Self-discharging goods case of side-turn bottom board

A side-turning, bottom-plate technology, which is applied in the direction of inclined load-carrying vehicles, etc., can solve the problem of high self-unloading efficiency of cargo boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

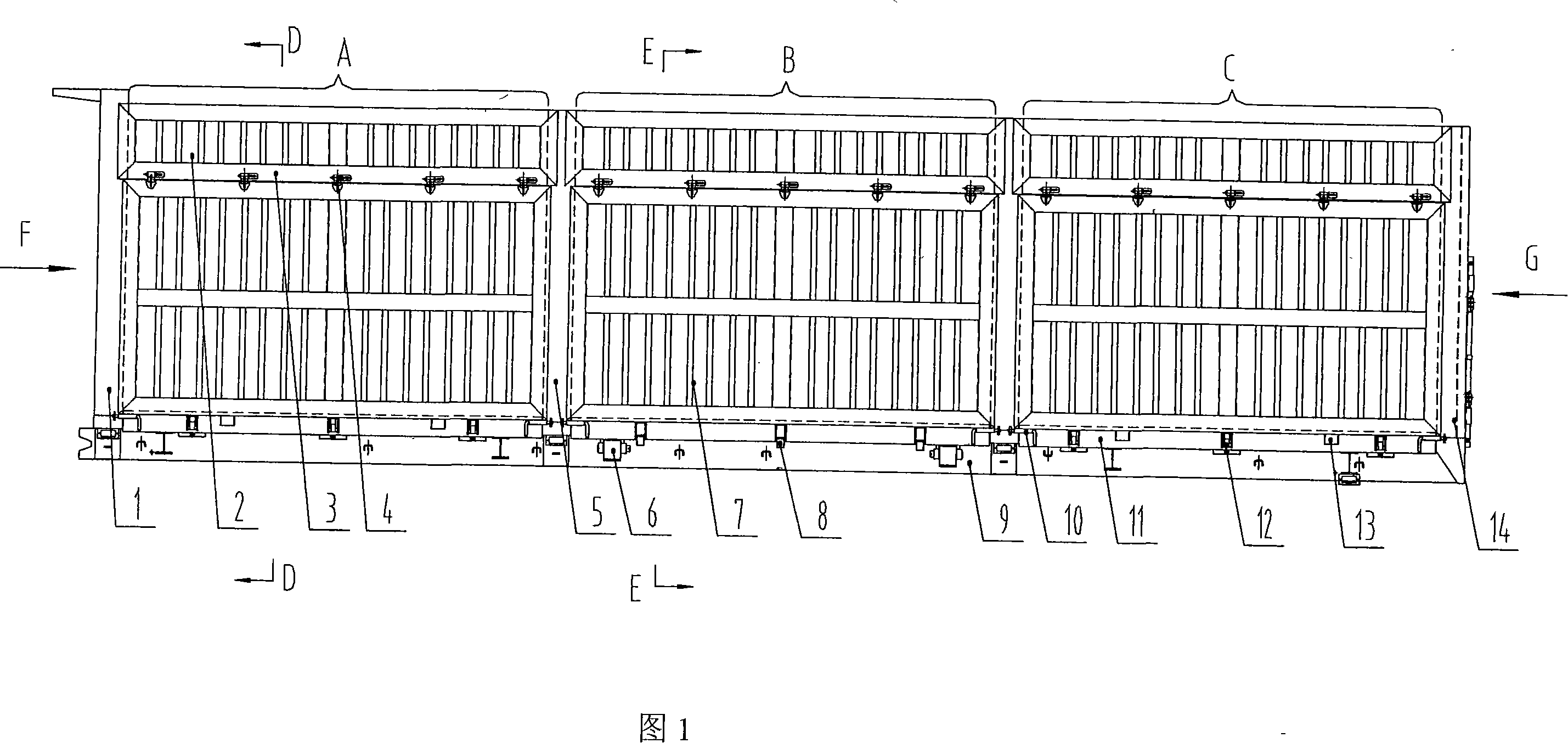

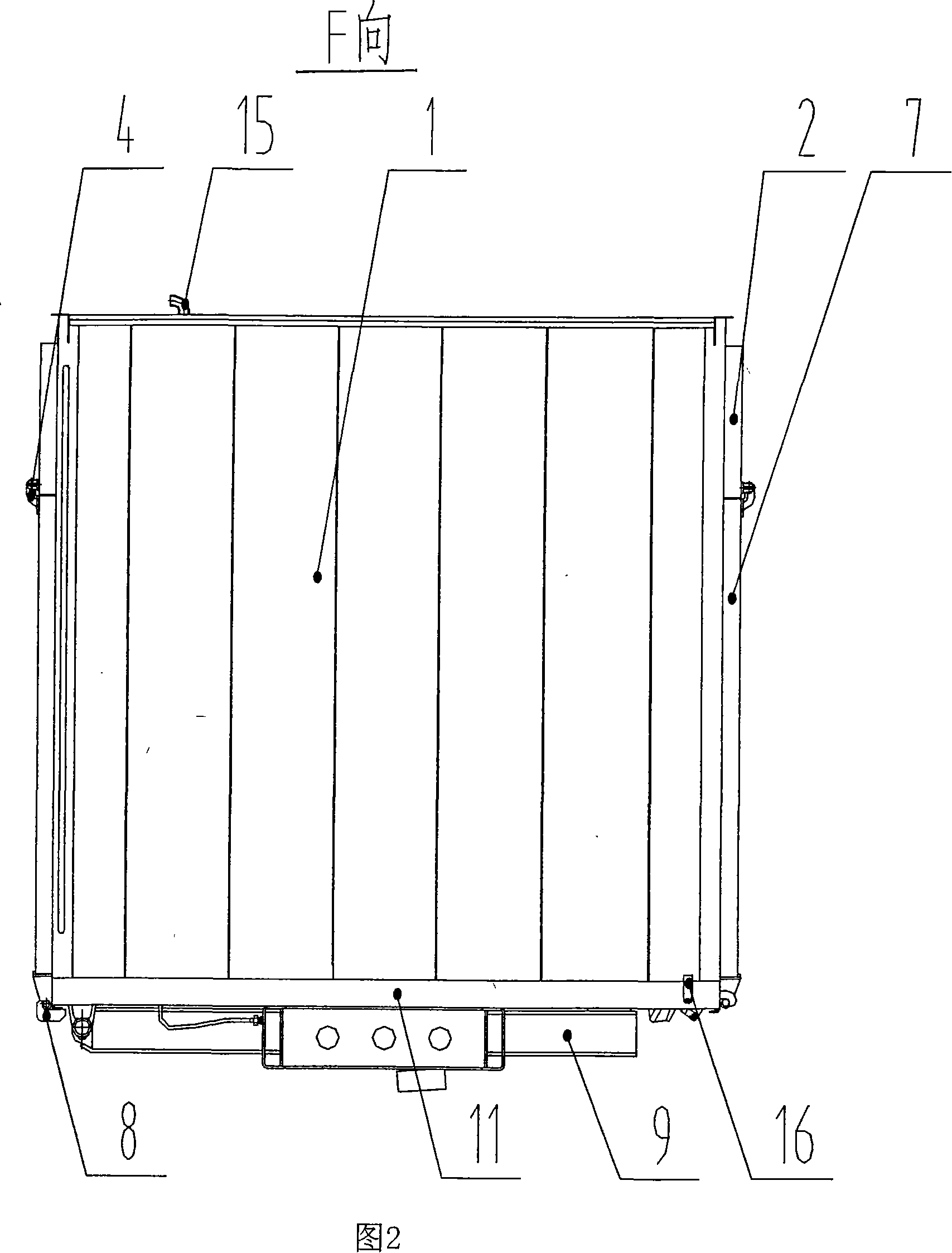

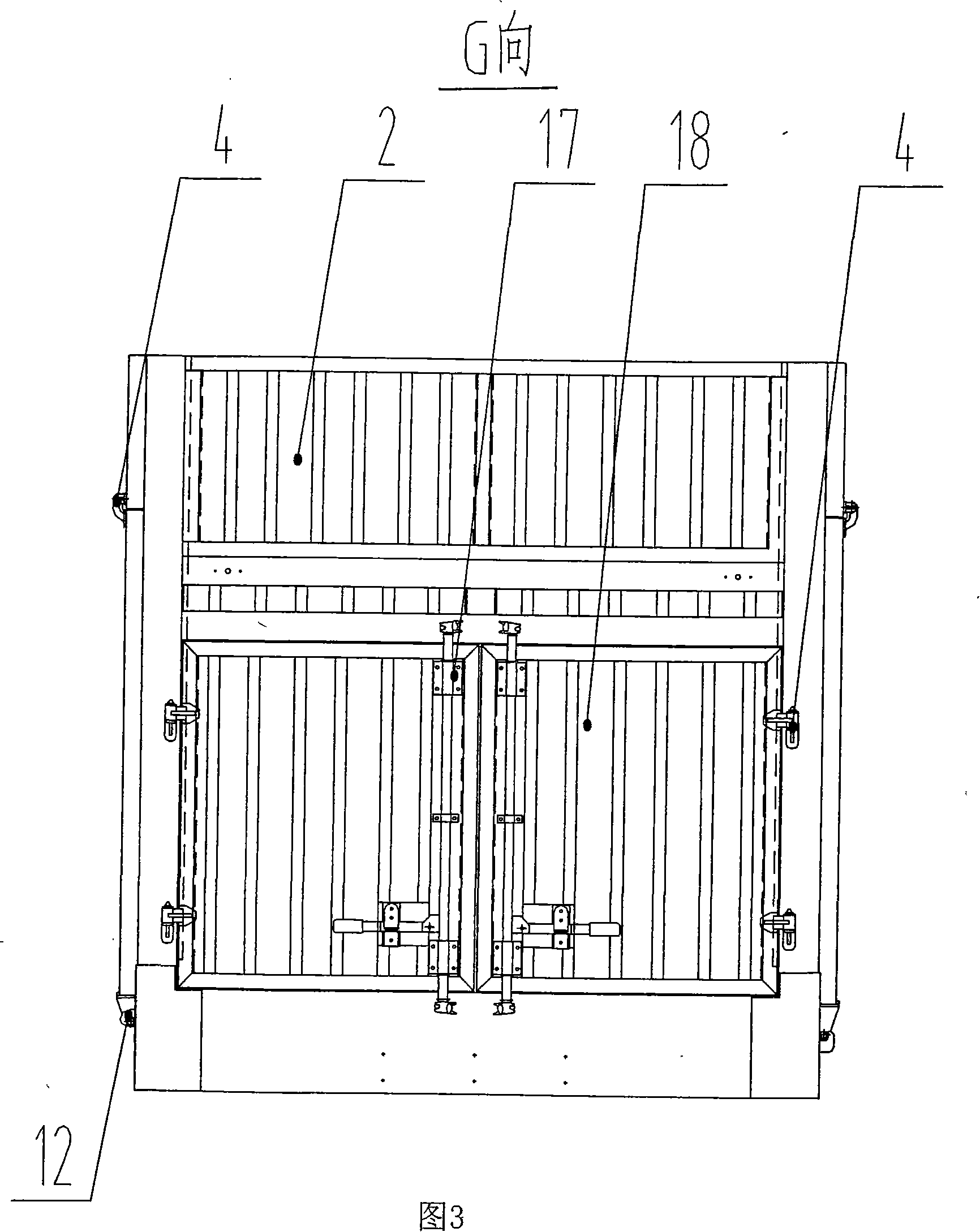

[0018]The present invention will be further described below in conjunction with accompanying drawing. Referring to Fig. 1, the present invention is combined into a whole self-unloading container by the front box body A, the middle box body B, and the rear box body C. The body column 5 forms the upper frame of the box body, the lower end of the fixed box plate frame 3 is hoisted by the rotating hinge shaft 4 to lift the movable box plate 7, the side of the bottom frame 9 has a turning sleeve 6, and a lifting base plate 11 is installed on the bottom frame 9. Upturning lock hook 8 is equipped with on bottom plate 11 undersides. Referring to Fig. 2, the figure is a front view of the front box panel 1, showing the state that the fixed box panel 2 and the movable box panel 7 on the side of the box body are connected by the rotating hinge shaft 4, and there is a water inlet 15 at the top of the front box panel 1 , the bottom end has a drain pipe mouth 16. Fig. 3 is the front view o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com