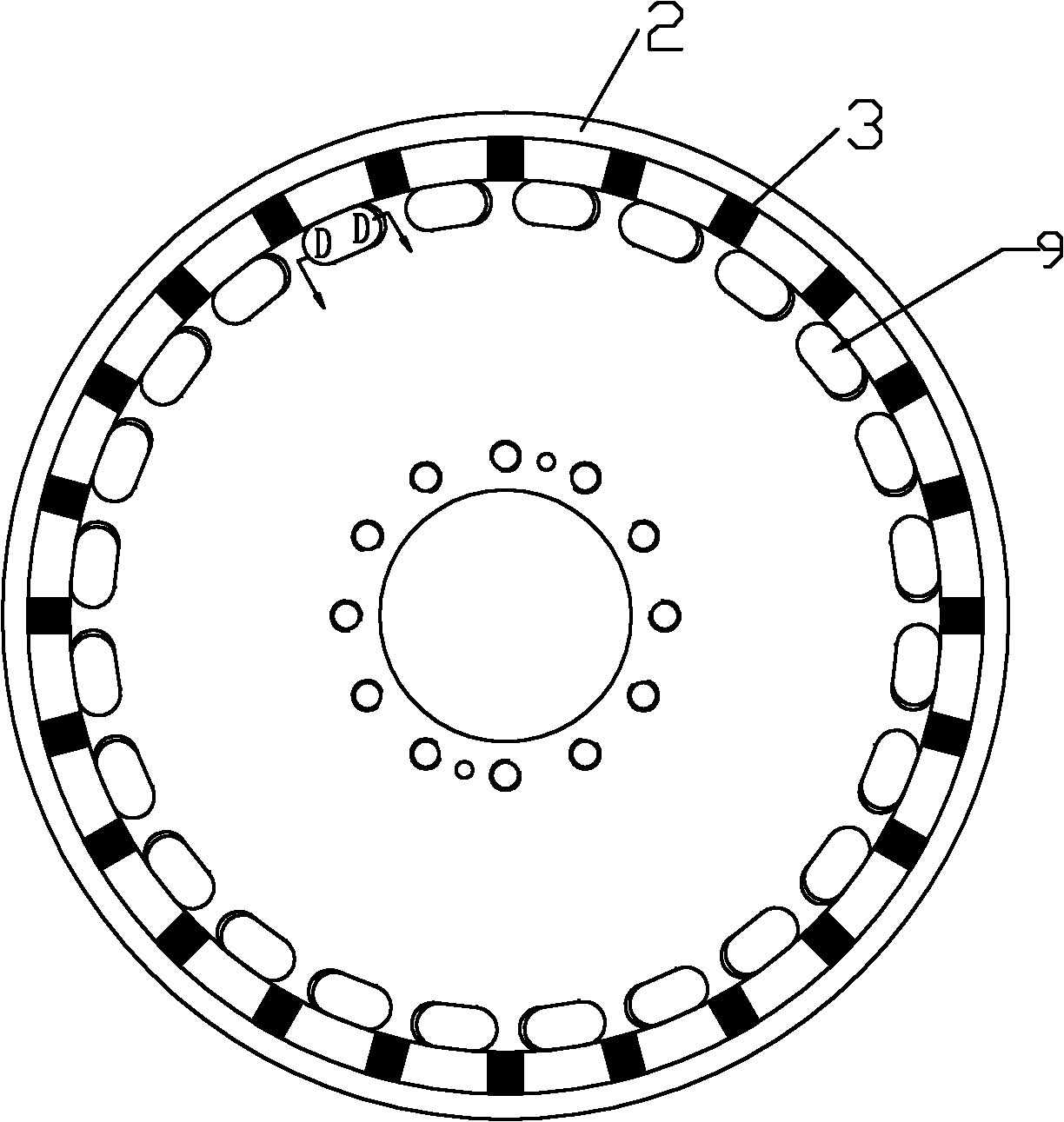

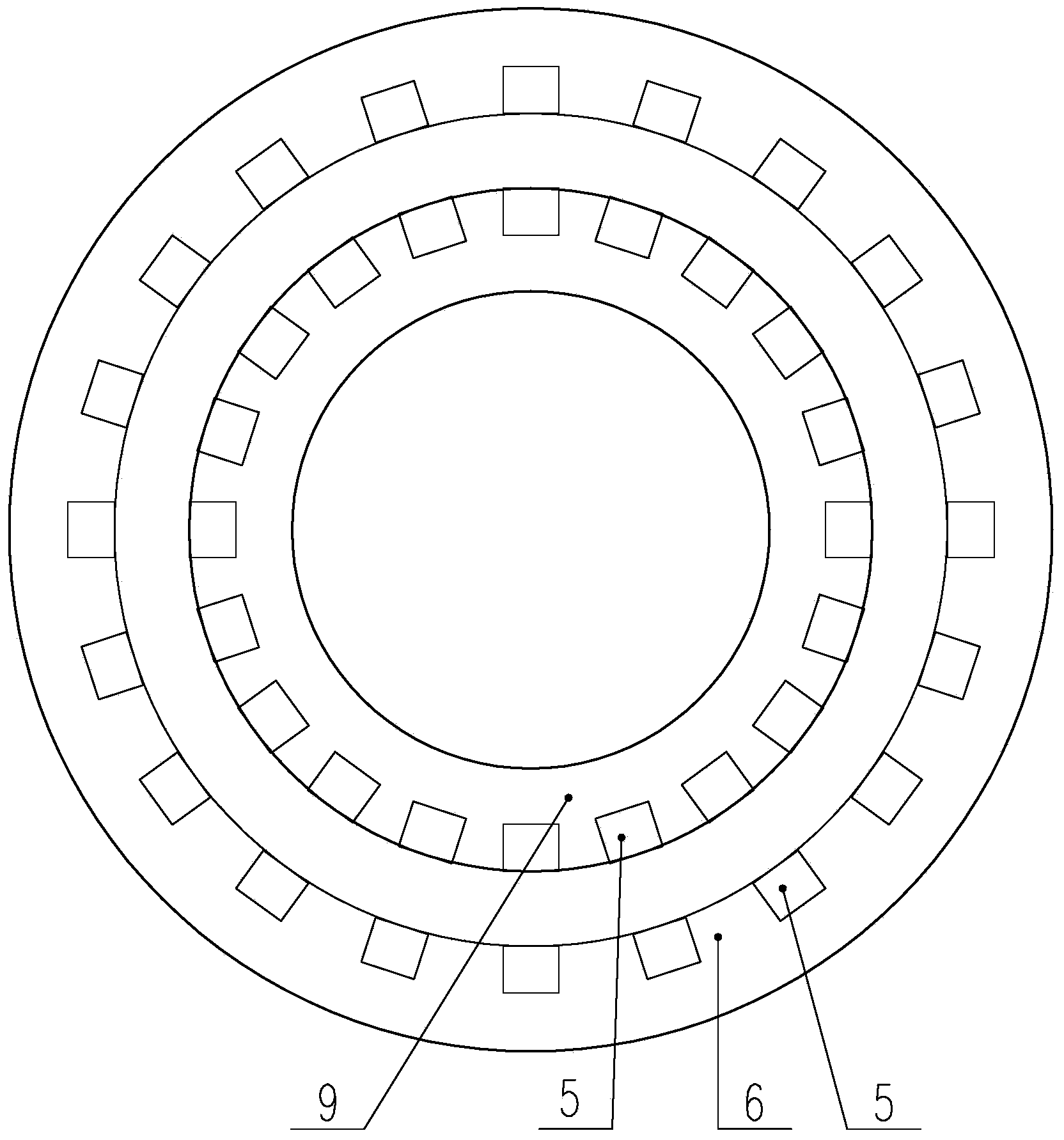

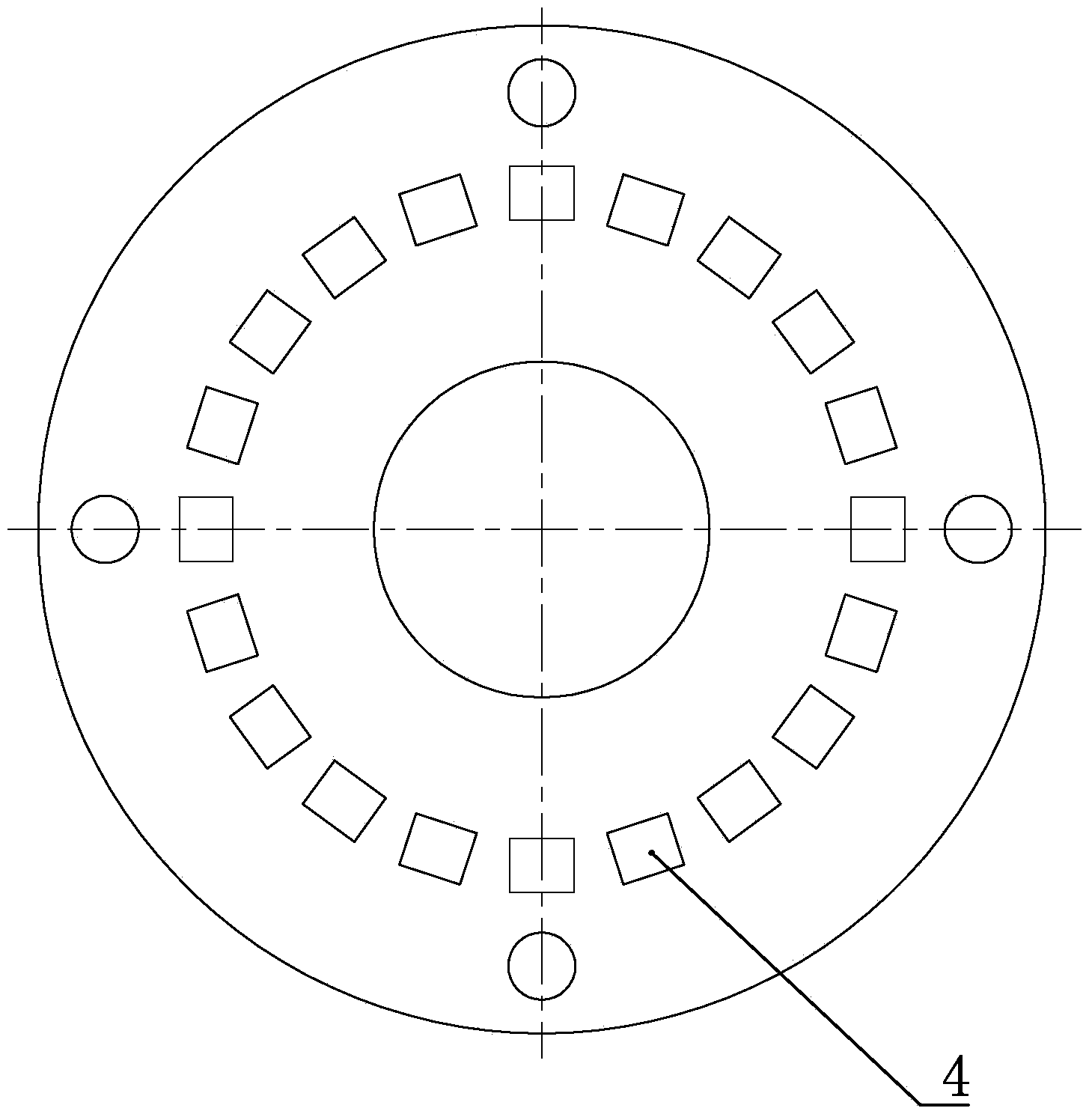

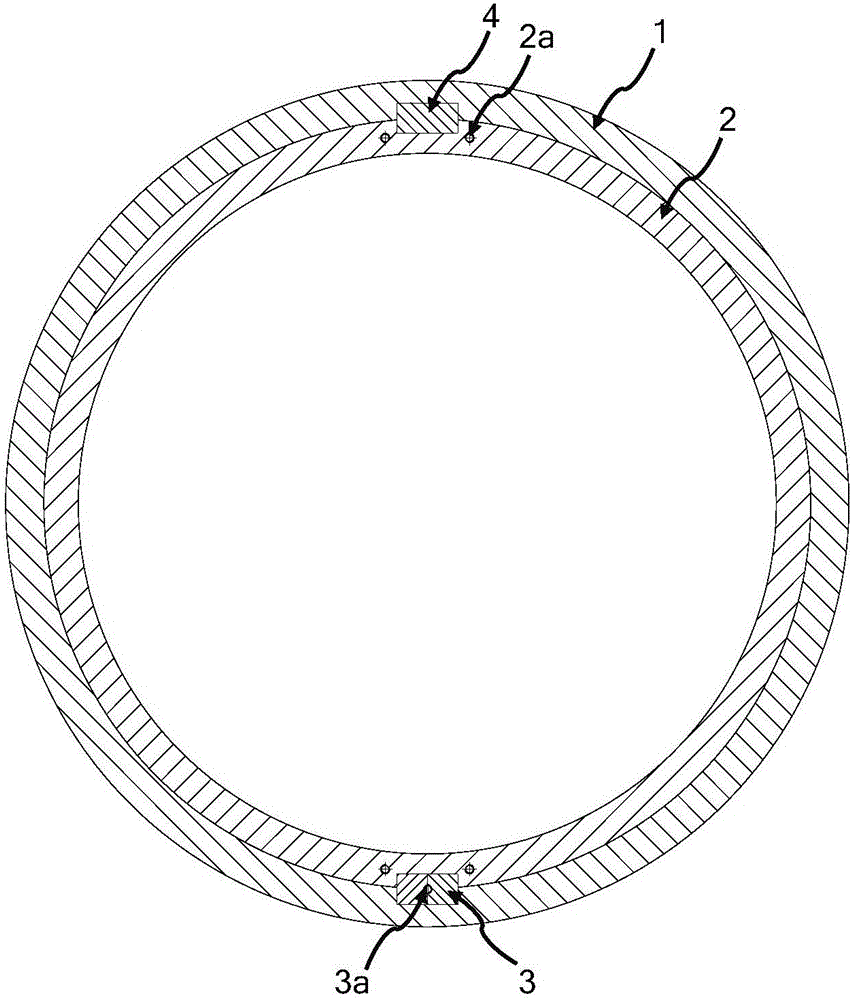

Magnetic field modulation type magnetic gear

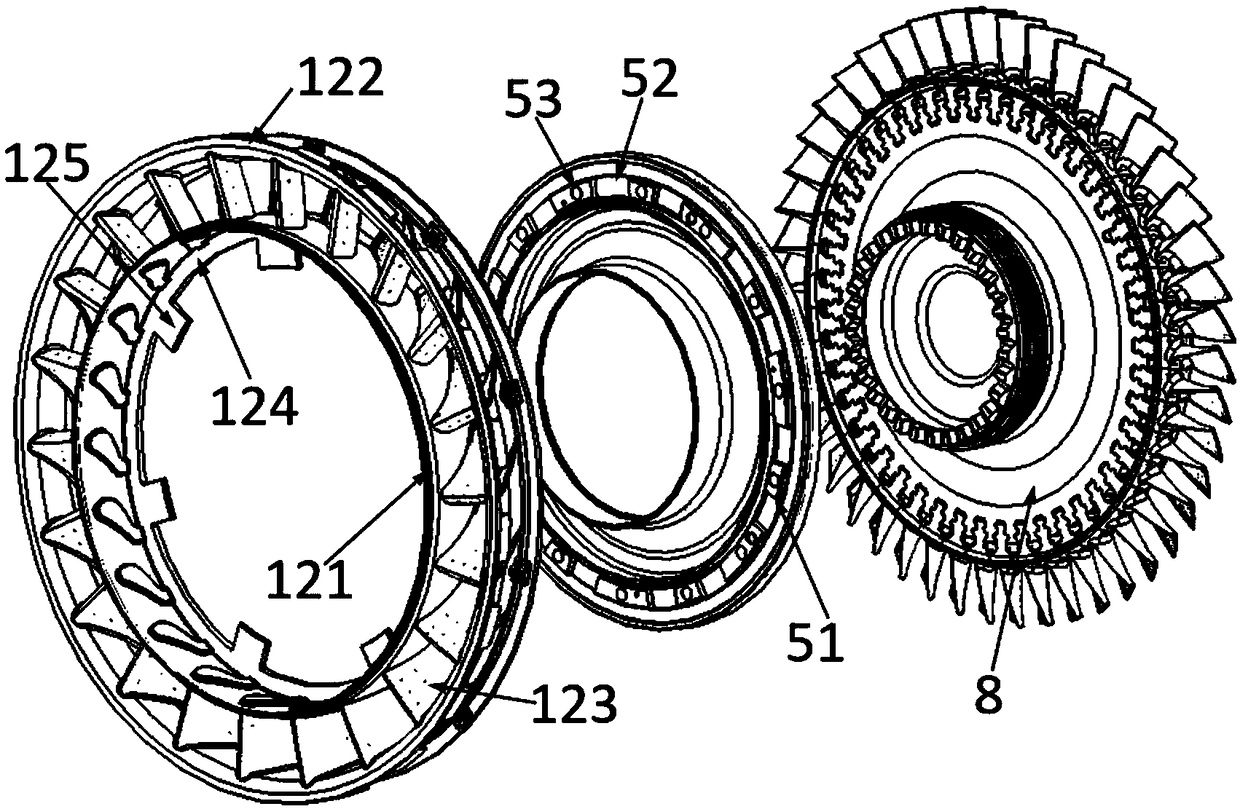

ActiveCN102195442AAchieve torque transmissionHigh mechanical strengthDynamo-electric gearsNon magneticMagnetic loop

