Patents

Literature

105results about How to "Improve product quality consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

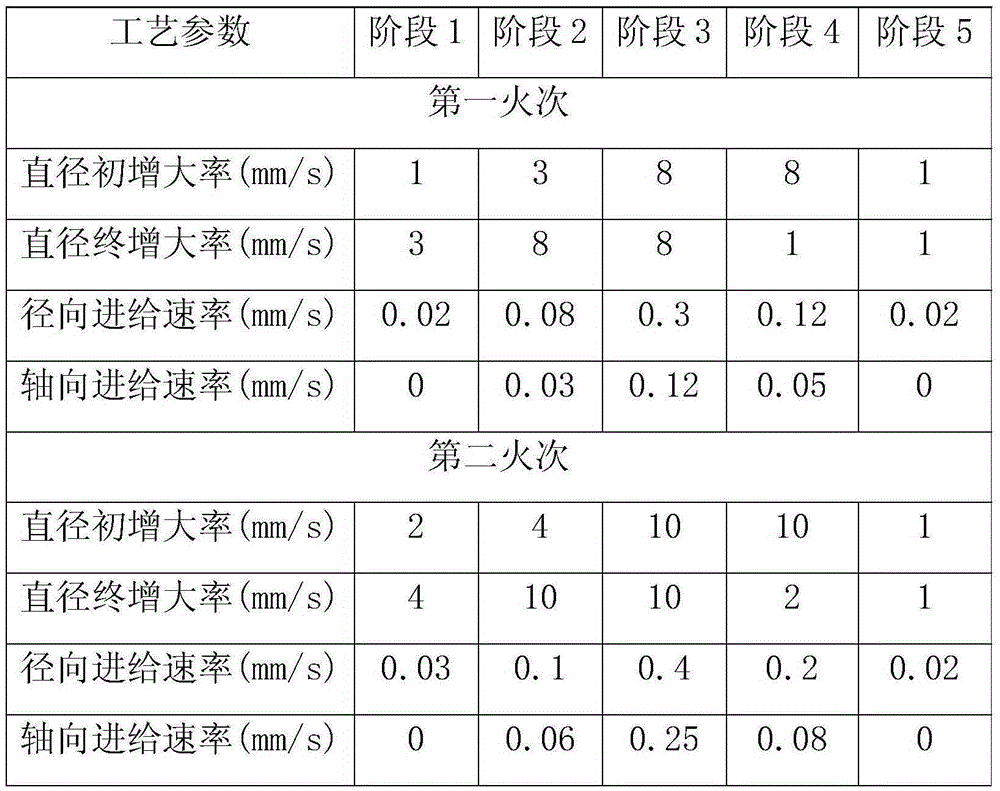

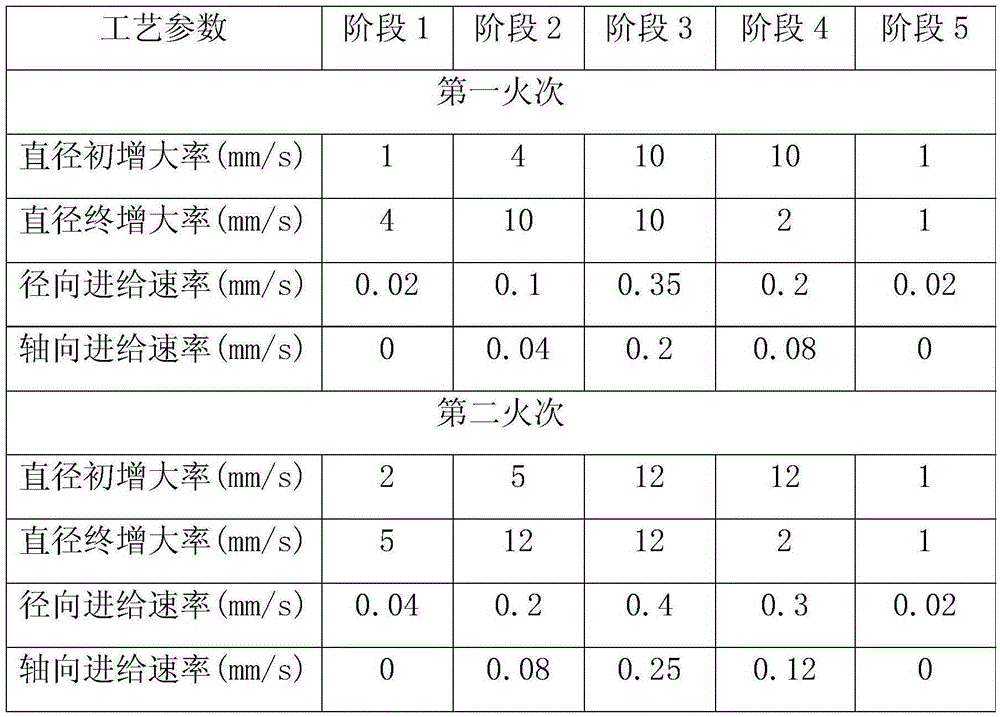

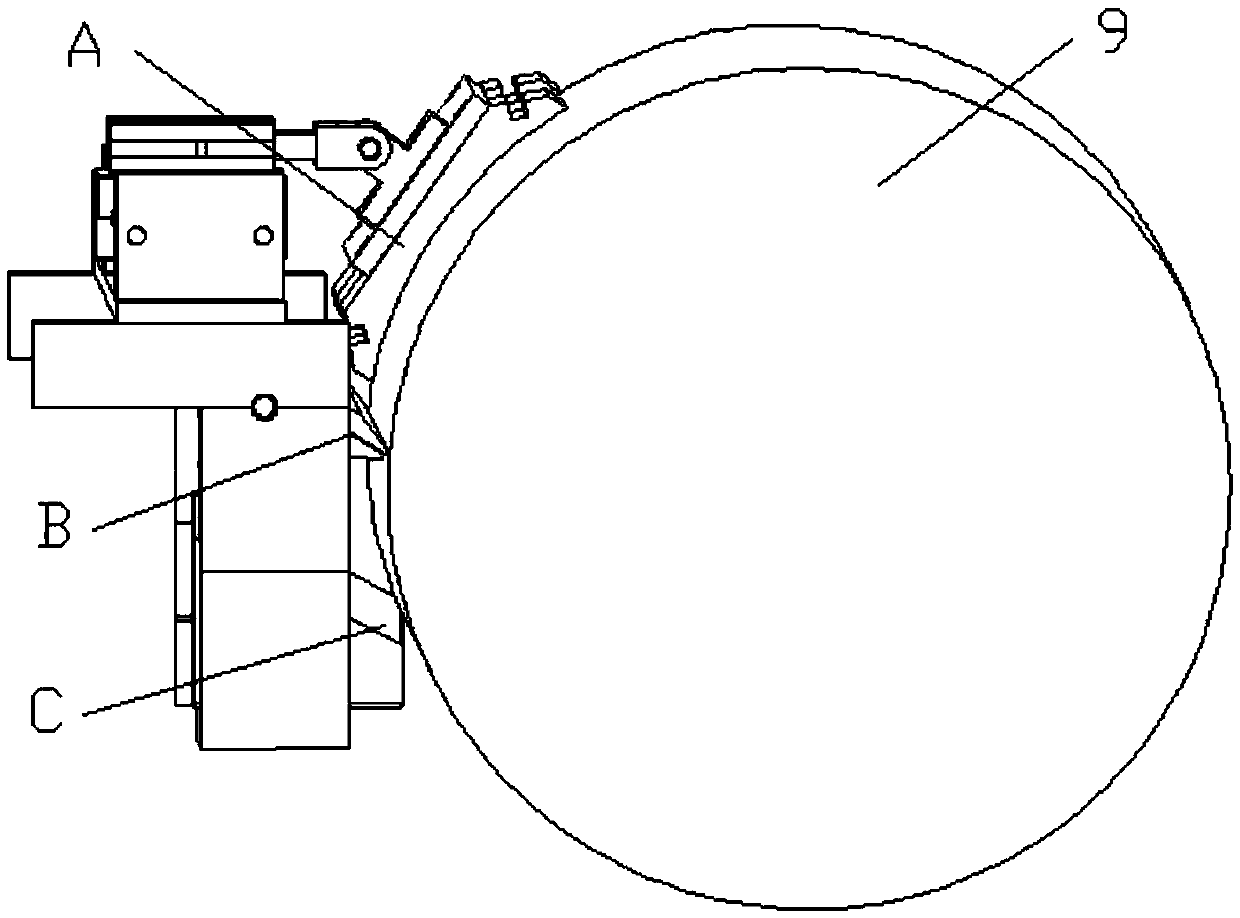

Rolling production method for integral aluminum alloy ring of super-large diameter

The invention belongs to the technical field of ring rolling forming and particularly relates to a rolling production method for an integral aluminum alloy ring of the super-large diameter. According to the technical scheme of the invention, a ring rolling forming technology is adopted, and through control over the rolling deformation temperature, the diameter increasement rate, the radial and axial feed rates, the radial and axial rolling reductions, the rolling ratio, the core roller diameter and the ring rolling heating number of an aluminum alloy ring piece of the super-large specification, the stable and continuous rolling process of the integral aluminum alloy ring of the super-large diameter is achieved, the size precision, the ovality and the radial and axial deformation quantities of the ring piece are effectively controlled, the product quality consistency is improved, the product percent of pass is increased, and technical index requirements of products are met.

Owner:CAPITAL AEROSPACE MACHINERY +1

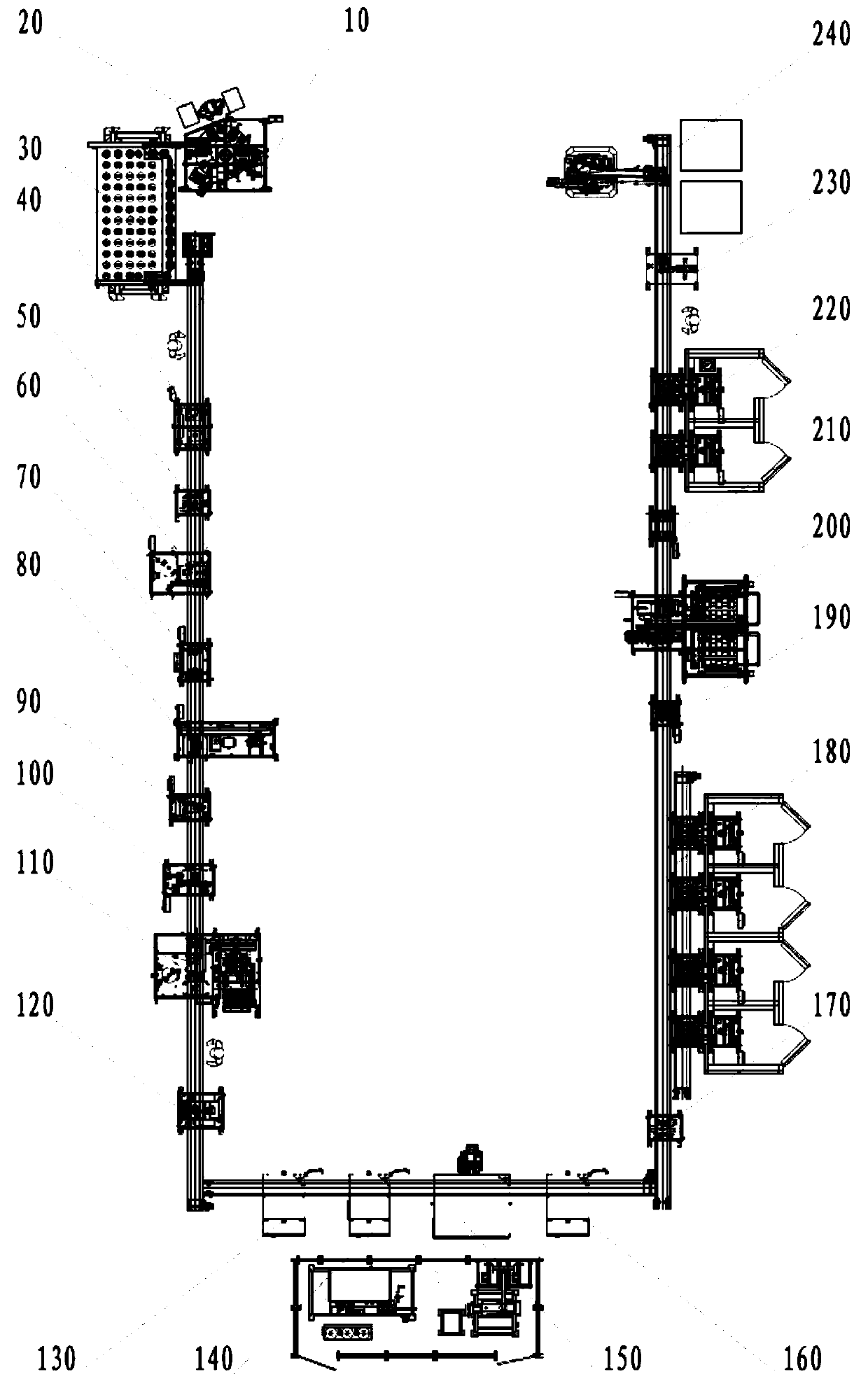

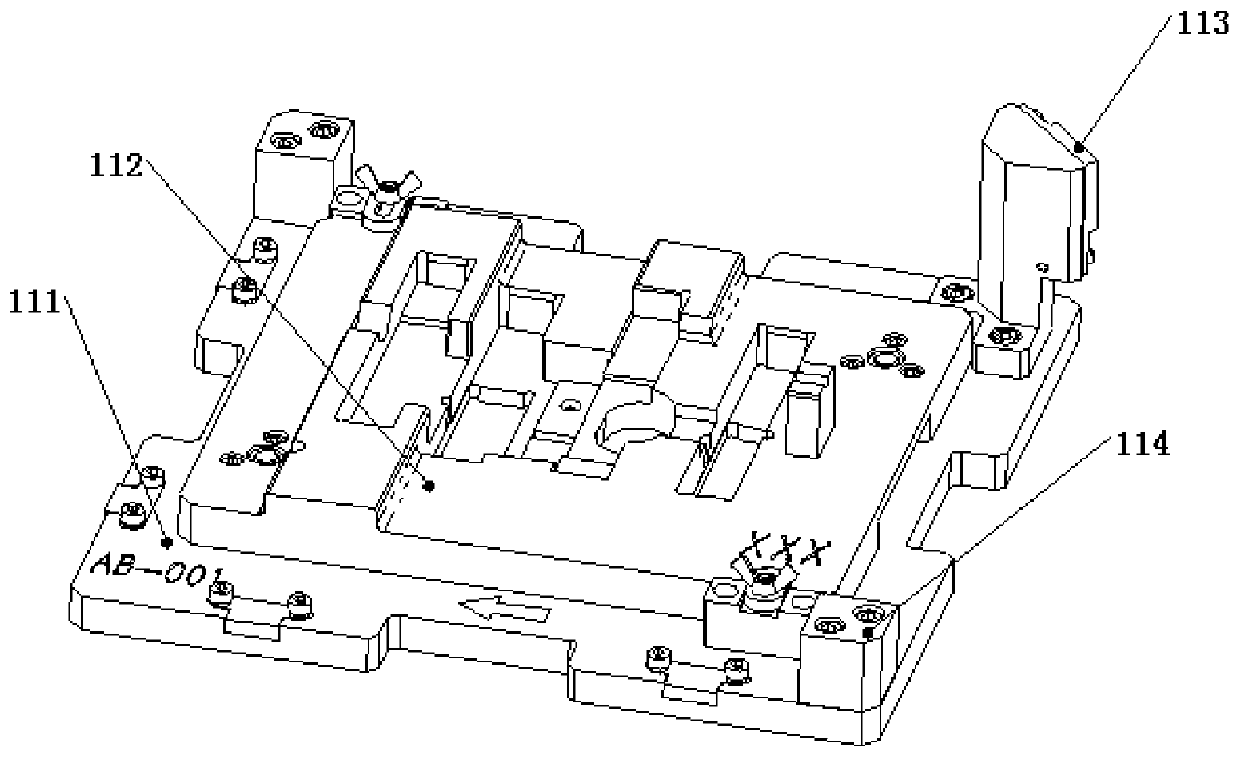

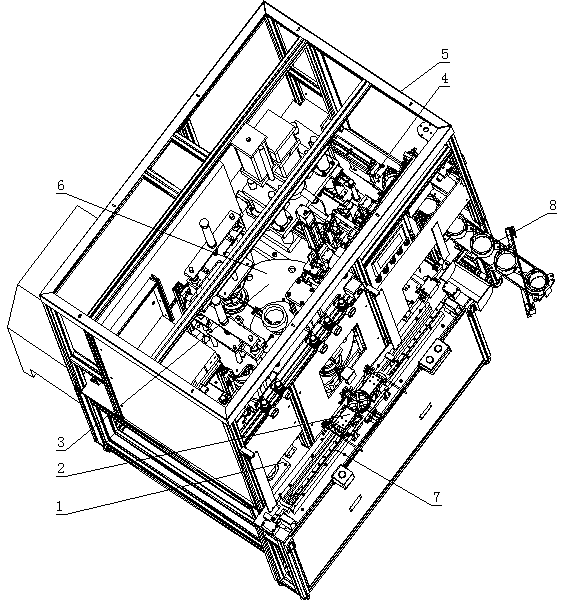

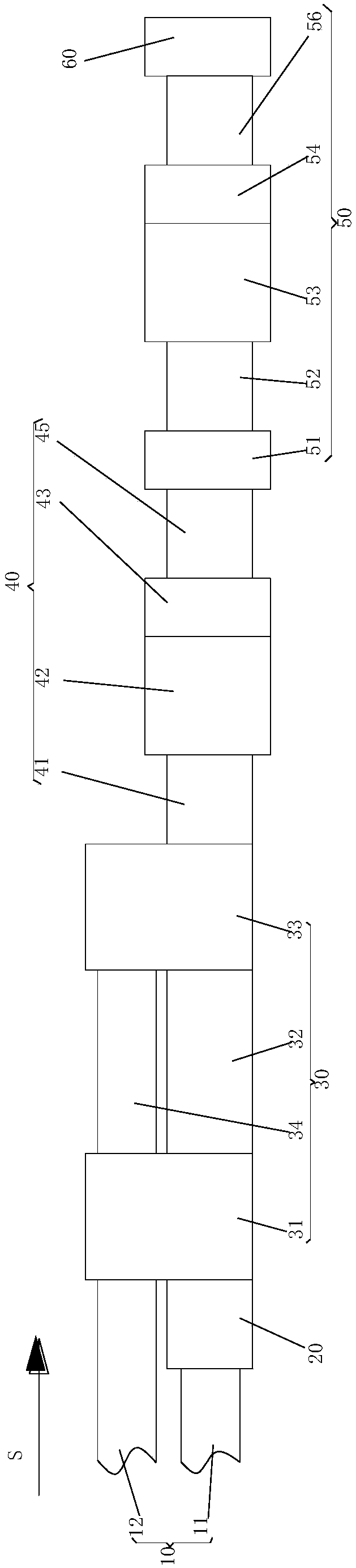

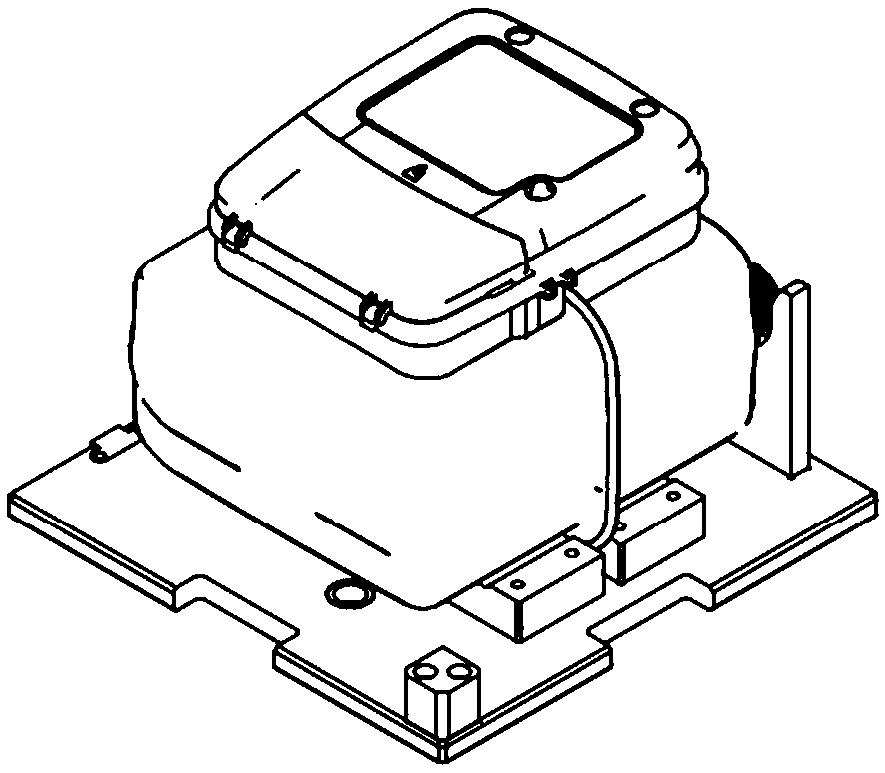

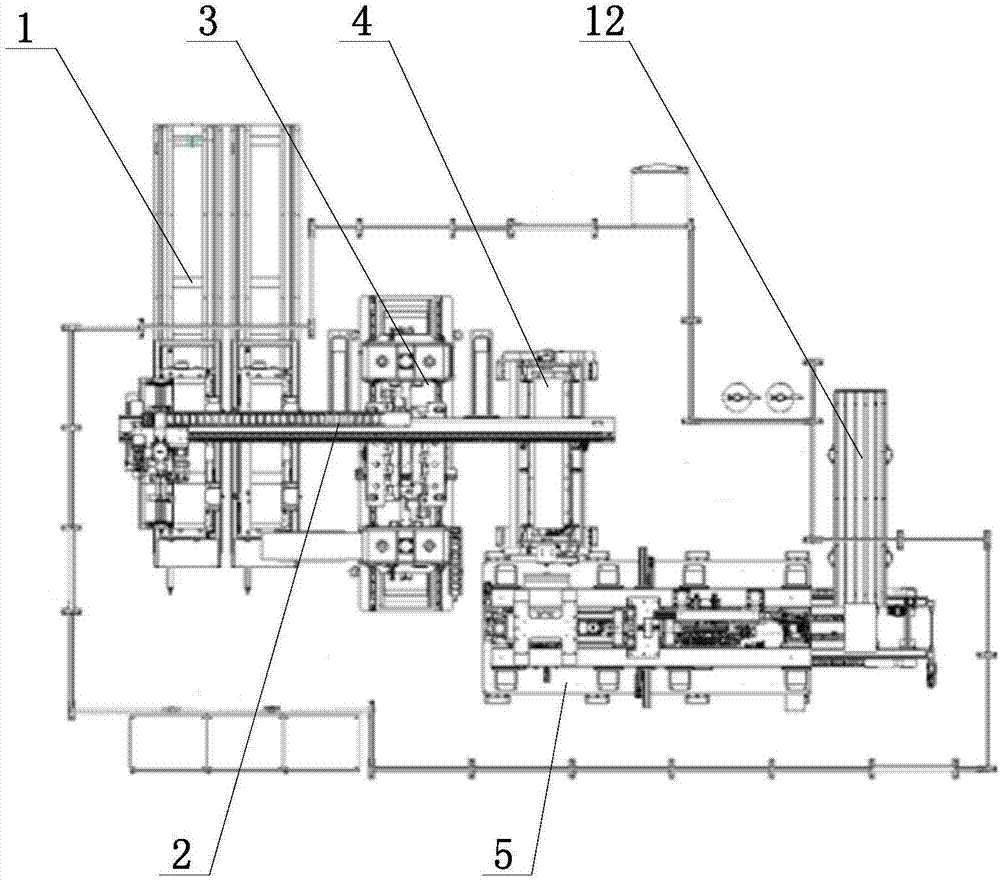

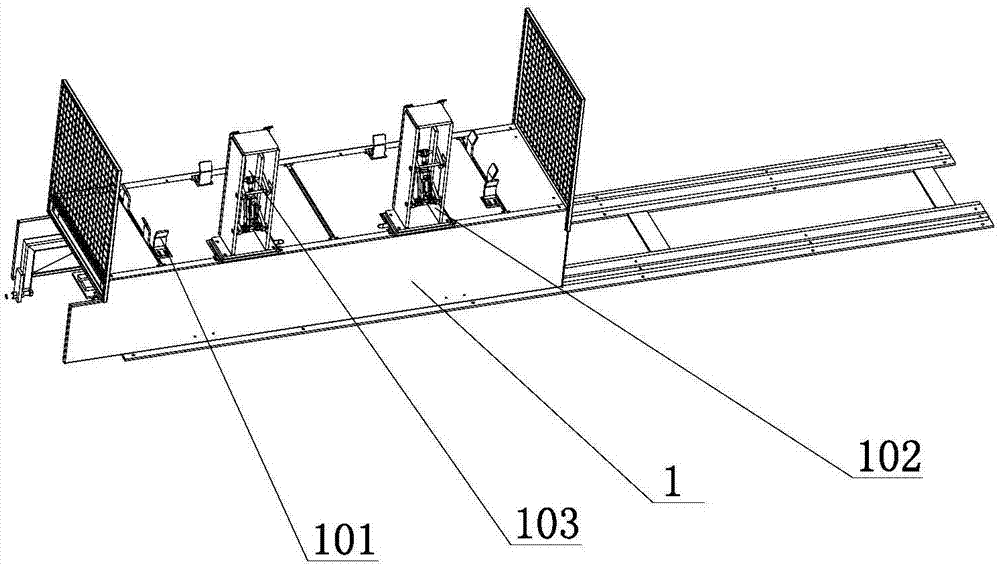

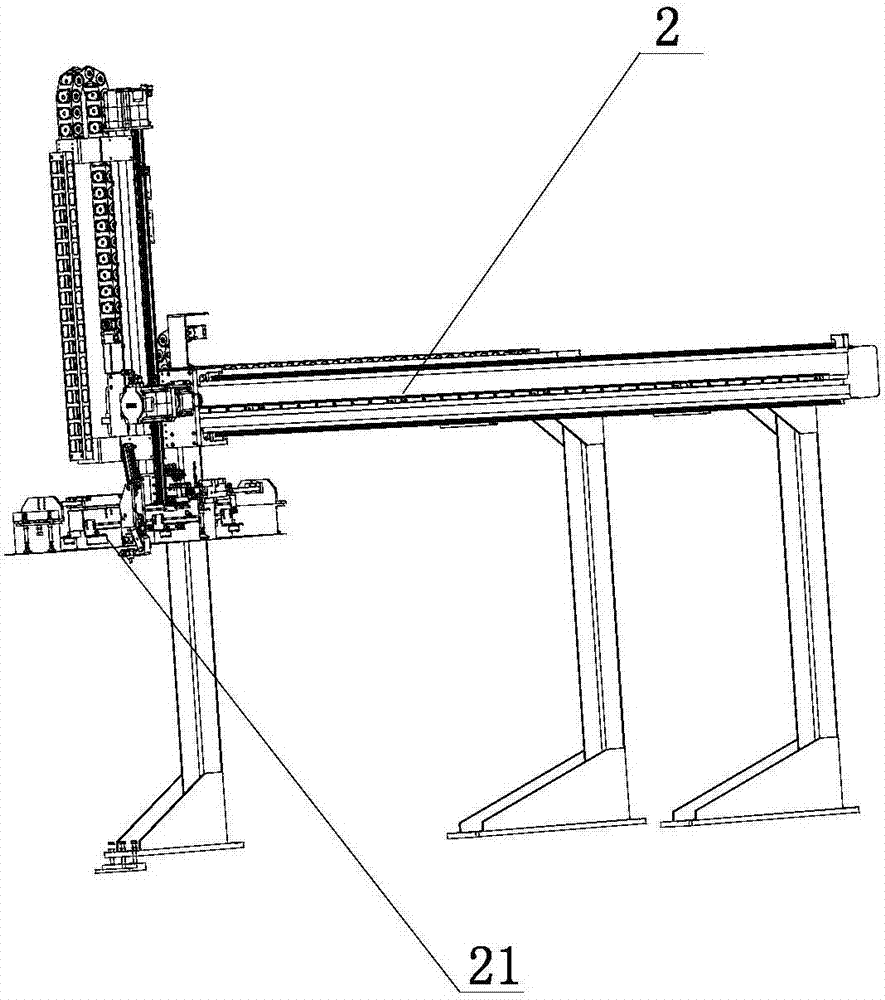

Automatic assembly production line for automobile air conditioner compressors

ActiveCN110587300AReduced manual productivityImplement automatic assemblyAssembly machinesMetal working apparatusProduction lineAutomobile air conditioning

