Patents

Literature

261results about How to "Achieve the intended purpose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

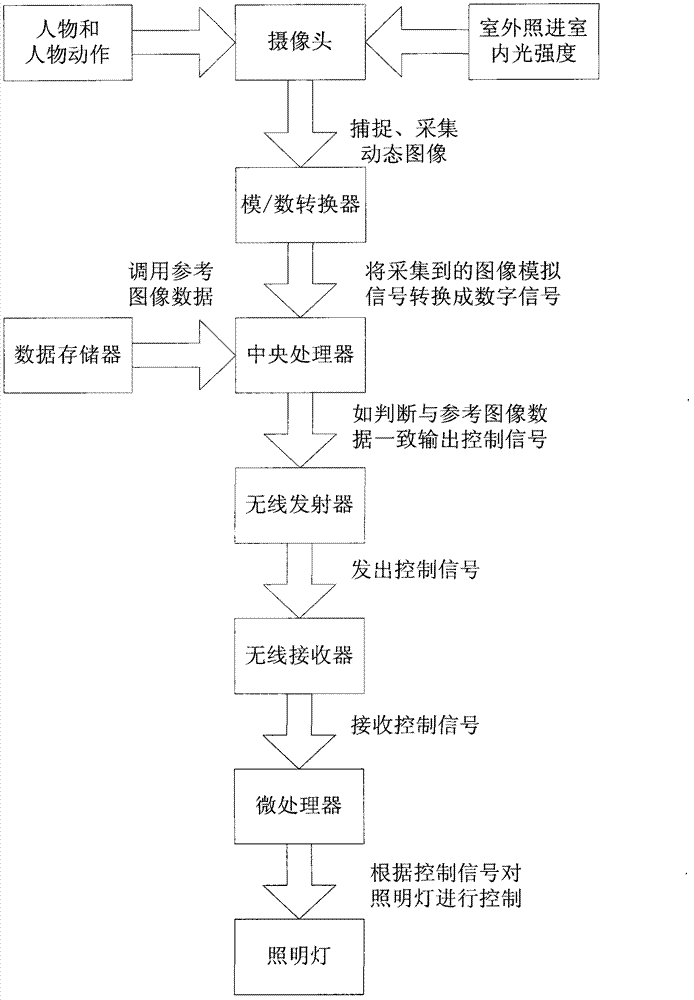

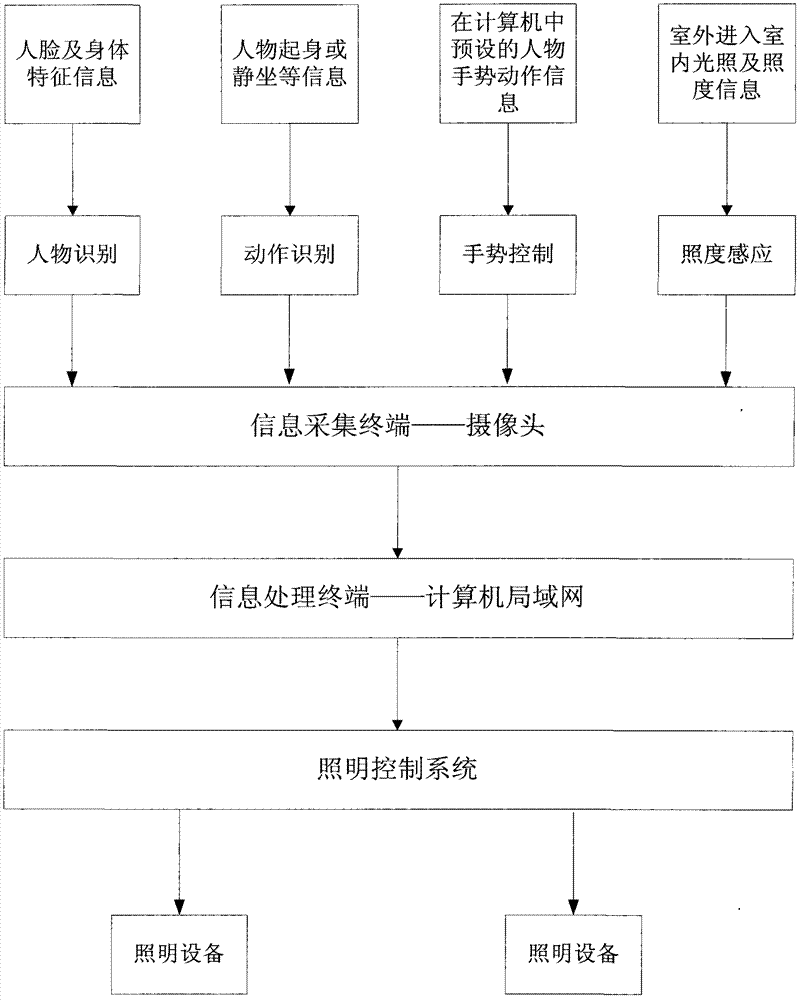

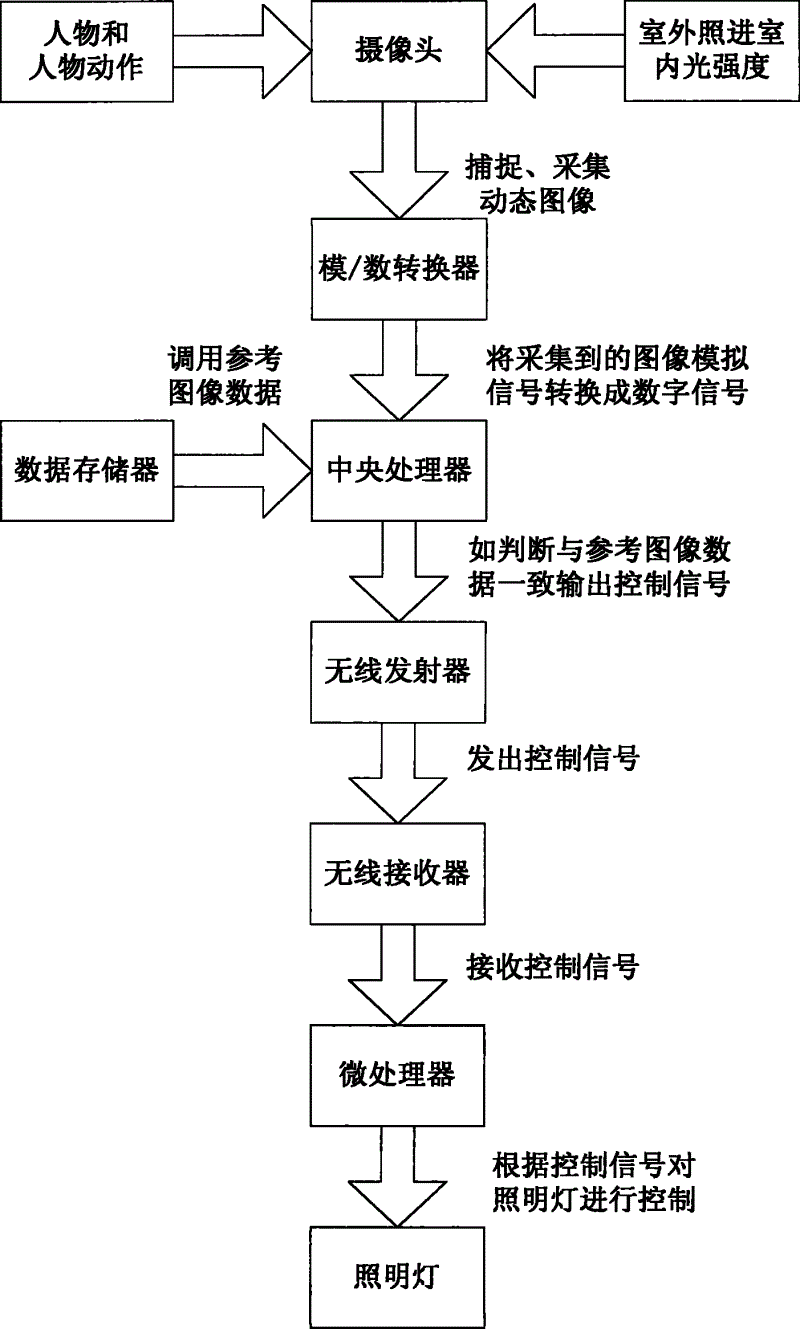

Intelligent indoor illumination control method and system based on dynamic video identification

InactiveCN102711315ARealize intelligent controlAchieve the intended purposeElectric light circuit arrangementEnergy saving control techniquesIlluminanceControl signal

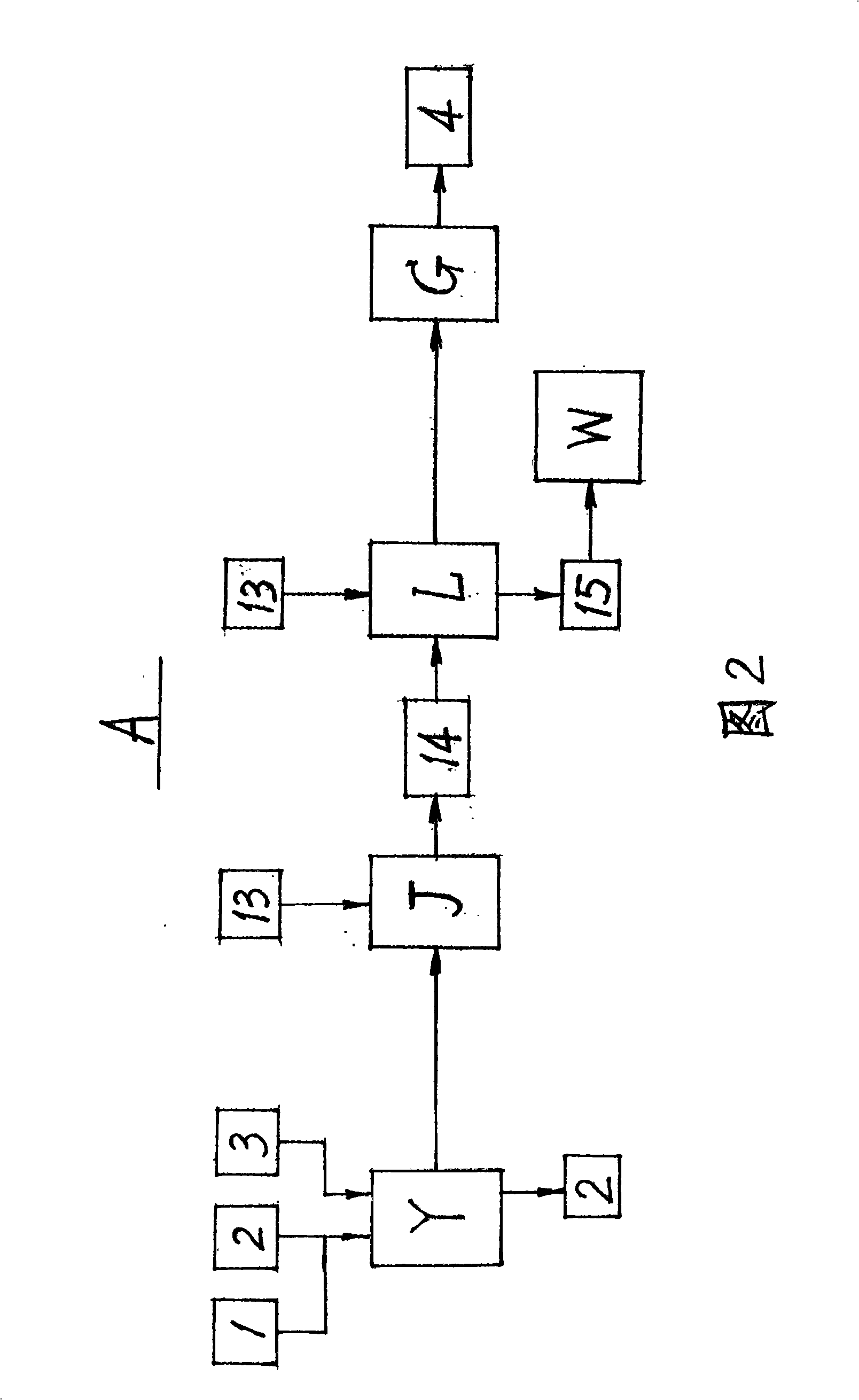

The invention discloses an intelligent indoor illumination control method based on dynamic video identification, which comprises the following steps of: (1) arranging an information acquisition module, and collecting an information source; (2) arranging a function control device; (3) arranging a light control device; (4) connecting all modules in the above steps mutually, electrifying and enabling the modules to work; (5) processing a signal by a central processing module, and outputting a light control signal; and (6) according to the received control signal, controlling a controlled luminaire by the light control device. The invention also discloses a system which implements the method. By a camera of the system disclosed by the invention, the intelligent control of a lighting system is effectively implemented by means of character recognition, movement recognition, gesture control, illuminance induction and the like so as to comfortably, flexibly and efficiently control illumination in a humanizing mode, so that the method is applicable to various indoor illumination application environments.

Owner:GUANGDONG LITE ARRAY

Polyvinyl chloride/chlorinated polyvinyl chloride skin foamed sheet and preparation method thereof

InactiveCN102040785AHigh surface hardnessIncrease productivityAntioxidantChlorinated polyvinyl chloride

The invention relates to a polyvinyl chloride / chlorinated polyvinyl chloride skin foamed sheet and a preparation method thereof, and the polyvinyl chloride / chlorinated polyvinyl chloride skin foamed sheet comprises the following materials in parts by weight: 60-90 parts of polyvinyl chloride, 10-40 parts of chlorinated polyvinyl chloride, 2.8-7 parts of stabilizer, 3-5 parts of foam regulator, 1-3 parts of foam nucleating agent, 0.5-2 parts of foaming agent, 0.6-1.5 parts of external lubricant, 0.5-1 part of internal lubricant, 0.5-2 parts of processing aids, 0.05-0.5 part of antioxidant and no more than 30 parts of filler. The preparation method is as follows: adding all the materials into a high-speed stirring machine, and mixing uniformly; heating to 90-120 DEG C, and carrying out heat preservation for more than 10 minutes; placing into a cold mixing machine, cooling down to 25-45 DEG C, tapping into a storage bin, extruding a foaming material through an extruder, and further carrying out vacuum shaping, cooling molding and edge trimming and finishing; and finally carrying out cutting and packaging according to the required length. The product has high surface hardness and great strength, is less prone to deformation, easy for processing, reasonable in manufacturing process, low in cost, good in quality and high in efficiency and has extensive popularization value and good economic and social benefits.

Owner:杜文军

Method for cultivating mushrooms by using fungi grass

The invention relates to a method for planting mushroom via mushroom grass, which uses large mushroom grass or the like as main material and uses bran as findings to realize the dual-spore mushroom cultivation. The invention comprises large mushroom grass, reed, alfalfa, gesso and superphosphate or the like. The invention can combine the protein and other nourishment and findings to improve the quality. And the invention uses the organic material to avoid pollution.

Owner:福建农大菌草技术开发公司

Manufacturing technology for high-speed and high-temperature precision deep groove ball bearing

The invention discloses a manufacturing technology for a high-speed and high-temperature precision deep groove ball bearing. A complete set of bearing product is manufactured by processing a forge piece blank into a workpiece billet with an outer ring and an inner ring, then respectively performing technical processes of respective technologies of cold rolling, thermal treatment, coarse grinding, thermal stabilization, fine grinding, grinding and the like, performing inspection and then performing cleaning and assembling. In the cold rolling technique, a cold rolling machine tool is used, a main driving forming rolling wheel is used as an outer die of a mold, and a driven forming mandril is used as an inner die of the mold, so that the forming rolling wheel drives the workpiece billet to rotate, and a supporting wheel pushes the forming mandril to forwards feed and extrude the workpiece billet to roll and form a product; in the thermal stabilization technique, the workpiece subjected to coarse grinding is subjected to heat preservation in a tempering furnace at temperature of 400 DEG C for 4 hours and then is taken out for natural cooling. The limit rotating speed of the complete set of bearing is 12,000 r / min, and the limit working temperature is 160 DEG C; the working noise is less than or equal to 45 dB; the rated load is Cr41.2KN and Cor24KN. The manufacturing precision is high, and the matching performance is high.

Owner:山东鑫兴精密轴承科技有限公司

A prepared tea combined by oolong tea with green tea or white tea

InactiveCN101006813AImprove taste qualityA fly in the ointment to cover up miscellaneous flavorsPre-extraction tea treatmentDigestive systemFlavorBead shape

The invention discloses prepared tea containing complementation combination of oolong and green tea or white tea, and belongs to the tea field. The invention is a kind of dominant complementation with one tea modifying another tea. The invention reinforces the synergy of the two kinds of tea. The invention is characterized in: preparing the tea to a combination with bead shape, clamping green or white tea in oolong (Tieguanyin is the best) leaves to prepare to bead shape, or packaging separately into lovers tea for keeping the advantages of the tow kinds of tea and overcoming the light and bitter flavor in common green or white tea, and foreign flavor in oolong. The invention can still have perfume after being soaked for several times, has the special characters of green tea and oolong, can be drunk in all seasons, and increases new product to the development of fine tea.

