Automatic riveting and welding equipment for connection wires

A technology of welding equipment and connecting wires, which is applied in the fields of welding and riveting, can solve problems such as poor product quality consistency, high production costs of enterprises, and high labor intensity of workers, so as to achieve high production efficiency, reduce production costs of enterprises, and reduce labor intensity of workers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

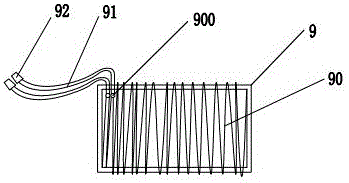

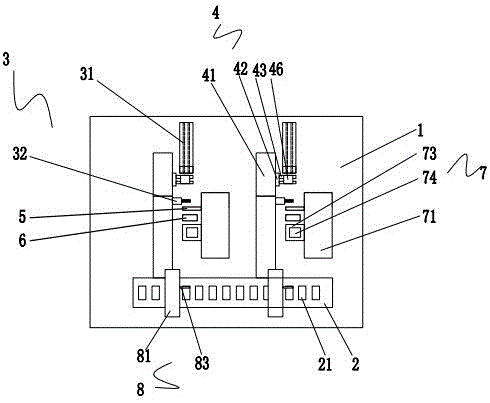

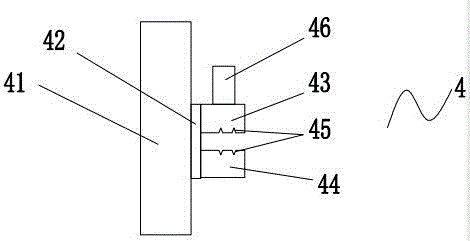

[0023] as attached Figure 2-5 As shown, a connecting wire automatic riveting, welding equipment, including a frame and a workbench 1 located on the frame, a circulating conveyor belt 2 is provided on the front side of the workbench 1, and a jig 21 is installed on the conveyor belt 2 , a coil support to be welded with one end of the connecting wire is placed on the jig-21, and a welding mechanism 8 is arranged above the jig-21; A stripping mechanism 4, a coating bag 5 containing flux, a tin furnace 6 and a riveting mechanism 7 are sequentially arranged between the welding mechanism 8, and after the connecting wire is cut, stripped and cut by the stripping mechanism 4, Clamped by the connecting wire feeding mechanism 3, the exposed part of the front end of the connecting wire passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com