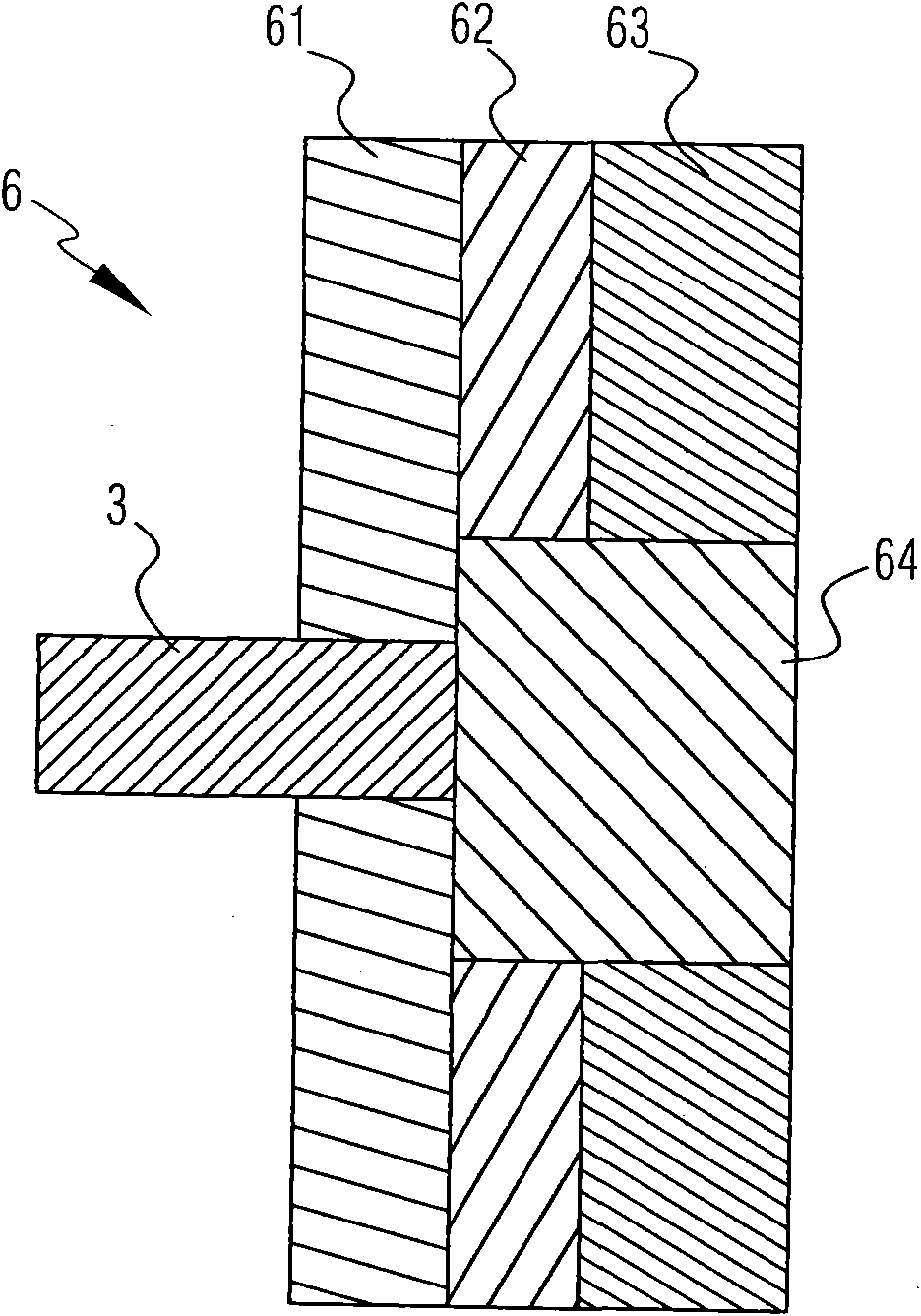

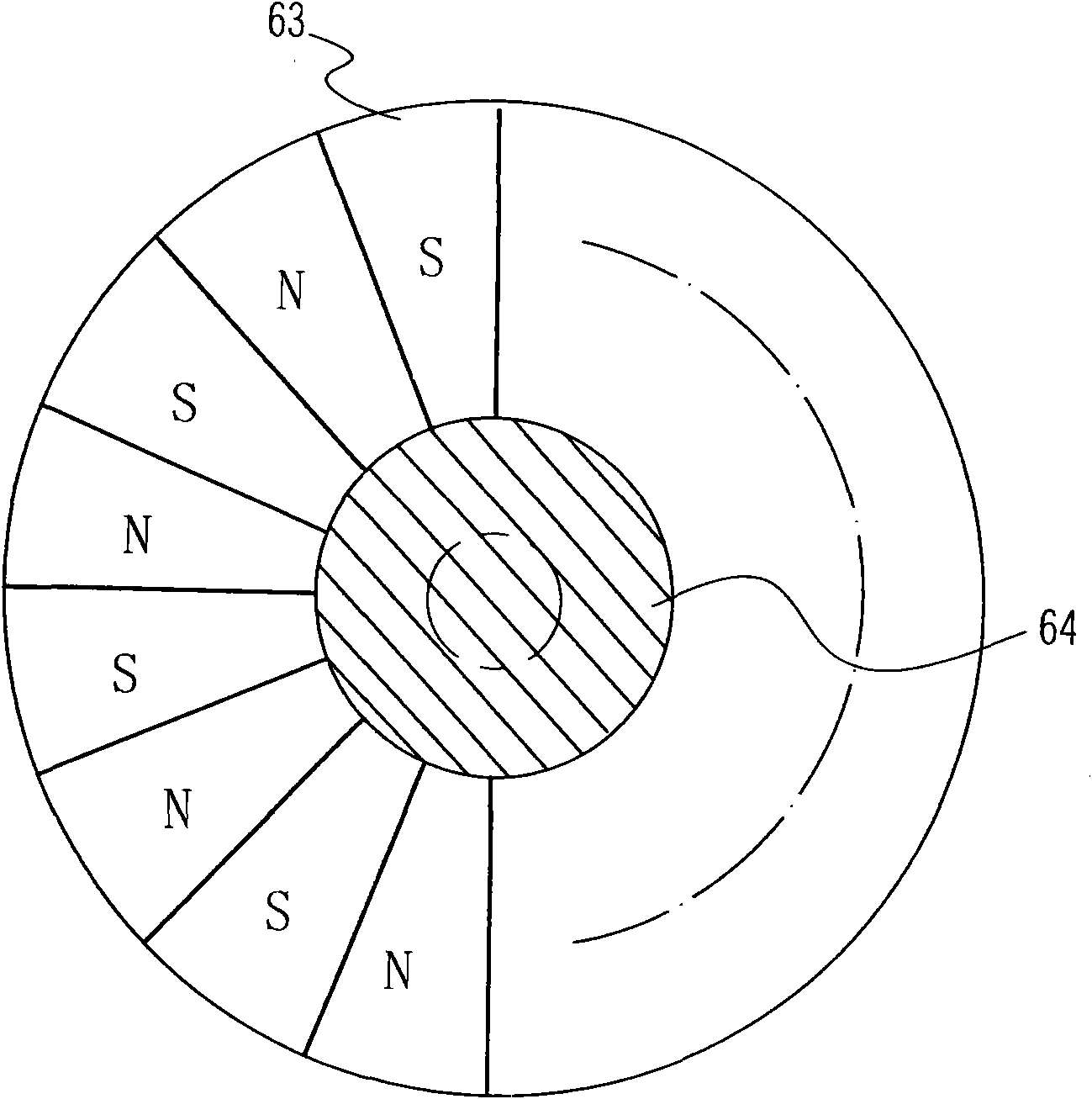

The invention discloses a magnetic field modulation type magnetic gear which is characterized by comprising an outer stator and an inner rotor, wherein an annular cavity is formed between the outer stator and the inner rotor, an adjustable magnet ring is arranged in the annular cavity, the outer stator consists of an outer stator iron core and 2N2 permanent magnets, and the polarities of the adjacent permanent magnets are opposite; the inner rotor consists of an inner rotor iron core and 2N1 permanent magnets, and the polarities of the adjacent permanent magnets are opposite; the inner rotor and the outer stator are connected through an output shaft; and the adjustable magnet ring is formed by arranging N1+N2 iron core blocks and N1+N2 non magnetic-conducting blocks into a ring shape in astaggered mode, and the adjustable magnet ring is connected with the output shaft of the adjustable magnet ring. Compared with the prior art, the magnetic gear provided by the invention has the following obvious protrude substantiality characteristic and outstanding advantages: the mechanical strength is increased, the volume is reduced, and the torque ripple is optimized.

Owner:NINGBO TIANAN MAGNETIC TRANSMISSION TECH CO LTD

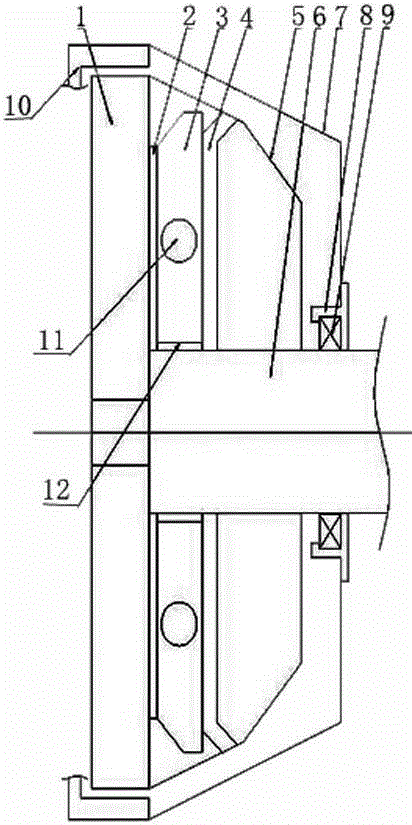

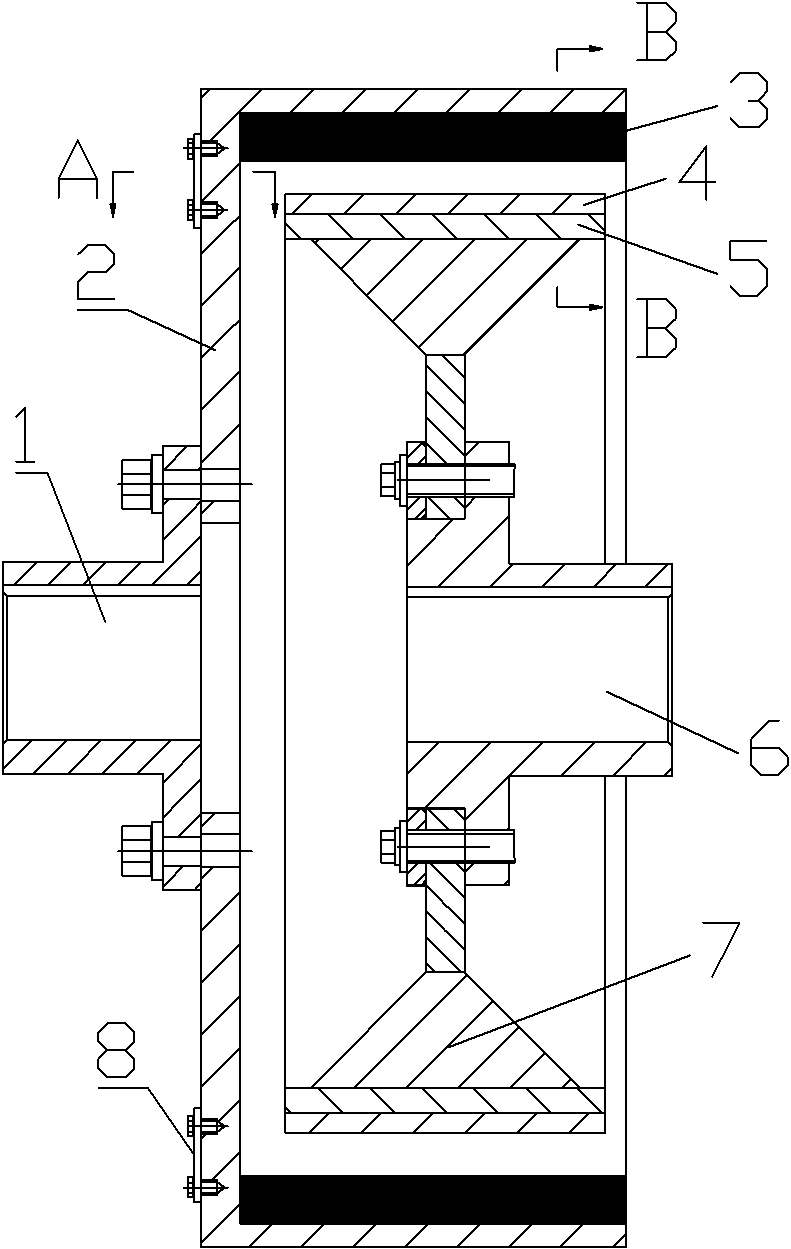

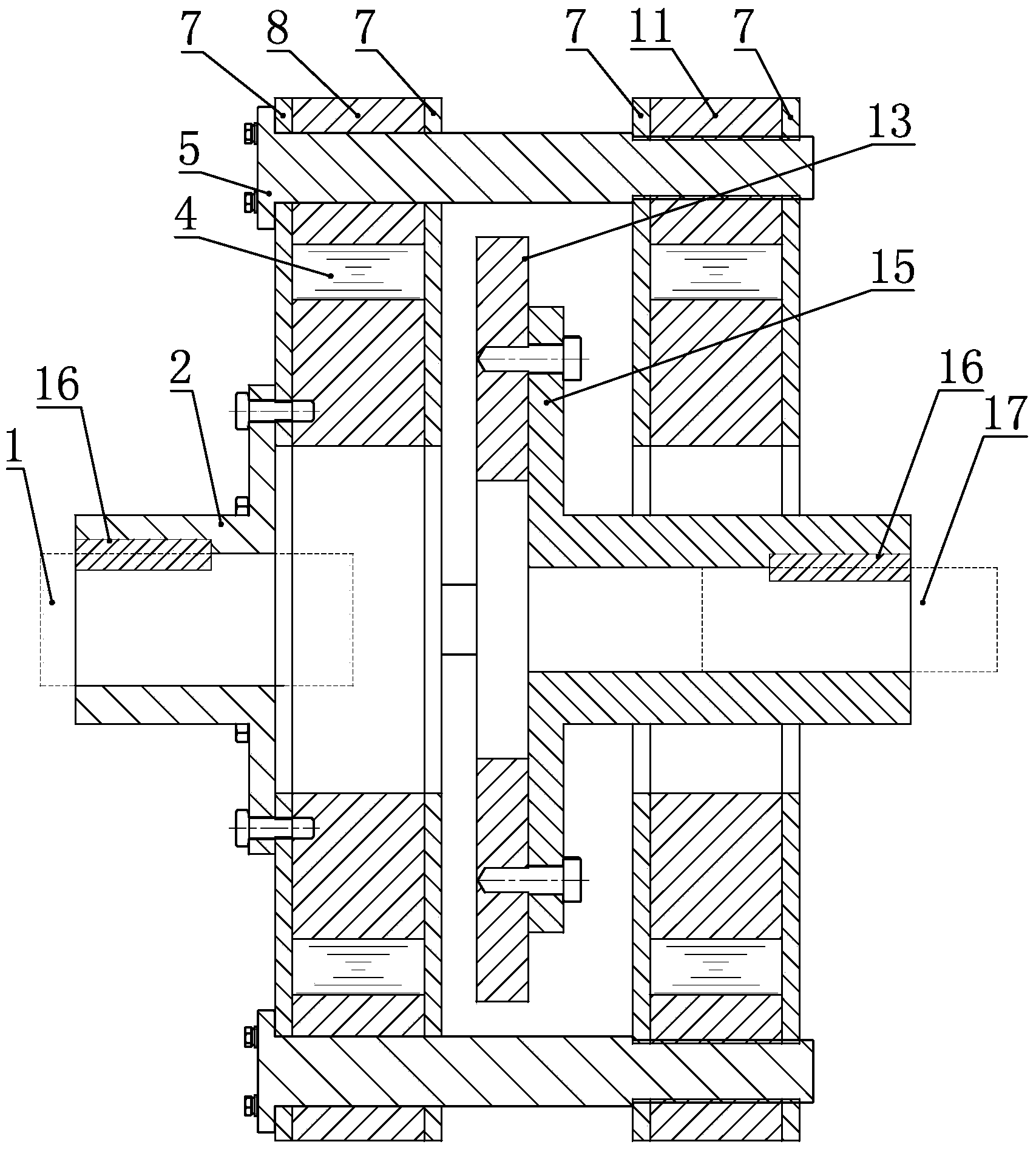

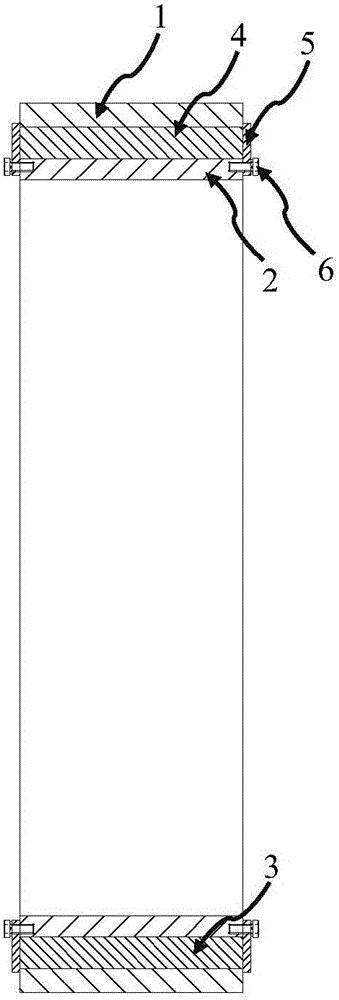

Internal radiation ring type static speed-adjusting permanent magnetic coupling

InactiveCN103346659AReduce capacityLarge centering errorEmergency protective circuit arrangementsDynamo-electric gearsMagnetic tension forceElectrical conductor

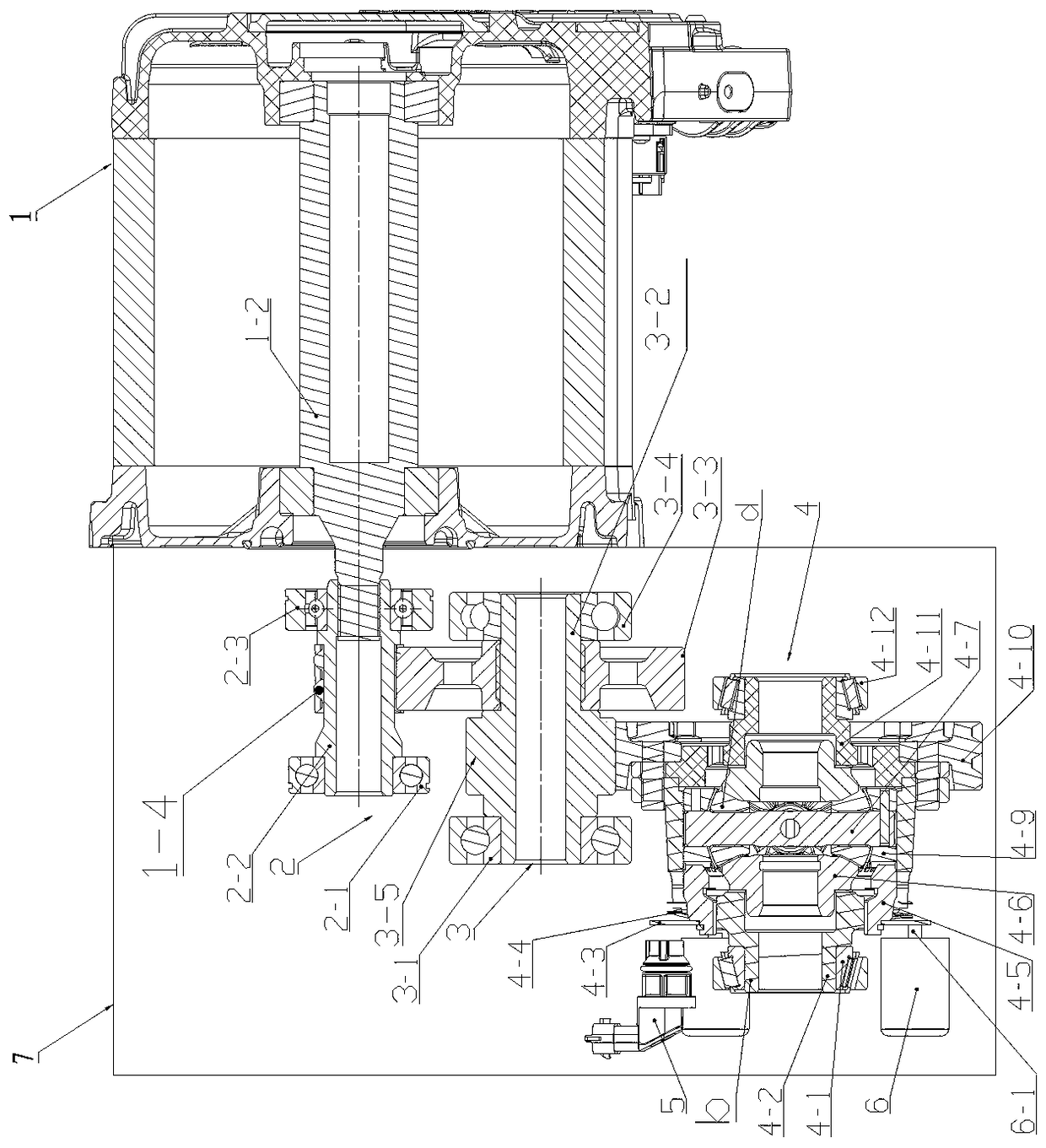

Provided is an internal radiation ring type static speed-adjusting permanent magnetic coupling. The internal radiation ring type static speed-adjusting permanent magnetic coupling is composed of a conductor outer rotor I, a permanent magnetic inner rotor II and a gearing face adjusting mechanism III, wherein the conductor outer rotor I is connected with a motor shaft (17) and a motor shaft key strip (18) through a motor shaft expansion sleeve to lead in motor power, the permanent magnetic inner rotor II is connected with a bearing shaft (19) and a bearing shaft key strip (20) through a bearing shaft expansion sleeve to output torque, and the gearing face adjusting mechanism III is adjusted in a manual mode to change the gearing area between the conductor outer rotor I and the permanent magnetic inner rotor II in a stationary state. The internal radiation ring type static speed-adjusting permanent magnetic coupling is characterized in that the conductor outer rotor I carries out high-speed rotation on an outer copper ring in a single circular ring inductor of the conductor outer rotor I so as to carry out radial fixation and air gap cutting on a magnetic force line of an internal radiation type integral magnetic ring of the permanent magnetic inner rotor II to produce eddy current on the outer copper ring, meanwhile, the eddy current produces an induced magnetic field, and the induced magnetic field and a permanent magnetic field are in interaction to achieve power connectionless transmission. Meanwhile, a high-efficiency heat dissipation device is used for reducing the temperature of the outer copper ring and the temperature of the internal radiation type integral magnetic ring, and stable operation of system magnetic force is ensured.

