Patents

Literature

30results about How to "Guaranteed assembly strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

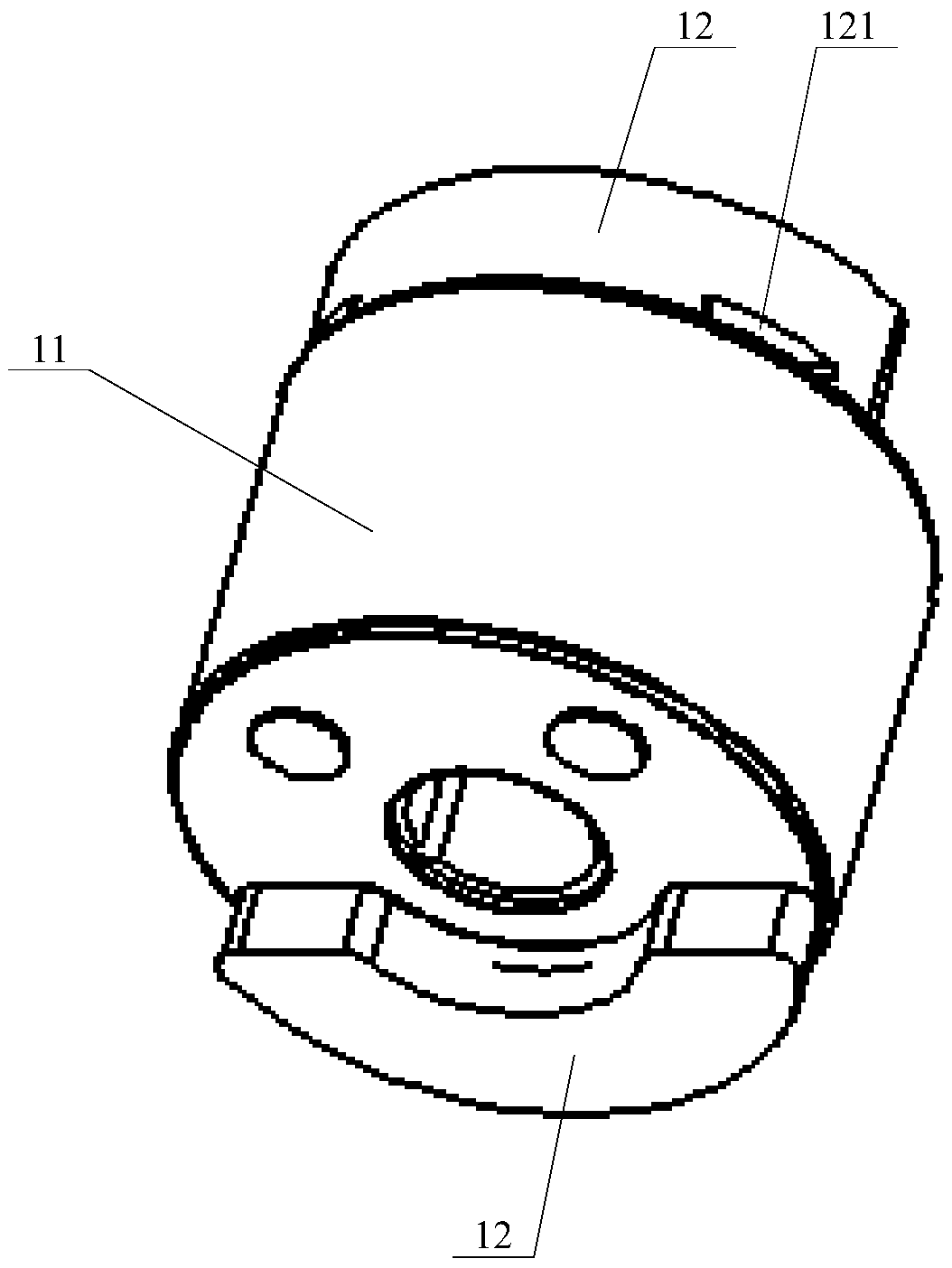

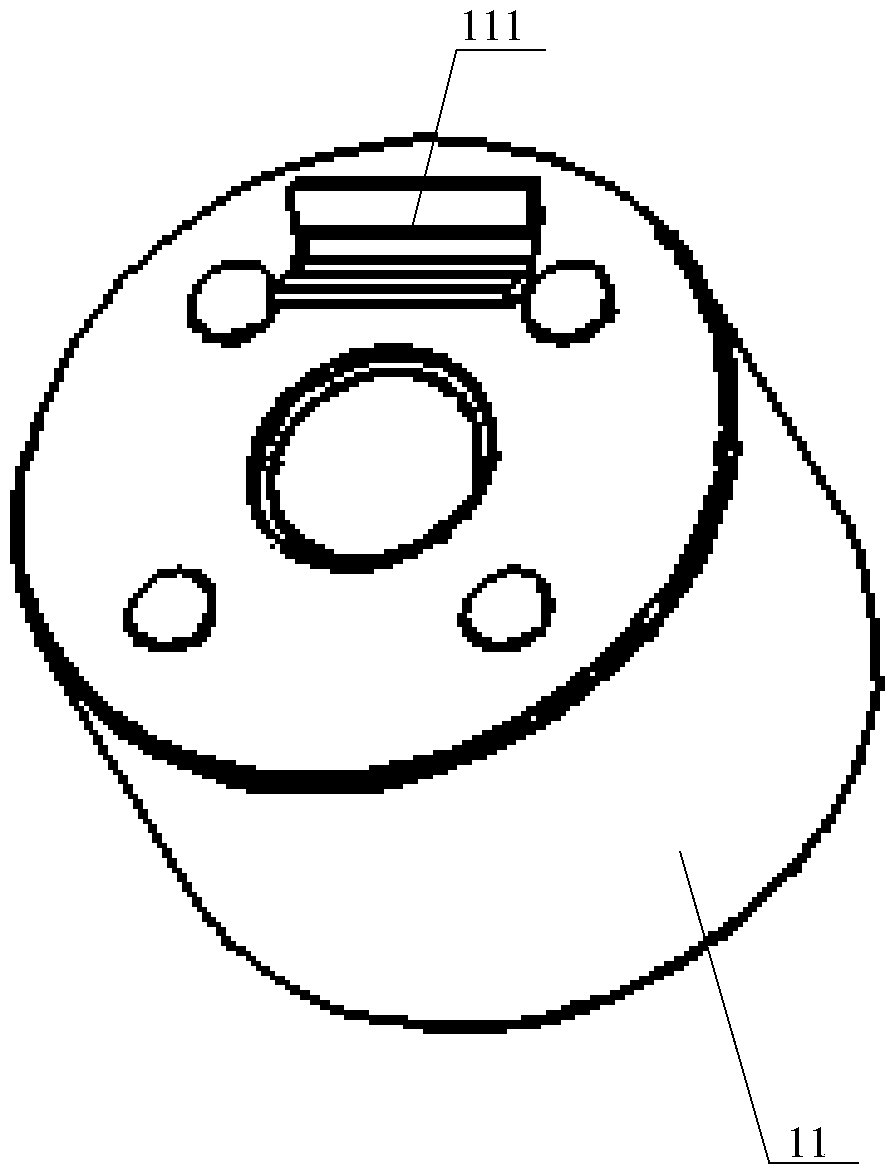

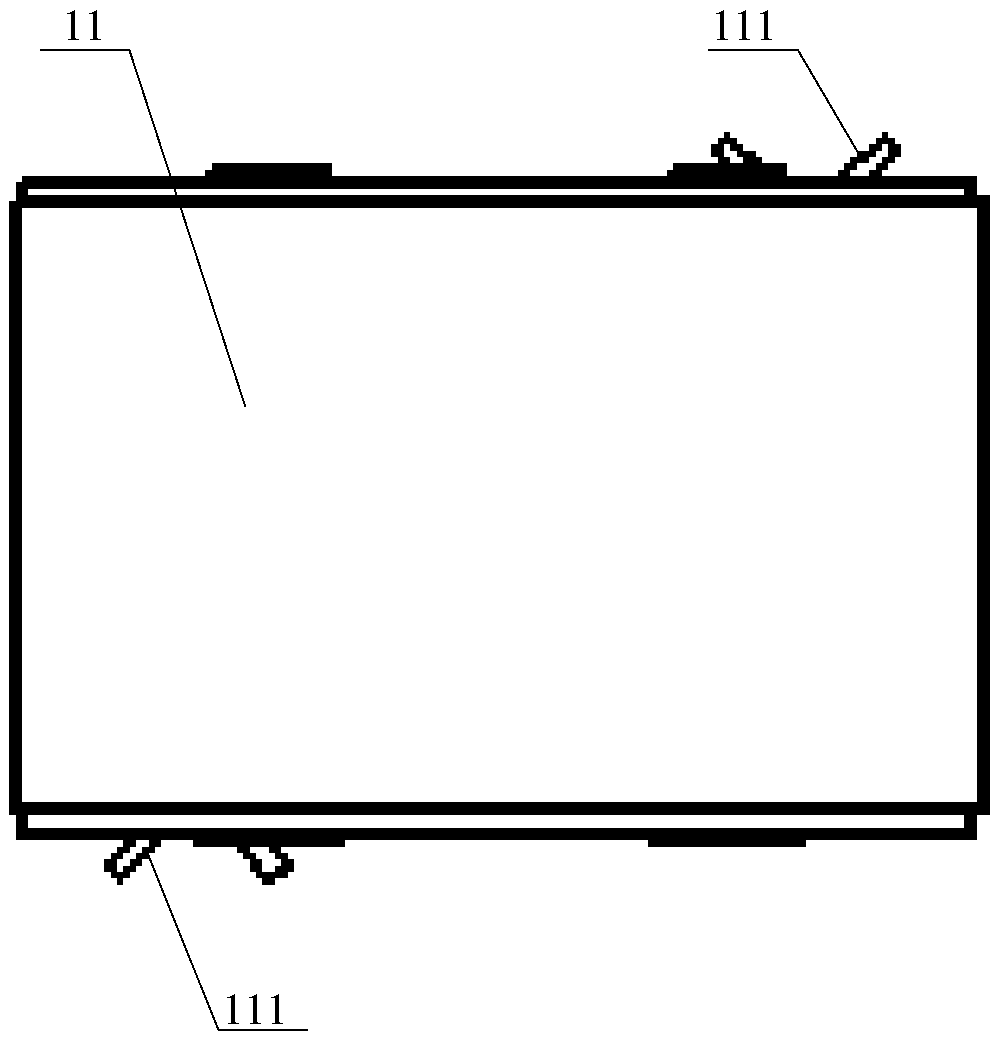

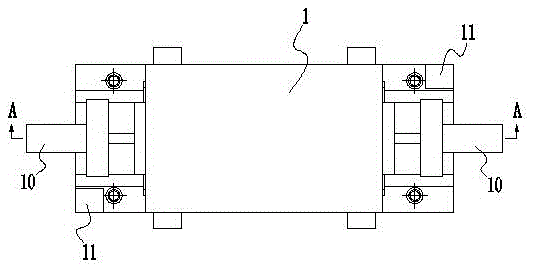

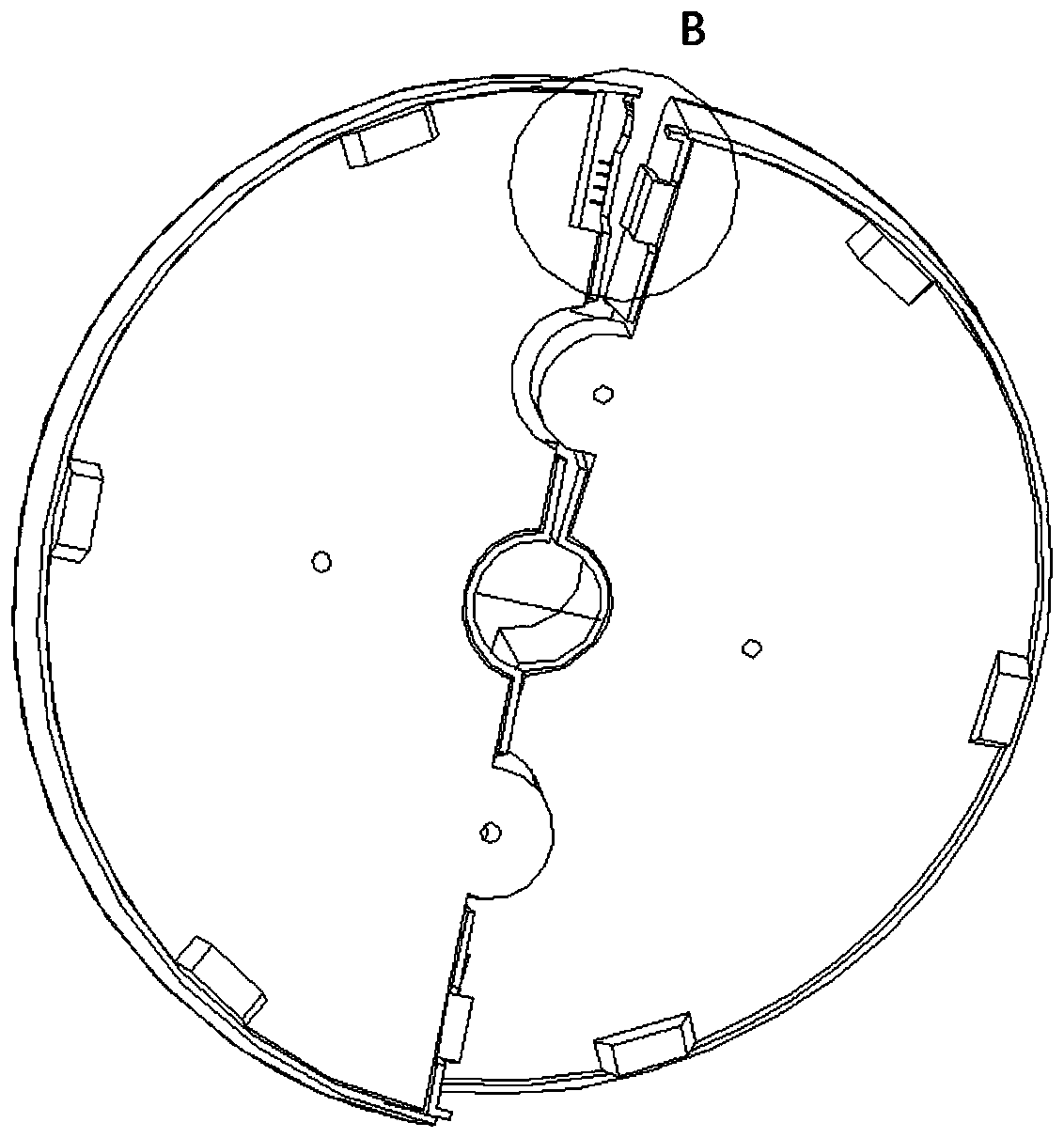

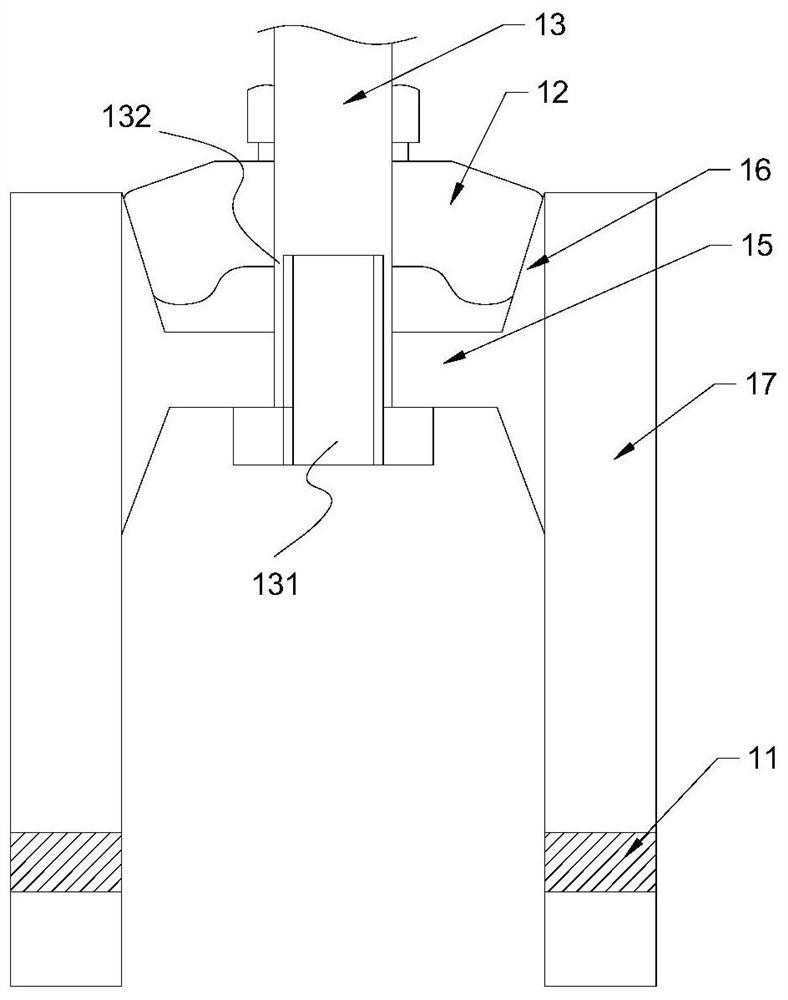

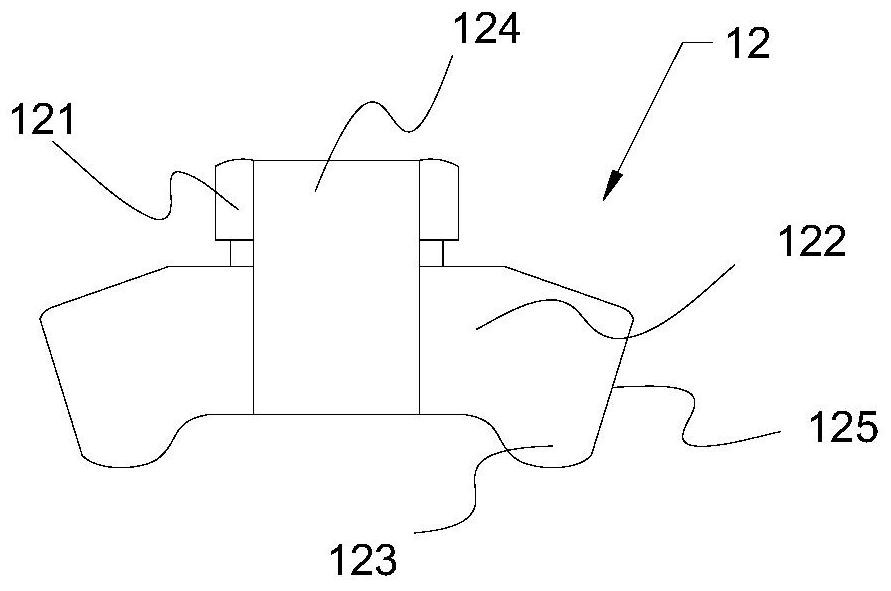

Motor and rotor assembly thereof

InactiveCN105515310AFew structural componentsThe overall structure is simpleCentering/balancing rotorsFastenerEngineering

The invention discloses a rotor assembly. The rotor assembly comprises a rotor body and a balance block which are matched with each other. The two ends of the rotor body are both provided with a clamp. The balance block is provided with clamping grooves matched with the clamps in a connected mode. In the assembling and using process, reliable assembly between the balance block and the rotor body is achieved through clamping connection between the clamps and the clamping grooves, and therefore the assembly strength of the whole assembly can be guaranteed under the condition that rivets and other auxiliary fasteners are not needed to be additionally arranged, structural components of the rotor assembly are remarkably reduced, the overall structure of the rotor assembly is simplified, and the assembly efficiency of the rotor assembly is improved; meanwhile, the clamps and the clamping grooves are matched and are consistent in specification, the assembly structure adaptability between balance blocks in different specifications and the rotor body and component universality are greatly improved, and the work condition adaption capacity of the components is improved. The invention further discloses a motor provided with the rotor assembly.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

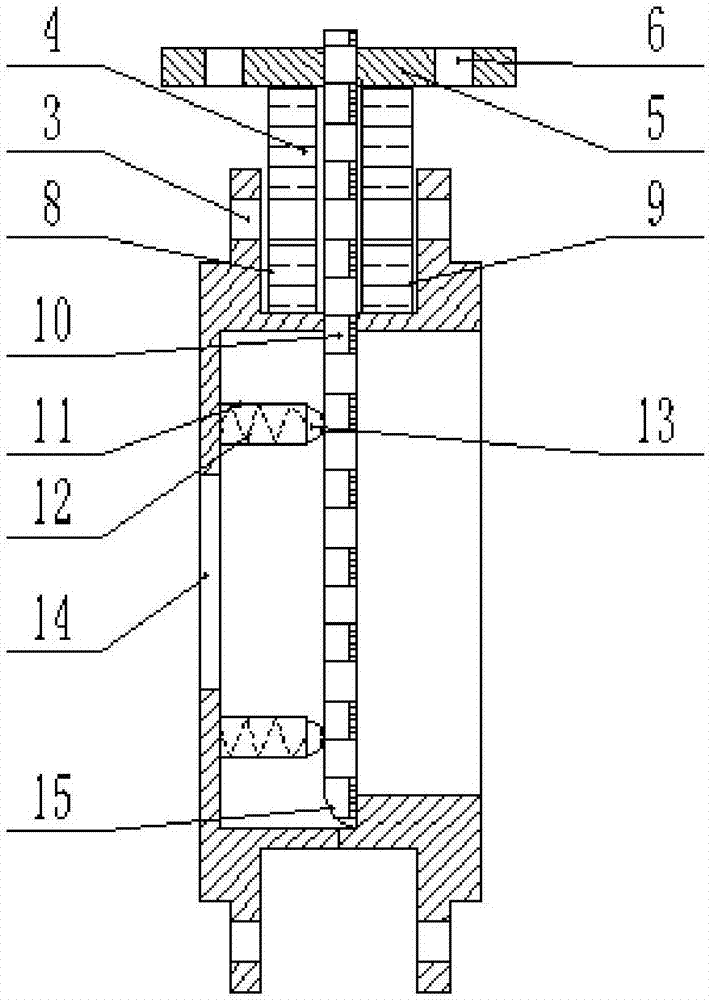

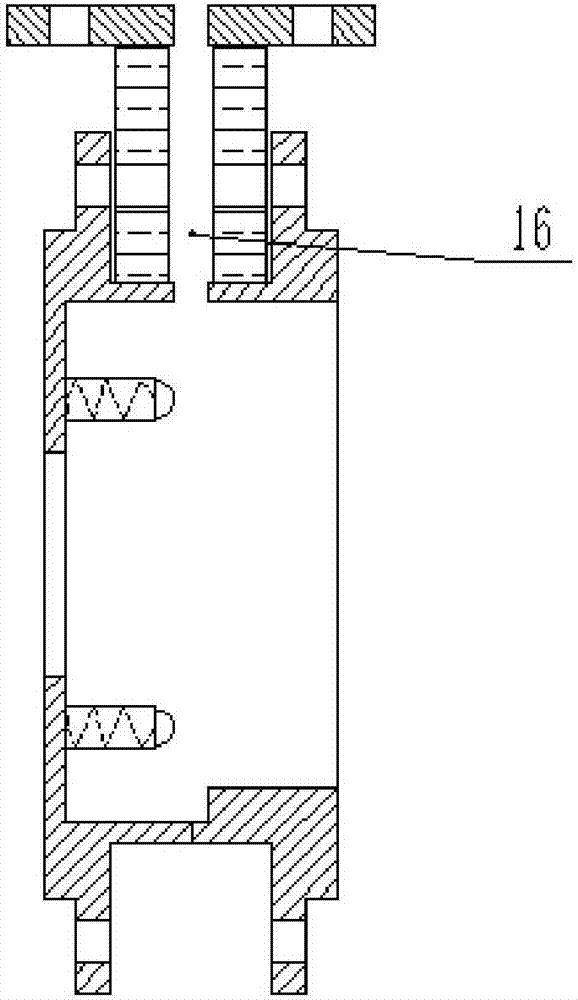

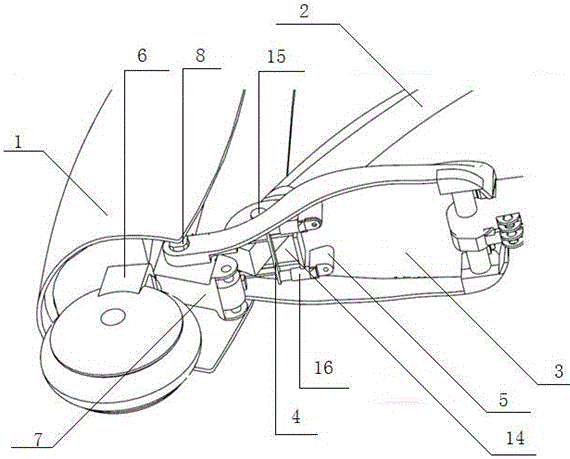

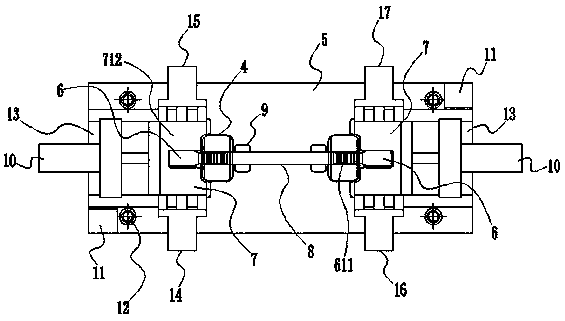

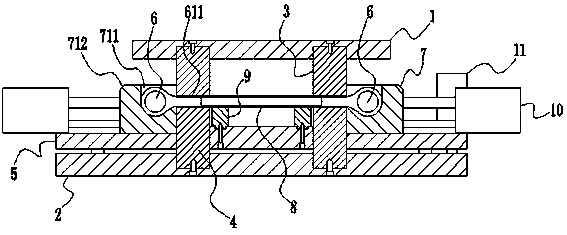

Integral riveting tool for I-shaped automobile thrust rod body and riveting method of integral riveting tool