The invention discloses an automatic assembly production line for automobile air conditioner compressors, and belongs to the technical field of automobile air conditioner compressors. The automatic assembly production line comprises a line body and a shell heating press-fitting and coding device, a shell cooling and transferring device, a wiring pole detection device, a shell component overturningdevice I, a lower bearing press-fitting device, a shell component positon detection device, a machine core magnetizing and shell enclosing device, a machine core resistance torque detection device, an abrasion resistant sheet assembly detection device, an eccentric block upper bearing automatic accommodating device, an end cover thread screwing device, nitrogen filling large leakage detection device, vacuuming helium filling device, a helium detection device, a helium recycling device, a shell component overturning device II, a workpiece operation detection device, an automatic heat conduction coating device, a controller assembly device, a controller air-tightness detection device, a comprehensive performance detection device, a vacuuming oil injection nitrogen filling device and a robotoff-line stacking device. By adopting the automatic assembly production line, automatic assembly and detection of the automobile air conditioner compressors are realized; and production efficiency isimproved.

Owner:CSIC PRIDENANJINGINTELLIGENT EQUIP SYST CO LTD

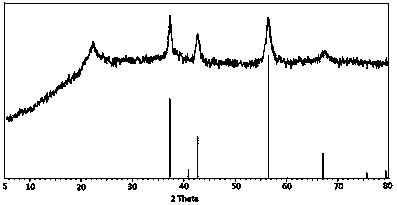

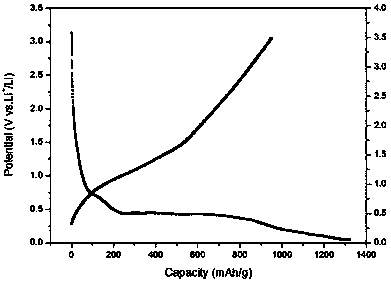

Preparation method of hydro-thermal coupling spray pyrolysis MnO2/graphene electrode material

InactiveCN103915613AStable structureWide variety of sourcesMaterial nanotechnologyHybrid capacitor electrodesActive agentGraphene electrode

The invention discloses a preparation method of a hydro-thermal coupling spray pyrolysis MnO2 / graphene electrode material, belonging to the technical field of electrode materials for energy storage systems. The preparation method comprises the following steps: uniformly mixing graphene oxide (GO) prepared by using a Hummer method with an aqueous solution of bivalent manganese salt and a doped metal ion compound, adding a dispersing agent, an oxidant and a surfactant, and ultrasonically dispersing for a certain period of time; putting the mixed solution into a hydrothermal kettle, adjusting the temperature, and keeping for a certain period of time; filtering and washing a reaction product to obtain a precursor; adding the dispersing agent and the surfactant into the precursor, uniformly stirring for mixing, and adjusting the solid-liquid ratio, inlet temperature and outlet temperature to perform spray pyrolysis in order to obtain a metal ion-doped MnO2 / graphene nanometer composite electrode material. According to the nanometer composite electrode material prepared by using the method, components are uniform and the batch stability is high.

Owner:SHANDONG RUNSHENG POWER TECH +1

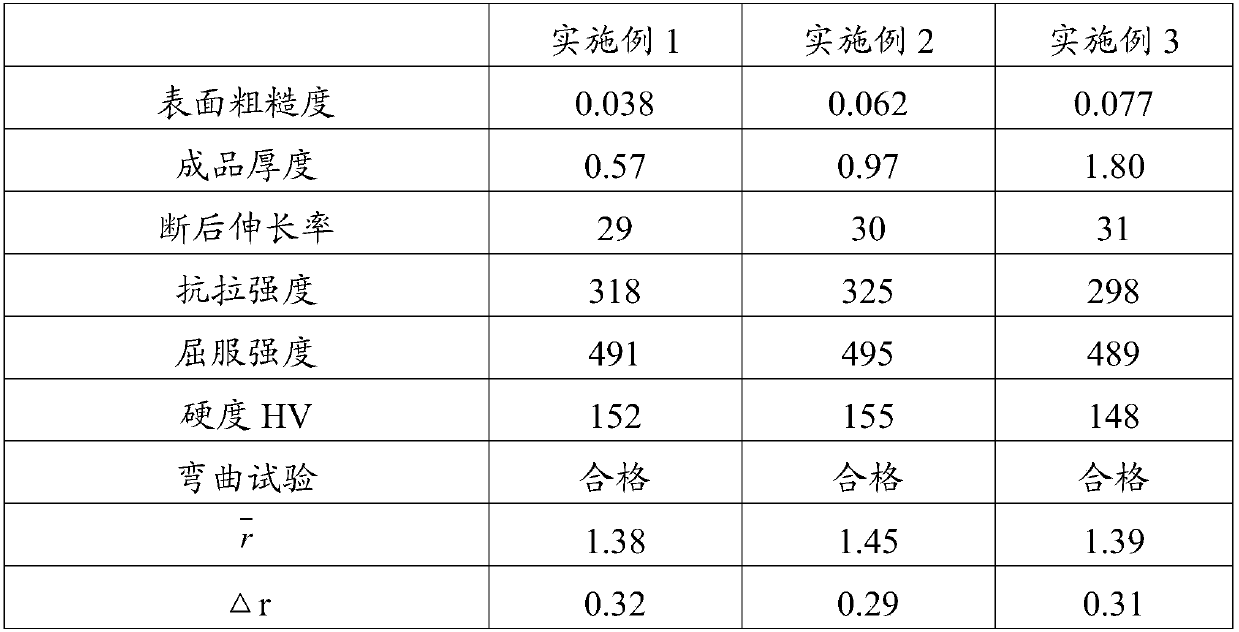

Production method of medium-chromium ferrite stainless steel cold-rolled strip steel

InactiveCN108856289AImprove processing stabilityImprove product quality consistencyFurnace typesRollsStrip steelContinuous annealing

The invention provides a production method of medium-chromium ferrite stainless steel cold-rolled strip steel. The method comprises the flowing steps of a rolling step, a continuous annealing step, acontinuous pickling step and an on-line leveling step, wherein the rolling step adopts a six-roller five-rack continuous rolling mill for rolling, wherein a total rolling deformation rate is 60%-85%;the six-roller five-rack continuous rolling mill comprises racks range from a first rack to a fifth rack, wherein the deformation rates from the first rack to the fifth rack are 25%-35%, 23%-33%, 20%-30%, 17%-27%, 15%-25% in sequence. The surface color uniformity and glossiness of the medium-chromium ferrite stainless steel cold-rolled strip steel produced by adopting the method are good, a yieldplatform is completely eliminated, the product quality consistency is high, and the yield is high.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

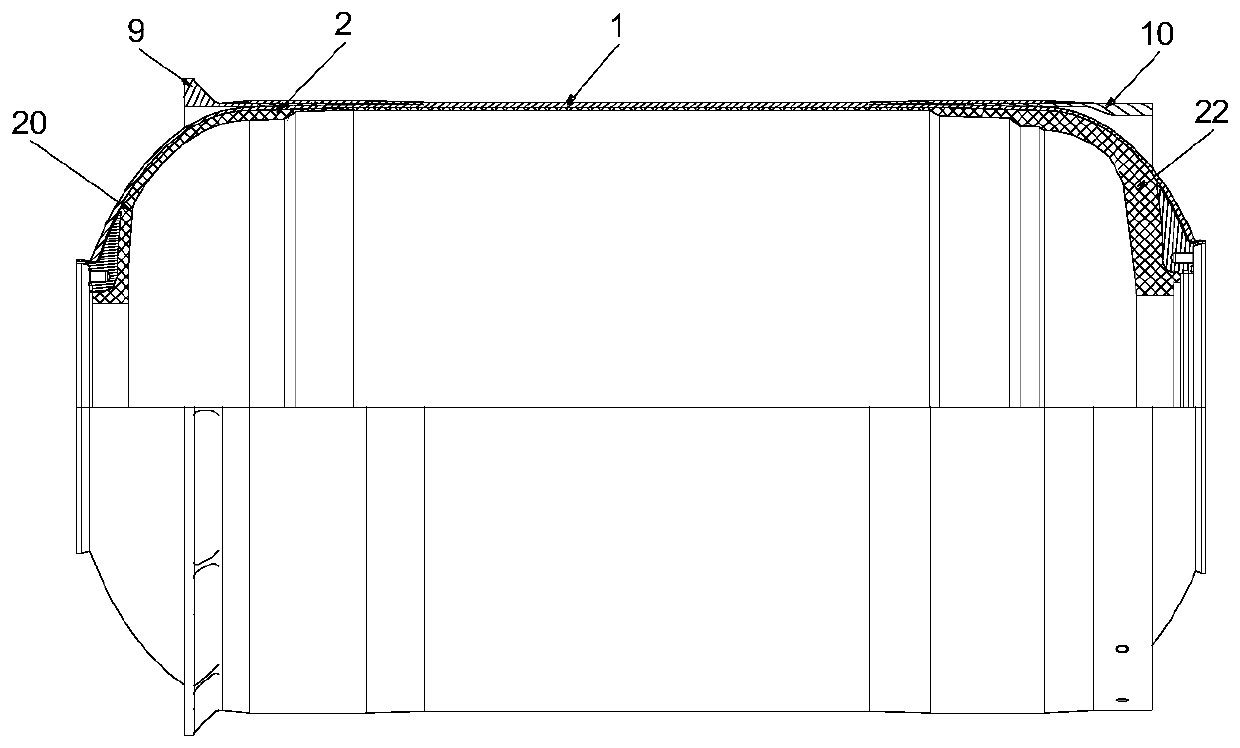

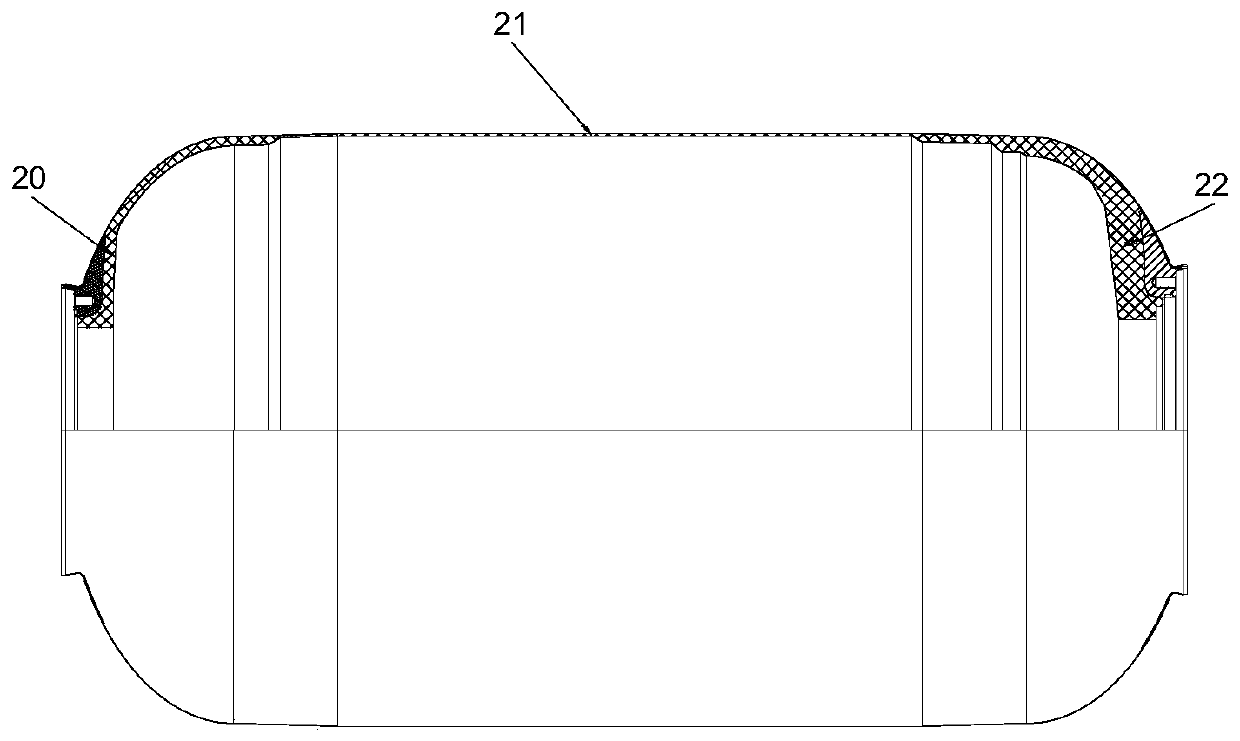

Charge combustion chamber shell and forming method thereof

ActiveCN109989852AThe preparation process is simple and reliableImprove adhesionRocket engine plantsFiberInsulation layer

The invention discloses a forming method of a charge combustion chamber shell. The charge combustion chamber shell comprises an outer shell and a heat insulation layer, the heat insulation layer is arranged on the inner surface of the outer shell, and the heat insulation layer comprises a front seal head heat insulation structure, a column section heat insulation structure and a rear seal head heat insulation structure which are sequentially distributed and connected in the length direction of the outer shell. The forming method of the charge combustion chamber shell characteristically involves the following steps of providing a winding core model, a seal head mold and heat insulation slurry; spraying the heat insulation slurry in the seal head mold, and preparing the front seal head heatinsulation structure and the rear seal head heat insulation structure by adopting a press moulding manner; assembling the front seal head heat insulation structure and the rear seal head heat insulation structure on the winding core model; spraying the heat insulation slurry on the outer surface of the winding core model to form the column section heat insulation structure; winding fibers on the outer surface of the heat insulation layer to form the outer shell; and curing to form the charge combustion chamber shell.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

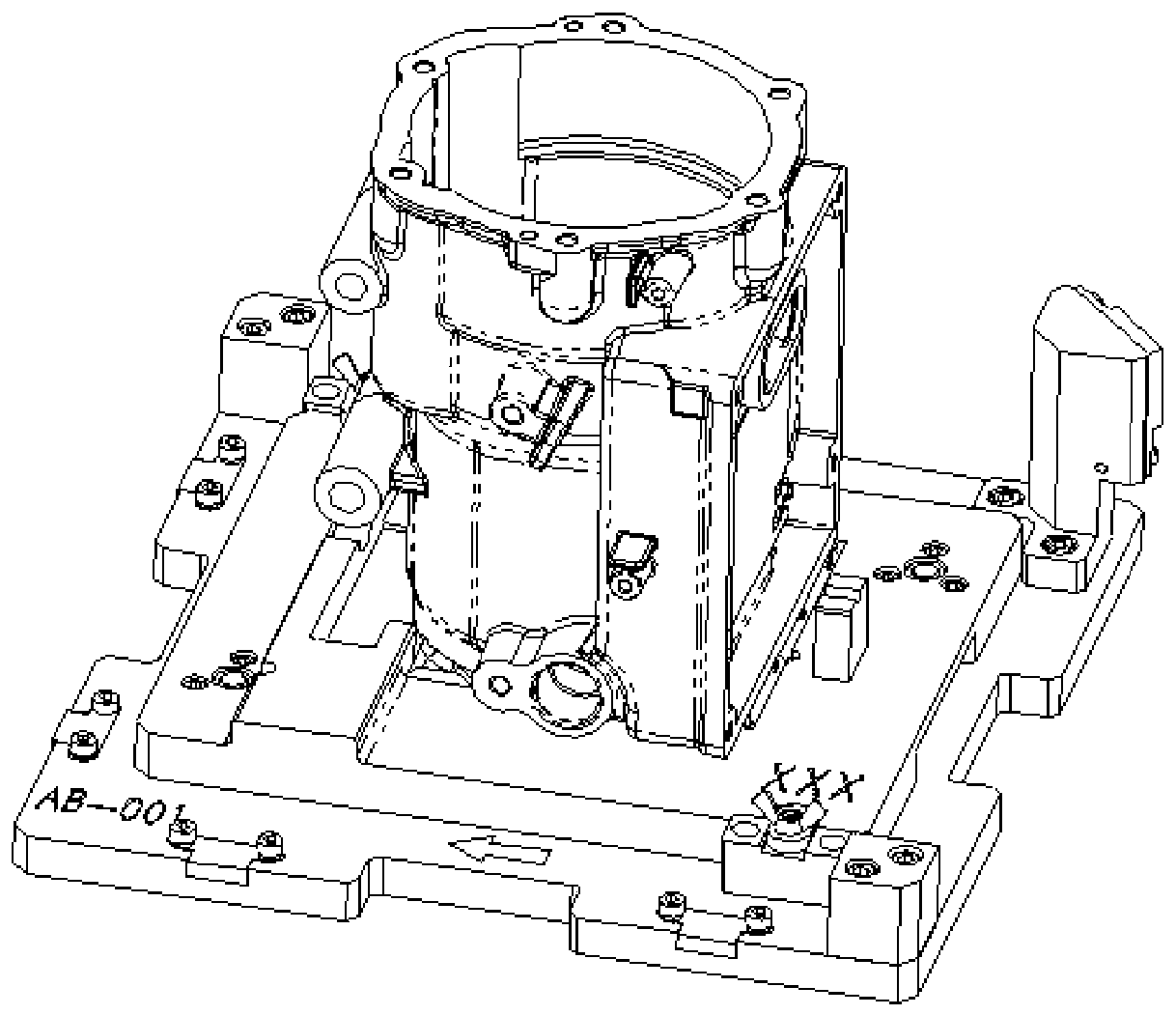

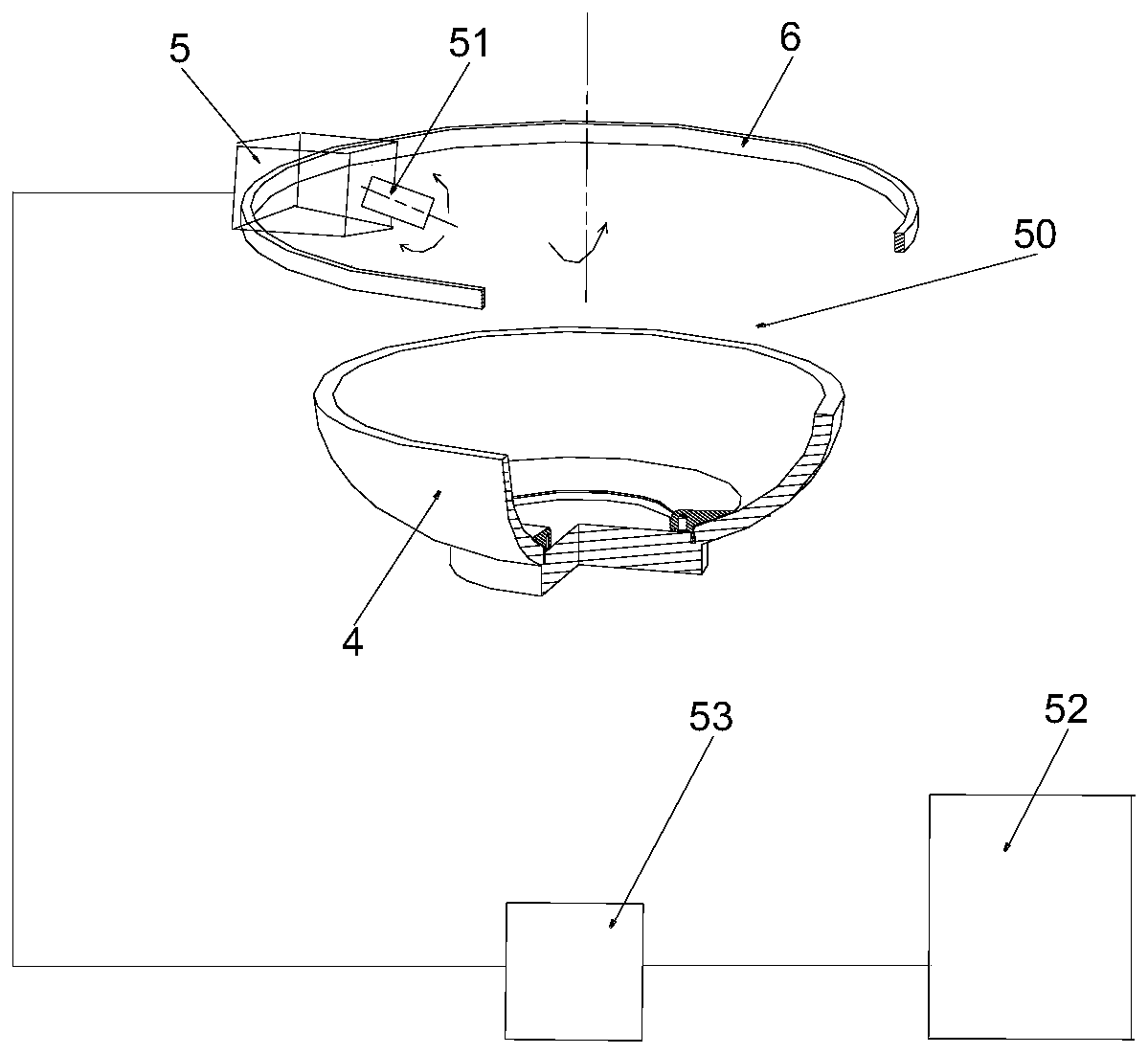

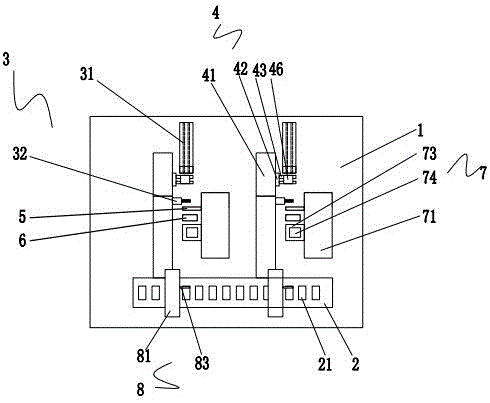

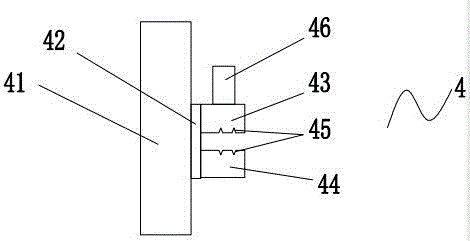

DC permanent magnet motor stator assembling machine

InactiveCN109802532AImprove assembly qualityImprove reliabilityManufacturing stator/rotor bodiesAssembly lineElectrical and Electronics engineering

The invention discloses a DC permanent magnet motor stator assembling machine, and the assembling machine comprises a rack and further comprises a gluing device for gluing a shell; a first assemblingdevice for realizing the installation of a magnetic shoe on a magnetic shoe rack; a second assembling device for assembling a magnetic shoe rack and the shell; a magnetizing device; a detection devicefor detecting the residual magnetism intensity of the magnetic shoe; a riveting device; an output device; and a conveying device, wherein the gluing device, the first assembling device, the second assembling device, the magnetizing device, the detection device, the riveting device, the output device and the conveying device are arranged on the rack. The assembling machine can realize assembly line assembly of the DC permanent magnet motor stator.