Owner:宝鸡泰华磁机电技术研究所有限公司

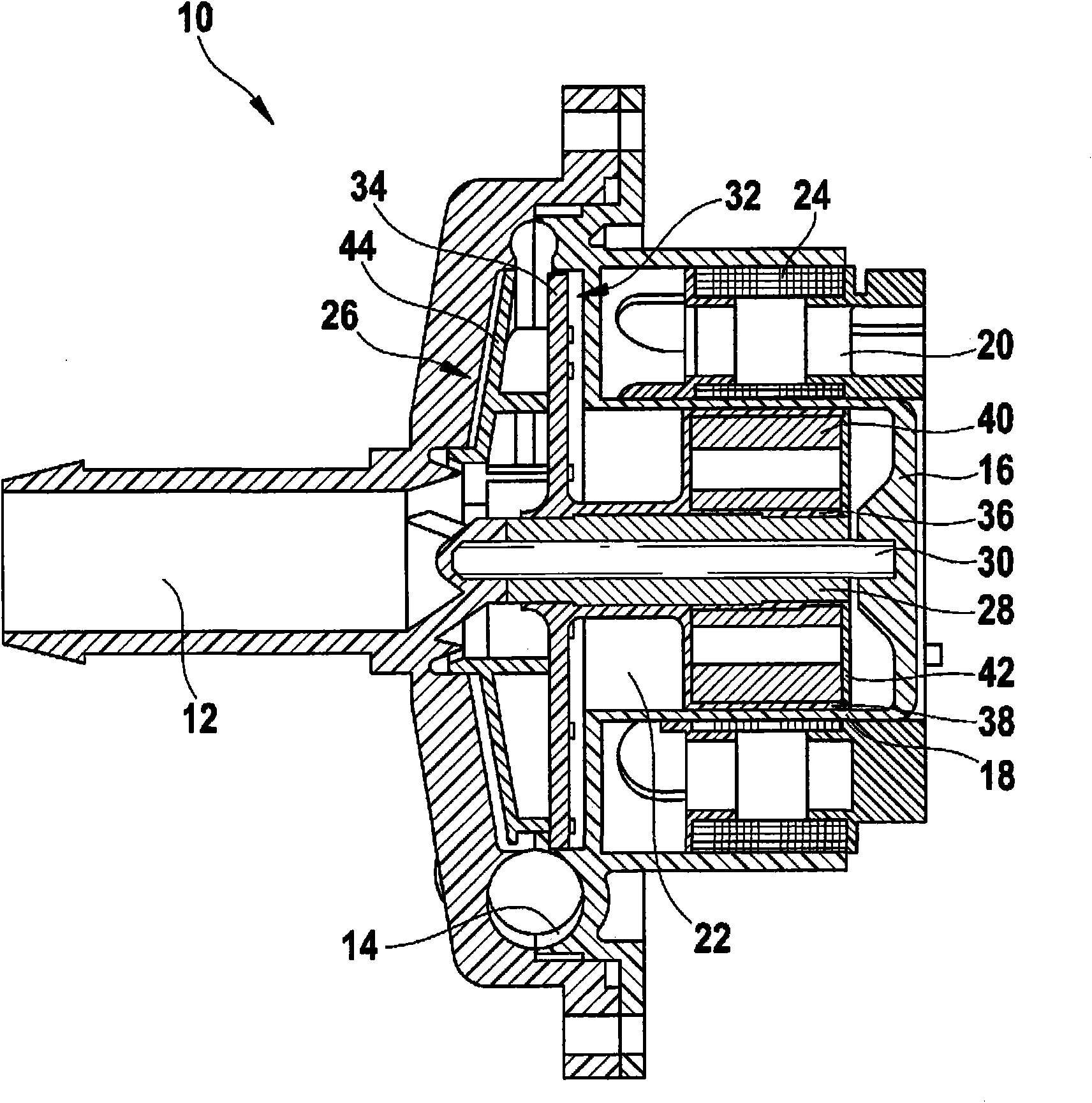

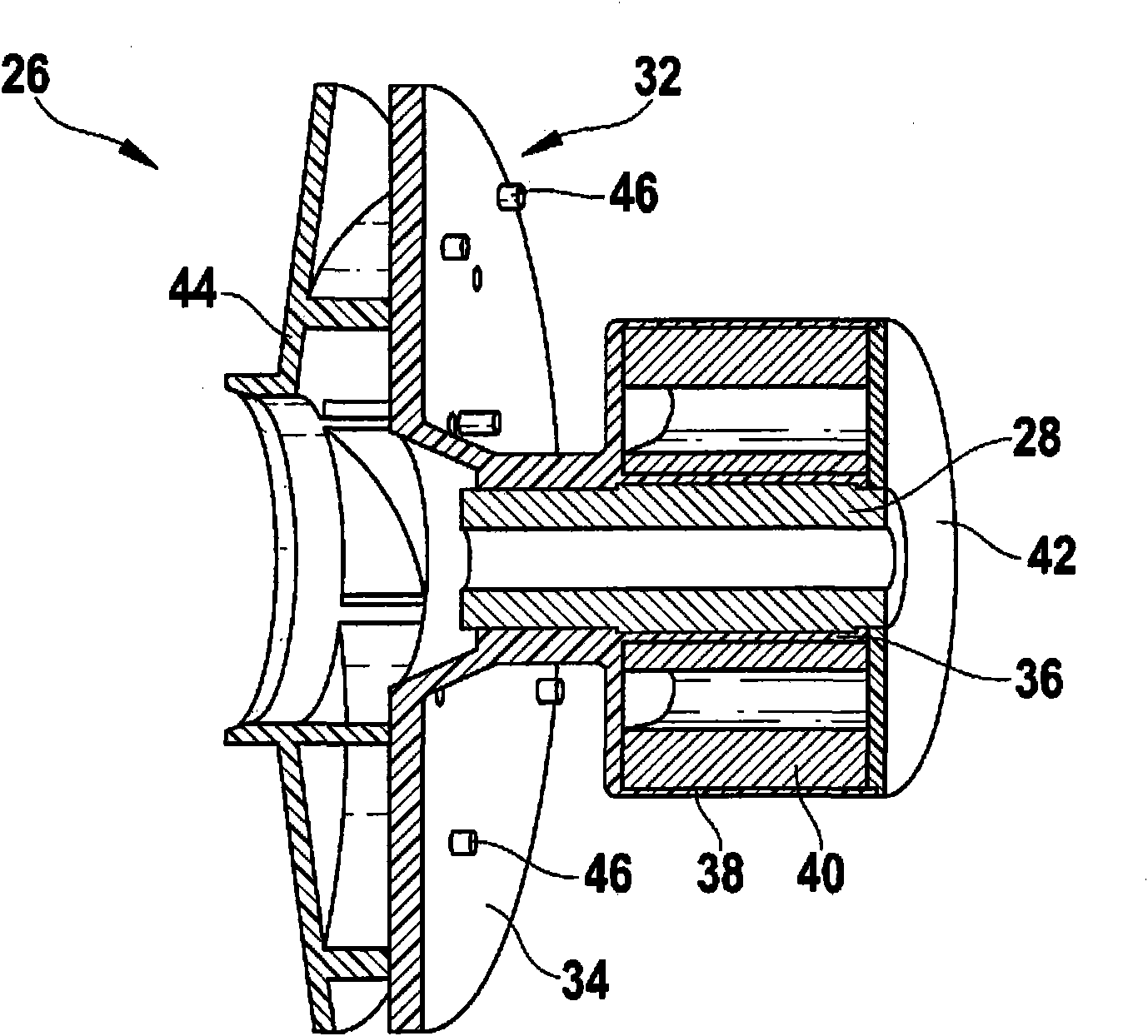

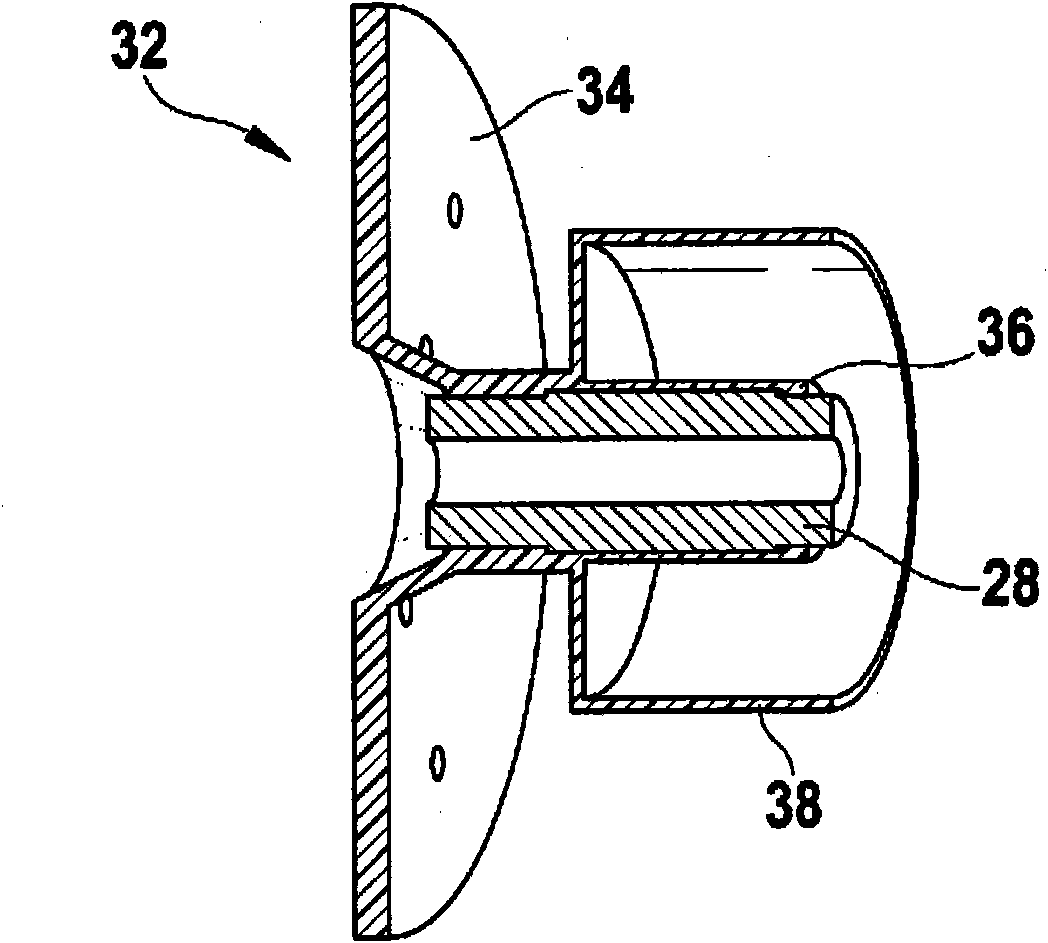

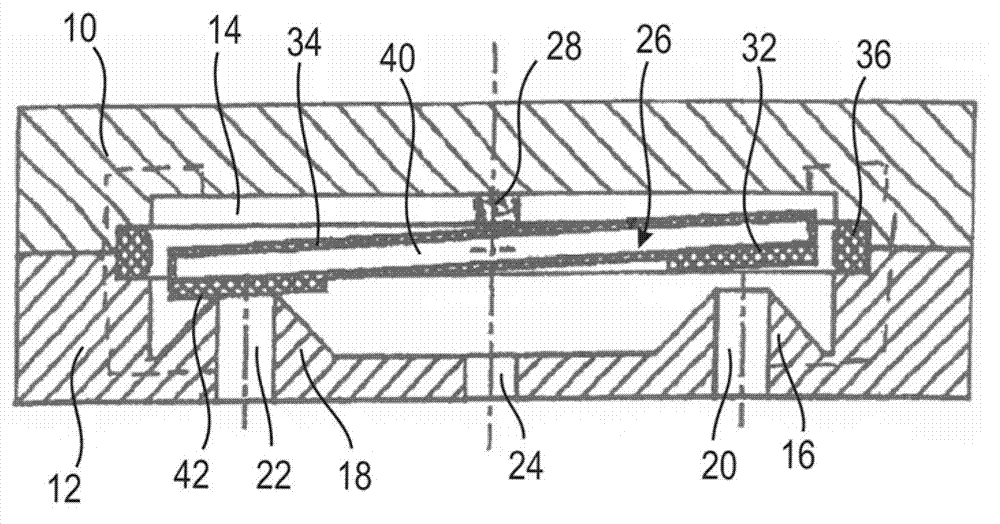

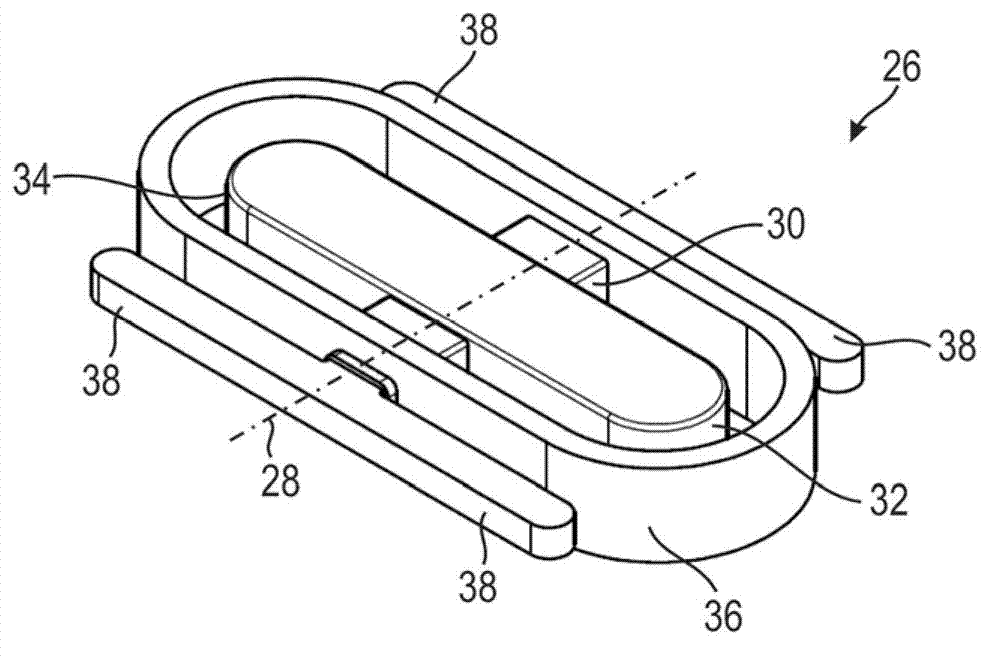

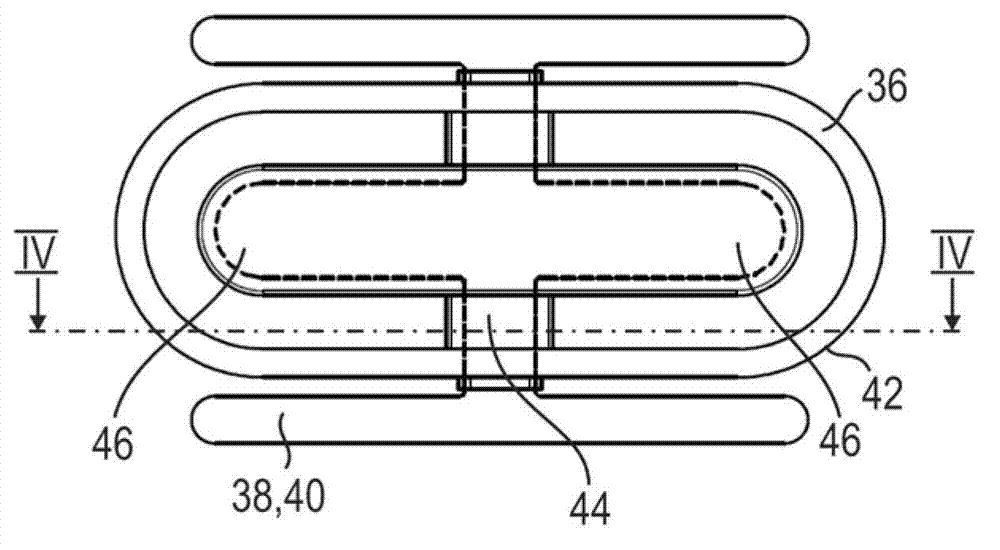

Pump rotor for a canned motor pump

InactiveCN101802411ASmall imbalanceSmall quality deviationPump componentsPump installationsImpellerRotor magnets

The invention relates to a pump rotor (26) for a canned motor pump. The pump rotor (26) comprises a base body (32) designed in one piece, with an impeller base disk (34) and a rotor holder bushing (36) and a rotor unit (40) with rotor magnets that are arranged on the rotor holder bushing (36).

Owner:ROBERT BOSCH GMBH

Gearbox unit

InactiveCN103402804AGuaranteed uptimeAchieve torque transmissionHybrid vehiclesToothed gearingsCombustionCoupling

The invention relates to a gearbox unit for a drive train of a motor vehicle, the drive train comprising at least one internal combustion engine and a first electric motor (and preferably also a second electric motor), comprising a first planetary gear system, a second, switchable planetary gear system, and a clutch for switching the second planetary gear system between a first operating state and a second operating state. The first planetary gear system comprises at least one first member for coupling to the first electric motor, a second member for taking up a drive power from the internal combustion motor, and a third member for outputting drive power. The second planetary gear system comprises at least one first member for coupling to the internal combustion engine, a second member for coupling to the second member of the first planetary gear system, and a third member. In the first operating state, the coupling holds the third member of the second planetary gear system. In the second operating state, the coupling couples the third member of the second planetary gear system in a rotationally fixed manner to the first or second member of the second planetary gear system.