ActiveCN106670327AAvoid the phenomenon of axial extensionGuaranteed processing efficiencyVehicle componentsHydraulic cylinderEngineering

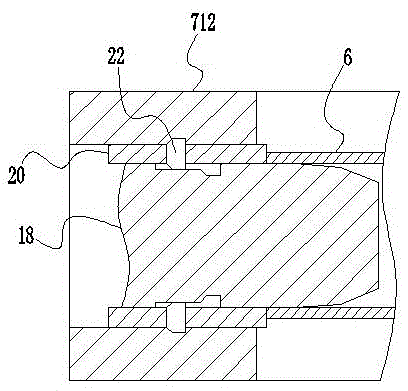

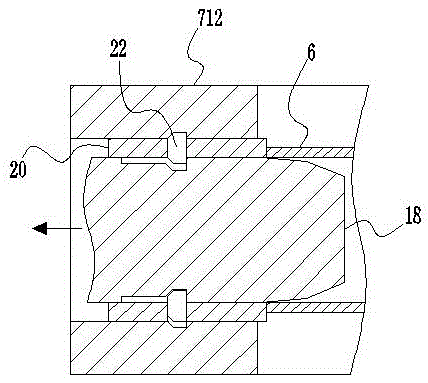

The invention discloses an integral riveting tool for an I-shaped automobile thrust rod body and a riveting method of the integral riveting tool. The tool comprises an upper installing plate, a lower installing plate, a floating plate, upper riveting dies and lower riveting dies, wherein the upper riveting dies and the lower riveting dies are arranged on the upper installing plate and the lower installing plate correspondingly, and the two upper riveting dies and the two lower riveting dies are arranged. The tool further comprises two ball head sliding bases connected to the floating plate in a sliding manner, and two equal-height blocks arranged on the floating plate. Two sliding base power cylinders are further fixedly connected to the floating plate. Under driving of the two sliding base power cylinders, the two ball head sliding bases can move close to each other or away from each other relatively along the floating plate. The two ball head sliding bases can drive two ball heads to be connected to the two ends of a pipe in a sleeving manner. The floating plate is further provided with a vertical power cylinder, the lower riveting dies penetrate the floating plate, the floating plate can move back and forth in the vertical direction under the action of the vertical power cylinder, and hydraulic cylinders or air cylinders are adopted as the sliding base power cylinders and the vertical power cylinder. Through the integral riveting tool and the riveting method, the quality of the thrust rod body is guaranteed, and integral riveting can be finished at a time.

Owner:BOGE RUBBER&PLASTICS ZHUZHOU CO LTD

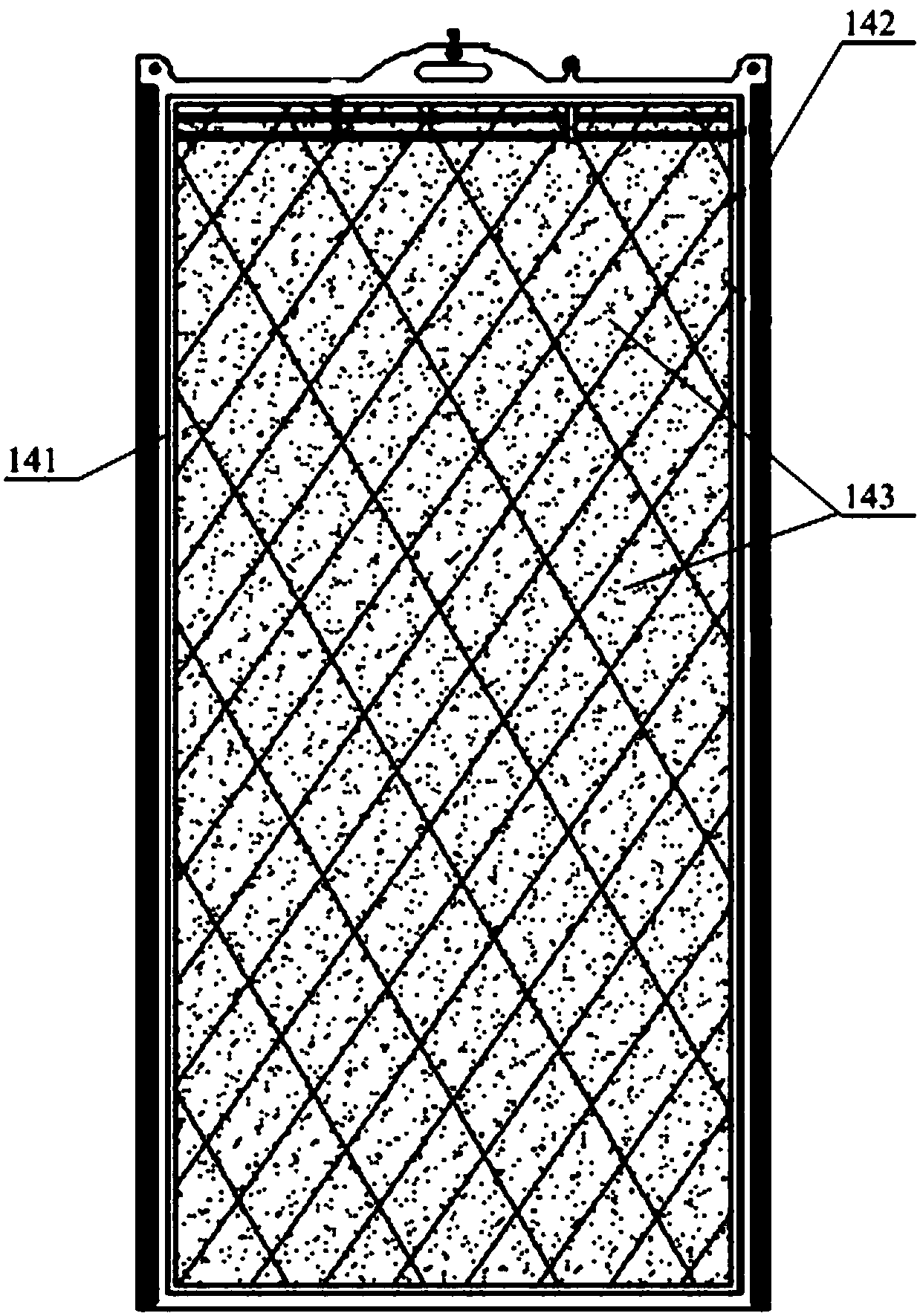

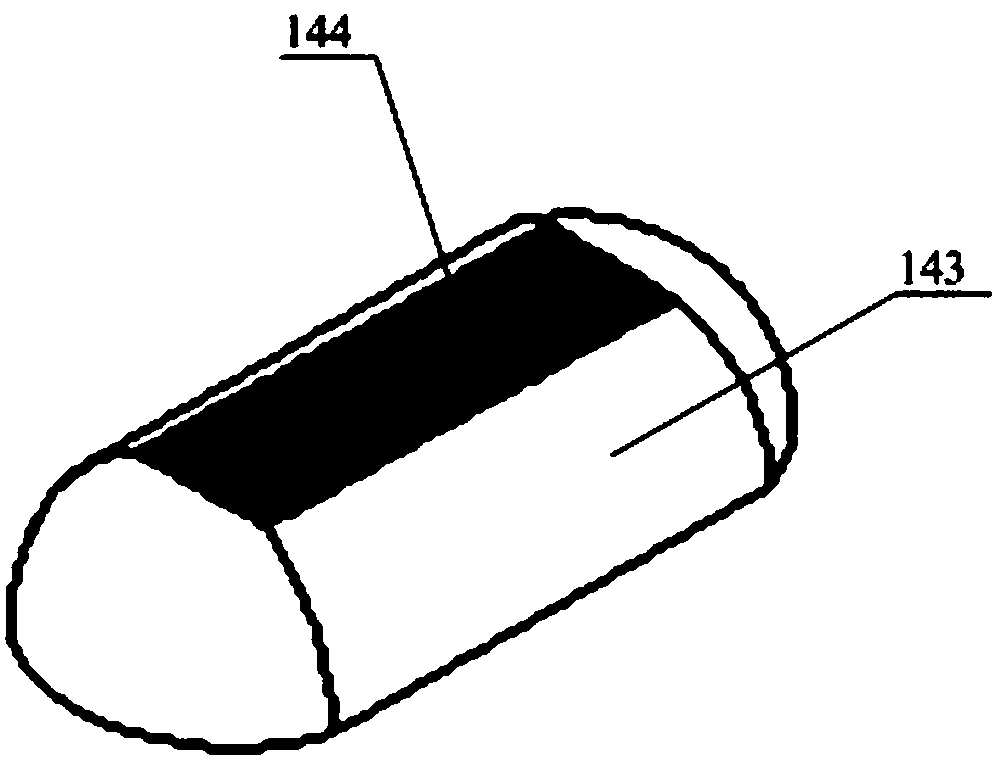

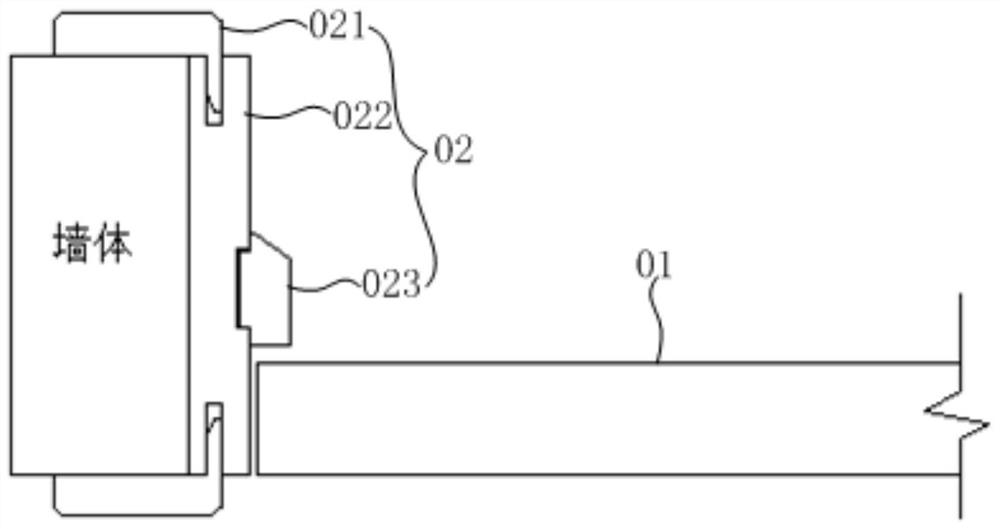

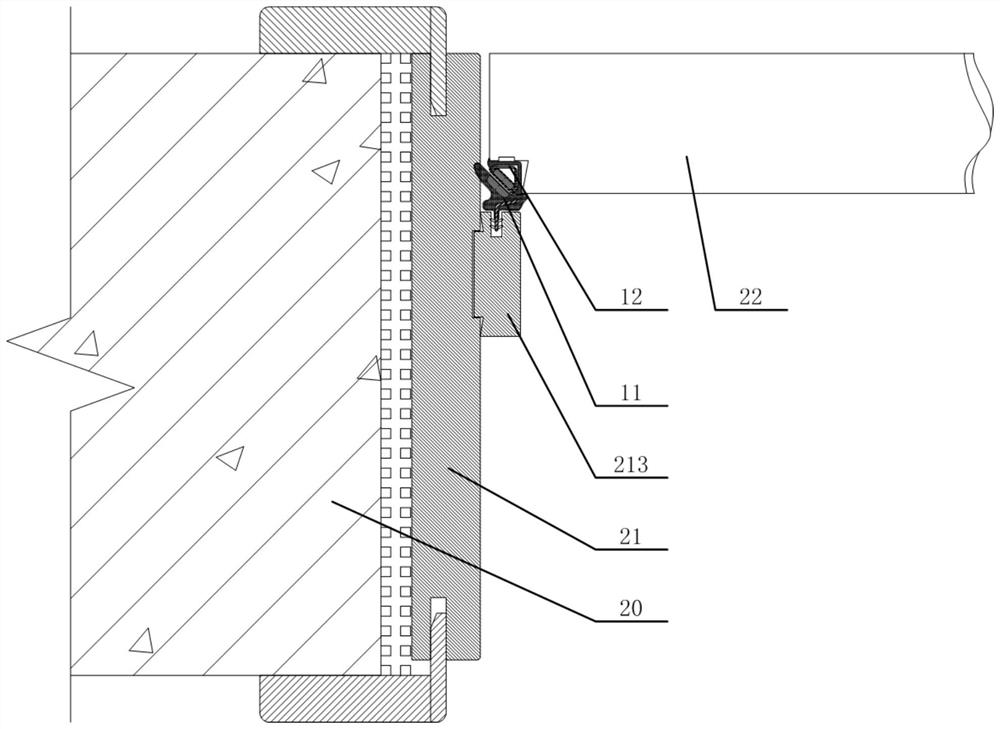

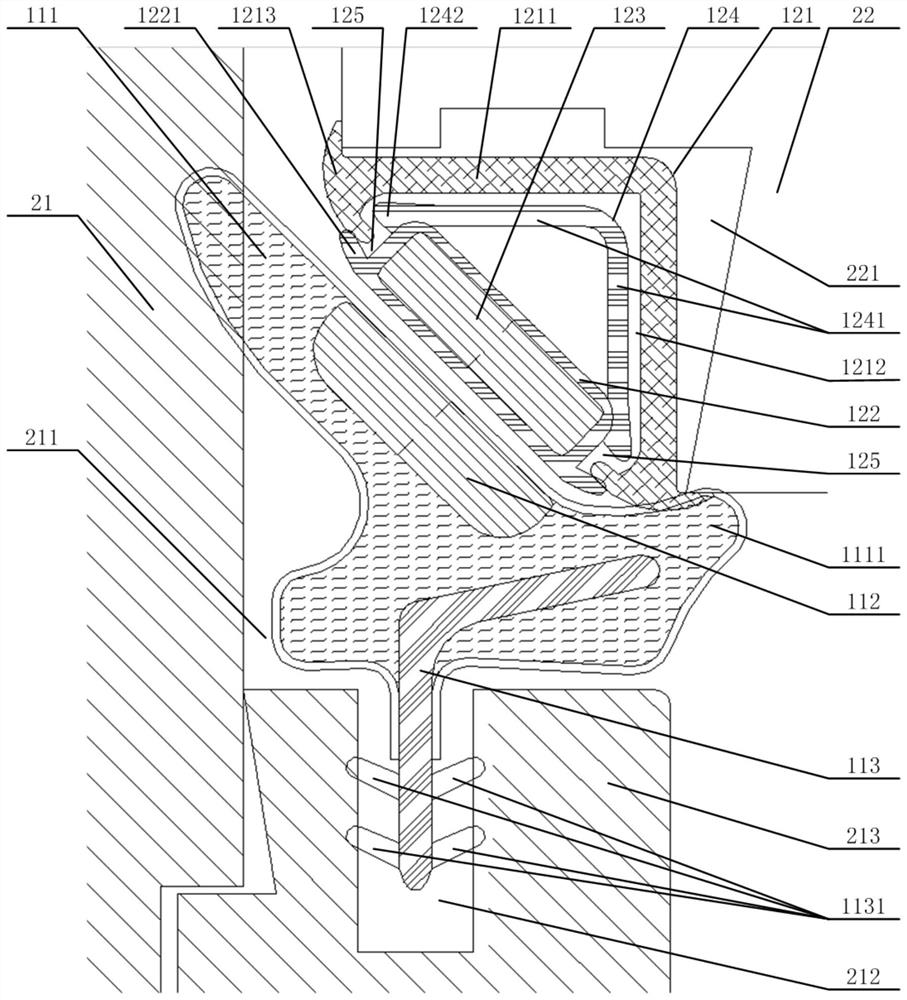

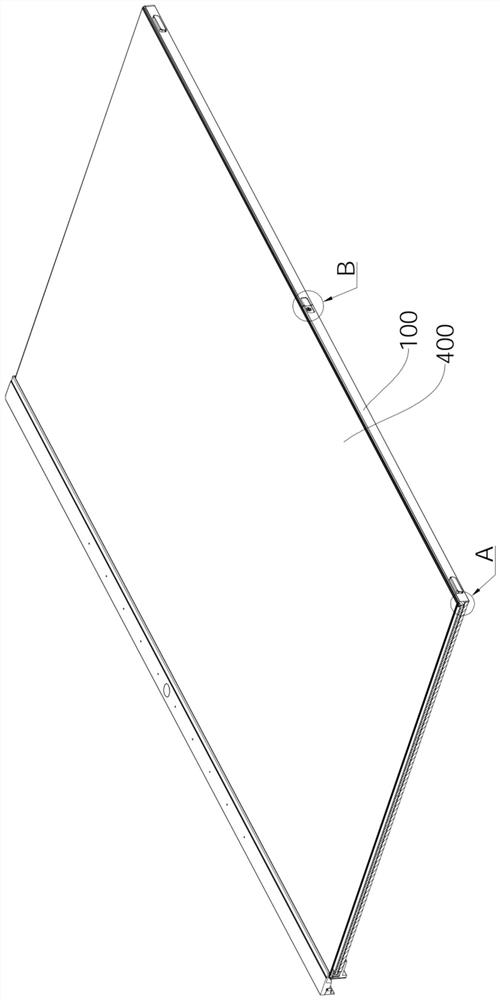

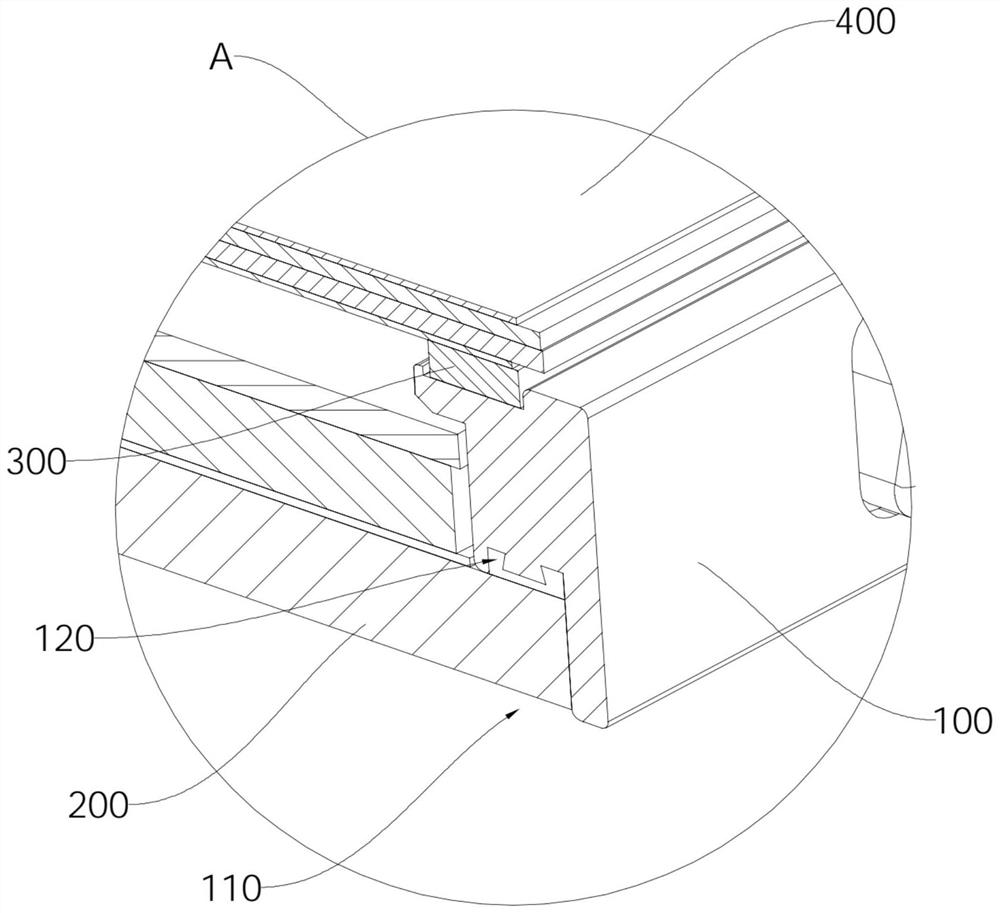

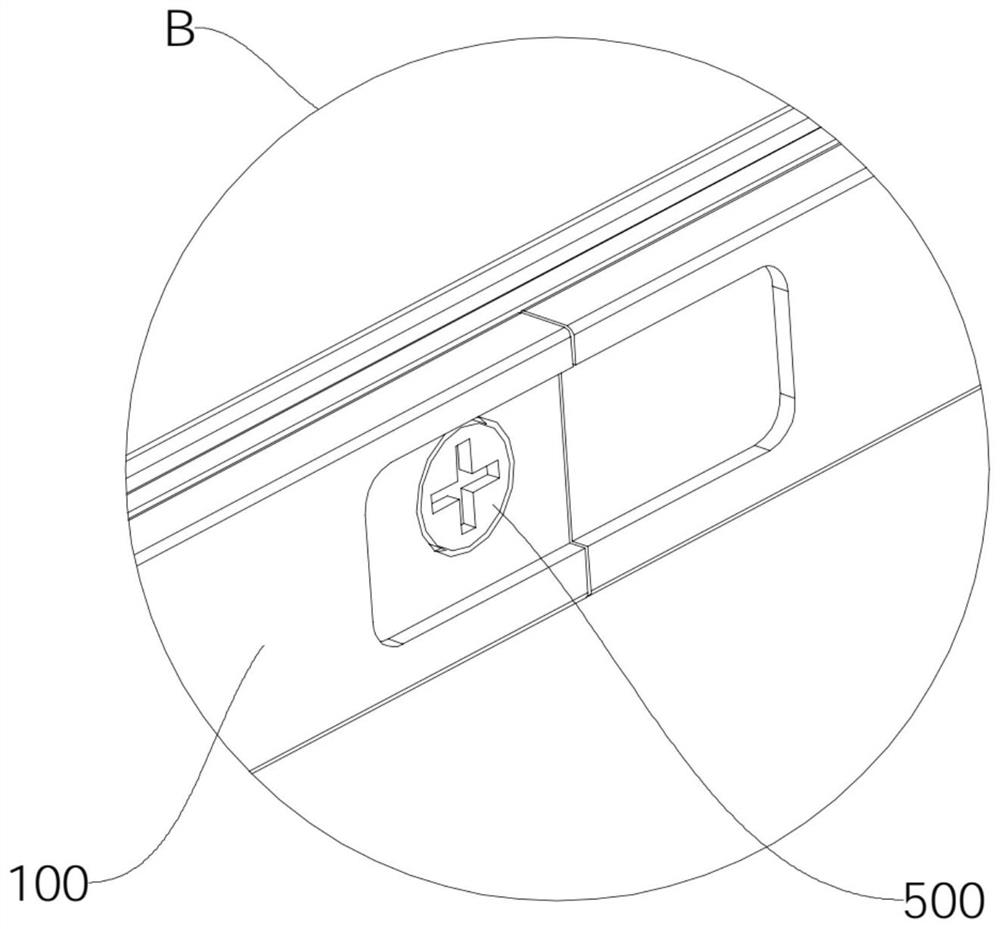

Building glass curtain wall

ActiveCN109736497AGuaranteed assembly strengthEasy to assemble and disassembleWallsArchitectural glassEngineering

The invention discloses a building glass curtain wall. The device comprises one or more supporting stand columns arranged side by side. The supporting stand columns are hollow stand columns. A closedhollow cavity is formed in the middle of each stand column. The glass curtain wall is arranged at the front ends of the supporting stand columns and is connected and fixed through connecting pieces installed on the supporting stand columns. Each connecting piece is provided with an assembling cavity. The supporting stand columns penetrate through the assembling cavities and extend out of two sidesof the connecting pieces. A vacuum cavity is formed in the glass curtain wall, small holes are formed in the positions, directly facing the connecting pieces, of the glass curtain wall, the small holes communicate with the vacuum cavity in the glass curtain wall, an adsorption head is arranged at the position, opposite to one small hole, of each connecting piece, the adsorption heads seal the small holes, and the connecting pieces and the glass curtain wall are positioned and fixed through secondary positioning needles. According to the building curtain wall, quick disassembly and assembly can be achieved, use is more flexible, indoor and outdoor temperature isolation can be effectively achieved, and the heat preservation performance is improved.

