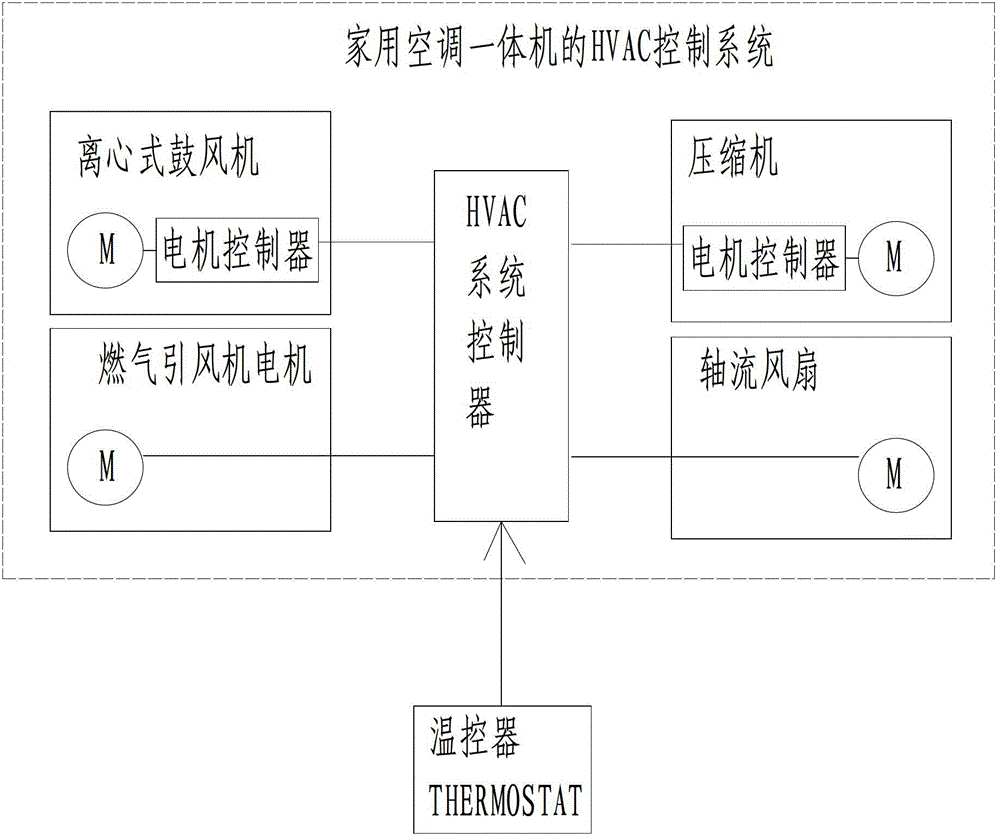

HVAC (heating ventilation and air conditioning) control system of household central air conditioner

A central air-conditioning and control system technology, applied in the control system, heating and ventilation control system, home appliances, etc., can solve the problems of complex structure, increased product cost, waste of resources, etc., to simplify the circuit structure, reduce product cost, reduce The effect of wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