Owner:MAGNA POWERTRAIN AG & CO KG

Magnetic pump

InactiveCN101818736AIncreased ability to transmit torqueEnhanced Magnetic Field CouplingPump componentsPump installationsMagnetic tension forceMagnetic field coupling

The invention provides a magnetic pump, which comprises a magnetic gear (5) and a pump body (16). A driving rotor (6), a driven rotor (10) and a non-magnetic isolating sleeve (11) are arranged in the magnetic gear (5); and in another form, the driven rotor (10) can also be combined with the pump body (16) into a whole body. A magnetic field modulation component (8) is also arranged in the magnetic gear (5) and arranged between the driving rotor (6) and the driven rotor (10). Owing to the arrangement of the magnetic field modulation component (8), the magnetic field coupling between the driving rotor (6) and the driven rotor (10) is enhanced, the functions of torque transfer and rotation speed transformation ratio are realized, and the capacity of transferring torque of the magnetic pump is improved.

Owner:SIEMENS CHINA

Rear electric drive assembly of hybrid vehicle

PendingCN108327529AGuaranteed efficiencySave installation spaceGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingAxial displacementReduction drive

The invention relates to a rear electric drive assembly of a hybrid vehicle. The rear electric drive assembly of the hybrid vehicle comprises a drive motor and a reducer assembly. The reducer assemblycomprises a differential assembly mounted in a reducer case, a differential left housing and a differential right housing are provided with extended sleeve sections through allowing semi-shafts to pass, the extended sleeve sections are supported on the reducer case by bearings, a main reduction gear is fixedly connected to the differential housing, the main reduction gear receives torque output by the drive motor, a rotatable planet carrier is arranged in the differential housing in a loose fit mode, one axial end face of the planet carrier is provided with an end face tooth, an axially movable gear ring is arranged in the differential housing, an end face tooth of a gear ring is arranged on one axial end face and corresponds to the end face tooth of the planet carrier, the other axial end of the gear ring is provided with a plurality of axial mounting posts, the axial mounting posts protrude from the differential to support a signal plate, a return spring is arranged between the signal plate and the differential housing, and driving devices for driving the signal plate to perform axial displacements are arranged on the reducer.

Owner:CHONGQING TSINGSHAN IND

Cylindrical rotating plate permanent magnet coupler

ActiveCN103915975AAvoid relative motionAchieve torque transmissionDynamo-electric gearsElectrical conductorTorque transmission

The invention discloses a cylindrical rotating plate permanent magnet coupler which comprises a first shaft and a second shaft. The first shaft and the second shaft are coaxial. The first shaft is provided with a permanent magnet rotating plate provided with an inner layer cylinder, an outer layer cylinder and a carrying magnet. The inner layer cylinder and the outer layer cylinder are arranged inside and outside the permanent magnet rotating plate in the diameter direction of the rotating plate in a corresponding mode. The carrying magnet is arranged between the inner layer cylinder and the outer layer cylinder and provided with a circle of permanent magnets. The polar direction of the permanent magnets is perpendicular to the axis of the permanent magnet rotating plate. Every two adjacent magnets are installed in a hetero-polar mode. The second shaft is provided with a conductor rotating plate provided with at least one conductor cylinder. The conductor cylinders are arranged in the gap between the inner layer cylinder and the carrying magnet and the gap between the outer layer cylinder and the carrying magnet. Transmission of different kinds of torque is achieved by adjusting the coupling area between rotors, the purposes of isolating vibration, reducing the speed and saving the energy are achieved, installing and debugging are easy, axial moving of a certain degree is allowed, torque transmission between the two parts can be achieved, and the purposes of isolating vibration, reducing the speed and saving the energy are achieved.

Owner:QINGDAO SPRING ENERGY TECH

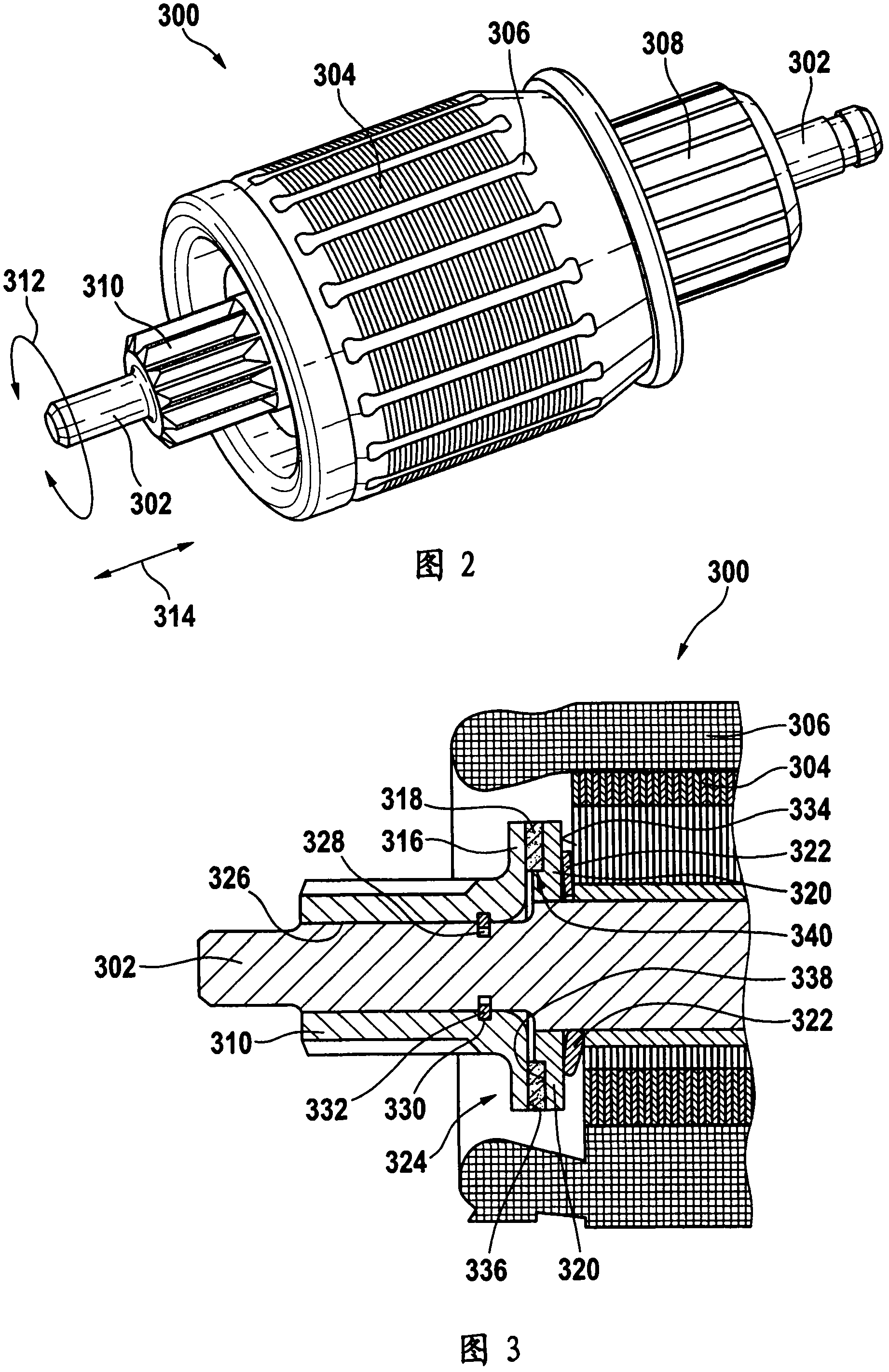

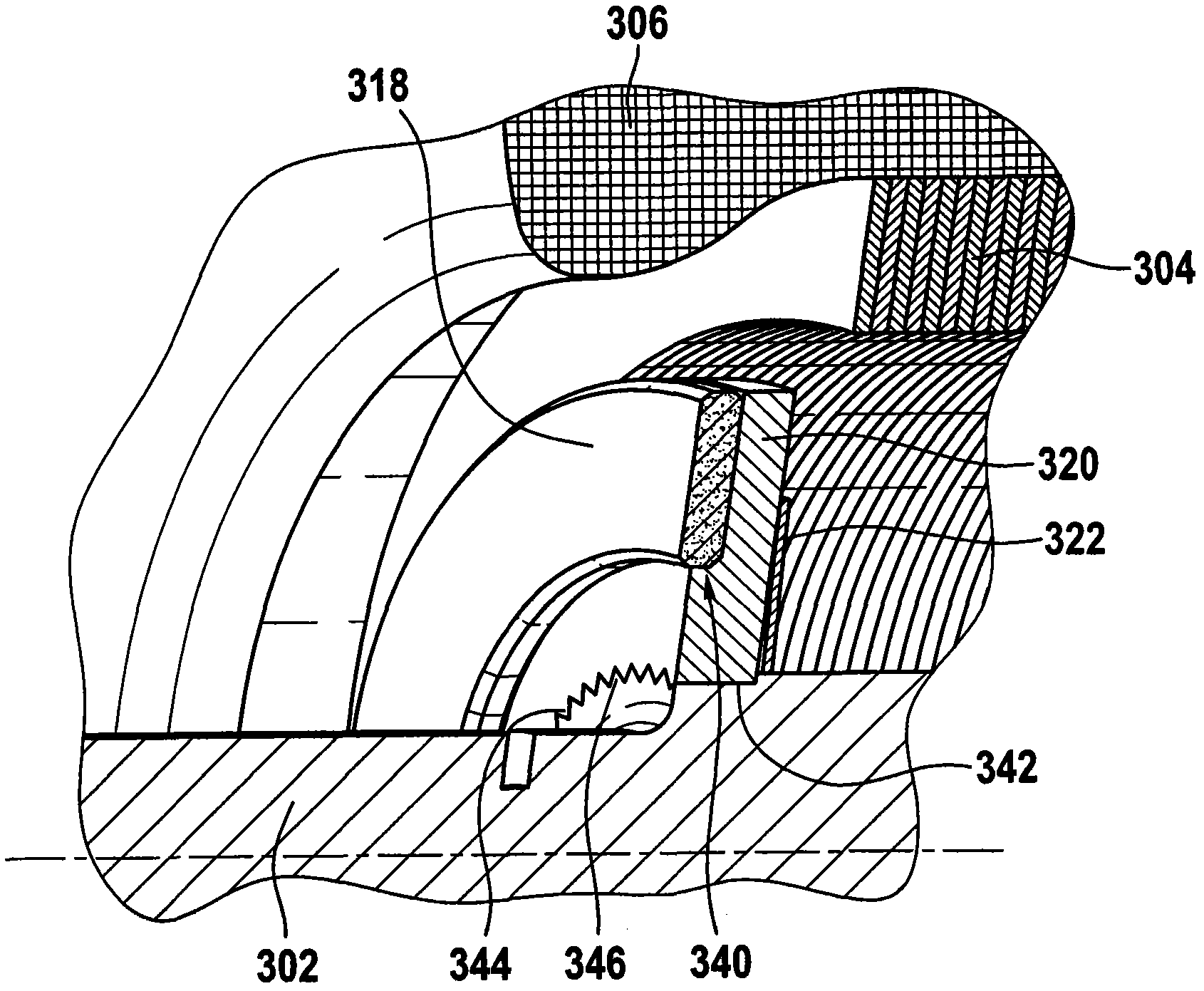

Armature for an electric motor for driving a starter device

InactiveCN102545472AEasy to replaceQuick changePower operated startersElectric motor startersMaximum torqueCombustion

The invention relates to an armature for an electric motor for driving a starter device of a combustion engine. The armature comprises an armature pinion which can be rotatably contained on an armature shaft and used for driving a middle transmission mechanism disposed at rear, and an armature iron core which is disposed on the armature shaft and has an armature winding. According to the invention, the armature pinion is positioned on the armature shaft along an axial direction, and a sliding clutch is disposed between the armature pinion and the armature shaft. The armature pinion and the armature pinion edge interact with a friction piece, a disc and a compression spring, forming the sliding clutch which slides when reaching to or exceeding a maximum torque limit Mmax determined by the structure. Furthermore, the armature pinion can be replaced by another armature pinion with different numbers of pinions without replacing the whole armature. Accordingly, gear ratio of a starter device can easily correspond to different demands.

Owner:ROBERT BOSCH GMBH

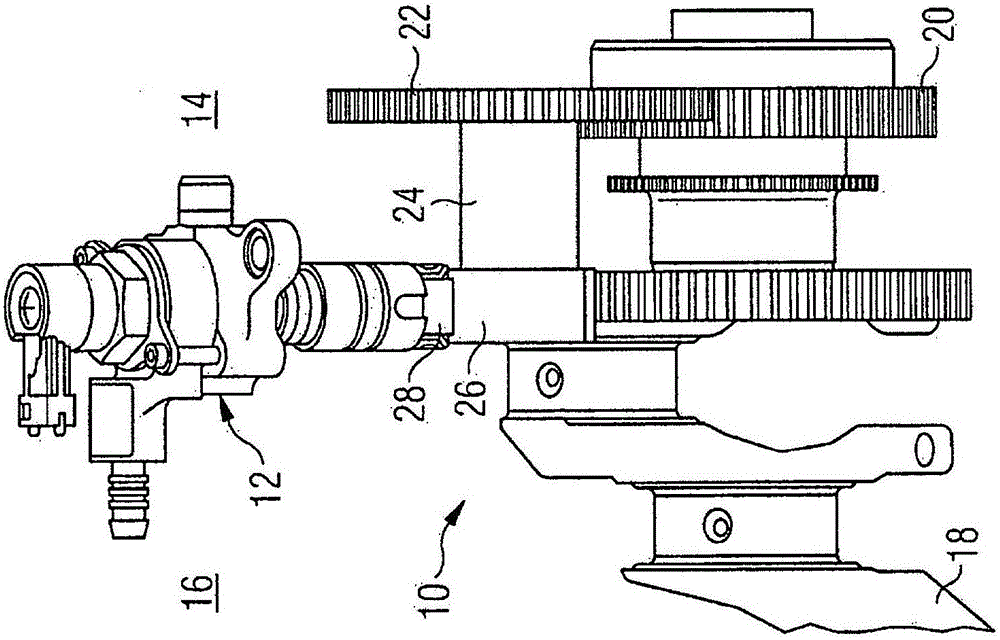

Fluid control element

ActiveCN103375612AAchieve torque transmissionOperating means/releasing devices for valvesMultiple way valvesFluid controlEngineering

Owner:BURKERT WERKE

Disk type torque limiting permanent magnet coupler

ActiveCN104600955ASimple structureEasy to manufacture and processDynamo-electric gearsMagnetConductive materials

The invention discloses a disk type torque limiting permanent magnet coupler. The disk type torque limiting permanent magnet coupler comprises a first shaft and a second shaft which are arranged in a split type and coaxial with each other, wherein a first shaft sleeve, a sliding sleeve I and a conductor rotary disk are arranged on the first shaft, the conductor rotary disk is composed of a steel disk and a conductor disk made of good conductive material, a portion of the first shaft sleeve is a square shaft, and matched with the first shaft sleeve through a square hole formed in the sliding sleeve I, the sliding sleeve I can move in the axial direction, limiting structures are arranged on two end faces of the conductor rotary disk, a second shaft sleeve and a load connection disk are arranged on the second shaft, the load connection disk is connected with a permanent magnet rotary disk through a connection rod, a permanent magnet is installed on the permanent magnet rotary disk, and positions of the permanent magnet and the conductor disk are corresponding to each other. According to the disk type torque limiting permanent magnet coupler, structure of the second shaft is simplified, only the one permanent magnet rotary disk is arranged on the disk type torque limiting permanent magnet coupler, the weight of the second shaft is greatly reduced, the second shaft is stable during the rotation process, and therefore mechanical friction and wear are reduced, vibratory interference is avoided, loss of a drive component is reduced, vibration is isolated, noise is reduced, installation and debugging are simple, and the size of an air gap is accurate to control.

Owner:QINGDAO SPRING ENERGY TECH

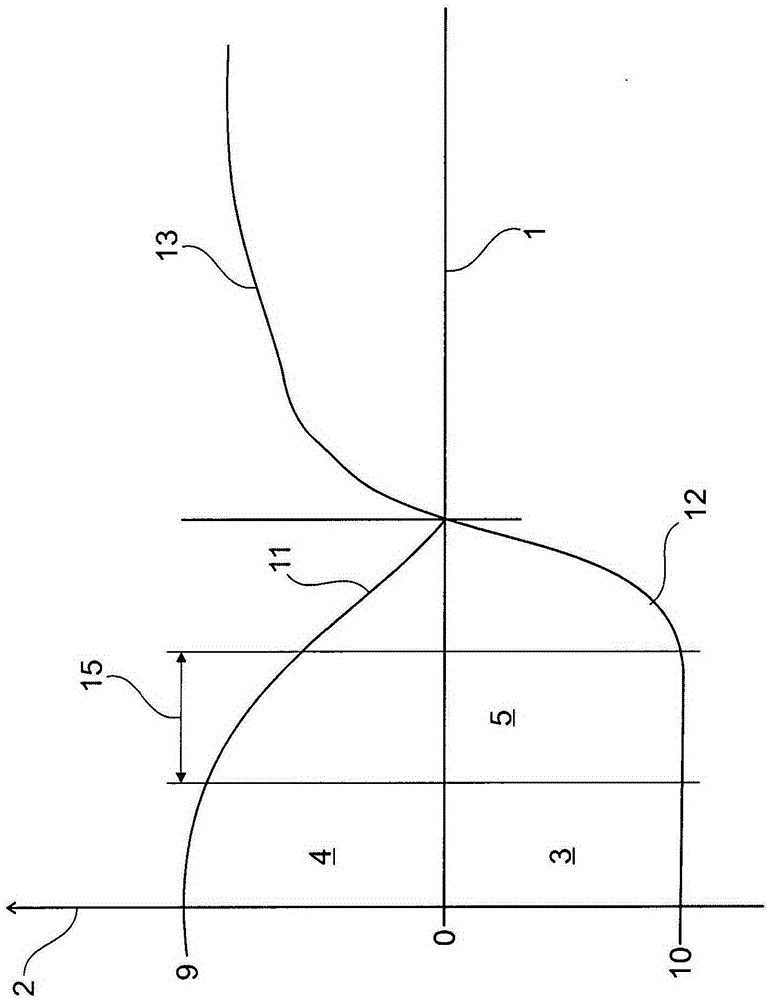

Drive train for a motor vehicle

InactiveCN102245416AAchieve torque transmissionReduce mechanical loadRotating vibration suppressionPower operated startersDrive shaftControl theory