Owner:TIANJIN FEIYU CURTAIN WALL DECORATION ENGCO

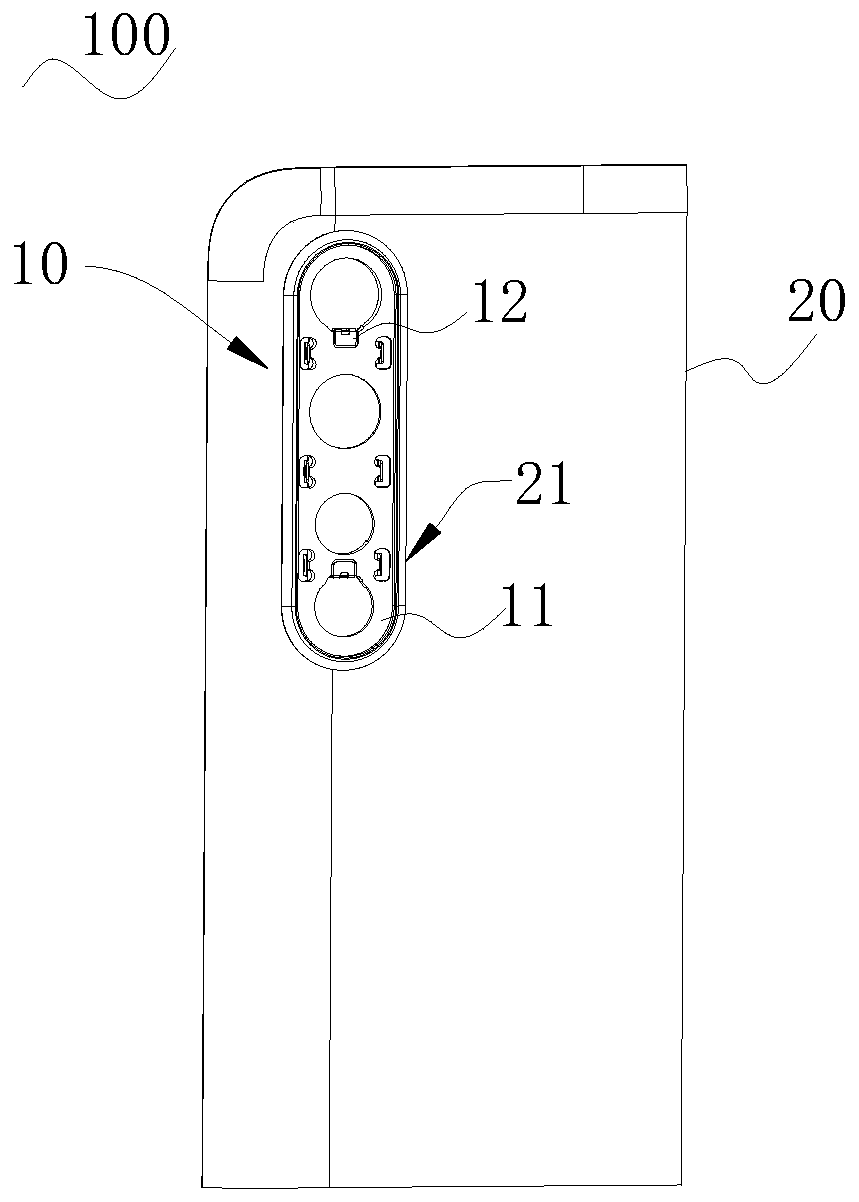

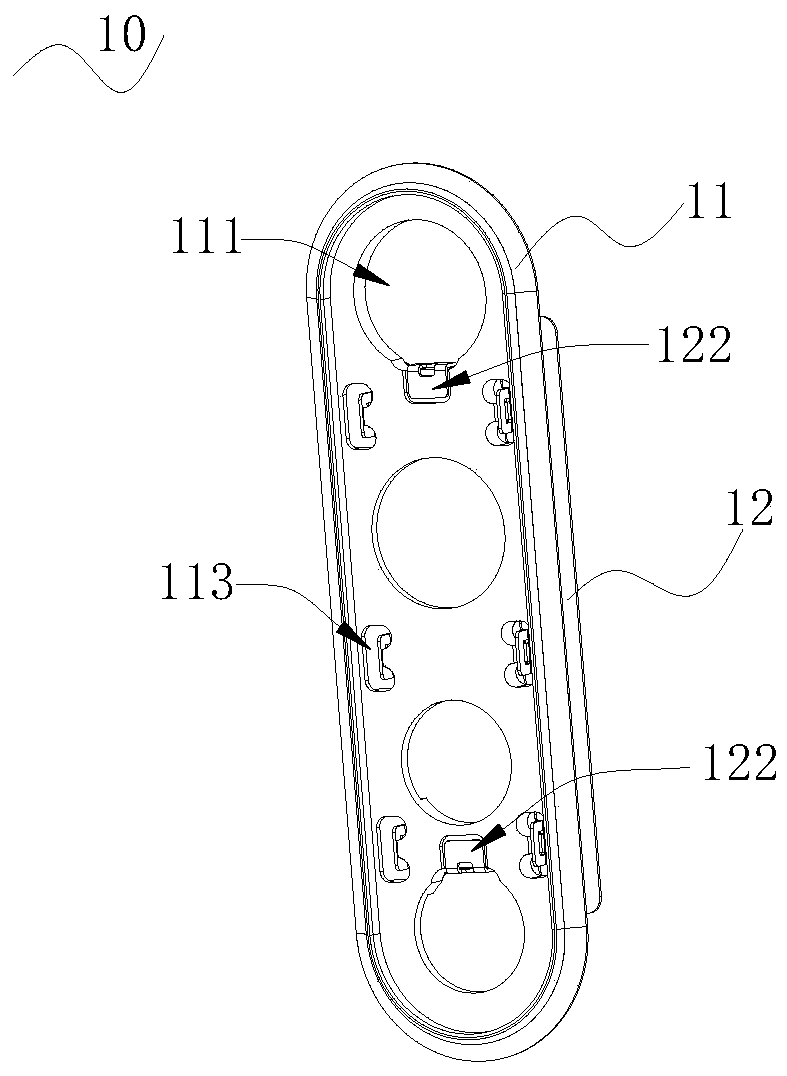

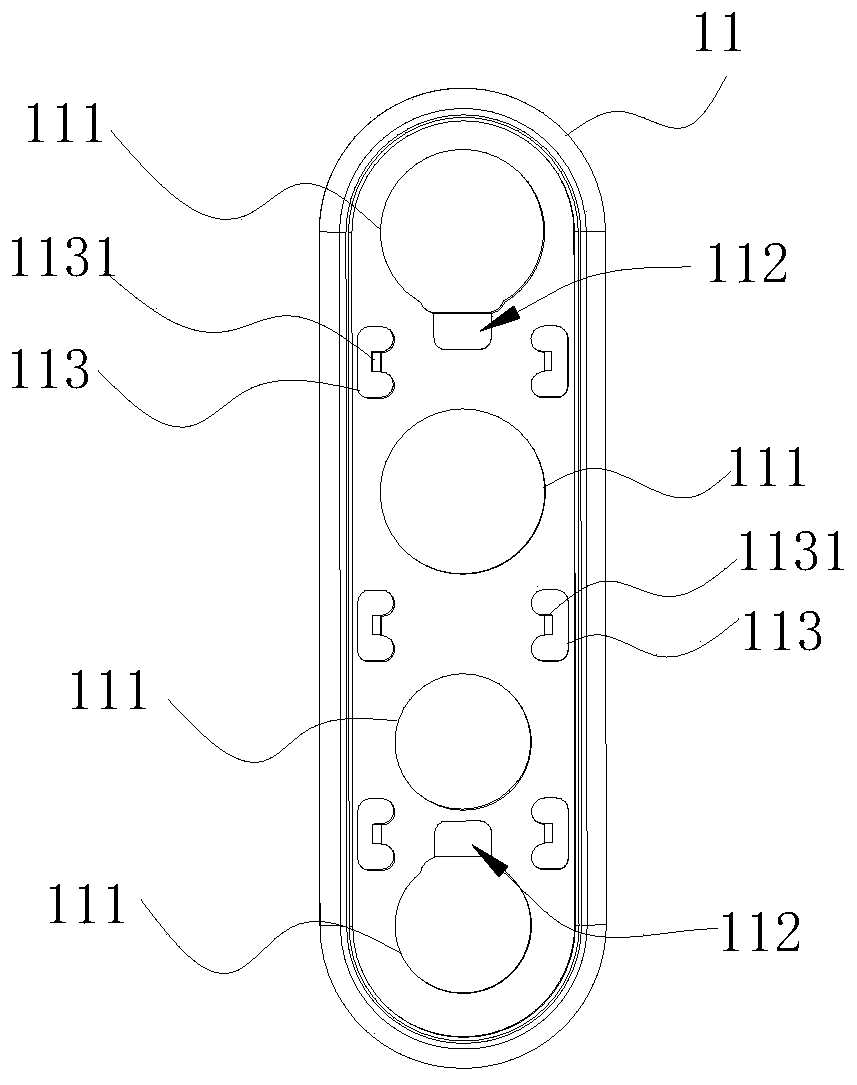

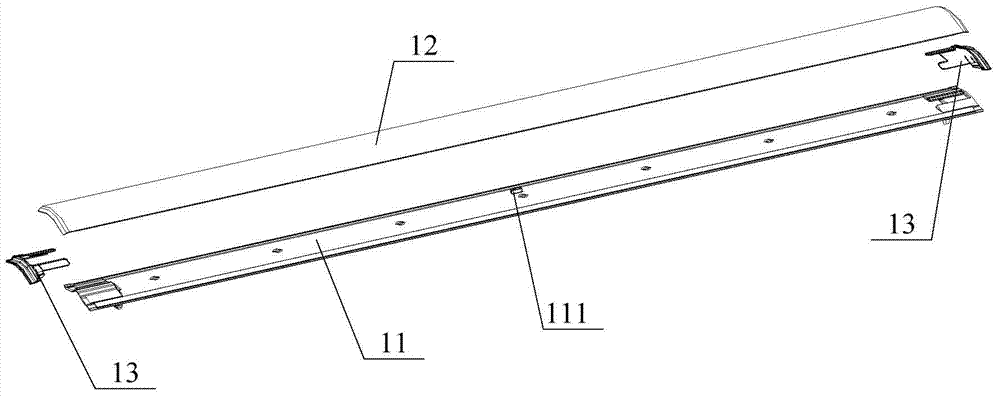

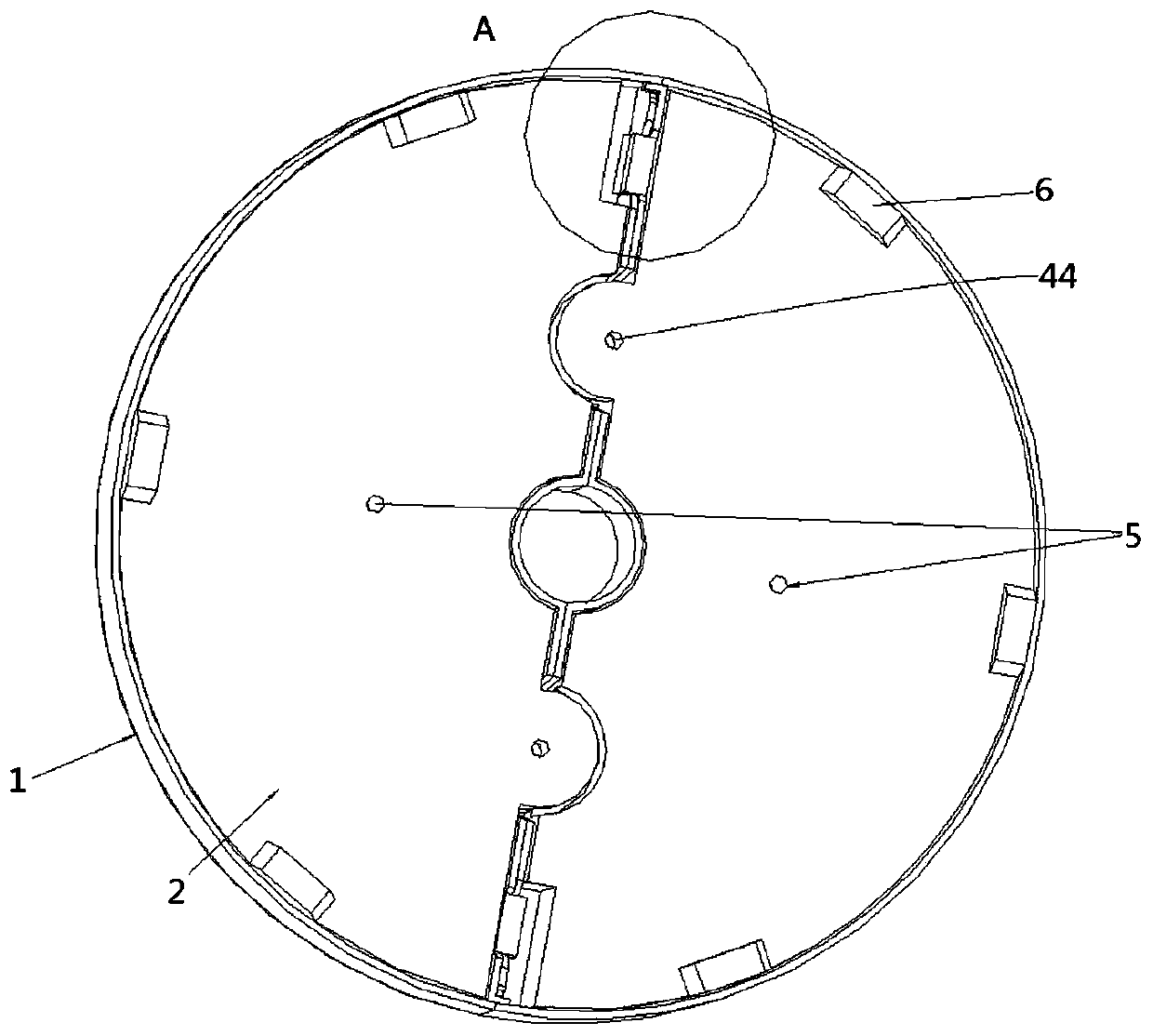

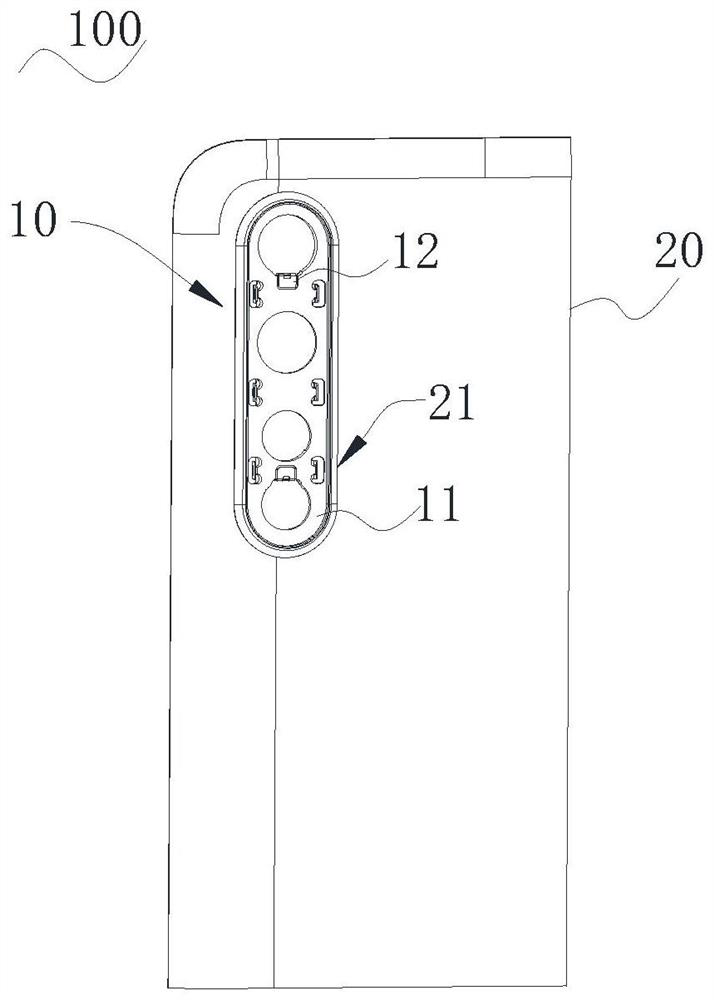

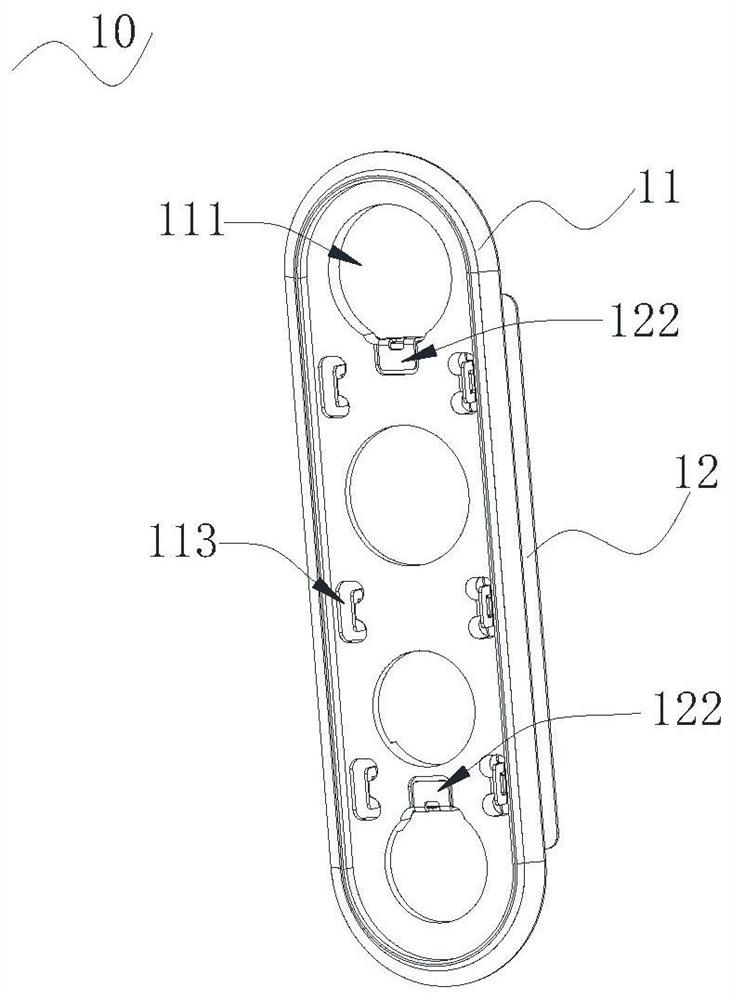

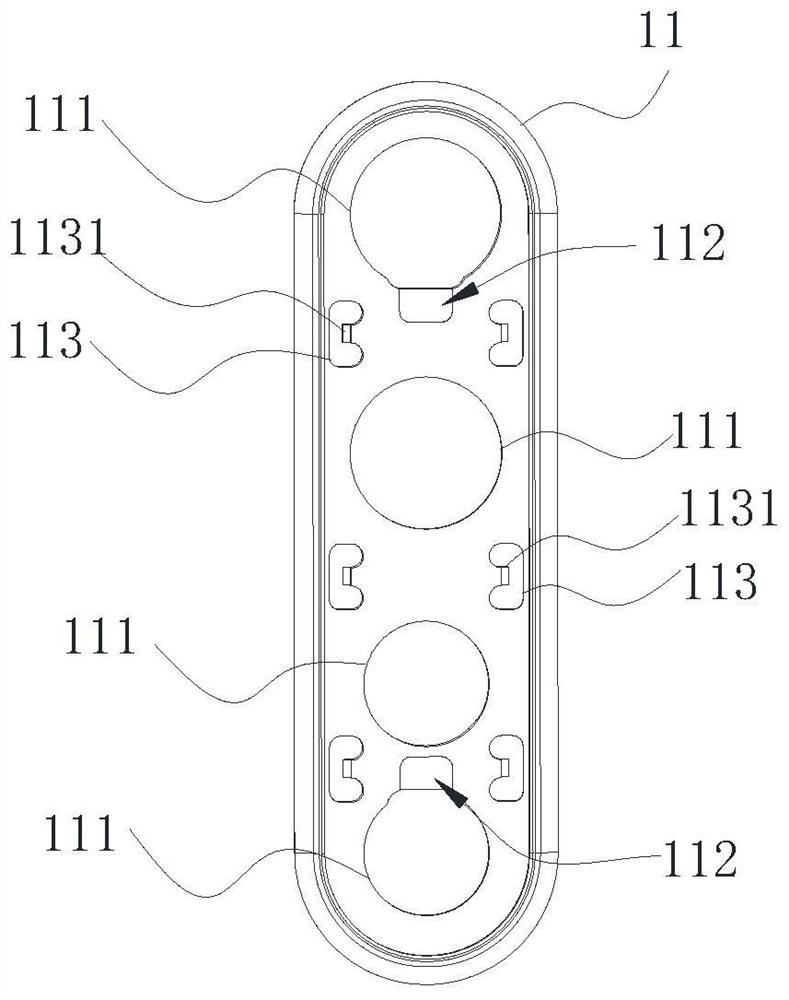

Camera decoration assembly and mobile terminal

ActiveCN110769136AReduce manufacturing costGuaranteed aestheticsTelevision system detailsColor television detailsStructural engineeringMechanical engineering