Owner:四川圣锦高新科技股份有限公司

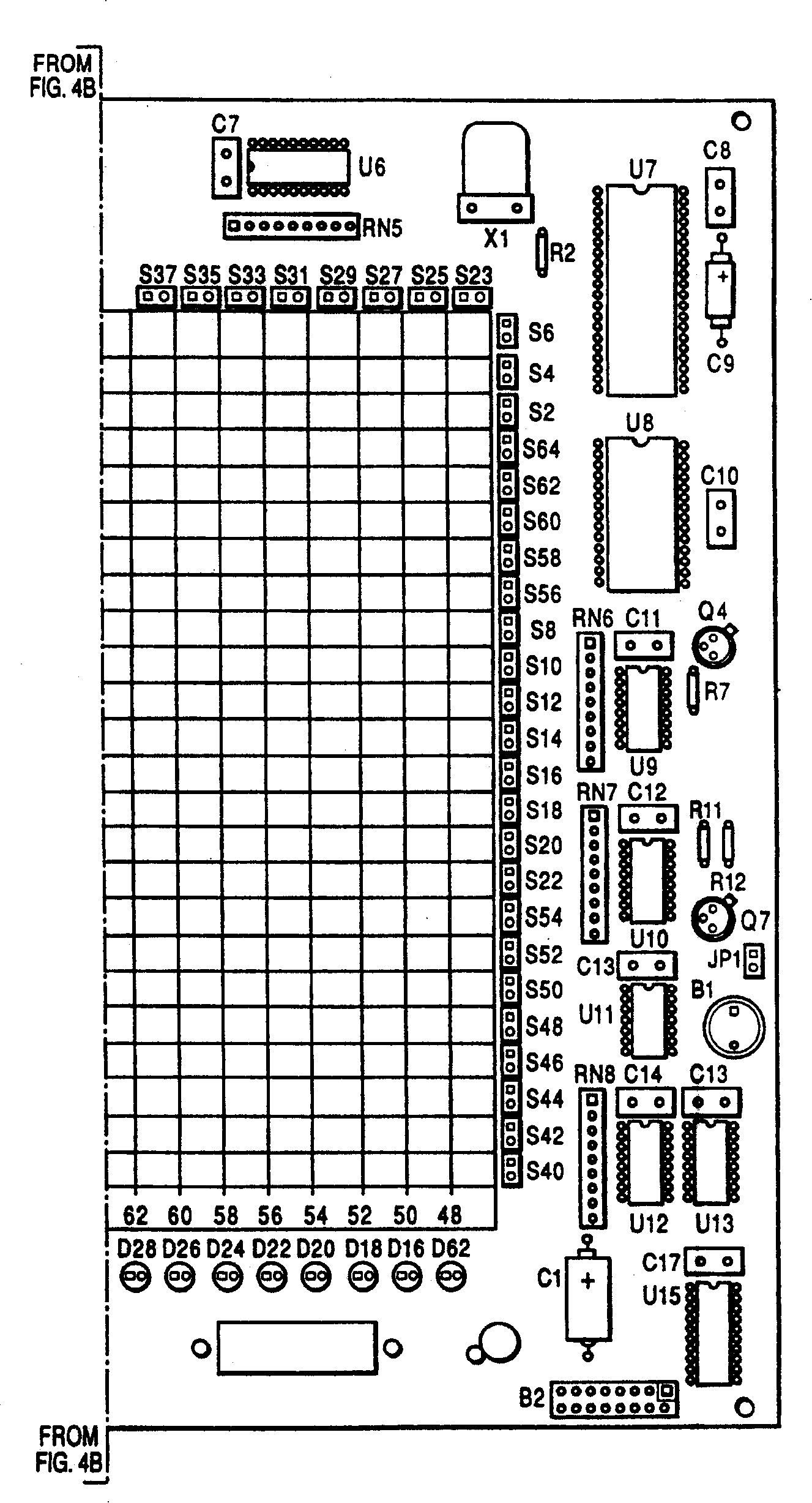

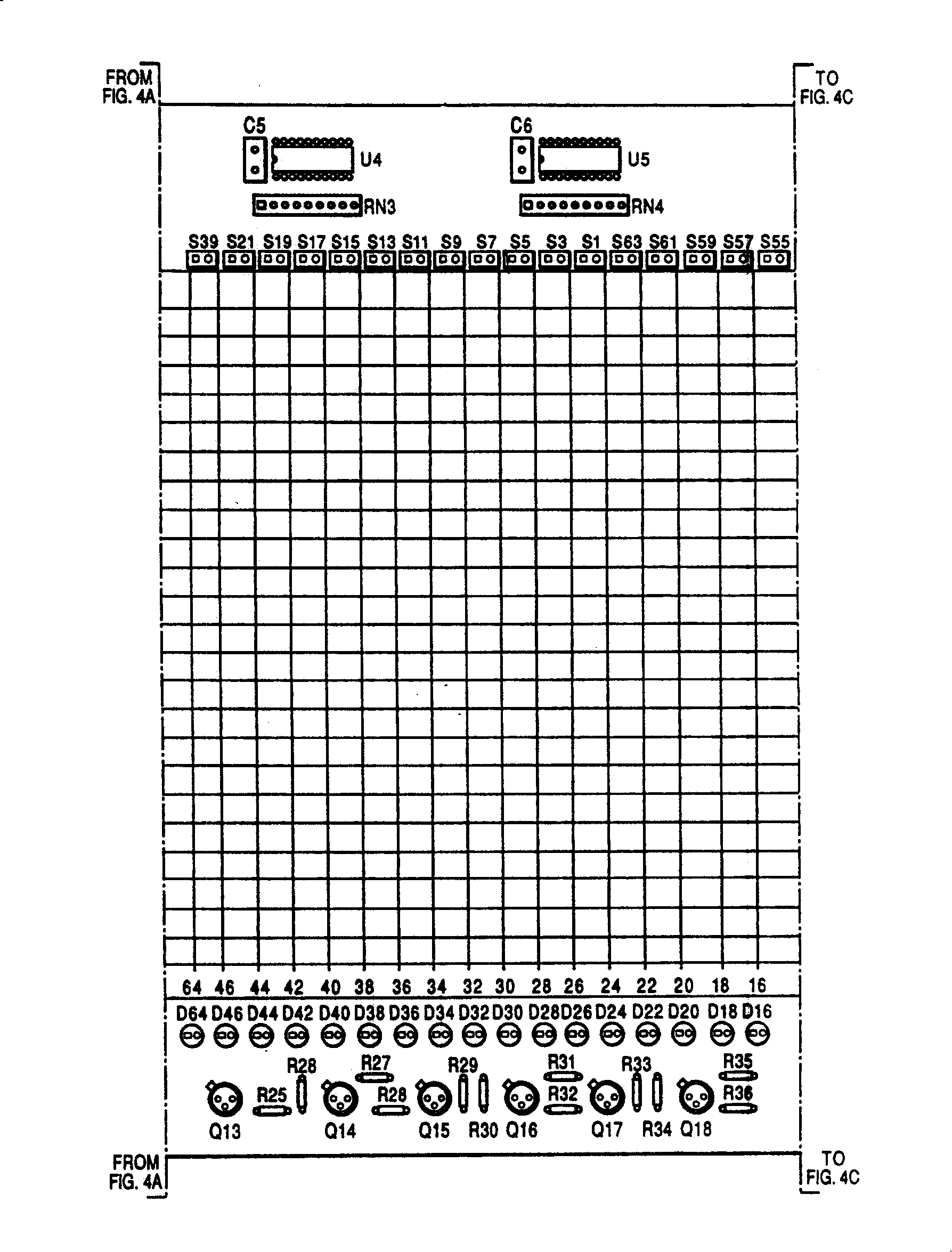

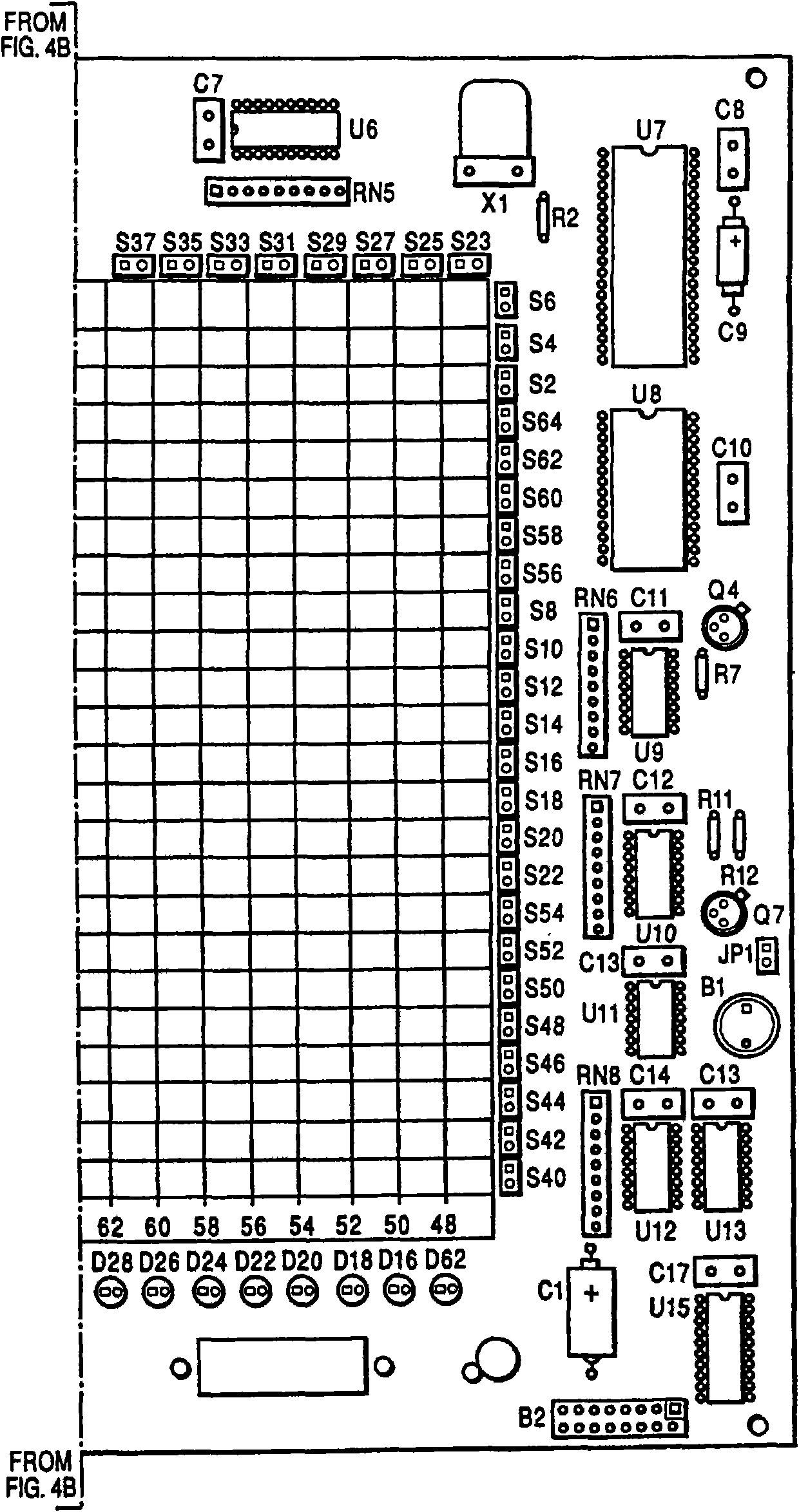

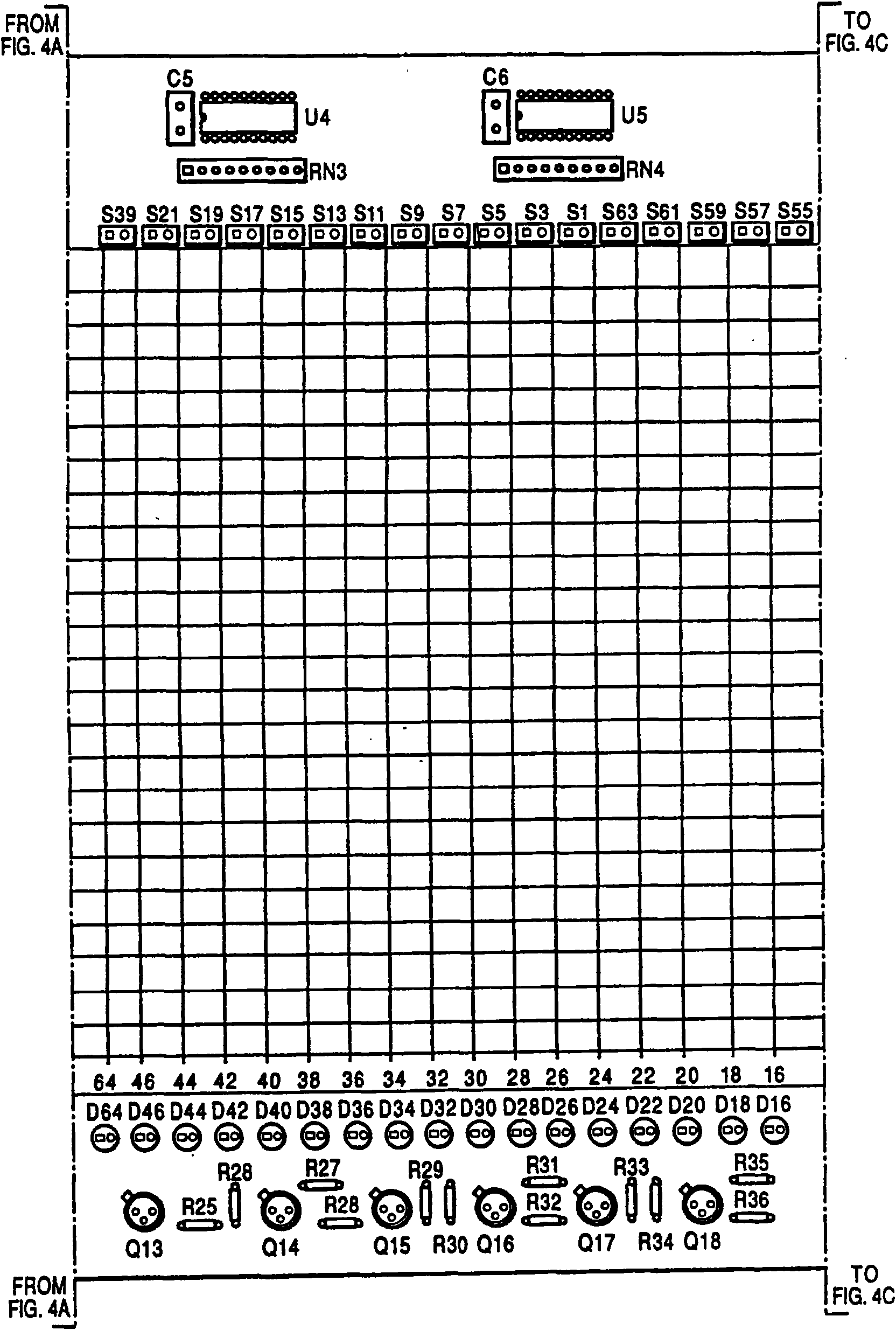

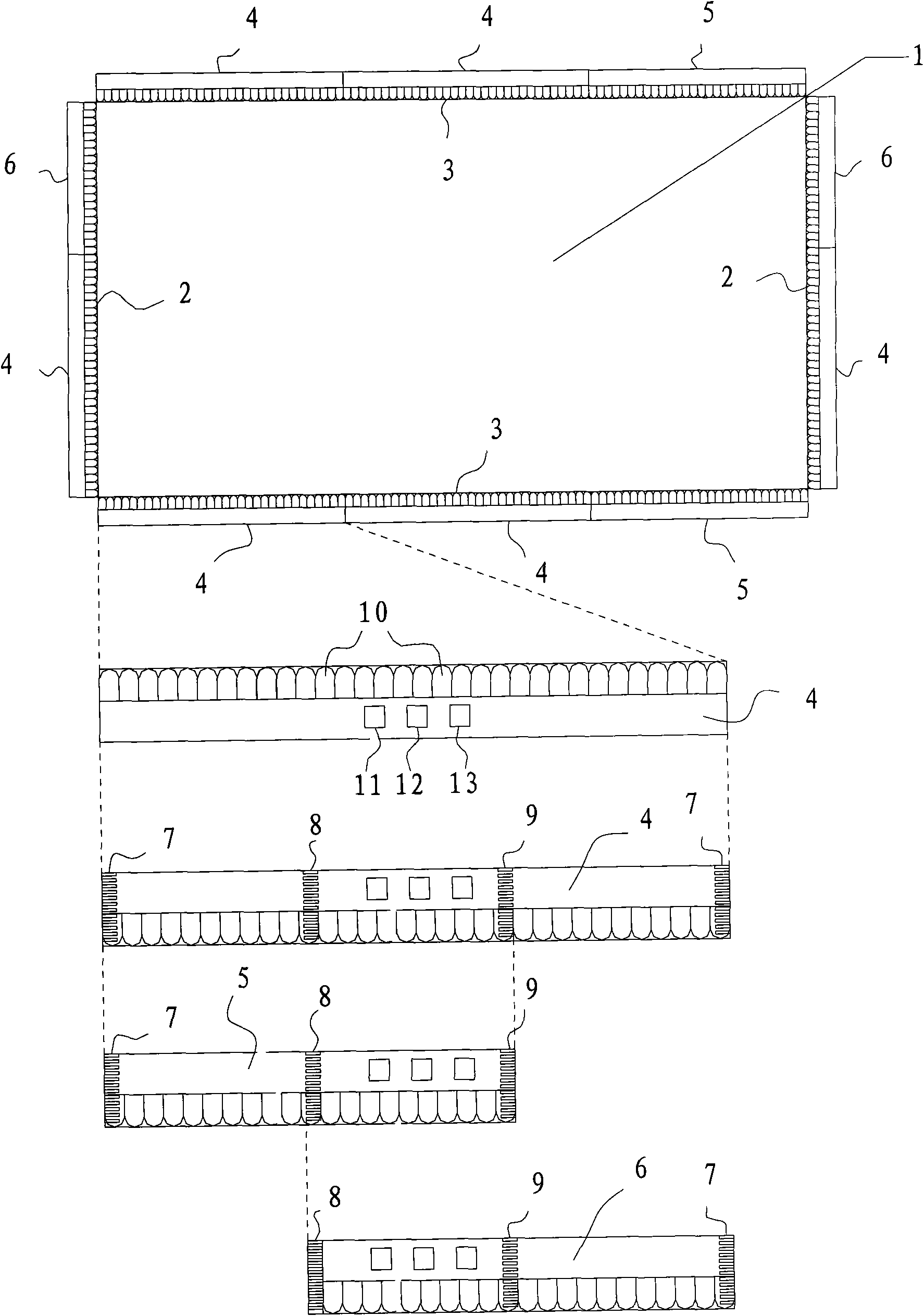

Infra-red ray emission and receiving circuit board unit and infra-red ray touch screen using same

InactiveCN101236474ASimple designImprove performanceElectromagnetic transmissionInput/output processes for data processingInfraredGround line

The invention discloses an infrared transmitting or receiving circuit board unit which can be cut and spliced at any position. The circuit board is provided with a power line, a grounding line, a clock signal line or a transport protocol line, an infrared pulse signal line and an infrared receiving signal line, which run through the circuit board unit. An encoder which is provided with a control input port, and a row driver and a column driver which are controlled and gated by the encoder are arranged at one end of the circuit board unit. An infrared touch screen of any size can be produced by splicing pieces of the circuit board unit. Through the corresponding ports on a controller unit, various circuit board units can be connected together and are capable of making a synchronous fractional scanning so as to increase scanning speed effectively. The invention is not necessary to aim at infrared touch screens of various sizes for making a second development, which significantly increases production efficiency, product quality stability and consistency, and reduces initial investment cost and quickens upgrade speed without limitation on adding or expanding more product categories.

Owner:贺伟

Automatic riveting and welding equipment for connection wires

ActiveCN106238854ARealize automatic cuttingReduce labor intensityOther manufacturing equipments/toolsMetal working apparatusHigh volume manufacturingEngineering

The invention relates to automatic riveting and welding equipment for connection wires. The automatic riveting and welding equipment comprises a rack and a worktable arranged on the rack, wherein a circular conveyer belt is arranged on the front side of the worktable; fixtures I for placing coils are arranged on the conveyer belt; welding mechanisms are arranged above the fixtures I in a spanning manner; connection wire material conveying mechanisms are arranged on the rear side of the worktable; and a wire stripping mechanism, a coating bag containing welding flux, a tin furnace and a riveting and pressing mechanism are sequentially arranged between each connection wire material conveying mechanism and the corresponding welding mechanism. The automatic riveting and welding equipment is reasonable in structure design; the connection wire material conveying mechanisms, the wire stripping mechanisms, the riveting and pressing mechanisms, the coating bags containing welding flux, the tin furnaces and the welding mechanism are arranged, so that automatic cutting, wire stripping, welding flux coating, tin soaking, riveting and welding of the connection wires are realized; the automation degree is high; the production efficiency is high; the automatic riveting and welding equipment is very suitable for large-scale production; the consistency of product quality is also high; worker labor intensity and enterprise production cost are also greatly lowered; and enterprise market competitiveness is enhanced.

Owner:江西百宏光电科技有限公司

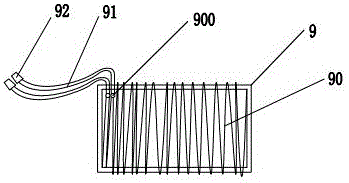

Processing method for medical catheter with built-in steel wire

ActiveCN102896754AEasy to operateImprove product quality consistencyTubular articlesEngineeringHardness

The invention relates to a processing method for medical treatment instruments, in particular to a processing method for an anesthesia catheter with a steel wire built in a catheter wall. The processing method for the medical catheter with the built-in steel wire is simple in operation and high in degree of automation. The anesthesia catheter with the steel wire built in the catheter wall is obtained through processes of raw material preparing, extrusion molding, scale mark printing, end socket drilling and the like. The processing method has the characteristics that the method is simple in operation, and obtained products are moderate in hardness, safe, reliable and the like.

