Integral riveting tool for I-shaped automobile thrust rod body and riveting method of integral riveting tool

A technology for riveting tooling and thrust rods, applied in vehicle parts, transportation and packaging, etc., can solve the problems of difficult distance to meet design requirements, low processing efficiency, etc., to achieve good product consistency, improve processing efficiency, and ensure dimensional accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

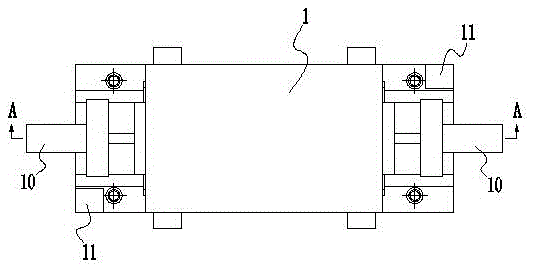

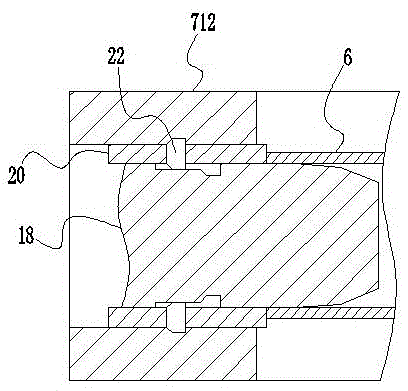

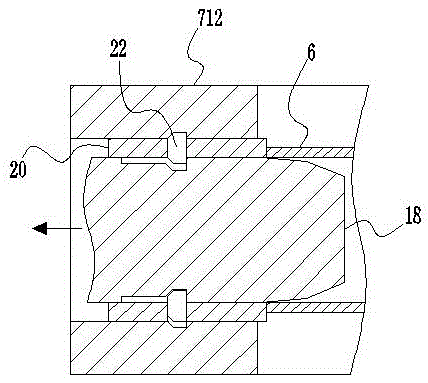

[0045] Example: such as Figure 1 to Figure 4As shown, a type I automobile thrust rod body integral riveting tooling, including the upper mounting plate 1 installed on the upper platen (not shown in the figure) of the press, and the upper platen 1 installed on the lower platen (not shown in the figure) of the press The lower mounting plate 2, the two upper riveting dies 3 arranged on the upper mounting plate 1, the two lower riveting dies 4 matched with the upper riveting die 3 arranged on the lower mounting plate 2 and the The floating plate 5 between the upper mounting plate 1 and the lower mounting plate 2, the overall riveting tooling of the I-type automobile thrust rod body also includes two balls for placing the ball head 6 that are slidably connected on the floating plate 5 Head slide 7, two equal-height blocks 9 for placing pipe body 8 arranged on the floating plate 5; two slide power cylinders 10 are fixedly connected on the floating plate 5, the two The piston rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com