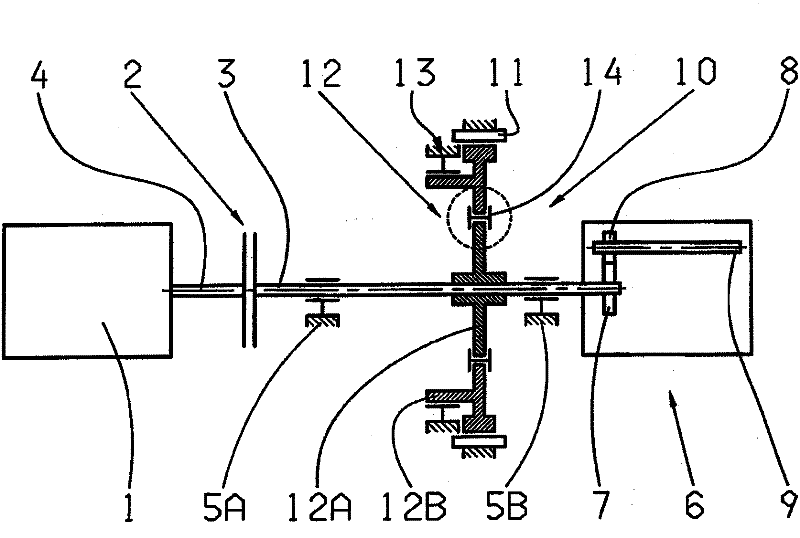

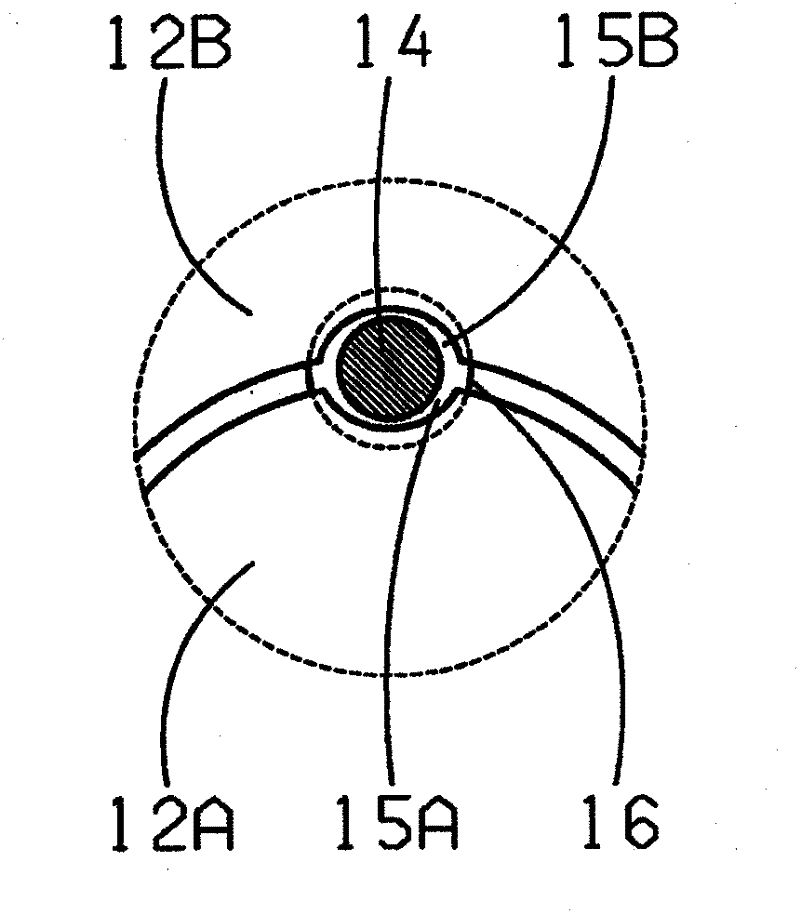

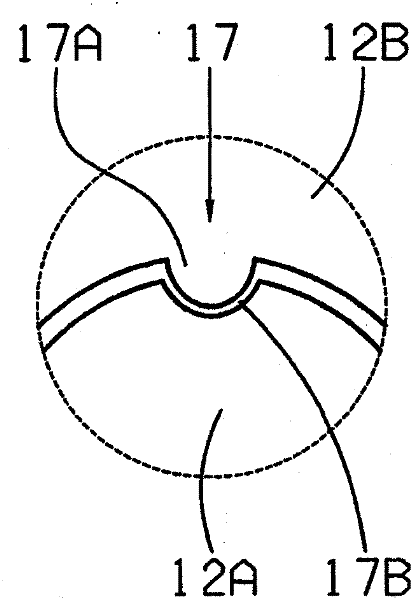

The invention relates to a drive train for a motor vehicle, comprising at least a rotatable drive shaft (3) and an electric motor (10) that has a stator (11) fixed to the housing and a rotor (12) that can rotate such that it is coupled to the drive shaft (3), characterized in that the rotor (12) is configured in at least two parts, the first rotor part (12A) being directly coupled to the drive shaft (3) and the second rotor part (12B) being directly drivable with the stator (11), and wherein the first rotor part (12A) and the second rotor part (12B) are coupled to each other in such a manner that torque can be transmitted and that both can be tilted in relation to each other. According to the invention, the second rotor part (12B) is rotatably supported by a rotor bearing (13) fixed to the housing and is aligned with respect to the stator (11).

Owner:ZF FRIEDRICHSHAFEN AG

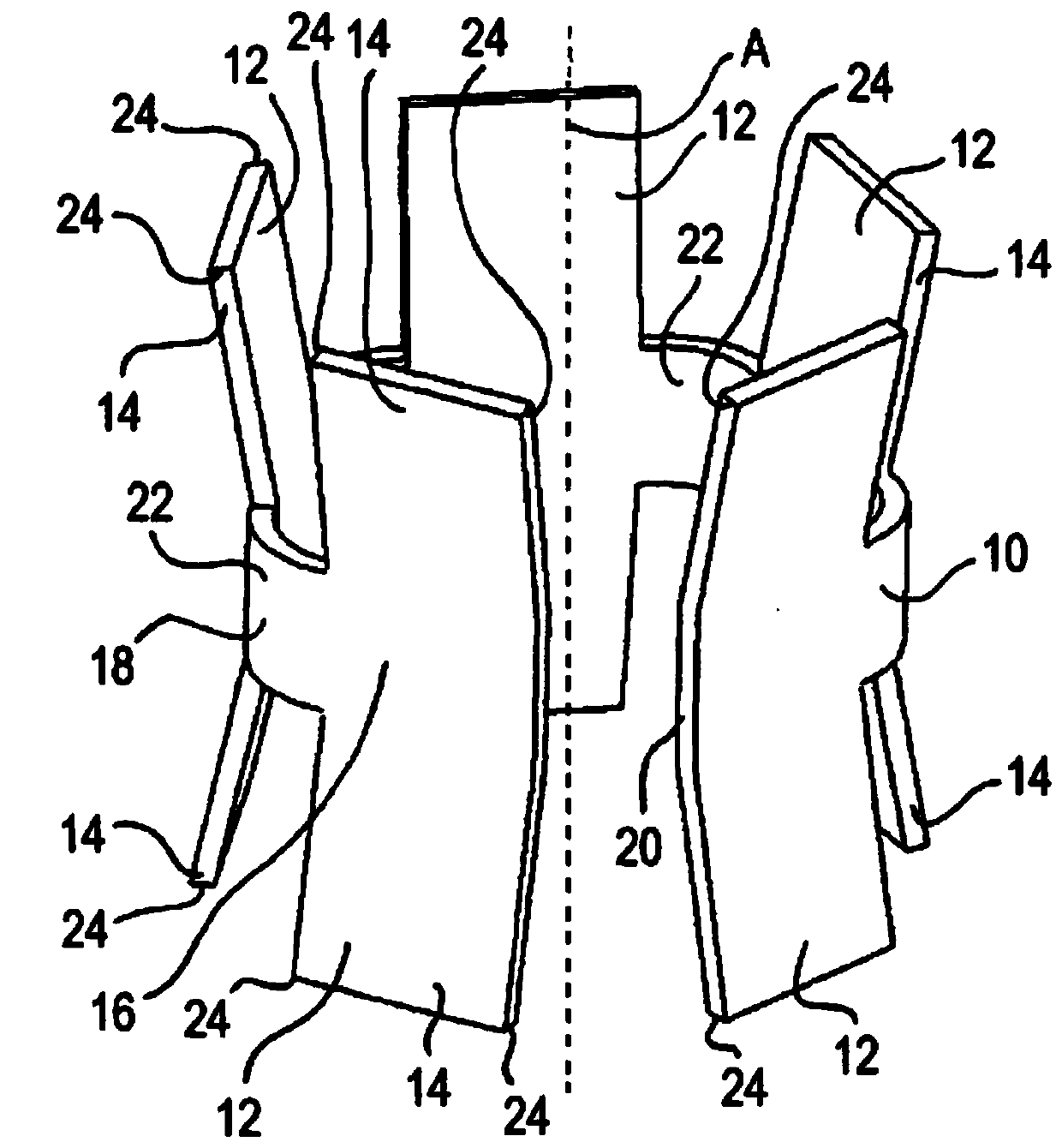

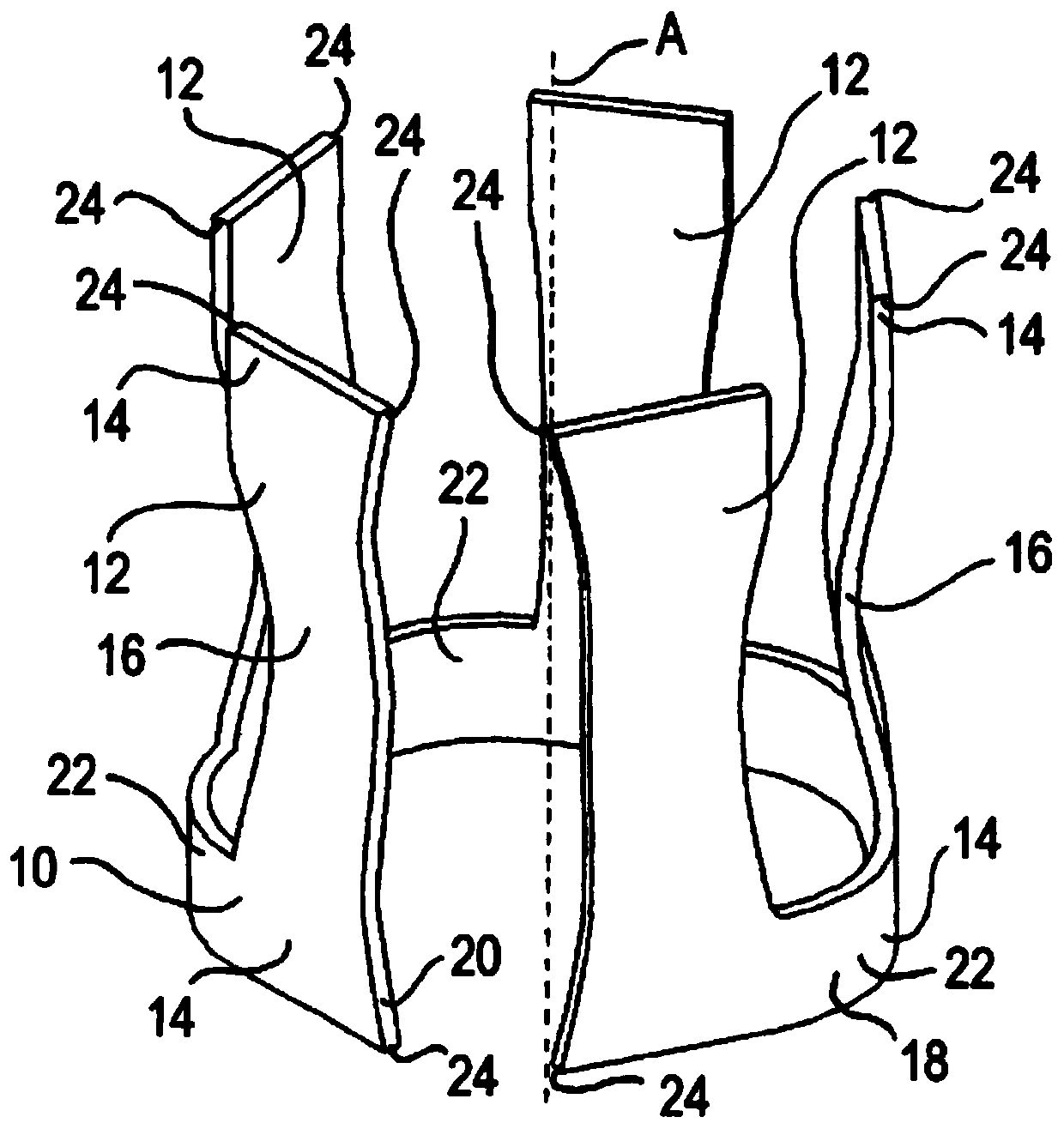

Floating positioning and torque transmission structure of turbine guide device

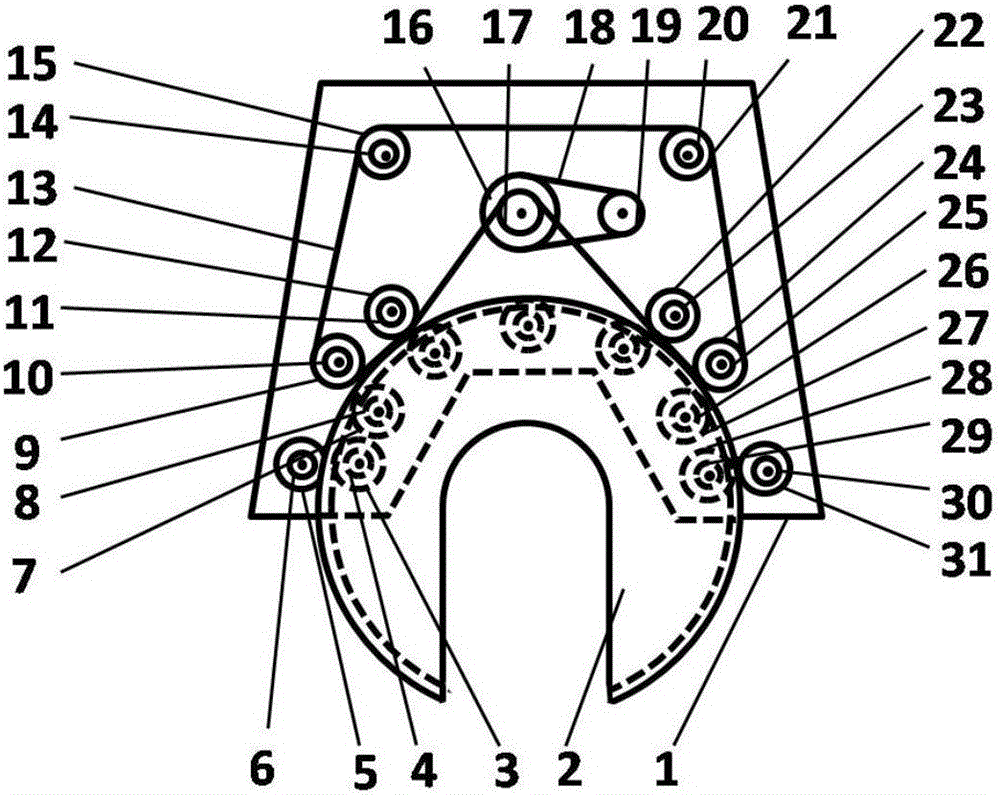

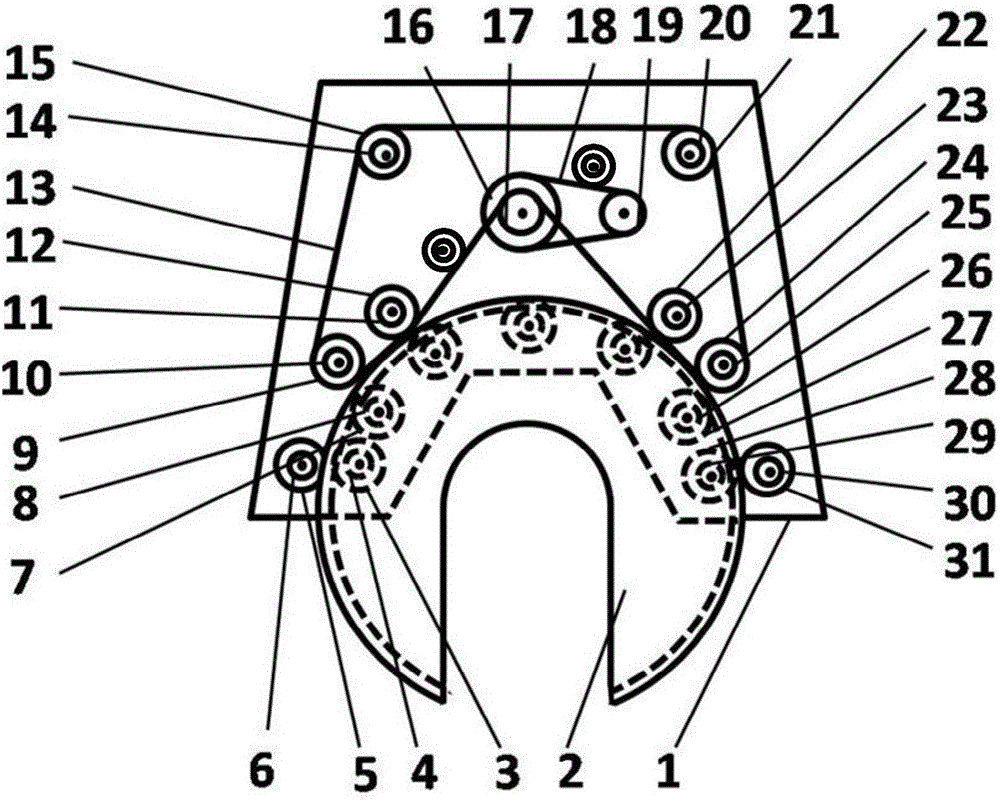

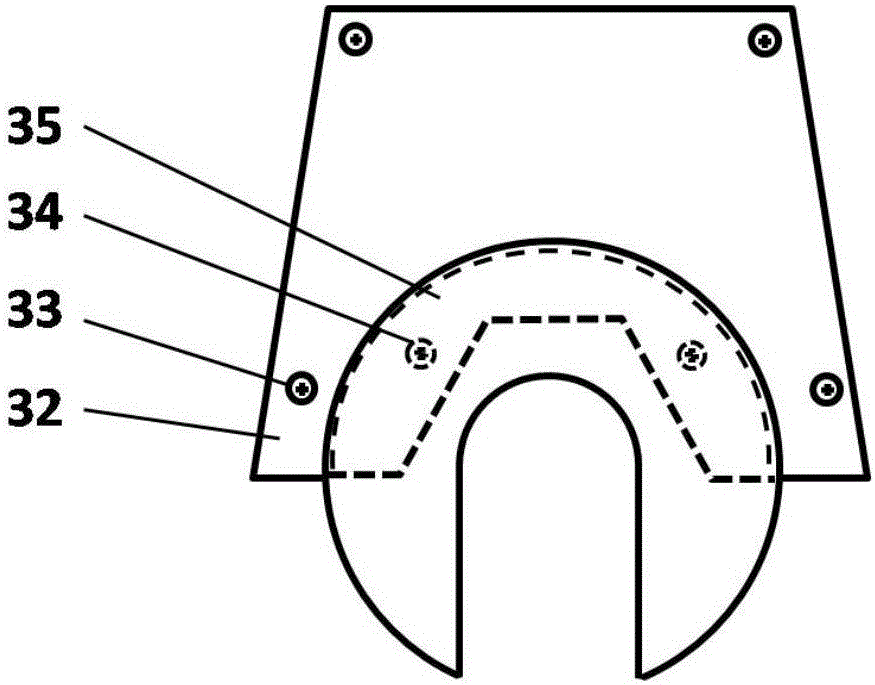

ActiveCN109404051APrecise positioningAchieve positioningBlade accessoriesLeakage preventionCombustionWorking environment

