DC permanent magnet motor stator assembling machine

A permanent magnet motor and stator group technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of poor product quality consistency, low production efficiency, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

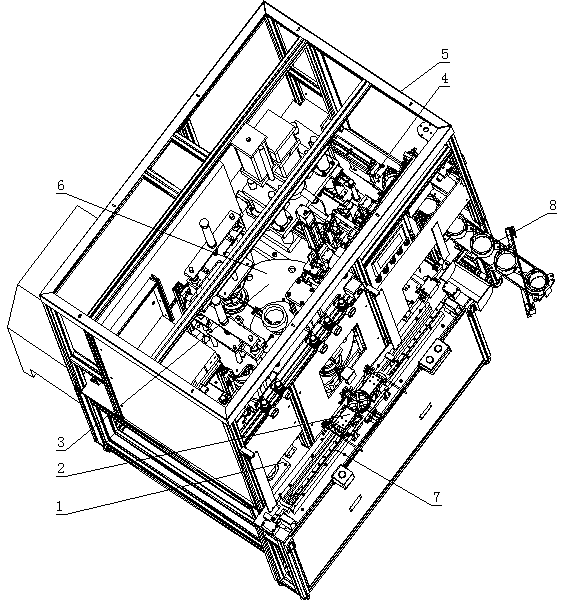

[0039] Such as figure 1 As shown, a DC permanent magnet motor stator assembly machine includes a frame 5, and also includes:

[0040] Gluing device 1 is used to glue the casing;

[0041] The first assembly device 2 is used to realize the installation of the magnetic tile on the magnetic tile frame;

[0042] The second assembly device 3 is used to realize the assembly of the magnetic tile frame and the casing;

[0043] The magnetizing device is used to realize the magnetization of the magnetic tile;

[0044] A detection device is used to realize the detection of the residual magnetism of the magnetic tile;

[0045] Riveting device, used to realize the installation of riveting screws on the stator;

[0046] The output device 4 is used to output the riveted stator;

[0047] The transfer device is used to transfer the casing on the gluing device 1 and the magnetic tile frame that has completed the installation of the magnetic tiles to the second assembly device 3. After the a...

Embodiment 2

[0051] The present embodiment is further limited on the basis of embodiment 1, as figure 1 As shown, as a specific implementation form of the transmission device: the transmission device includes a linear transmission part and a circular transmission part;

[0052] The first assembly device 2 includes a clamp for clamping the magnetic tile rack, the clamp is installed on the linear transmission part, and under the action of the linear transmission part, the magnetic tile rack can perform linear motion;

[0053] The circular transfer part includes a turntable 6 and a casing clamping station arranged on the turntable 6;

[0054] The second assembling device 3 , magnetizing device, detecting device, and riveting device are sequentially arranged circularly around the turntable 6 , and during the rotation of the turntable 6 , the casing is completed in the second assembling device 3 , magnetizing device, detecting device, Transfer between riveting devices. This scheme provides a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com