The invention provides a camera decoration assembly and a mobile terminal, the camera decoration assembly comprises a decoration part and a fixing part, the decoration part is used for being arrangedon a shell of the mobile terminal in a penetrating mode, a mounting hole in the decoration part is used for mounting a camera assembly of the mobile terminal, and a mounting position is arranged on the decoration part; the fixing part comprises a fixing body and a fixing arm, and the fixing body is used for being fixed to the inner surface of the shell; the fixing arm is arranged on the fixing body in a bendable mode so as to be fastened at the installation position of the decorating part in a bent mode, and the decorating part is fixed to the shell. Through cooperation of the decorating partand the fixing part, the fixing arm of the fixing part fixed to the inner surface of the shell can be bent and fastened to the installation position of the decorating part, and it is guaranteed that the decorating part can be stably fixed to the shell. When the camera assembly is impacted by an external force, the decorative part can be effectively prevented from falling off from the shell under the fastened force of the fixed arm, the assembly strength of the decorative part and the shell is ensured, the camera assembly can be stably installed, and the use experience of a user is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Air guide plate device

InactiveCN104848511AGuaranteed assembly strengthAssembly precisionAir-flow control membersIndustrial engineeringUltimate tensile strength

Owner:GREE ELECTRIC APPLIANCES INC

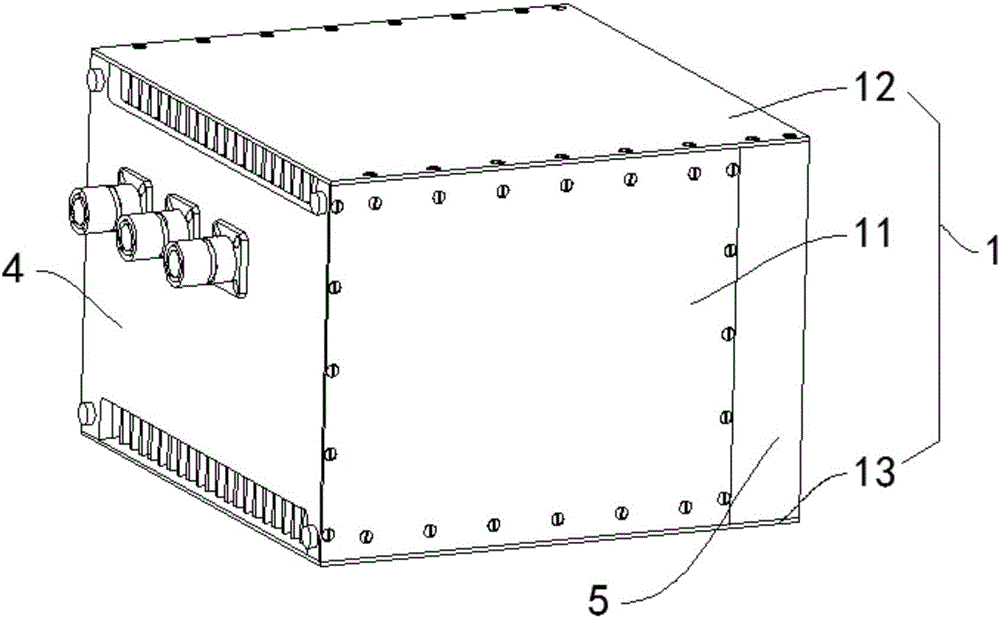

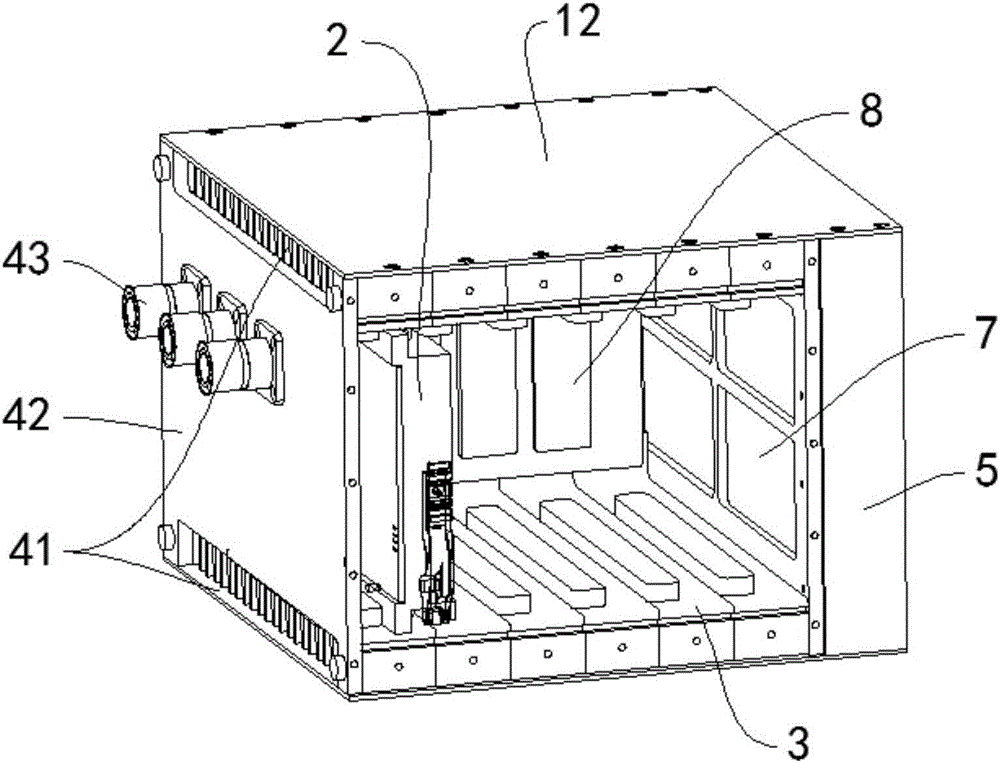

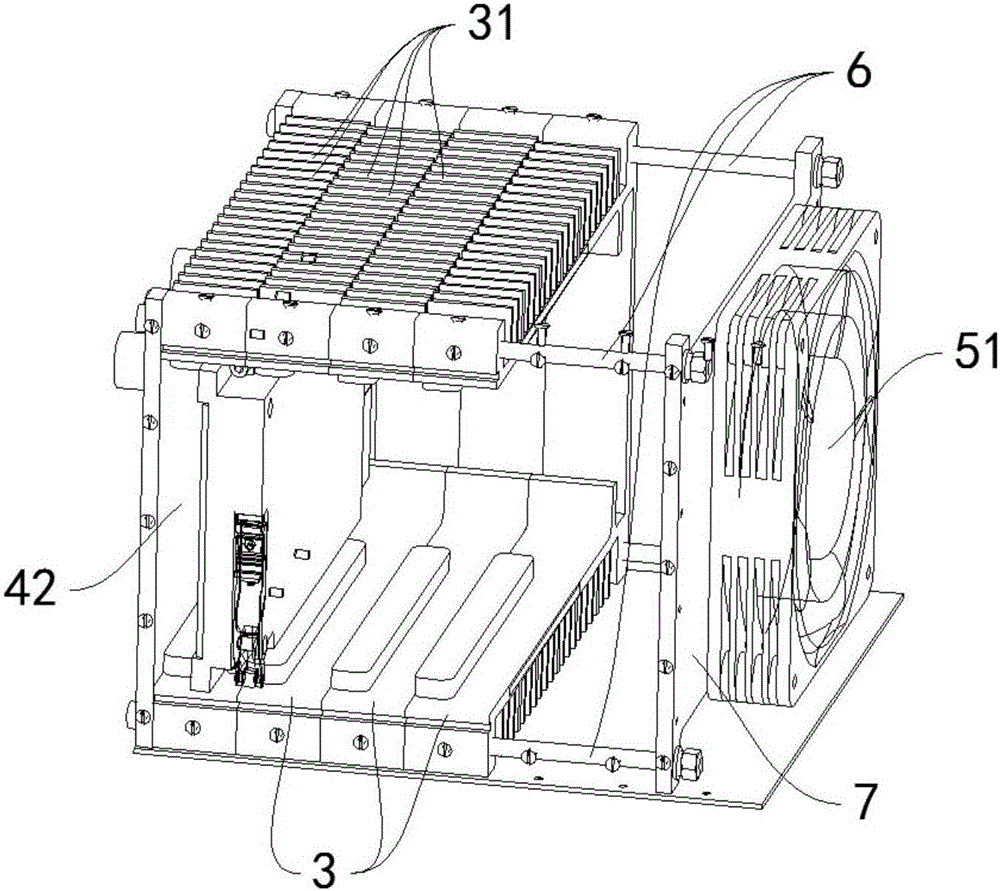

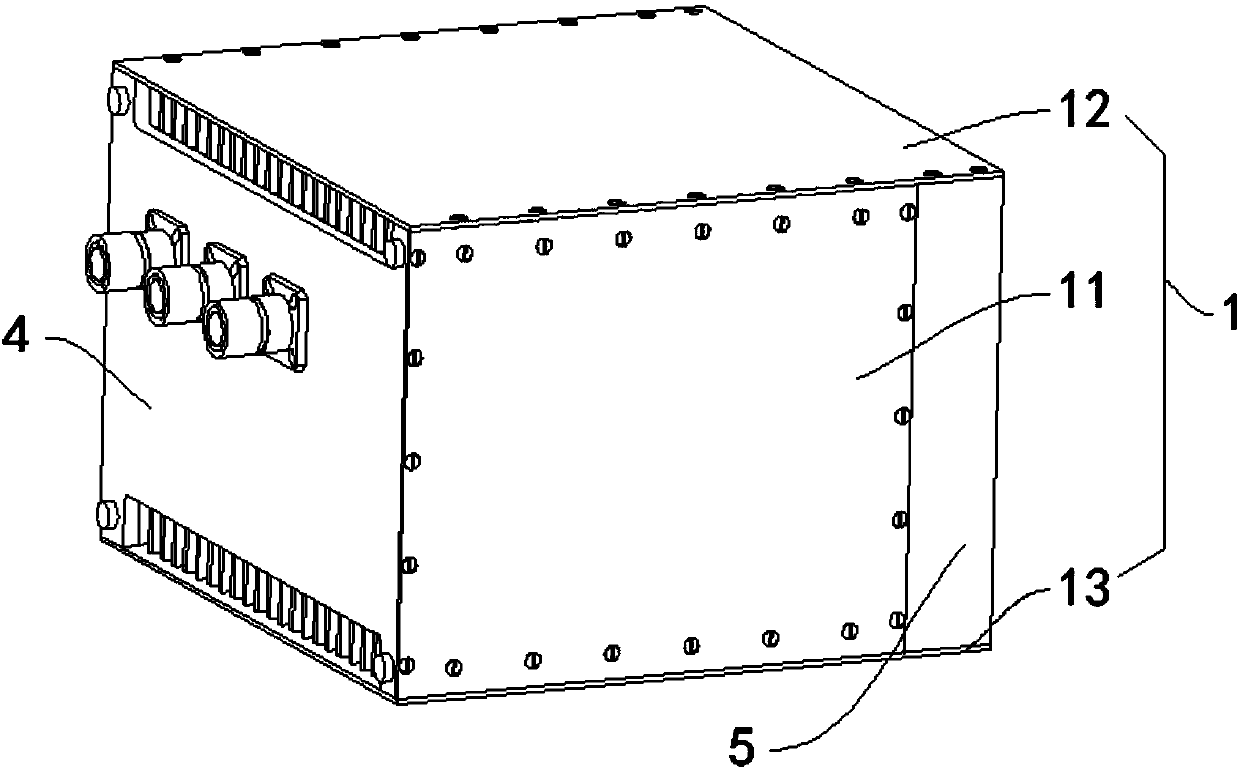

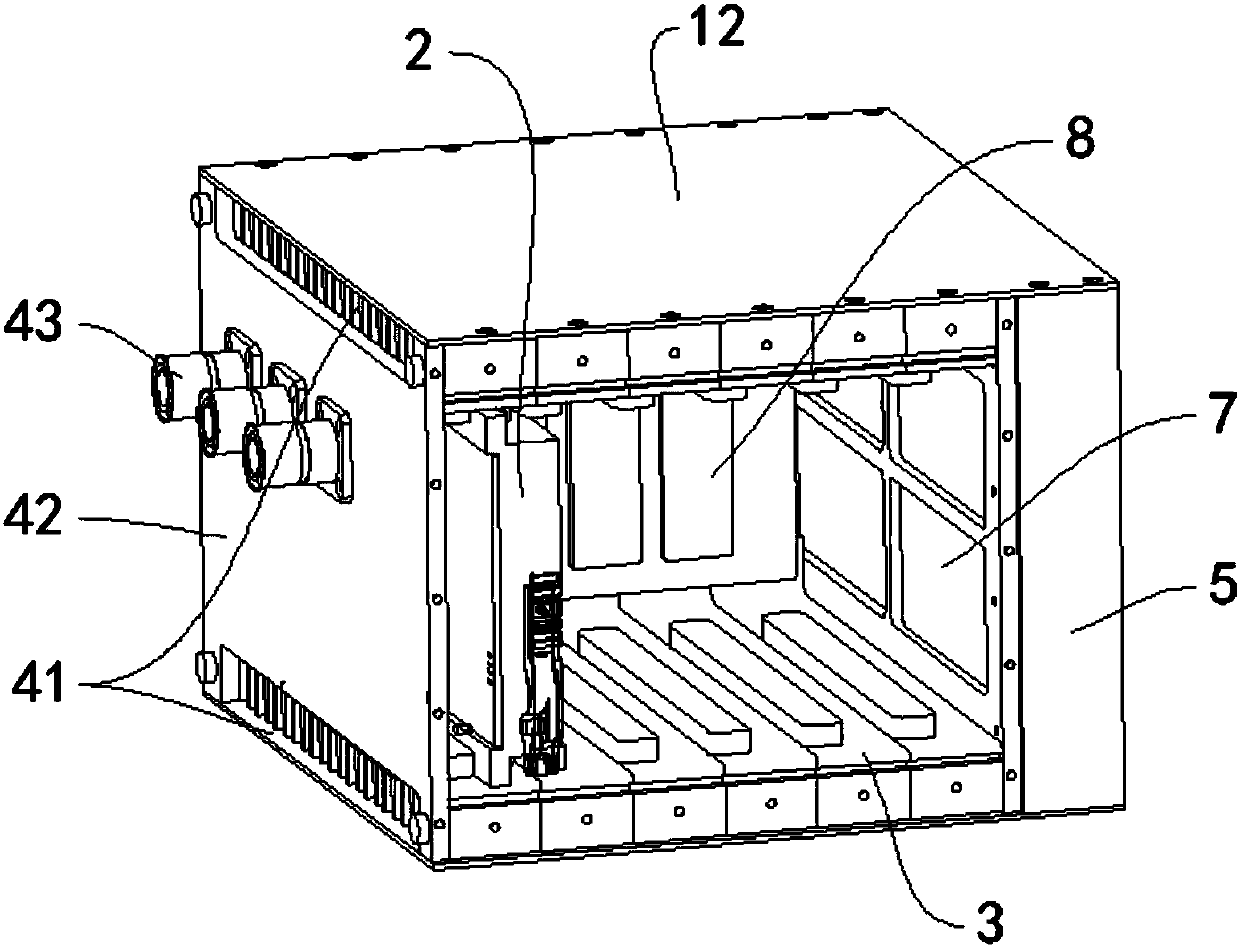

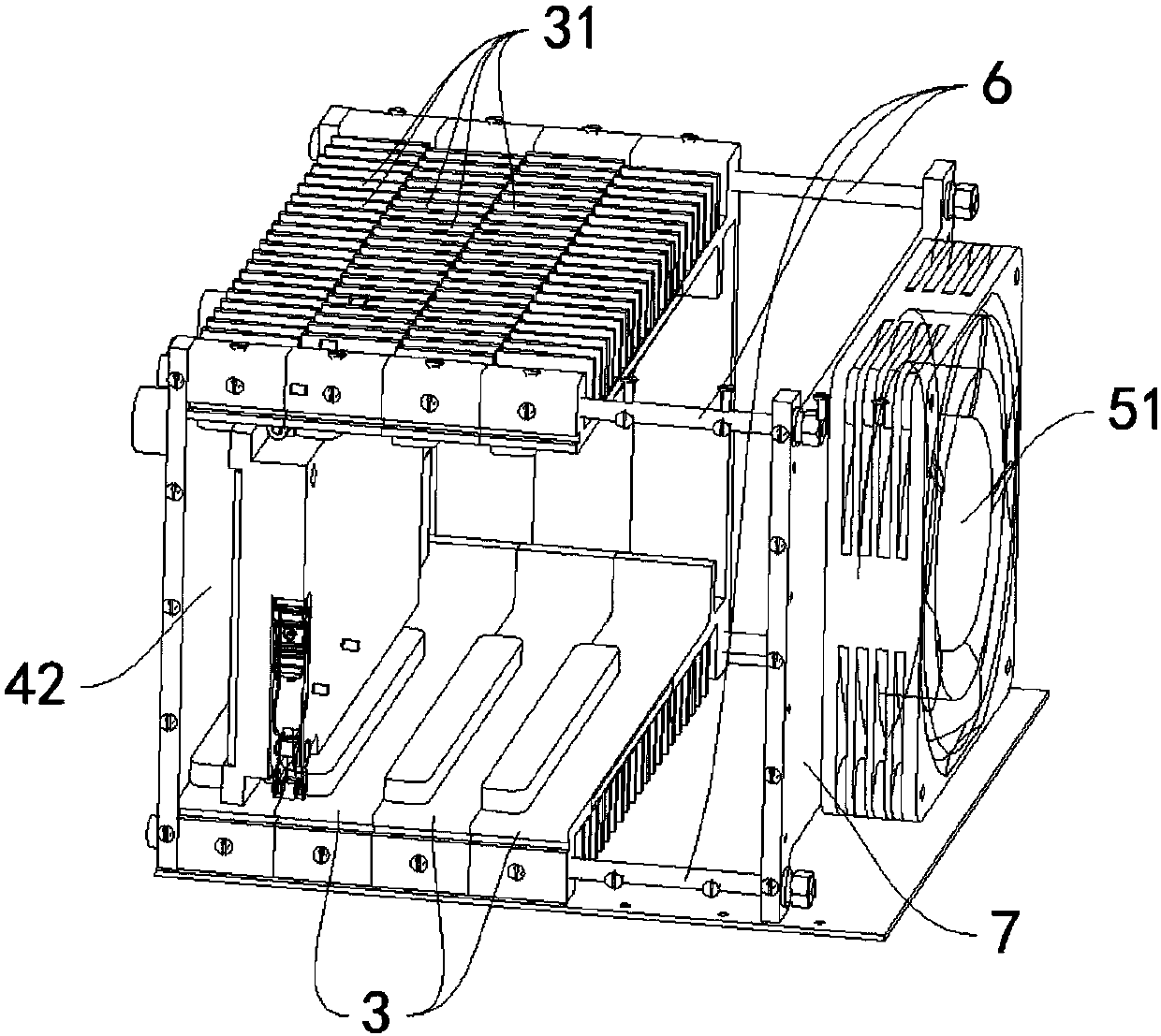

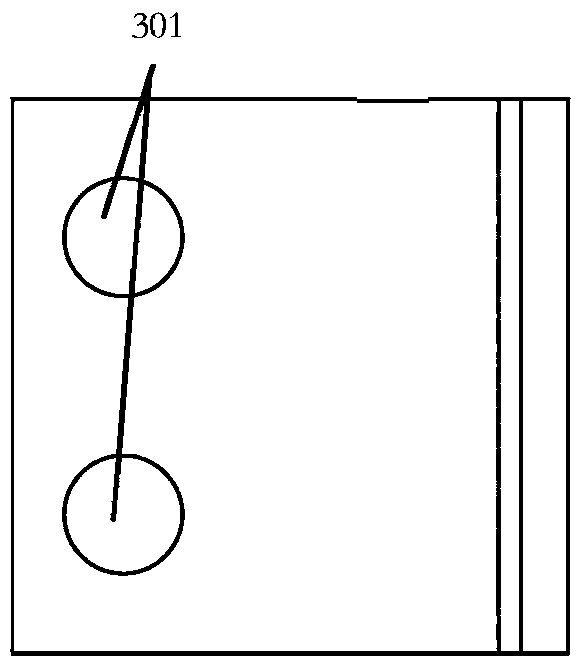

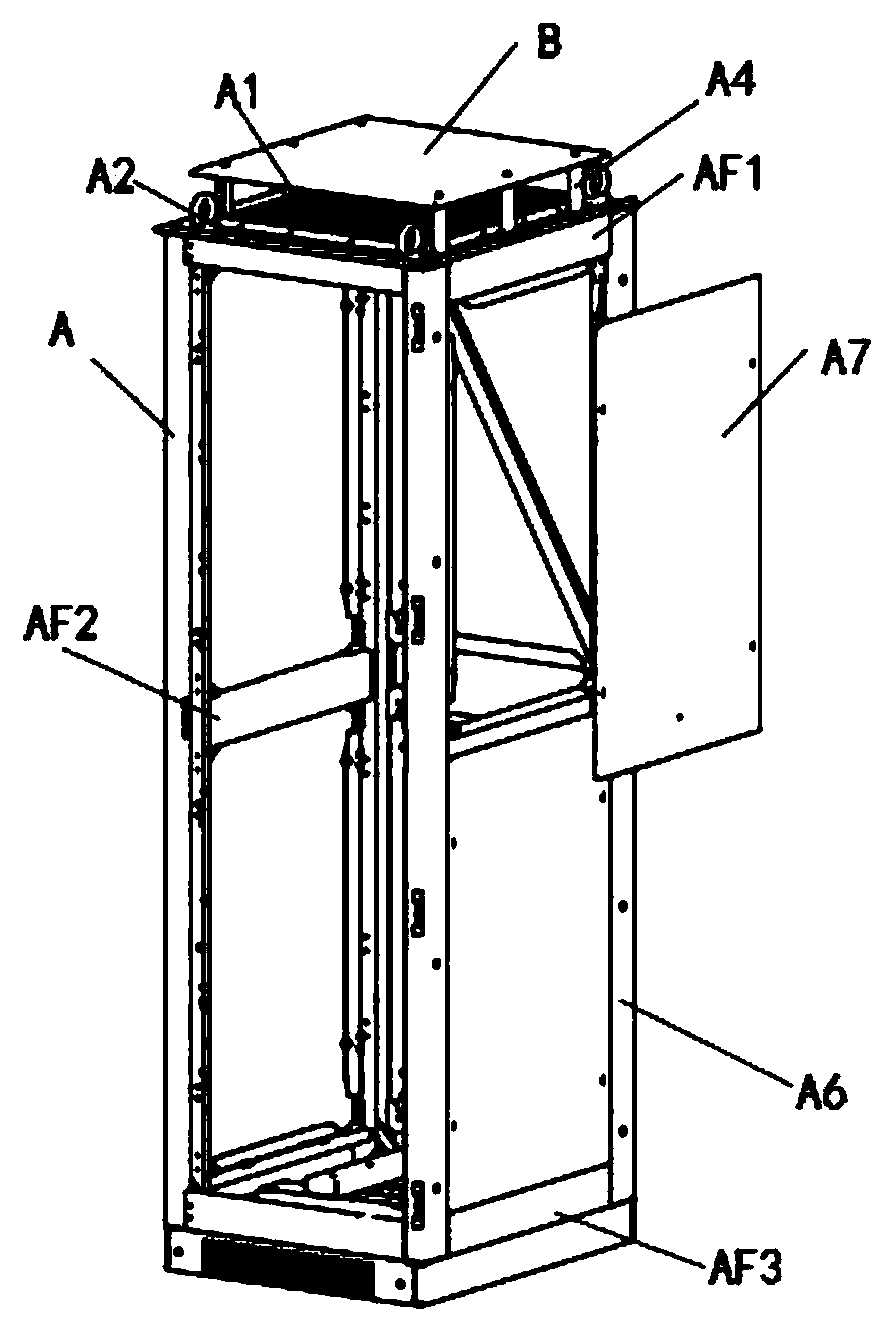

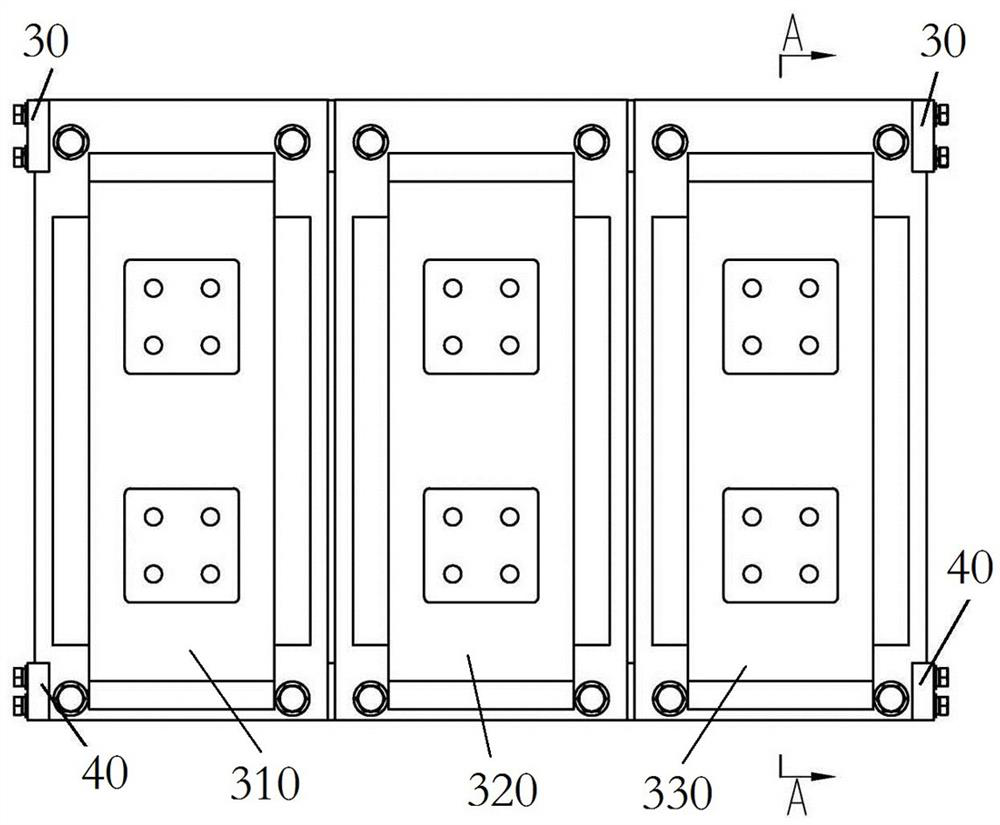

Modular airtight cold guide case

ActiveCN105934141ASimplify Design TasksImprove cooling effectCooling/ventilation/heating modificationsCooling effectEngineering

The invention relates to a modular airtight cold guide case, which comprises an airtight case body, cold guide plug-ins and a plurality of cold guide modules, wherein the plurality of cold guide modules are arranged in the airtight case body side by side; the cold guide plug-ins are clamped into the cold guide modules respectively; an adapter plate is arranged at one side of the airtight case body; a fan is arranged at the other side of the airtight case body; the airtight case body comprises a front end plate, an upper end plate and a lower end plate; a plurality of cooling teeth are arranged on the upper end surface and the lower end surface of each cold guide module; and the cooling teeth between the adjacent cold guide modules are arranged in a staggered manner. The modular airtight cold guide case can be applied to all occasions employing the airtight cold guide case. For different airborne models, the number of the plug-ins used in the case only needs to be confirmed and a corresponding number of cold guide modules are selected to be assembled, so that the design task is greatly simplified; the human cost and the production cost are reduced; the cooling teeth are arranged in the staggered manner; and the cooling effect is improved.