Owner:ZHEJIANG FERT MEDICAL DEVICE

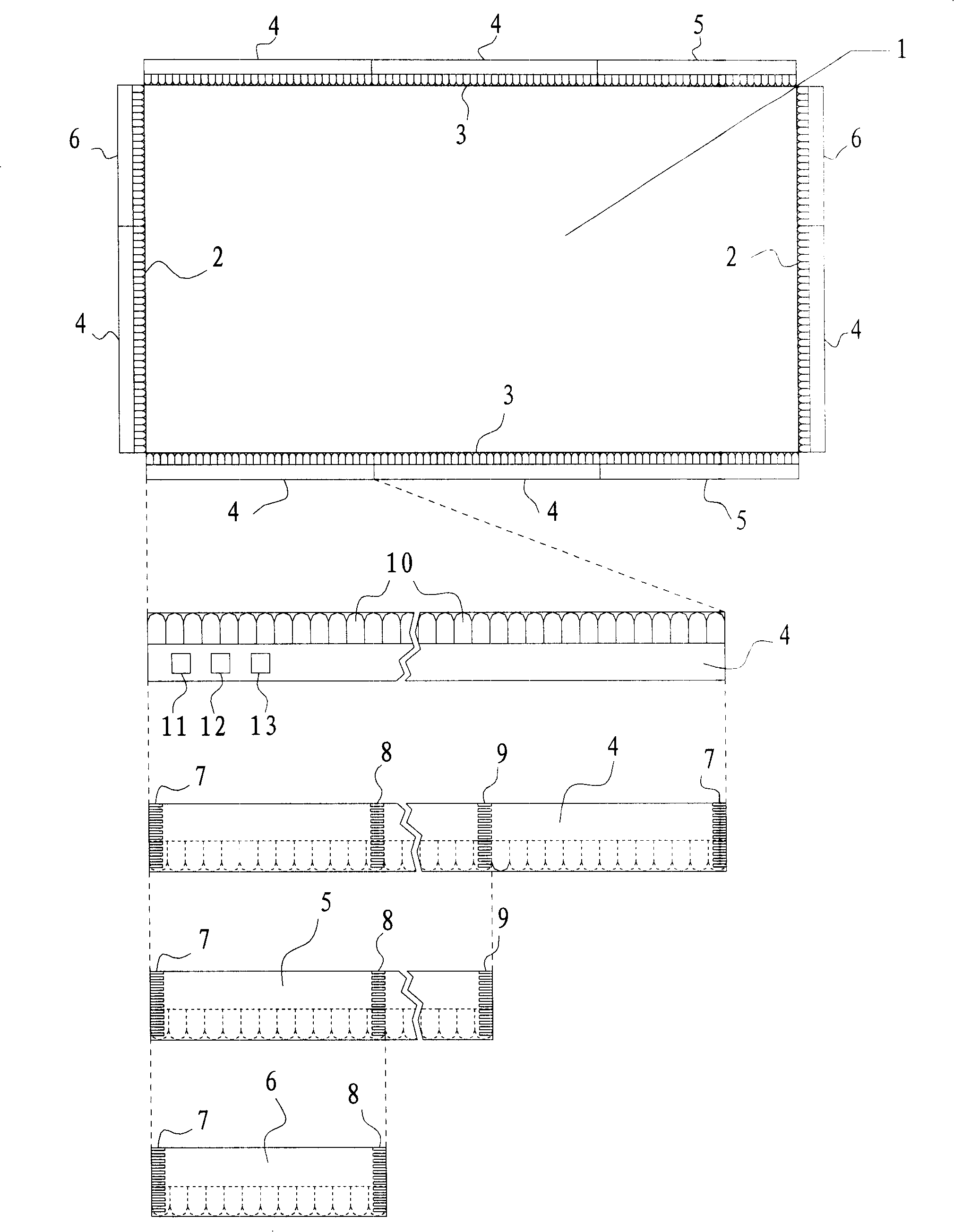

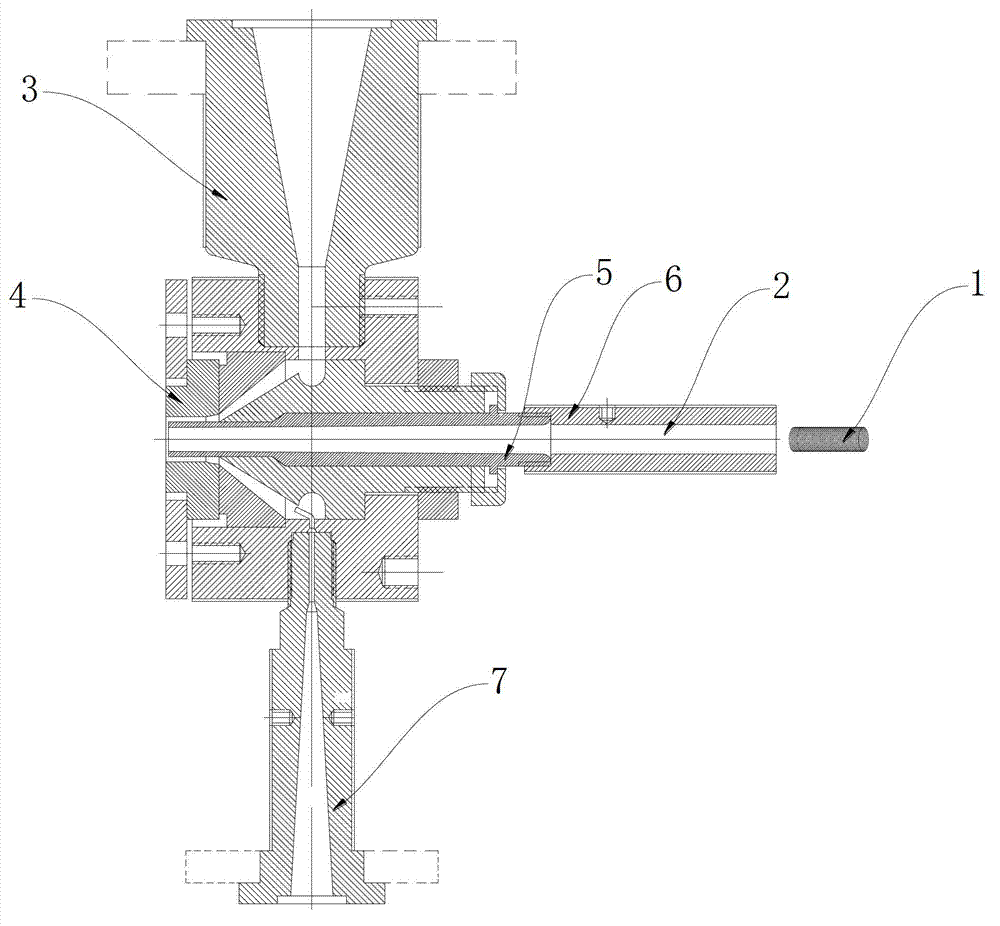

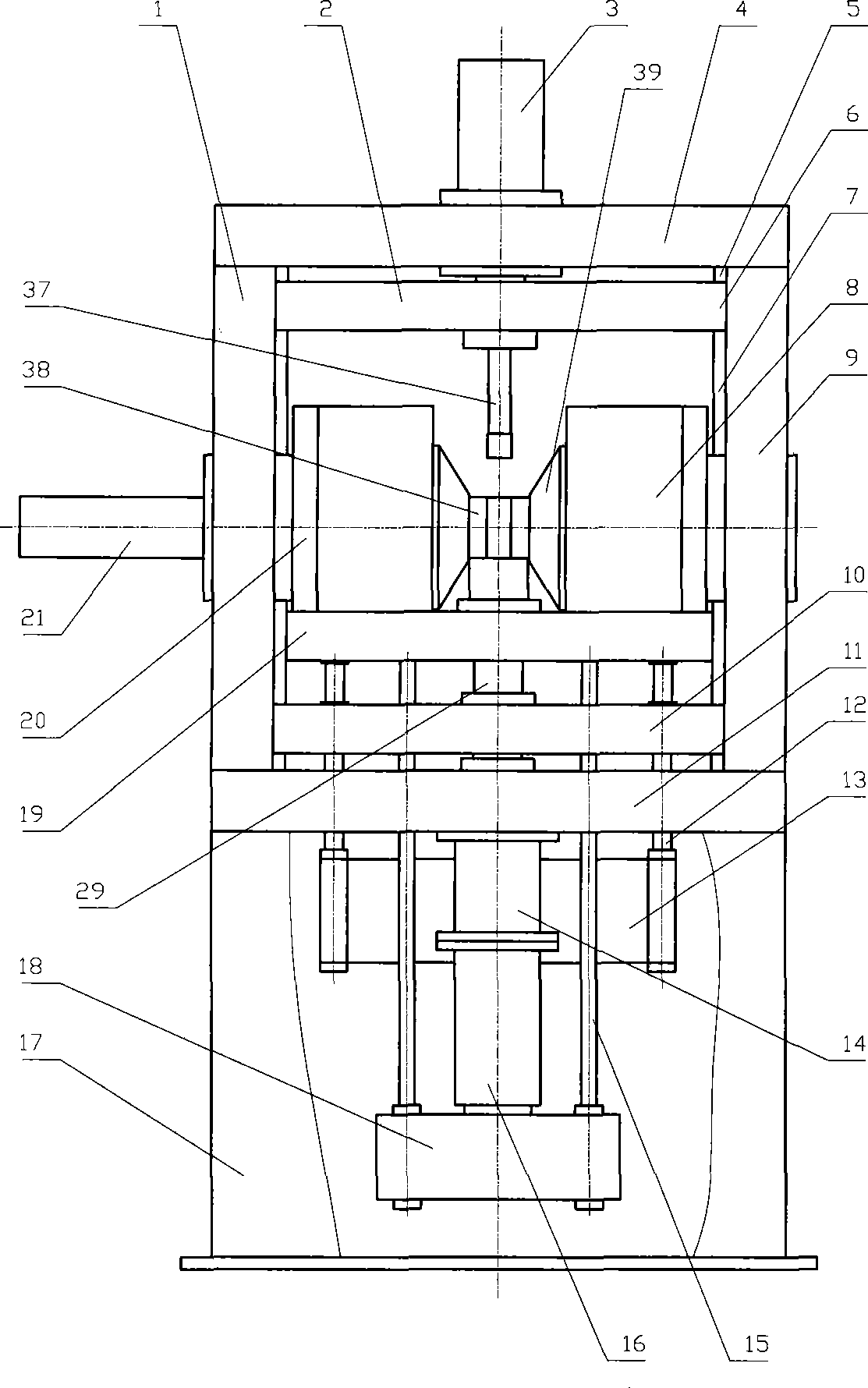

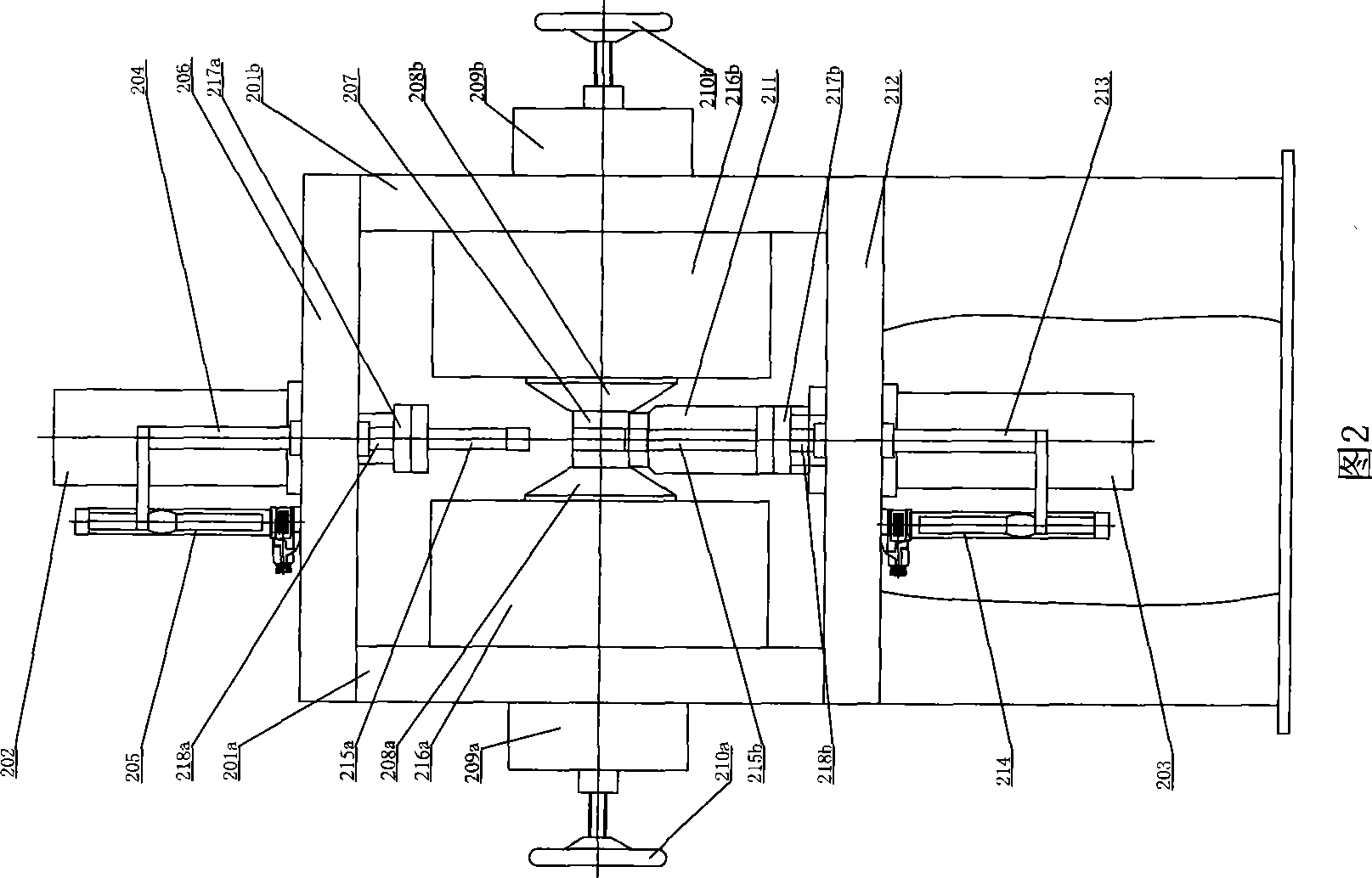

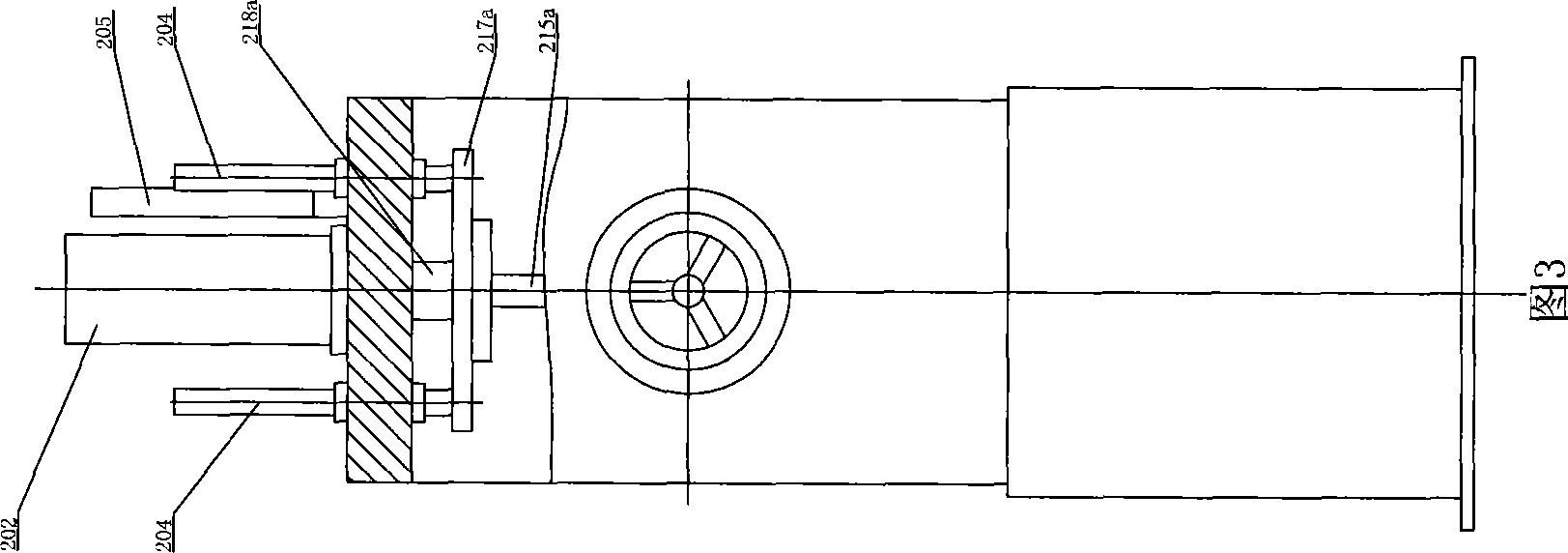

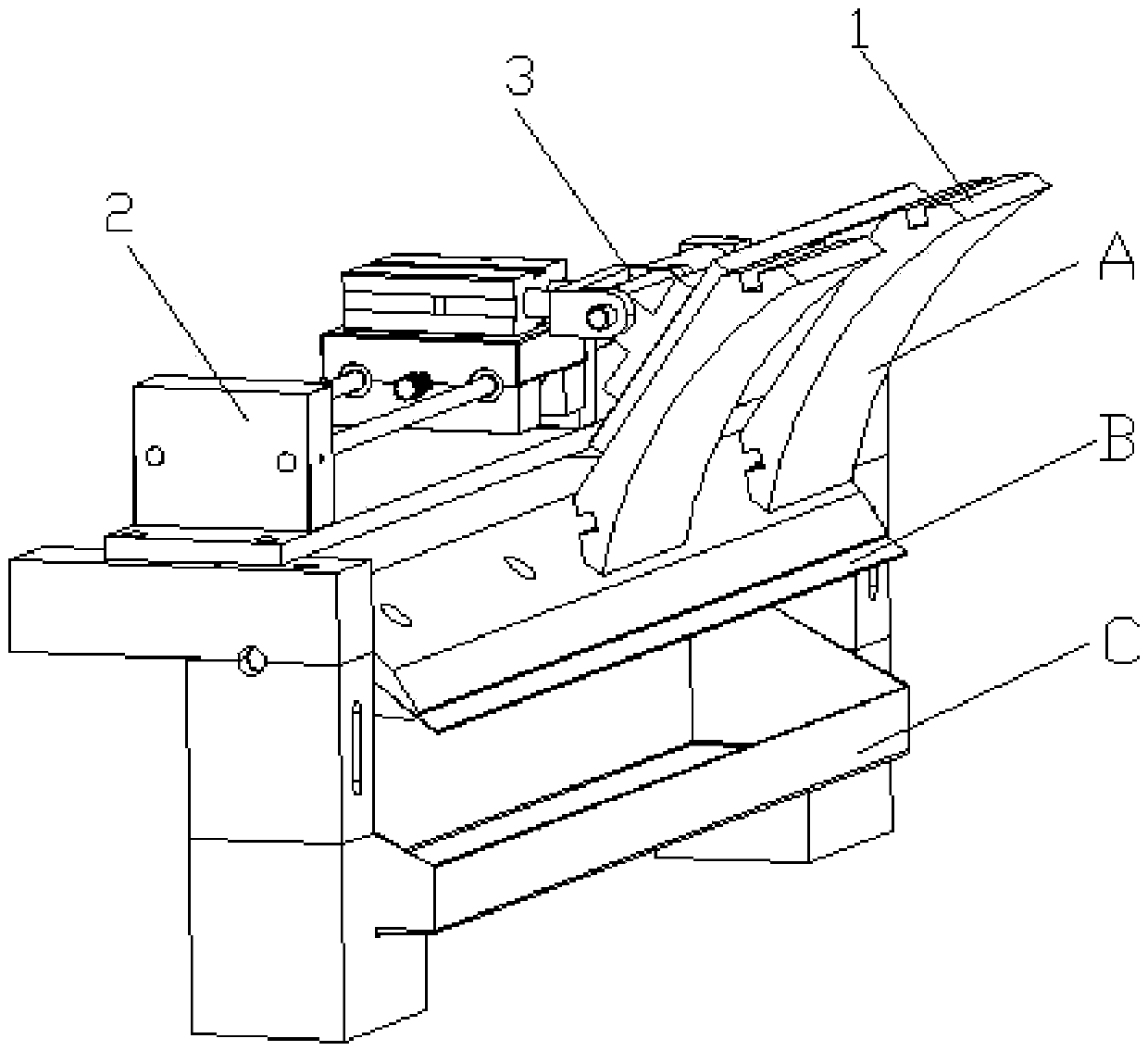

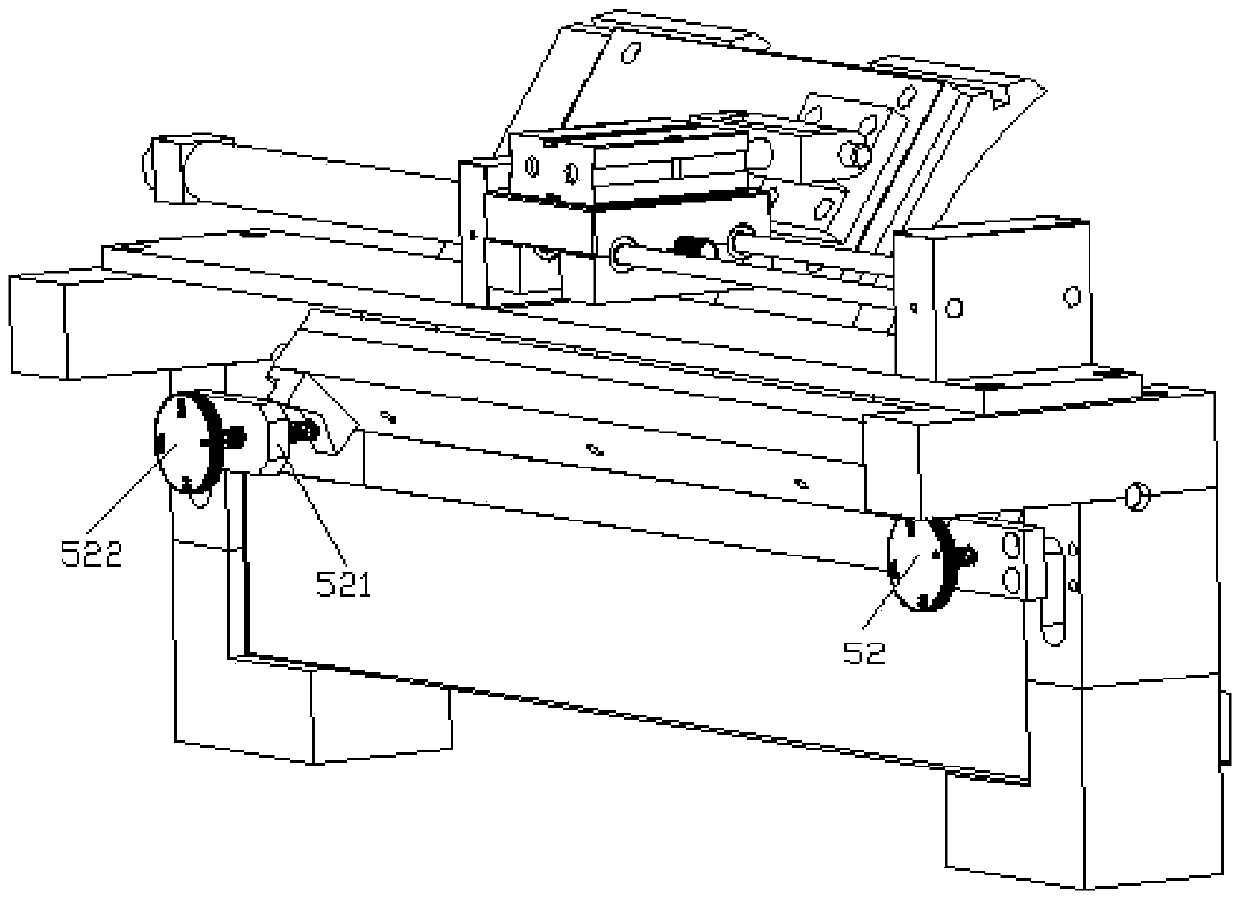

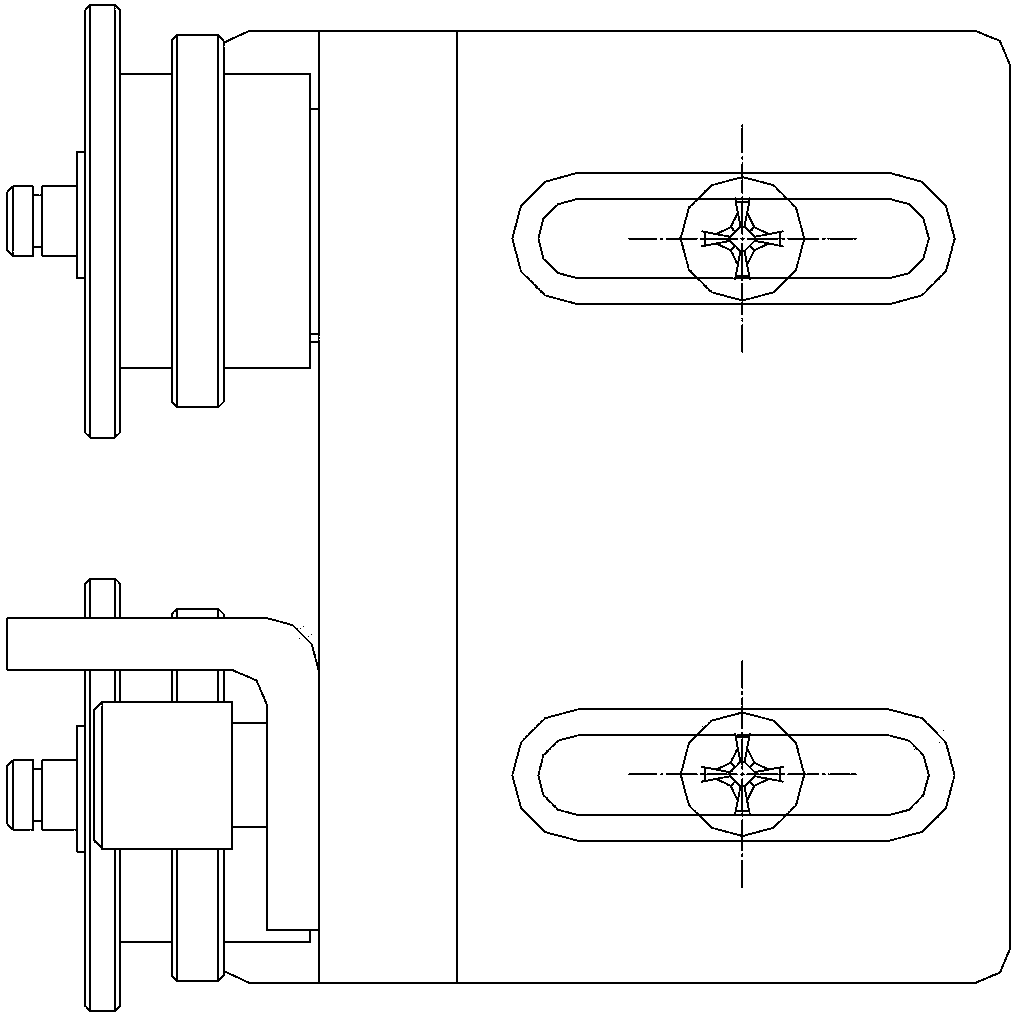

Positional control bidirectional pressed moulding press

The invention discloses a position control two-direction pressing moulding press, comprising a stander formed by the connection of a stander side plate, an upper beam and a lower beam; an upper cylinder fixed on the upper beam; a lower cylinder fixed on the lower beam; an upper die mounting plate installed on an upper die; a lower die mounting plate installed on a lower die; an upper cylinder displacement sensor fixed on the stander; and a lower cylinder displacement sensor fixed on the stander, wherein, the upper cylinder displacement sensor and / or the lower cylinder displacement sensor detect / detects the displacement of the upper cylinder and / or the lower cylinder, generating a displacement signal related to the displacement, and the displacement is processed by a displacement controller and then controls the oil supply state of an oil line of the upper cylinder / or the lower cylinder through a servo proportional valve. The moulding press can precisely press the production height according to production requirements, is characterized by convenient adjustment of the pressed product height and simple arrangement and can markedly improve the quality and dimensional uniformity of pressed products.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

