Device for compensating for tolerances

A technology of tolerance and compensation components, applied in the direction of thin plate connection, threaded fasteners, connecting components, etc., can solve problems such as limiting structural size, and achieve the effect of avoiding rotation, effective torque transmission, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

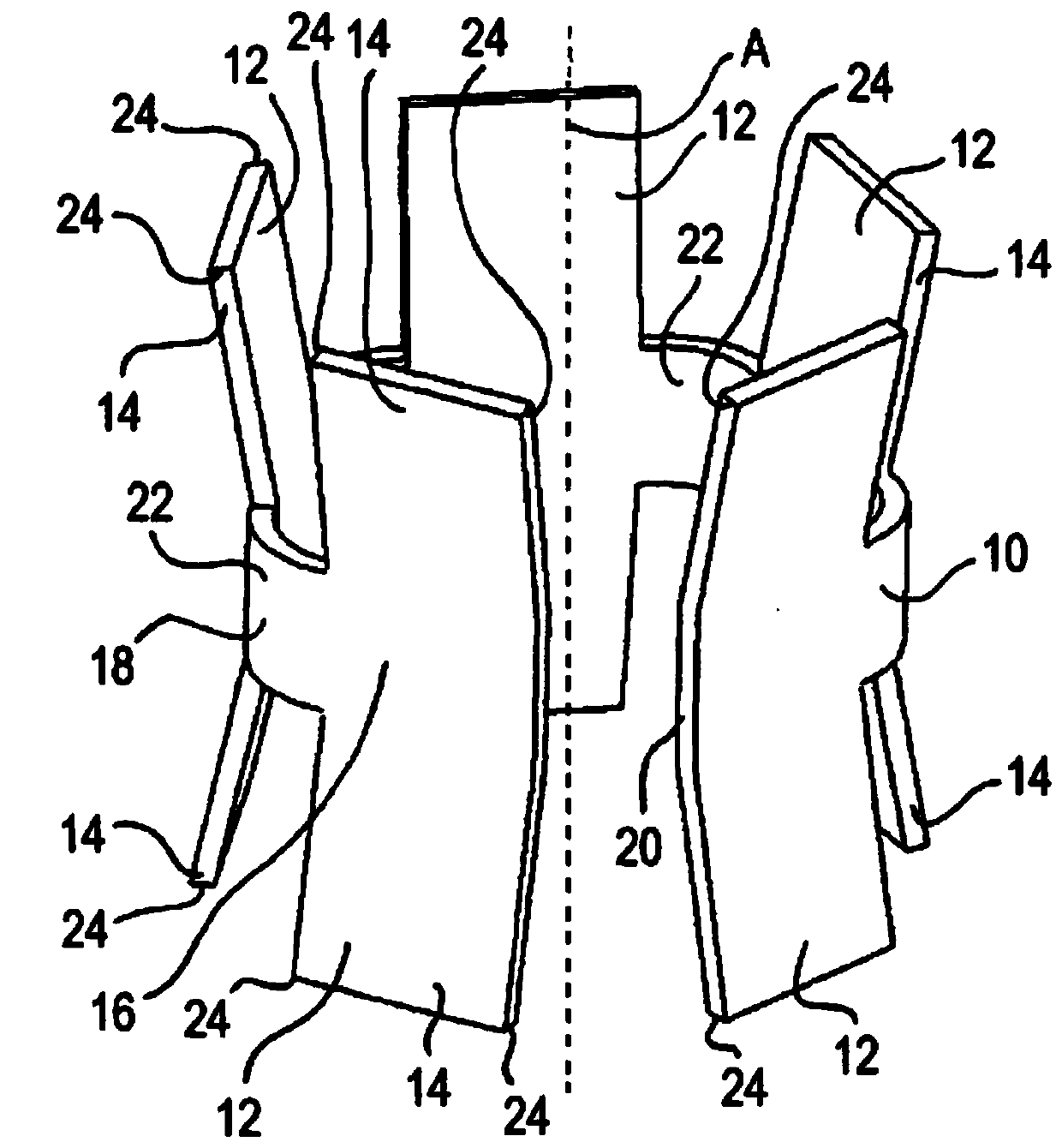

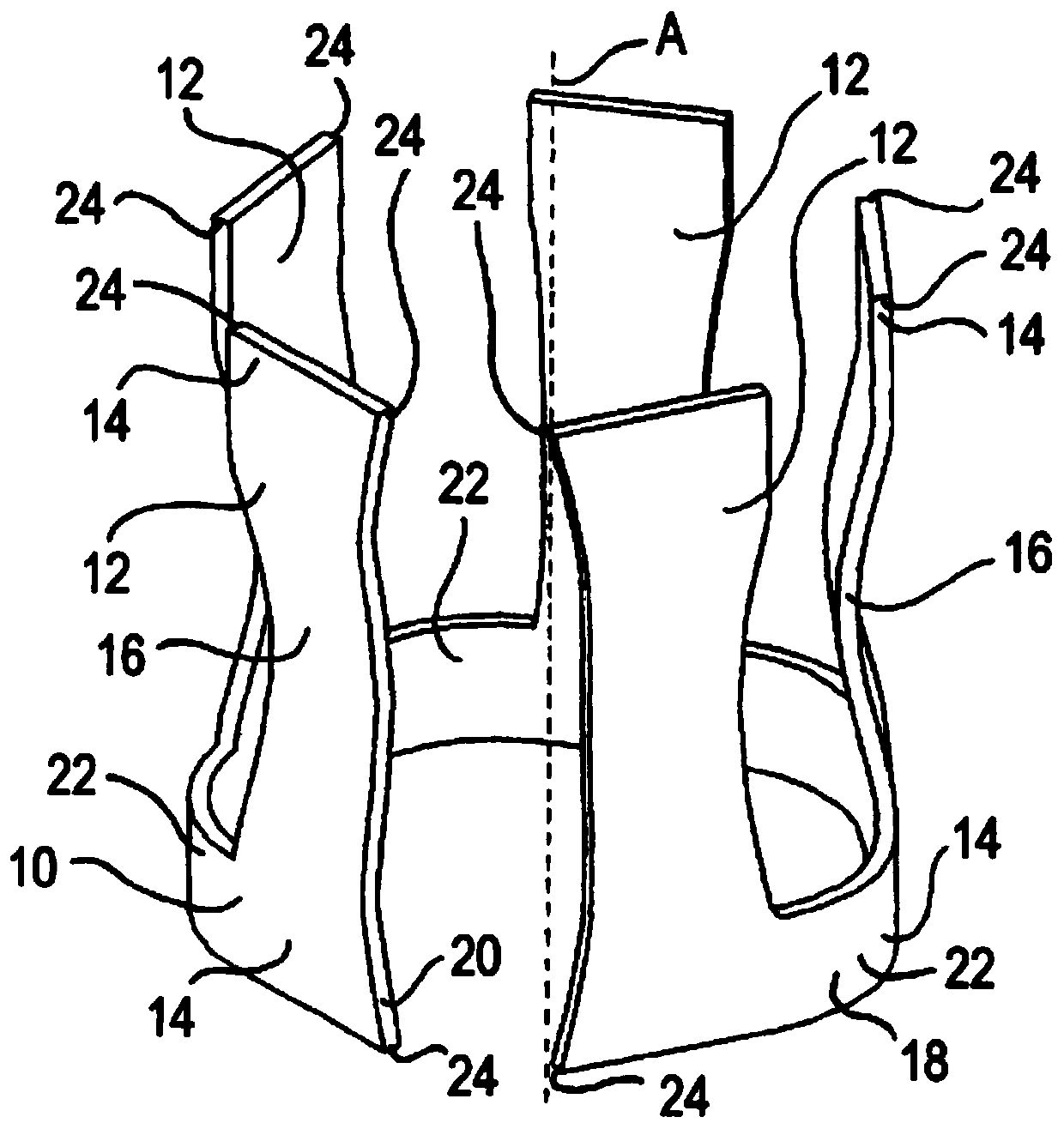

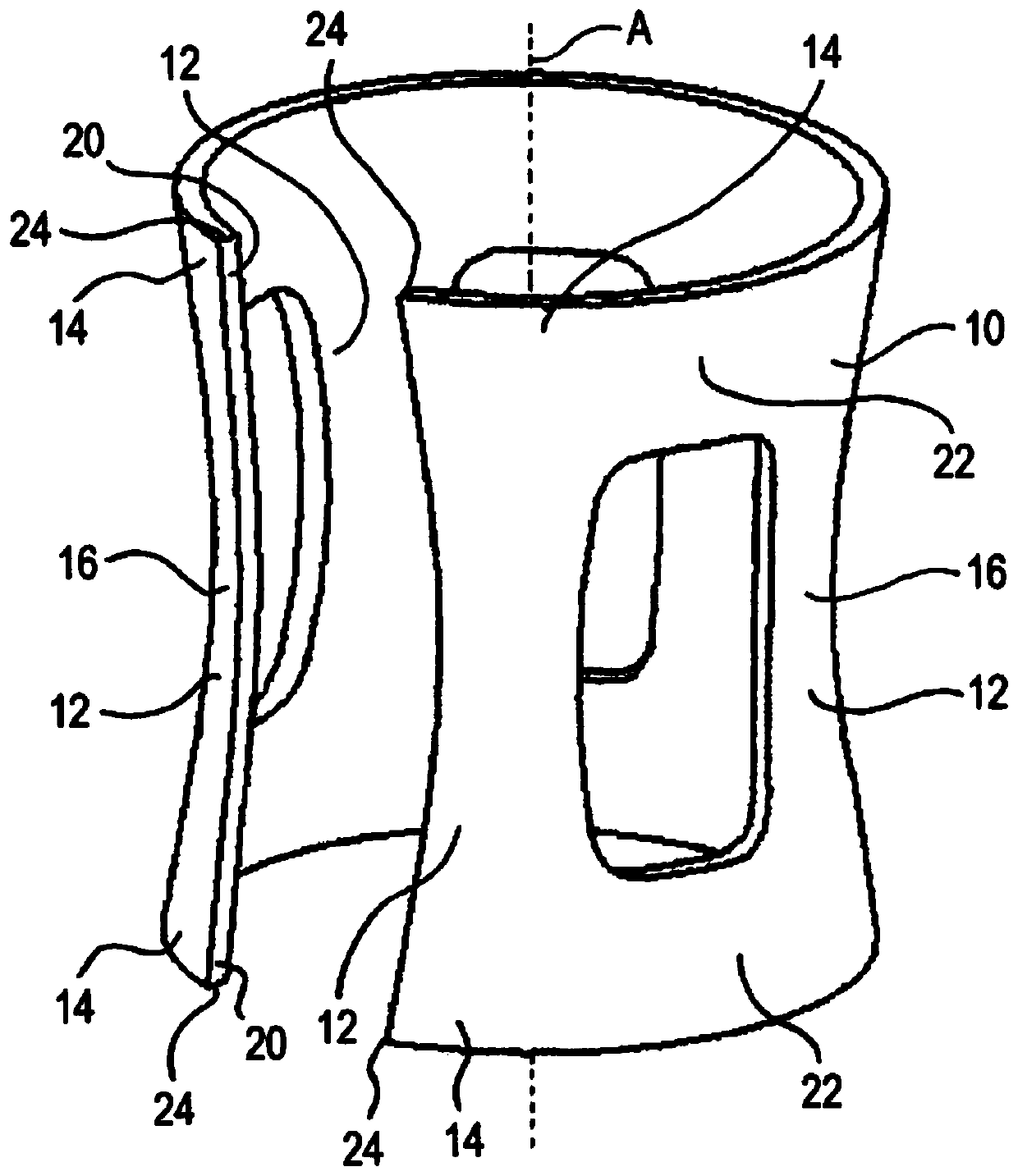

[0034] figure 1 Shown is a spring element 10 according to a first embodiment. The illustrated spring element 10 has five spring arms 12 arranged around a longitudinal central axis A of the spring element 10 , wherein the longitudinal extension of each spring arm 12 is at least approximately aligned with the longitudinal central axis A.

[0035] Viewed longitudinally, each spring arm 12 has two opposite end portions 14 between which a middle section 16 of the spring arm 12 is located. In this case, the two ends 14 of the spring arm 16 are further from the longitudinal center axis A than the middle section 16 . In other words, the end portions 14 are pushed radially outwards in the axial direction, while the intermediate section 16 is bent radially inwards in the direction of the longitudinal central axis A. As shown in FIG.

[0036] The spring arms 12 are connected to each other by means of connecting rings 18 which are interrupted by grooves 20 . The slot 20 is at least app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com