Poller type wheel of vehicle

A universal wheel, a new type of technology, applied in the direction of wheels, vehicle parts, transportation and packaging, can solve the problems of noise, offset, inflexible force center of the universal wheel, etc., to improve flexibility, eliminate noise, Well-stressed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

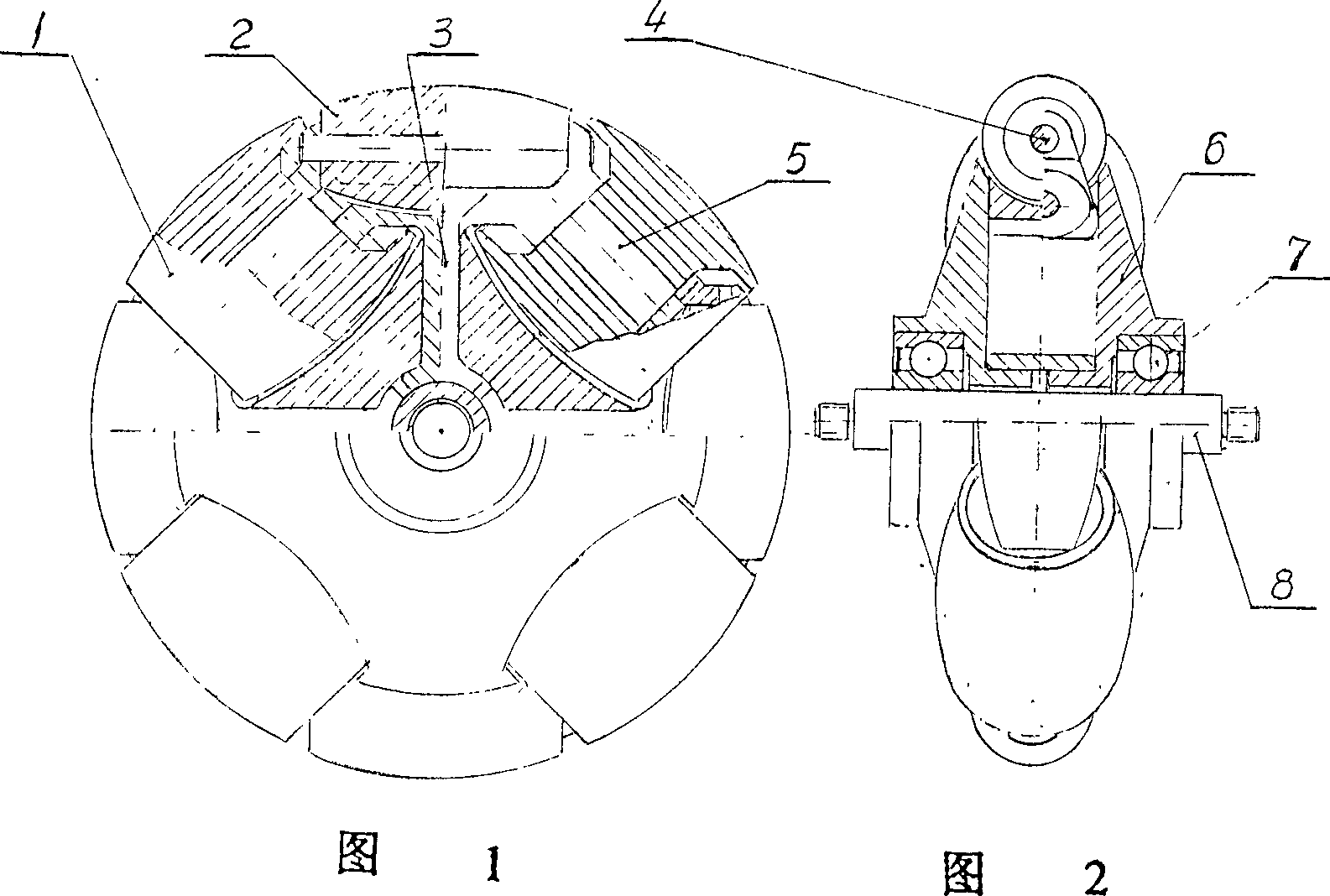

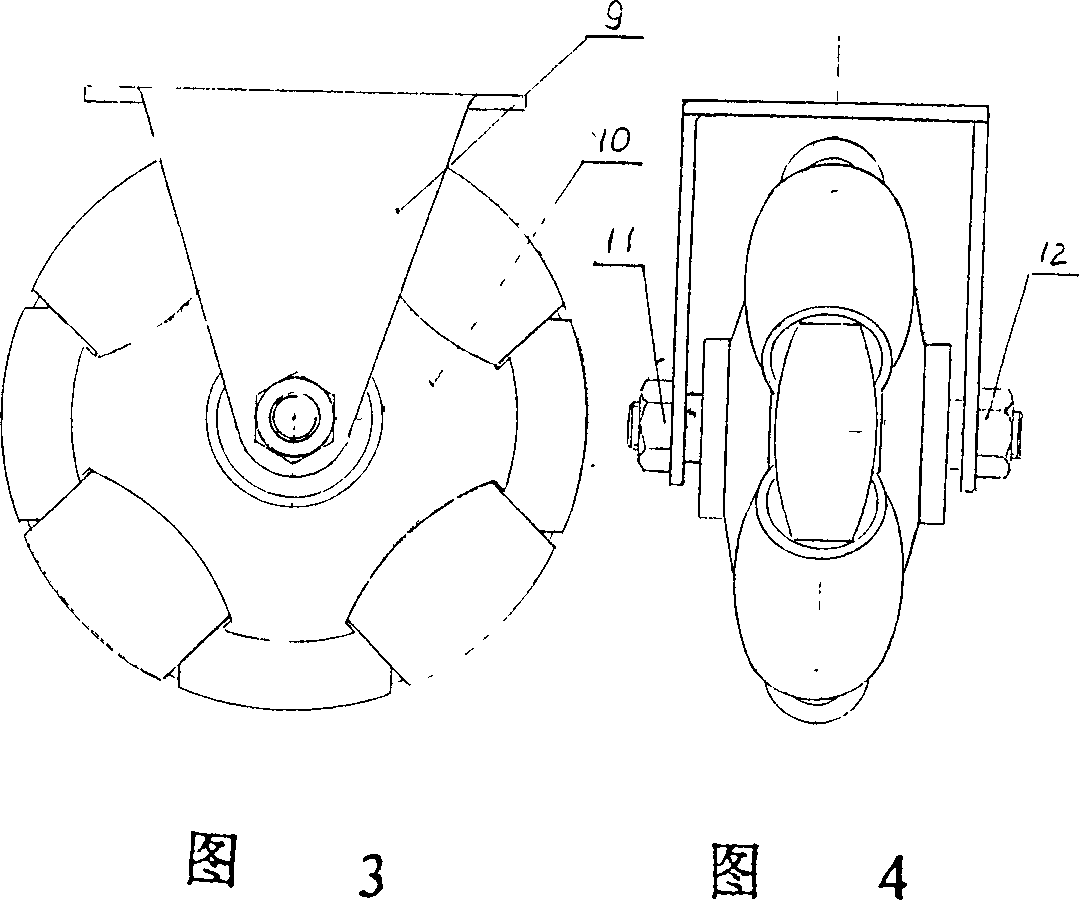

[0022] Fig. 1 is the implementation figure of four pairs of large and small drum-shaped rollers, in which there is a groove on the half hub (6) to insert the Y-shaped support (3) into the groove, above the Y-shaped support (3) There are shaft holes on the left and right fork heads to install the mandrel (4). On the mandrel (4), the small drum-shaped roller (2) is installed, and the middle part between the adjacent Y-shaped brackets (3) has shaft holes on the left and right. The short mandrel (5), on which the large drum-shaped rollers (1) are installed, the large drum-shaped rollers (1) and the small drum-shaped rollers (2) are alternately distributed on the entire rim of the wheel superior. If viewed from the axial view direction of the universal wheel, the outer contours formed by these large and small drum-shaped rollers (1) (2) are arranged into an outer circle. Finally, the outer ends of the two half-hub discs are loaded with rolling bearings (7), and the central axis (8...

