High-efficiency cooling pipe for refrigeration equipment and surface blurring method thereof

A heat dissipation pipe, high-efficiency technology, applied in the direction of tubular components, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of large amount of consumables, occupying a large space, difficult to control the height of convex ribs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

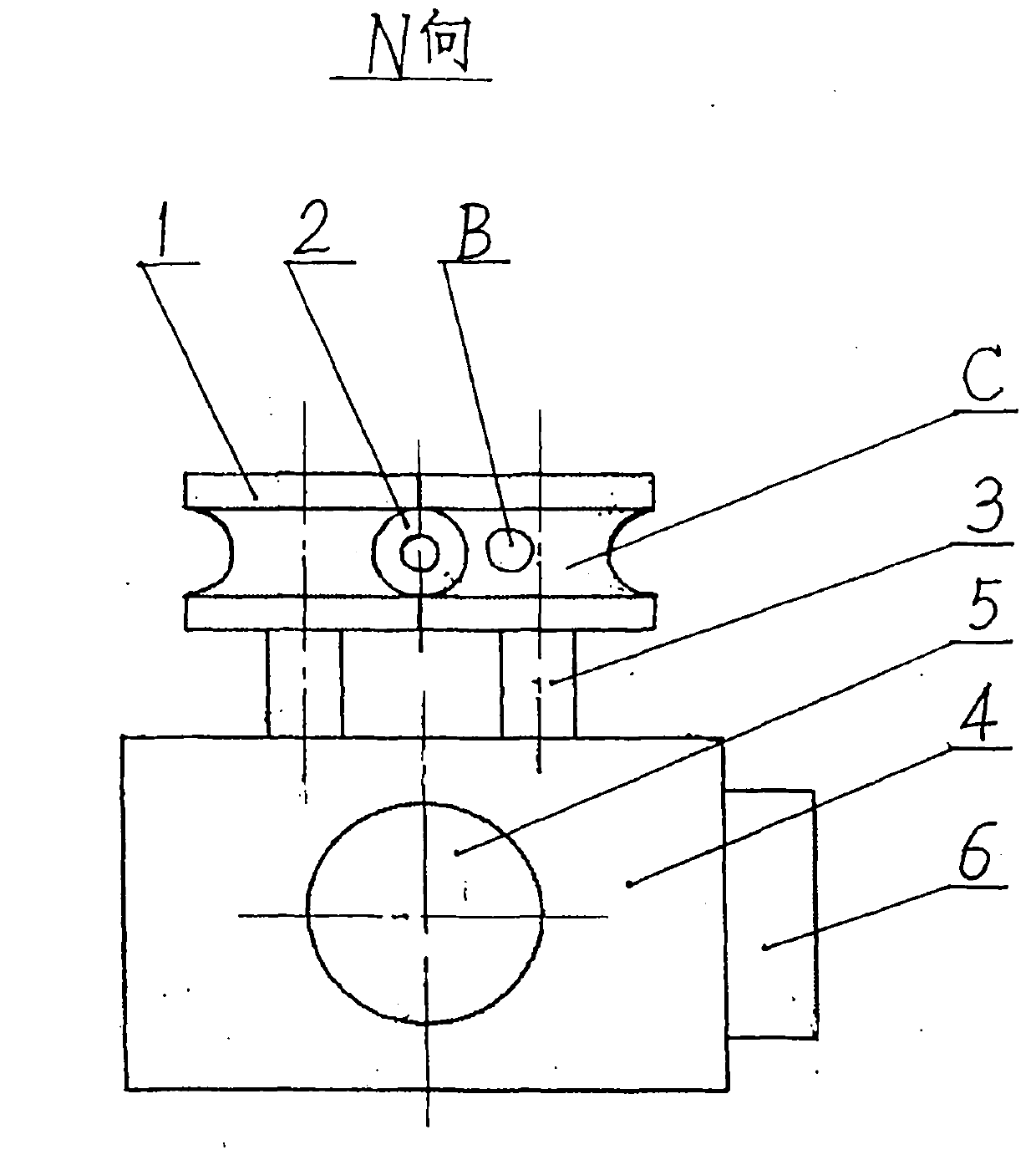

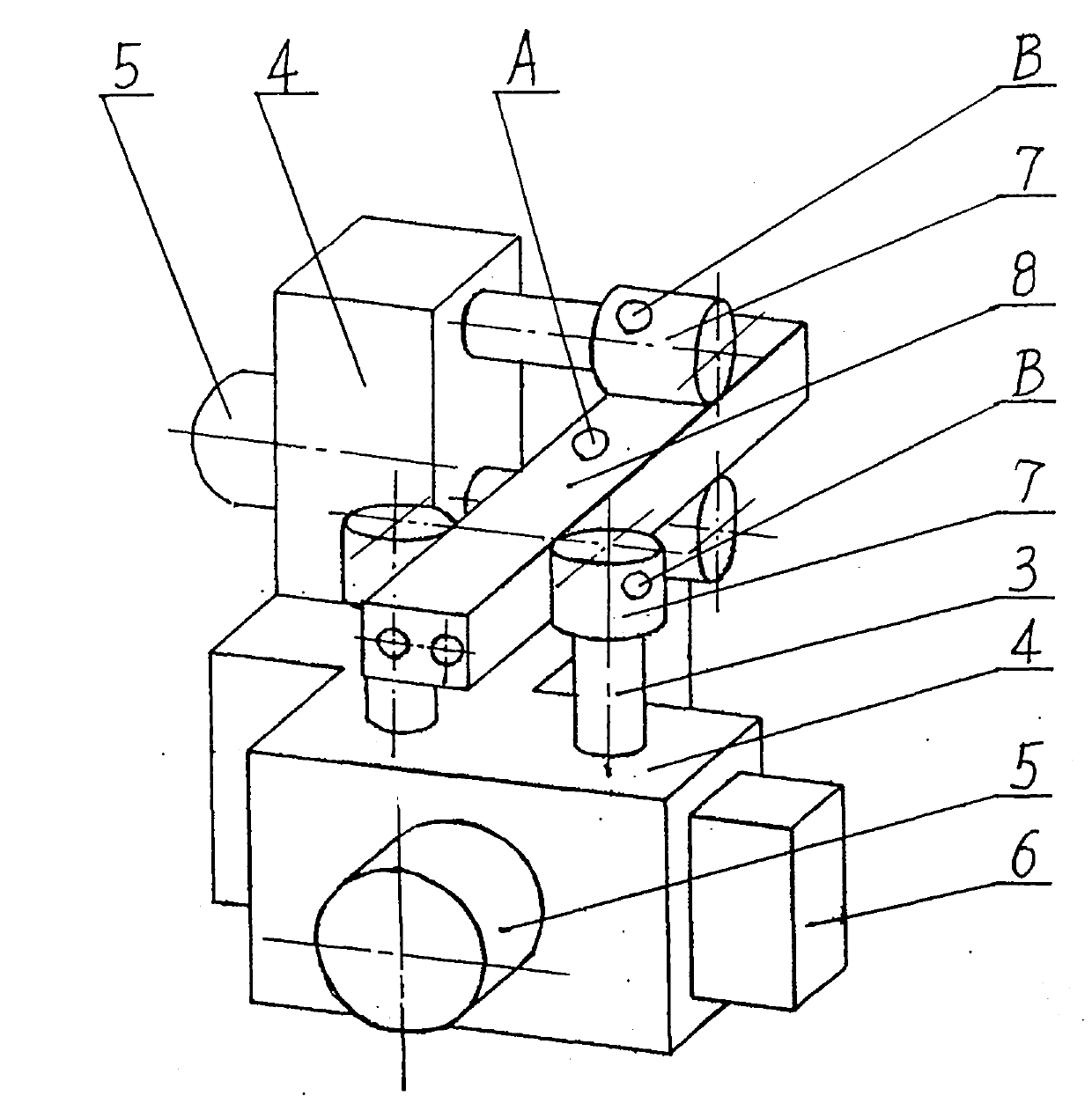

