Drive system of high-pressure fuel pump, high-pressure fuel pump assembly and internal combustion engine

A driving system and high-pressure pump technology, applied in liquid fuel engines, charging systems, fuel injection pumps, etc., can solve the problems of high cost, high fuel consumption, high weight, etc. glitch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

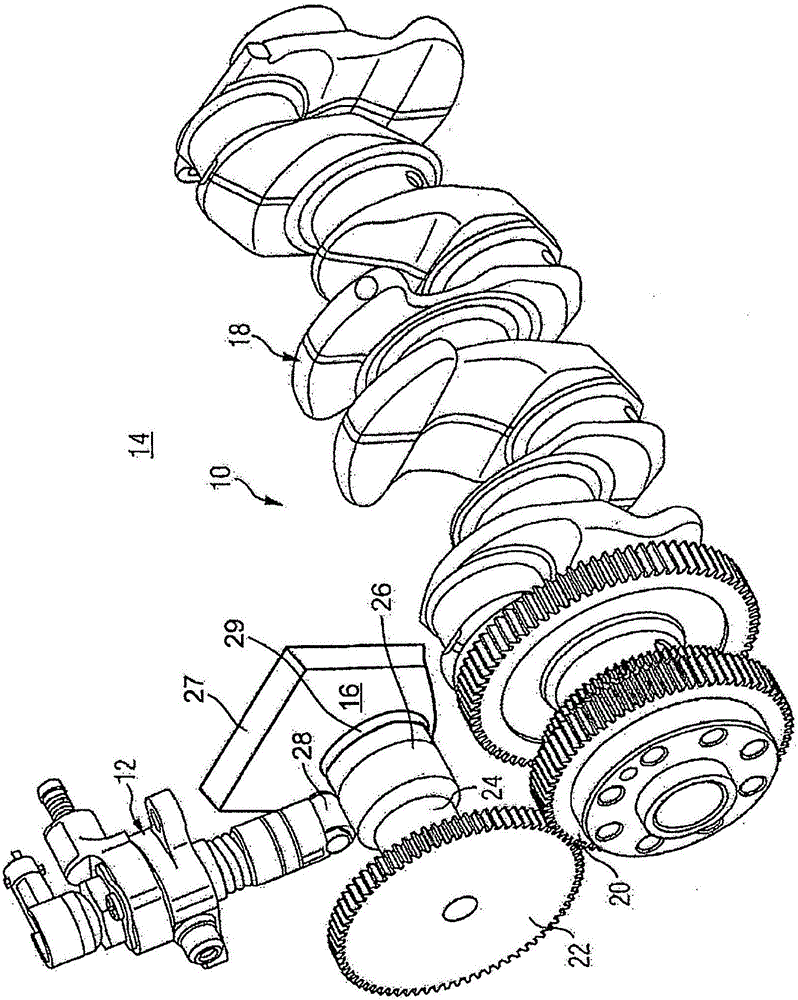

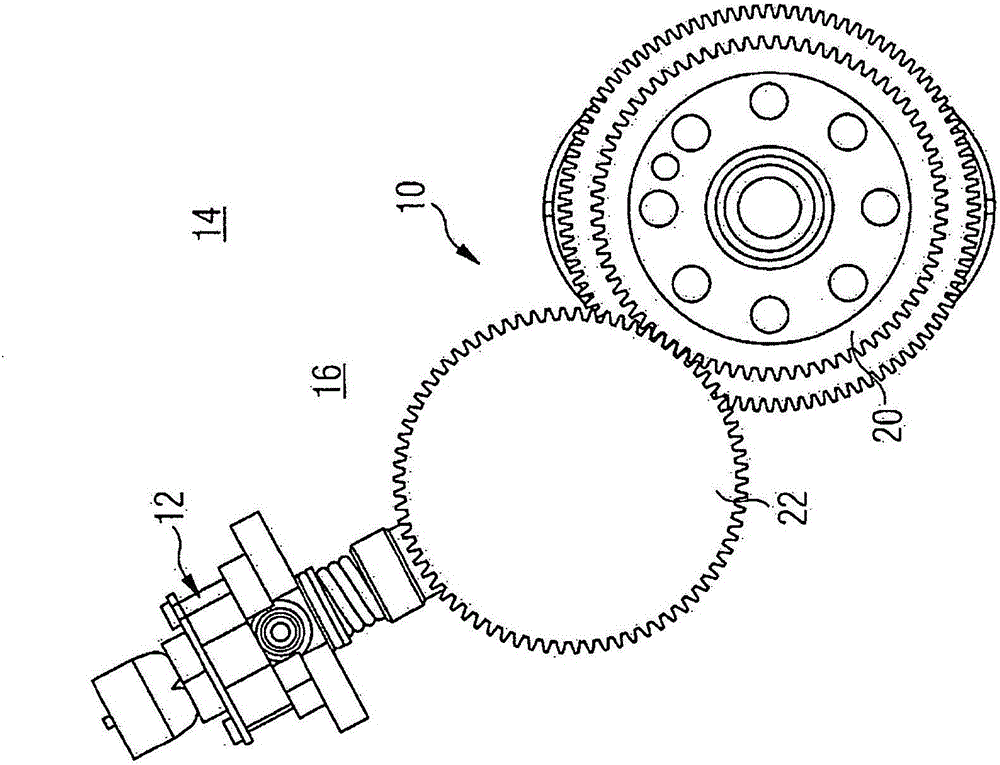

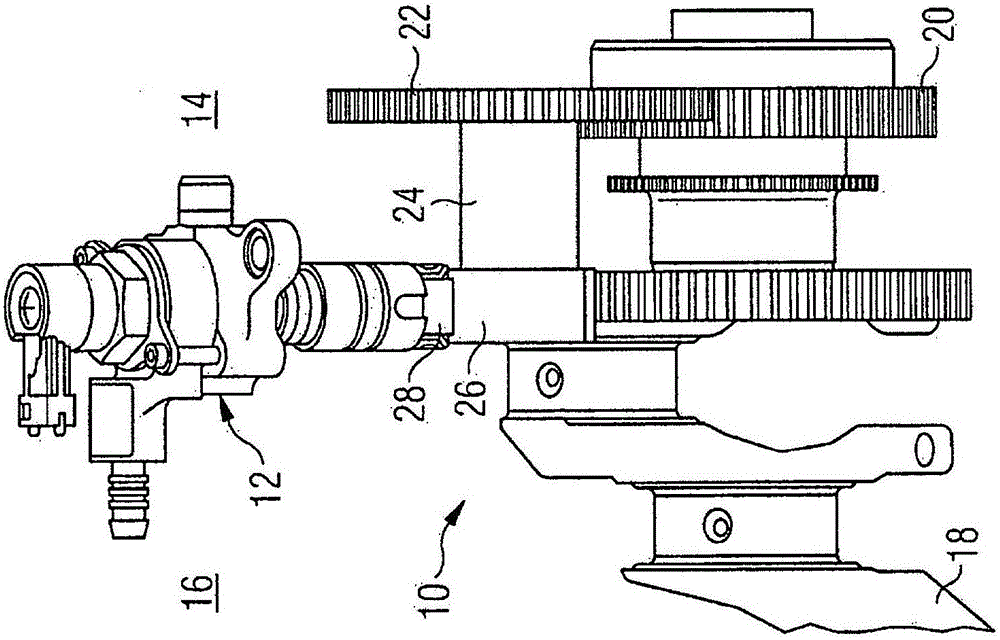

[0051] figure 1 A first exemplary embodiment of a drive system 10 according to the invention of a high-pressure fuel pump 12 of an internal combustion engine 14 which is installed in a high-pressure fuel pump assembly 16 according to the invention is shown.

[0052] exist figure 1 The high-pressure fuel pump assembly 16 shown in is installed in the internal combustion engine 14 according to the invention.

[0053] The drive system 10 has the shown drive train, which is coupled on the drive side to a crankshaft 18 and on the output side to a camshaft, not shown in detail here, for the control valves.

[0054] exist figure 1 In the embodiment shown, the internal combustion engine 14 is a diesel engine with common rail technology, and the high-pressure fuel pump 12 is arranged upstream of a so-called rail or high-pressure accumulator on the input side.

[0055] The crankshaft 18 of the internal combustion engine 14 is provided with a crank gear 20 on the end side. The cranksh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com