Owner:BEIJING INST OF RADIO MEASUREMENT

A modular airtight cold conduction chassis

ActiveCN105934141BSimplify Design TasksImprove cooling effectCooling/ventilation/heating modificationsModularityCooling effect

The invention relates to a modular airtight cold guide case, which comprises an airtight case body, cold guide plug-ins and a plurality of cold guide modules, wherein the plurality of cold guide modules are arranged in the airtight case body side by side; the cold guide plug-ins are clamped into the cold guide modules respectively; an adapter plate is arranged at one side of the airtight case body; a fan is arranged at the other side of the airtight case body; the airtight case body comprises a front end plate, an upper end plate and a lower end plate; a plurality of cooling teeth are arranged on the upper end surface and the lower end surface of each cold guide module; and the cooling teeth between the adjacent cold guide modules are arranged in a staggered manner. The modular airtight cold guide case can be applied to all occasions employing the airtight cold guide case. For different airborne models, the number of the plug-ins used in the case only needs to be confirmed and a corresponding number of cold guide modules are selected to be assembled, so that the design task is greatly simplified; the human cost and the production cost are reduced; the cooling teeth are arranged in the staggered manner; and the cooling effect is improved.

Owner:BEIJING INST OF RADIO MEASUREMENT

Knife-shaped gate valve body and manufacturing process thereof

InactiveCN107448660AAvoid breakingAchieve assembly strengthFoundry mouldsSlide valveEngineeringMiddle line

The invention discloses a knife-type gate valve body, which includes a shell, which is composed of a left valve body and a right valve body with an annular hollow structure and the same outer diameter, which are bonded and spliced, thereby forming a cavity structure inside the shell. The left valve body is far away from the The opening on one side of the right valve body is used as a water inlet, and a ring-shaped boss extends outward from the edge of the water inlet. A telescopic sleeve is fixed inside the ring-shaped boss along a direction perpendicular to the water inlet, and a spring is fixed inside the telescopic sleeve. One end is fixed on the ring-shaped boss, and the other end is fixed with the top block at the top of the telescopic sleeve. The corresponding positions of the fixed block, the connecting plate and the shell are provided with a through chute along the vertical centerline of the shell, thereby forming a slideway. It also includes a valve plate slidingly matched with the slideway, so as to extend into the inside of the shell through the slideway; the present invention realizes the elimination of the gap when the knife-type gate valve body is closed through the cooperation of the valve plate, the telescopic head, the spring and the top block. The sealing degree of the knife gate valve is guaranteed, and the use efficiency of the knife gate valve is improved.

Owner:江苏盐发机械有限公司

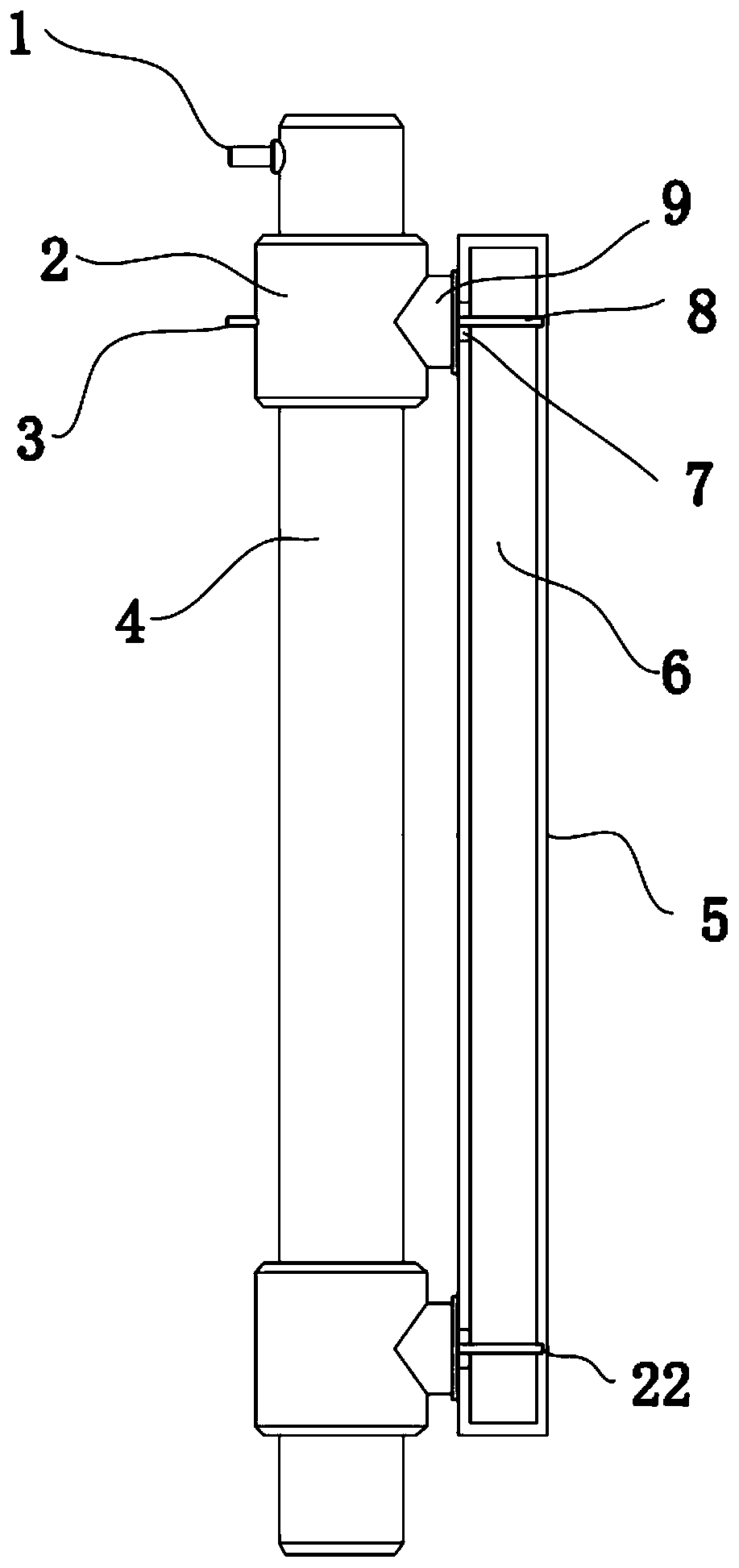

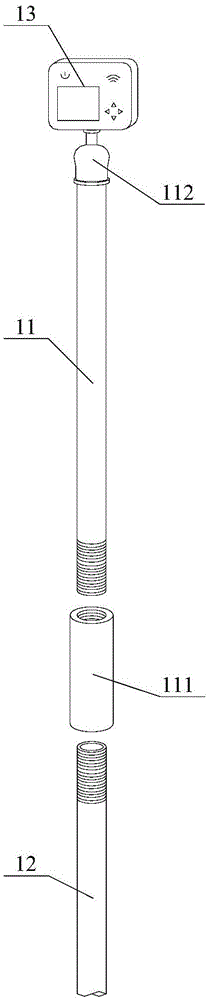

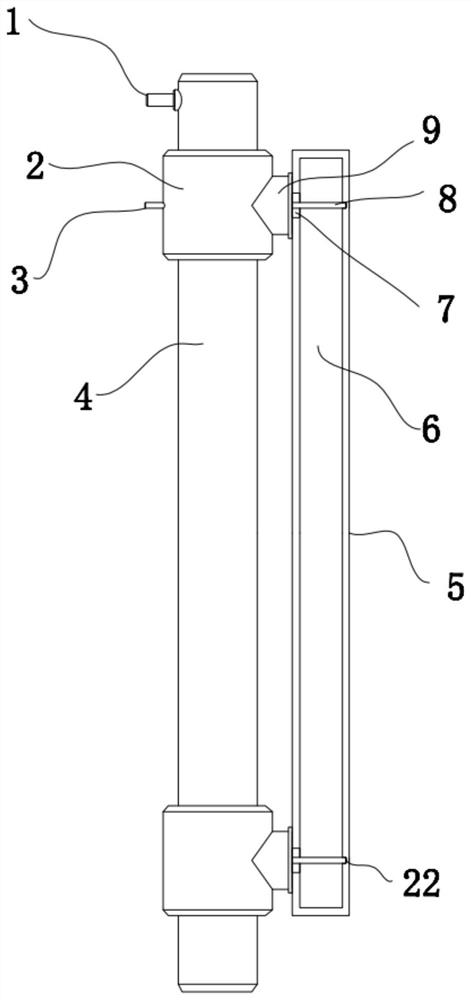

Two-stage inspection auxiliary device

InactiveCN105119201ASimple and fast operationOperational securityApparatus for overhead lines/cablesSwitchgearHigh intensityEngineering

The invention discloses a two-stage inspection auxiliary device, comprising a front rod body and a rear rod body which are detachably and coaxially connected in sequence, wherein the front end of the front rod body is provided with a detection terminal. In a assembly and use process, the detection terminal can be stretched into a relatively narrow workspace or a higher workspace by holding the front rod body and the rear rod body by a worker, meanwhile rod body lengths which can be operated by the worker can be flexibly adjusted according to the different demands of actual working conditions by disassembling or assembling the rear rod body and the front rod body, so that demands of use for inspection operations of multiple working conditions under high strength can be met; the two-stage inspection auxiliary device is simple in operation, safe and reliable in operation process, and high in work efficiency.

