Precision gear, its gear mechanism and production method of precision gear

A manufacturing method and technology of gear mechanism, applied in the direction of gear mechanism, mechanically driven clock, components with teeth, etc., can solve problems such as operability and easy assembly, achieve defect-free reliability, suppress microscopic loss, The effect of uniform pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment L

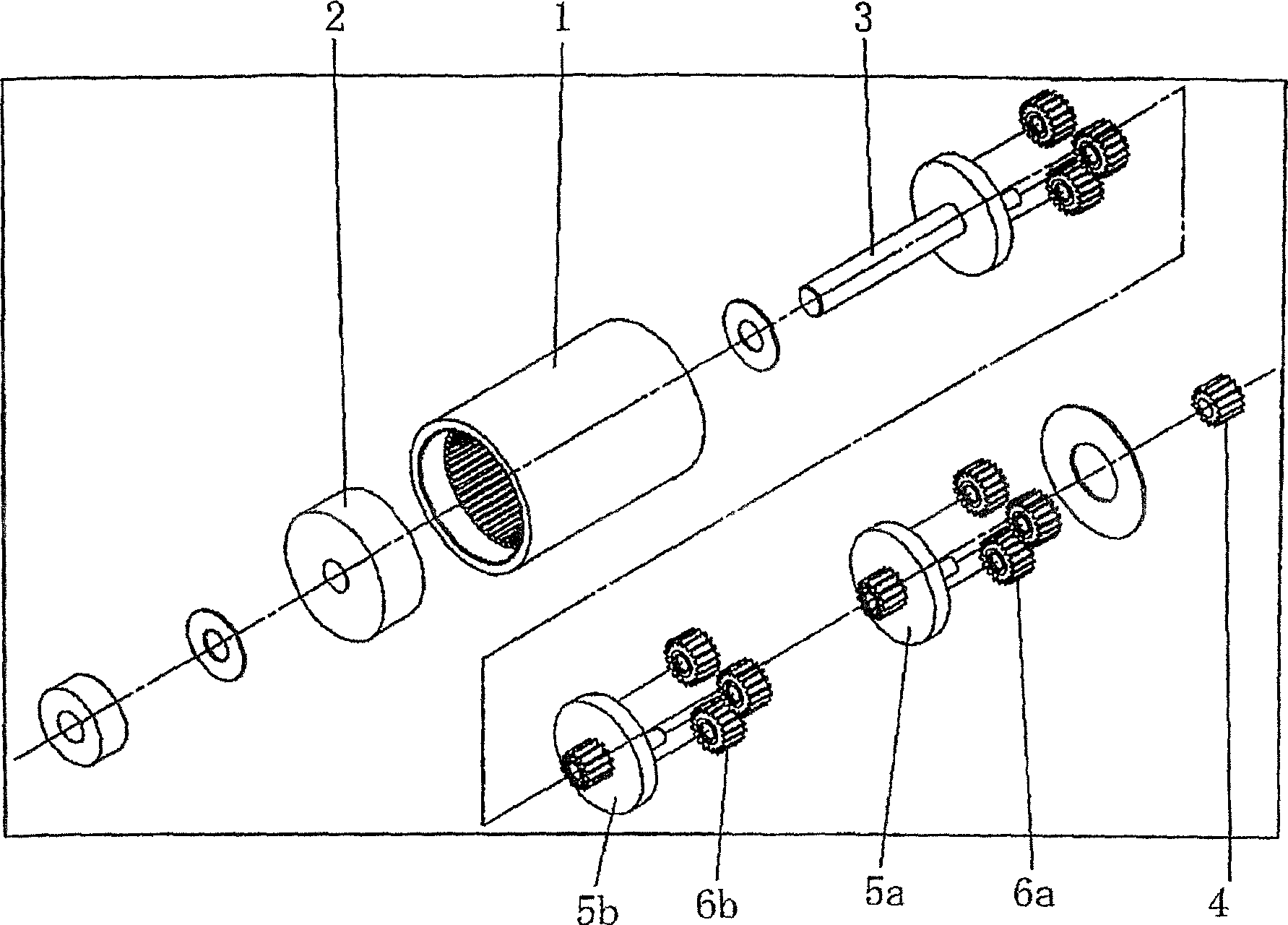

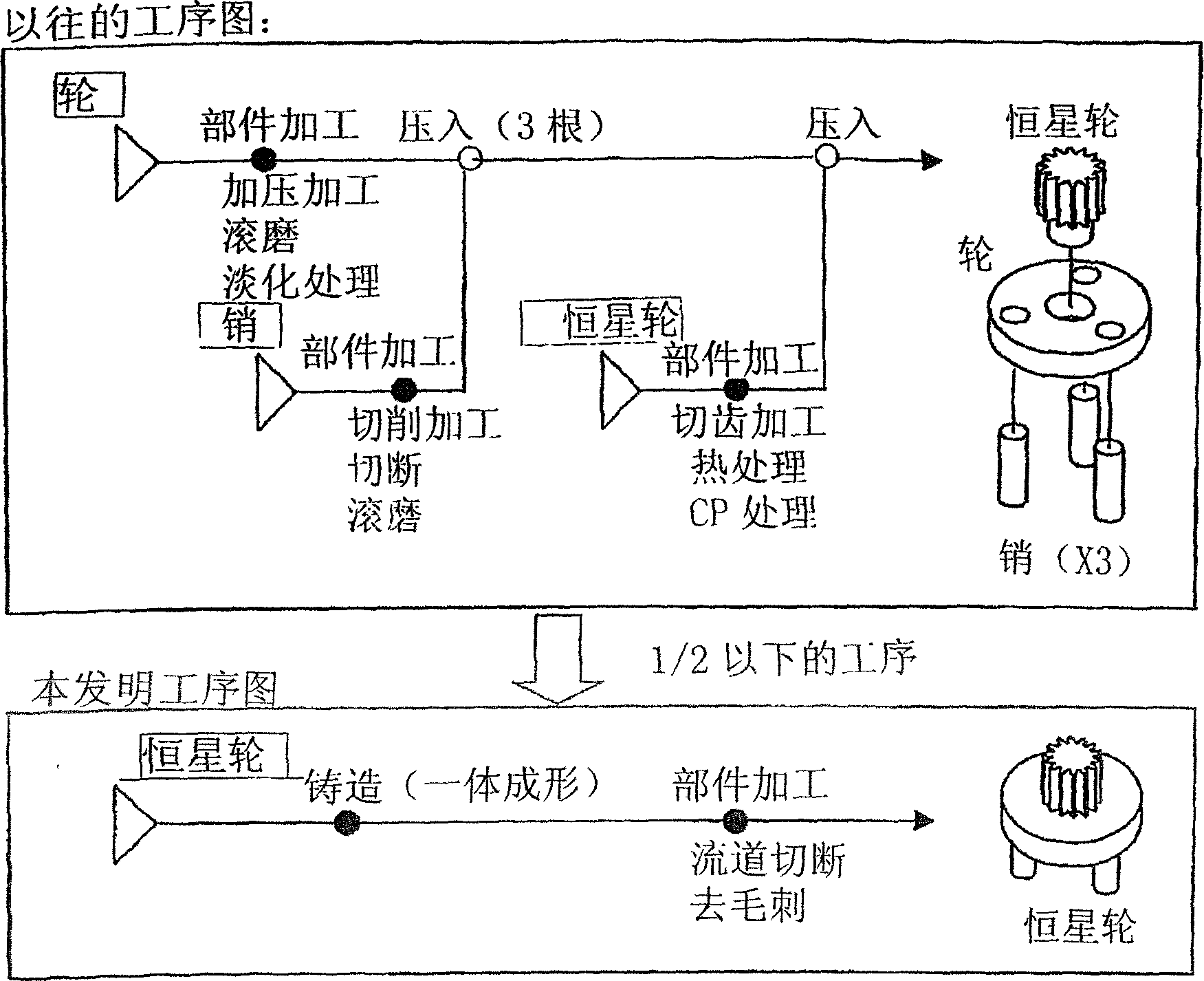

[0072] Examples L and M are examples in which precision gears containing Cu as the main component are formed. In the present invention, the maximum elongation is exhibited, and it is possible to form a precision gear having a tensile strength of 1850 MPa or more exceeding 1500 MPa of conventional materials. In particular, the elongation limit of Example L was very high at 3.9%, and a precision gear with the best damage resistance in the present invention was obtained. As a result, a gear mechanism with extremely high reliability against destructive operation defects can be obtained. Figure 5 This is a side enlarged photograph of the integrated stellar wheel L obtained by a scanning electron microscope. 7 is a sun gear, 8 is a pallet, and 9 is 3 shafts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com