Embodiment 2

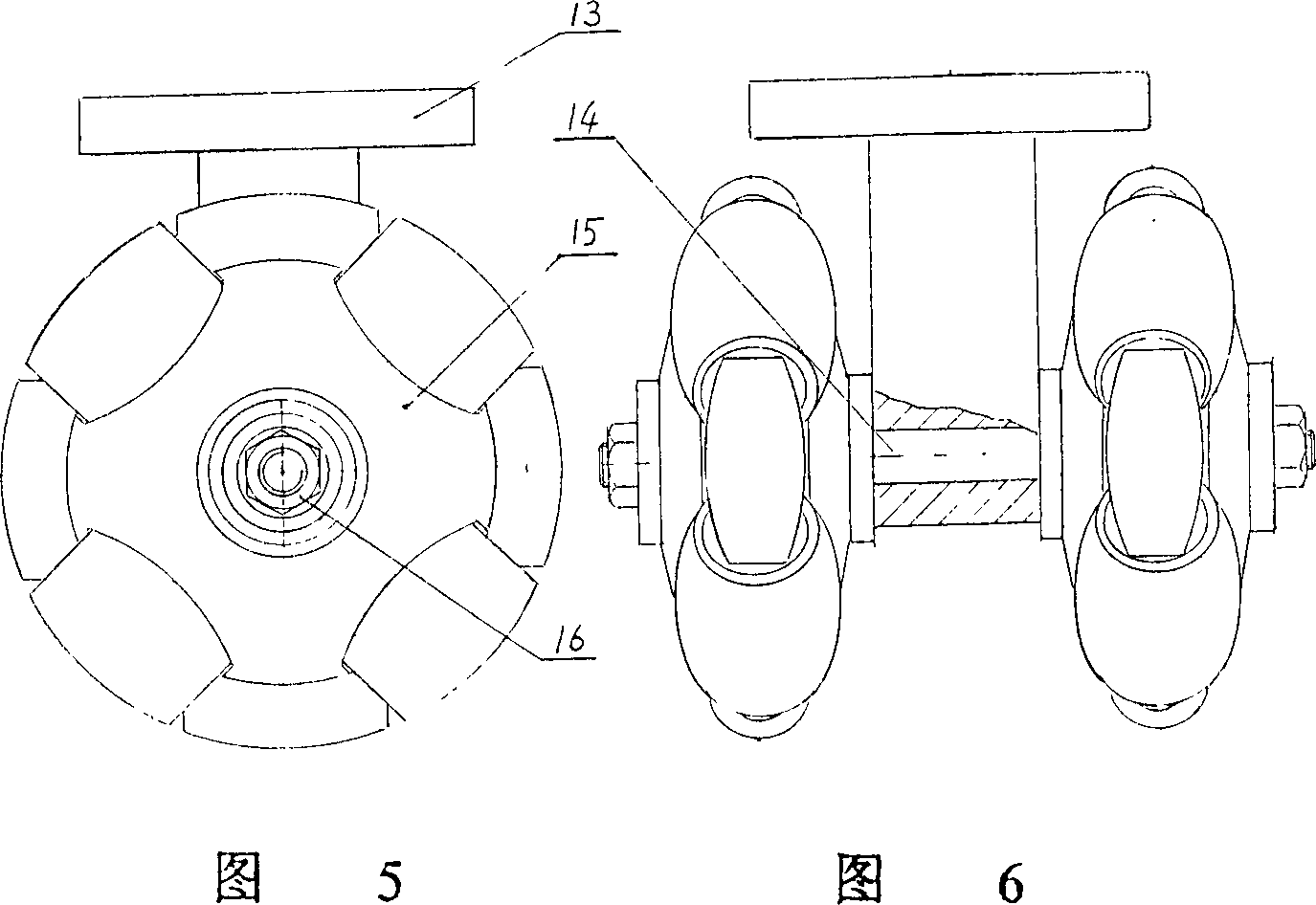

[0027] Fig. 9 and Fig. 10 are the embodiment of five pairs of large and small drum-shaped rollers. Among the figures, there is a groove on the half hub (6) to insert the Y-shaped support (3) into the groove, and the Y-shaped support (3) ) above the left and right fork heads respectively have shaft holes to install the mandrel (4), on the mandrel (4) a small drum-shaped roller (2) is installed, and the middle part between the adjacent Y-shaped brackets (3) has shafts on the left and right. The short mandrel (5) can be installed in the hole, and the large drum-shaped roller (1) is installed on the short mandrel (5), and the large drum-shaped roller (1) and the small drum-shaped roller (2) are alternately distributed on the wheel on the entire rim. If viewed from the axial view direction of the universal wheel, the outer contours formed by these large and small drum-shaped rollers (1) (2) are arranged into an outer circle. Finally, the outer ends of the two half-hub discs are lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com