An automatic cutting and forming device for honeycomb ceramic wet blank

An automatic cutting and forming device technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of low production efficiency, low efficiency, and affecting product appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

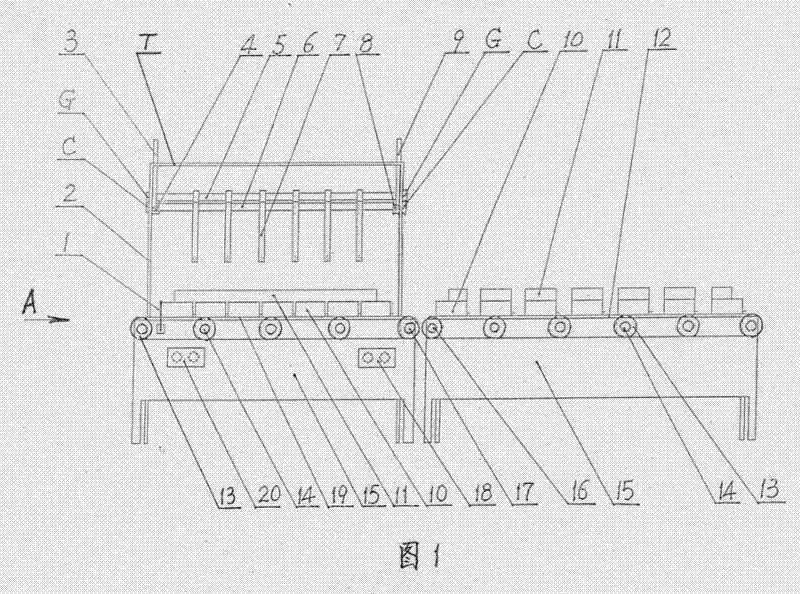

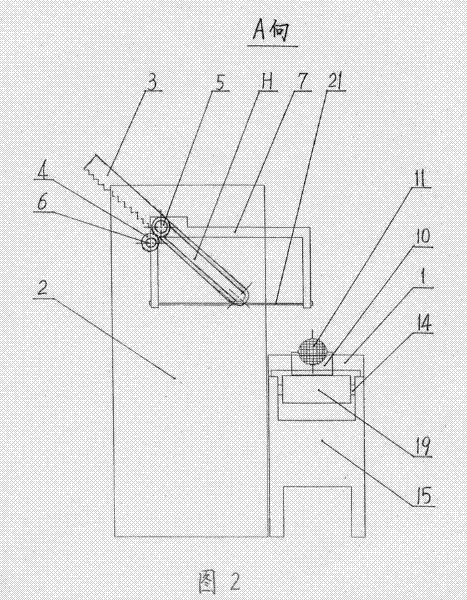

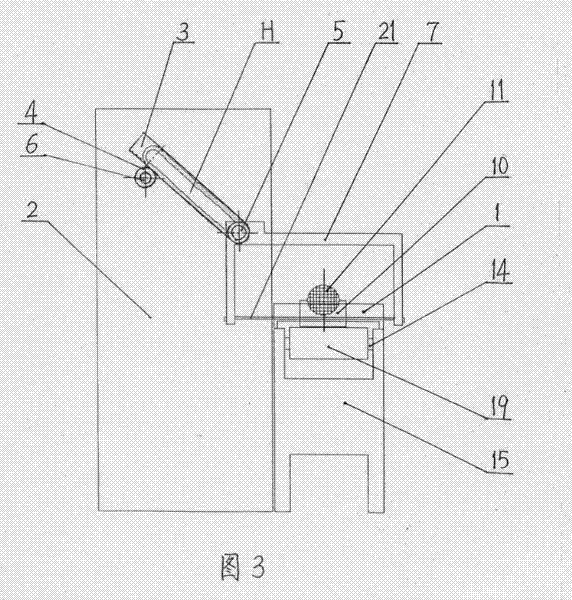

[0015] The embodiments of the present invention will be described below with reference to the drawings.

[0016] Refer to figure 1 , The blank holder, the transmission worktable, the cutter, the support 2 and the transmission system and the electrical system are combined to form the overall structure of the present invention. The covered slow conveyor belt 19 and the fast conveyor belt 12 are respectively sleeved with drive roller shafts 14 and installed on their respective work benches 15, driven by the slow drive shaft 17 and the fast drive shaft 16, respectively, and connected back and forth to form a transmission work station. A cutting switch 20 and a transmission switch 18 are respectively installed on the side of the workbench 15. The brackets 2 are two vertical plate structures, which are fixed on the side of the workbench 15 of the slow conveyor 19 and arranged in parallel. The top surfaces of the brackets 2 at the front and rear ends are connected and reinforced by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com