Slugging machine for brass solder water radiator

A technology of water radiator and cutting machine, which is applied in the direction of metal processing machinery parts, large fixed members, feeding devices, etc., can solve the problems of poor positioning accuracy, low work efficiency, and high labor intensity of operators, and achieve convenient operation and high production efficiency. High efficiency and the effect of improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

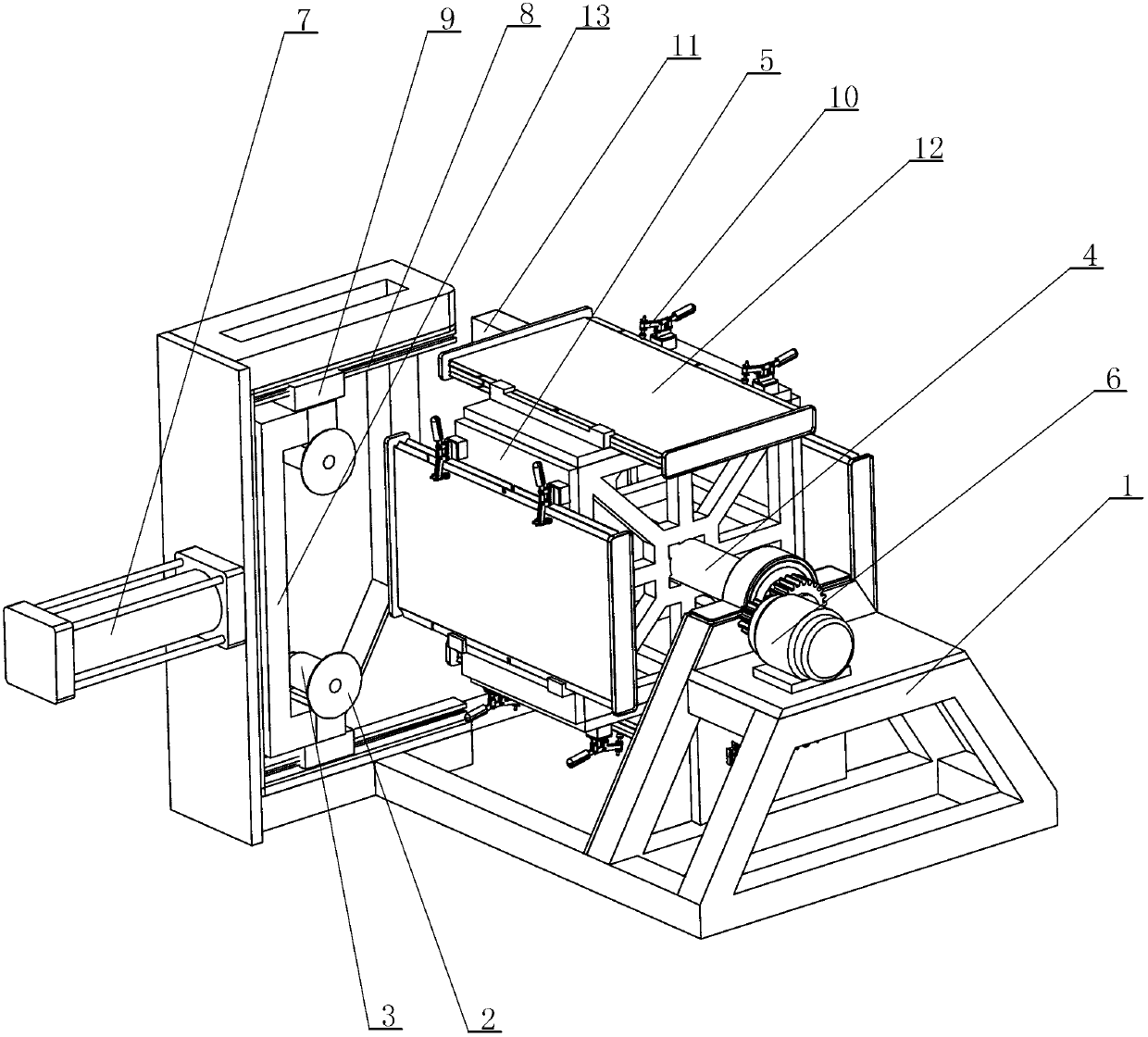

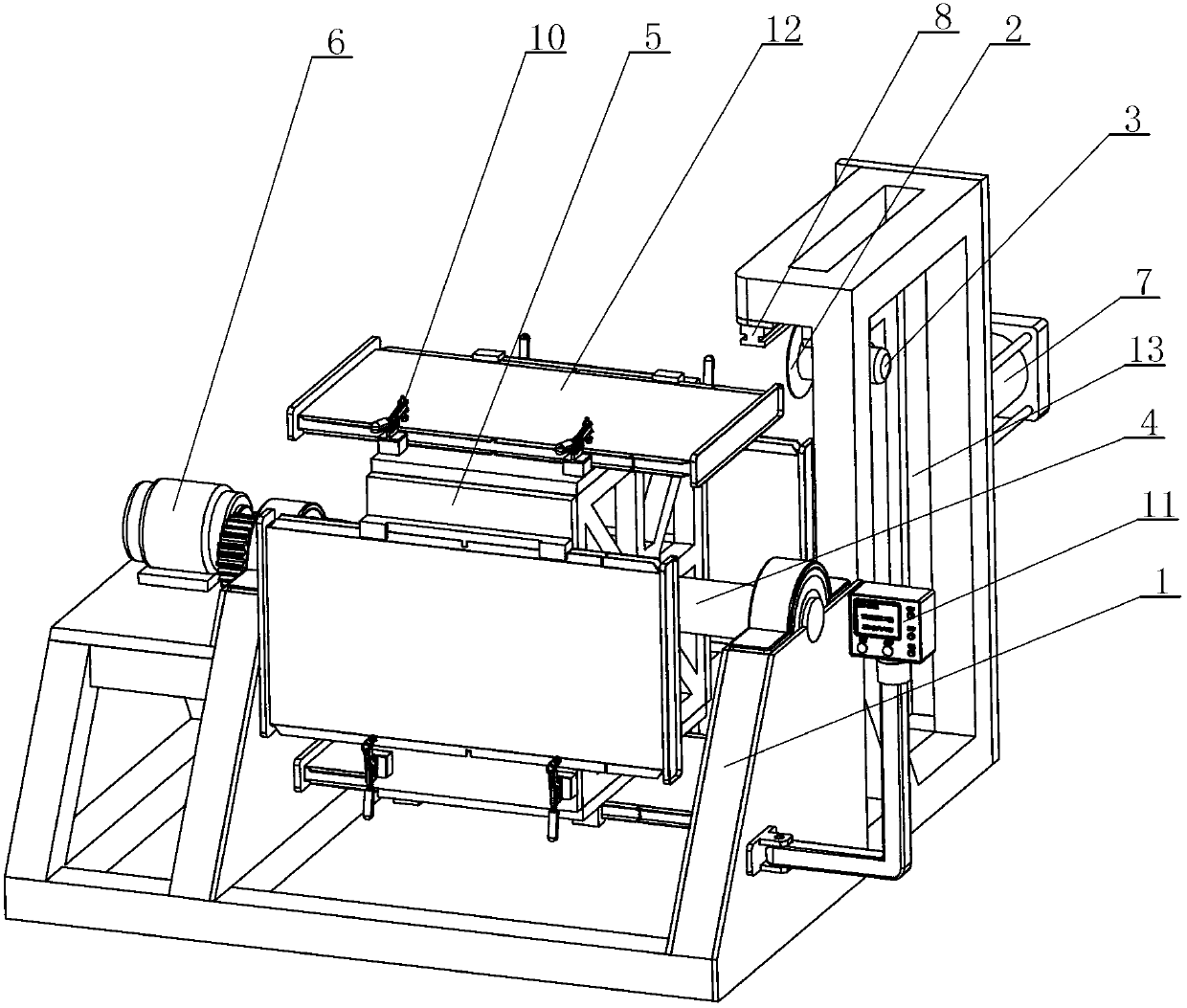

[0014] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0015] Such as figure 1 combine figure 2 As shown, a brazing water radiator notching machine includes a frame 1, a cutter 2 and a cutter motor 3, the cutter 2 is fixed on the output shaft of the cutter motor 3 and is driven to rotate by the cutter motor 3, the machine A rotary shaft 4 is installed on the frame 1, and a rotary positioning table 5 capable of clamping the brazing water radiator 12 is fixed on the rotary shaft 4. The rotary shaft 4 is driven by a servo motor 6 to rotate at an equal angle, and the side of the rotary positioning table 5 Be provided with the feed knife rest 13 of linear reciprocating motion, cutter motor 3 is fixed on the feed knife rest 13, feed knife rest 13 links to each other with linear drive device 7, cutter 2 and cutter motor 3 are two and They are respectively fixed on the upper and lower ends of the feed tool holder 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com