The invention relates to a floating positioning and torque transmission structure of a turbine guide device, and is applicable to the field of ground combustion gas turbines, aero-engines and the like. An air baffle structure capable of sealing a rim of a turbine rotor blade is added to a front cavity of a turbine disk, a positioning rib structure is arranged on the air baffle structure, a floating positioning bulge is arranged on the turbine guide device in a matched manner, floating positioning and torque transmission of the turbine guide device are realized by the aid of the positioning riband floating positioning bulge structure, the expansion deformation constraint of the turbine guide device in the hot-state working environment is reduced to the maximum extent, and the hot stress ofthe guide device is reduced. The structure has great engineering application significance in prolonging of the life of the high-pressure turbine guide device of a ground combustion gas turbine or anaero-engine. Compared with traditional high-pressure turbine guide device structures and turbine disk front cavity baffle structures, the structure has the advantages that through the ingenious structural design, centered torque transmission of the high-pressure turbine guide device and high-efficiency rim sealing of rotor and stator end areas of a high-pressure turbine can be realized.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

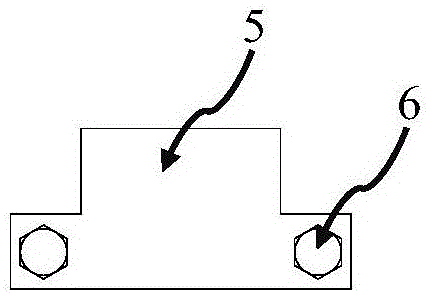

Device for compensating for tolerances

ActiveCN109790862ANo risk of damageAchieve torque transmissionPinsNutsEngineeringMechanical engineering

Owner:WITTE AUTOMOTIVE GMBH

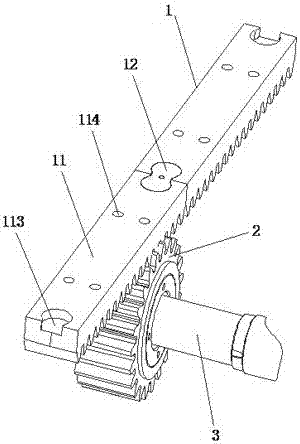

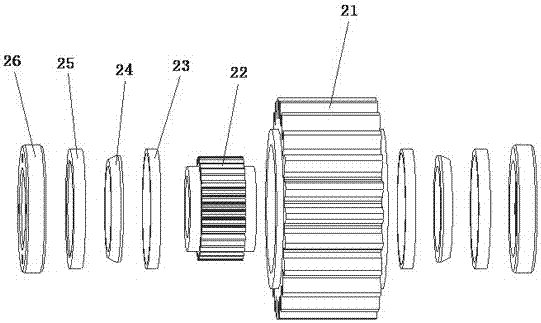

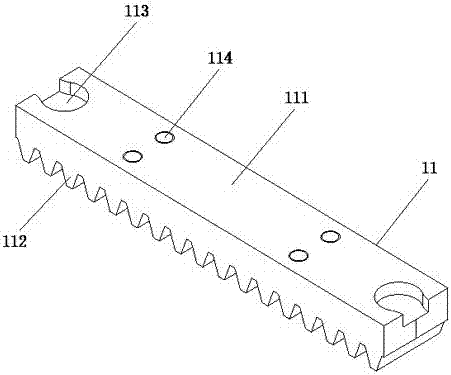

Multistage speed change mechanism of wire harness binding device and speed change method and application of multistage speed change mechanism of wire harness binding device

InactiveCN105836238AGuaranteed intermeshingAdjust the tensionPackaging machinesGear wheelElectric machinery

The invention discloses a multistage speed change mechanism of a wire harness binding device and a speed change method and application of the multistage speed change mechanism of the wire harness binding device. Motor torque transmission, the first-stage speed change and the second-stage speed change are achieved through gear synchronous belt transmission. The outward-expansion angle of a tensioning wheel is achieved through an eccentric bearing, and therefore the tensioning degree of a second-stage synchronous belt is regulated. A rotating body with an equivalent gear structure and an enveloping engagement structure between a gear part of the rotating body and a synchronous belt are adopted, and therefore continuous rotation of the rotating body with a notch and the third-stage speed change of a transmission are achieved. A structure for axially pressing and fixing the rotating body through an inner side guide wheel is achieved through a groove structure in the inner side of the rotating body. Due to the adoption of the structure of the rotating body with the notch, wire harnesses and other packaged objects can be allowed to relatively and continuously rotate relative to the rotating body in the notch. The multistage speed change mechanism can be used for various automatic binding tools or devices used for binding adhesive tape, cotton, cloth, plastic and other materials.

Owner:杭州鼎巅科技有限公司

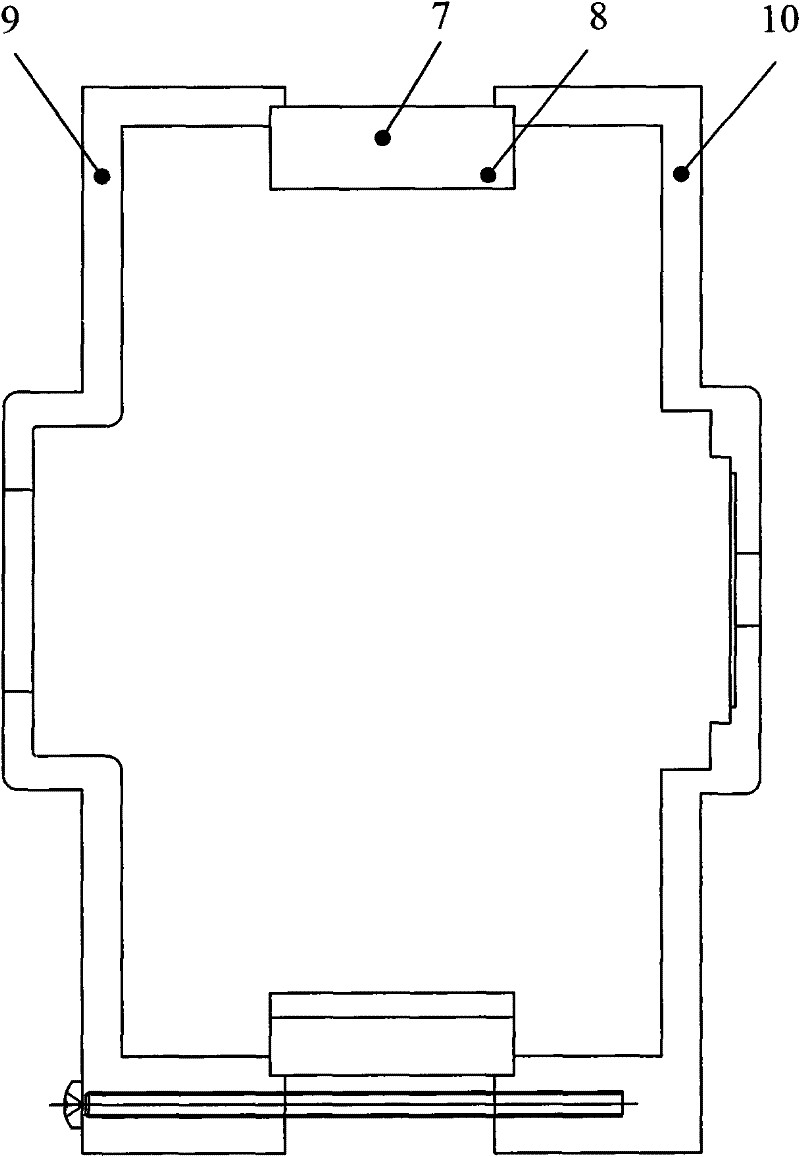

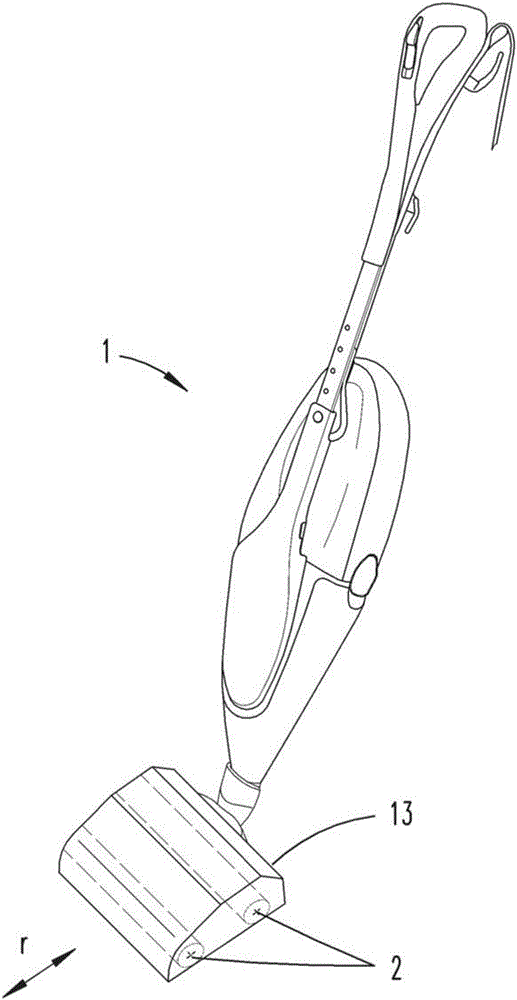

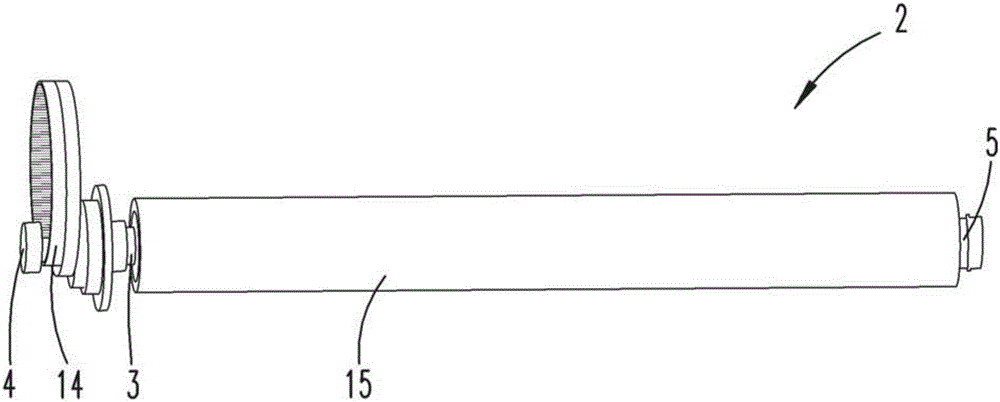

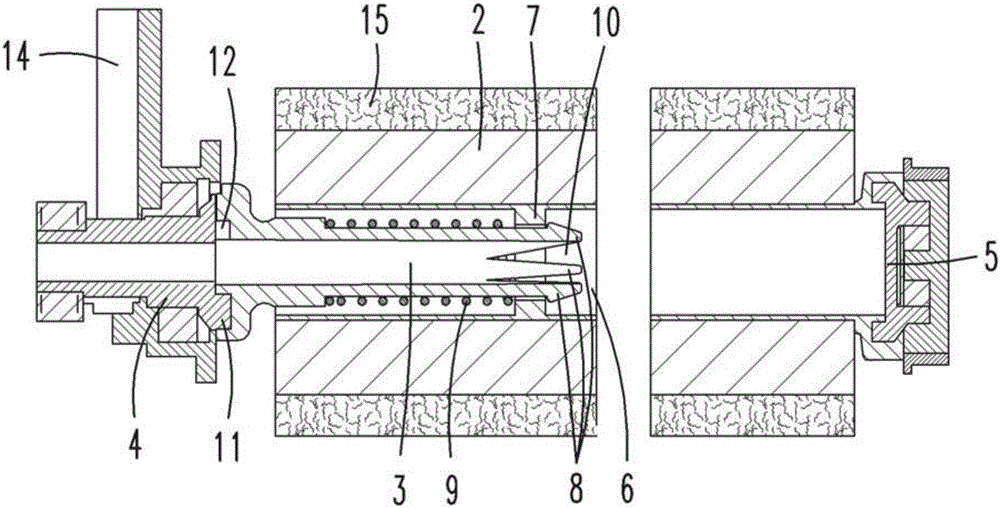

Cleaning device with cleaning roller with rotating bearing

InactiveCN106343924AOvercoming the effect of the stop surfaceOvercome uniformity issuesCarpet cleanersFloor cleanersDrive shaft

The present invention relates to a cleaning apparatus (1), in particular a floor cleaning apparatus, which has a cleaning roller (2) with rotating bearing for cleaning the surface, and the cleaning roller (2) is provided with a roller driving part (3) co-rotating with a drive shaft on the apparatus side. The roller driving part (3) can be at least partially introduced in an axial roller gap (6) of the cleaning roller (2), wherein couplers (7, 8) capable of cooperating with each other is formed on the roller driving part (3) and the roller gap (6). In order to provide the cleaning apparatus (1), different fixing devices for the cleaning roller (2) are arranged on the drive shaft. In this way, the roller driving part (3) has a roller driving part spring (3), and the couplers (7, 8) are fixed mutually through the roller driving part spring under an installed state to transmit torque.

Owner:VORWERK & CO INTERHOLDING GMBH

Reed coupler

PendingCN111503171AGuaranteed lubrication effectAchieve torque transmissionYielding couplingEngine lubricationCouplingRetainer

Provided is a reed coupler. A plurality of tooth grooves in a circular arc-shaped curve tooth profile are arranged on two half couplers in a one-to-one correspondence mode, strip-shaped reeds are respectively clamped in each pair of tooth grooves, and the reeds are combined to form a flexible integral structure through a reed retainer, so that torque transmission is realized, the elasticity is good, and the buffering and damping capacity is high; a pair of casings with a semi-annular structure are arranged outside the pair of half couplings and the reeds in a covering mode, the two ends and the outer sides of the reeds are limited by the casings, unexpected axial and radial shifting is prevented, lubricating oil is injected through oil injection holes, the lubricating effect of the contactparts of the tooth grooves and the reeds is ensured, the machining process is good, the heat treatment is simple, the structure is compact, the assembly operation is convenient, the production and manufacturing process is simplified, and the economy is good.

