Automatic plate loader device of concrete block forming machine

A technology of block forming machine and automatic plate loading machine, which is applied to ceramic forming machines, manufacturing tools, etc., can solve problems such as easy occurrence of accidents, increased unsafe hidden dangers, and inability to keep up with the progress of cooperation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

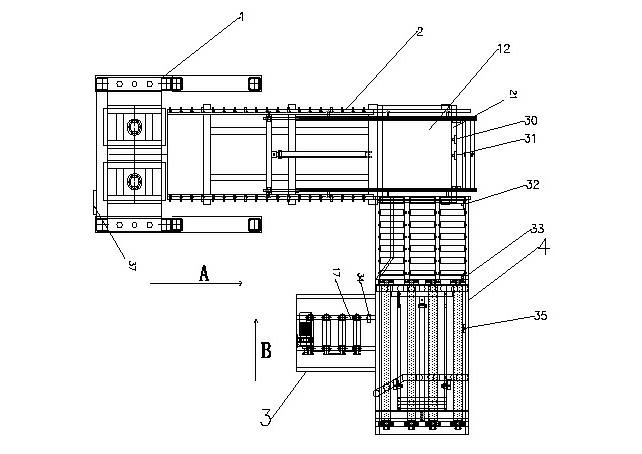

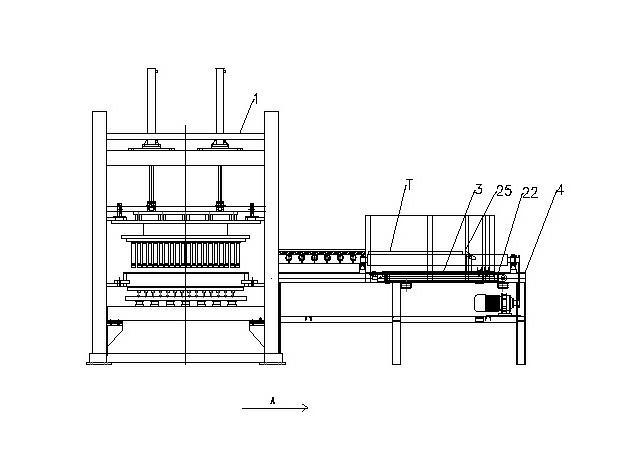

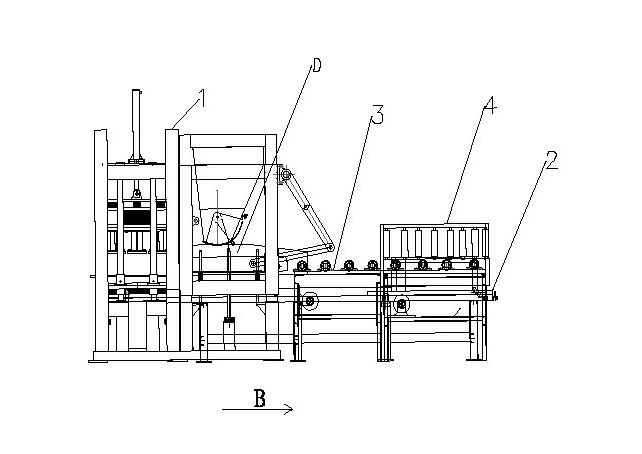

[0019] refer to figure 1 , the pallet conveying frame 3 and the pallet device 4 are arranged in a "T" shape, and are connected and installed with the pallet moving device 2 of the block forming machine 1 to form a "凵"-shaped plane layout, so that the block forming machine 1 and the pallet The distance of the conveying frame 4 is close, the structure is compact, the occupied area is small, and the transportation pallet is convenient. On the support channel steel 17 of the bearing chamber on the pallet transport frame 3, a running start proximity switch 34 is arranged, and a plate delivery to position proximity switch 35 is installed on the outer baffle plate of the rear end of the push plate device 4. The front limit proximity switch 32 of the push plate is installed, and the rear limit proximity switch 33 of the push plate is installed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com