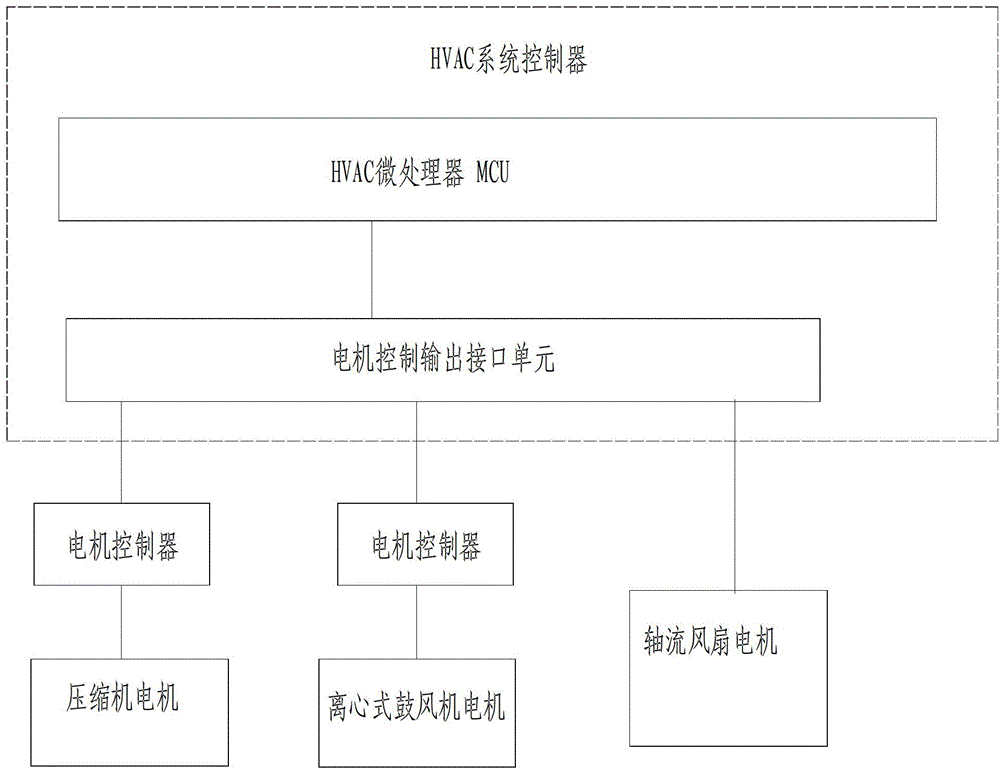

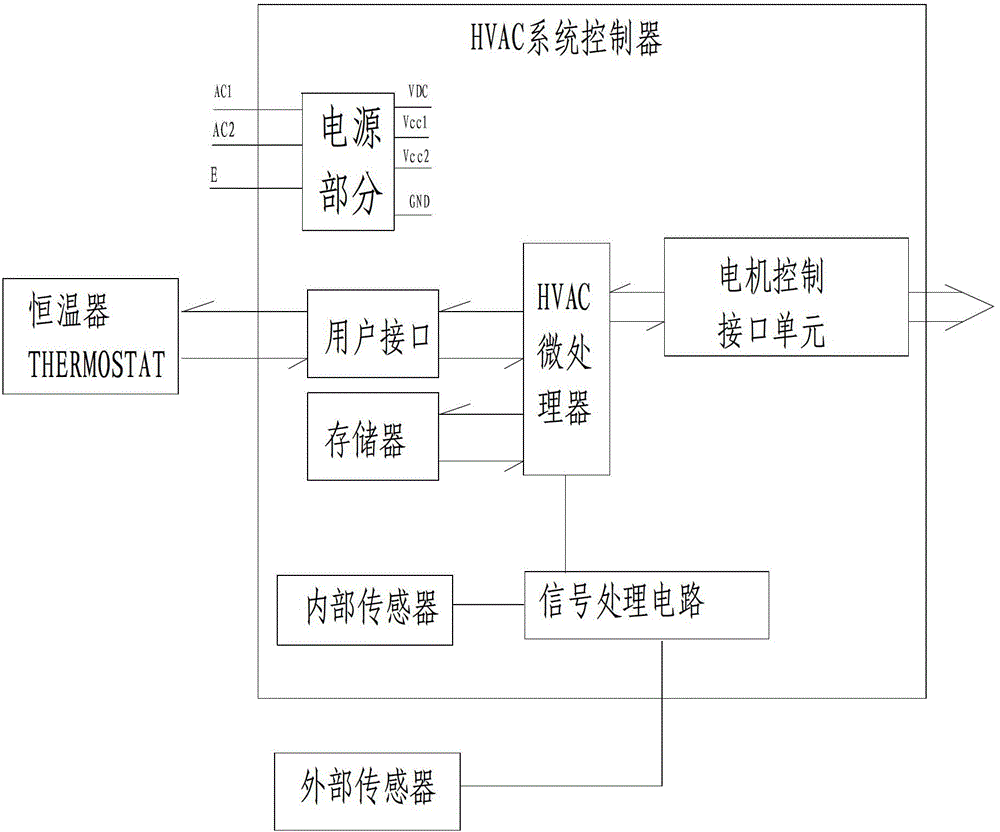

[0033] Embodiment one: image 3 , Figure 4 As shown, an HVAC control system for a household central air conditioner includes an HVAC system controller, a centrifugal blower motor, a compressor motor, and an axial fan motor, wherein the HVAC system controller includes an HVAC microprocessor, internal sensors, and external sensors , memory, signal processing circuit, user interface, motor control interface unit and power supply part, the power supply part supplies power to each part of the circuit, the internal sensor and external sensor send the detection signal to the HVAC microprocessor through the signal processing circuit, and the compressor motor adopts Permanent magnet synchronous motor without motor controller, centrifugal blower motor and axial fan motor are AC motors, motor control interface unit includes inverter unit, rotor position detection unit, 2-way relay and its driving circuit, HVAC microprocessing The inverter drives the permanent magnet synchronous motor w...

Embodiment 2

[0035] Embodiment two: Image 6As shown, the difference from Embodiment 1 is that the centrifugal blower motor adopts a permanent magnet synchronous motor without a motor controller, the compressor motor and the axial fan motor are AC motors, and the motor control interface unit includes an inverter unit, a rotor The position detection unit and the 2-way relay and its drive circuit, the HVAC microprocessor drives the permanent magnet synchronous motor without a motor controller through the inverter unit, and the rotor position detection unit converts the rotor position signal of the permanent magnet synchronous motor without a motor controller It is sent to the HVAC microprocessor for processing, and the HVAC microprocessor controls the compressor motor and the axial fan motor through 2-way relays and their drive circuits.

Embodiment 3

[0036] Embodiment three: Figure 7 As shown, the difference from Embodiment 1 is that the axial flow fan motor adopts a permanent magnet synchronous motor without a motor controller, the compressor motor and the centrifugal blower motor are AC motors, and the motor control interface unit includes an inverter unit, a rotor The position detection unit and the 2-way relay and its drive circuit, the HVAC microprocessor drives the permanent magnet synchronous motor without a motor controller through the inverter unit, and the rotor position detection unit converts the rotor position signal of the permanent magnet synchronous motor without a motor controller It is sent to the HVAC microprocessor for processing, and the HVAC microprocessor controls the motor of the compressor and the motor of the centrifugal blower through a 2-way relay and its drive circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com