Owner:ZHENJIANG SUODA COUPLING

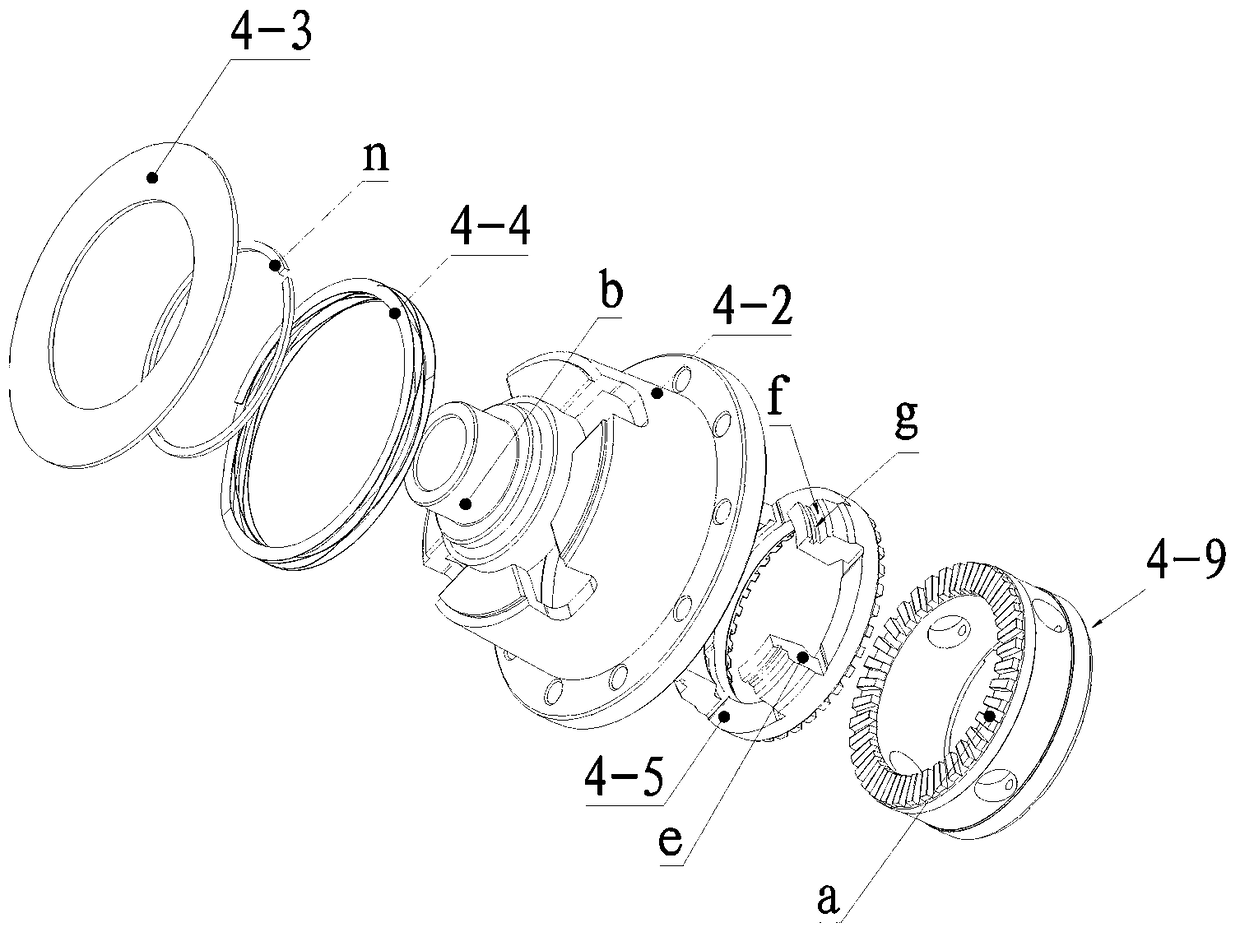

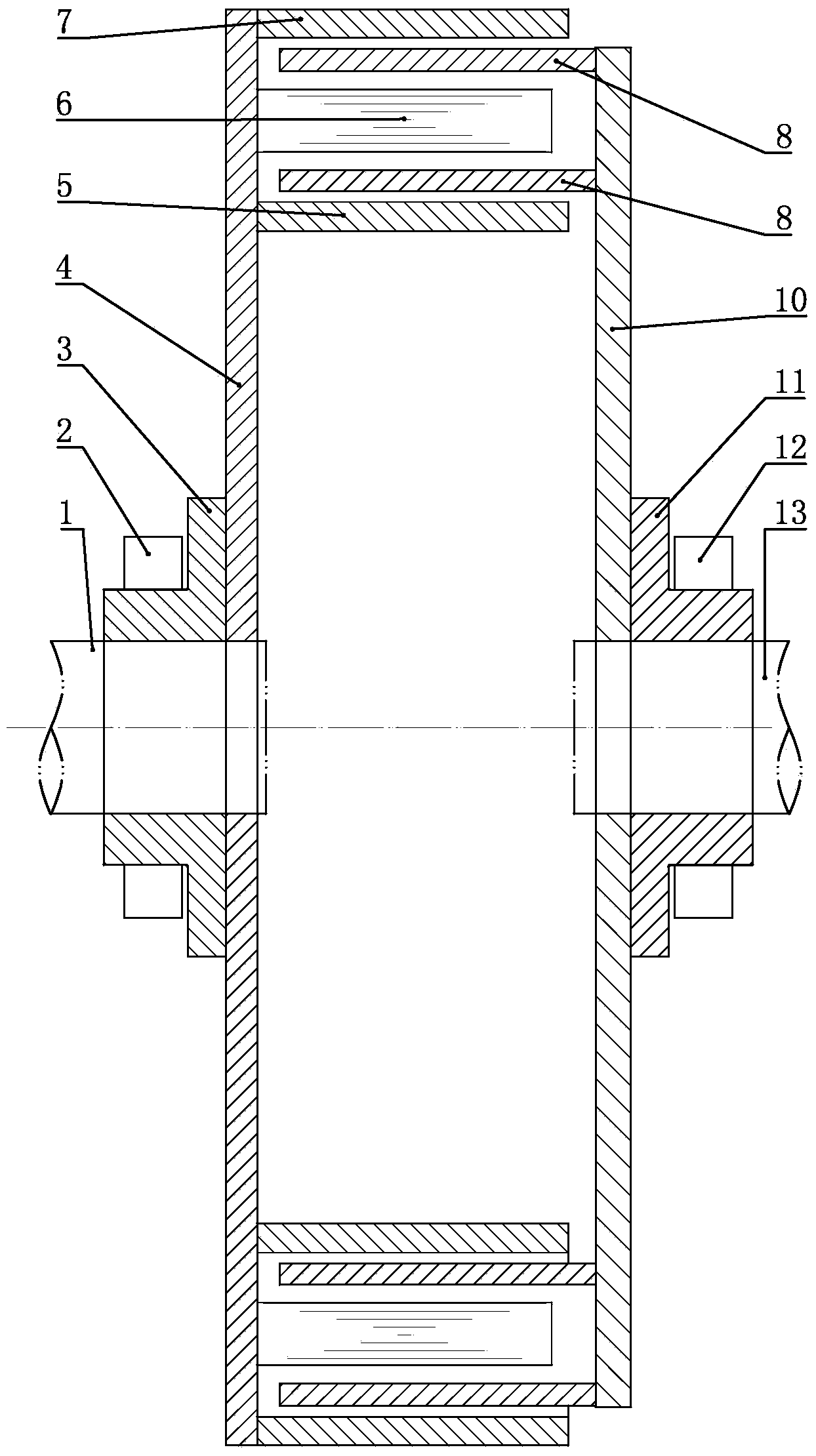

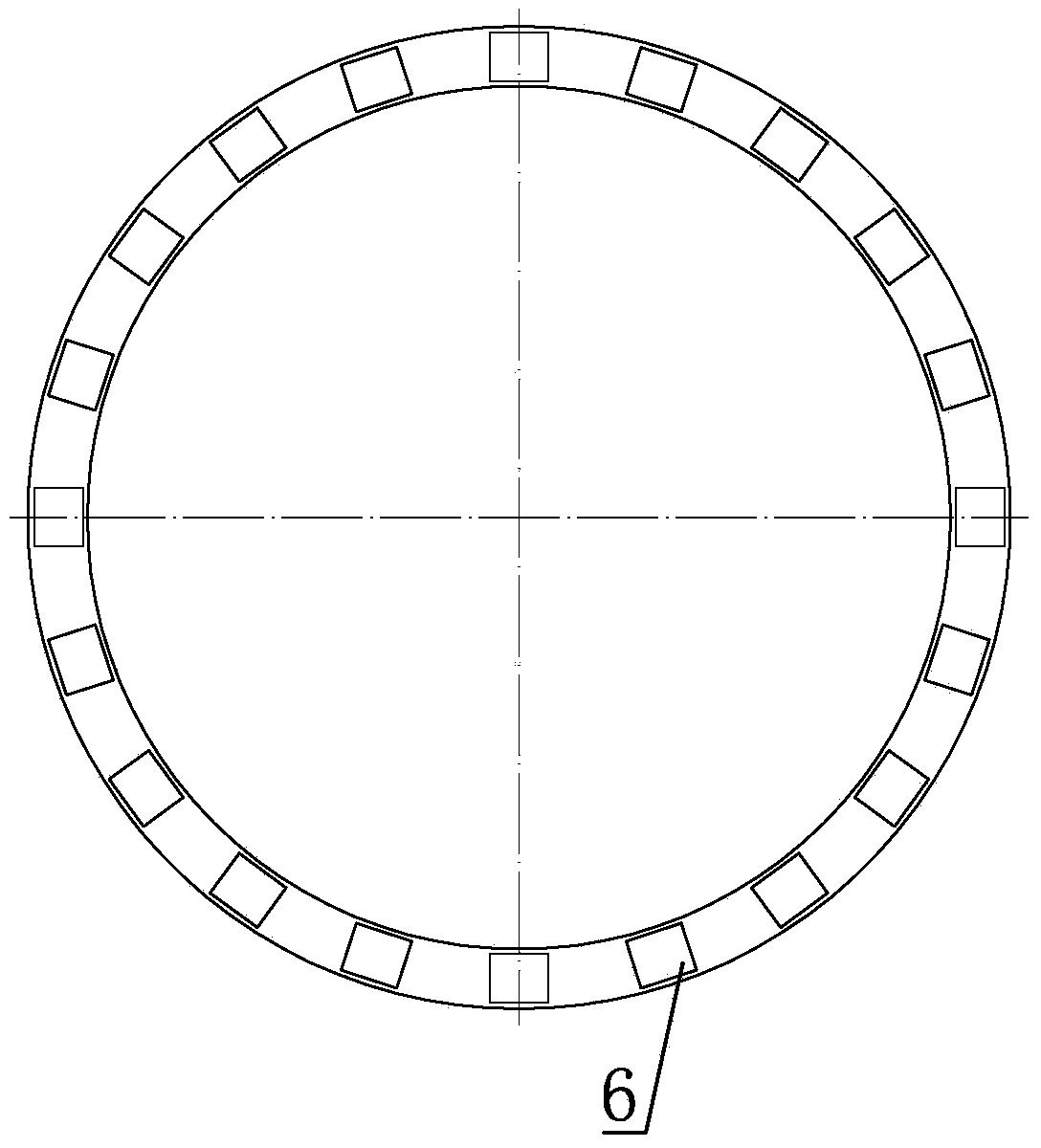

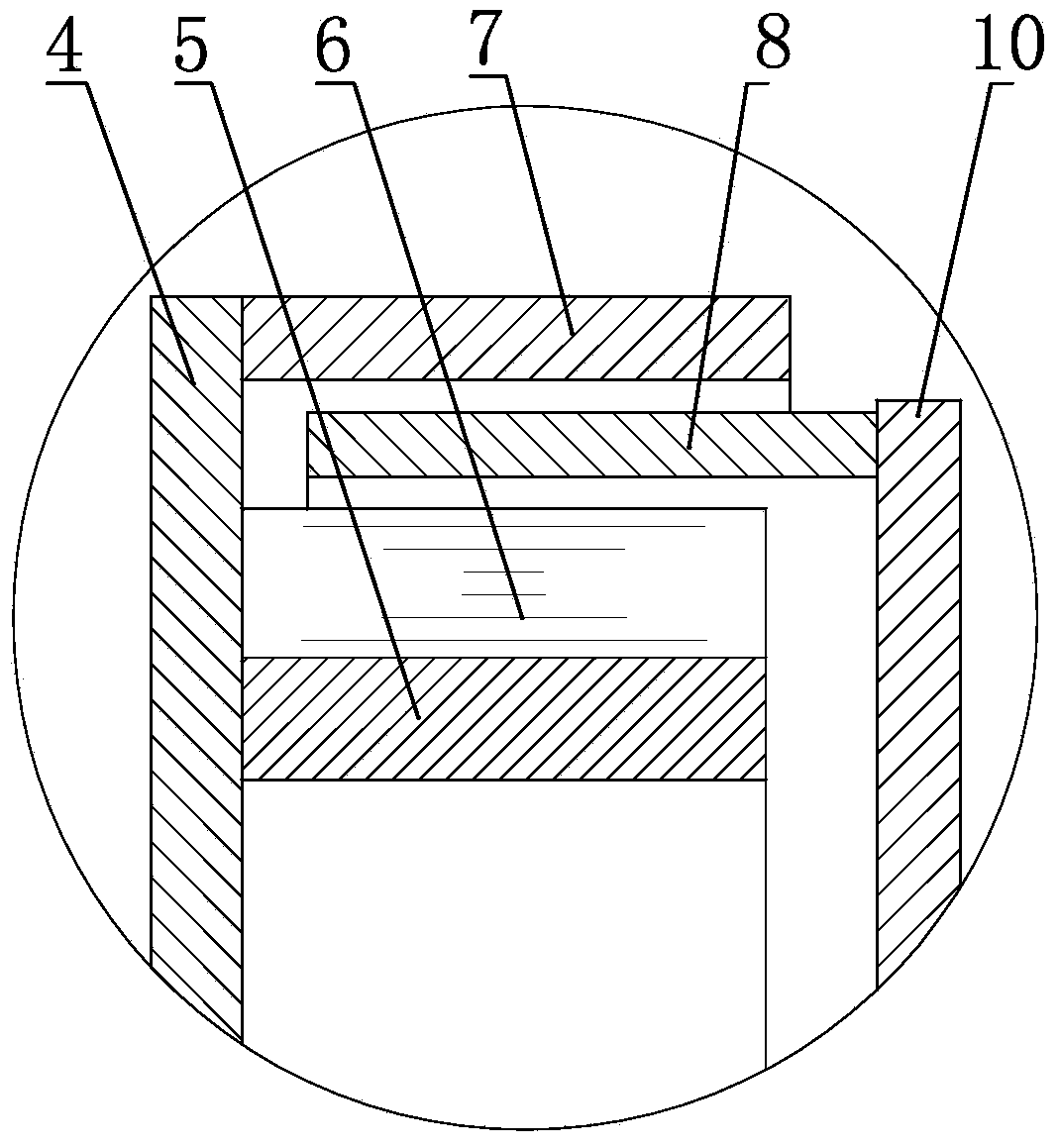

A novel mining vehicle elastic coupling

The invention provides a novel mining vehicle elastic coupling comprising an engine flywheel located in a flywheel shell. An outer shell is connected in the flywheel shell. The engine flywheel achieves output via a power output shaft, which is fixed in a bearing base via a bearing at an output portion of the outer shell, and then output is performed. The connecting face, facing the power output shaft direction, of the engine flywheel is successively provided with a friction sheet, a driven wheel assembly, a diaphragm spring and a pressure plate, wherein the friction sheet, the driven wheel assembly, the diaphragm spring and the pressure plate are connected with the engine flywheel through the power output shaft to form one coupling. The novel mining vehicle elastic coupling can achieve torque transmission of large-power engines without slip, and can eliminate radial, axial and angular impact of a whole power system effectively through the diaphragm spring in the pressure plate and a damping spring in a driven plate, thereby achieving stable transmission of power.

Owner:东风重工(十堰)有限公司

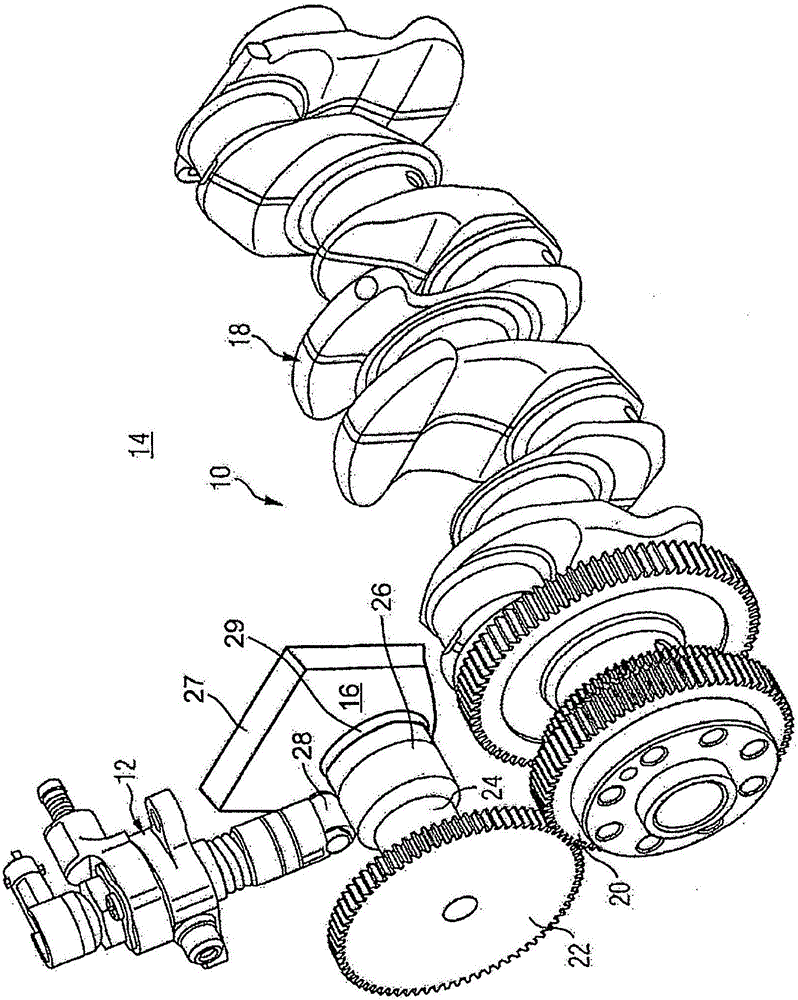

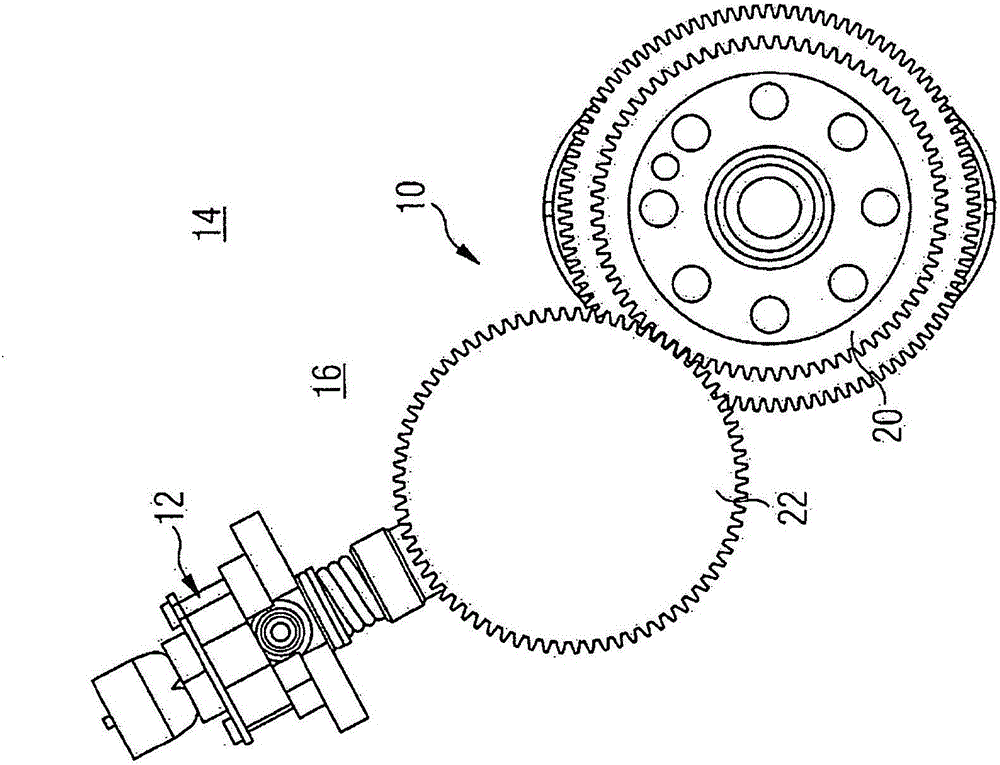

Drive system of high-pressure fuel pump, high-pressure fuel pump assembly and internal combustion engine

InactiveCN105765212ASave construction spaceReduce frictional powerPositive displacement pump componentsFuel injecting pumpsInternal combustion engineCam

The invention relates to a drive system (10) of a high-pressure fuel pump (12) of an internal combustion engine (14). The system comprises a drive train which is coupled on the input side to a crankshaft (18) and on the output side to a valve-controlling camshaft. The system also comprises at least one drive-system cam (26) driving the high-pressure fuel pump (12) directly and situated in the drive train at a distance from the valve-controlling camshaft. The drive system has no chain and no toothed belt for driving the drive-system cam. The invention also relates to a high-pressure fuel pump assembly and to an internal combustion engine.

Owner:BAYERISCHE MOTOREN WERKE AG

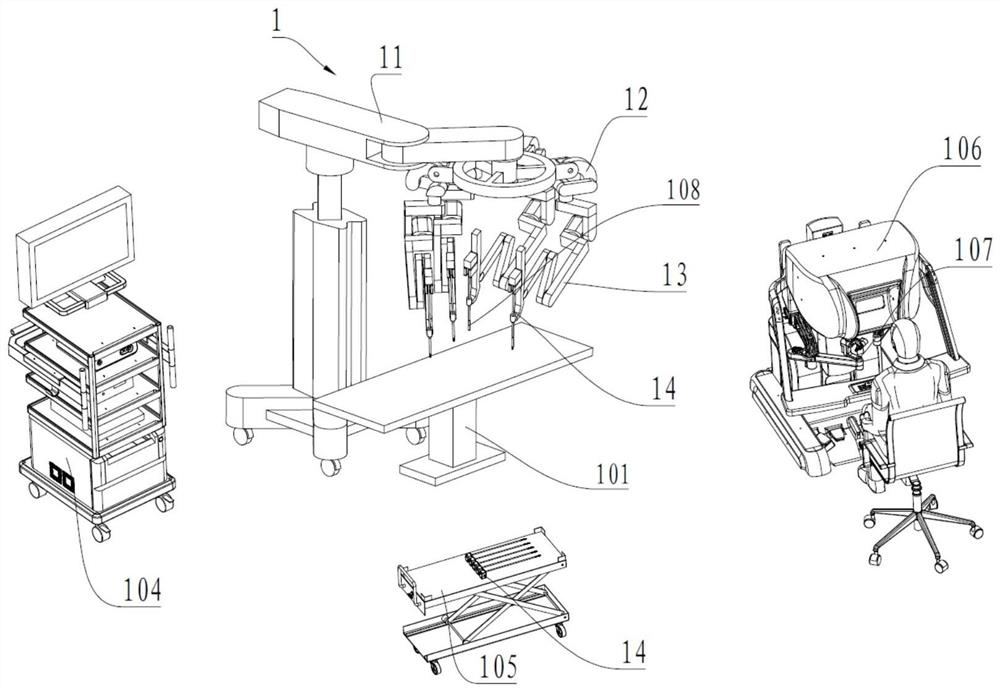

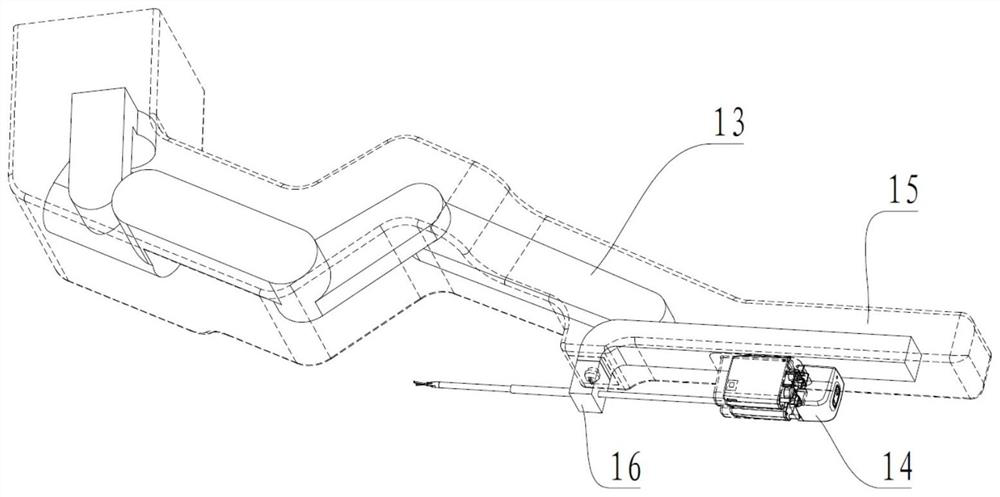

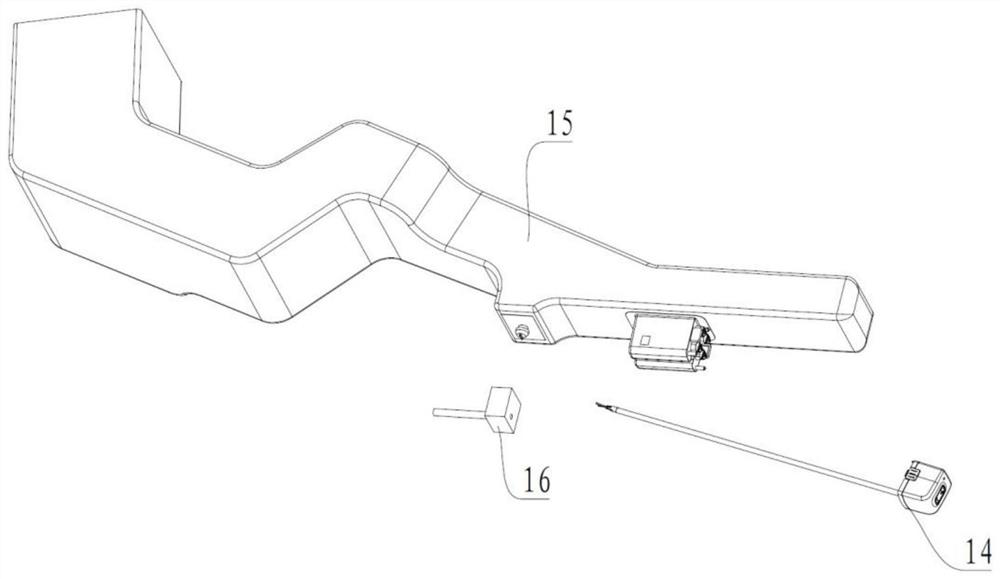

Isolation device and surgical equipment

ActiveCN113143467AAvoid the risk of contamination of surgical devicesImprove sealingDiagnosticsSurgical manipulatorsReoperative surgeryMechanical engineering

