Rolling production method for integral aluminum alloy ring of super-large diameter

A technology with super-large diameter and production method, applied in the direction of metal rolling, etc., can solve the problems of weakened ring rigidity, large cross-section change, sticking rollers, etc., to improve the consistency of product quality, improve product qualification rate, and meet the requirements of technical indicators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A ring rolling billet with an outer diameter of 3965 mm, an inner diameter of 3224 mm and a height of 575 mm was prepared by free forging. After turning and passing the flaw detection inspection, it was placed in an electric furnace and heated with the furnace at a heating temperature of 445 °C and a holding time of 12 hours.

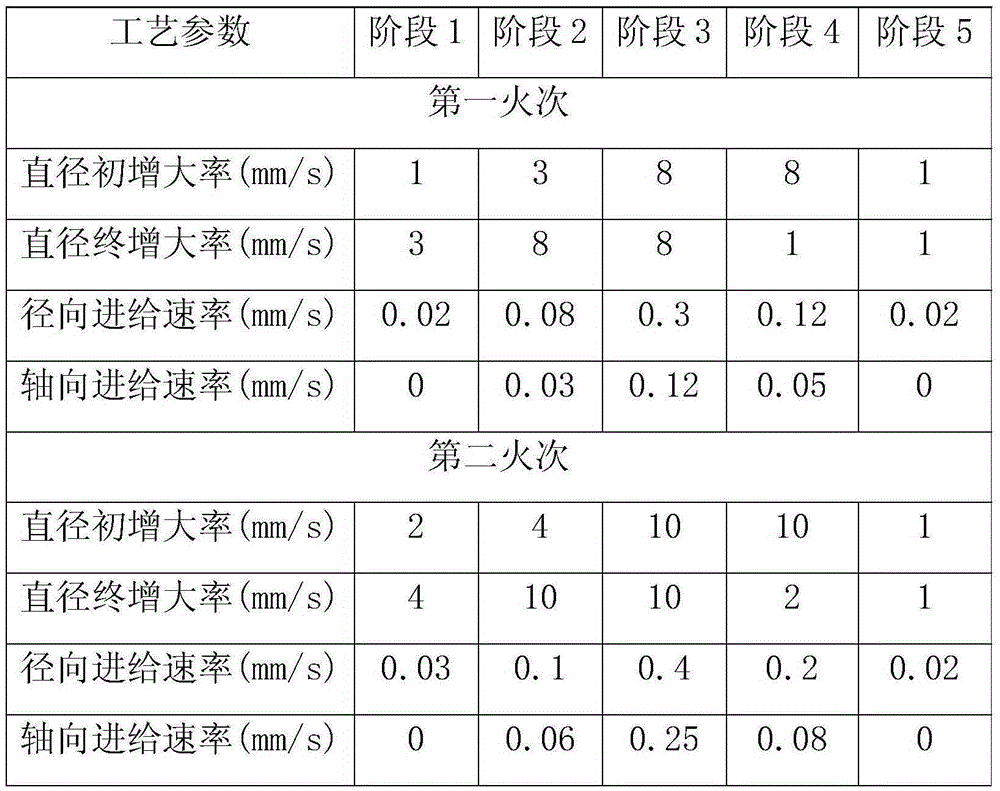

[0068] Transfer the heated ring rolling billet to the ring rolling mill and use the Φ500mm core roll for the first fire ring rolling. The ring is rolled to an outer diameter of 5130mm and a height of 510mm, and then it is returned to the furnace for heat preservation. The heat preservation temperature is 446°C and the heat preservation time is 2.1h; The Φ800 core roll is used for the second fire ring rolling. The rolling process parameters are shown in the table below. The ring is rolled to an outer diameter of 8760mm, an inner diameter of 8379mm and a height of 470mm. The rolling process parameters are shown in the table below.

[0069]

[007...

Embodiment 2

[0072] The ring rolling billet with an outer diameter of 4100mm, an inner diameter of 3300mm and a height of 550mm is cleaned and inspected for flaws, and then placed in an electric furnace to be heated with the furnace at a heating temperature of 440°C and a holding time of 12.2h.

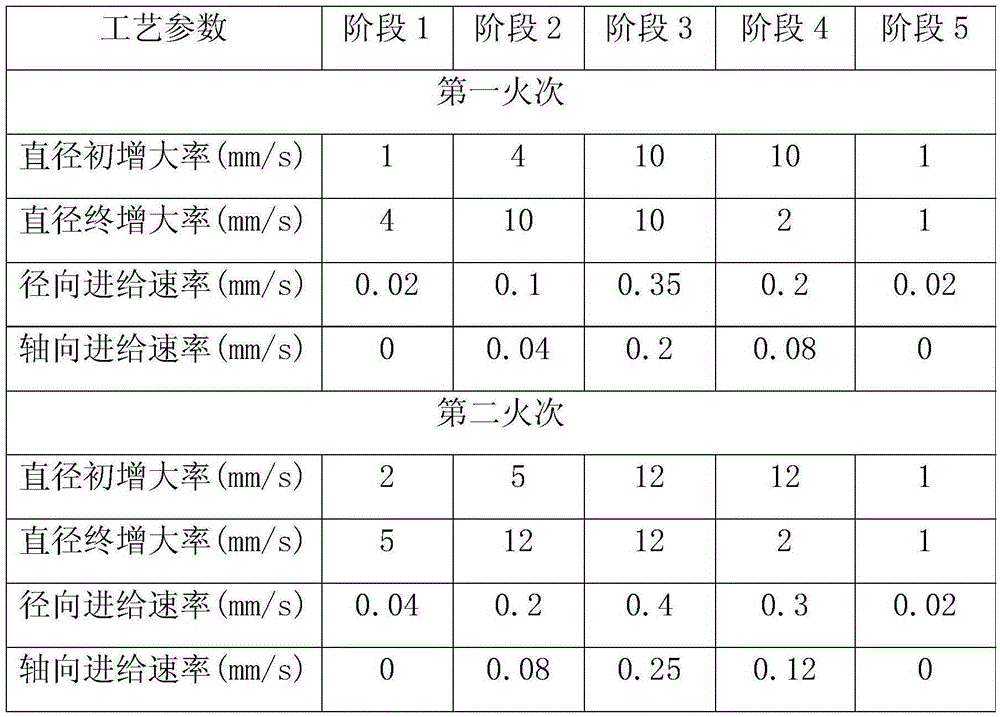

[0073] Transfer the heated ring rolling blank to the ring rolling mill and use the Φ500mm core roll for the first fire ring rolling, rolling the ring to an outer diameter of 5800mm and a height of 500mm, and then return it to the furnace for heat preservation at a heat preservation temperature of 446°C and a heat preservation time of 2.1h; The Φ800 core roll is used for the second fire ring rolling. The rolling process is shown in the table below. The ring is rolled to an outer diameter of 9205mm, an inner diameter of 8812mm and a height of 460mm. The rolling process parameters are shown in the table below.

[0074]

[0075] After size measurement, the roundness of the ring is 35mm, which is les...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com