Floating positioning and torque transmission structure of turbine guide device

A turbine guide, floating positioning technology, applied in the direction of machine/engine, stator, engine components, etc., can solve problems such as increasing structural complexity, and achieve the effect of eliminating thermal stress problems, reducing self-locking flow, and reducing expansion and deformation constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

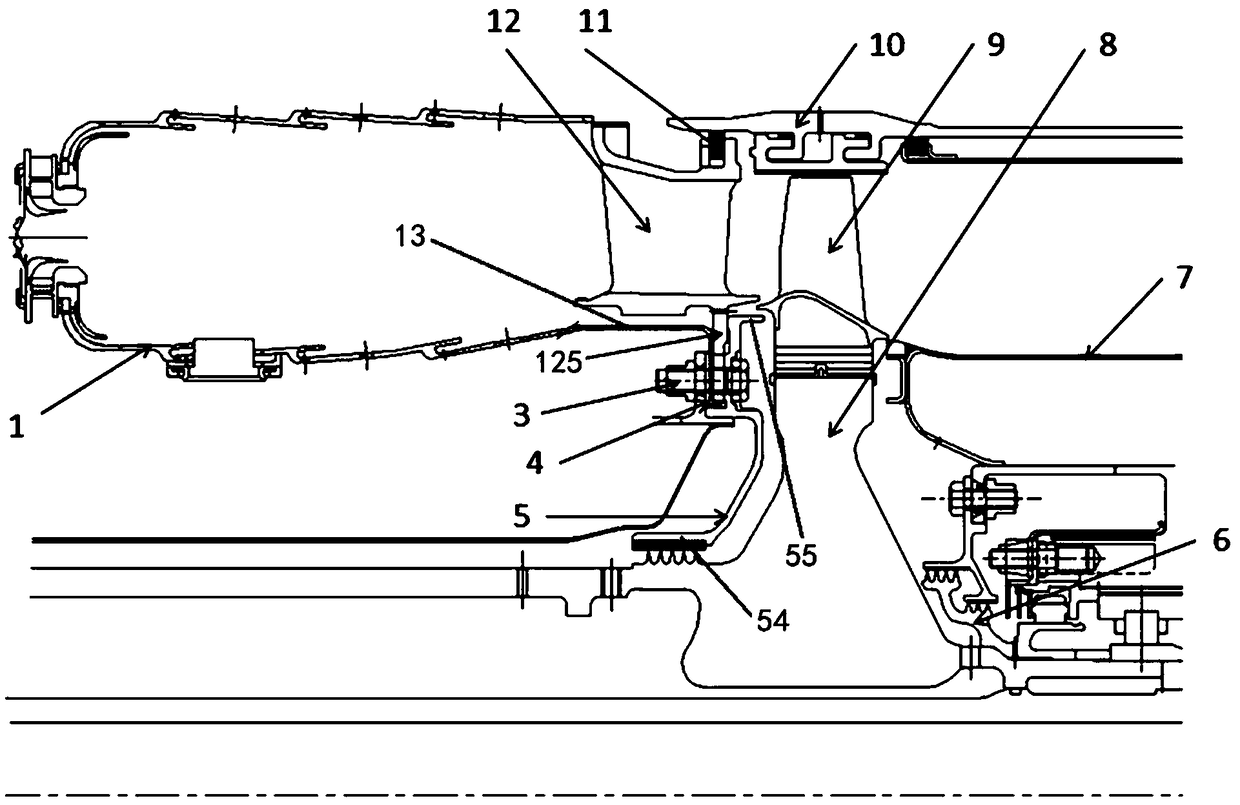

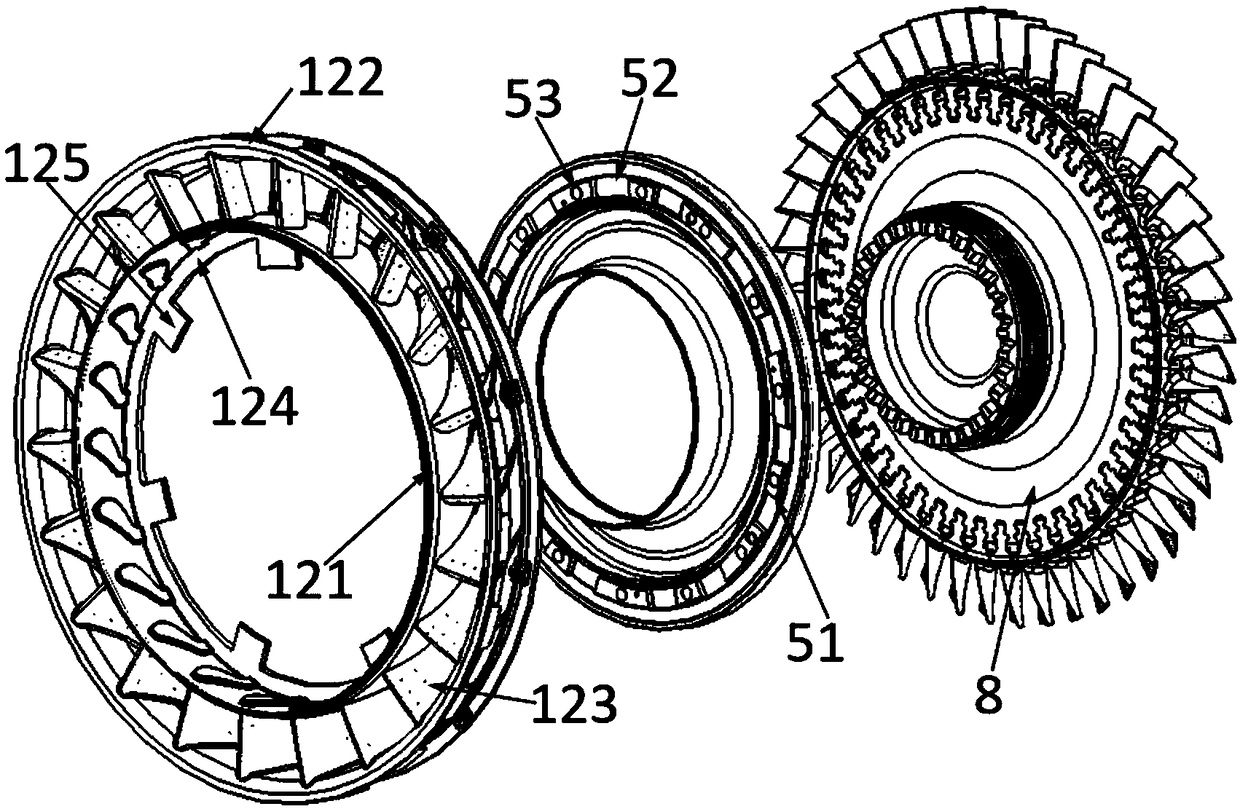

[0020] Such as figure 1 , 2 As shown, this embodiment is a design scheme of applying the floating positioning and torsion transmission structure of the turbine guider of the present invention in the downstream of an aeroengine combustion chamber. In this embodiment, the high-pressure turbine guide 12 and the high-pressure turbine rotor are sequentially arranged downstream of the combustor flame tube 1, and the high-pressure turbine rotor includes a high-pressure turbine disk 8 and high-pressure turbine rotor blades 9 arranged on the peripheral edge of the high-pressure turbine disk 8 The high-pressure turbine guide 12 is arranged axially upstream of the high-pressure turbine rotor blades 9 , and the upstream of the high-pressure turbine dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com