Owner:STATE GRID ZHEJIANG CIXI POWER SUPPLY +2

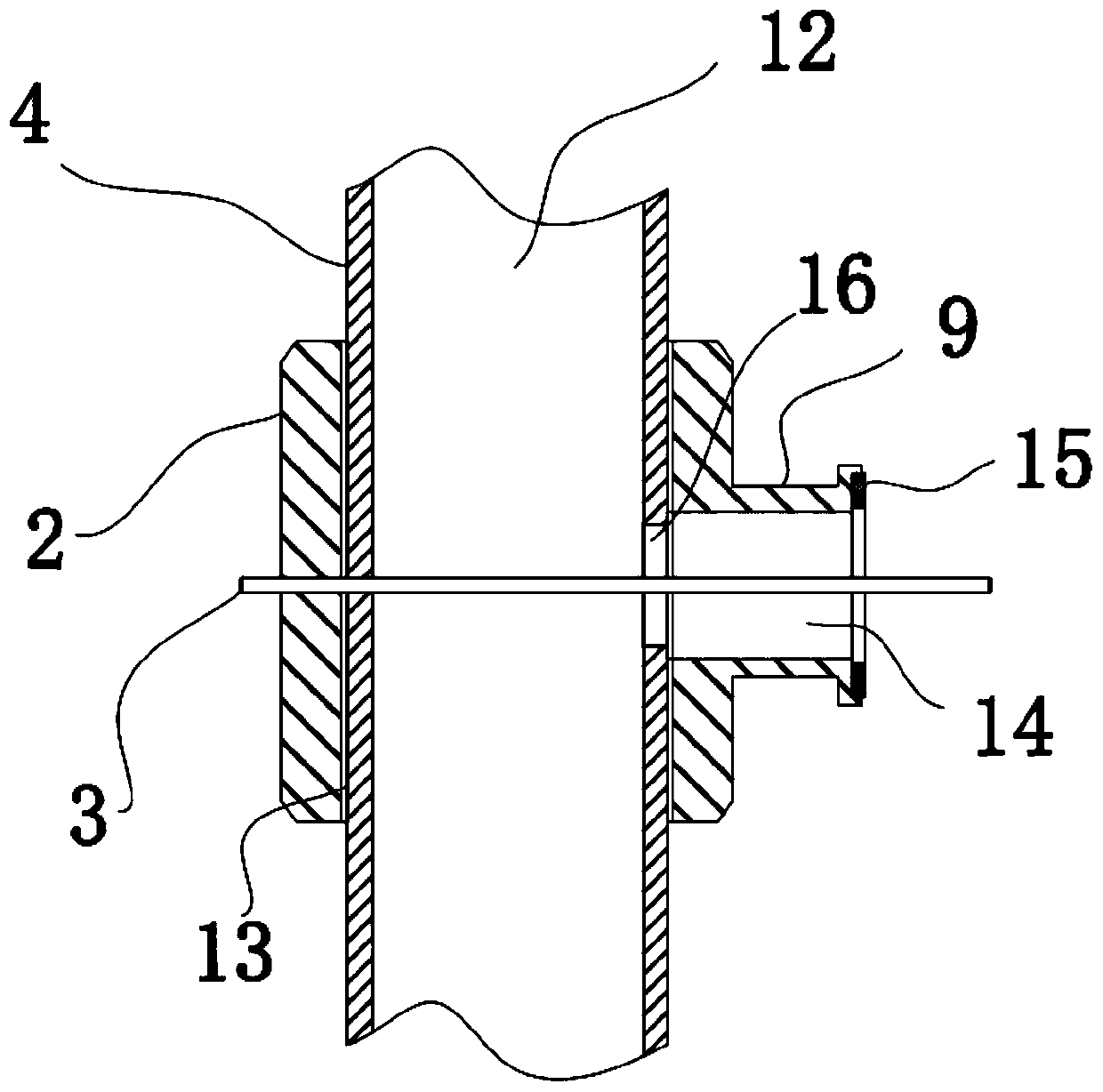

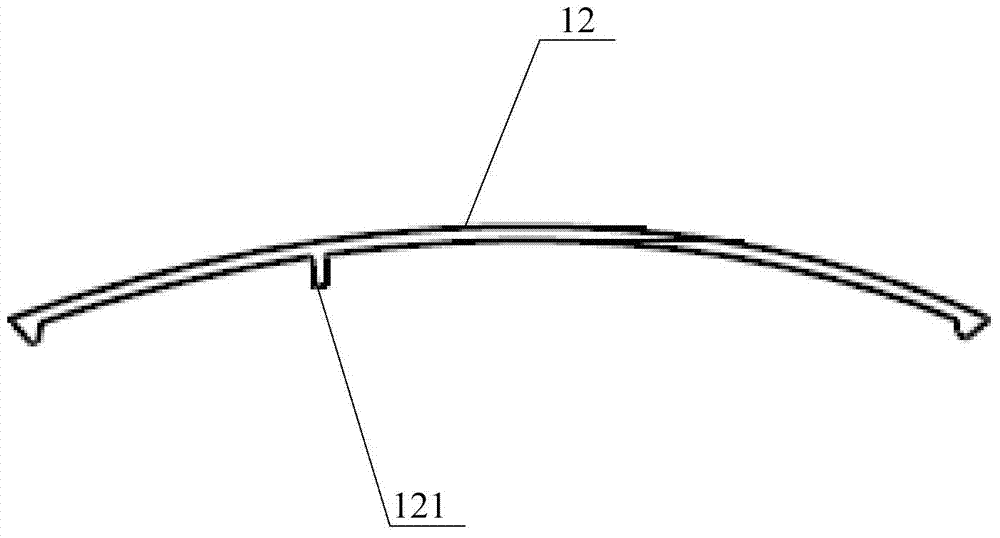

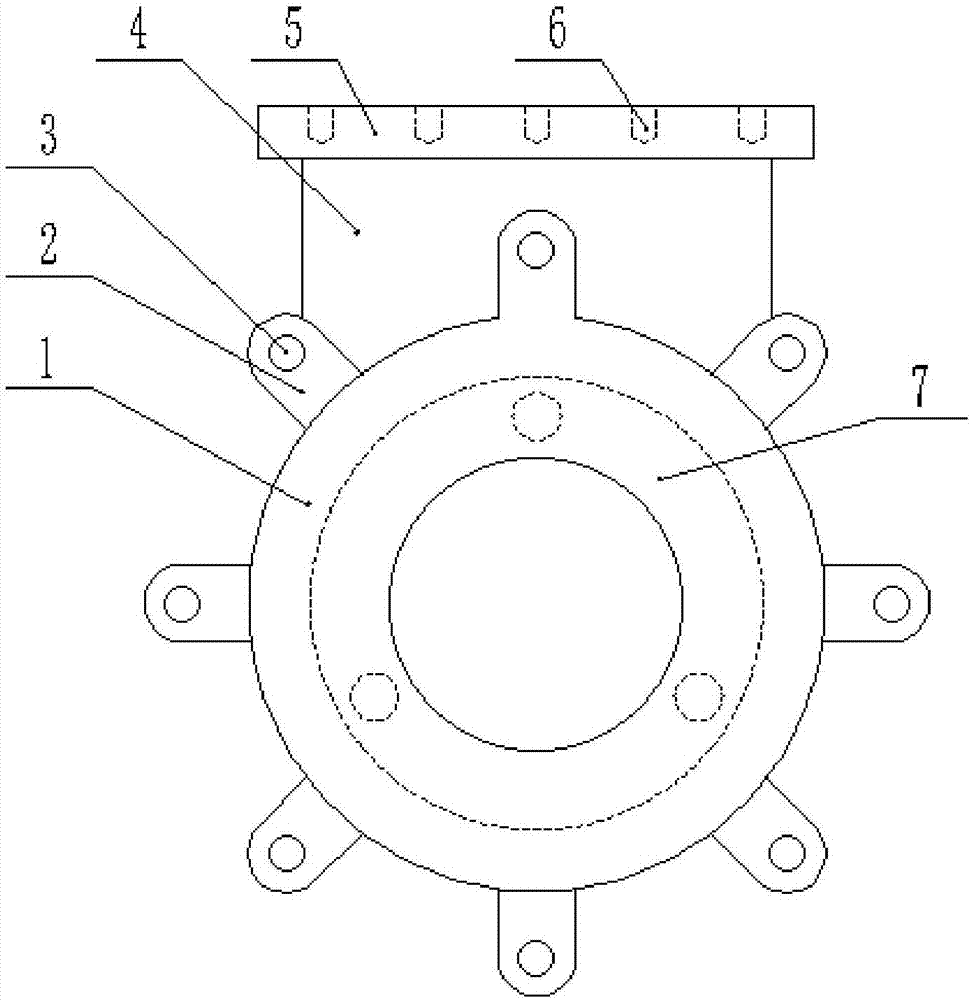

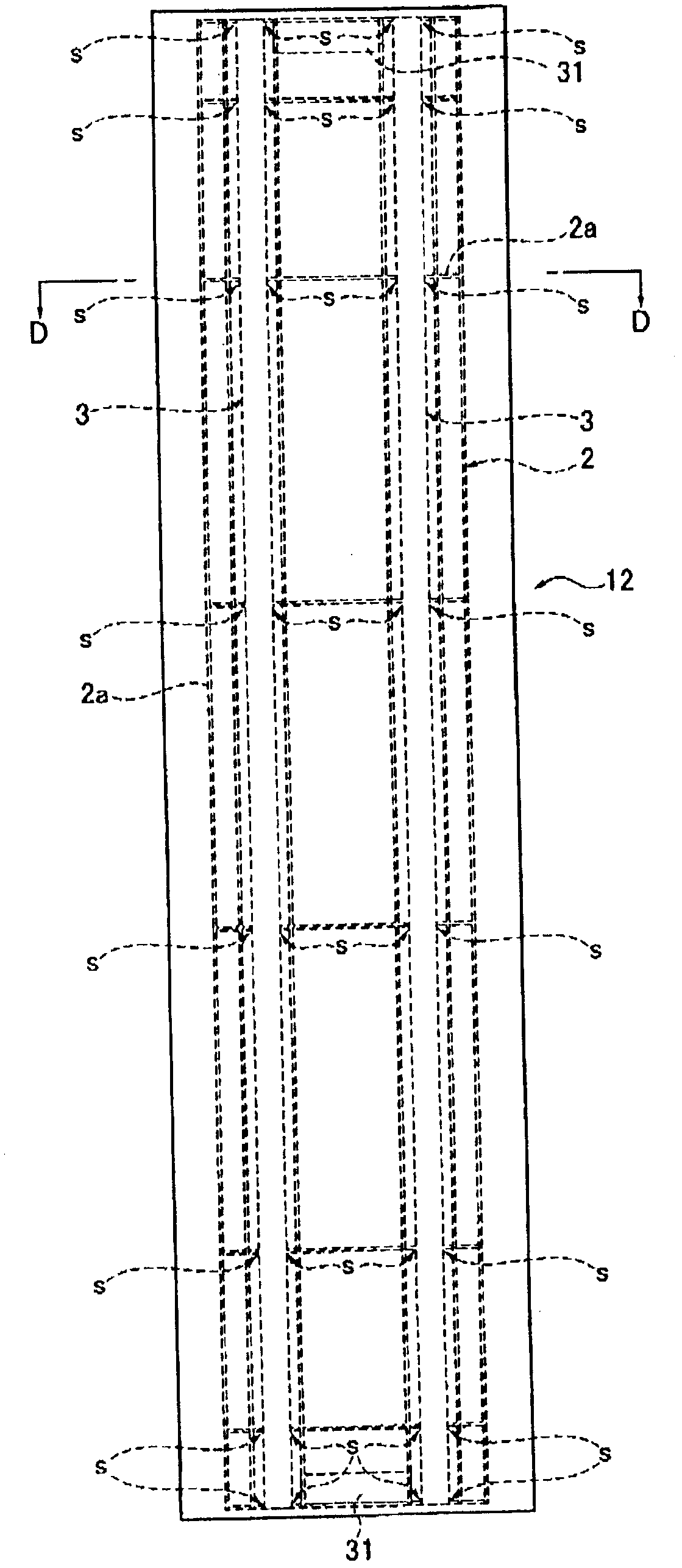

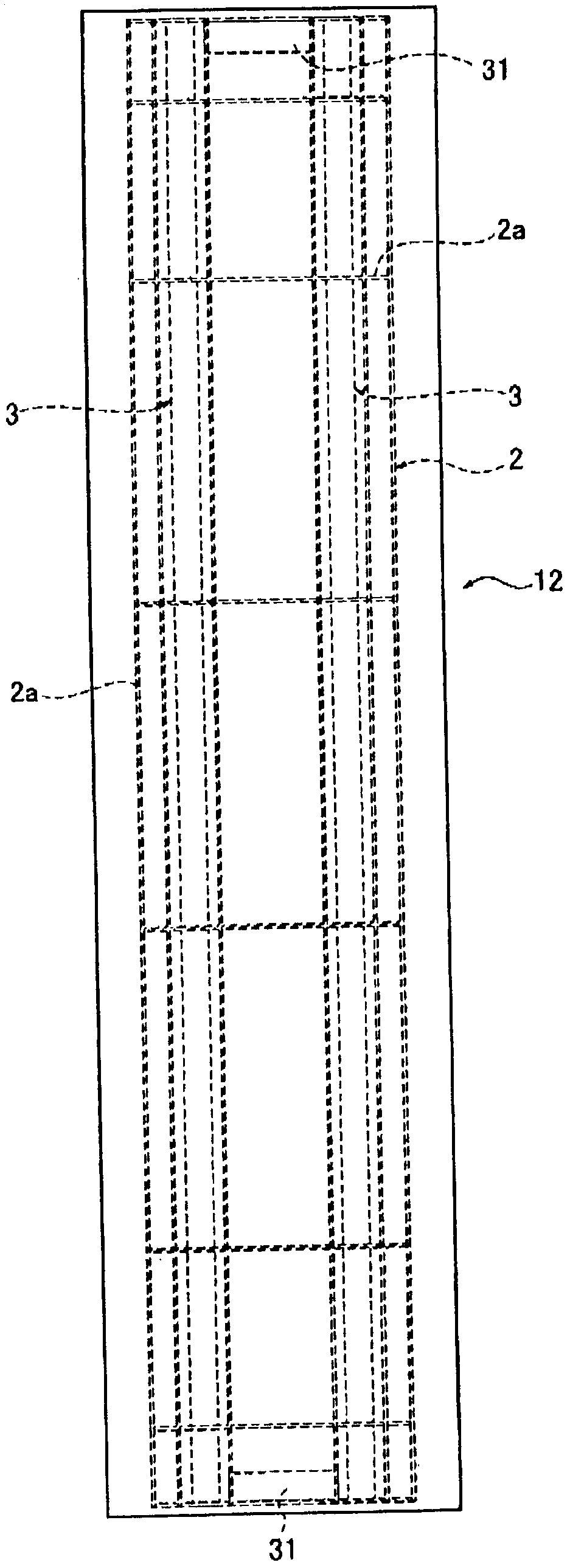

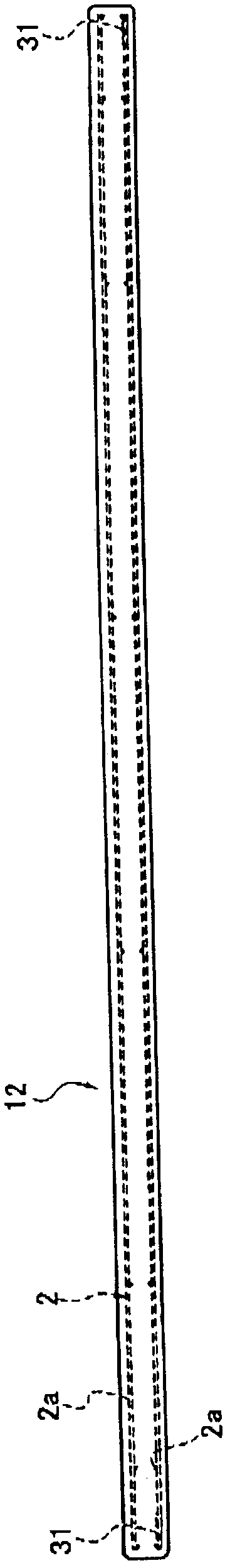

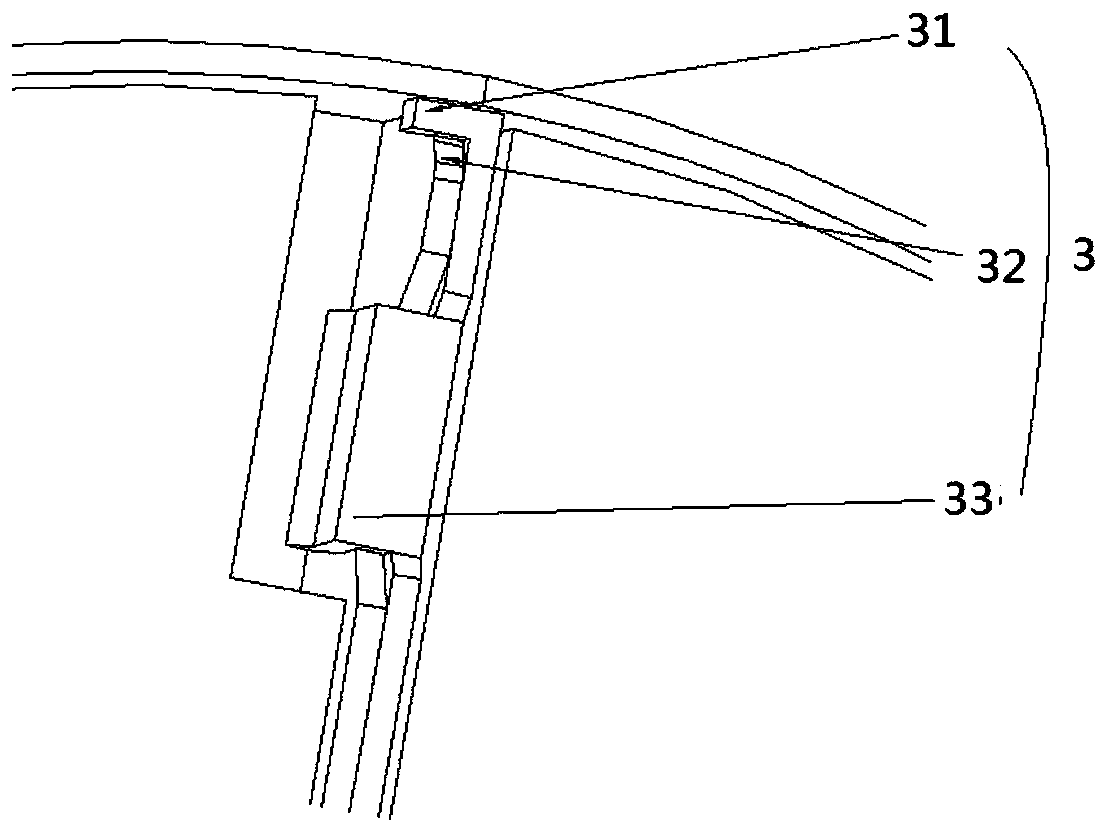

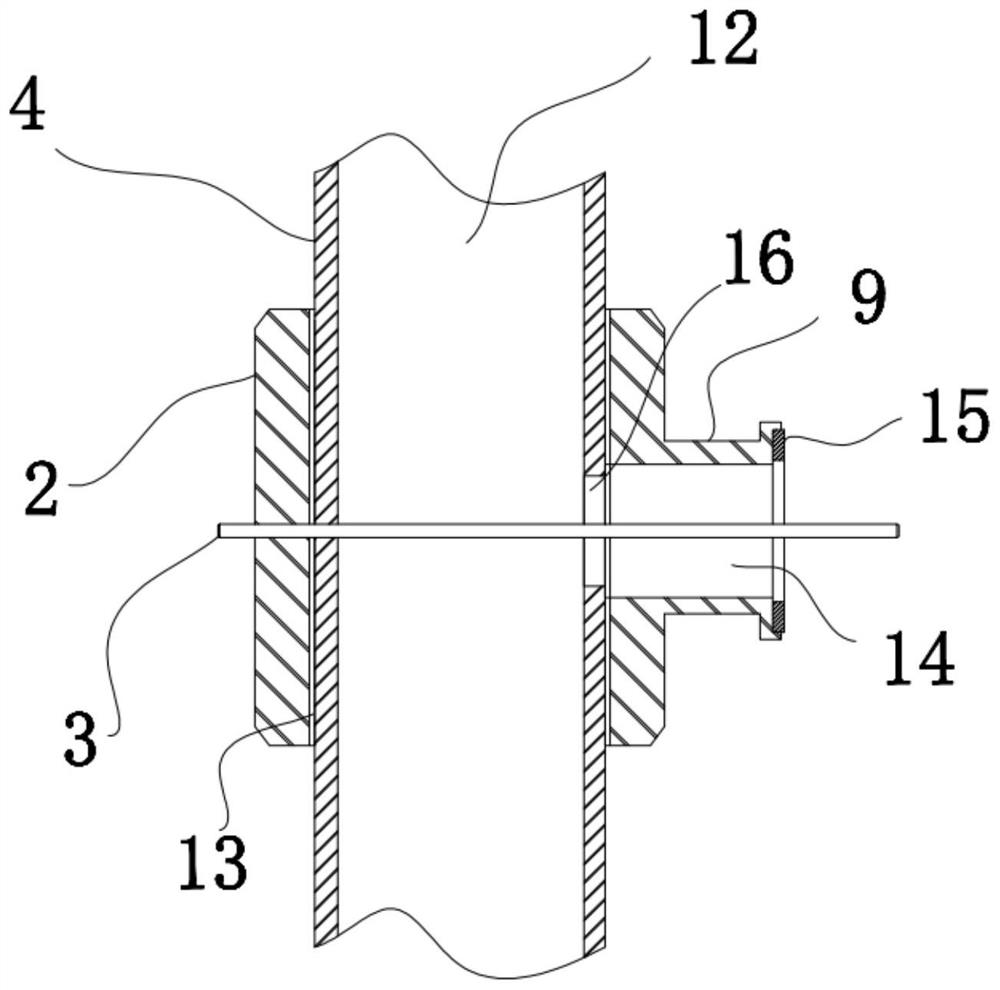

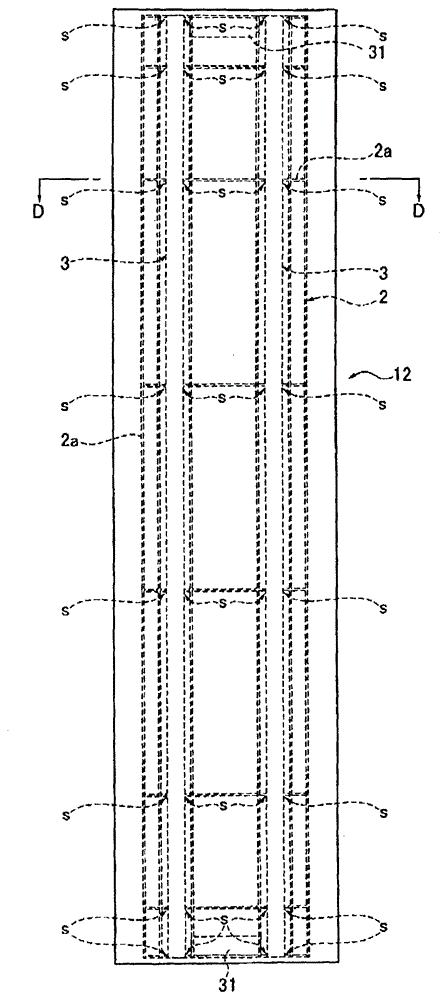

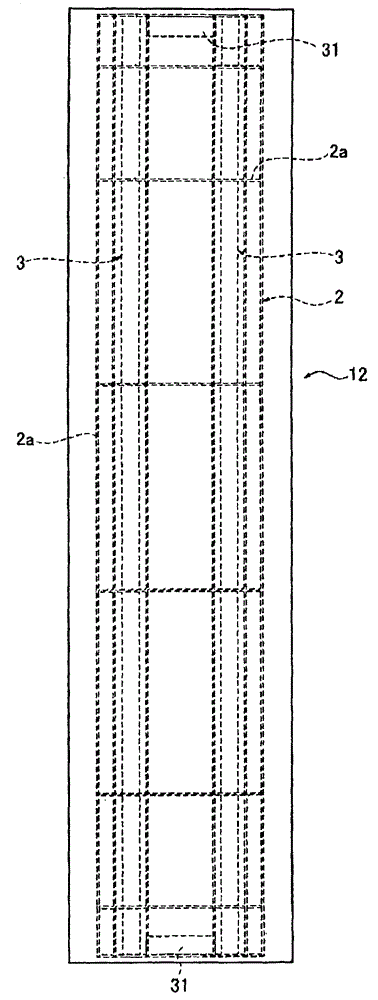

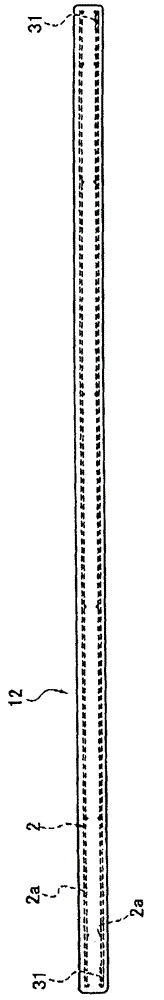

Assembling structure on a light foam concrete unit

The object of the invention is to provide an assembling structure arranged on an ALC with high precision while exhibiting high reliability in mounting strength of the unit to be assembled. The assembling structure on the ALC unit comprises: an outer wall panel (12) as the ALC unit buried with a reinforcement frame (2) with a metal slice (3) and an outer substrate piece (52), wherein a self-flapping screw (4) screwed from the side of the outer wall substrate piece (52) is screwed into the metal slice (3), therefore the outer wall substrate piece (52) is assembled on the outer wall panel (12) and an outer wall decoration plate (53) is adhered on the surface of the outer wall substrate piece (52) by an adhesive.

Owner:SEKISUI CHEM CO LTD

Assembled chassis and fan

PendingCN110701093AReduce volumeTake up less packaging spacePump componentsLighting and heating apparatusRolling chassisAutomotive engineering

The invention provides an assembled chassis and a fan. The assembled chassis comprises sub chassis provided with accommodating tanks, first connecting parts arranged on the sub chassis, counterweightpieces arranged in the accommodating tanks, and second connecting parts arranged on the counterweight pieces, wherein the multiple same sub chassis are assembled as a whole by the first connecting parts; and the multiple same counterweight pieces are assembled as a whole by the second connecting parts. The assembled chassis is low in cost, less in occupied space and high in strength of connectingstructures.

Owner:GREE ELECTRIC APPLIANCES INC

Architectural glass curtain wall

ActiveCN109736497BGuaranteed assembly strengthEasy to assemble and disassembleWallsArchitectural glassThermal insulation

Owner:TIANJIN FEIYU CURTAIN WALL DECORATION ENGCO

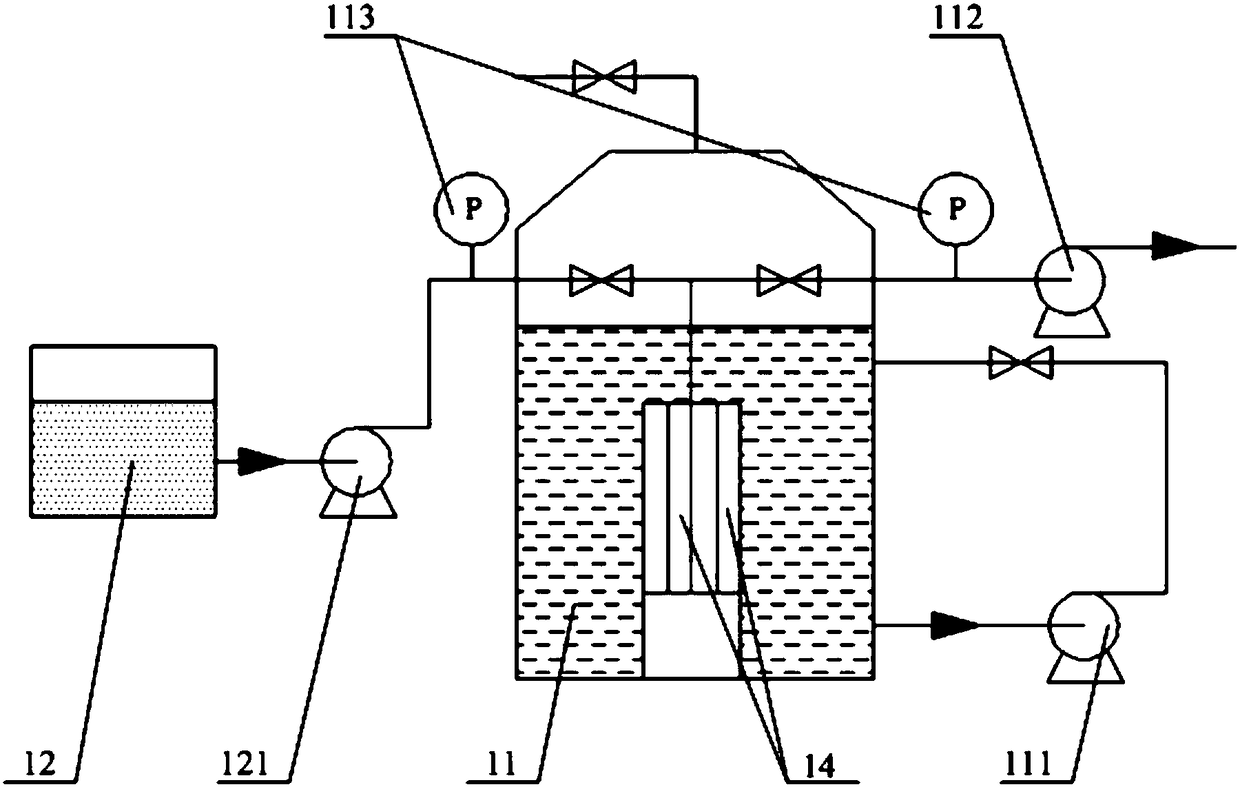

Anaerobic membrane bioreactor and using method thereof

PendingCN108178298AEnsure structural stabilityGuaranteed operating efficiencySpecific water treatment objectivesWater contaminantsBiochemical engineeringEngineering

The invention discloses an anaerobic membrane bioreactor. The anaerobic membrane bioreactor comprises an anaerobic tank, a circulating pump, a suction pump, a backwashing tank and a backwashing pump,wherein the circulating pump and the suction pump are respectively connected with the anaerobic tank; the water inlet end of the backwashing pump is communicated with the backwashing tank; the water outlet end of the backwashing pump is connected with the anaerobic tank; a plurality of membrane components are successively arranged in parallel in the anaerobic tank; each membrane component comprises a support plate and a flat plate membrane which are parallel to each other. The membrane components of the anaerobic membrane bioreactor can be relatively efficiently and completely washed. The invention also discloses a using method of the anaerobic membrane bioreactor.

Owner:中科瑞阳膜技术(北京)有限公司

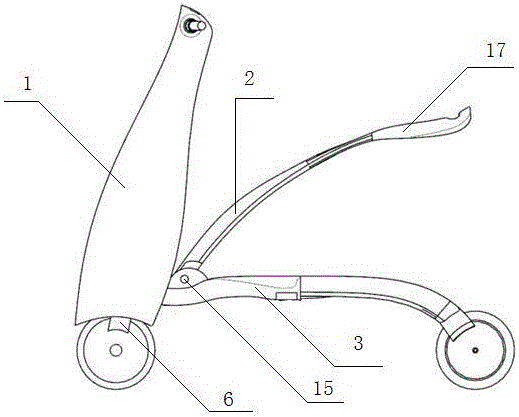

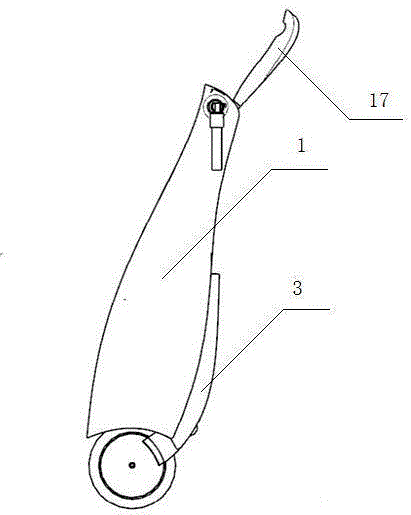

A frame of an electric folding bike

InactiveCN103832525BSimple and smooth appearanceReduce volumeFoldable cyclesElectric vehicle charging technologyVehicle frameEngineering

The invention discloses a frame of an electric folding bicycle, which comprises a handlebar frame, a seat tube and a pedal, and is characterized in that: the handlebar frame is connected with the pedal shaft, the seat tube is connected with the pedal shaft, bit device. The frame of the electric folding bicycle of the present invention is composed of a handlebar frame and a pedal. The pedal can be folded up and down relative to the handlebar frame, and the seat tube can be folded up and down relative to the pedal. During the folding process of the vehicle, only the seat tube and the pedal need to be folded , the folding process of the whole frame only needs two steps, and it does not take a few seconds. It is extremely convenient to carry, go up and down stairs, store, and charge.