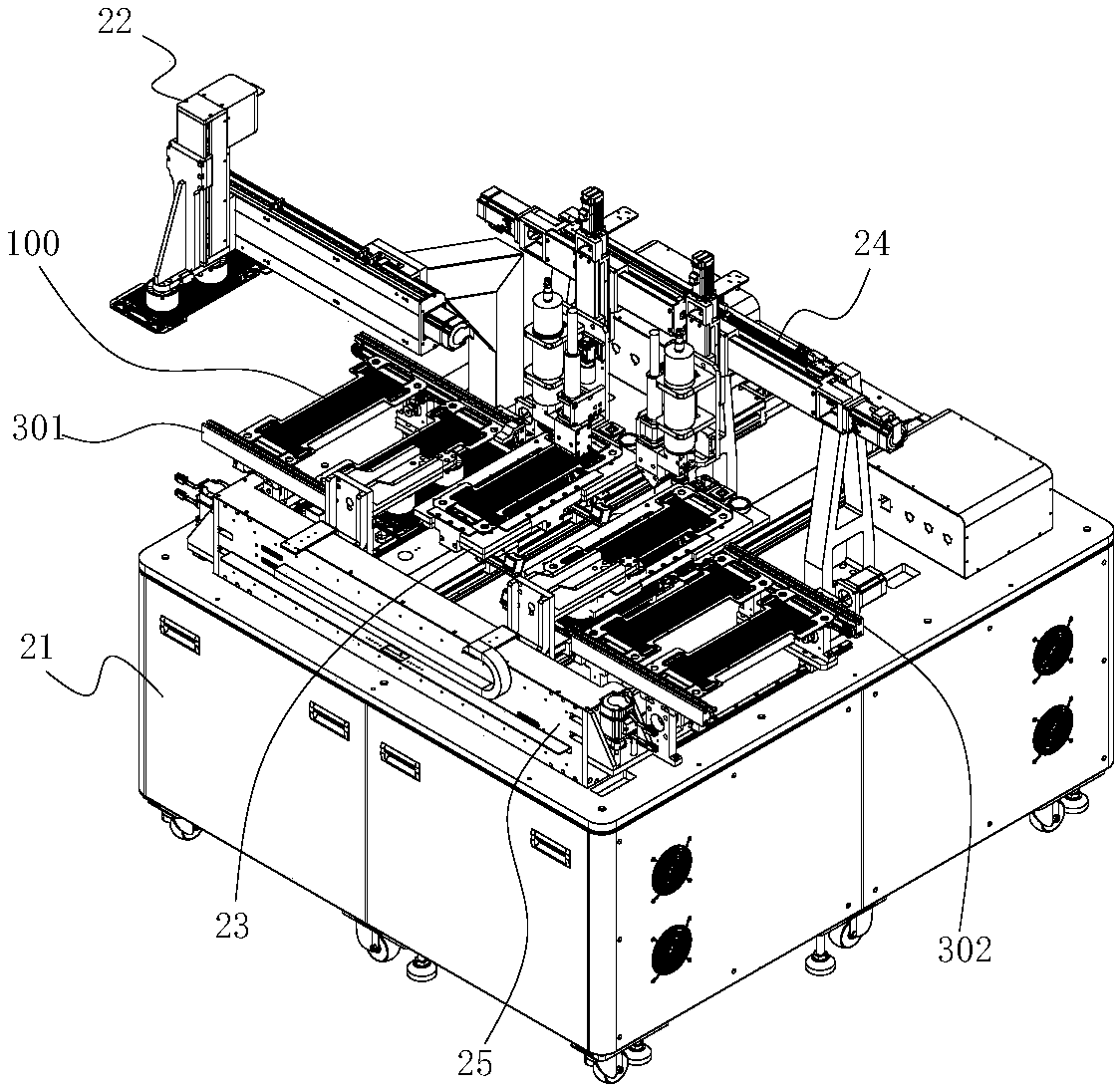

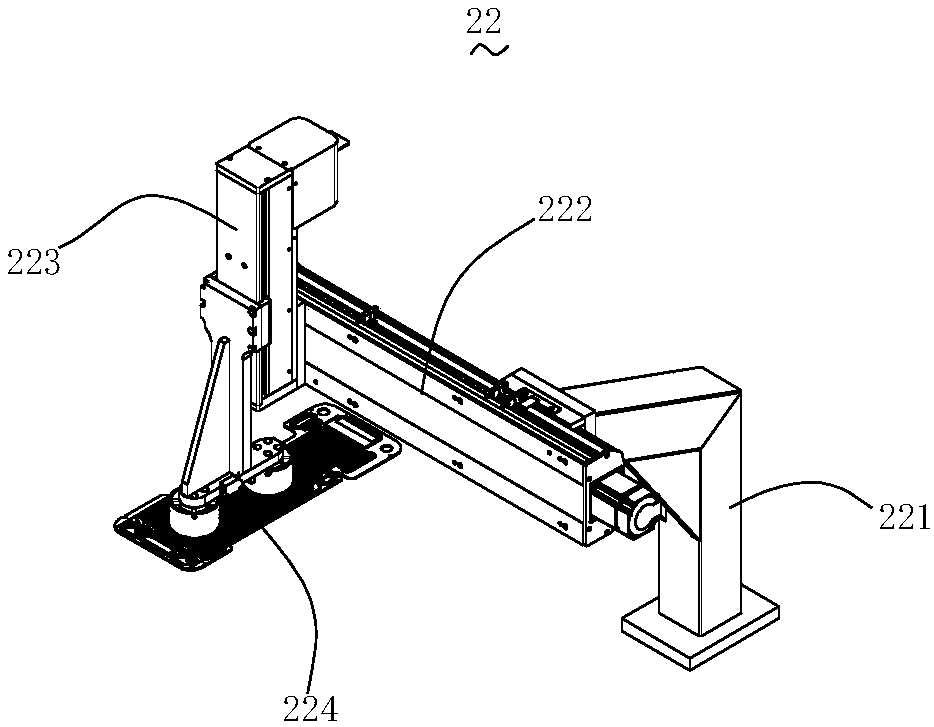

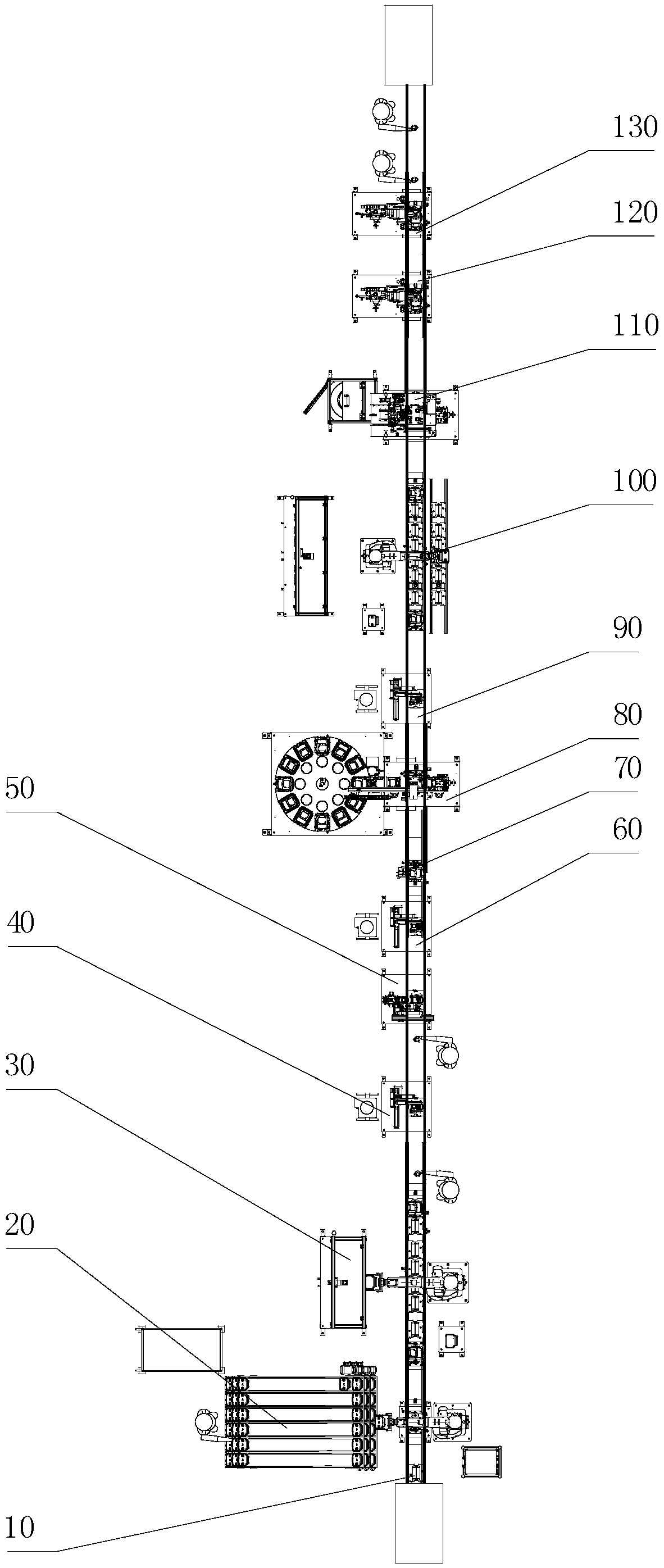

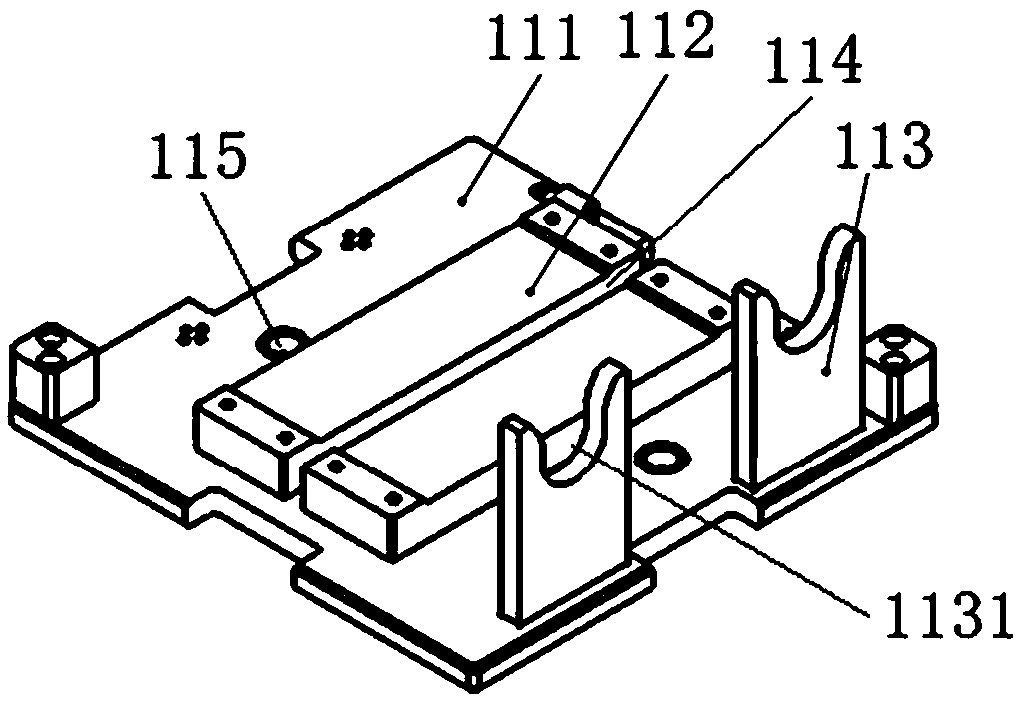

Full-automatic production line of fuel cell pole plates

PendingCN108565472AImprove efficiencyImprove plate product yieldCell electrodesAutomatic controlFuel cells

The invention provides a full-automatic production line of fuel cell pole plates. The full-automatic production line comprises a feeding device, an adhesion glue dispensing device, an adhesion device,a negative pole face glue dispensing device, a positive pole face glue dispensing device, a discharging device, a control server and the like. The full-automatic production line performs full-automatic control operation through the control server. The feeding device comprises a positive pole plate feeding device and a negative pole plate feeding device. The adhesion glue dispensing device is usedfor conducting glue dispensing operation on the adhered face of a positive pole plate. Adhesion operation is performed by utilizing the adhesion device, glue dispensing is conducted on negative polefaces of double pole plates through the negative pole plate feeding device, and glue dispensing is conducted on positive pole faces of the double pole plates through the positive pole plate feeding device so that manufacturing of the finished products double pole plates can be completed. The discharging device outputs the finished products double pole plates. By applying the technical scheme, theproblem can be solved that the low mechanical and automatic degree of a fuel cell pole plate production process causes low processing production efficiency of fuel cell pole plates and poor consistency of processing production quality of the fuel cell pole plates.

Owner:SHENZHEN SECOND INTELLIGENT EQUIP CO LTD

Intelligent final assembly production line for metering instrument

The invention discloses an intelligent final assembly production line for a metering instrument. The intelligent final assembly production line comprises a line body and further comprises an automaticbase meter feeding device, a ventilation tidying device, a master control board fixing device, a nameplate installing device, a nameplate fixing device, a final assembly information input device, a face cover installing device, a face cover fixing device, an automatic testing device, a plastic package installing device, a meter number pasting device and a qualification certificate pasting device,all of which are sequentially arranged in the conveying direction of the line body. The intelligent final assembly production line solves the problems that in the existing metering base meter (particularly a gas metering base meter) final assembly and testing process, the manual production efficiency is low, the assembling precision and the testing accuracy are hard to guarantee, and equipment compatibility is poor. The intelligent final assembly production line can meet the flexible production requirements of multiple kinds and multiple brands of products, assembling and testing informationis fed back in time, unified control is conducted, intelligent gas metering base meter final assembly and testing are achieved, the manual operation is greatly reduced, the production cost is reduced,and the production efficiency is improved.

Owner:CSIC PRIDENANJINGINTELLIGENT EQUIP SYST CO LTD

Nitrogen-contained phenol-formaldehyde resin, its preparation method and application

InactiveCN1803873AImprove flame retardant performanceProcess stabilityLayered productsHydrogenNitrogen

The disclosed nitrogenous phenolic resin has chemical formula as C6H3R1OH- (CH2- C6H2R2OH)n-CH2-X (n=2-9) with R1 and R2 as same or not hydrogen, alkyl, phenyl or hydroxyl and X as nitrogenous monomer. The product can be prepared with low cost and well quality by copolymerizing the phenols, formaldehyde and nitrogenous monomer, or drafting the pre-polymer of phenols and formaldehyde with the monomer, and has wide application.

Owner:康富春

Method for removing ceramic layers of thermal barrier coating

InactiveCN106269648AEfficient removalGood removal effectCleaning using liquidsReciprocating motionSand blasting

The invention discloses a method for removing ceramic layers of a thermal barrier coating. The method includes the steps that (1) a turbine working blade is clamped on a tool fixture; (2) a nozzle is mounted in a spray gun; (3) under the condition of soft limiting control, the spray gun with the nozzle is slowly moved to the current surface, where one ceramic layer is to be removed, of the turbine working blade, and the target distance is kept; (4) an eddy current pulse water jet switch is turned on, and the nozzle is made to reciprocate line by line in the axial direction of the turbine working blade; (5) after the ceramic layer on the current surface of the turbine working blade is completely removed, the blade is rotated by 180 degrees through a rotating shaft on the tool fixture; and (6) the step (3) and the step (4) are conducted to remove the ceramic layer on the other face. When the method is used for removing the ceramic layers, the ceramic layers are continuously stripped off layer by layer, a metal bottom layer is not damaged, the metal bottom layer does not need to be coated supplementarily, the procedures are simple, and re-coating of the ceramic layers is facilitated; and compared with a traditional mechanical sand blasting method, process parameters are accurately controlled in the method, and product quality consistency is high.

Owner:AECC AVIATION POWER CO LTD

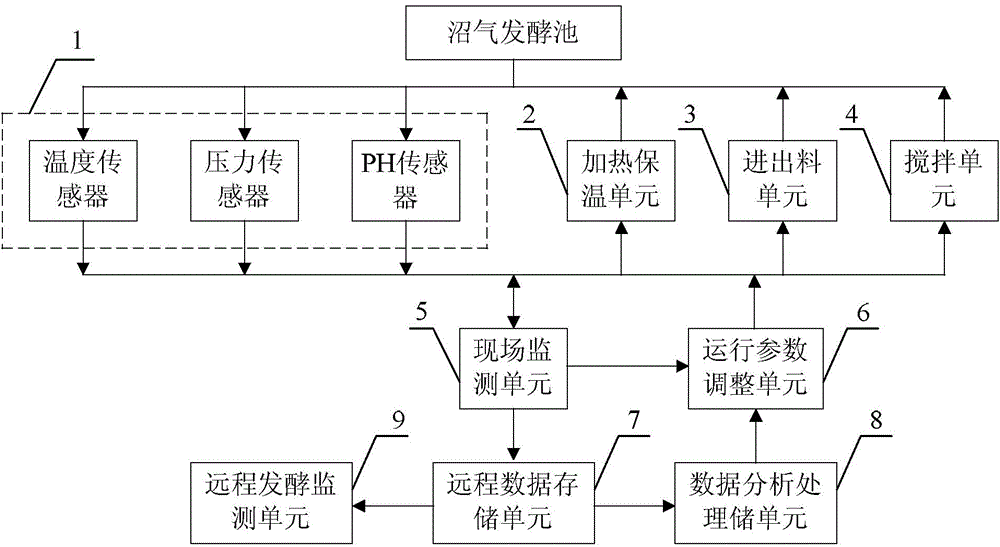

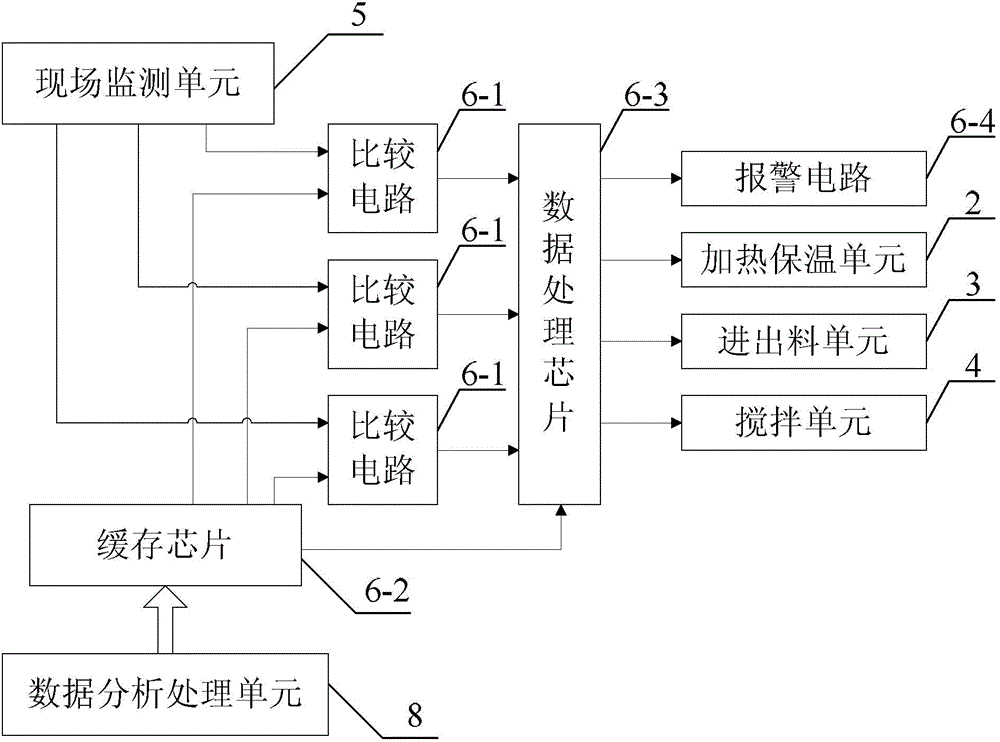

Biogas fermentation process state control system and biogas fermentation process state control method thereof

ActiveCN104407587ARealize monitoringEasy to controlTotal factory controlProgramme total factory controlControl systemState parameter

The invention relates to monitoring techniques of biogas fermentation process states, in particular to a biogas fermentation process state control system and a biogas fermentation process state control method thereof. Sensors of a detection unit are disposed at corresponding positions in a biogas fermentation tank and used for various state parameters of the biogas fermentation tank; a field failure detection unit judges whether or not the state parameters, such as temperature, pressure and PH value, of the biogas fermentation tank are normal according to detection result of the detection unit, sends out an alarm signal if the state parameters are abnormal for a long time, compares the data to corresponding target values if the state parameters are normal, calculates corresponding corrected values and transmits the corrected values to a heating and insulation unit, a feeding and discharging unit and a stirring unit, thus correcting their running states. The process above is in a continuous cycle, the biogas fermentation process state is monitored and controlled, and fermentation process repeatability and product quality uniformity are improved. The biogas fermentation process state control system and the biogas fermentation process state control method thereof are applicable to monitoring of the biogas fermentation process.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

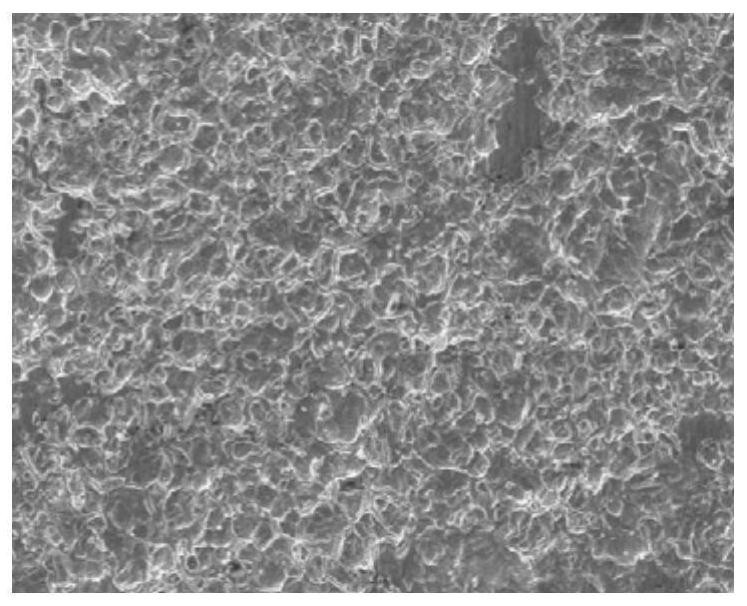

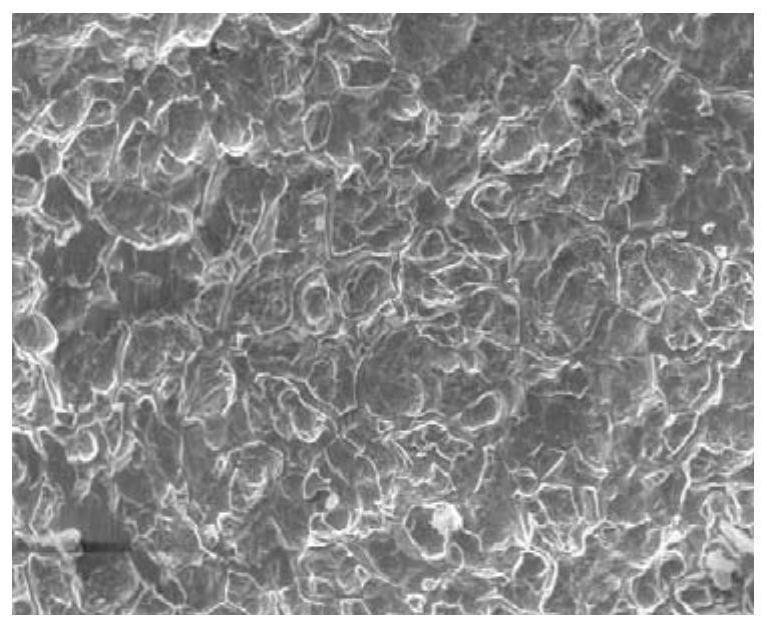

Surface treatment method for 304-series high-grade panel stainless steel raw materials

PendingCN112501422AImprove processing stabilityImprove product quality consistencyFurnace typesHeat treatment furnacesSS - Stainless steelMaterials science

The invention provides a surface treatment method for a stainless steel coil. The surface treatment method comprises the following steps of (1) annealing the stainless steel coil to be treated at thetemperature of 1, 005 DEG C to 1, 095 DEG C; (2) carrying out descaling and shot blasting treatment on the annealed stainless steel coil by adopting a large-elongation wire with the elongation of 1.5%to 2%; and (3) carrying out acid pickling on the stainless steel coil subjected to descaling and shot blasting treatment. By adjusting and optimizing the annealing process, the descaling and shot blasting process and the acid pickling process, the stability of annealing and acid pickling is guaranteed, the annealing performance is excellent, the surface is uniform after acid pickling, the roughness meets the requirement, the quality is obviously improved, and the comprehensive yield is also improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Infrared transmitting or receiving circuit board unit and infrared touch screen

InactiveCN101526867AFlexible choiceSimple designElectromagnetic receiversInput/output processes for data processingProduct typeInfrared

The invention discloses an infrared transmitting or receiving circuit board unit capable of cutting and mutual splicing on a free position as well as an infrared touch screen consisting of the circuit board unit. The circuit board unit is provided with a power cord, an earth wire, a clock signal wire or a transfer protocol control wire, an infrared pulse signal wire and an infrared receiving signal wire, wherein a line driver and a row driver are arranged in the middle of the circuit board unit. The circuit board units can be spliced to form the infrared touch screens of any size and are respectively connected through corresponding ports of a controller unit, thereby carrying out synchronous fractional scanning to effectively improve the scanning speed. The infrared transmitting or receiving circuit board unit does not need to be developed again to the infrared touch screens with different sizes, thereby greatly improving the production efficiency; meanwhile, the circuit board unit has the advantages of flexible selection of splicing points, less restriction on processing conditions and ideal product quality stability and consistency; therefore, the product updating speed can be improved and product types can be increased and expanded without restriction.