Owner:吴卫清

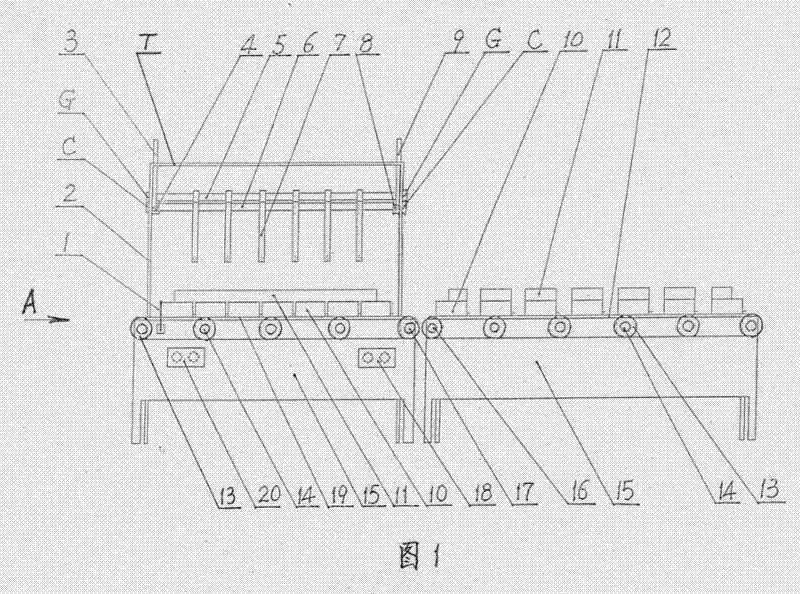

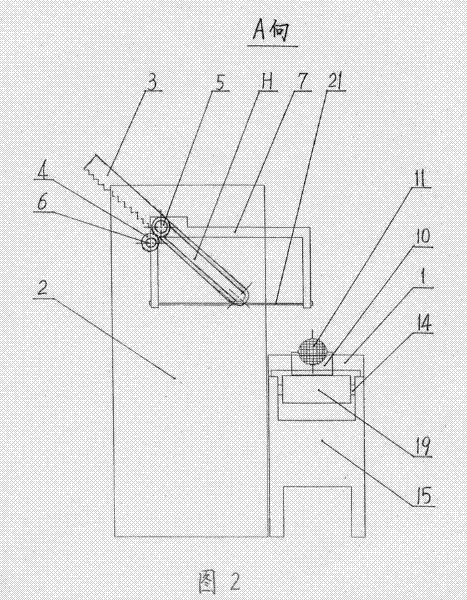

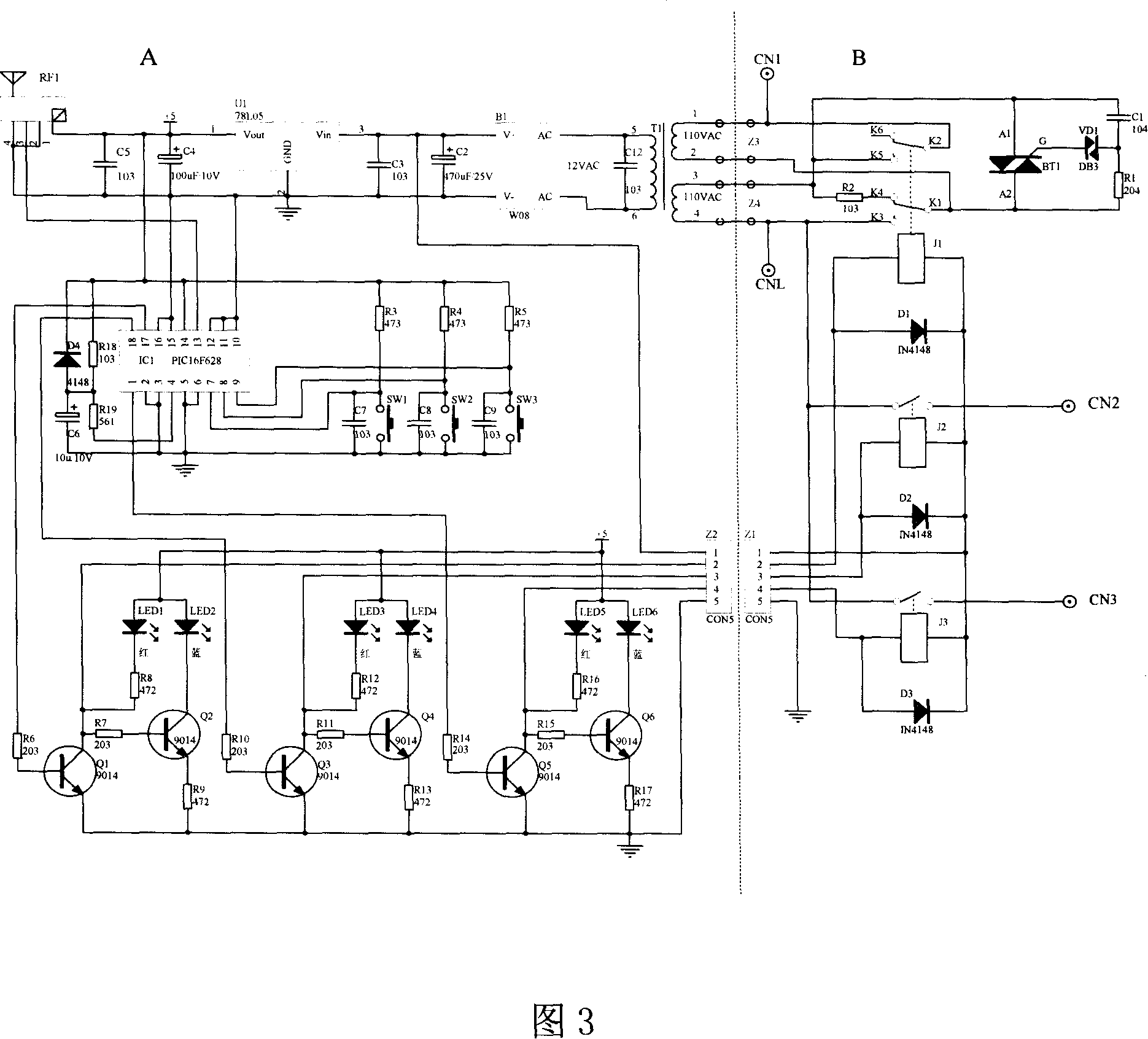

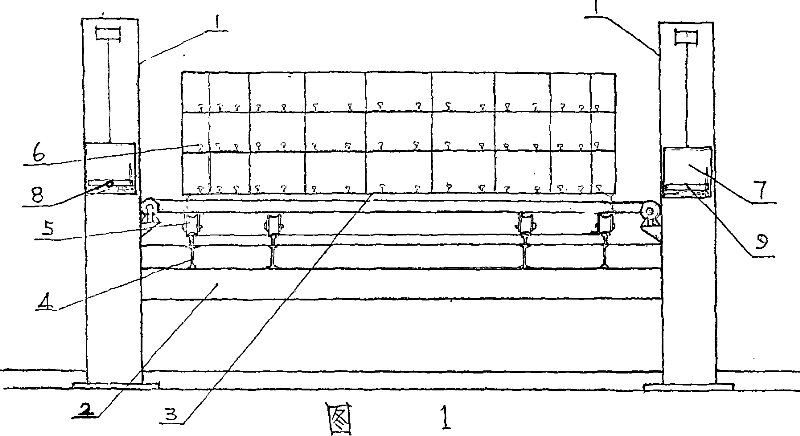

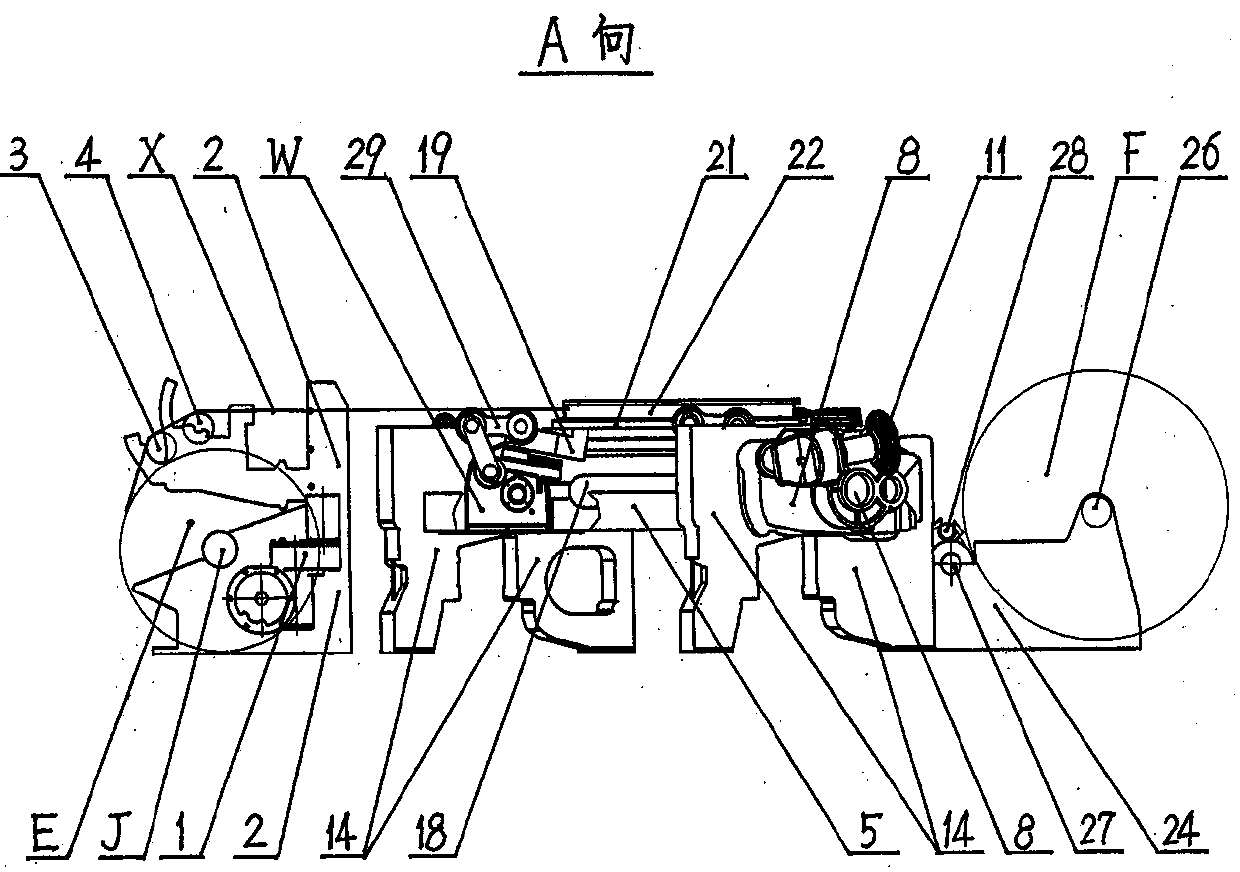

An automatic cutting and forming device for honeycomb ceramic wet blank

InactiveCN102267174ARealize automatic cuttingIncrease productionCeramic shaping apparatusConveyor beltMetal

An automatic honeycomb ceramic wet blank cutting and forming device is characterized in that a plurality of gantries (10) are arranged on a delivery working platform, a support (2) is arranged beside the delivery working platform, tool rests (7) are sheathed on a tool bar (5), two ends of the tool bar (5) are arranged in a slideway (H) of the support (2) at two ends, and a transmission rack (3) is arranged at the front end. A bearing (C) is sheathed at two ends of a drive rotation axle (6) and erected in shaft holes of the support (2) at two ends, a transmission gear (4) is sheathed at the front end and meshed with the transmission rack (3). A cutting motor (29) is started, the transmission gear (4) is driven by the drive rotation axle (6) to be meshed with the transmission rack (3), the tool bar (5) drives n tool rests (7) to slide down along the slideway (H), a metal wire blade (21) is embedded in gaps of the gantries (10), a cylindrical wet blank (11) is cut into n+1 sections, and the tool rests (7) return. A transmission motor (24) is started, and the gantries (10) are delivered to a fast conveyor belt (12) from a slow conveyor belt (19) and can be automatically separated off to take away the formed wet blank (11), thus being capable of cutting a plurality of wet blanks (11) at a time.

Owner:GAOTANGSHENG LIANXIN ENVIRONMENTAL PROTECTION TECH CO LTD

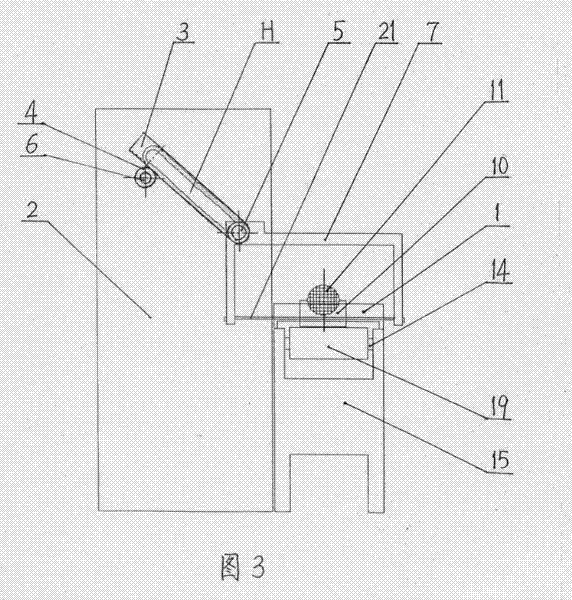

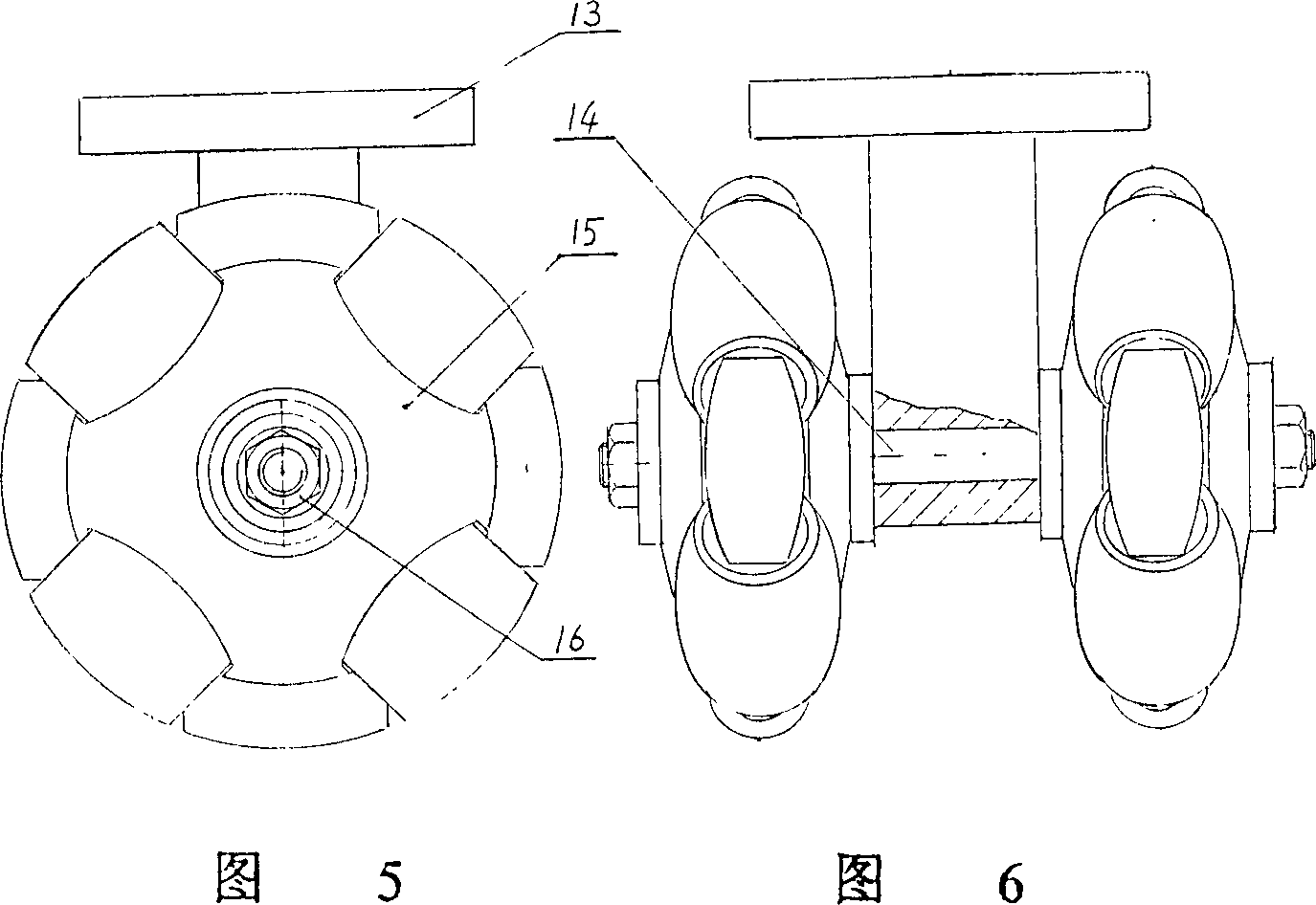

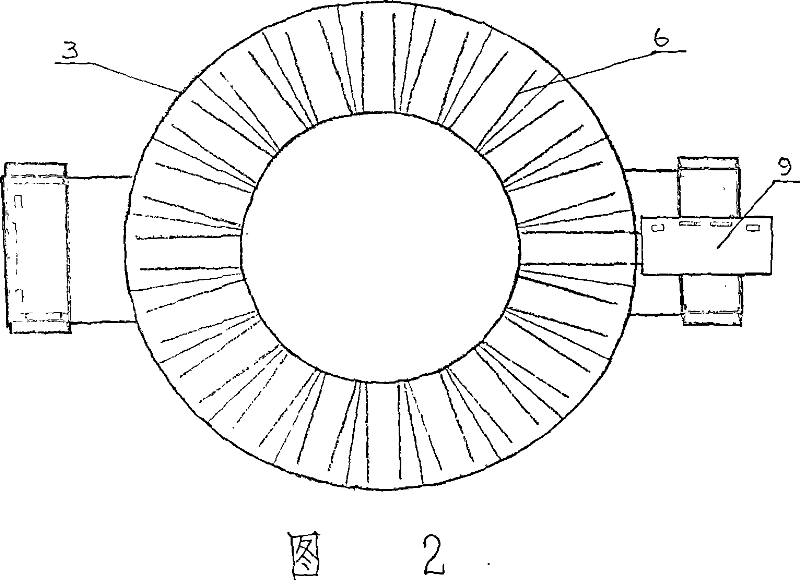

Poller type wheel of vehicle

A vehicle's wheel able to move in any direction is composed of big and small drum-shaped rollers, supporting frame, central axle, semi-hub disk and screw-nut sets. It can be used as drive wheel and driven wheel.

Owner:黄善钧 +1

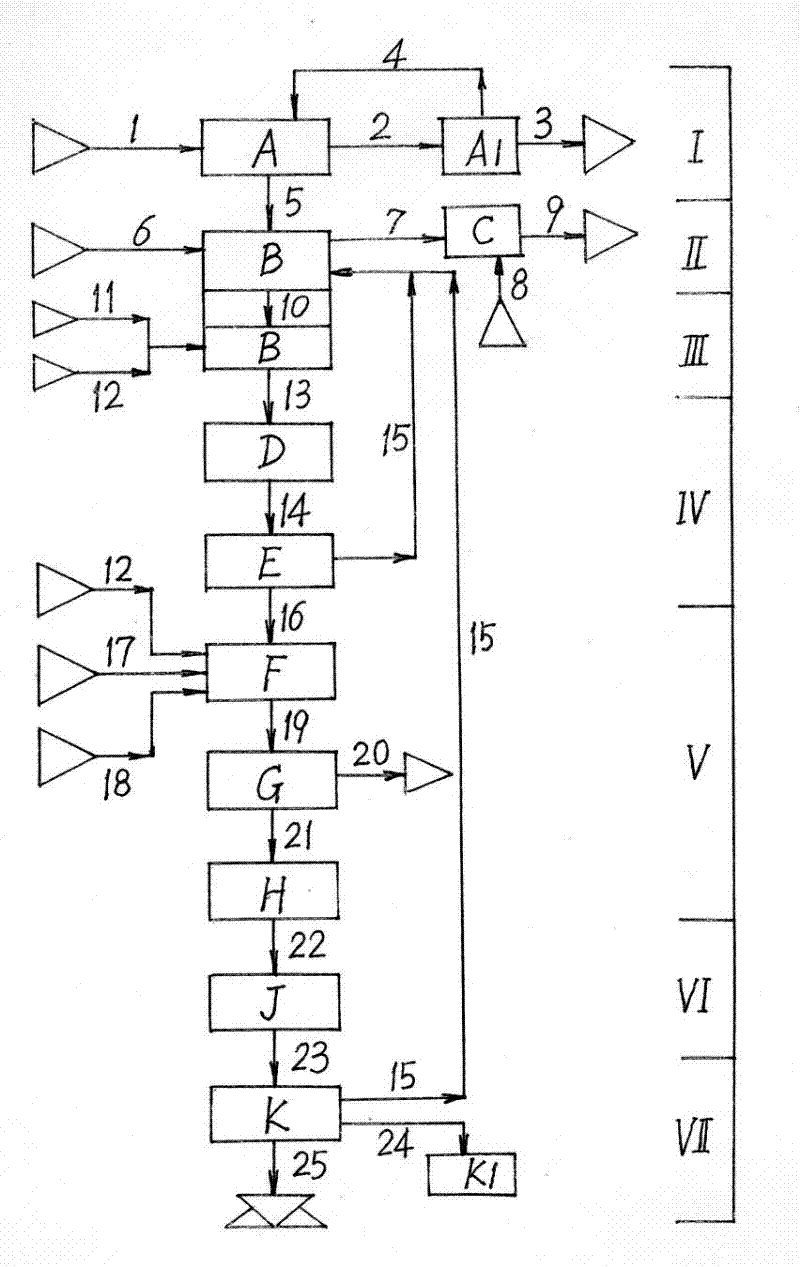

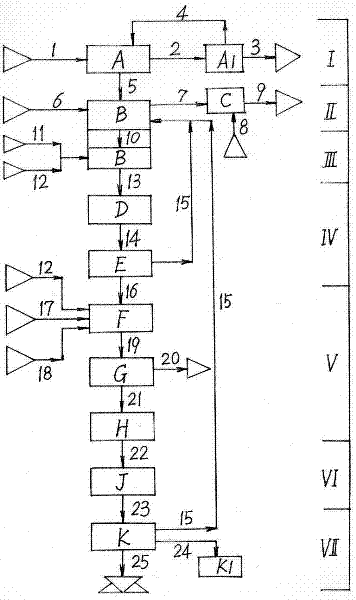

Method for performing comprehensive treatment by utilizing waste water from production of ternary monomer

ActiveCN102491575AReasonable designCompact configurationOrganic chemistryOrganic compound preparationDistillationFiltration

The invention relates to a method for performing comprehensive treatment by utilizing waste water from the production of a ternary monomer. A corresponding production line is arranged, and the method comprises the following process steps: a distillation and dealcoholization process (I), an extraction process (II), a back extraction process (III), a concentration and dehydration process (IV), a hot melting and fine filtration process (V), a dehydration and crystallization process (VI) and a preparation and drying process (VII), wherein a alcohol acid mixed solvent (6) is added in the extraction process (II); liquid alkali (11) and purified water (12) are added in the back extraction process (III); sulfuric acid (17), activated carbon (18) and the purified water (12) are added in the hot melting and fine filtration process (V); and an m-phthalic acid-5-sodium sulfonate finished product (25) is finally prepared under the process conditions of corresponding temperature, water and time of each of all the processes, and the m-phthalic acid-5-sodium sulfonate finished product (25) is used for preparing ammonium-free waterborne polyester resin and waterborne polyurethane, is also a monomer of the polyester resin for synthesizing a bonding agent for food packaging. According to the method disclosed by the invention, the pollution of the waste water is solved, an environment is protected, the value is created, and the economic and social benefits are significant.