Owner:路海燕

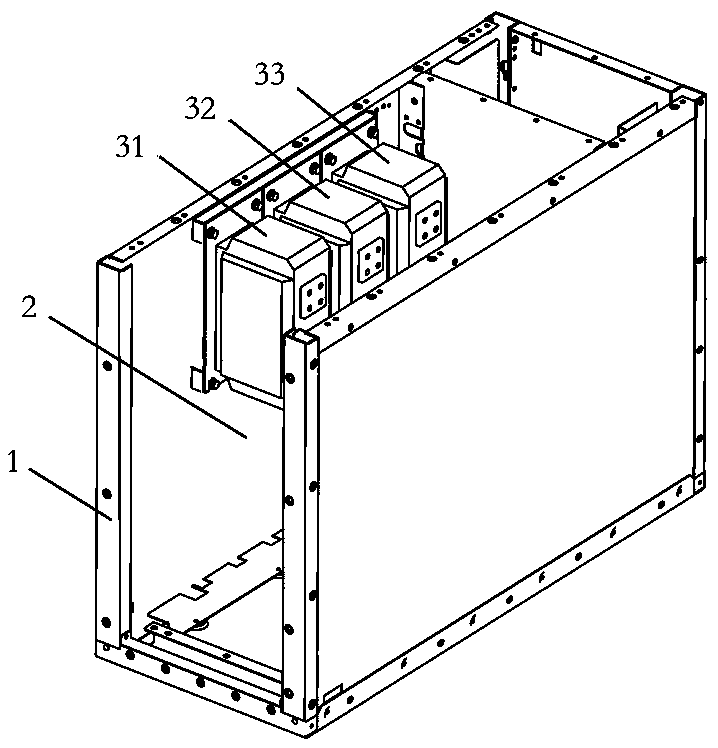

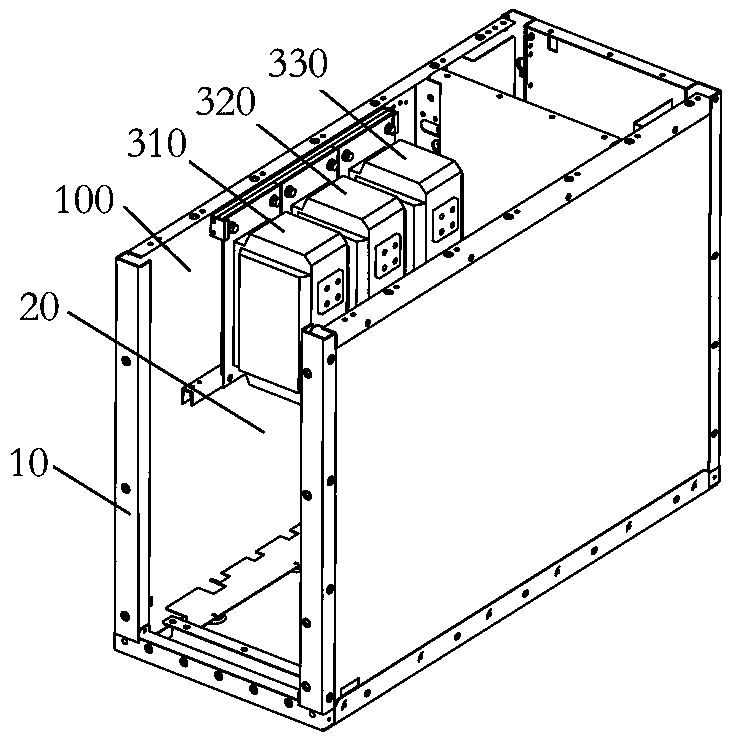

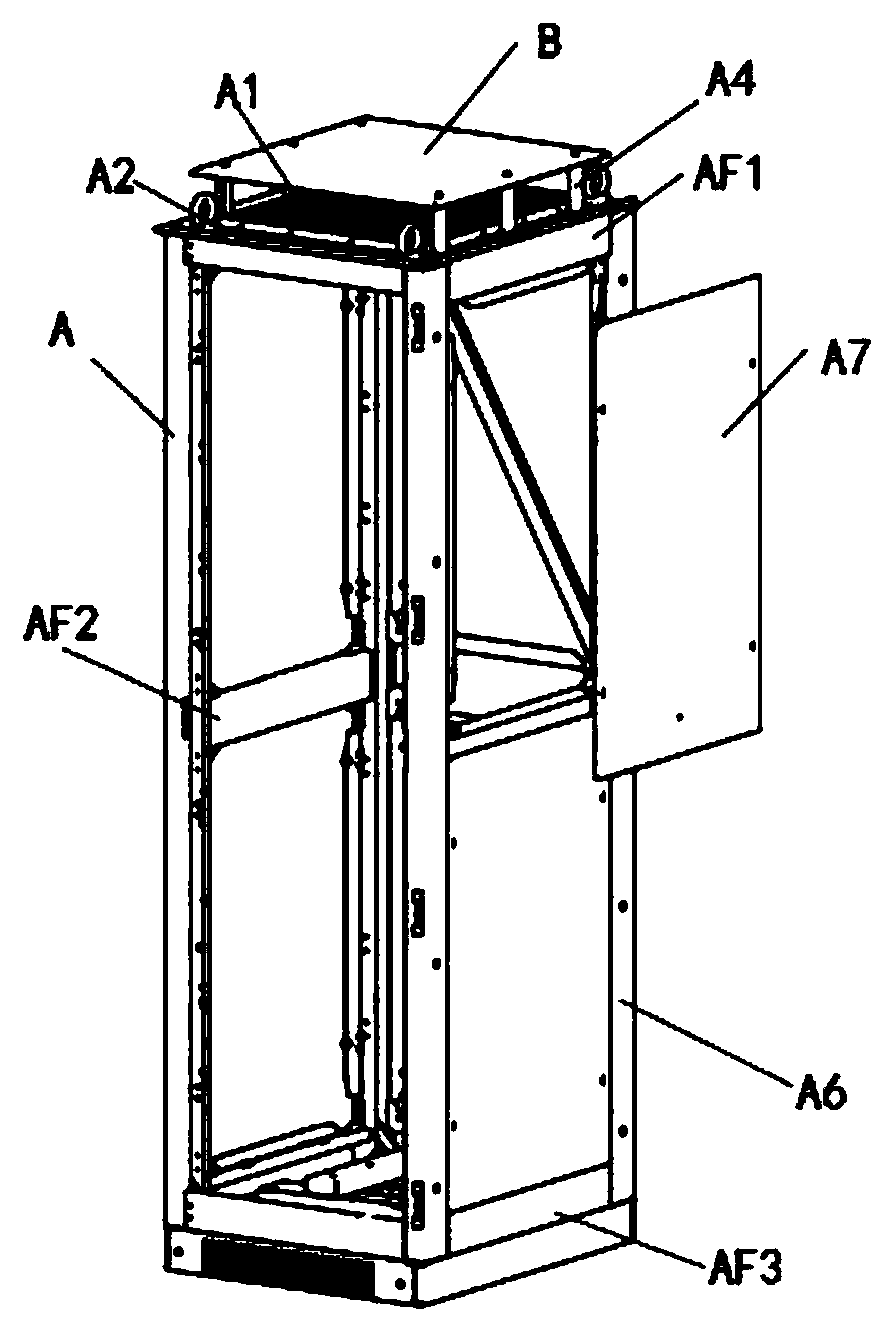

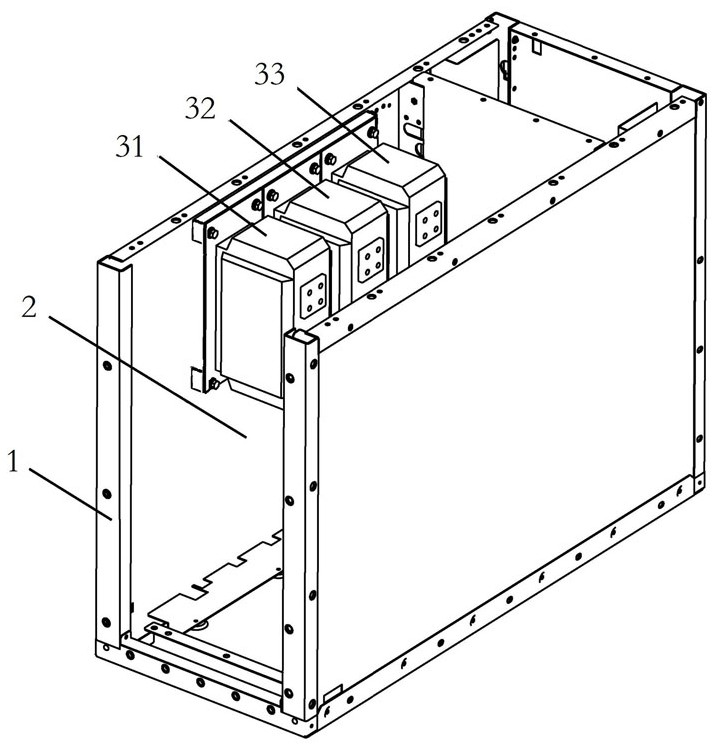

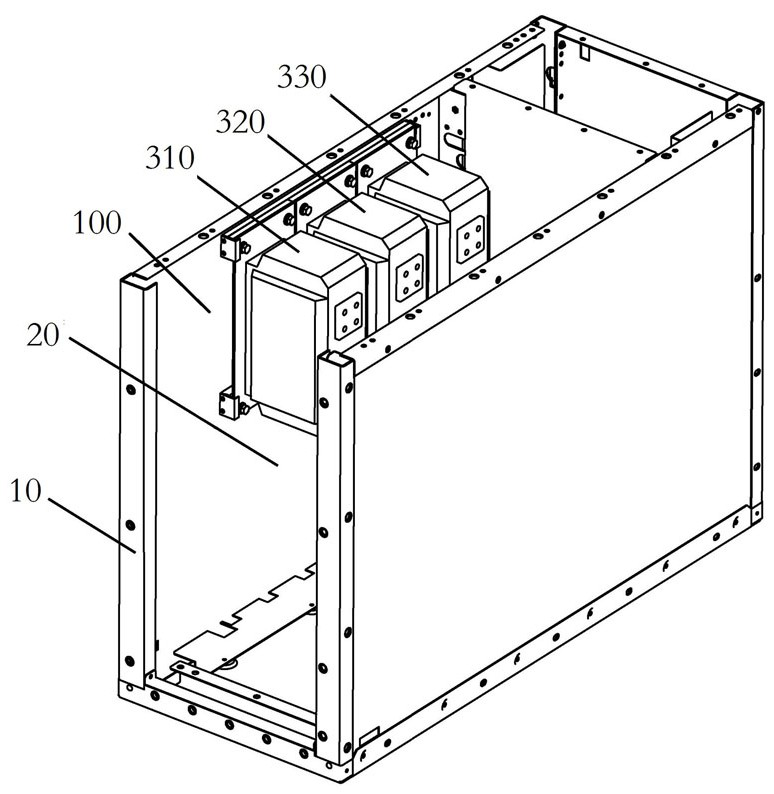

Switch cabinet body, switch cabinet and transformer installation structure thereof

ActiveCN108988157ASolve installation difficultiesEasy to installSubstation/switching arrangement casingsTransformerMechanical engineering

The invention relates to a switch cabinet body, a switch cabinet and a transformer installation structure, The transformer mounting structure includes a side plate hook structure for fixing on the side plate of the cabinet body and a transformer hook structure for fixing on the transformer and hook-and-match with the side plate hook structure so that the transformer is mounted on the side plate ofthe cabinet body. The transformer mounting structure further includes a fixing structure for fixing the transformer on the side plate of the cabinet body. The transformer mounting structure is provided with a hook-and-tie structure and a fixing structure. When the transformer is installed, the hook-and-tie structure fixed on the transformer and the side plate hook-and-tie structure fixed on the side plate of the cabinet body are hooked and matched first, the transformer is mounted on the side plate of the cabinet body, and then the transformer is fixed through the fixing structure. The invention solves the problem that the transformer is difficult to be installed when the transformer is installed vertically in the prior art.

Owner:PINGGAO GRP +1

Magnetic attraction door assembly

PendingCN114086843AImprove operational efficiencyEasy to useWing fastenersClassical mechanicsEngineering

The invention provides a magnetic attraction door assembly. A main magnetic attraction assembly extending in the circumferential direction of a door plate is arranged on the edge portion of the door plate; the main magnetic attraction assembly comprises a base frame fixed to the door plate, a main magnetic attraction strip embedded in the outer side of the base frame and a main magnet packaged in the main magnetic attraction strip, and the outer wall of the main magnetic attraction strip is obliquely arranged relative to the main extension face of the door plate; an auxiliary magnetic attraction assemby matching the main magnetic attraction assembly in an aligned mode is arranged on the edge portion of a door frame in the circumferential direction of the door frame; the auxiliary magnetic attraction assembly comprises a soft sealing strip fixed to the door frame, and an auxiliary magnet matching the main magnetic attraction strip in a magnetic attraction mode are embedded in the soft sealing strip; when the door plate and the door frame are closed, the outer wall of the soft sealing strip is matched with the outer wall of the main magnetic attraction strip in an aligned attaching and abutting mode. According to the magnetic attraction door assembly, the structural adaptability between the door plate and the door frame of the magnetic attraction door assembly is good, and the structural sealing performance and the sound insulation effect are good after the magnetic attraction door is closed.

Owner:闼闼家居科技(北京)有限公司

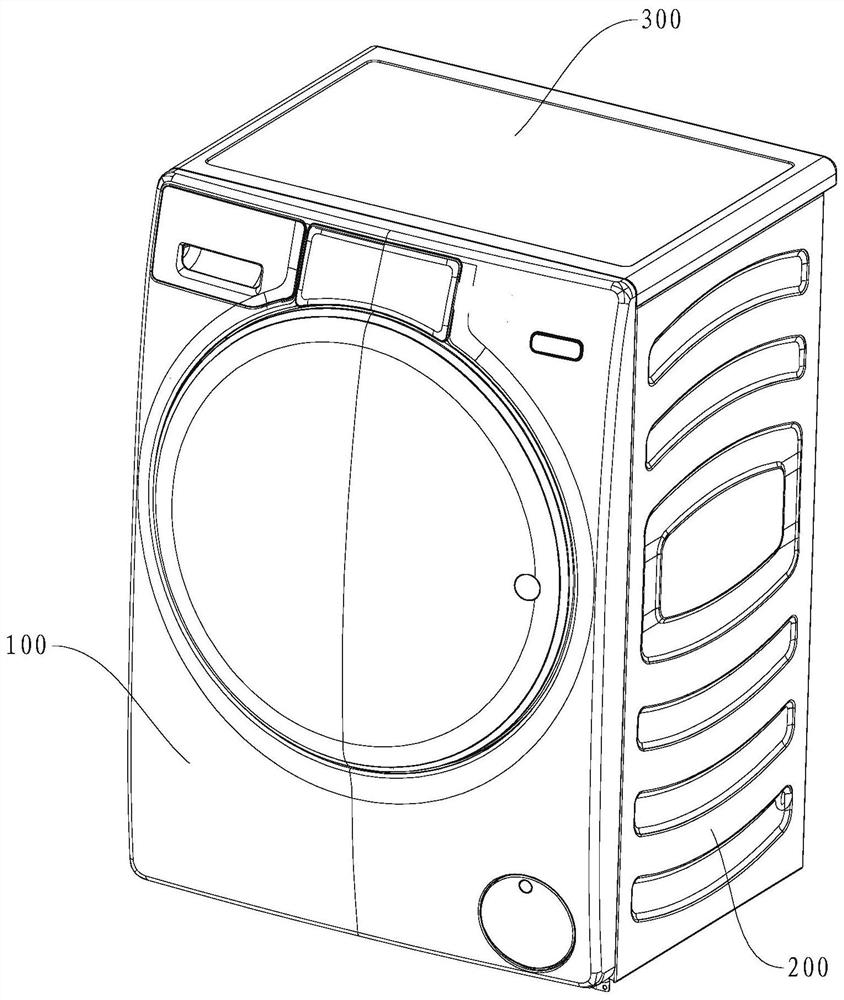

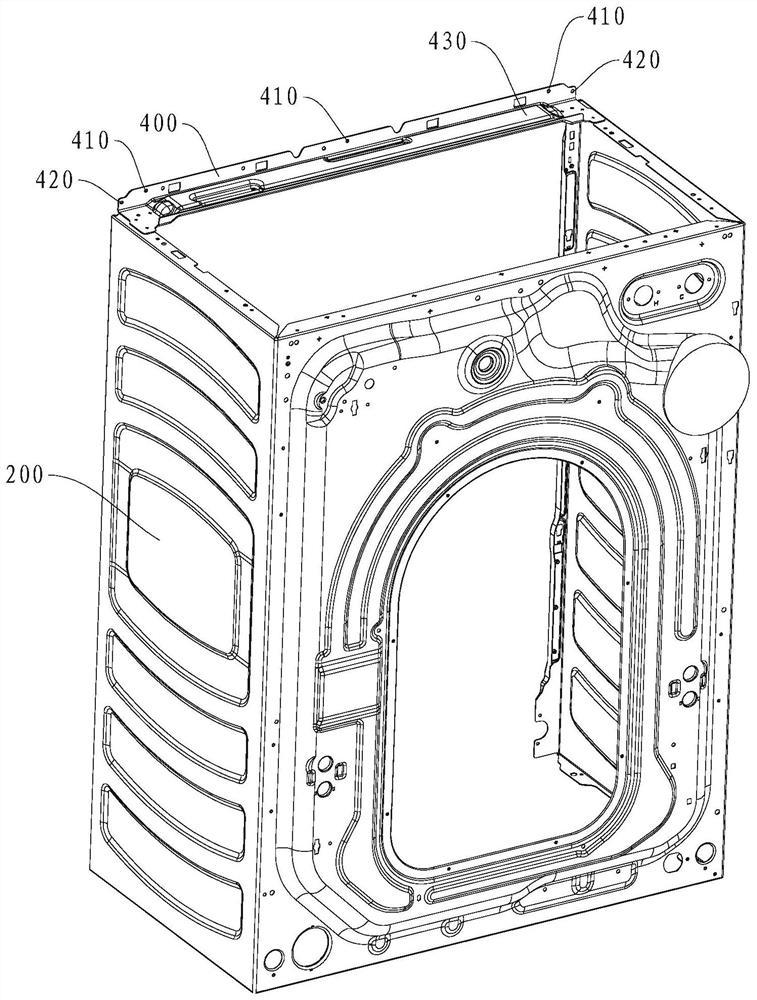

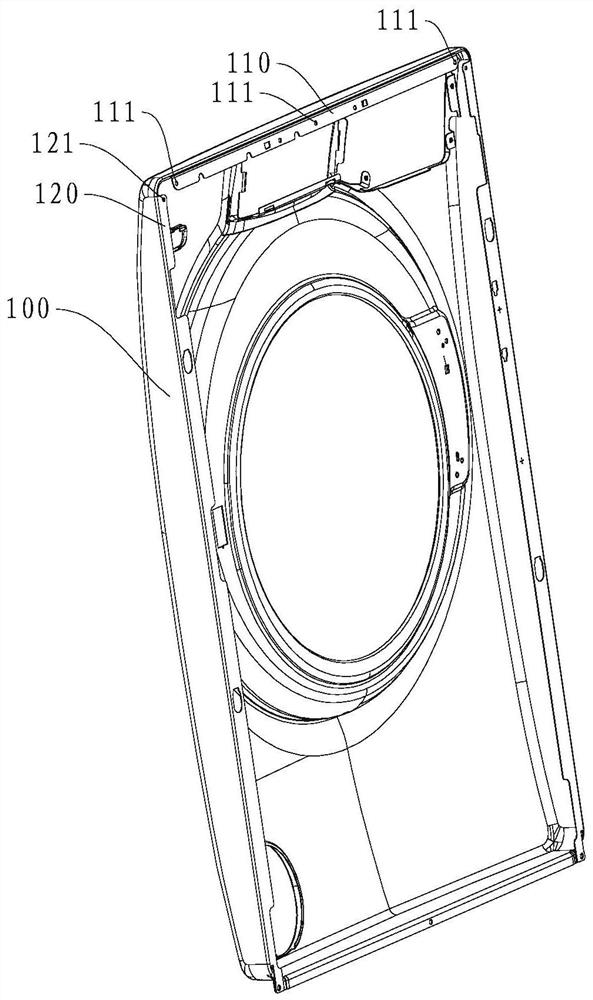

Washing machine front plate installing structure and washing machine

PendingCN111764117AImprove stabilitySimple and fast operationOther washing machinesTextiles and paperLaundry washing machineStructural engineering

The invention discloses a washing machine front plate installing structure and a washing machine. The washing machine comprises a box body and a table top fixed to the box body, the front end face ofthe box body is an integrated front plate, the installing structure comprises a reinforcing part, the reinforcing part is of an L-shaped cross beam structure, the reinforcing part is fixed to a side plate of the box body, a flange is arranged on the side, opposite to the table top, of the front plate, and the front plate is hung on the side edge of the reinforcing part through the flange and fixedly connected with the reinforcing part. According to the washing machine front plate installing structure, the reinforcing part is fixedly connected with the box body, then the front plate is hung onthe side edge of the reinforcing part, finally the front plate and the reinforcing part are fixed, operation is easy and convenient, the reinforcing part can play a certain role in supporting and fixing the front plate, and the stability of the overall structure of the washing machine is enhanced; and by means of the suspension installation mode, the assembly gap is guaranteed, and the assembly strength is guaranteed.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

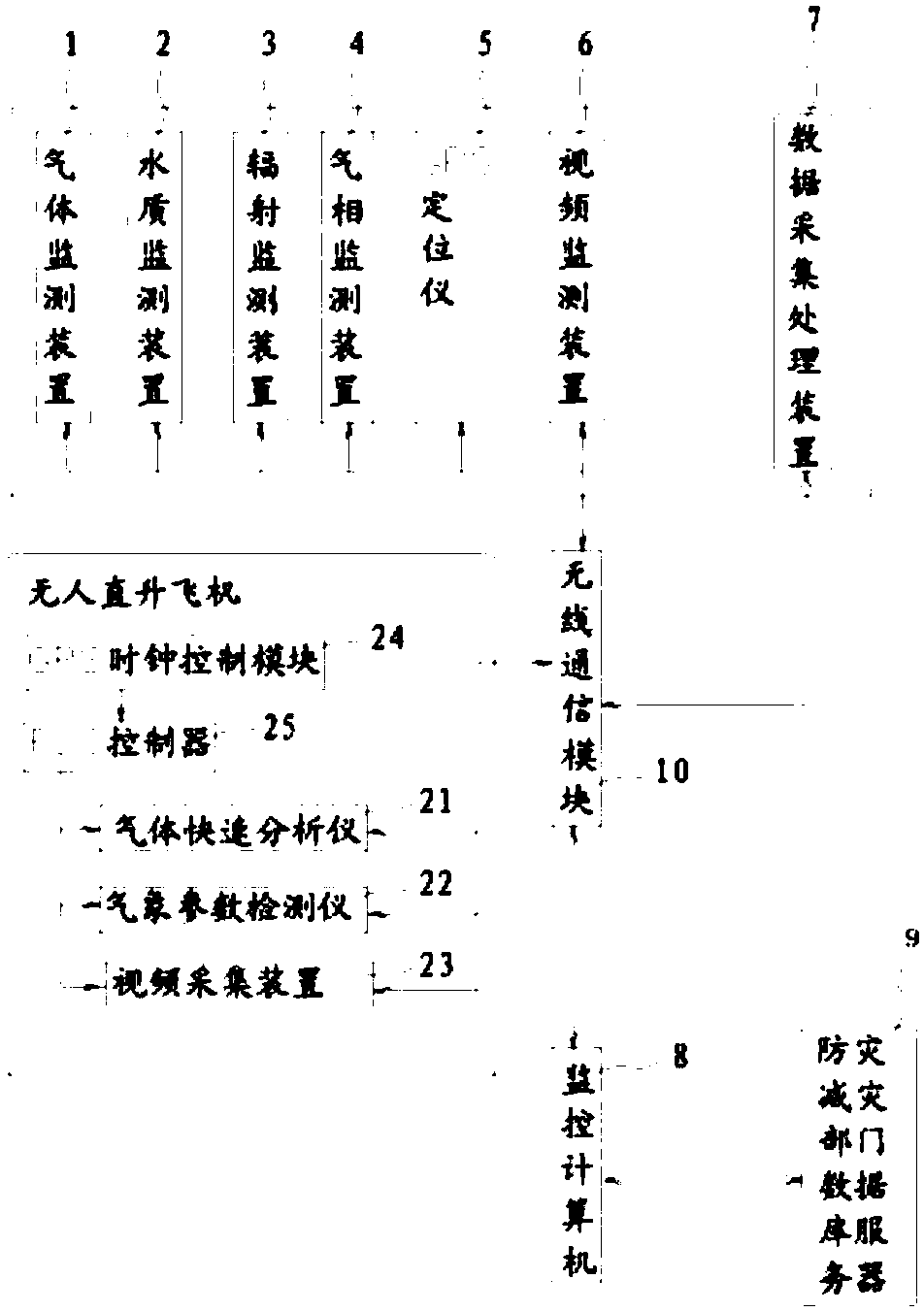

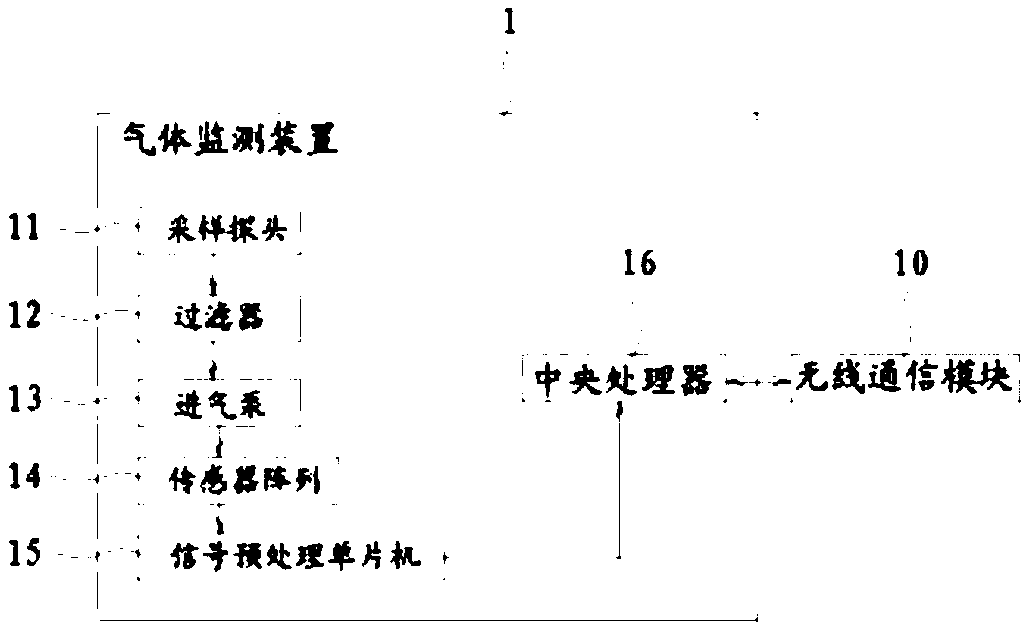

Comprehensive liquid-blocking type server case for vehicle-mounted water quality monitoring

InactiveCN110908450APrevent infiltrationEfficient EvacuationMeasurement devicesDigital processing power distributionDatabase serverIn vehicle

The invention discloses a comprehensive liquid-blocking type server case for vehicle-mounted water quality monitoring. The comprehensive liquid-blocking type server case comprises a case body and a cover plate, the upper wall of the box body is provided with an exhaust groove which is communicated with the hollow interior of the box body and is used as an exhaust passage; the case body further comprises vertical rods arranged in the longitudinal direction and sheet-shaped blocking pieces arranged between the vertical rods. The vertical rods are arranged in parallel to form a bracket of the case body; and the side wall of the bracket is sealed by the blocking pieces. In combination with other structures, the defects that in the prior art, the liquid blocking effect is poor, leaked liquid seeps into the case body through the side wall of the case, and the serious accident of short circuit of components of the database server in the case is likely to happen are effectively overcome.