Owner:贺伟

Automatic cleaning device of milling roller

InactiveCN105363700AReduce manufacturing costImprove work efficiencyDirt cleaningCleaning using toolsPulp and paper industry

The invention provides an automatic cleaning device of a milling roller. The cleaning device is matched with the milling machine in use and comprises a roller wiping device and a roller scraping device which are successively arranged from top to bottom, wherein the roller wiping device comprises a scraping unit, a cylinder unit and a connection part; the scraping unit comprises cleaning brushes and a cleaning brush fixing plate; a plurality of cleaning brushes are fixedly mounted on the cleaning brush fixing plate; the cylinder unit comprises a roller wiping cylinder used for controlling the scraping unit to move left and right and a positioning cylinder used for controlling the scraping unit to move forth and back; the positioning cylinder is connected with the cleaning brush fixing plate through the connection part; the roller wiping cylinder drives the positioning cylinder to move left and right so as to driven the scraping unit to move left and right. The automatic cleaning device of the milling roller has the beneficial effects that the cleaning device can automatically and effectively clean the milling roller of a milling machine, the operation efficiency, the qualified rate and the consistency of the product quality are improved, and the production cost of enterprise is reduced.

Owner:TIANJIN ENERGIES

Machine vision-based online detection method for apertures of LED glass lamp cups

InactiveCN108876773AHigh degree of automationImprove work efficiencyImage enhancementImage analysisMachine visionEngineering

The invention relates to a machine vision-based online detection method for the apertures of LED glass lamp cups. According to the method, the functions of performing real-time monitoring and classifying on the apertures of the LED glass lamp cups on a conveyor belt are achieved; the automation degree of lamp cup production is improved; and the defects of low manual detection efficiency, incapability of guaranteeing product quality consistency and the like are overcome. The method has the advantages of high efficiency, high detection precision, online detection and the like; the production efficiency of enterprises can be greatly improved; the consistency of product quality is improved; the enterprises can be promoted to realize intelligent manufacturing and fine management modes; and thecomprehensive competitiveness of the enterprises is improved.

Owner:HANGZHOU DIANZI UNIV

Automatic welding line of washing machine inner tub

ActiveCN107336026AHigh positioning accuracyHigh degree of automationOther manufacturing equipments/toolsHome appliance efficiency improvementLaundry washing machineElectric machinery

The invention relates to an automatic welding line of a washing machine inner tub. The automatic welding line comprises a feeding trolley, a truss mechanical hand, a trimming special machine, an automatic turning feeder and an edge rolling, welding and notching integrated machine in sequence. The edge rolling, welding and notching integrated machine comprises a machine frame. An edge rolling mechanism, a welding mechanism and a stamping mechanism are sequentially fixed to the machine frame. The edge rolling mechanism comprises an edge rolling roller connected with a motor. An edge rolling roller path is arranged below the edge rolling roller. An edge rolling embracing arm is arranged in the edge rolling roller path and connected with a transverse moving base. A first transit base is arranged at the rear end of the edge rolling mechanism. The welding mechanism comprises a cantilever arranged above the first transit base. A transverse moving welding mechanical hand is fixed to the cantilever. A welding positioning die and a welding machine are arranged above the cantilever. A second transit base is arranged below the welding mechanism. The stamping mechanism comprises a stamping mechanical hand, a stamping upper die and a stamping lower die. A turning table is arranged at the rear end of the stamping mechanism. A discharging slide rail is arranged on one side of the turning table. The automatic welding line of the washing machine inner tub is high in automation degree, saves labor and is high in product percent of pass.

Owner:WUXI IDO SCI & TECH CO LTD

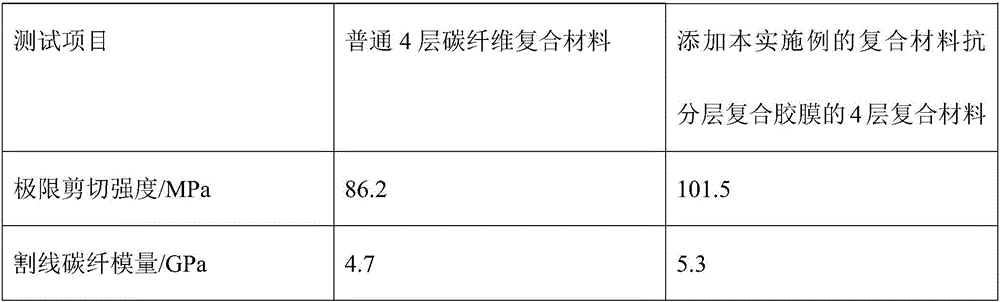

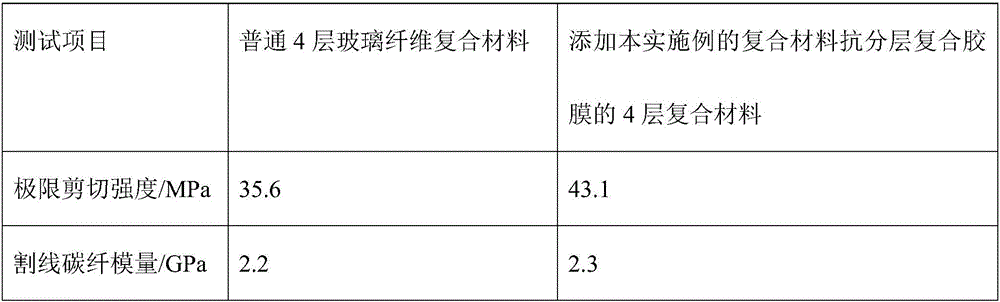

Composite material anti-layering composite adhesive membrane and preparation method of membrane

ActiveCN106590453AImprove mechanical propertiesImprove anti-delamination abilityNon-macromolecular adhesive additivesFilm/foil adhesivesThermoplastic elastomerToughness

The invention discloses a composite material anti-layering composite adhesive membrane and a preparation method of the membrane. The adhesive membrane is prepared in the steps that 10-15% of milled fibers, 65-75% of thermosetting resin, 12-18% of thermoplastic elastomer powder or tough adhesive membrane and 2-3% of reaction accelerant are evenly mixed by mass to form a mixture, and the mixture is clamped between an upper release film and a lower release paper and pressed into the composite material anti-layering composite adhesive membrane by a press roller, wherein the thickness of the composite material anti-layering composite adhesive membrane is 0.5-5 mm. The milled fibers are introduced between layers, and after hot pressing, countless fiber flocks distributed in a three-dimensional needle shape are embedded between fabric fiber layers to achieve a connection function of a pin; a high-elasticity matrix or a tough adhesive membrane layer is introduced between the layers to achieve the aims of enhancing toughness between the layers and inhibiting layer forming and crack growth, so that impact damage resistance and layering resistance of a composite material laminated board structure are greatly improved.

Owner:GUANGDONG YATAI NEW MATERIAL TECH CO LTD +1

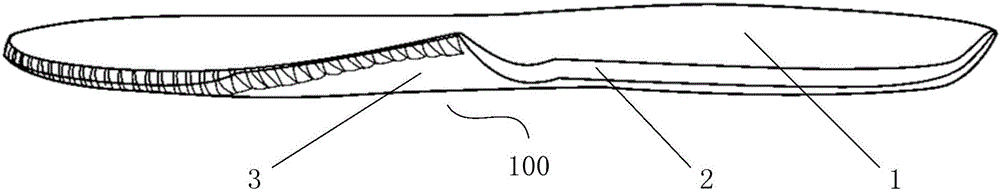

Elastic heat-insulating breathable moisture-absorbing insole and manufacturing method thereof

InactiveCN106273936AImprove bindingMeet wearing needsInsolesSynthetic resin layered productsSnipsPolyester

The invention relates to an elastic heat-insulating breathable moisture-absorbing insole and a manufacturing method thereof. The elastic heat-insulating breathable moisture-absorbing insole comprises a straight snip velour fabric layer, an opening foam polyurethane layer and an acupuncture polyester fiber felt layer which are sequentially combined to be a whole from top to bottom. The elastic heat-insulating breathable moisture-absorbing insole integrates heat insulation, elasticity, breathability and moisture absorption and can meet the wearing requirements of outdoor activities in winter; the layers of the insole are combined firmly, and the insole is resistant to treading, is not layered, is not subjected to pilling and is suitable for being used in shoes of troops and armed police and public security people who are high in winter training intensity. The elastic heat-insulating breathable moisture-absorbing insole is mature in process, high in product quality consistency and suitable for large-mass production.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

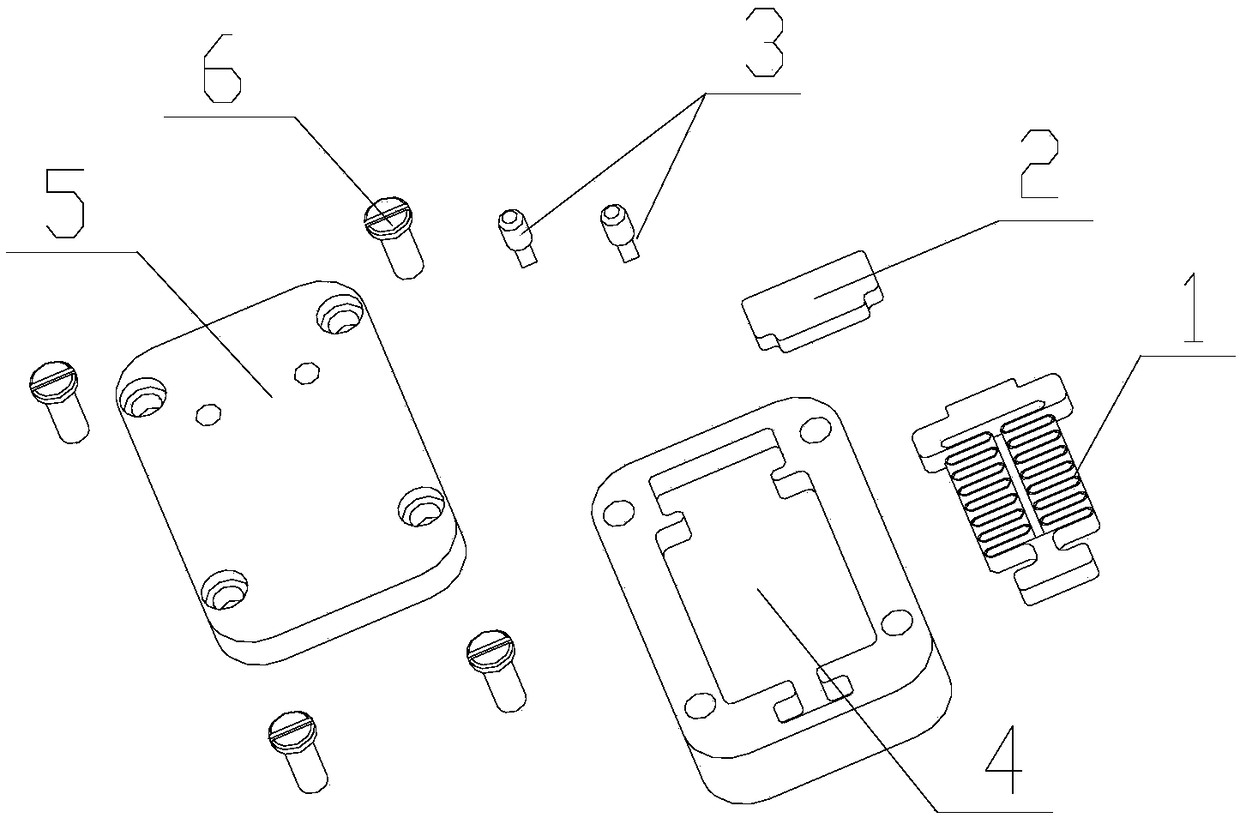

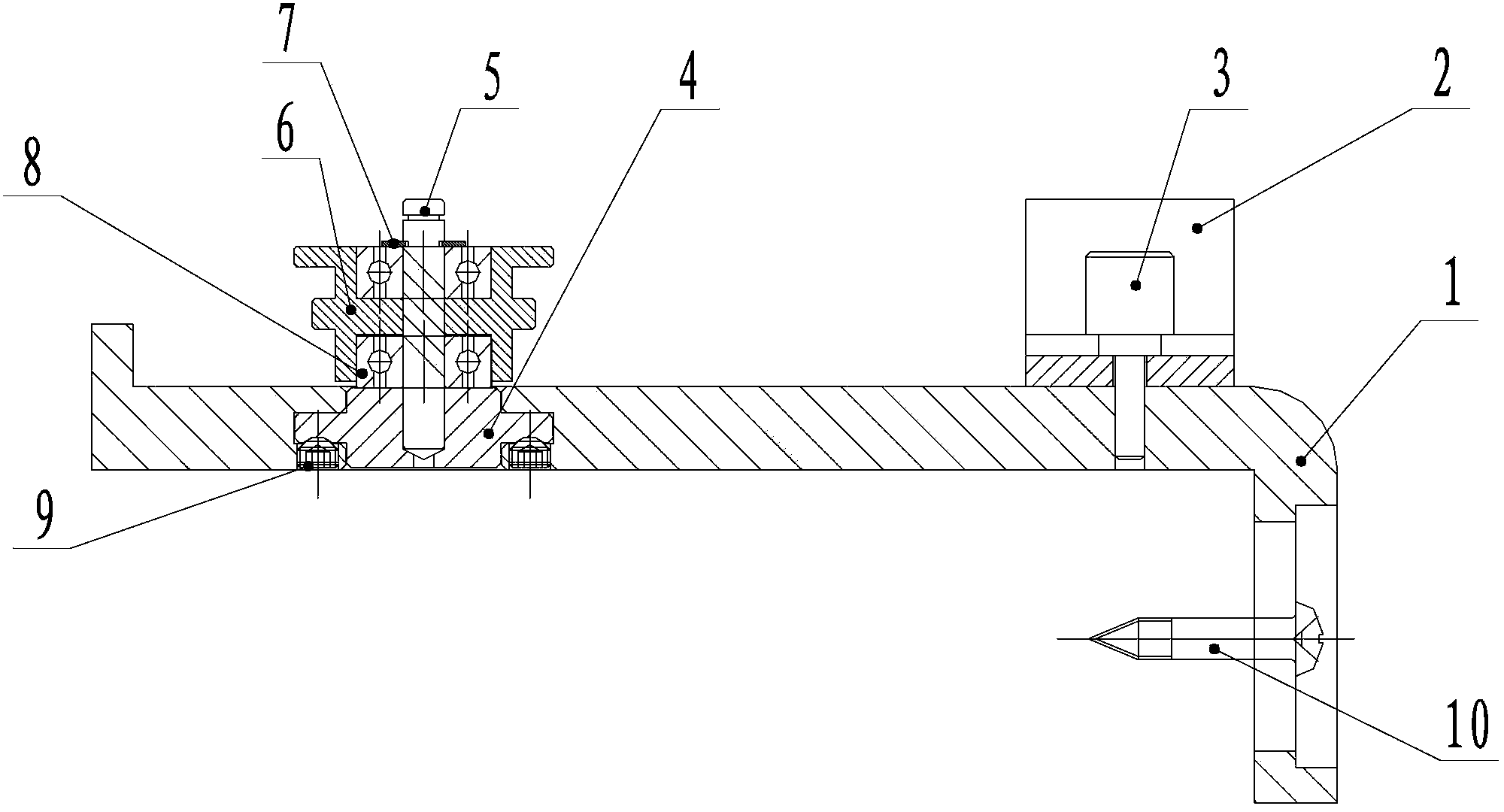

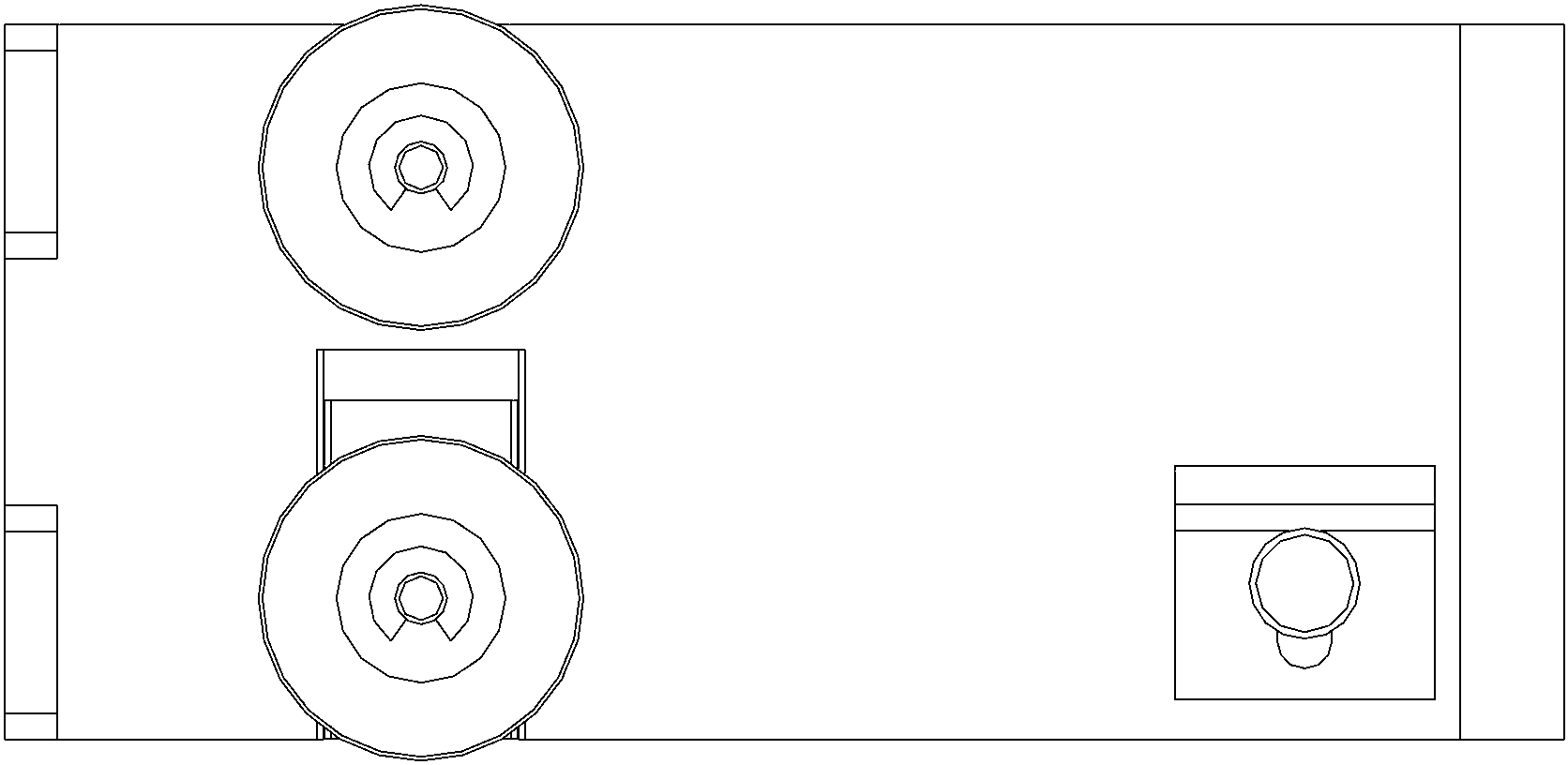

Locking type inertia switch

InactiveCN108630489AAchieve conductionWith lock in placeElectric switchesInterference fitSuction force

The invention discloses a locking type inertia switch which comprises a magnet (2), a screw (6) a spring mass block (1), a conductive column (3), a shell (4) and a cover plate (5), wherein one end ofthe spring mass block (1) is fixedly connected with the shell (4), the other end of the spring mass block (1) keeps a certain distance from the shell (4), one end of the conductive column (3) is a cylinder and is fixedly arranged in a conductive column hole in the cover plate (5) in an interference fit mode (5), and the other end of the conductive column (3) is a rectangular sheet, the cover plate(5) is fixedly installed with the shell (4) through the screw (6) to realize locking in place. According to the locking type inertia switch, when the spring mass block senses overload, the spring mass block overcomes the force resistance of the spring under the action of inertia force and the suction force of the spring mass block and the magnet until the spring mass block is in contact with theconductive column, so that the on and off of the circuit are realized, and the in-place locking function is achieved.

Owner:湖北三江航天红林探控有限公司

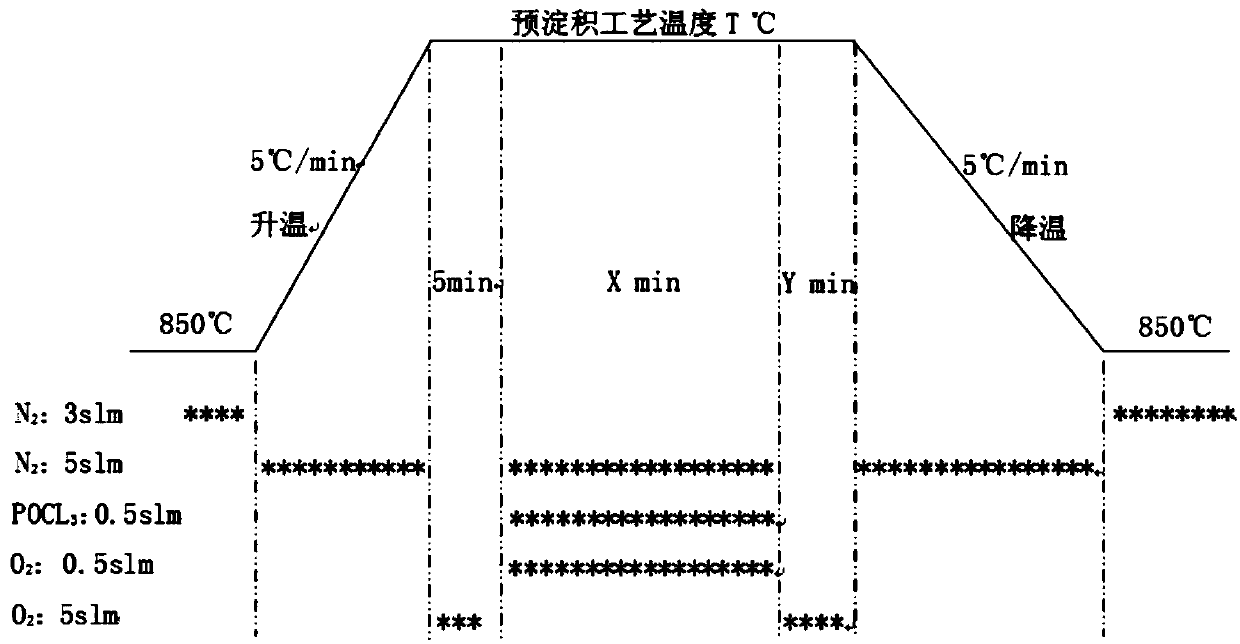

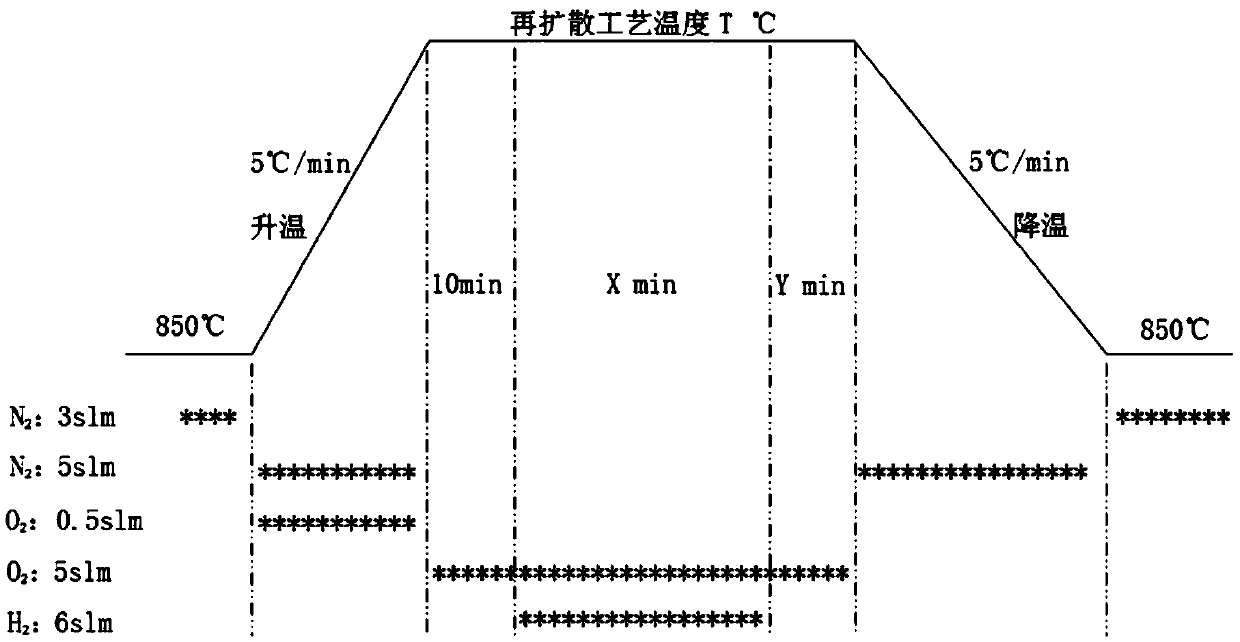

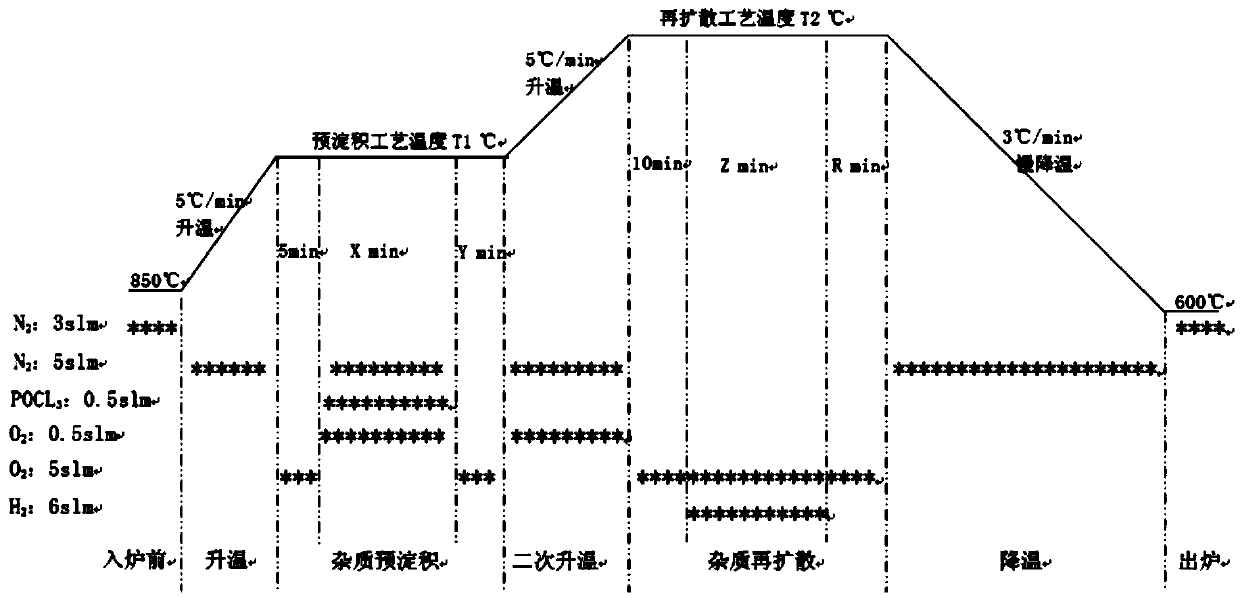

Impurity diffusion process in semiconductor device preparation process

ActiveCN109671620AImprove the contamination problemPlay an annealing effectFinal product manufactureSemiconductor/solid-state device manufacturingImpurity diffusionDevice material