[0012] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

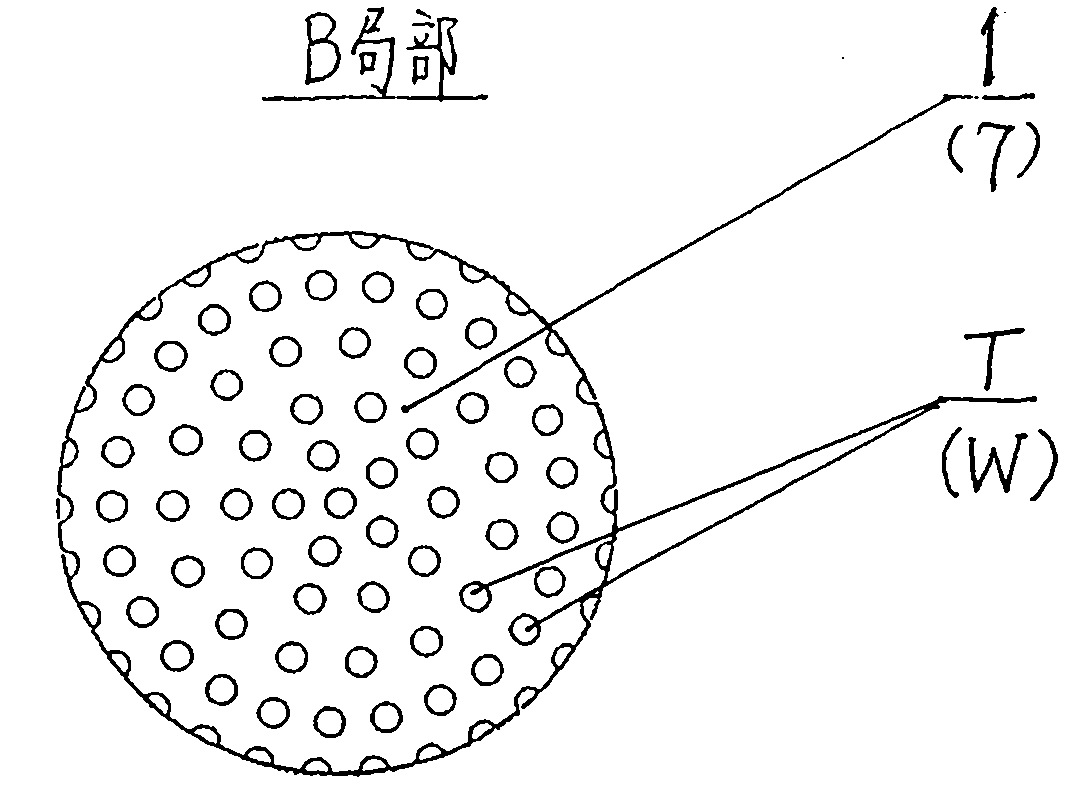

[0013] refer to figure 1 , figure 2 , Two rollers 1 form a pair of rollers, and the roller shafts 3 are installed on the gearbox 4 respectively, and the gearbox 4 is driven by the motor 5, and the frequency regulator 6 is installed on the gearbox 4. The circular heat pipe 2 is interspersed between the two rollers 1. The inner groove C of the roller 1 clamps the heat pipe 2 tightly on both sides. There are several microscopic protrusions T on the inner groove C, densely covering the whole Inner concave wheel groove C, two rollers 1 carry out relative rolling on the heat dissipation pipe 2, the heat dissipation pipe 2 runs in the horizontal direction, and the frequency regulator 6 automatically adjusts the speed of the motor 5 according to the running speed of the heat dissipation pipe 2, so that the speed of the roller 1 Matching with the running spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com