Owner:SHANDONG JINSHENG NEW MATERIAL TECH

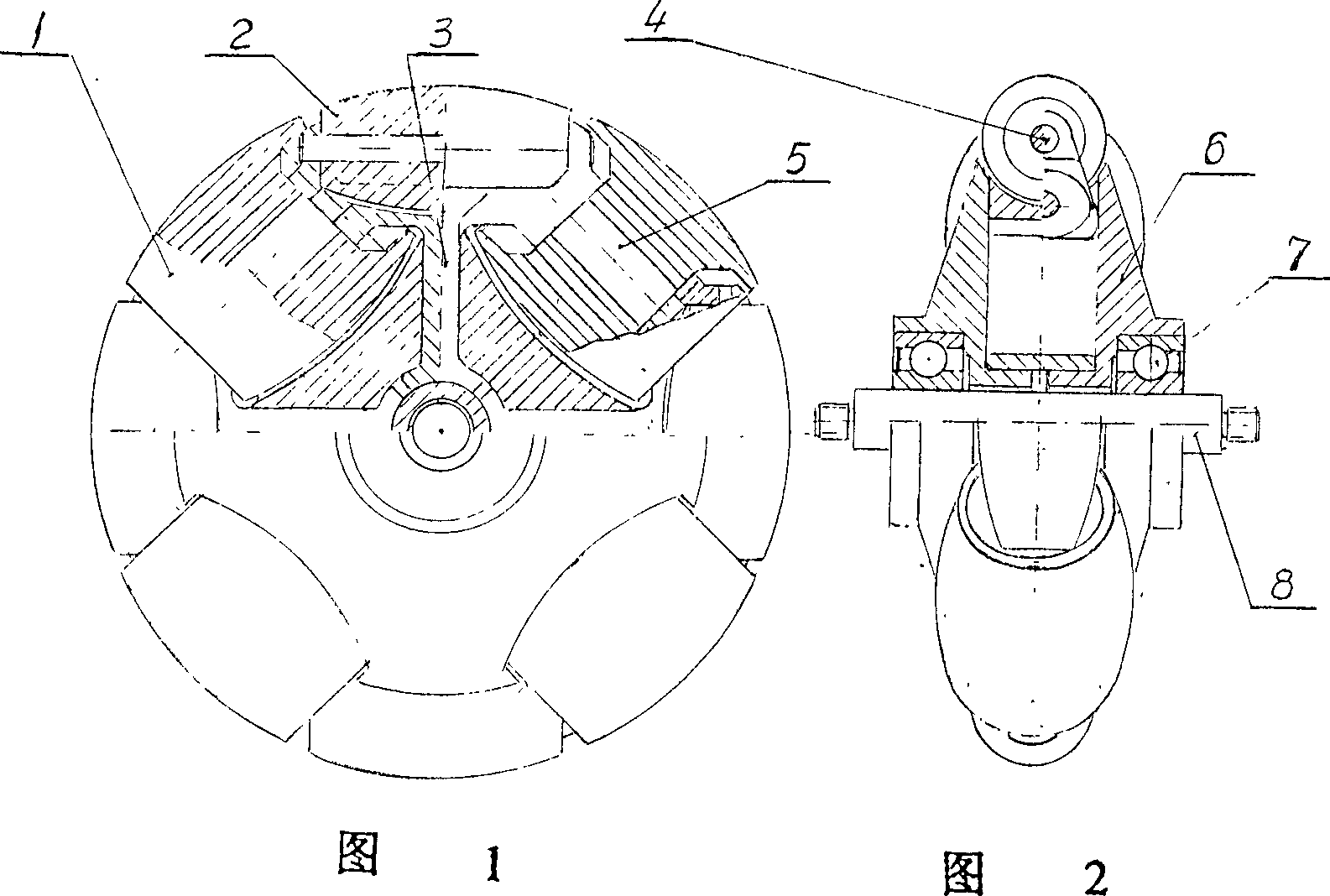

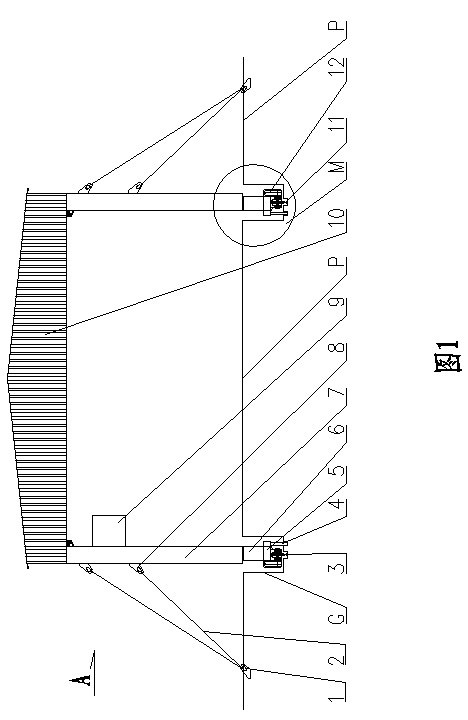

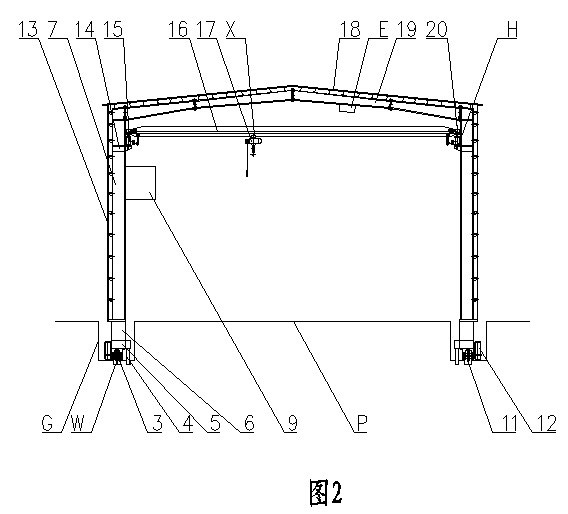

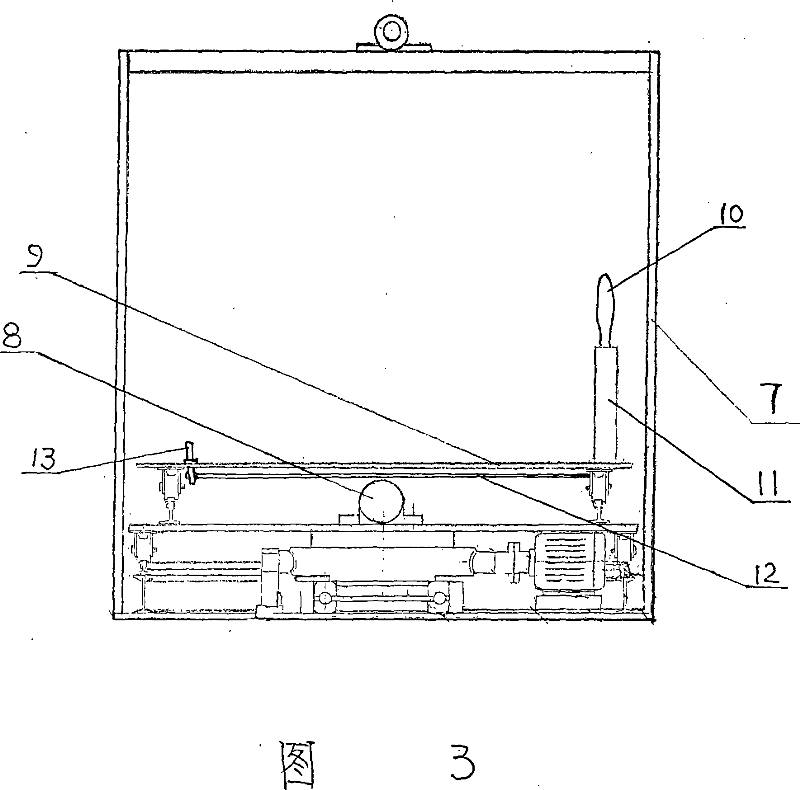

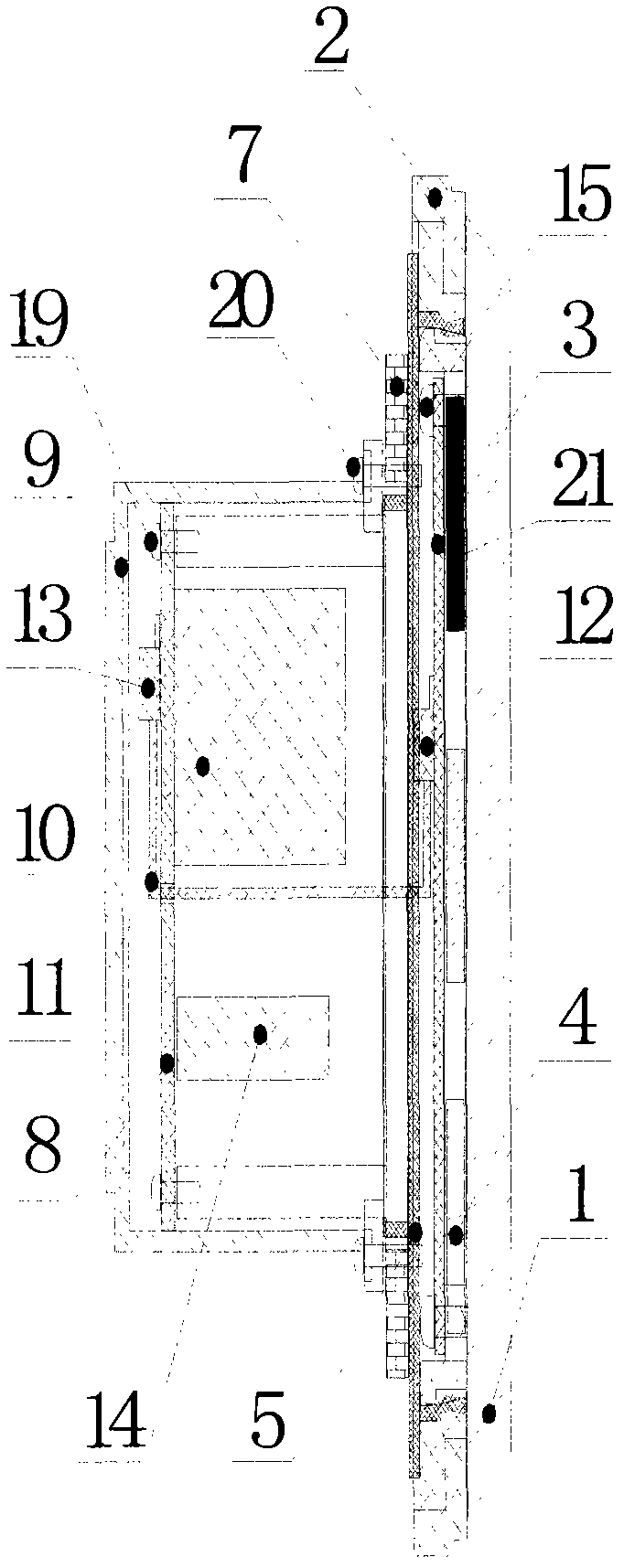

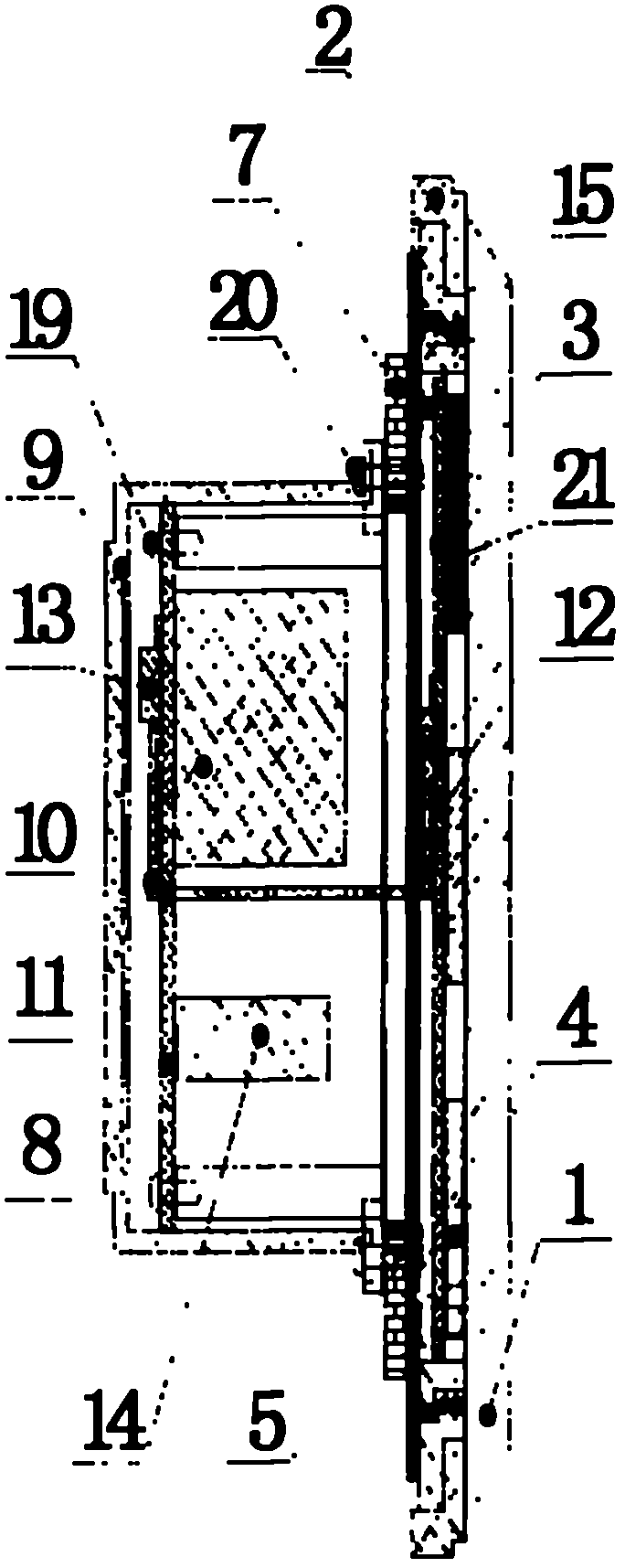

Self-moving steel structure workshop

InactiveCN102425318AImprove on-site conditionsQuality assuranceBuilding constructionsIndustrial buildingsHuman–machine interfaceBrake

The invention provides a self-moving steel structure workshop which is composed of a steel structure workshop, a movable base, a braking and anchoring device and an electrical control system. The steel structure workshop is mounted on a support beam (6), a driving motor (25) is arranged at the end part of a ground beam (5), and a traction roller (21) and a load roller (3) are arranged on the bottom surface of the ground beam (5). In an operation process, the driving motor (25) drives the traction roller (21) so as to drive the ground beam (5) to move along a track (11) in the middle of a base trench (G). A human-computer interface (R) and an electrical box (V) are arranged in a control room (7), and the control room (7) is connected with each electrical component as well as controls each electrical component. In a positioning process, a brake (27) locks a motor shaft (29), a positioning oil cylinder (4) and a manual rail clamping device (22) fix the ground beam (5), and a steel pull rope (2) tensions and fixes the steel structure workshop. Shipbuilding parts are processed on the site in the steel structure workshop. The structure is flexible in control and safe in use, can realize the synchronous follow-up according to the shipbuilding progress, effectively improves the working conditions of the processing and transporting site, has fast progress and high efficiency, and is suitable for the matched application of large shipbuilding plants.

Owner:SHANDONG ZHONGTONG STEEL STRUCTURE ENG

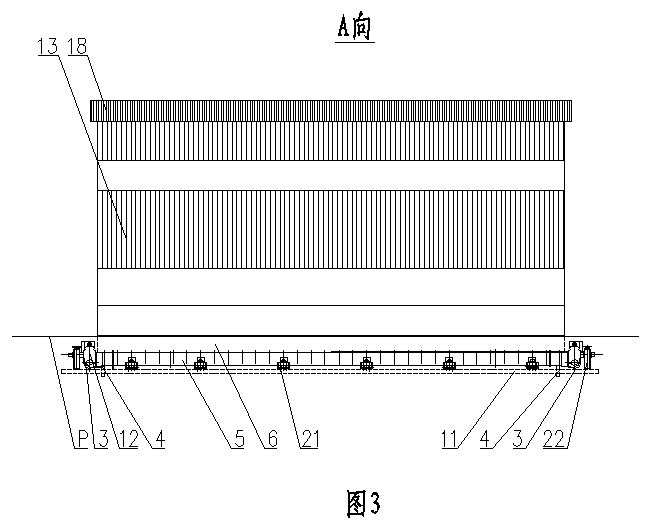

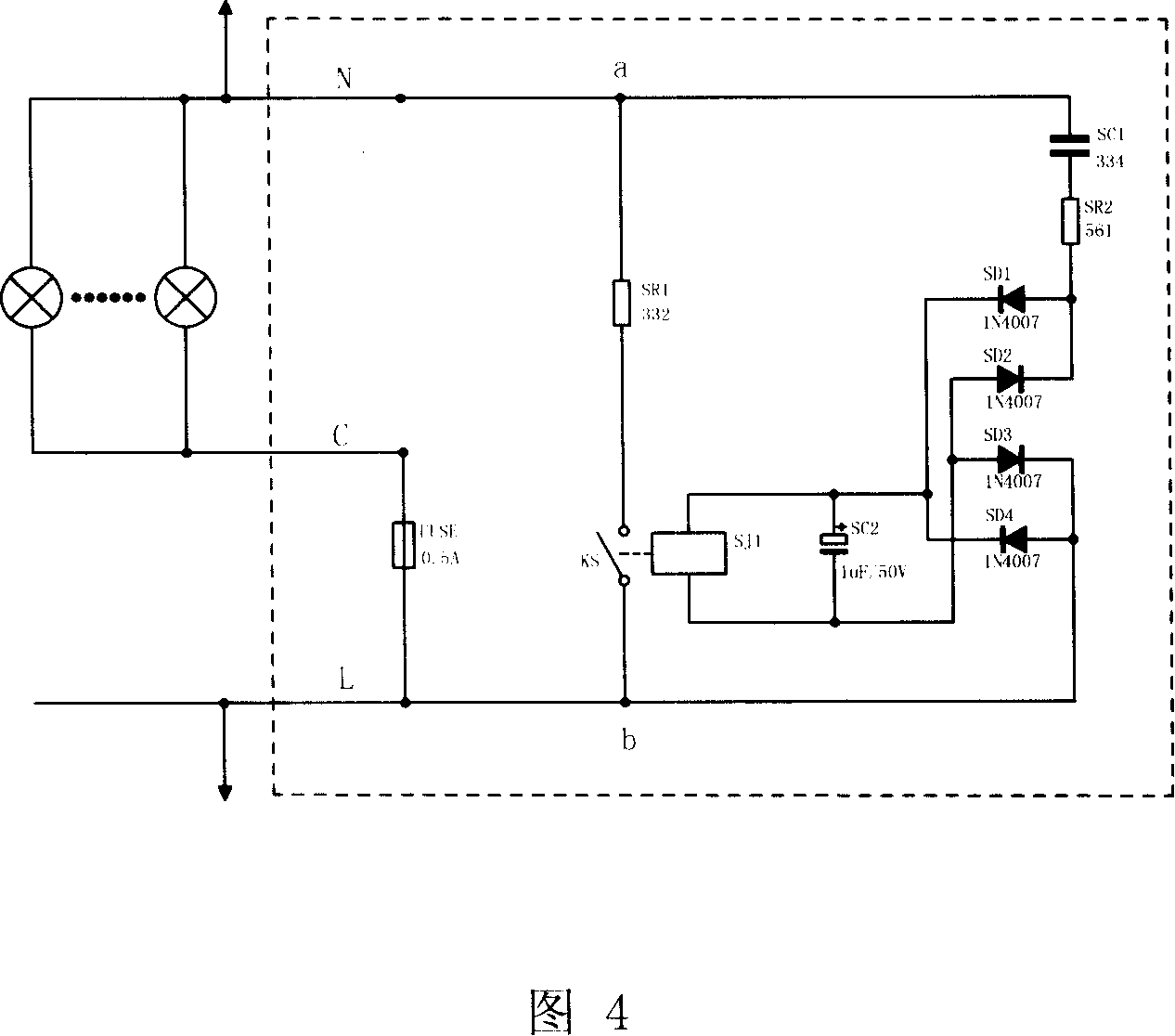

A remote control touch intelligent switch

InactiveCN101127520ASave raw materials and manpower and material resourcesConvenient and reliable remote control modificationElectronic switchingTouch panelTouch switch

The utility model discloses a remote-controllable intelligent touch switch, belonging to the structure and circuit of daily used light controlled switch. A single fire wire is used to supply electricity to realize the light controlled structure of automatic operation of the switch and the touch switch intelligent of the circuit. The utility model is characterized in comprising a cover frame; wherein, a rear cover is arranged on the back the cover frame; a panel is arranged at the front end surface of the cover frame; a glass touch panel, a PVC character layer and a light sheet, a duotone LED light and a circuit board stretched into the rear cover are arranged in the middle of the cover frame inside the panel respectively; an electronic component is arranged in the middle of the rear cover, and a circuit board is arranged at the other end of the rear cover. The utility model has the advantages of adopting the method of supplying power by a single fire wire, overcoming the problem of laying out a plurality of zero wires in the prior art, not only saving the raw material, the manpower and the material resources, but also being very convenient and reliable to remold the remote control of the laid out lighting and the lighting in the old houses; therefore, the simple and convenient operation, open-and-shut display, stable and reliable operation can be achieved.