The invention discloses an impurity diffusion process in a semiconductor device preparation process, and belongs to the technical field of semiconductor device manufacturing. The process first performs an impurity pre-deposition process, and then a diffusion furnace is heated to a re-diffusion temperature T2 at a rate of 5 DEG C / min under a mixed atmosphere of nitrogen and oxygen; the impurities are re-diffused, and finally the diffusion furnace is placed under a nitrogen atmosphere of 5 slm to be cooled to below 600 DEG C at a rate of 3 DEG C / min, and a silicon wafer is taken put and then naturally cooled. The impurity pre-deposition and diffusion process in the furnace are completed at one time to avoid the influence of repeated lifting and lowering temperature on product parameters andperformance and shorten a large amount of process time.

Owner:NO 47 INST OF CHINA ELECTRONICS TECH GRP

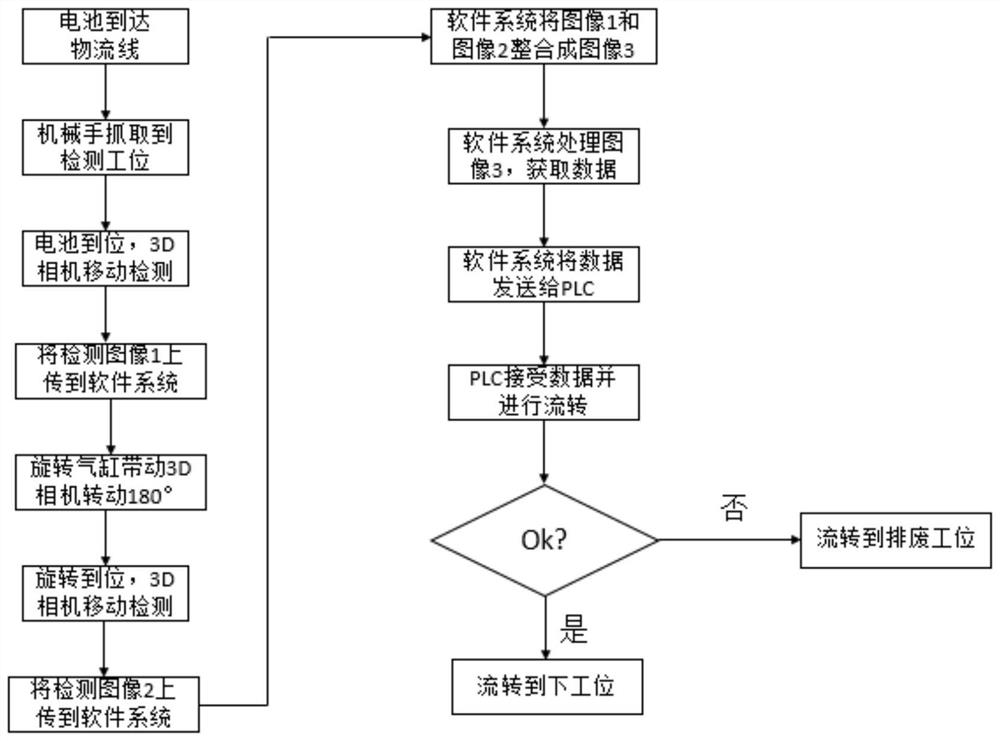

Power battery sealing nail welding detection device and method

PendingCN113640304AEasy to detectAvoid noiseOptically investigating flaws/contaminationSteroscopic systemsPower batteryImaging processing

The invention discloses a power battery sealing nail welding detection device and method, the device comprises an image acquisition part and an image processing part, the image acquisition part comprises a 3D camera, a motion assembly for driving the 3D camera to rotate and move, a support frame and a base, the support frame is used for supporting the motion assembly, the support frame and a battery for detection are fixed on the base, the 3D camera scans the battery to be detected for multiple times under the action of the motion assembly, and the image processing part is connected with the data end of the 3D camera and used for processing scanned images. According to the invention, the 3D camera is adopted for detection, so that the welding projection height and the concave depth of a sealing nail can be detected.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

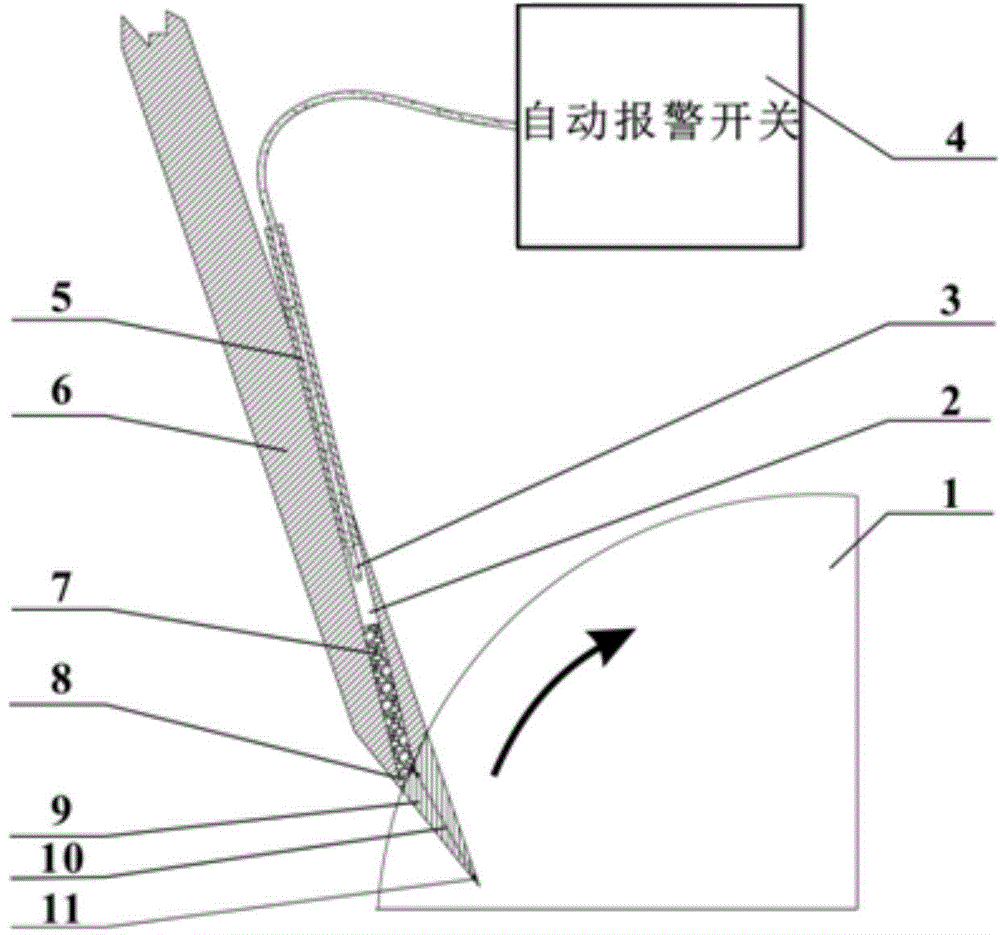

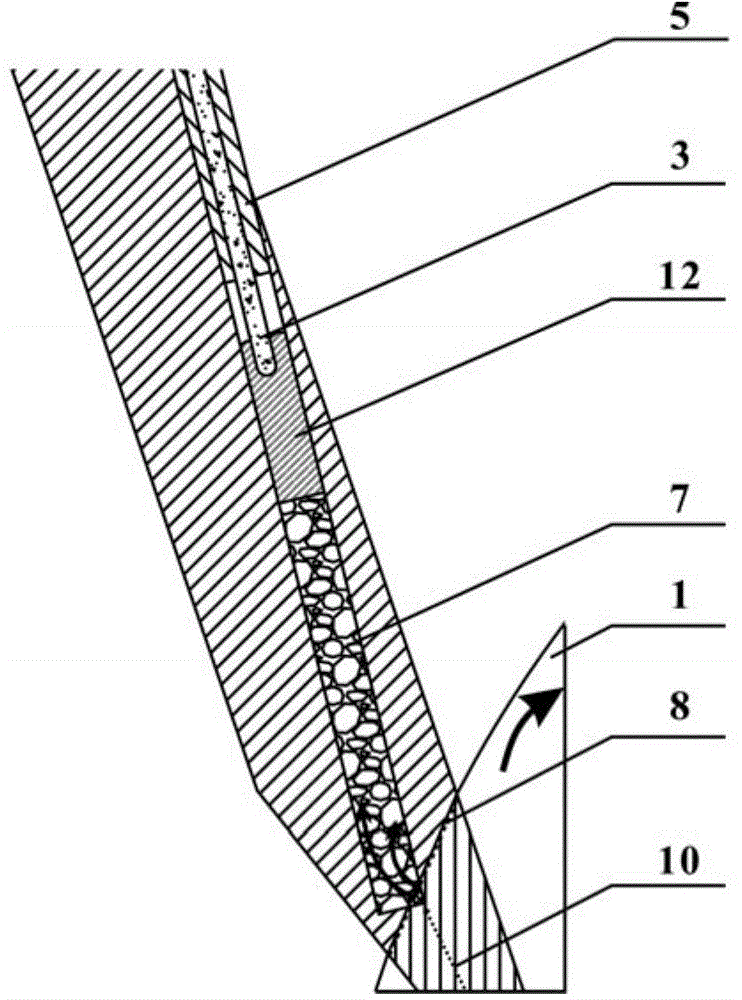

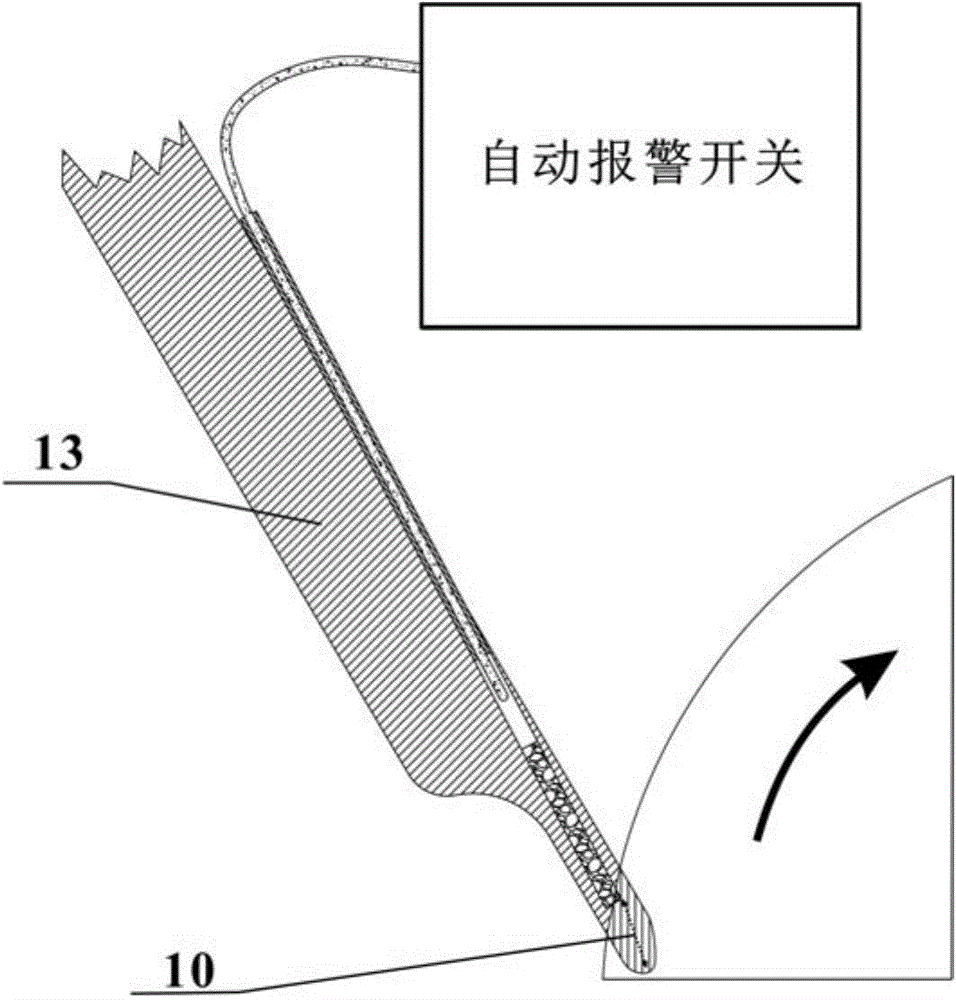

Coating scraper with automatic abrasion alarming switch

ActiveCN104646239ARealize automatic alarm functionSpeed up the flowLiquid surface applicatorsCoatingsPulp and paper industryContact type

The invention discloses a coating scraper with an automatic abrasion alarming switch, and particularly relates to a contact type coating scraper or blade for scraping ornament of a solution on a roller in a gravure coating / printing, and relief block coating / printing technology. The coating scraper is provided with a micro hole which is a straight blind hole; the bottom of the straight blind hole reaches the critical line of the blade abrasion loss when the scraper is scraped; the opening part of the micro hole is provided with an alarming switch lead connected with the automatic alarming switch. When the scraper blade is abraded to the critical line, the bottom of the blind hole is worn to form a through hole; after the solution enters the through hole, the solution is in contact with the alarming switch lead, and the automatic alarming switch is triggered.

Owner:SOUTH CHINA UNIV OF TECH

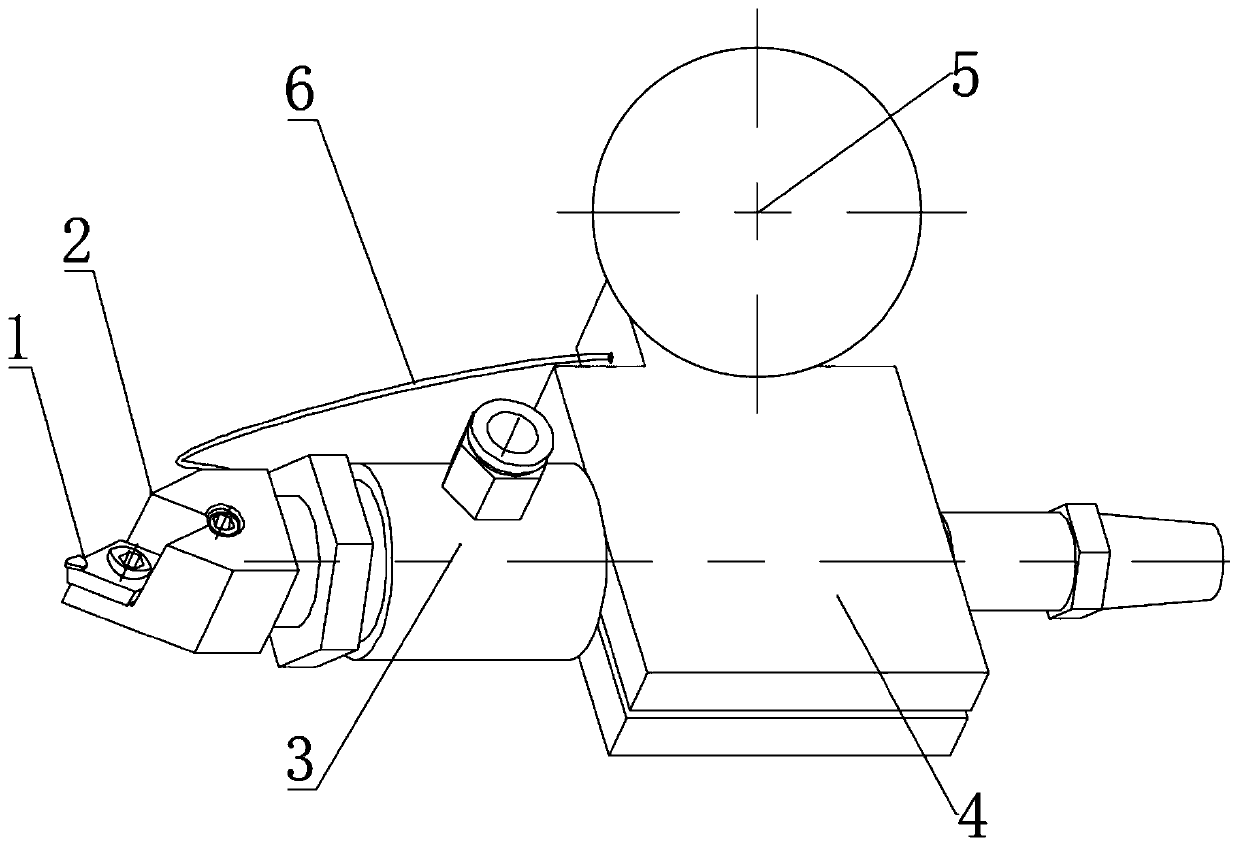

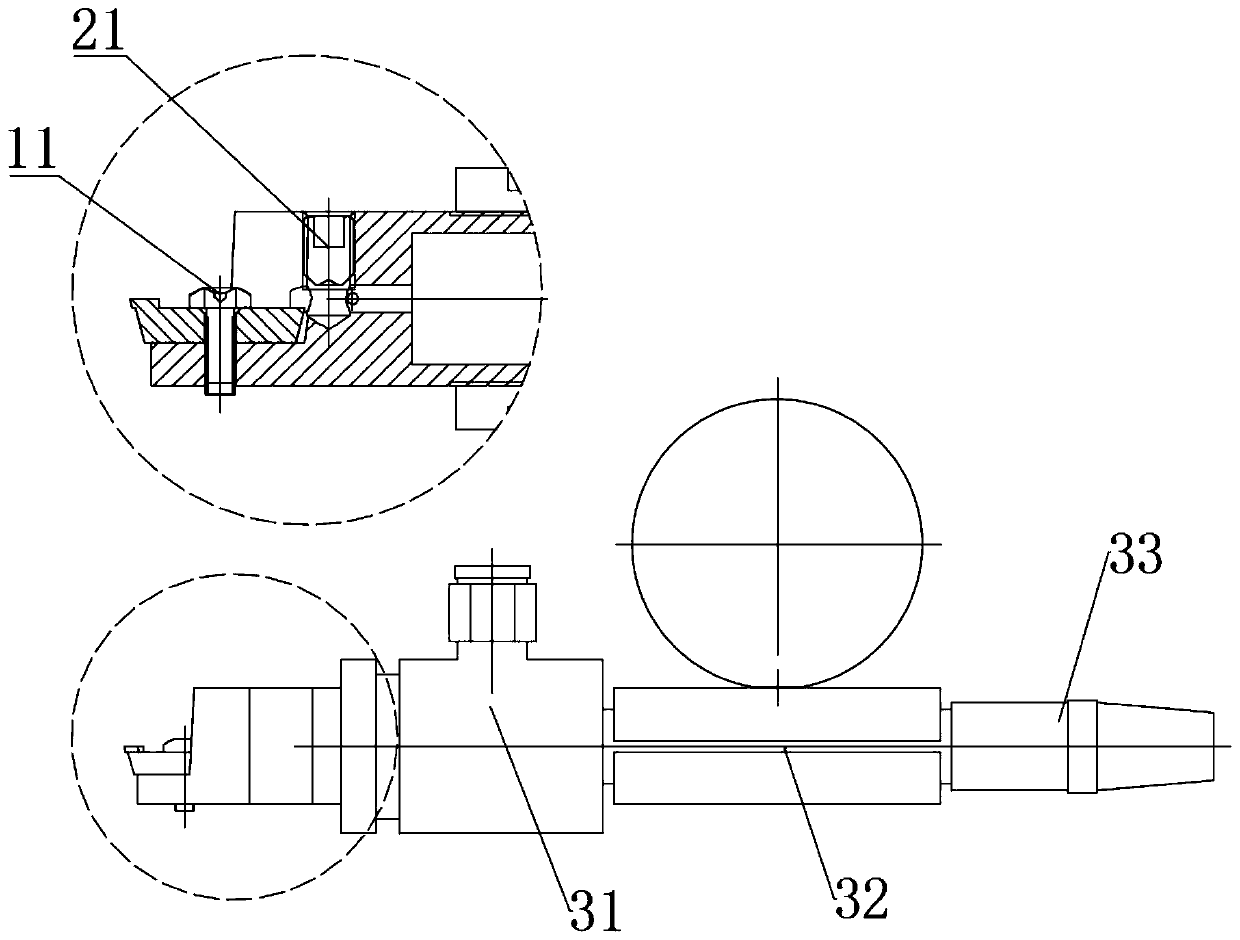

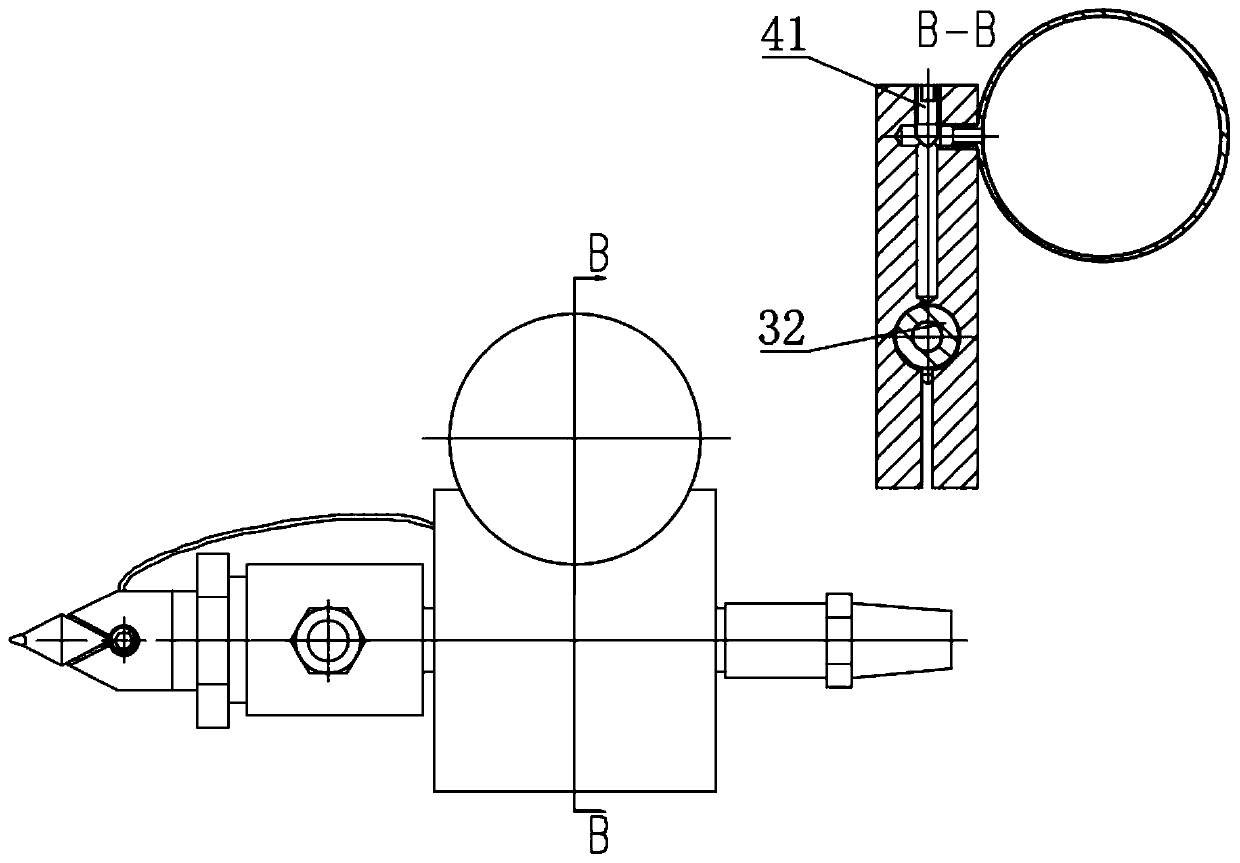

Integrated vortex cooling tool suitable for mechanical processing of energetic materials

