Drive train for a motor vehicle

A technology of power train and vehicle, applied in the field of power train, can solve problems such as the influence of the actual power of the motor, and achieve the effect of improving the service life and reducing the mechanical load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

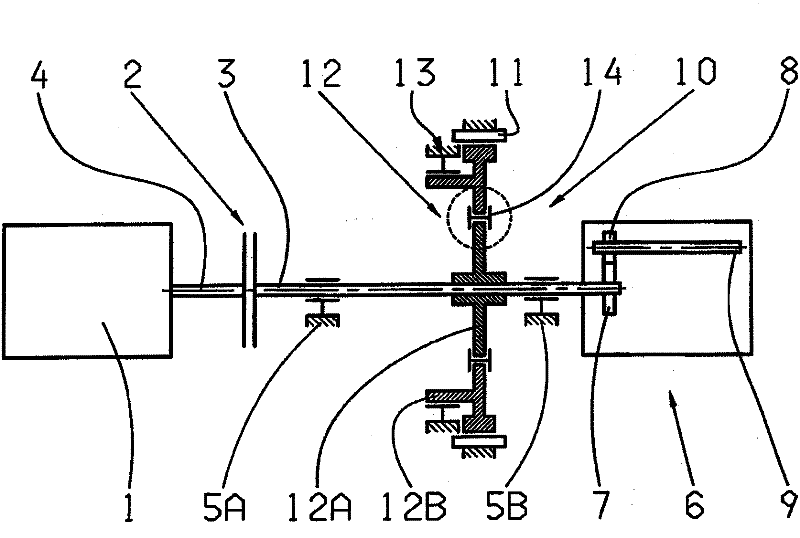

[0022] exist figure 1 shows that the drive motor 1 is coupled to the drive shaft 3 via a clutch 2 serving as a friction-locking (reibschlüssig) starting clutch. Thus, in the engaged state of the clutch 2 , the torque generated by the drive motor 1 is transmitted from the motor output shaft 4 via the clutch 2 to the drive shaft 3 of the drive train. Conversely, in the engaged state, no torque is transmitted from the drive motor 1 to the drive shaft 3 via the clutch 2 . The drive shaft 3 is rotatably supported by two shaft bearings 5A, 5B fastened to the housing and serves as an input shaft for a transmission 6 of the countershaft transmission type, for which purpose a resistive A gear 7 is arranged in a rotationally opposite manner, which transmits the torque from the drive shaft 3 to the gear 8 of the intermediate shaft 9 of the transmission 6 .

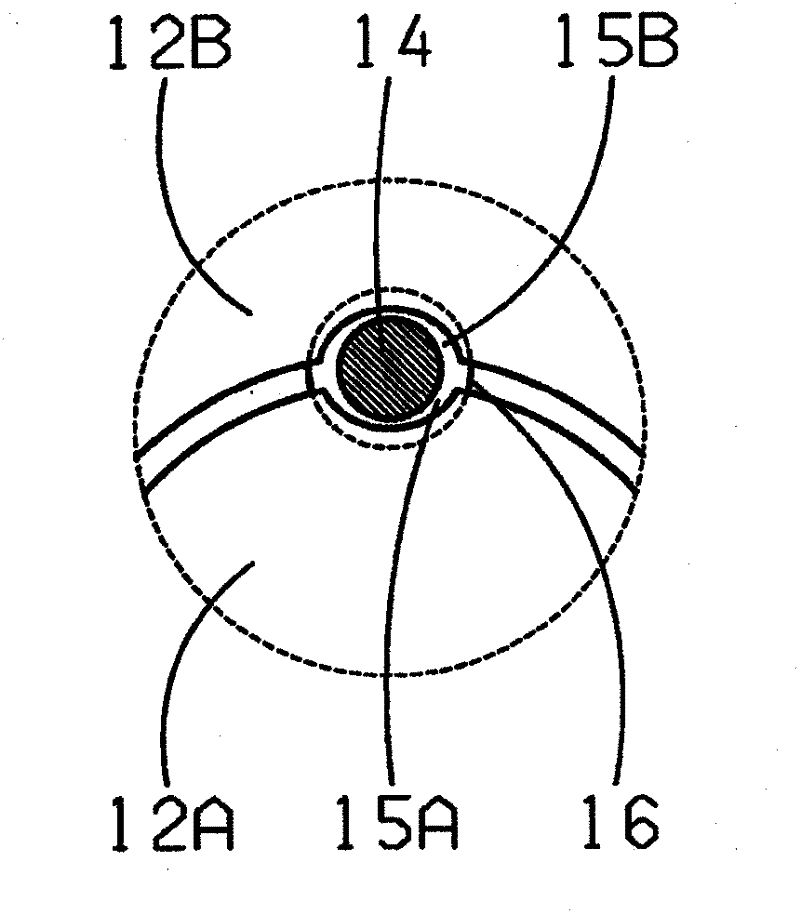

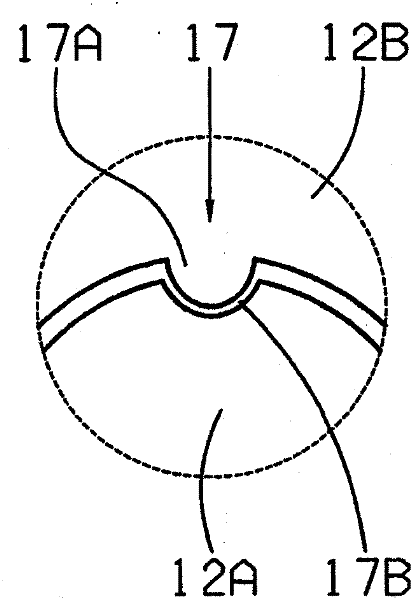

[0023] Arranged around the drive shaft 3 is an electric motor 10 equipped with a stator 11 affixed to the housing and a two-part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com