Owner:DONGGUAN PERFECT SCI & TECH

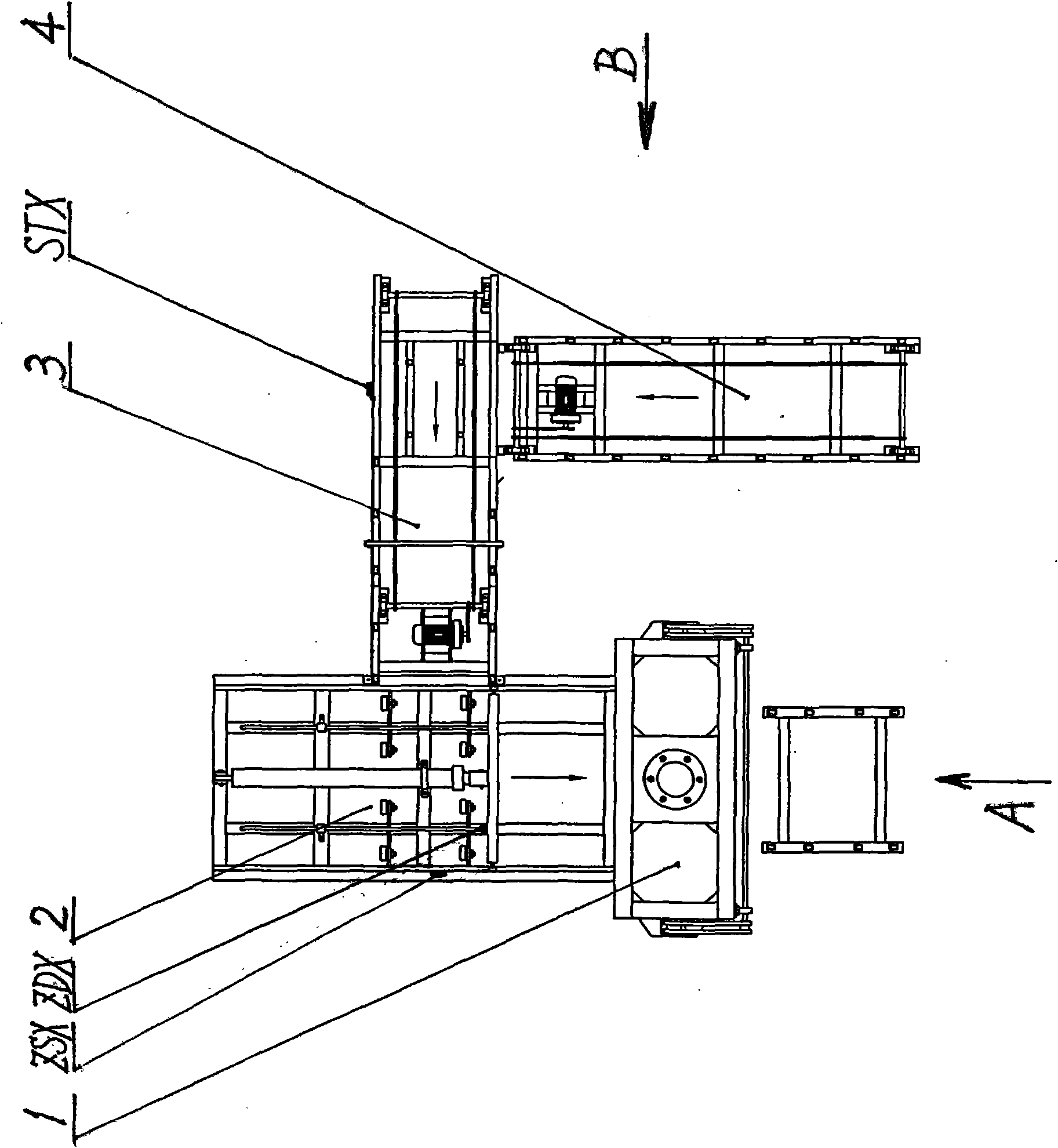

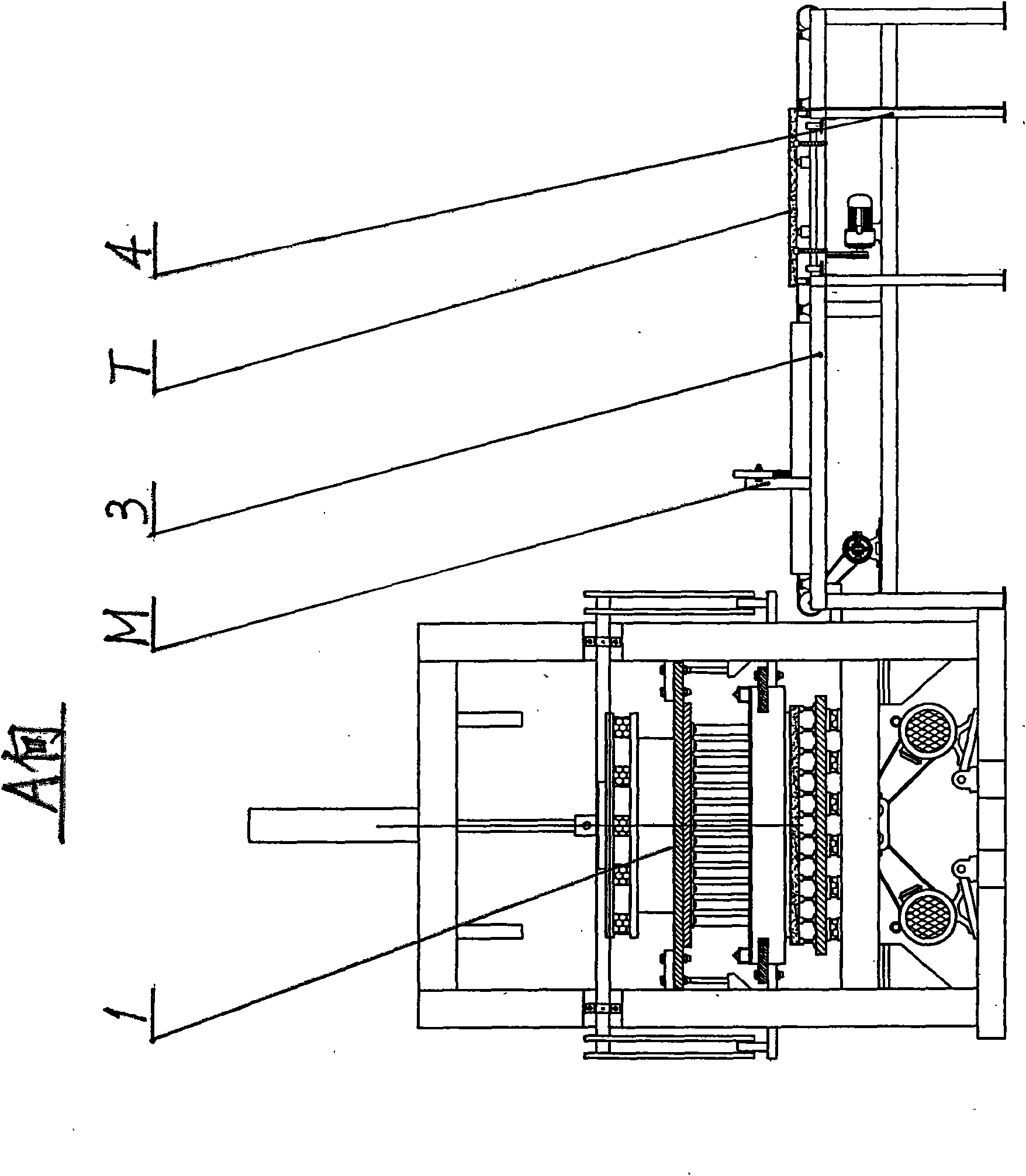

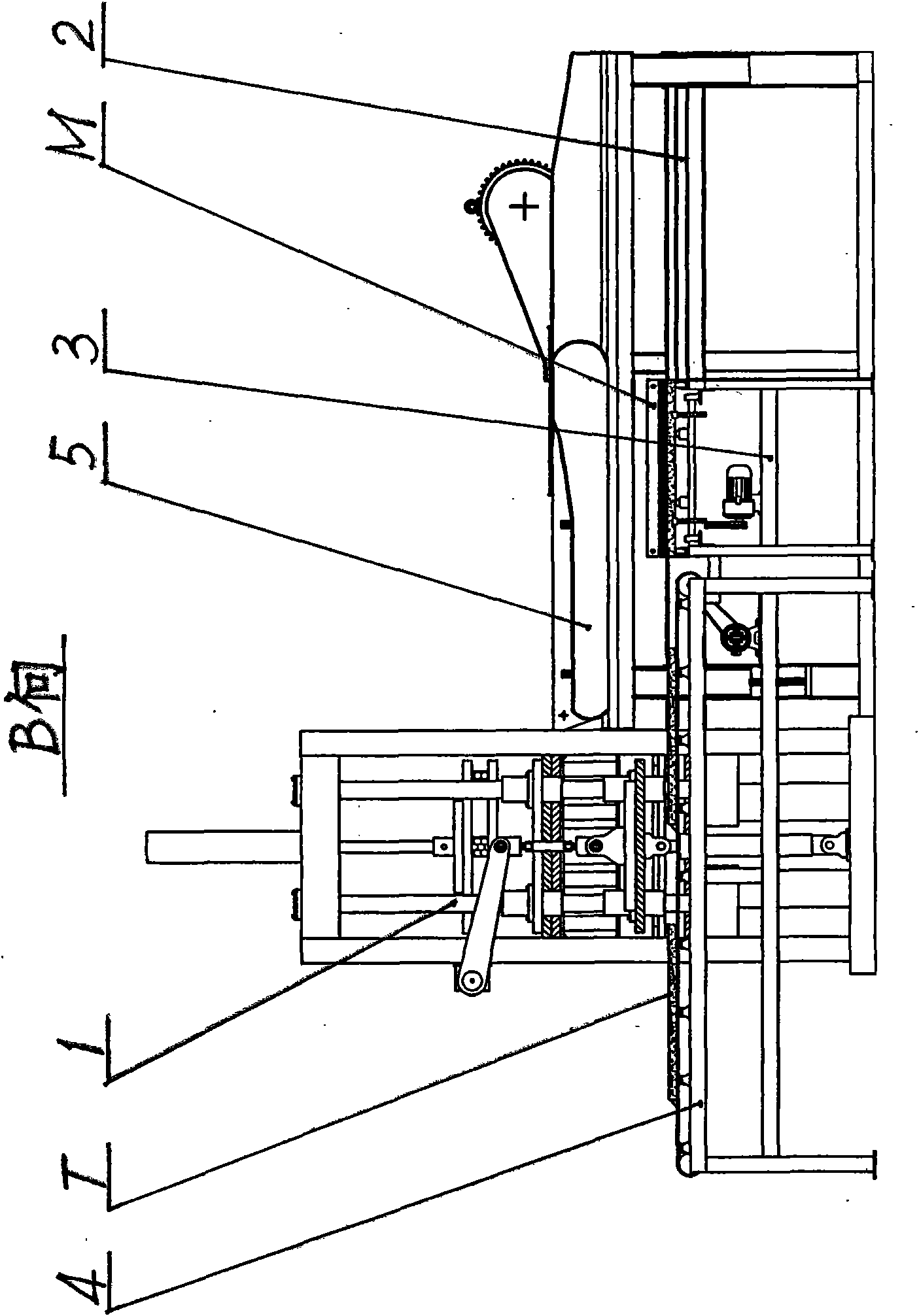

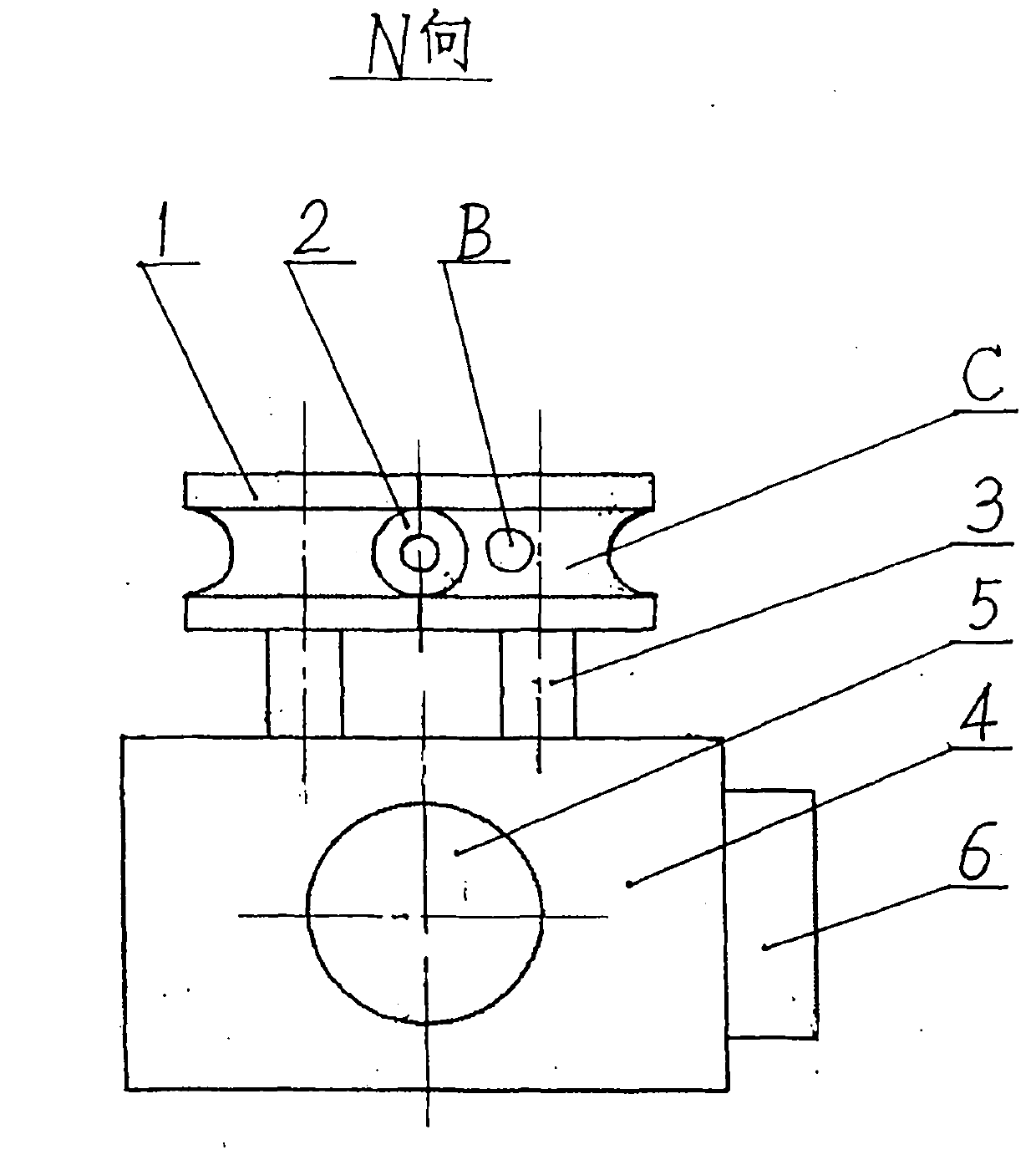

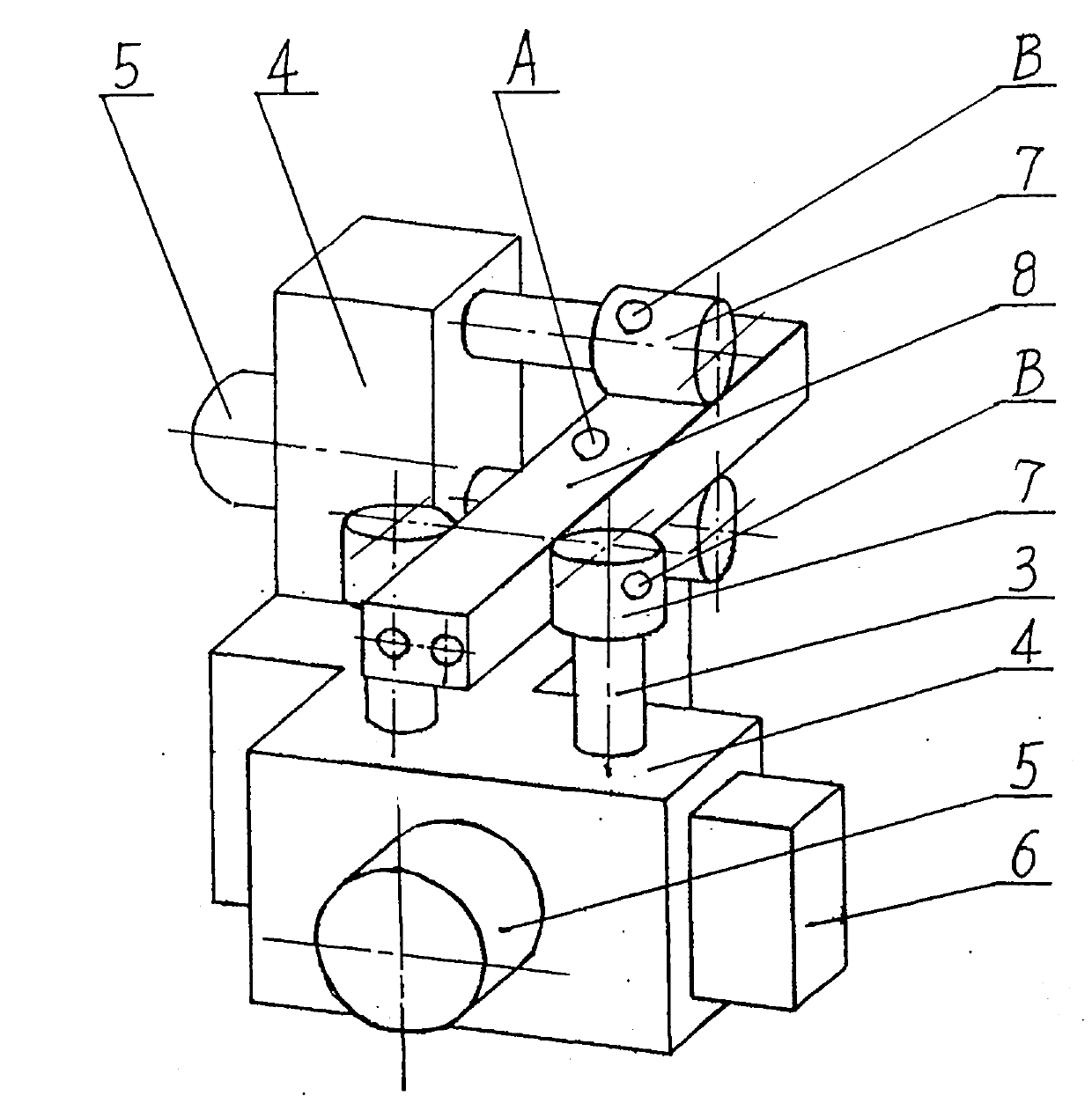

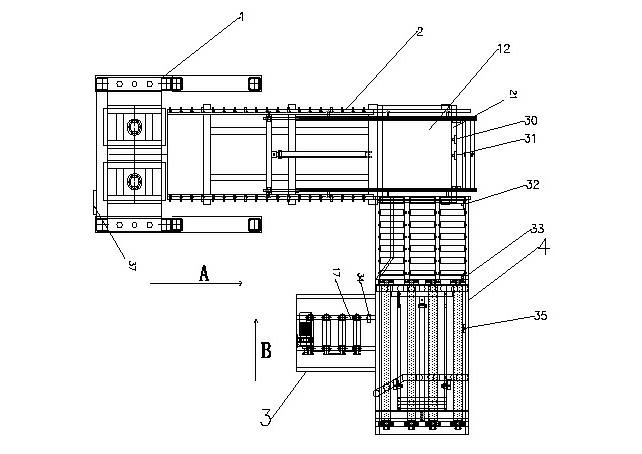

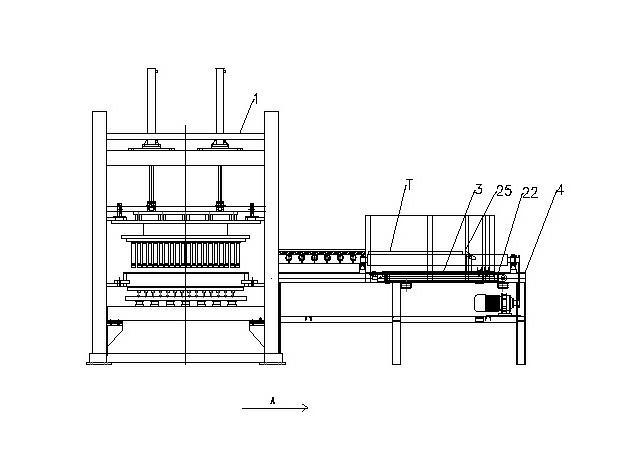

Automatic transporting device for pallets for building block forming machine

The invention discloses an automatic transporting device for pallets of a building block forming machine. In the automatic transporting device, a pallet conveying rack (4) is in a 'T'-shaped plane arrangement with a pallet transporting rack (3) and in an 'n'-shaped arrangement with a pallet moving device (2). Blocks formed by a block forming machine (1) are carried away by a transport cart (C). When a front pallet (T) contacts a transport starting travel switch (ZDX) of the pallet moving device (2), a transport motor (8) is started to enable the pallet transporting rack (3) to convey the pallet (T) to the pallet moving device (2); when the front pallet (T) contacts a transport-stopping and conveying-starting travel switch (ZSX), the transport motor (8) stops, a conveying motor (20) starts and pallet conveying rack (4) conveys the pallet (T) to the pallet transporting rack (3); and when the pallet (T) contacts a conveying stop travel switch (STX), the conveying motor (20) stops and a new pallet (T) is placed on the pallet conveying rack (4). Thus, that pallets (T) are placed on all stations of a transmission mechanism is ensured, and the automatic transporting device orderly operates with the production of the block forming machine (1) to form an automatic circulating system. The automatic transporting device has the advantages of stable and reliable operation, time and labor conservation, low cost and high efficiency.

Owner:山东高唐华通液压机械有限公司

Air circular rotary garage parking

The invention relates to a vertical parking garage suspended in the air on the road. It has two sets of support posts with each having four vertical posts fixed with horizontal beam which has round guide track with steel wheel between them, garage on the parking frame, parking space on the garage, guide track on the ground of the parking lot, lifter between each support post, rotary chassis inside the lifter and air cylinder, magnetic structure at the head of the air cylinder piston rod, guide track on the surface of the bottom board of the lifter, wheel supported parking platform parked on the guide track, and a magnetic structure at the head of the air cylinder piston rod matching with the downward bending iron block at the end of the parking platform. Combing the mechanical principles, it realizes the automatic parking and getting of cars.

Owner:福州纳百立体停车设备有限公司

New technology for plating golden yellow on automotive hub

The invention discloses new technology for plating golden yellow on an automotive hub, which comprises the technical steps: galvanizing, pre-plating copper, brightly plating copper, plating nickel, plating golden yellow, and the like. The chemical composition formula contained in each L of plating solution is that: galvanizing solution comprises 220 to 240g of potassium chloride, 40 to 55g of zinc chloride, 30 to 35g of boric acid, and 15 to 25ml of brightener; copper pre-plating solution comprises 70 to 85g of copper phosphate, 280 to 350g of phosphor copper potassium, 4 to 6ml of ammonia water, and 3 to 5ml of brightener; the bright copper plating solution comprises 200 to 220g of copper sulfate, 70 to 90g of sulfuric acid, 0.06 to 0.08g of chloride ion, and 4 to 8ml of brightener; nickel plating solution comprises 260 to 300g of nickel sulfate, 30 to 50g of nickel chloride, 30 to 40g of boric acid, 0.6 to 1ml of brightener, 8 to 12ml of softening agent, and 2 to 4ml of wetting agent; and golden yellow plating solution comprises 120 to 140g of imitation gold salt and 2 to 4ml of ammonia water. After the plating, water washing and drying are performed, and a polyurethane paint is sprayed on the surface of the automotive hub. The new technology for plating golden yellow on the automotive hub radically eliminates the damage and environmental pollution of sodium cyanide and chromic anhydride to human bodies; the plated golden yellow automotive hub is luxurious and attractive, has strong corrosion resistance, and is suitable for high-class automotive assembly.