ActiveCN109759611AImprove surface finish qualitySimple structureTurning toolsMaintainance and safety accessoriesCold airTemperature control

The invention discloses an integrated vortex cooling tool suitable for mechanical processing of energetic materials. The integrated vortex cooling tool comprises a diamond blade, the base center of the diamond blade is provided with a standard pressing positioning hole, a pressing screw is installed in the positioning hole, the diamond blade is assembled on a cutter head through the pressing screw, a cold air flow and cutting fluid cross passage is arranged inside the cutter head, the passage intersection is sealed through a sealing screw to form a cutting fluid atomization chamber, the end ofthe cutter head is provided with a thread to be connected with the cold air end of a vortex pipe, the vortex pipe communicates with an external compressed gas source through a pipe joint, and a clampbase is internally provided with a cutting liquid heat conduction and flow regulating passage. Based on an existing mature mechanical processing technology of the energetic material, current generalprocessing equipment is used in cooperation, a micro-lubrication and temperature-controlled cutting processing method is introduced, surface high-quality processing of PBX composite explosive parts isfacilitated, and meanwhile, the effective inhibitory effect is achieved on the problems of product cutting heating, discharging, impact stability losing and the like.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

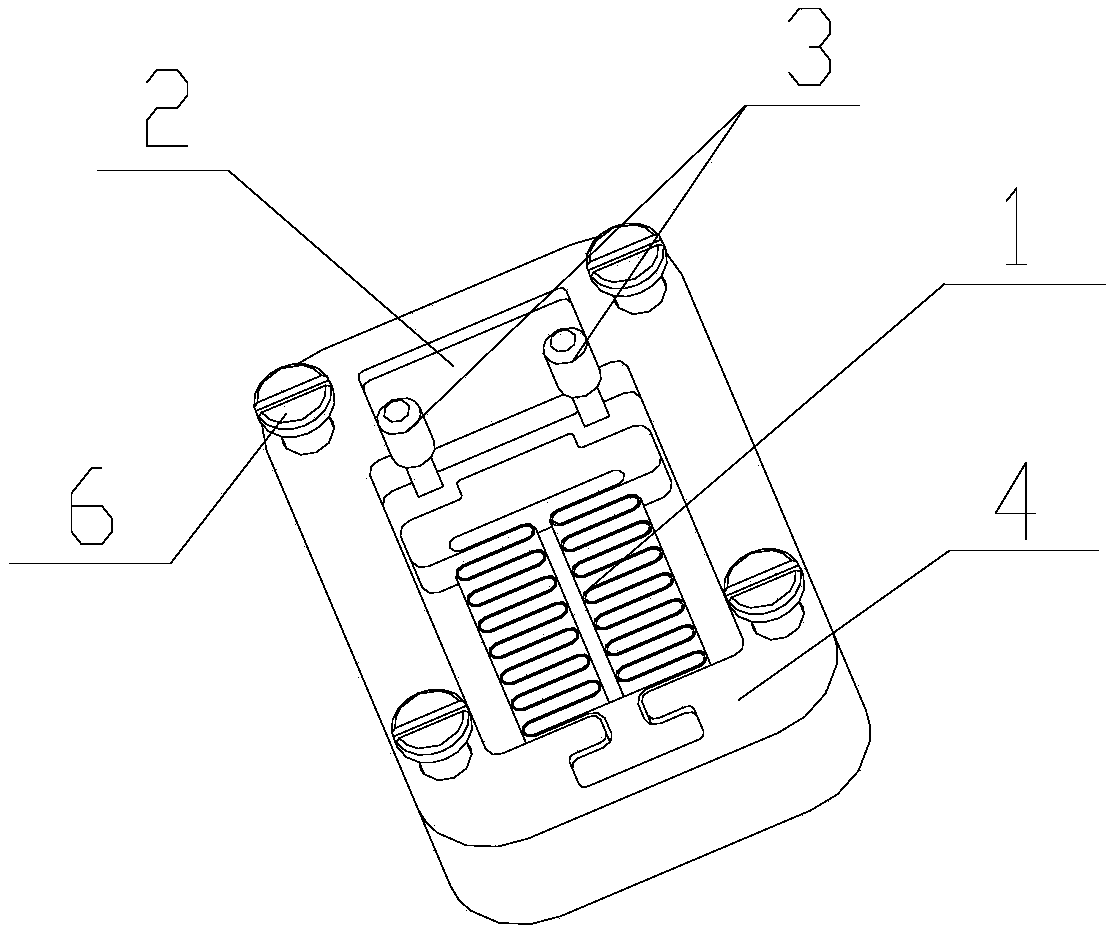

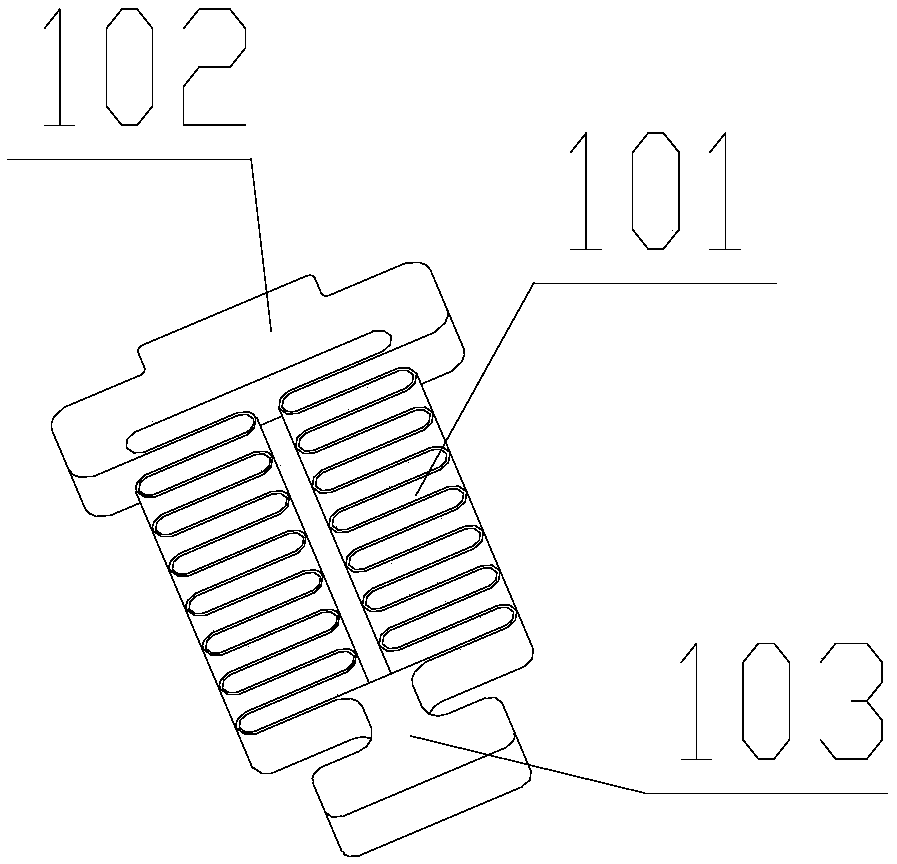

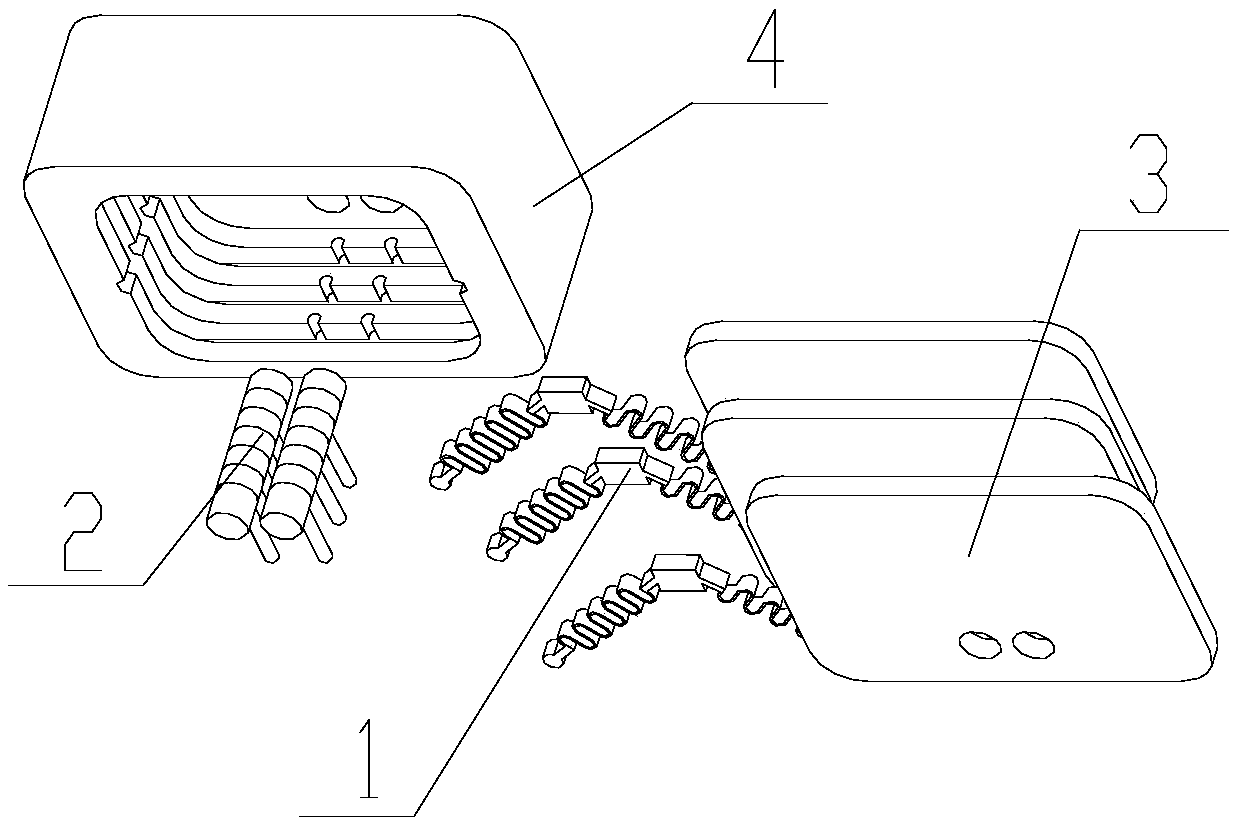

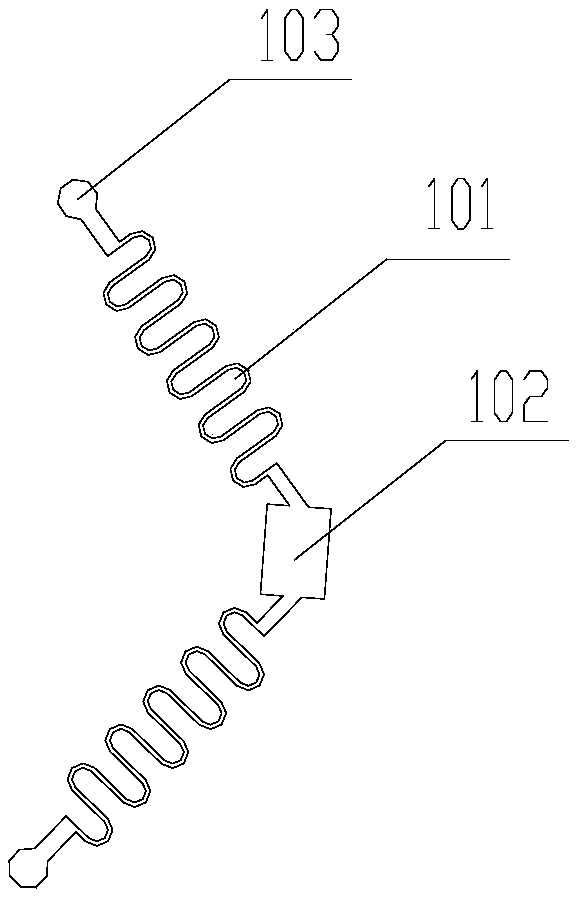

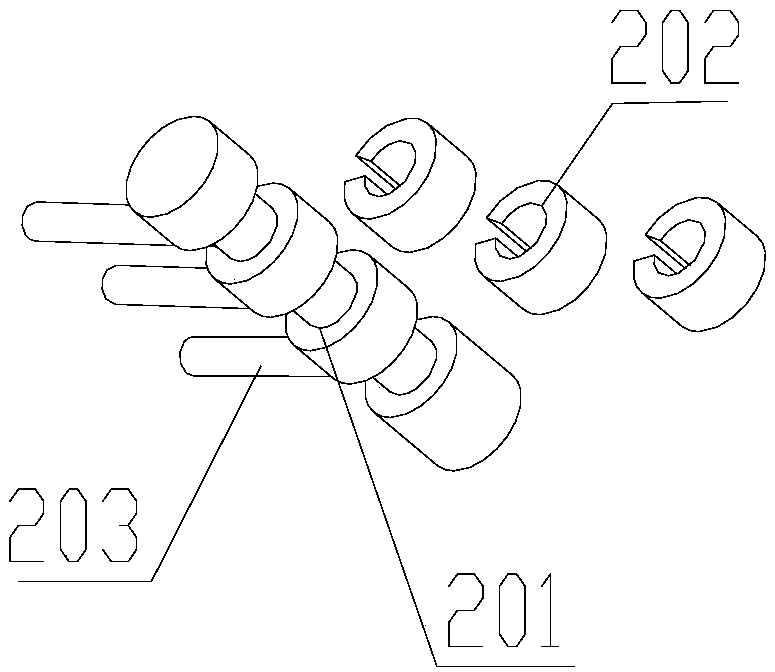

Planar multi-layer inertia switch

ActiveCN108807071AReduce volumeImprove product quality consistencyElectric switchesExternal circuitEngineering

The invention discloses a planar multi-layer inertia switch. The planar multi-layer inertia switch comprises a shell (4), a partition plate (3), a spring mass block (1) and electrode parts (2), wherein the partition plate (3) is arranged in a groove (402) in a matching way, the spring mass block (1) comprises a planar spring (101), a mass block (102) and a cylinder (103), the electrode parts (2) are arranged in through holes in the partition plate (3), and a wire (203) is welded with a groove part of each electrode part (2) and penetrates through a through hole (405) of the shell (4). In the planar multi-layer inertia switch, the spring mass block collides with the electrode parts along a sensitive direction of the spring mass block when external acceleration is applied to the inertia switch, so that connection and disconnection of an external circuit are achieved; and switch conversion under different overload threshold conditions can be achieved by adjusting a spring parameter and adjusting distance between the spring mass block and the electrode parts.

Owner:湖北三江航天红林探控有限公司

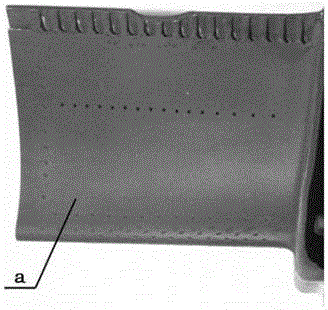

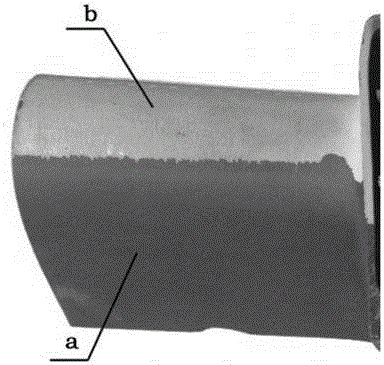

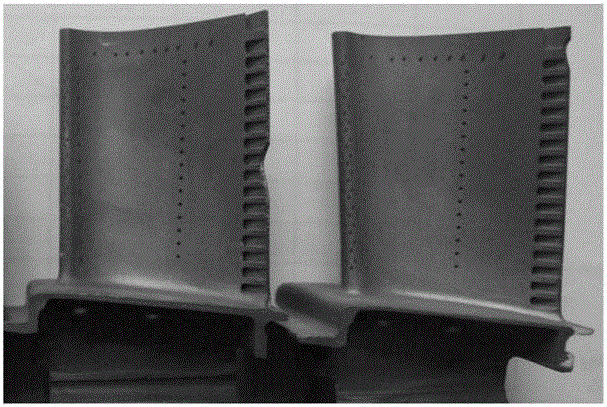

Compressor rotor blade body waviness processing technology and detection method

InactiveCN108080898AImprove product quality and product consistencyReduce workloadPolishing machinesMeasurement devicesSurface finishingEngineering

The invention relates to a compressor rotor blade body waviness processing technology and a detection method. The compressor rotor blade body waviness processing technology comprises the steps of using software for numerical-control modeling; locally optimizing a numerical-control model; compiling for completing a numerical-control program; using the compiled numerical-control program for processing; and finishing a blade body, and only carrying out surface finishing when using a polishing machine for polishing the blade body so as to improve the surface roughness. An equipment advantage of afive-axis numerical-control machining center is fully utilized, the allowance of the blade body is accurately controlled, zero-allowance machining is carried out, the allowance has no need to be removed by polishing, and only the blade body needs to be subjected to surface finishing, so that the profile tolerance and the waviness of five-axis numerical-control machining can be integrally remained,the product quality and the product consistency are improved, and the workload of a polishing process can be further greatly reduced; and meanwhile, a three-coordinate measuring machine is adopted for detecting the waviness, so that a detection result can be accurately and objectively fed back, visual comparison has no need to be carried out through a standard specimen, and the influence of a human factor on a measuring result is greatly reduced.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

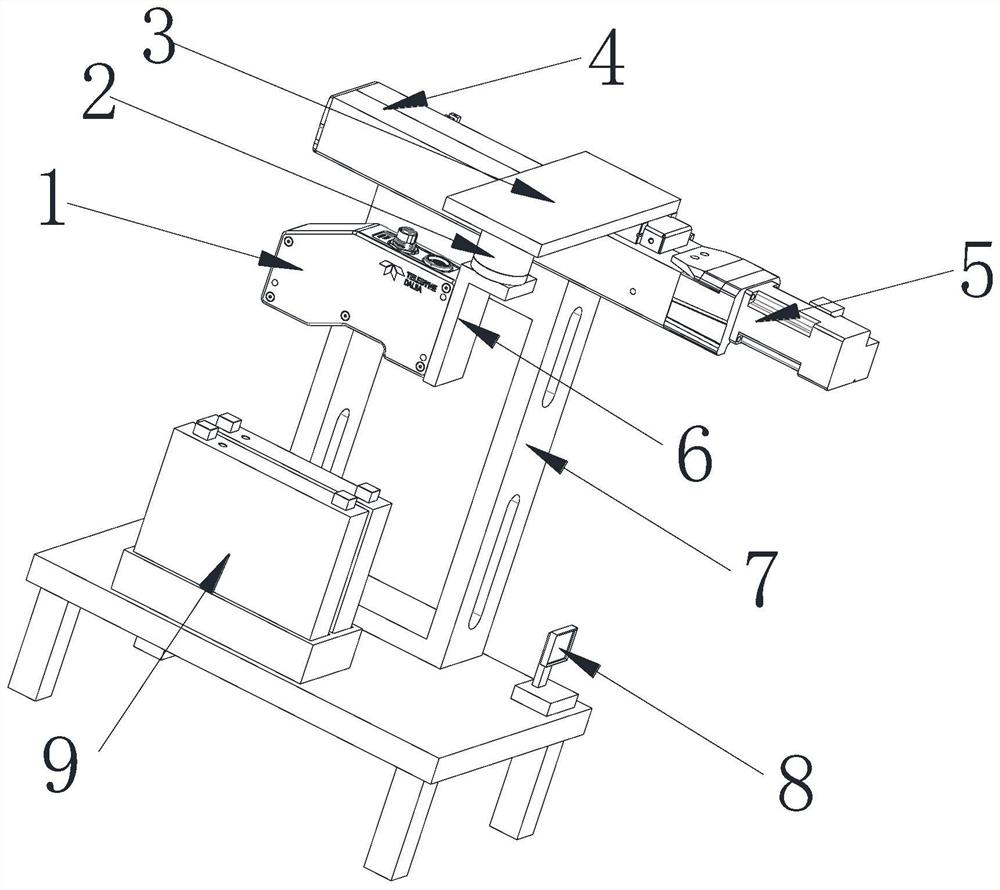

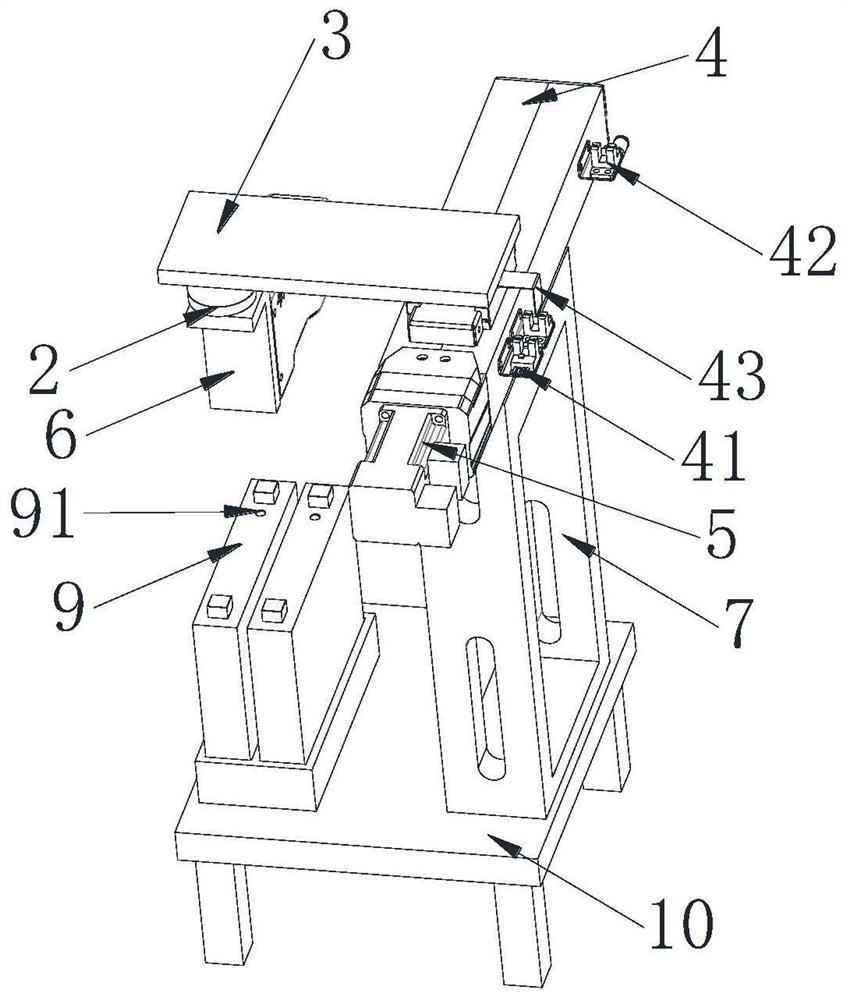

IC pin correction device and correction method

InactiveCN104284572AReduce work intensityAvoid injuryElectrical componentsEngineeringCorrection method

The invention provides an IC pin correction device which comprises a bottom plate piece support, a first shaft rod, a second shaft rod, a first bearing, a second bearing and a movable shaft sleeve movable piece. The movable shaft sleeve movable piece is adjustably arranged on the bottom plate piece support, the first shaft rod is arranged on the movable shaft sleeve movable piece, and the second shaft rod is arranged on the bottom plate piece support. The first bearing is arranged on the first shaft rod, the second bearing is arranged on the second shaft rod, and when a material transfer pipe containing ICs passes between the first bearing and the second bearing, IC pins are corrected. The invention further relates to a correction method of the IC pin correction device. According to the IC pin correction device and the correction method, the processing procedure is simplified, processing efficiency is improved, product quality consistency is improved, the work intensity of operators is obviously reduced, the operators are prevented from being hurt, and the safety of the IC pin correction device and the correction method is increased.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com