The invention relates to an isolation device and surgical equipment. The surgical equipment comprises the isolation device and a surgical device, wherein the isolation device is used for being matched with the surgical device, and the surgical device comprises a first target object, a second target object and a transmission mechanism; the isolation device comprises a first film body used for wrapping the first target object and a second film body used for wrapping the second target object, and the second film body is in sealed connection with the first film body; and the second film body is provided with a transmission connector, the transmission connector and the second film body are integrally formed or connected in a sealed mode, and the transmission connector is used for being connected with the transmission mechanism to achieve torque transmission. By means of the isolation device provide by the invention, a sterile environment with better sealing performance can be established for the surgical equipment, and the protection performance of the surgical equipment is improved.

Owner:SHANGHAI MICROPORT MEDBOT (GRP) CO LTD

Permanent magnet coupler

InactiveCN104682661AAvoid relative motionAchieve torque transmissionDynamo-electric gearsElectrical conductorTorque transmission

The invention discloses a permanent magnet coupler. The permanent magnet coupler comprises a shaft A and a shaft B which are separated, wherein the shaft A and the shaft B are coaxial; a permanent magnet rotary table is arranged on the shaft A; an inner barrel, a carrying magnet and an outer barrel are arranged on the permanent magnet rotary table in sequence from inside to outside; a circle of permanent magnets are mounted on the carrying magnet; the magnetic pole directions of the permanent magnets are vertical to the axis of the permanent magnet rotary table, and the magnetic poles of adjacent magnets are mounted in a heterospolar mode; a conductor rotary table is arranged on the shaft B, one or more conductor barrels are arranged on the conductor rotary table, and the conductor barrels are arranged in the gaps among the inner barrel, the outer barrel and the carrying magnet. According to the invention, N and S poles of the magnets are arranged in an adjacent mode, a magnetic line passes through the corresponding conductor barrel, and when the magnetic line and the corresponding conductor barrel move relative to each other, the magnetic line is cut by the corresponding conductor barrel, eddy current is generated in the conductor barrel, and then an opposite sensing magnetic field is generated by the eddy current, so that the relative movement between the magnetic line and the corresponding conductor barrel is prevented, the torque transmission between the magnetic line and the corresponding conductor barrel is realized, and the purposes of vibration isolation, speed reduction and energy reduction are achieved.

Owner:盐城华力达科技有限公司

Permanent magnet soft starter

InactiveCN101841282AAvoid burnsAchieve torque transmissionDynamo-electric motors/converters startersDynamo-electric gearsMagnetEngineering

The invention provides a novel motor soft starter, which has the advantages of realizing smooth start, reducing current impulse and prolonging the service life, along with simple structure, low cost and high reliability. Because the mechanical connection is absent between a driving rotor and a driven rotor, the motor soft starter can reduce the vibration of the conventional system by 50 to 85 percent. The motor soft starter can prevent a motor from being burnt due to overheating caused by mechanical failure or blockage. The motor soft starter comprises the driving rotor and the driven rotor, wherein the driving rotor mainly comprises a driving coupling (1), a driving rotor disc (2), and permanent magnets (3); and the driven rotor consists of a driven rotor disc (7), a magnetic steel ring (5), an inductive copper ring (4), and a driven coupling (6). The motor soft starter is characterized in that: the magnetic steel ring (5) and the inductive copper ring (4) are fixed at the periphery of the driven rotor disc (7) in a barrel shape; the driven rotor disc (7) which is coaxial with the driving rotor disc is in transmission connection with the driven coupling (6) coaxially; and the permanent magnets (3) which are opposite to the inductive copper ring (4) axially are distributed on the inner circumference of the driving rotor disc (2).

Owner:JIANGSU YINMAO HLDG GROUP +1

Cylindrical rotating plate permanent magnet coupler

InactiveCN103915978AAvoid axial thrustIncrease coupling areaDynamo-electric gearsElectrical conductorTorque transmission

The invention discloses a cylindrical rotating plate permanent magnet coupler which comprises a first shaft and a second shaft. The first shaft and the second shaft are separated and are coaxial. The first shaft is provided with a shaft sleeve I, a permanent magnet rotating plate, an inner layer carrying magnetic cylinder and an outer layer carrying magnetic cylinder. The inner layer carrying magnetic cylinder and the outer layer carrying magnetic cylinder are made of ferromagnetic materials. The inner wall of the inner layer carrying magnetic cylinder and the inner wall of the outer layer carrying magnetic cylinder are respectively provided with one circle of permanent magnets uniformly distributed. The pole direction of the permanent magnets is perpendicular to the axis of the rotating shaft. Every two adjacent magnets are installed in a hetero-polar mode. The second shaft is provided with a shaft sleeve II, a conductor rotating plate and a conductor cylinder connected with the conductor rotating shaft. The conductor cylinder is made of an excellent conductor. A gap between the conductor cylinder and the inner layer carrying magnetic cylinder and a gap between the conductor cylinder and the outer layer carrying magnetic cylinder keep equal. Transmission of different kinds of torque is achieved by adjusting the coupling area between rotors, the purposes of isolating vibration, reducing the speed and saving the energy are achieved, installing and debugging are easy, axial moving of a certain degree is allowed, torque transmission between the two parts can be achieved, and the purposes of isolating vibration, reducing the speed and saving the energy are achieved.

Owner:QINGDAO SPRING ENERGY TECH

Disc-shaped rotary-plate permanent magnetic coupler

InactiveCN103915976AAvoid axial thrustIncrease coupling areaDynamo-electric gearsTorque transmissionVibration isolation

The invention discloses a disc-shaped rotary-plate permanent magnetic coupler. The disc-shaped rotary-plate permanent magnetic coupler comprises a first shaft and a second shaft which are separated and coaxial, wherein the first shaft is provided with a hub I, a disc-shaped permanent magnetic rotary plate I and a disc-shaped permanent magnetic rotary plate II, the disc-shaped permanent magnetic rotary plate I and the disc-shaped permanent magnetic rotary plate II are arranged in parallel, the disc-shaped permanent magnetic rotary plate I is arranged on the first shaft through the hub I, the two disc-shaped permanent magnetic rotary plates are connected through a connection rod, one or more circles of permanent magnets are arranged in the disc-shaped permanent magnetic rotary plates I and II, poles of adjacent permanent magnets are arranged in a heterospolar or homopolar mode, the two rotary plates are arranged oppositely according to poles of the permanent magnets, and the directions of the poles are axially distributed along the permanent magnetic rotary plate; the second shaft is provided with a hub II and a conductor rotary plate, the second shaft is sleeved with the hub II in a connected mode, and the conductor rotary plate is connected with the hub II through bolts and arranged between the two permanent magnetic rotary plates. Different types of torque can be transmitted by adjusting the coupling area of rotors, and the purposes of vibration isolation, speed reduction and energy saving are achieved; meanwhile, installation and debugging are relatively easy, a certain amount of axial movement is allowed, torque transmission between the two permanent magnetic rotary plates and the conductor rotary plate is achieved, and the purposes of vibration isolation, speed reduction and energy saving are achieved.

Owner:QINGDAO SPRING ENERGY TECH

Vehicle having a belt pulley and standstill air conditioning

ActiveCN105408158AComfortable and fast restartShorten the timePower operated startersInternal combustion piston enginesClose couplingFreewheel

The invention relates to a vehicle, comprising an internal combustion engine, a belt-driven starter generator, and an auxiliary power take-off for auxiliary units, which auxiliary output can be decoupled. At least an air-conditioning compressor and an electric machine are usable as a motor and a generator as a belt-driven starter generator are provided as auxiliary units in the auxiliary power take-off. The vehicle is characterized in that the auxiliary power take-off is decoupled and coupled by means of a form-closed coupling, in particular a switchable ratchet freewheel, and that standstill air conditioning is occurs during the standstill of the internal combustion engine in short stop phases by rotating the auxiliary units backwards and the internal combustion engine is started after the stop phase by reversing the direction of rotation of the electric machine.

Owner:SCHAEFFLER TECH AG & CO KG

Double-layer cylindrical permanent magnetic coupler

InactiveCN108054899AAvoid axial thrustIncrease coupling areaPermanent-magnet clutches/brakesPhysicsFerromagnetism

Provided is a double-layer cylindrical permanent magnetic coupler. The double-layer cylindrical permanent magnetic coupler is composed of a first rotor and a second rotor; the first rotor is a cylindrical permanent magnetic rotor and composed of an outer magnetic ring, a middle magnetic ring and an inner magnetic ring which are installed at a non-ferrousmagnetic permanent magnetic disc, an annulargap is formed between the outer magnetic ring and the middle magnetic ring, and an annular gap is formed between the middle magnetic ring and the inner magnetic ring; the outer magnetic ring is composed of a ferro-magnetic outer cylinder and a permanent magnet fixed to the inner side of the outer cylinder, the inner magnetic ring is composed of a ferro-magnetic inner cylinder and a permanent magnet fixed to the outer side of the inner cylinder, and the middle magnetic ring is composed of a permanent magnet installed on the non-ferrousmagnetic permanent magnetic disc; the second rotor is a conductor rotor composed of an outer conductor ring and an inner conductor ring which are installed on a non-ferrousmagnetic installation disc, wherein the outer conductor ring of the second rotor is located in the gap between the outer permanent magnetic ring and a middle permanent magnetic ring and forms a coupling relationship with the permanent magnets on the outer permanent magnetic ring and themiddle permanent magnetic ring through air gaps, and the inner conductor ring forms a coupling relationship with the permanent magnets on the middle permanent magnetic ring and the inner permanent magnetic ring through air gaps. The first rotor is connected to a first shaft, the second rotor is connected to a second shaft, and the first shaft and the second shaft can be an input shaft or an output shaft for each other. The magnetic pole directions of the permanent magnets installed on the outer permanent magnetic ring, the middle permanent magnetic ring and the inner permanent magnetic ring are perpendicular to the axis of a rotary disc, and magnetic poles of adjacent magnets are different.

Owner:盐城市金海洋机电科技有限公司

Gear and rack transmission mechanism suitable for circular motion

PendingCN107882941AAvoid stickingSolve the problem of not being able to achieve circular motionFriction gearingsGear driveDrive shaft

The invention relates to a gear and rack transmission mechanism suitable for circular motion. The gear and rack transmission mechanism comprises a circumferential rack arrangement assembly and a driving gear assembly; the circumferential rack arrangement assembly is fixed to an arc-shaped basic support, and the driving gear assembly is connected to a driving shaft in a sleeving manner and is matched and meshed with the circumferential rack arrangement assembly; the circumferential rack arrangement assembly comprises a rack; the driving gear assembly comprises a driving outer gear and a drivinginner gear; the rack is linear and achieves circumferential arrangement in a manner of replacing a curve with a straight line; the overall driving gear assembly can rotate around the driving shaft; and tooth structures of the driving outer gear and the driving inner gear are crowned teeth. According to the gear and rack transmission mechanism, the standard rack forms fan-shaped teeth, the drivingouter gear is meshed with the teeth, and therefore circular motion is achieved, the problem that gear-rack transmission of non-fan-shaped teeth and taper gears cannot do circular motion is solved, and the standard rack-gear circumferential driving is achieved.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Static connection structure of keys

ActiveCN106050841APrecise vibrationAchieve torque transmissionKey type connectionsTorque transmissionEngineering

The invention discloses a static connection structure of keys. The static connection structure of the keys comprises a containing part and a contained part embedded into the containing part; at least two key grooves distributed in the circumferential direction in a spaced mode are formed in the contact face of the containing part and the contained part; and one of the key grooves is matched with a flat key, and the other key is matched with a tangential key. The connection structure accurately positions the containing part and the contained part through the advantages of good centering, high positioning precision, and good impact and vibration resistance of the flat key, and achieves torque transmission between the containing part and the contained part through the characteristic of good torque transmission performance of the tangential key, so that stable connection between the containing part and the contained part is achieved through cooperation of the two keys, and the phenomenon that the containing part and the contained part are likely to loosen due to impact, vibration or heavy loads is avoided; meanwhile, the tangential key can be subjected to match grinding so as to compensate for errors caused during manufacturing and assembling and deformation generated during using, so that the purposes of reducing the processing difficulty, bringing convenience to assembly and maintenance and reducing the processing and maintenance cost are achieved.

Owner:CHONGQING GEARBOX

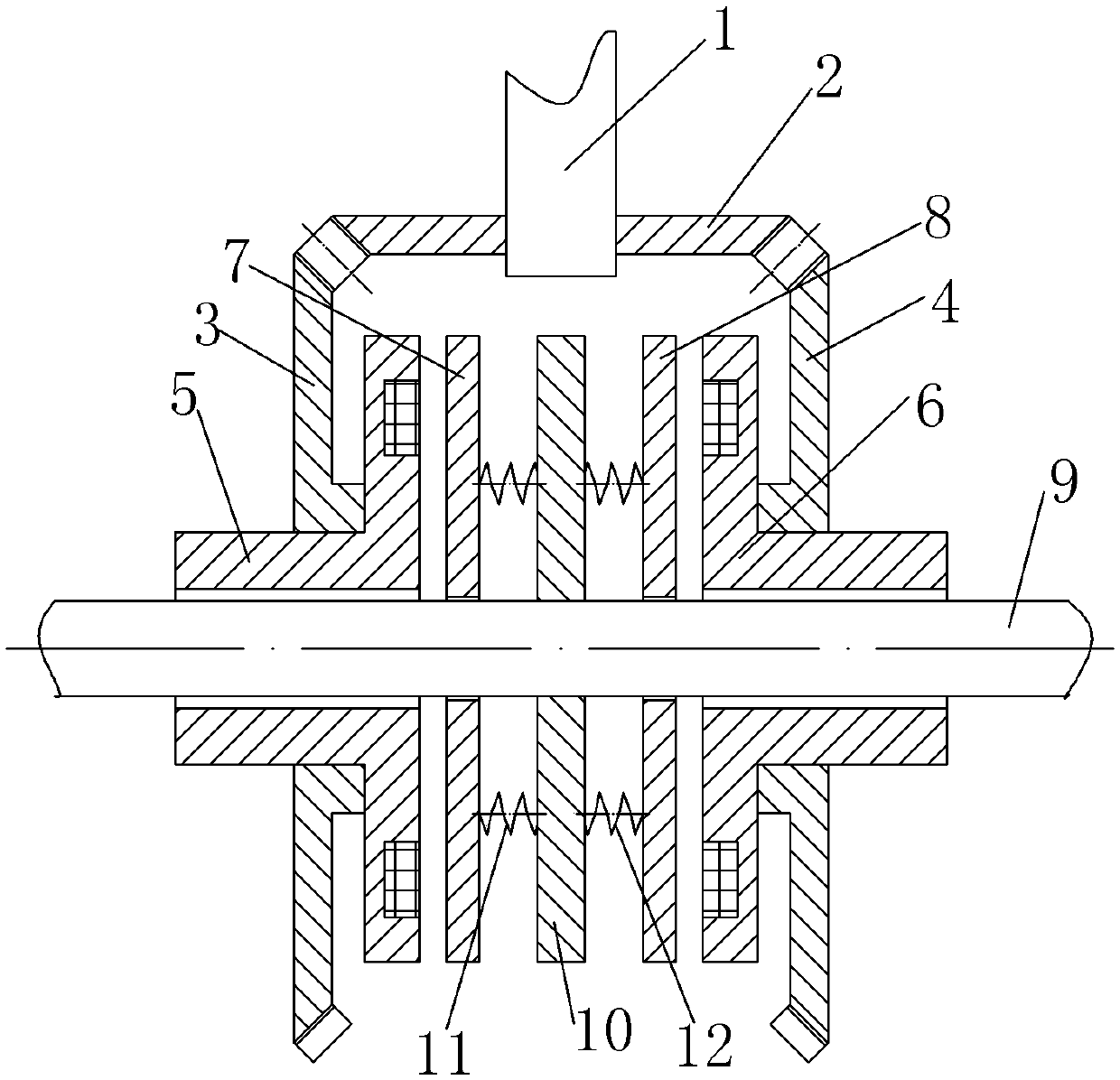

Reversible electromagnetic clutch

PendingCN105370751AAchieve torque transmissionSimple structureMagnetically actuated clutchesElectromagnetic clutchDrive shaft

The invention discloses a reversible electromagnetic clutch. The reversible electromagnetic clutch comprises a driving shaft, a driven shaft, a first electromagnet and a second electromagnet, wherein a main bevel gear is arranged on the driving shaft; two sides of the main bevel gear are respectively meshed with a first bevel gear and a second bevel gear; the first bevel gear is sleeved on the first electromagnet; the second bevel gear is sleeved on the second electromagnet; a first compression ring, a main compression ring and a second compression ring are also successively arranged between the first electromagnet and the second electromagnet on the driven shaft; at least one first tension spring is arranged between the first compression ring and the main compression ring; at least one second tension spring is arranged between the second compression ring and the main compression ring. The reversible electromagnetic clutch has the beneficial effect that the driven shaft can operate in different directions according to load conditions under the condition that the rotation direction of the driving shaft is not changed; meanwhile, the reversible electromagnetic clutch is simple in structure and convenient to operate.

Owner:CHONGQING CHENGSHUO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com