Owner:梁新中

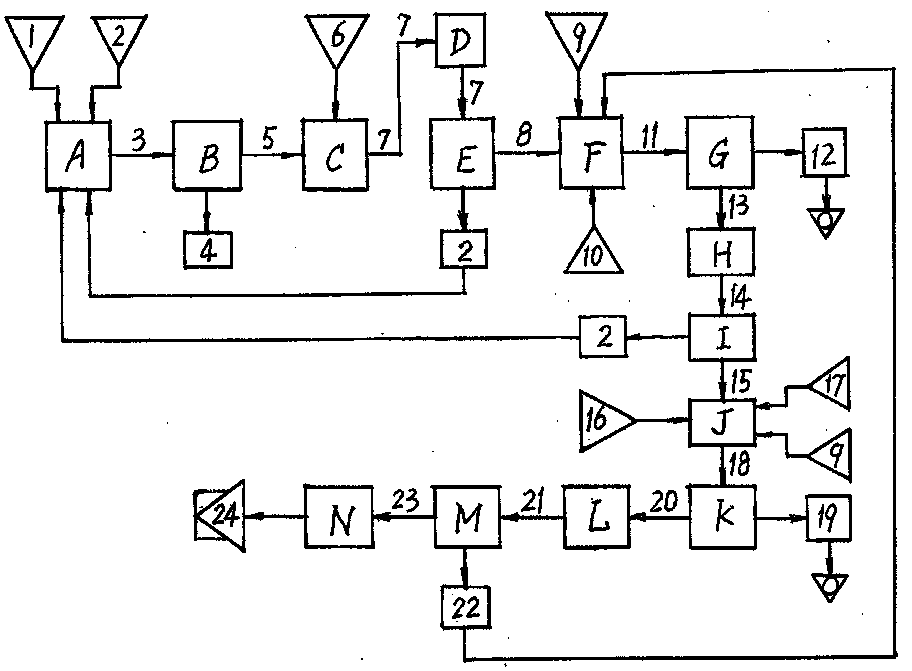

Method for extracting m-phthalic acid-5-sodium sulfonate from ternary-monomer industrial waste water

ActiveCN104003910ALow costReduce pollutionOrganic chemistryOrganic compound preparationIndustrial waste waterDecomposition

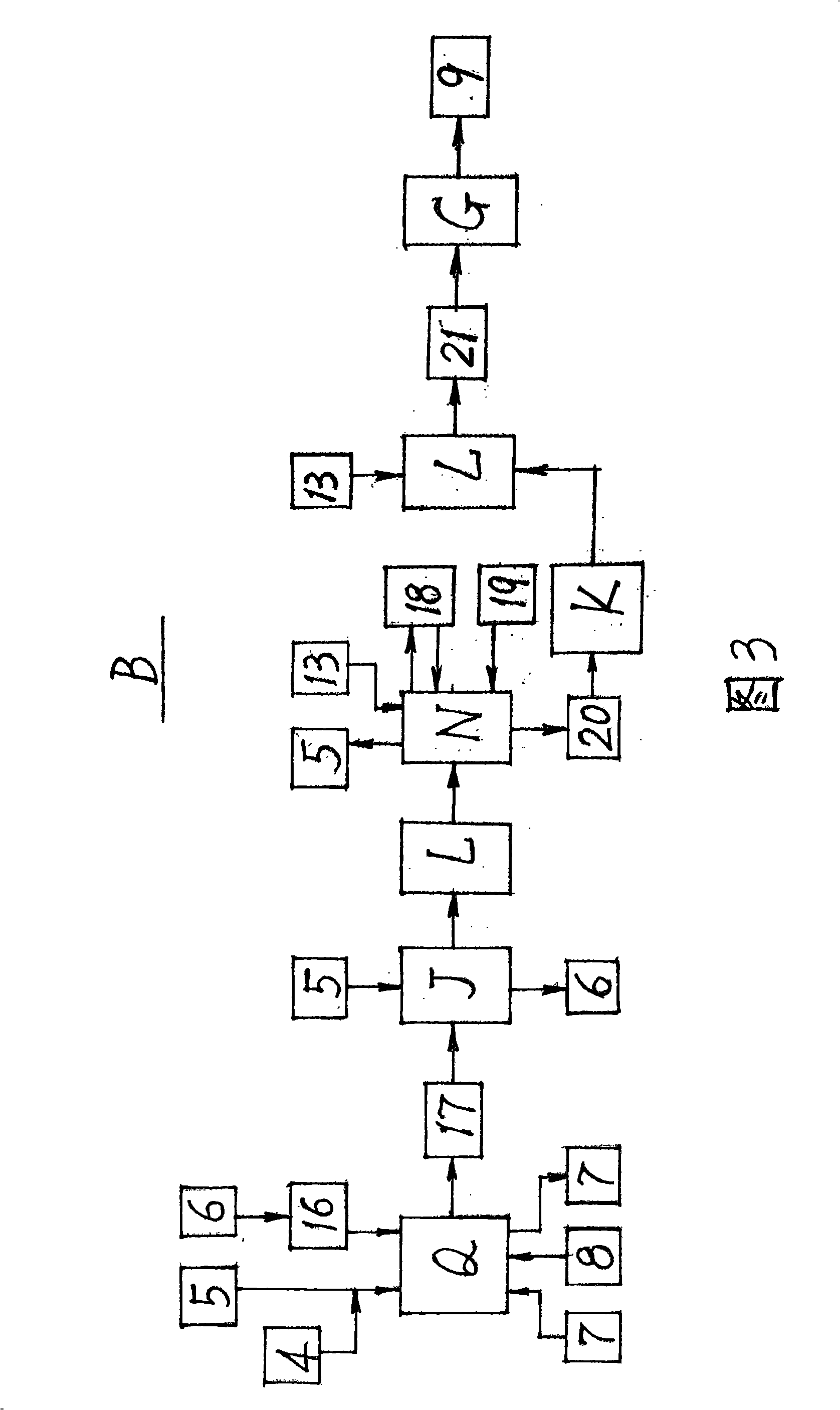

Provided is a method for extracting m-phthalic acid-5-sodium sulfonate from ternary-monomer industrial waste water. A sediment crystallization tank (A), a pressure filter (B), an ester decomposition tank (C), a high-pressure pump (D), a distillation tower (E), a decoloration and impurity absorption kettle (F), a filter (G), a concentration and crystallization kettle (H), a centrifugal hydroextractor (I), a flash melting kettle (J), a fine filter (K), a secondary concentration and crystallization kettle (L), a rubber lining water extractor (M) and a drying machine (N) are connected to be a production line, the ternary-monomer industrial waste water serves as the main raw material, an organic precipitant (2), sodium hydroxide (6), activated carbon (9), deionized water (16), sulfuric acid (17) and activated carbon (9) are sequentially added in related devices according to process requirements through the process procedures of various processes, and finished m-phthalic acid-5-sodium sulfonate (24) is prepared under the specific temperature, time and process conditions of the process procedures of various processes. The method can further extract out sodium sulfate crystals (4) in the waste water. Pollution is reduced, environment is protected, waste is turned into wealth, and double purposes are achieved.

Owner:SHANDONG JINSHENG NEW MATERIAL TECH

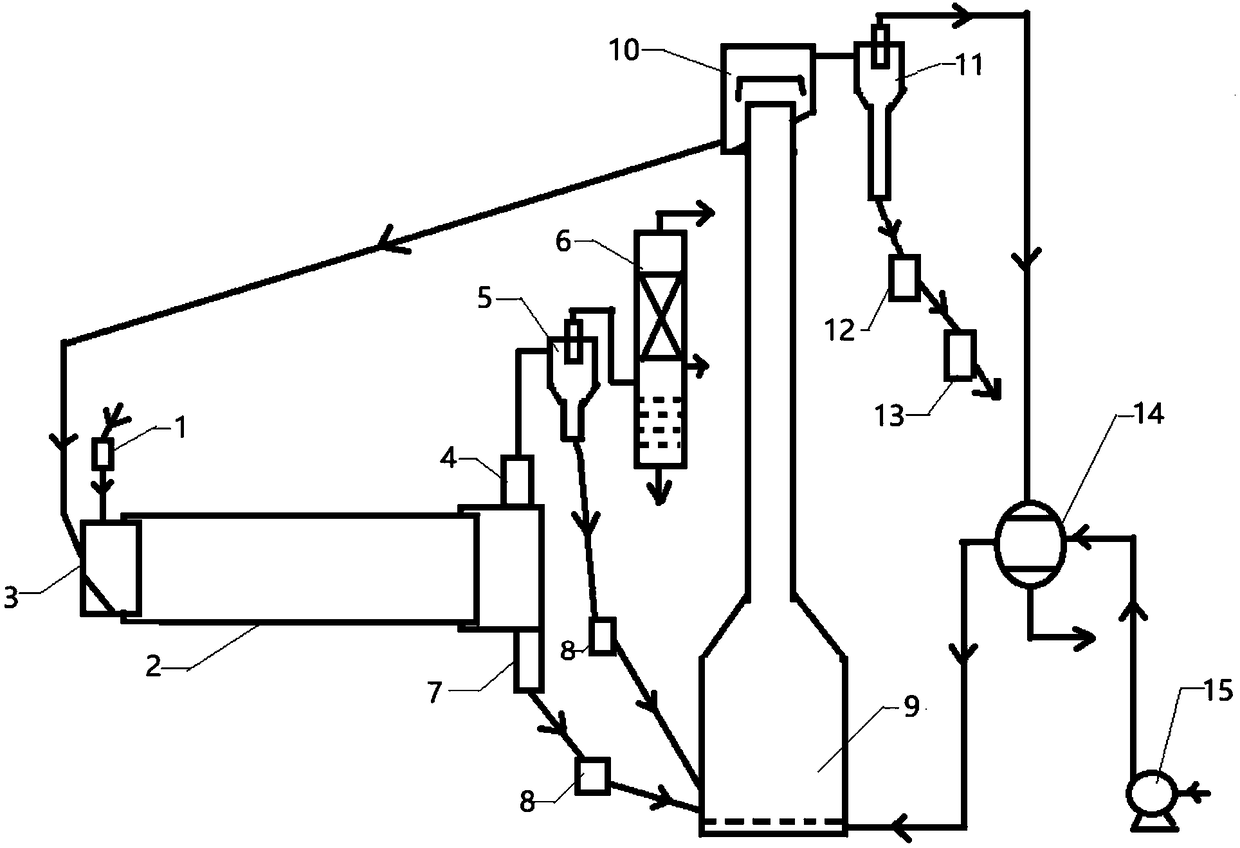

Functional microbial agent and preparation method thereof

InactiveCN104478600AImprove survivabilityPromote the formation of aggregate structureBacteriaMicroorganism based processesDiseaseMicrobial agent

The invention relates to a functional microbial agent and a preparation method thereof. A seed tank (6), a fermentation tank (5), a storage tank (9) and a metering filling tank (10) serving as main devices, a steam engine (2) and a steam filter (16) serving as heating sterilization devices, an air compressor (8), a gas storage tank (7), a freezing dryer (12), an oil-water separator (11), an air coarse filter (13), a pressure-reducing valve (14) and an air fine filter (15) serving as sterile air supply devices and a purified water tank (1), a circulating water tank (4) and a water pump (B) serving as circulating constant-temperature devices are connected through sealing pipelines to constitute a production line, technical processes, namely, an empty fermentation tank disinfection and liquid-added fermentation tank disinfection are carried out and a strain(A) is added into a culture solution in the seed tank (6) and is subjected to technical processes, namely, an inoculation and expanding propagation step and a storage filling step to prepare the functional microbial agent finished product. The functional microbial agent has the characteristics that the fertilizer efficiency is high, the microbial agent can promote plants to prevent insect pests diseases, the soil structure is improved and the microbial agent is non-toxic and harmless and is conductive to environment friendliness, the sustainable and long-term development of the farmland is promoted and increases in both production and income are promoted.

Owner:SHANDONG DADI BIOTECH

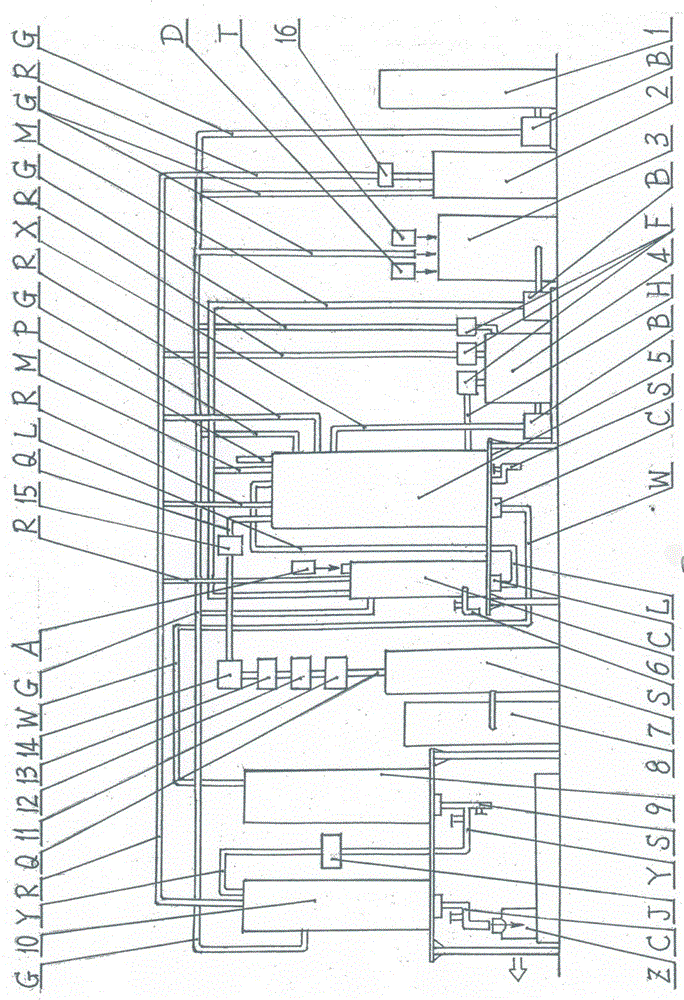

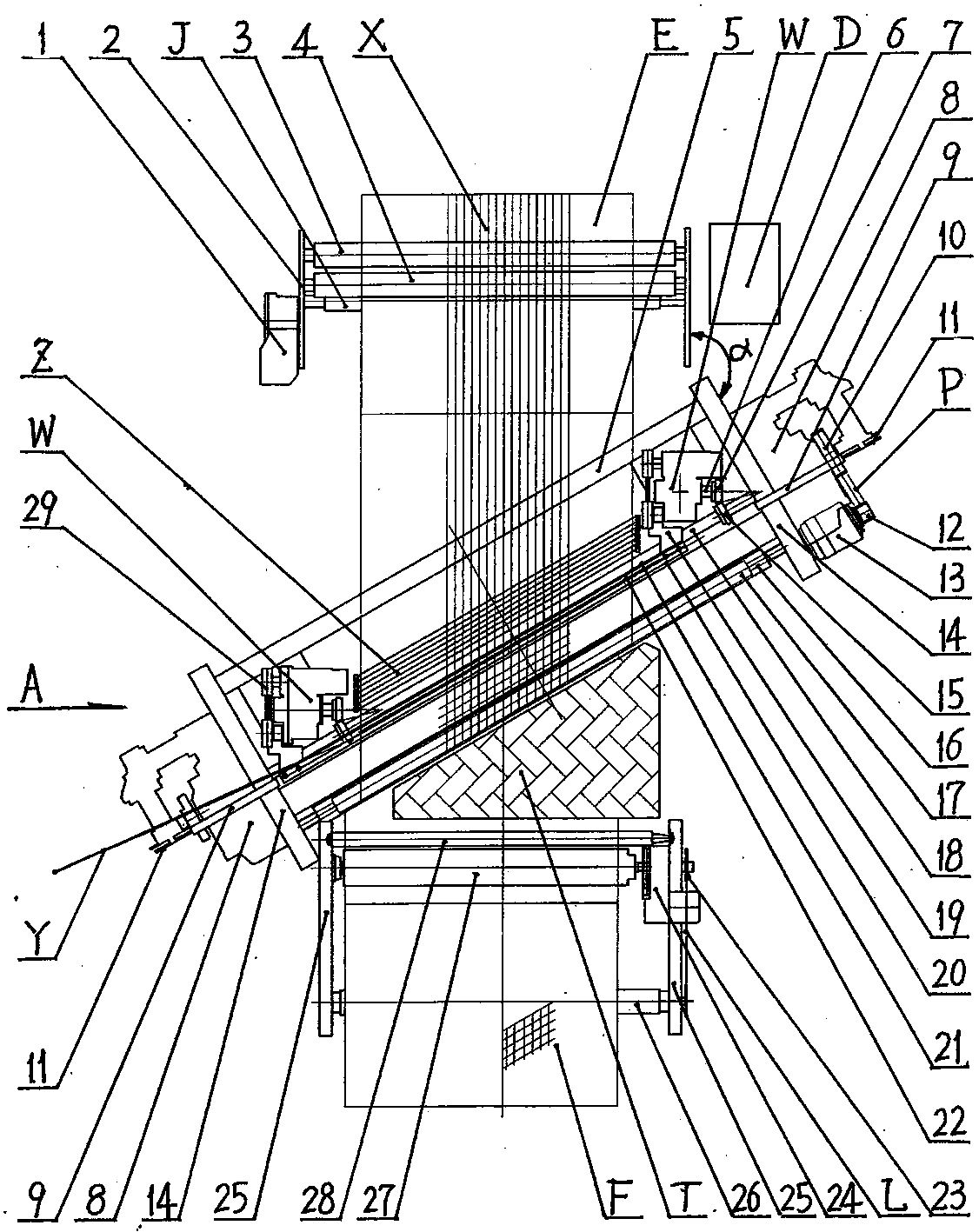

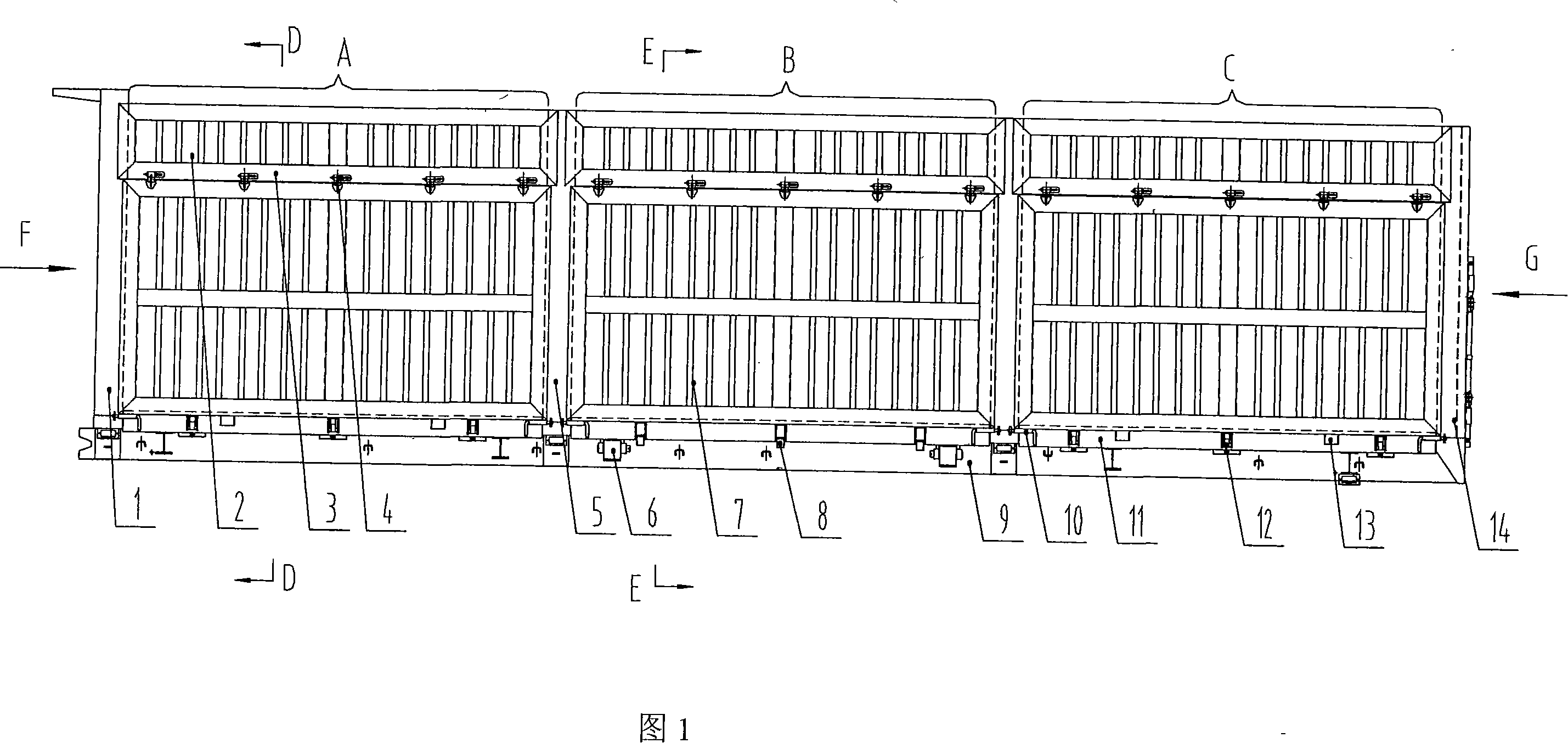

Rapier loom special for wide fabric

The invention provides a rapier loom special for wide fabric. According to the rapier loom special for the wide fabric, a main machine frame (14) and a let-off machine frame (2) are arranged at an oblique angle (alpha), a conjugate cam mandrel (6) is fixedly provided with a beating-up bevel gear (7) and is meshed with a main shaft bevel gear (15) on an inclined main transmission shaft (18) in a transmission mode, the main transmission shaft (18) drives the conjugate cam mandrel (6) to rotate, the conjugate cam mandrel (6) is fixedly provided with a conjugate cam (38) to make contact with a small swinging arm (39) in an abutting mode to enable the small swinging arm (39) to swing, the small swinging arm (39) is fixedly connected with a rocker arm (30), the rocker arm (30) is movably connected with a connection rod (29), and the connection rod (29) is connected with a driving sliding block (19) to drive a guide rail beam (21), a wefting insertion guide rail (20) and a reed (22) to move on a linear guide rail (32) in a reciprocating mode. The linear guide rail (32) is fixed to a wefting insertion box body (34) and is arranged in the same direction of a warp (X). The wefting insertion guide rail (20) and the linear guide rail (32) are arranged in an inclined direction so that the warp (X) and weft (Y) can be intersected in an inclined mode. The rapier loom special for the wide fabric can adjust the intersecting angle of the warp (X) and the weft (Y) and can directly weave the wide fabric.

Owner:LIAOCHENG YOUJIA TEXTILE MACHINERY

Mixed auxiliary material for preparing low-protein feed capable of digesting amino acids

InactiveCN102165991AReduce wasteMaintain nutritional contentFood processingAnimal feeding stuffVegetable oilEssential amino acid

The invention provides a mixed auxiliary material for preparing a low-protein feed capable of digesting amino acids, which is applicable to premix self-made feed for small and medium-sized farms. The mixed auxiliary material accounts for 13-35% of the low-protein feed capable of digesting amino acids, and is prepared from 15-70% of conventional protein feed, 26-81% of non-conventional feed, 0.7-3% of essential amino acid and 0.4-1% of enzymic preparations. In the preparation process, vegetable oil and fat and adipose which account for less than 15% of the total quantity of the mixed auxiliary material and calcium hydrophosphate which accounts for less than 5% of the total quantity of the mixed auxiliary material can be added according to needs. Under the precondition of keeping equivalent nutrients with a high-crude-protein daily ration, the protein content of 1-4% in the feed is reduced. By using the invention, soybean meals can be saved, and waste of the amino acid, feed cost and environment pollution also can be reduced. The low-protein feed capable of digesting amino acids can be conveniently prepared by using the auxiliary material disclosed by the invention; and thereby the auxiliary material is suitable for being applied and popularized in domestic small and medium-sized farms.

Owner:周春朋

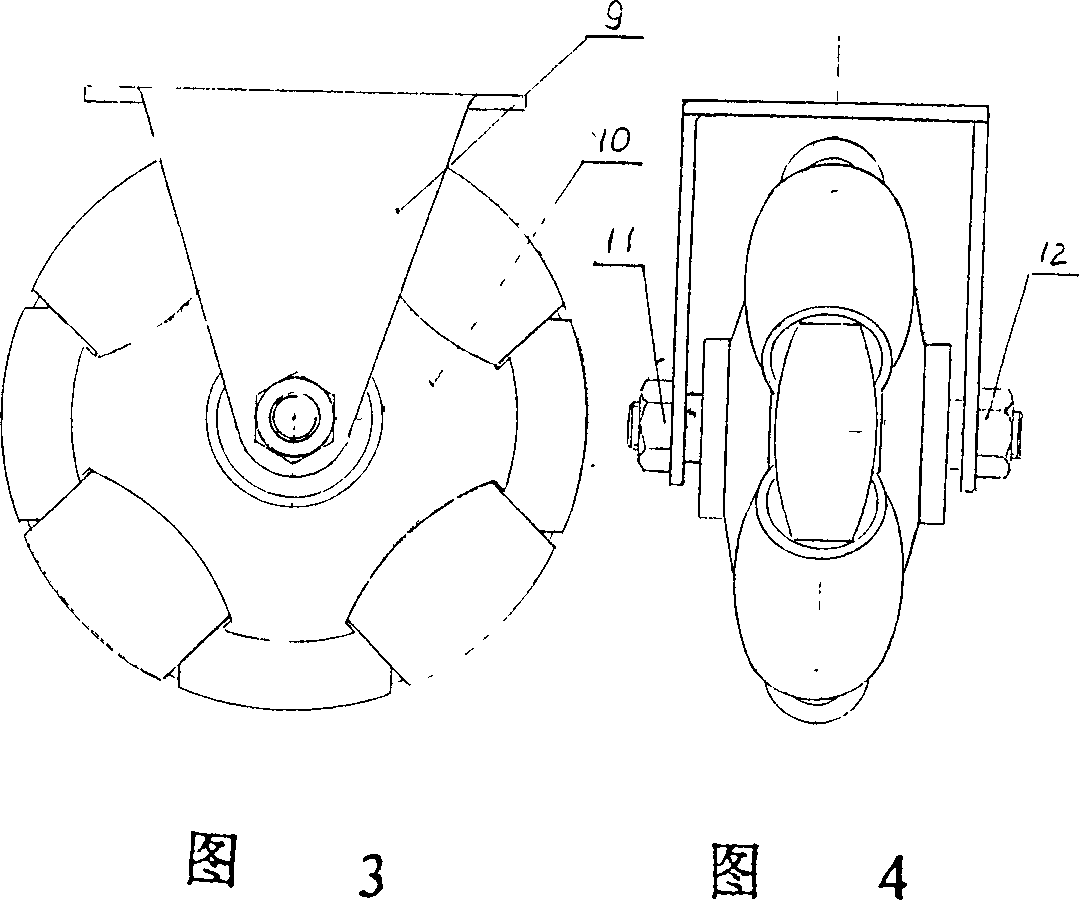

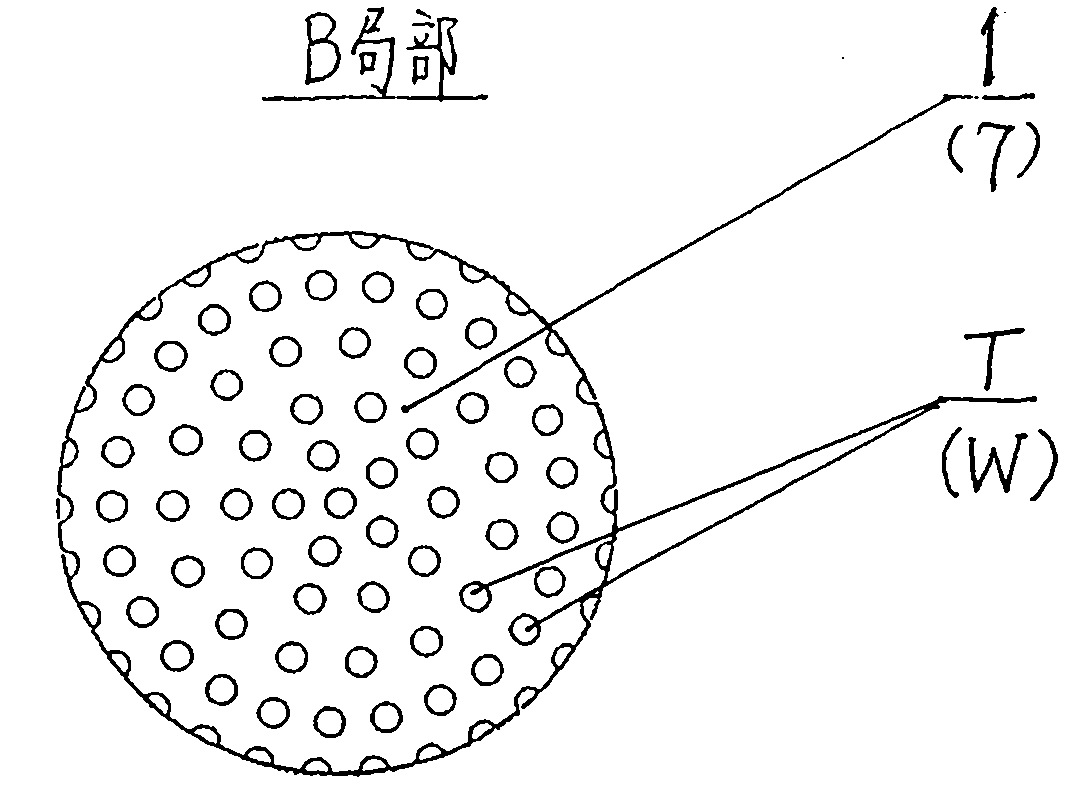

High-efficiency cooling pipe for refrigeration equipment and surface blurring method thereof

InactiveCN102003905AImprove cooling conditionsImprove cooling effectTubular elementsElectric machineCooling effect

The invention relates to a high-efficiency cooling pipe for refrigeration equipment and a surface blurring method thereof. The surface blurring method comprises the following steps of: forming a roller pair by two opposite rollers (1), assembling sleeve roller shafts (3) on a gearbox (4) and connecting with a motor (5) to be assembled into processing equipment; and mounting a frequency variator (6) on the gearbox (4), driving the gearbox (4) by the motor (5) to drive the roller shafts (3) together with the two rollers (1) to relatively rotate and roll a cooling pipe (2) clamped in the middle of the roller pair so that micro-bumps (T) or micro-dents (W) are distributed on the surface of the cooling pipe (2), wherein the heights of the micro-bumps (T) or the depths of the micro-dents (W) are 20-300 micros, the diameters are 40-300 micros, and the distribution density is 1-23piece / mm<2>. Or the blurring treatment is carried out in such a way that a front cylindrical roller pair and a rear cylindrical roller pair can be respectively assembled by four cylindrical rollers (7) to relatively roll the rectangular cooling pipe (8) from the four sides, i.e. the top, the bottom, the left and the right. The blurred cooling pipe has great cooling area, good cooling effect, high heat exchange efficiency, low manufacture cost and high production efficiency.

Owner:LIAOCHENG TIANYI IND PROD DESIGN

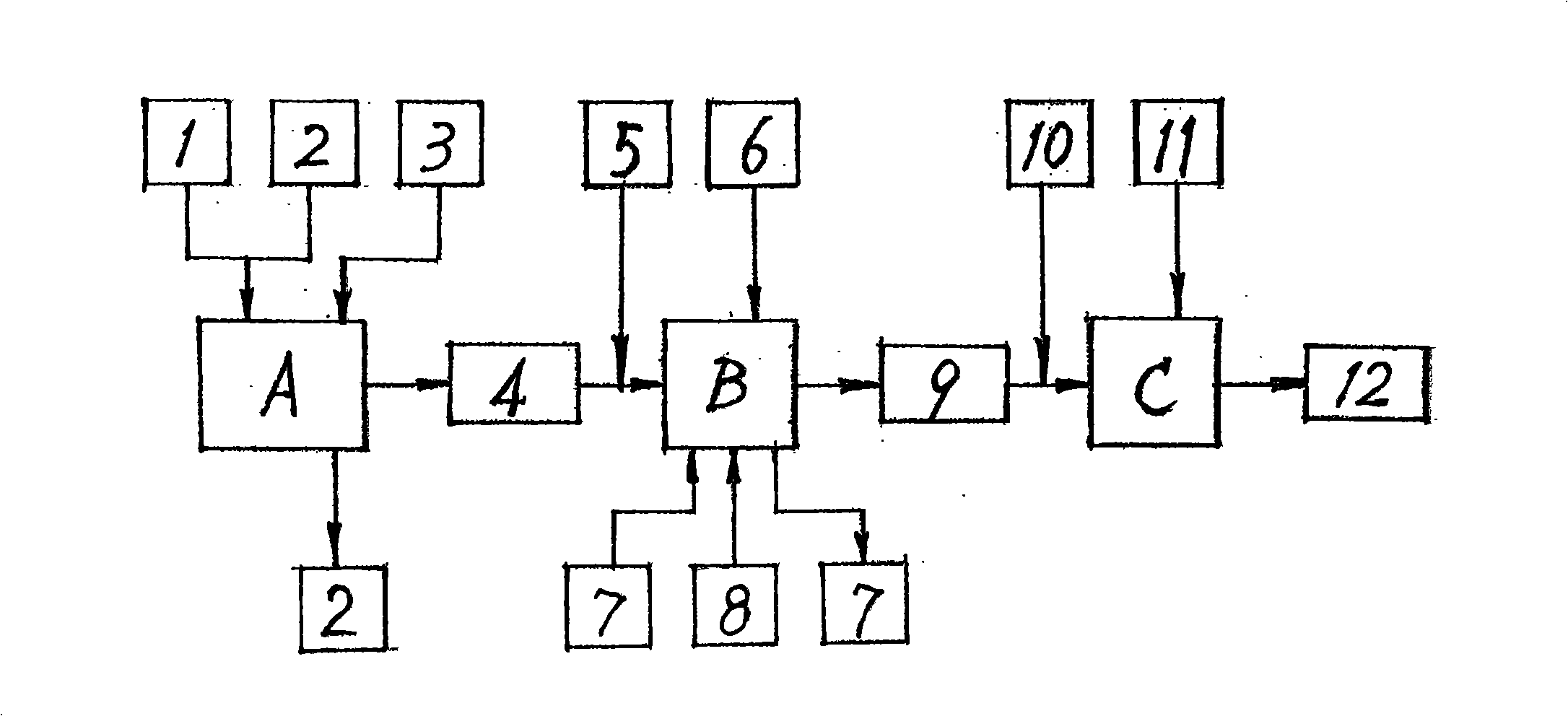

Preparation process of deoxycholeic acid of bear

InactiveCN101289488AThe process steps are simpleReasonable process routeSteroidsChemical recyclingChenodeoxycholic acidChemical reaction

A preparation method for ursodeoxycholic acid regards chenodeoxycholic acid (1) as raw materials; in technological processes, after adopting corresponding equipment and adding excipient according to the proportional variety and dosage, chemical reactions are carried out through the process flow of an oxidation process (A), a hydrogenation process (B), and a purification process (C) in particular temperature and environmental conditions. In the oxidation process (A), an oxidant (3) and a solvent I 2 are added for oxidation reaction to generate an intermediate (4); in the hydrogenation process (B), a catalyst (6) and a solvent II(5) are added for hydrogenation reaction to get ursodeoxycholic acid crude products (9); in the purification process (C), a passivating agent (11) and a solvent III (10) are added for producing the products of ursodeoxycholic acid (12). The process route of the invention is reasonable; the chemical reactions are mild and safe; the operating conditions are easy to be controlled; the yield is high and the invention makes great progress in the research and production of artificially synthesizing ursodeoxycholic acid (12).

Owner:SHANDONG AOCTER CHEM

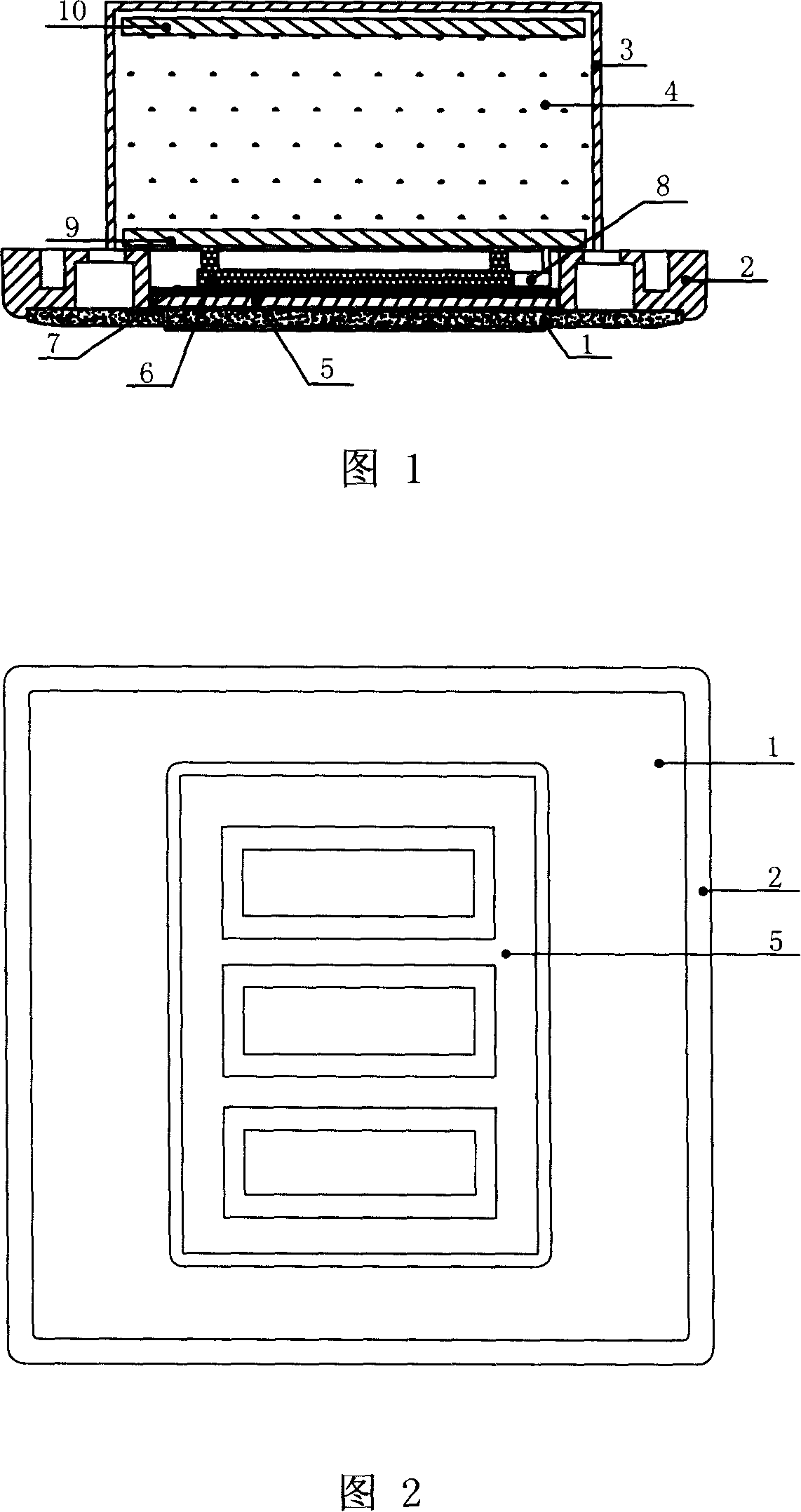

Method for manufacturing novel wall surface remote-control unit with crystal glass panel and product

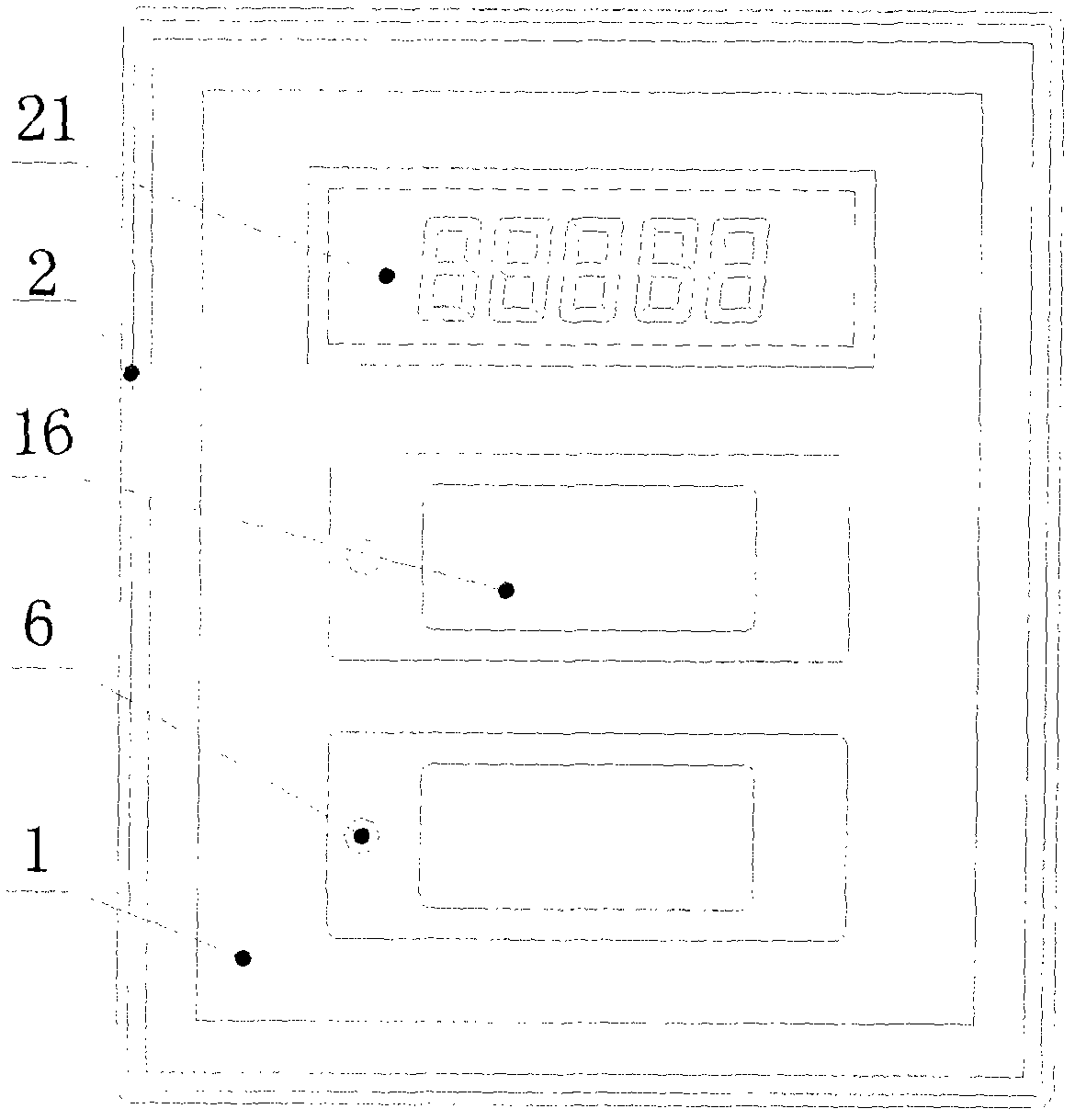

ActiveCN102665337AThe manufacturing method is simple and efficientLess process flowTransmission systemsElectric light circuit arrangementFixed frameEngineering

The invention discloses a method for manufacturing a novel wall surface remote-control unit with a crystal glass panel. The method comprises the steps of (1) setting the crystal glass panel which serves as a casing of the remote-control unit; (2) setting a fixing frame, and setting a master control circuit board inside the central portion of the fixing frame; (3) setting a fixing iron plate, setting an accessory frame, a power supply and emission circuit board and a rear cover on the inner side of the fixing iron plate; and (4) connecting the fixing iron plate with the inner side of the fixing frame, fixing the crystal glass panel on the outer side of the fixing frame, and connecting the accessory frame, the power supply and emission circuit board and the rear cover to the inner side of the fixing iron plate sequentially. The invention also provides the novel wall surface remote-control unit with the crystal glass panel implementing the method. The remote-control unit has the advantages that multi-connected control of household lighting and scene lighting control are achieved through the wall surface remote-control unit, so that intelligent control of modern household lighting is humanized, intelligent and diversified.

Owner:DONGGUAN PERFECT SCI & TECH

Start-up method of fluidized bed roaster

The invention relates to a start-up method of a fluidized bed roaster, which is characterized by comprising: firstly preparing a start-up material from pyrite with a sulfur mass fraction of 35% or more and pure sulfur; selecting dry slag as the bed layer base material; and carrying out oil-injection ignition to heat the bed layer of the roaster, introducing air when the roaster bed temperature reaches about 250 DEG C to maintain the material bed at a micro-boiling state, slowly adding a small amount of the start-up material, wherein a part of pure sulfur in the start-up material reaches the ignition point and begins burning to emit heat during the micro-boiling heating process, controlling the heating rate at 50 DEG C / h or lower under the micro-boiling condition with the outlet temperature of the fluidized bed roaster as the reference, closing an oil gun and stopping the oil heating system when the bed material temperature reaches 700 DEG C to complete start-up operation, and then transferring to the normal production of the fluidized bed roaster. Practical use proves that the start-up method provided by the invention achieves the intended purpose and is suitable for the start-up operation of the fluidized bed roaster for production process of sulfuric acid from pyrite.

Owner:WENGFU (GRP) CO LTD

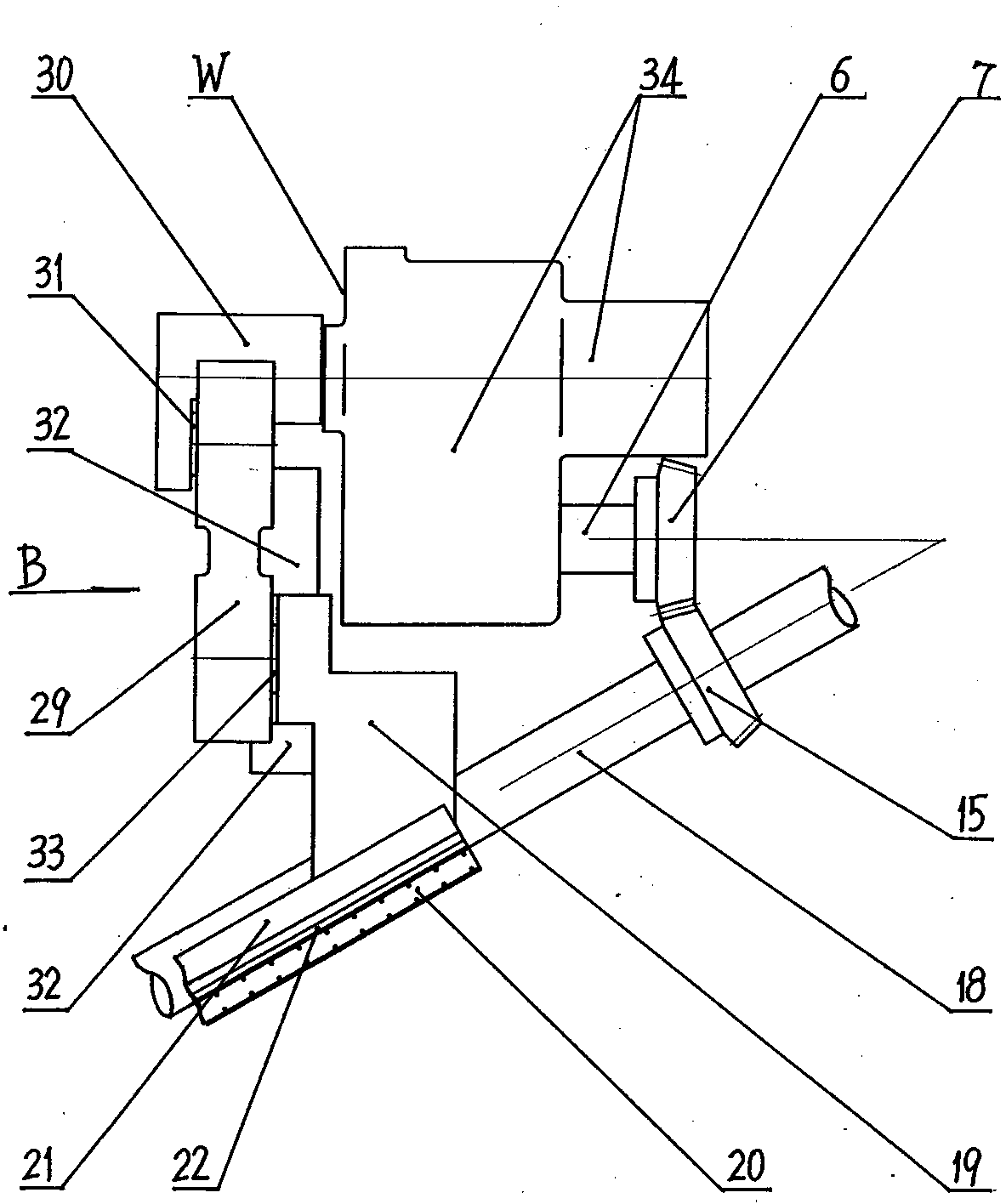

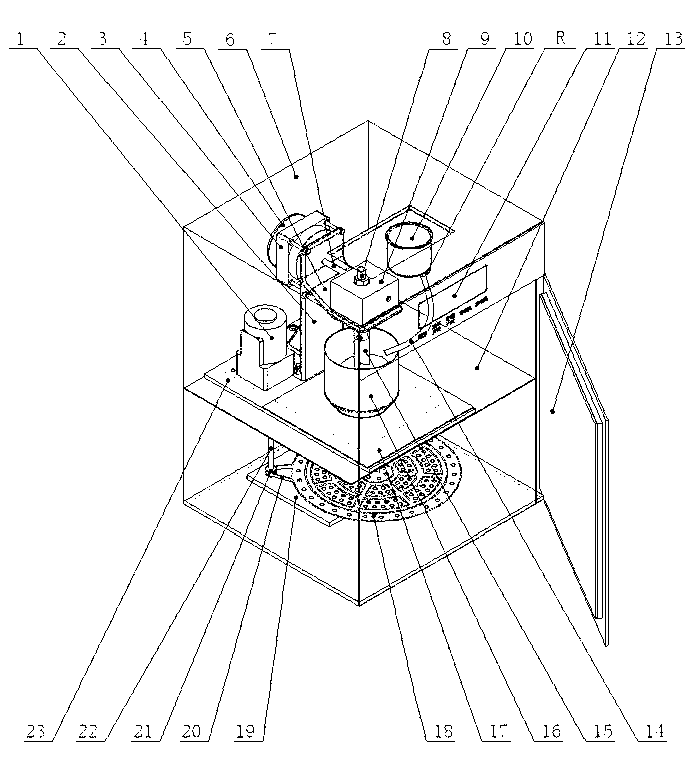

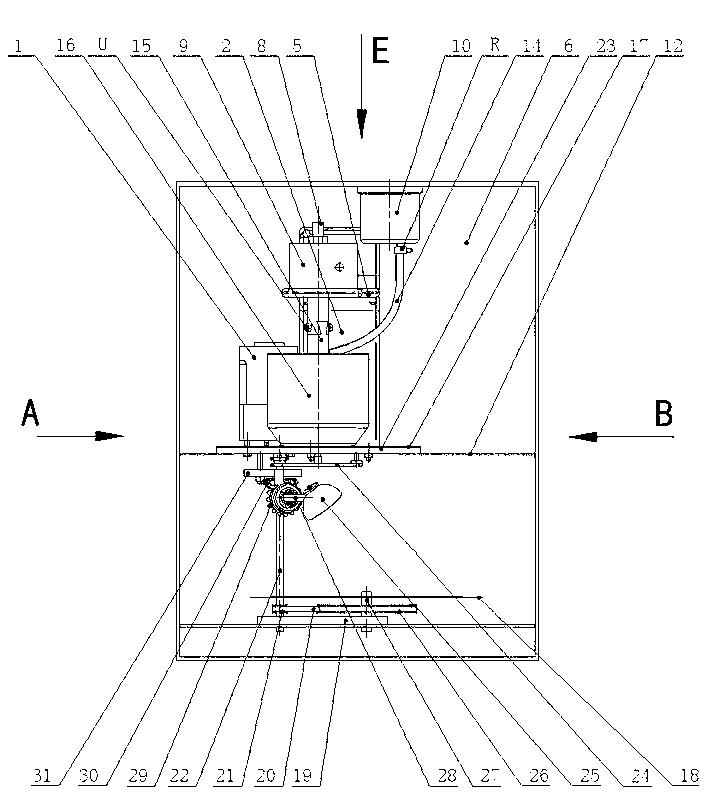

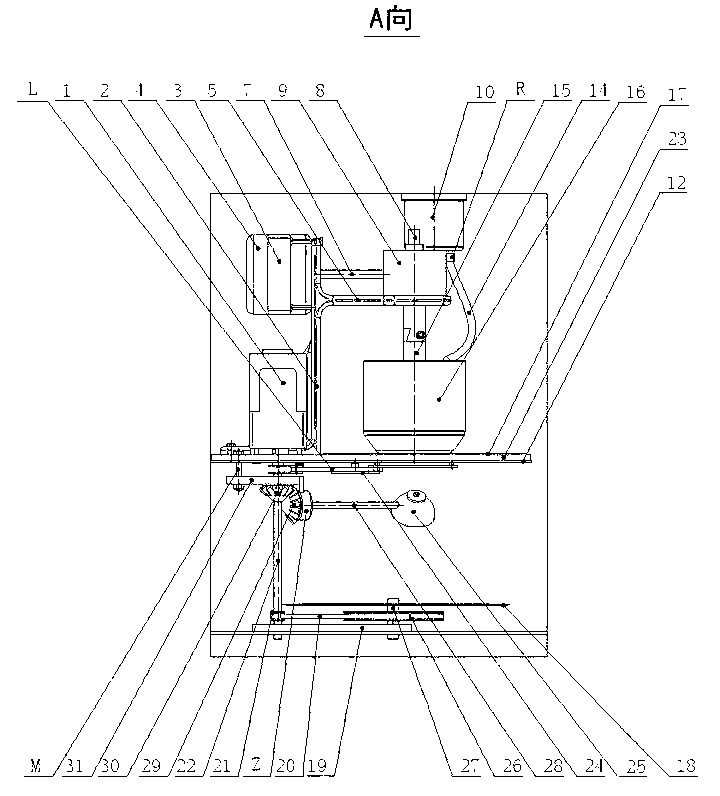

Household steamed bread kneading and forming machine

ActiveCN103229942AReasonable structureEasy to operateKitchen equipmentFood preparationTransmission beltEngineering

The invention relates to a household steamed bread kneading and forming machine. A kneading motor (4) is connected with a speed reducer (9) and is arranged on a motor stand (2); a speed reducer shaft (8) is connected with an auger shaft (15) and extends in a kneading bin (16); the kneading bin (16) is arranged on a cutting aperture plate (23); a speed reducing forming motor (1) is arranged at the back of the cutting aperture plate (23); and a forming transmission shaft (22) is connected with a cutting surface connecting rod (L) and a movable pull rod (24) through crank shafts (Q). A transmission bevel gear wheel (30) of the forming transmission shaft (22) is in meshed transmission with a spoon arm bevel gear wheel (29) of a spoon arm (28); a small transmission wheel (21) is connected with a transmission wheel (26) through a transmission belt (20), and a fine-toothed comb (18) is driven to rotate. The speed reducing forming motor (1) pulls a movable blade (32) to open and close through the forming transmission shaft (22) with the cutting surface connecting rod (L) and the movable pull rod (24); and dough inside the kneading bin (16) falling through a dough cutting hole (K) is cut and falls into a forming spoon (25), and the dough is turned over onto the fine-toothed comb (18). The machine can be matched with heating and steaming tools, and the requirement of manufacturing steamed bread is met.

Owner:SHANDONG JIAYI INTELLIGENT ELECTRICAL APPLIANCE CO LTD

Quick zinc sulfate electroplating process

A quick zinc sulfate electroplating process comprises the following steps: firstly, removing oil on a work piece, washing the workpiece by water, acid and water respectively, then soaking the workpiece into electroplating liquid in a galvanizing bath, taking out the work piece, washing the workpiece by water, then passivating the workpiece, washing the workpiece by water again, and drying the workpiece with hot wind. Content of chemical materials in each liter of the electroplating liquid is as follows: 80 to 150 grams of zinc sulfate, 120 to 180 grams of potassium chloride, 25 to 30 grams of buffer, 1 to 2 grams of additive and 20 to 25 grams of lustre-coating agent. The workpiece is soaked in the electroplating liquid for 10 to 15 minutes at a temperature of between 5 and 60 DEG C, and the pH value of the electroplating liquid is 4 to 5. The technical conditions of soaking the workpiece in the electroplating liquid in order to galvanize are as follows: the current density is 2 to 5A / dm; the cathode motion speed is 15 to 20 times per minute. By using the process to galvanize the workpiece, the deposition velocity is quick; dispersive power is good; corrosion resistance is strong; electroplating time is reduced by 60 percent; processing cost is reduced by 30 percent; production efficiency is high; and economic benefit is good.

Owner:梁新中

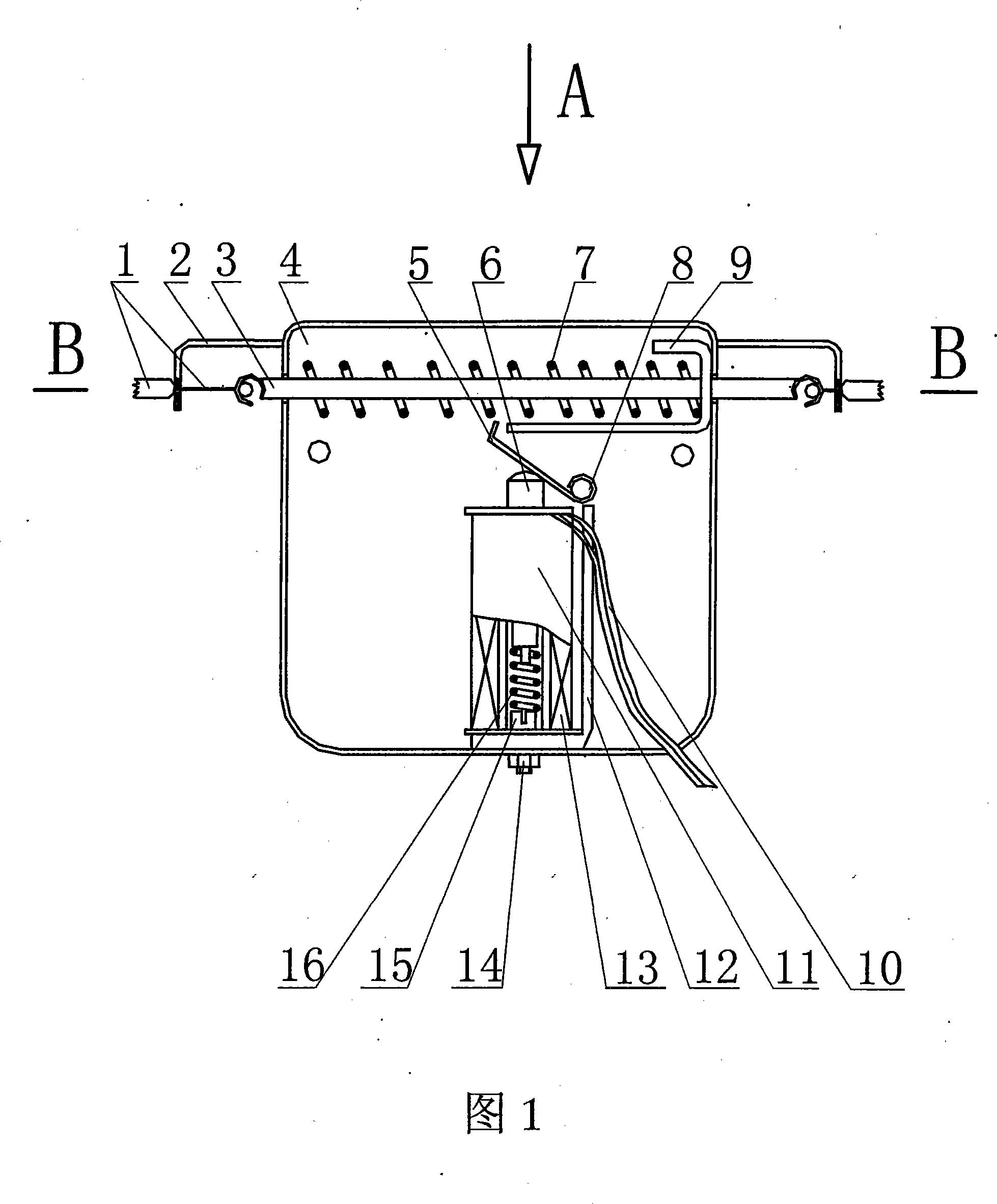

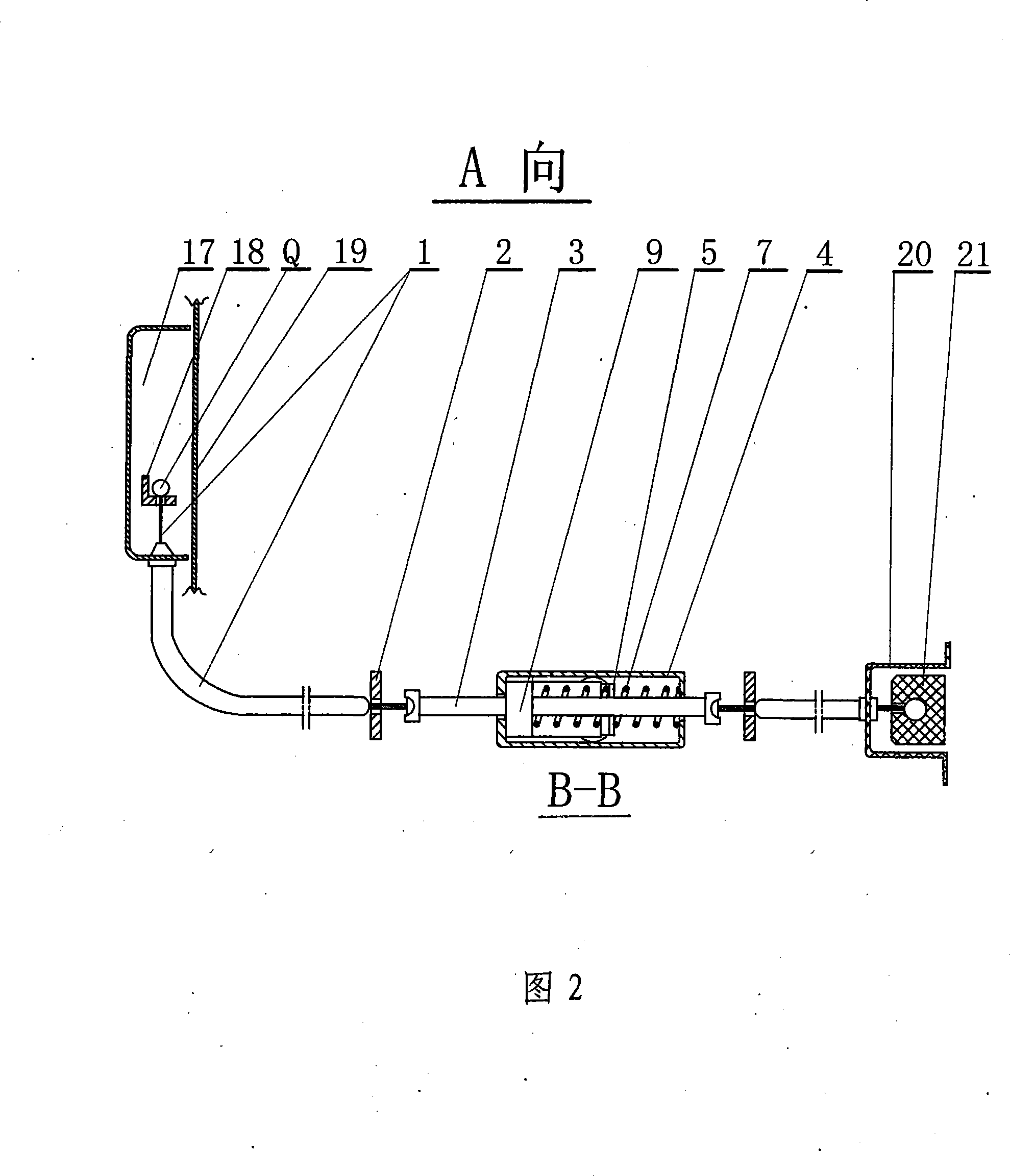

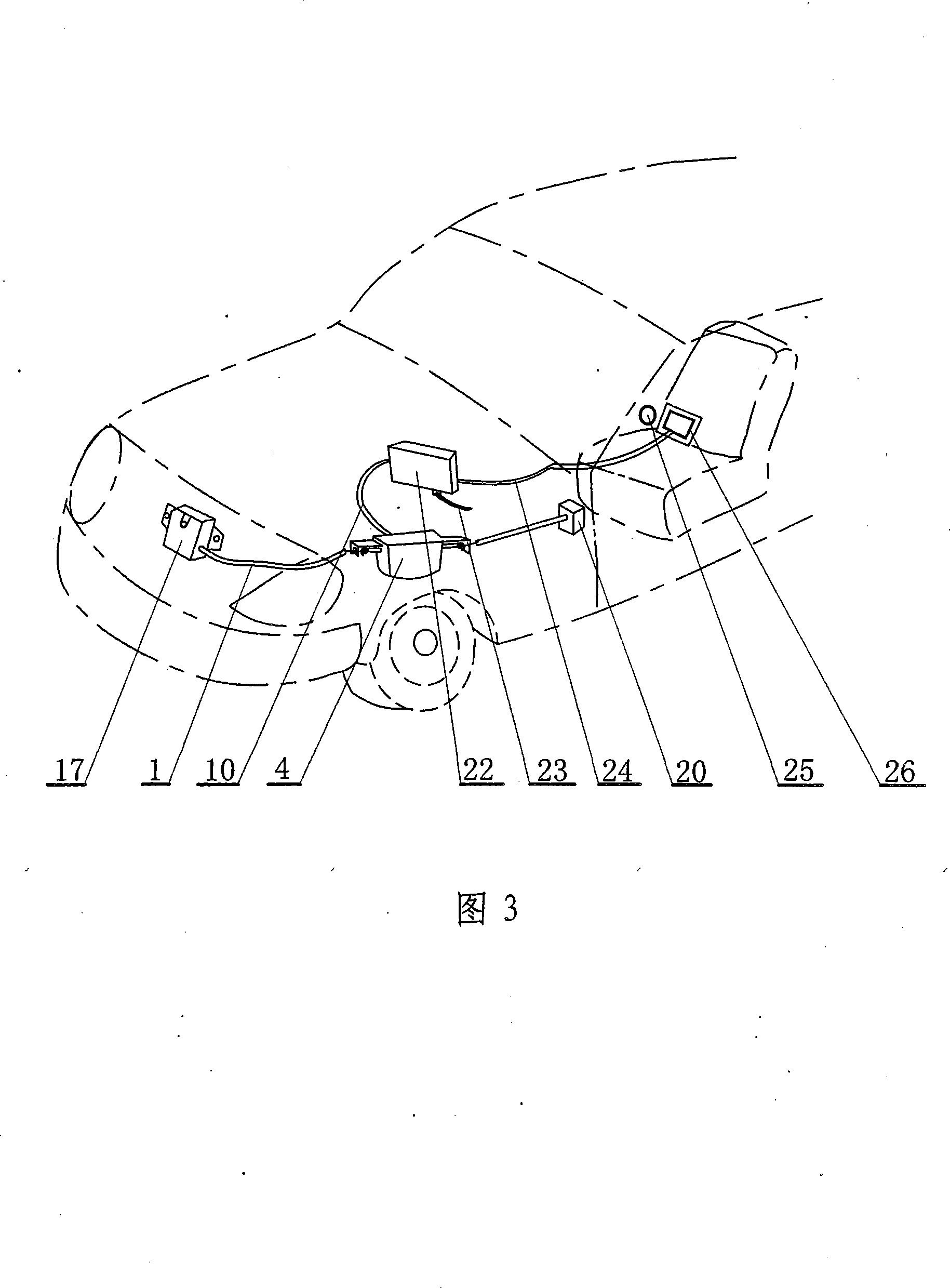

Automobile cover cap lock electromagnetic controller

InactiveCN101235690AControl onPrevent openingNon-mechanical controlsElectrical locking actuatorsElectrical controlElectric control

The invention relates to a vehicle engine cover lock electromagnetic controller, wherein a slide bar (3) which is sleeved with a spring (7) is through to be supported and mounted on the upper portion of a casing body (4), a retaining pawl (9) is welded on a bar body, both ends of the slide bar (3) which are provided with hooks are extended out of the casing body (4) to connect with a soft steel bracing cable (1), which are connected in an engaging motion with a vehicle engine cover lock (17) and an opening handle (21), a conical spring (16) and an armature iron (6) are mounted in a central hole of an electromagnet (11) in the casing body (4), and the armature iron (6) is upwards connected with an electro-magnetism latch hook (5). The electromagnet (11) can be communicated with an electric control device through an electrical wire (10), when the electric control device is electrified, the electro-magnetism latch hook (5) is downwards absorbed by the electromagnet (11), the retaining pawl (9) is not blocked, the slide bar (3) can be driven to slide through pulling the soft steel bracing cable (1), and the vehicle engine cover lock (17) is opened. If electromagnet (11) is not electrified, the electro-magnetism latch hook (5) stops the retaining pawl (9), and the slide bar (3) can not slide, and the soft steel bracing cable (1) can not be pulled, and the vehicle engine cover lock (17) can not be opened. The vehicle engine cover lock electromagnetic controller has the advantages of convenient installation, strong versatility and excellent anti-theft property.

Owner:孙宗炎

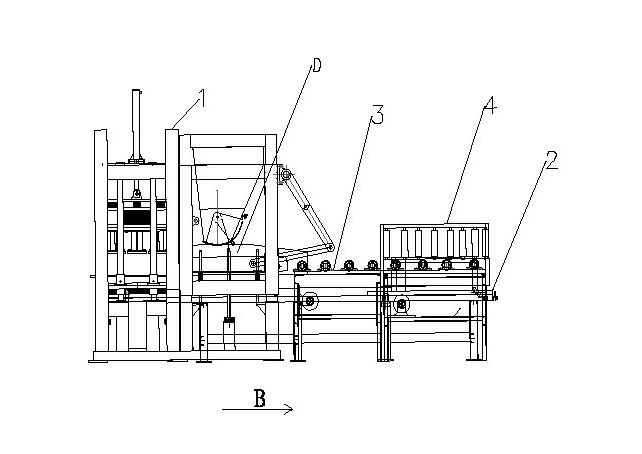

Automatic plate loader device of concrete block forming machine

ActiveCN102581931ACompact structureReasonable layoutCeramic shaping apparatusAutomatic controlProgrammable logic controller

The invention discloses an automatic plate loader device of a concrete block forming machine. A supporting plate conveying rack, a plate pushing device and a plate moving device of the concrete block forming machine are fittingly arranged in a 'U'-shaped plane layout manner, and each of the supporting plate conveying rack and the plate pushing device consists of a body, a transmission mechanism and an electrical system in a combined manner. The automatic plate loader device further comprises a control system consisting of a programmable logic controller (PLC), the control system is connected with the electrical systems via circuits, and controls the transmission mechanisms via the electrical systems, a stack of supporting plates on the supporting plate conveying rack are conveyed to the plate pushing device via conveying rollers, and the plate pushing device conveys the supporting plates into a plate box of a plate conveyor one by one. Full-automatic control, semi-automatic control and manual control can be realized. The automatic plate loader device is an all-steal structure, and is high in strength and stable in running. The automatic plate loader device is combined with the plate box of the concrete block plate conveyor, and has the advantages that the automatic plate loader device realizes automatic plate loading, improves work efficiency, is flexible in operation, coordinated in action and convenient in use, saves labor, reduces labor intensity, eliminates potential safety hazards, reduces cost and the like.

Owner:山东高唐华通液压机械有限公司

Oily sludge pyrolysis treatment and residue biohumic acid green repair process

InactiveCN109336350AHarmlessThe repair method is reasonableSolid waste disposalDirect heating destructive distillationAir preheaterGas solid

The invention relates to an oily sludge pyrolysis treatment and residue biohumic acid green repair process which is characterized in that crushed oily sludge and circulating solid hot ash are added from the front end of a rotary reactor and then are stirred, mixed, quickly heated, vaporized and pyrolyzed; pyrolysis oil and gas separated by a gas-solid separator enter a fractionation tower to obtain distillate oil or synthetic crude oil and tower bottom oil; pyrolysis residues enter a calcined fluidized bed through a return controller and subjected to mixed combustion heating with hot fluidizedair; after secondary gas-solid separation at the top of the calcined fluidized bed, the large and medium-sized particle hot ash is returned to the rotary reactor through a circulating pipe, the fineparticle ash flows into a cooling tank to be discharged as residues, and flue gas is discharged after passing through an air pre-heater; after being heated by the air pre-heater, air pressurized by afan flows into the bottom of the calcined fluidized bed as the hot fluidized air; cooled residues are subjected to heavy metal detoxification and pelletization with humic acid substances, so that thesoil self-repair and planting functions are restored.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of dietary fibers from peanuts

The invention relates to a preparation method of dietary fibers from peanuts, which comprises the following steps: wet peanut residues are taken as raw materials and proper amount of process water and accessories are added to prepare peanut residue pulps through hardening and tempering process; under certain conditions of temperature, time and environment, the peanut residue pulps respectively pass through various procedures to undergo chemical reaction and processing; the peanut residue pulps pass through a filter pressing procedure and are prepared into filter cakes with thickness of 20-40mm; the filter cakes are subjected to flash drying process and the dried filter cakes have moisture content of 15-20%; the filter cakes are broken up and are coarsely ground by flour mills to uniform powder; the powder is sterilized by microwave sterilizers and then is conveyed to a super micron mill for micronization to prepare the dietary fibers from peanuts; the dietary fibers have protein content more than or equal to 35%, moisture content less than or equal to 12%, ash content less than or equal to 6%, total content of dietary fibers more than or equal to 60%, water-holding capacity more than or equal to 20%, swelling coefficient more than or equal to 13ml / g and fineness of 100-380 meshes. The dietary fibers from peanuts can fully extract the nutritions in the peanut residues and have good quality, wide application, high added-value of products, high production efficiency, low production cost and good economic benefits.

Owner:SHANDONG GAOTANG LANSHAN GRP CORP

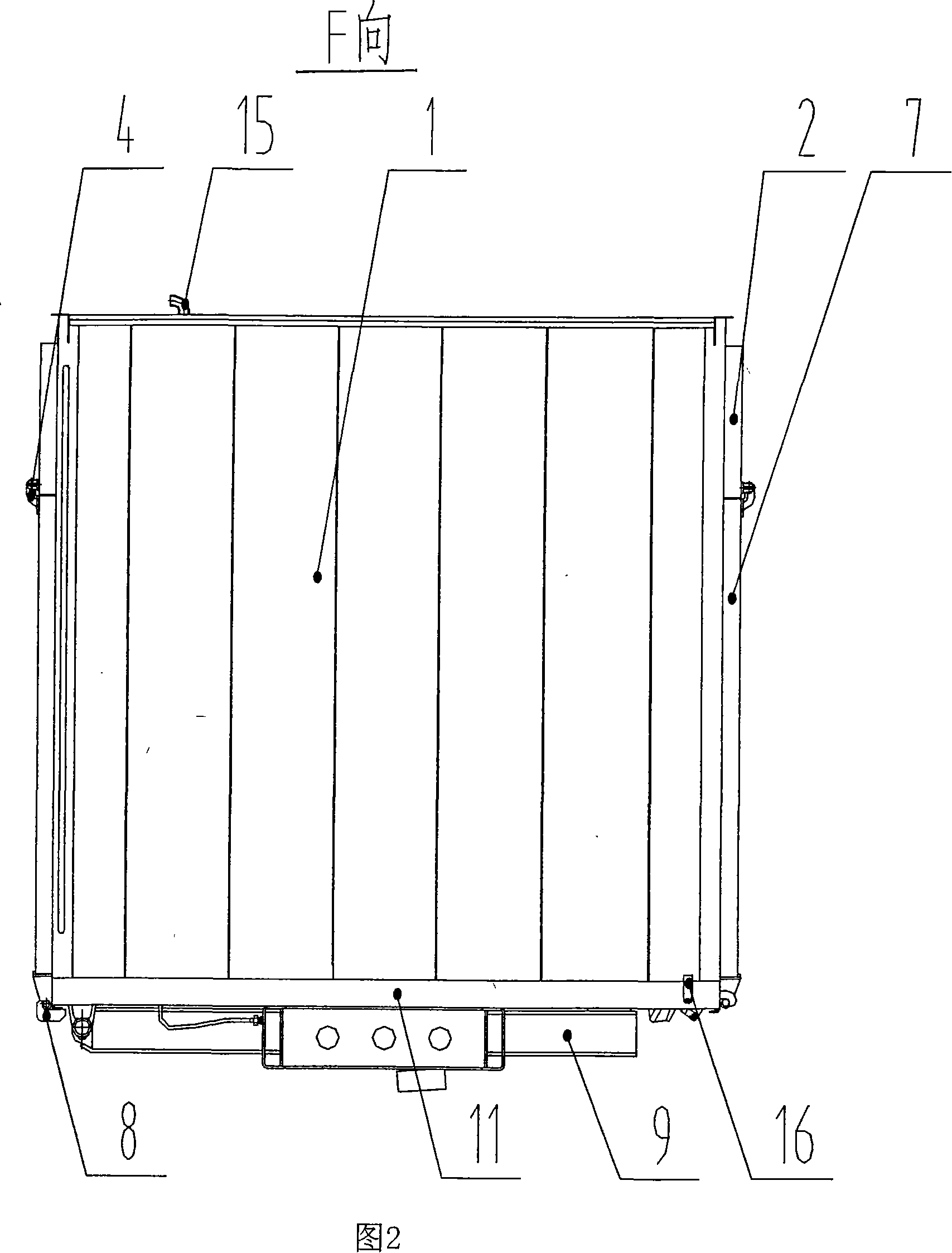

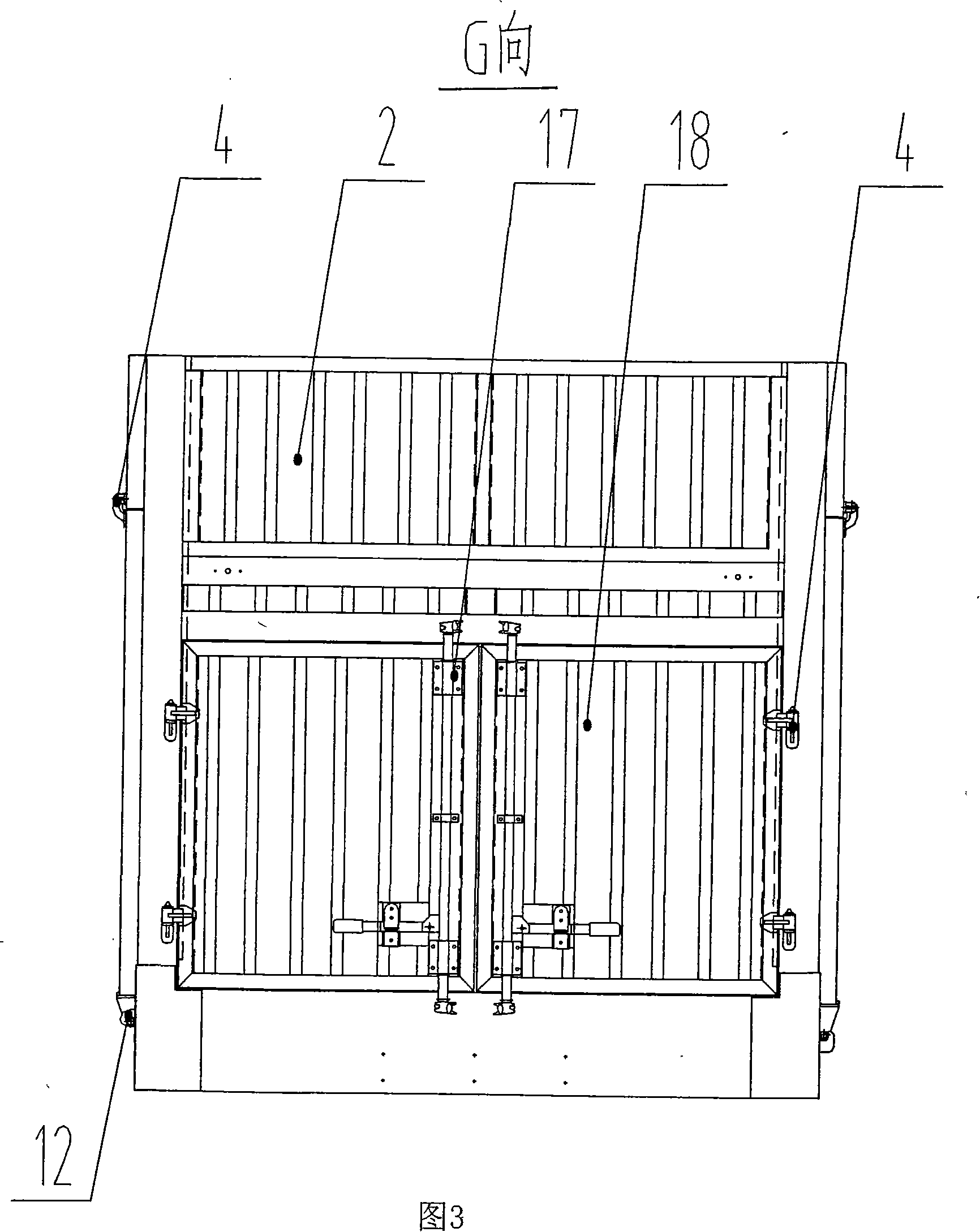

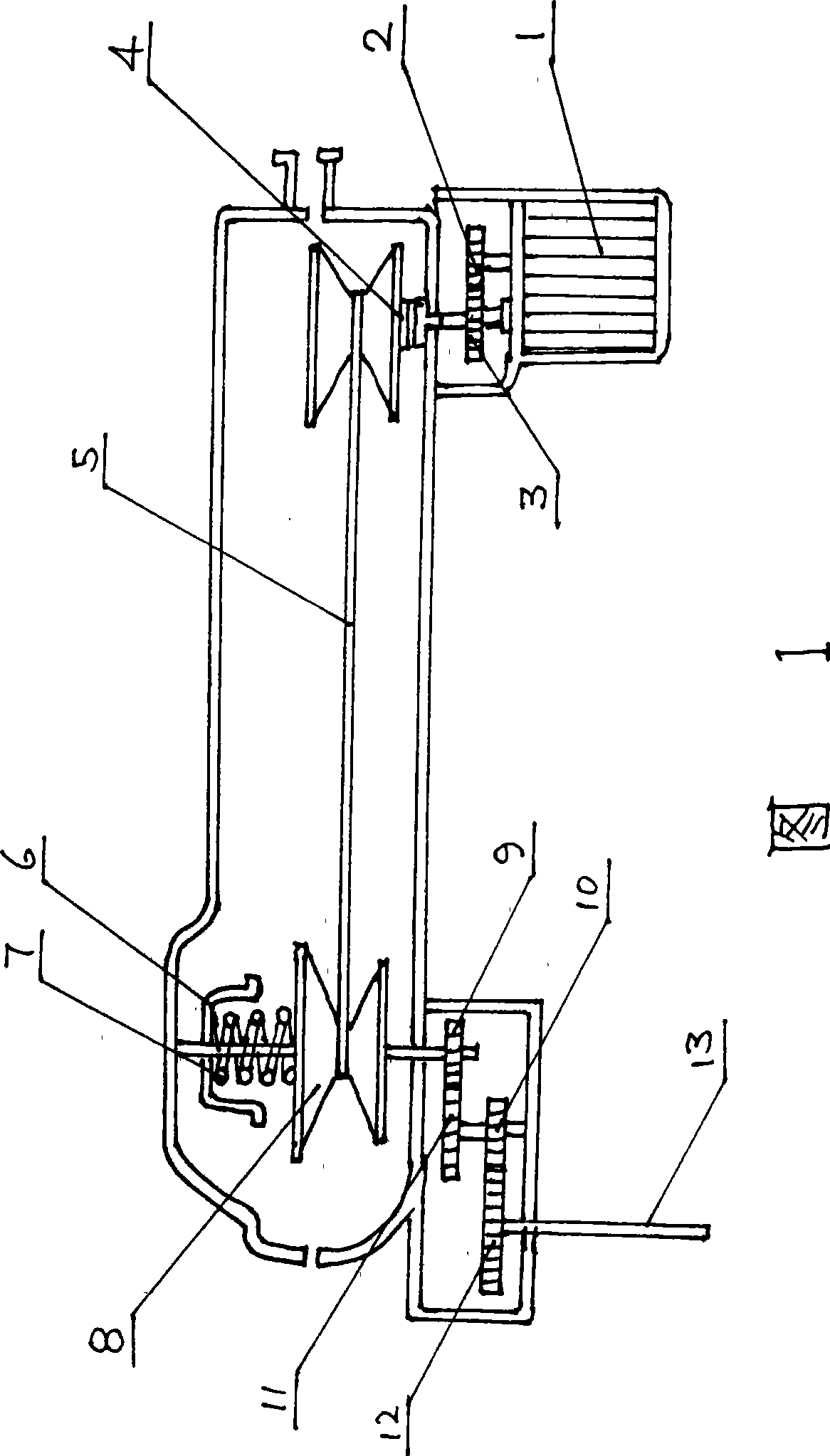

Self-discharging goods case of side-turn bottom board

InactiveCN101108596ASpeed up logistics turnoverEasy to operateVehicle with tipping movementControl systemRotating hinge

A side-turn bottom board self-dismantle packing case is provided, which is composed of multiple sections of case, a hydraulic pressure lifting cylinder (20) arranged at the bottom surface of a lifting bottom board (11), a rotating hinged axle (4) at the two sides of the case arranged with a movable case board (7) by hanging; and the movable end edge beam (30) of the lifting bottom board (11) arranged with an automatic case opening structure (12), which matches with a case board lock hook (24) at the lower end of the movable box board (7). A control system controls an air pipeline (51) by a circuit, to control an oil road (54) and a hydraulic pressure machine. One side of the lifting bottom board (11) is connected with a bottom frame (9) by a turning axle (25) to work as a fixing end. An automatic opening switch controls the automatic box opening structure (12) to loose an box board lock hooker (24), then lift a lifting switch (57) to control the hydraulic pressure lifting cylinder (20) to operate the movable end of the operation lengthwise lifting board (11) to dismantle goods by turning automatically to one side of the fixing end. The material single direction self-dismantle is quick and safe, the operation is convenient and flexible, which improves the transmission and dismantling efficiency.

Owner:山东迅力特种汽车有限公司

Chromium-contaminated soil humic acid environment-friendly in-situ restoration process

InactiveCN106180172AThe repair method is reasonableQuick fixContaminated soil reclamationReducing agentHumic acid

Humic acid green in-situ restoration process of chromium-contaminated soil, the first step is to add humic acid substances with a chromium ratio of 5-20:1 when the chromium-contaminated soil is crushed; the second step is to restore the chromium-contaminated soil less than 3mm After more than 1 hour, according to the detected hexavalent chromium content, spray into the strong reducing agent solution according to the chromium ratio of 10-30:1, mix well and force reduction; the third step is to spray the chromium-contaminated soil into the soil after reduction The ratio of 1‑5:100 liquid humic acid is granulated and granulated, which wraps and blocks the exudation and migration of hexavalent chromium in the particles, realizes permanent reduction and fixation, and restores the function of soil planting.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Acceleration transmission mechanism of novel electric vehicle

InactiveCN101367421ASmooth startSpeed up fastWheel based transmissionMotorcyclesClutchElectric vehicle

The invention discloses a novel speed-raising transmission mechanism for an electric motor car, which belongs to a transmission device for an electric bicycle or an electric motorcycle. The middle part close to the rear wheel on the lower end of a frame of the electric motor car is provided with a motor which rotates a gear of a central axis to drive a speed-raising gear to play a role in raising the speed and to drive an overrunning coupler to rotate to work; a belt pulley drives a rear idler to work so as to achieve infinite variable speed effect; and the rear idler rotates a central speed transforming gear, then an axle sliding gear rotated by a sliding gear rotates an axle. The speed-raising transmission mechanism utilizes the overrunning coupler in the belt transmission of the motorcycle; meanwhile, the speed-raising transmission mechanism is combined with the prior speed-change mechanism of the electric motor car or the electric motorcycle to achieve the infinite variable speed. Therefore, the speed-raising transmission mechanism contributes to an ideal electric motor car with the independent motor, stable starting, quick speed raising, strong capacity of climbing, long sliding time and electricity conservation.

Owner:林伯祥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com