Owner:XIAN TIANHENG MEASURING INSTR

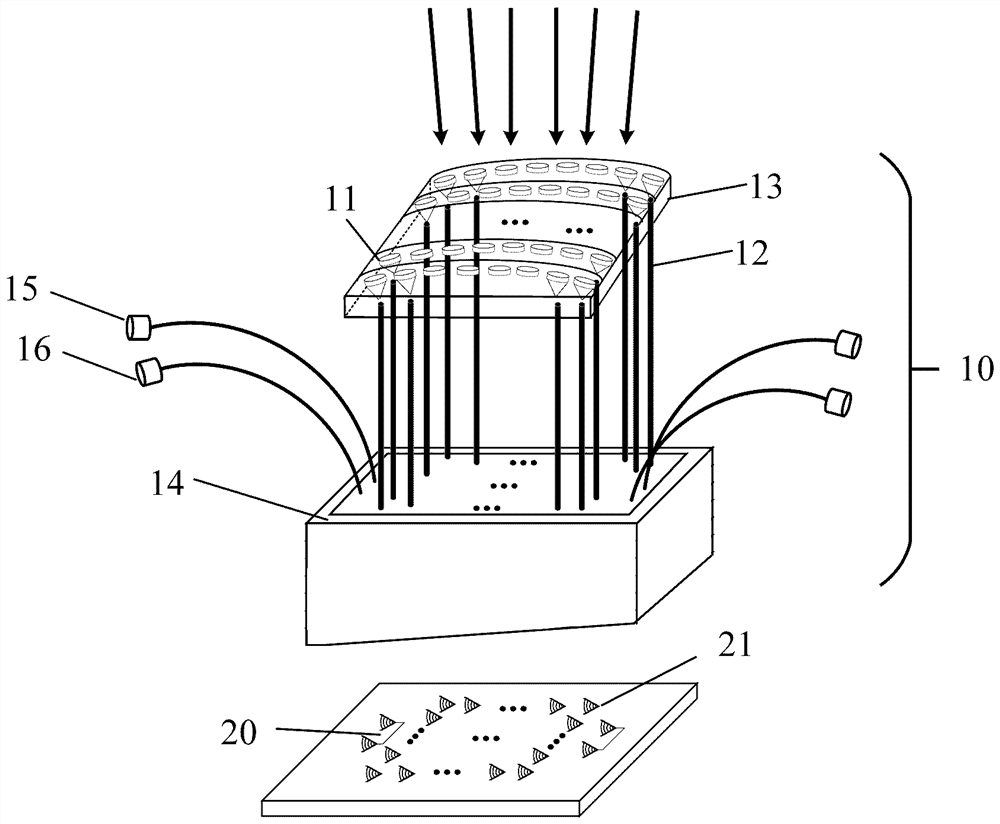

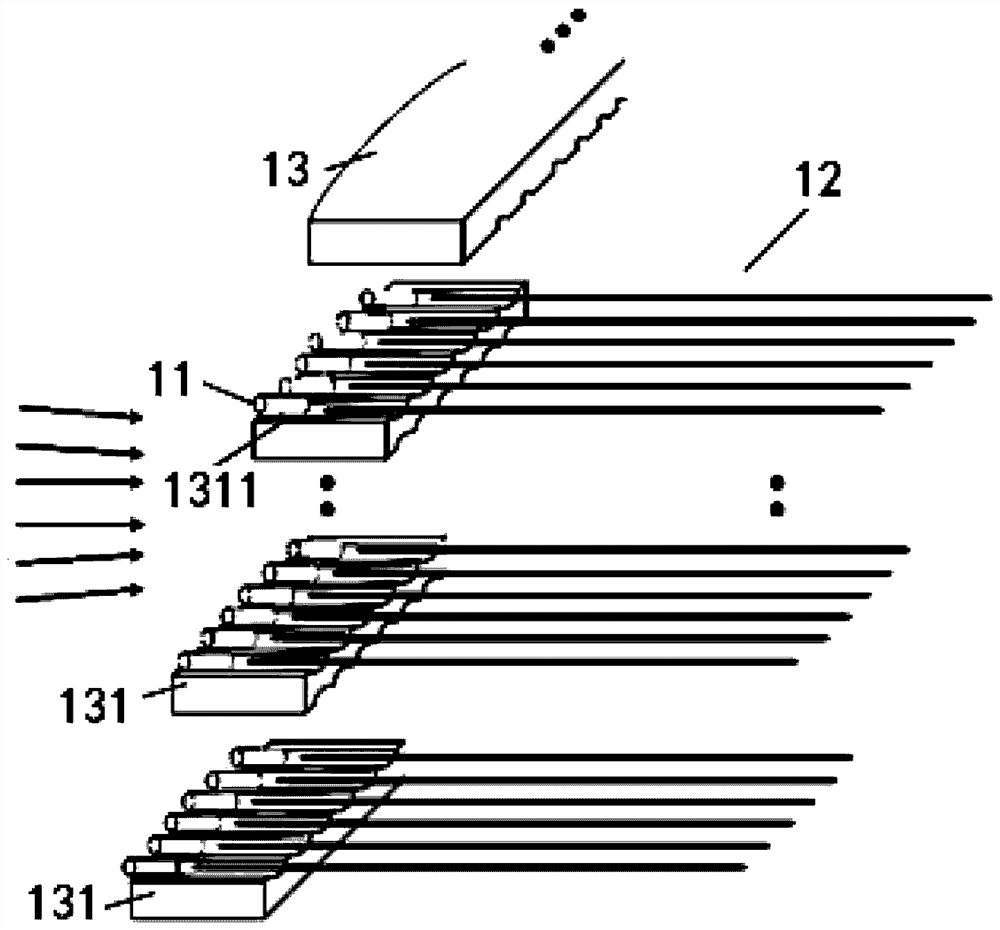

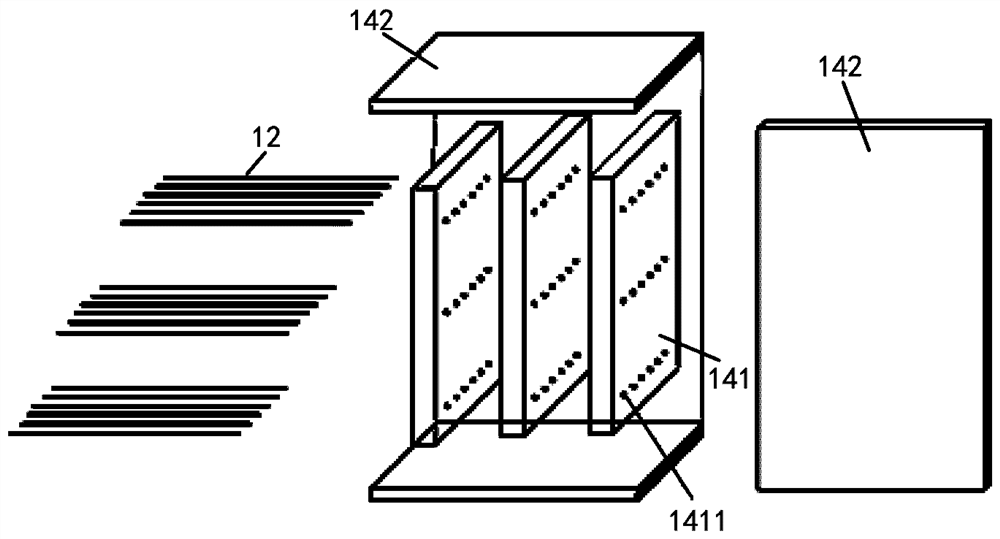

Packaging process of multi-transmission-channel laser radar optical coupling system

InactiveCN111856431AGuaranteed transmission efficiencyEasy to useWave based measurement systemsGratingFiber array

The invention provides a packaging process of a multi-transmission-channel laser radar optical coupling system. The packaging process of the multi-transmission-channel laser radar optical coupling system comprises the following steps: a primary assembly step and a packaging step: mounting a plurality of lenses of a lens array and first ends of a plurality of optical fibers of an optical fiber array structure at a plurality of mounting positions of a first fixing structure in a one-to-one correspondence manner, and packaging and fixing the lenses and the first ends of the optical fibers to thefirst fixing structure; a secondary assembly step: mounting second ends of the plurality of optical fibers at a plurality of mounting positions of a second fixing structure in a one-to-one correspondence manner; a secondary packaging step: packaging and fixing the second ends of the optical fibers to the second fixing structure; and a grating array structure fixing step: aligning a plurality of gratings of a grating array structure with the second ends of the plurality of optical fibers one by one and packaging and fixing the gratings and the second ends. According to the invention, the problem that optical fibers of an optical coupling system of a laser radar in the prior art are easy to misplace is solved.

Owner:INFORMATION SCI RES INST OF CETC

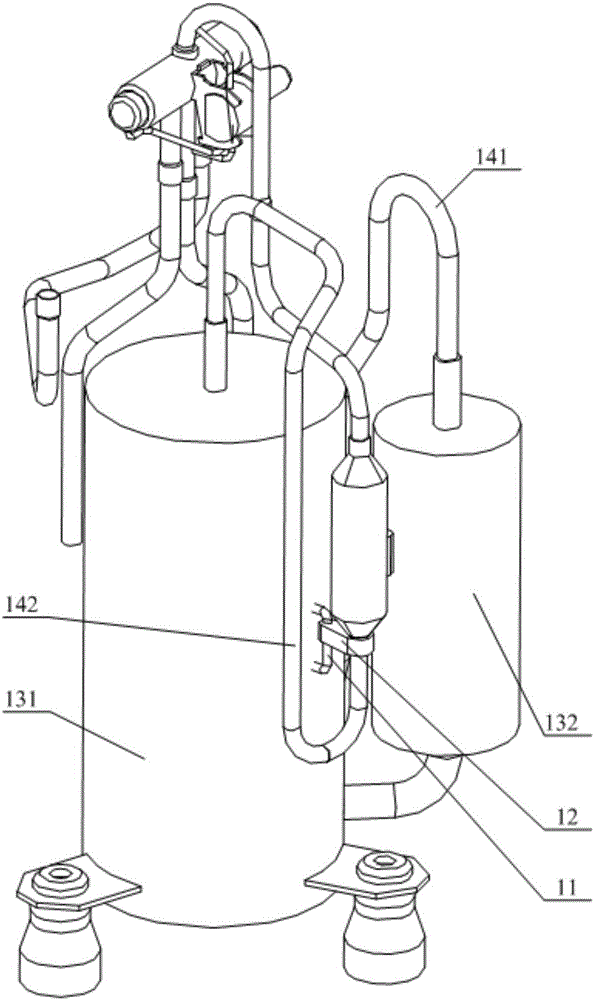

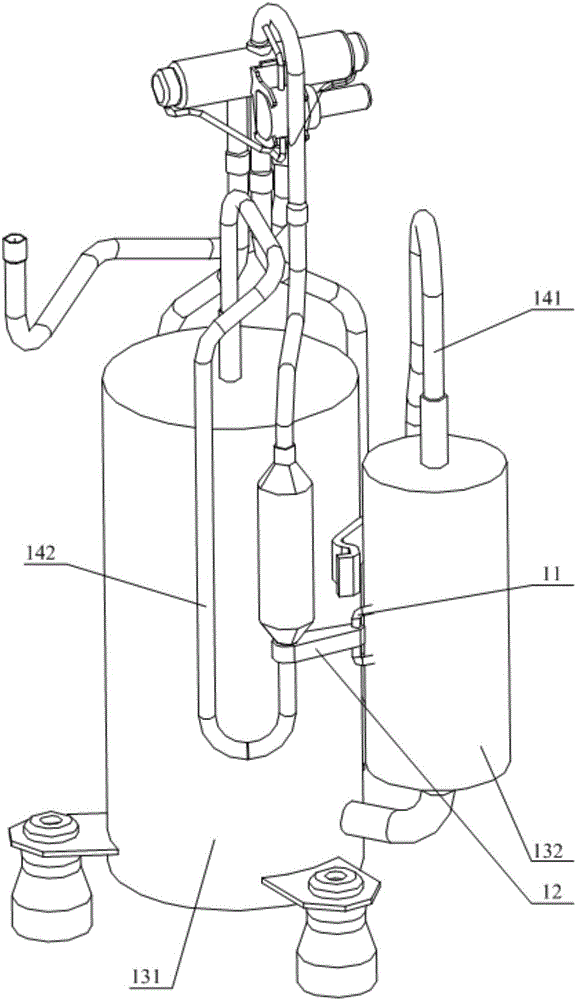

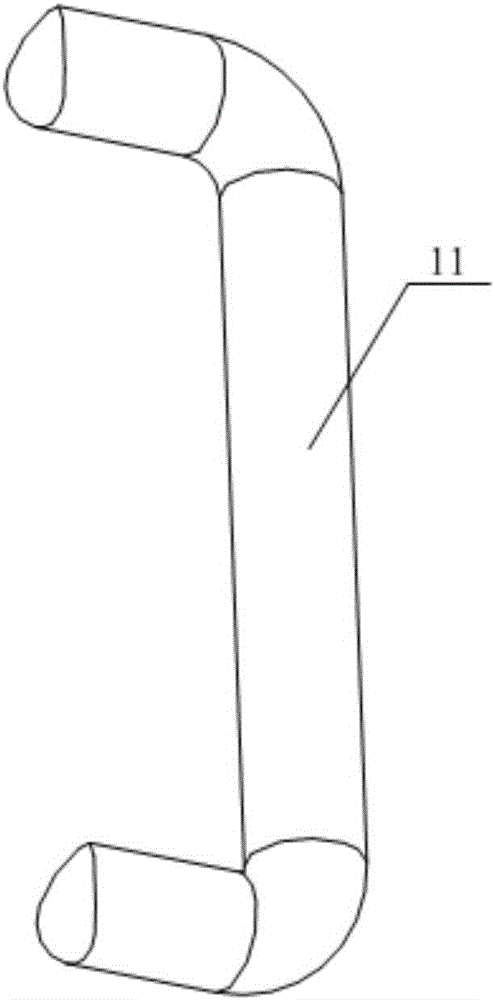

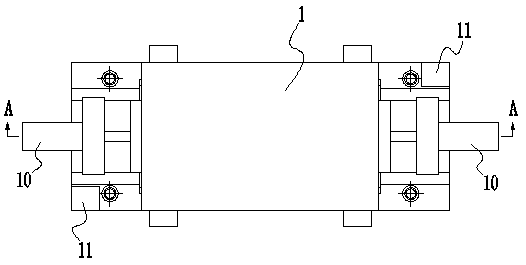

Refrigeration equipment and compressor assembly thereof

The invention discloses a compressor assembly. The compressor assembly comprises a machine body and a pipeline. A fixing support lug is arranged on the machine body. A limiting fixing piece is fixedly connected between the fixing support lug and the pipeline. In the assembly operating process, the fixing support lug is reliably matched with the limiting fixing piece, and a stable and reliable fastening limiting structure is formed between the pipeline and the machine body, so that pipeline vibration generated during equipment start or stop is lowered effectively, loosening or damage, caused by pipeline vibration, of or to the pipeline and related components of the pipeline is avoided, and the reliability and operating stability of the whole structure of the compressor assembly and the refrigeration equipment are guaranteed. The invention further discloses the refrigeration equipment applying the compressor assembly.

Owner:GREE ELECTRIC APPLIANCES INC

An integral riveting tooling and riveting method for an i-type automobile thrust rod body

ActiveCN106670327BAvoid the phenomenon of axial extensionGuaranteed processing efficiencyVehicle componentsHydraulic cylinderEngineering

The invention discloses an integral riveting tool for an I-shaped automobile thrust rod body and a riveting method of the integral riveting tool. The tool comprises an upper installing plate, a lower installing plate, a floating plate, upper riveting dies and lower riveting dies, wherein the upper riveting dies and the lower riveting dies are arranged on the upper installing plate and the lower installing plate correspondingly, and the two upper riveting dies and the two lower riveting dies are arranged. The tool further comprises two ball head sliding bases connected to the floating plate in a sliding manner, and two equal-height blocks arranged on the floating plate. Two sliding base power cylinders are further fixedly connected to the floating plate. Under driving of the two sliding base power cylinders, the two ball head sliding bases can move close to each other or away from each other relatively along the floating plate. The two ball head sliding bases can drive two ball heads to be connected to the two ends of a pipe in a sleeving manner. The floating plate is further provided with a vertical power cylinder, the lower riveting dies penetrate the floating plate, the floating plate can move back and forth in the vertical direction under the action of the vertical power cylinder, and hydraulic cylinders or air cylinders are adopted as the sliding base power cylinders and the vertical power cylinder. Through the integral riveting tool and the riveting method, the quality of the thrust rod body is guaranteed, and integral riveting can be finished at a time.

Owner:BOGE RUBBER&PLASTICS ZHUZHOU CO LTD

Comprehensive liquid blocking type vehicle-mounted water quality monitoring framework

InactiveCN110908451APrevent infiltrationEfficient EvacuationMeasurement devicesDigital processing power distributionIn vehicleDatabase server

According to a comprehensive liquid blocking type vehicle-mounted water quality monitoring framework, a database server is placed in a hollow server case, and the server case comprises a case body anda cover plate; the upper wall of the box body is provided with an exhaust groove which is communicated with the hollow interior of the case body and is used as an exhaust passage; the case body further comprises vertical rods arranged in the longitudinal direction and sheet-shaped blocking pieces arranged between the vertical rods. The vertical rods are arranged in parallel to form a bracket of the case body; and the side wall of the bracket is sealed by the blocking pieces. In combination with other structures, the defects that in the prior art, the liquid blocking effect is poor, leaked liquid seeps into the case body through the side wall of the case, and the serious accident of short circuit of components of the database server in the case is likely to happen are effectively overcome.

Owner:XIAN TIANHENG MEASURING INSTR

Display module

PendingCN114360380AGood lookingStrong sense of technologyNon-linear opticsIdentification meansDisplay deviceEngineering

The invention relates to the technical field of displays, in particular to a display module. The invention provides a display module which comprises a middle frame, a composite back plate, a connecting piece and a display OC layer, the periphery of the middle frame is bent and spliced end to end to form a closed frame type structure, one side of the middle frame is in glue joint with the composite back plate, the other side of the middle frame is connected with the display OC layer through the connecting piece, and the whole display OC layer is suspended above the middle frame. The end-to-end spliced closed frame structure is formed by the middle frame, so that the appearance integrity of the display module can be improved, and meanwhile, the strength of the middle frame can be enhanced. And on the other hand, the display OC layer is connected with the middle frame through the connecting piece, and the whole display OC layer is suspended above the middle frame, so that the appearance of the display module has a sense of science and technology on the premise of ensuring the assembly strength, and the attractiveness of the display module can be improved.

Owner:ALLIN OPTO ELECTRONICS SUZHOU CO LTD

Camera decoration components and mobile terminals

ActiveCN110769136BReduce manufacturing costGuaranteed aestheticsTelevision system detailsColor television detailsMechanical engineering

The present invention provides a camera decoration assembly and a mobile terminal. The camera decoration assembly includes a decoration and a fixing piece, the decoration is used to pass through the casing of the mobile terminal, and the installation hole on the decoration is used to install the camera of the mobile terminal. Assemblies, the decorative parts are provided with installation positions; the fixing parts include a fixed body and a fixed arm, the fixed body is used to be fixed on the inner surface of the housing; At the mounting position of the component, the decorative component is fixed on the housing. Through the cooperation of the decorative part and the fixing part, the fixing arm of the fixing part fixed on the inner surface of the casing can be bent and fastened to the installation position of the decorative part, so as to ensure that the decorative part can be stably fixed to the casing. When impacted by an external force, under the fastening force of the fixed arm, the decorative part can be effectively prevented from falling out of the housing, ensuring the assembly strength of the decorative part and the housing, ensuring that the camera assembly can be installed stably, and improving user experience.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Biological deodorization box shell protection type steel structure

PendingCN111841303AImprove firmnessImprove smoothnessDispersed particle separationAir quality improvementMechanical engineeringMesh grid

The invention discloses a biological deodorization box shell protection type steel structure. The steel structure comprises a top steel structure surface, a bottom steel structure surface and four side steel structure surfaces, the top steel structure surface comprises a top main beam outer frame and a plurality of top auxiliary beams, the two ends of all the top auxiliary beams are welded with the corresponding top main beams, the bottom steel structure surface comprises a bottom main beam outer frame and a plurality of bottom auxiliary beams, the side steel structure surface comprises a sidemain beam outer frame and a plurality of side auxiliary beams, the two ends of each side auxiliary beam are welded to the corresponding side main beams, and the top steel structure surface, the bottom steel structure surface and the four side steel structure surfaces are each in a square grid shape. The steel structure is arranged on the surface of a FRP shell of the biological deodorization box,so that the firmness and the extrusion resistance of the shell are improved, and meanwhile, the steel structure can endure long-distance transportation, the safety is greatly improved, the overall firmness is guaranteed, the service life of the steel structure can be prolonged, and the maintenance cost of the steel structure is reduced.

Owner:朱红良 +1

Switch cabinet body, switch cabinet and its transformer installation structure

ActiveCN108988157BEasy to installIncrease job securitySubstation/switching arrangement casingsTransformerEngineering

The invention relates to a switch cabinet body, a switch cabinet and a transformer installation structure, The transformer mounting structure includes a side plate hook structure for fixing on the side plate of the cabinet body and a transformer hook structure for fixing on the transformer and hook-and-match with the side plate hook structure so that the transformer is mounted on the side plate ofthe cabinet body. The transformer mounting structure further includes a fixing structure for fixing the transformer on the side plate of the cabinet body. The transformer mounting structure is provided with a hook-and-tie structure and a fixing structure. When the transformer is installed, the hook-and-tie structure fixed on the transformer and the side plate hook-and-tie structure fixed on the side plate of the cabinet body are hooked and matched first, the transformer is mounted on the side plate of the cabinet body, and then the transformer is fixed through the fixing structure. The invention solves the problem that the transformer is difficult to be installed when the transformer is installed vertically in the prior art.

Owner:PINGGAO GRP +1

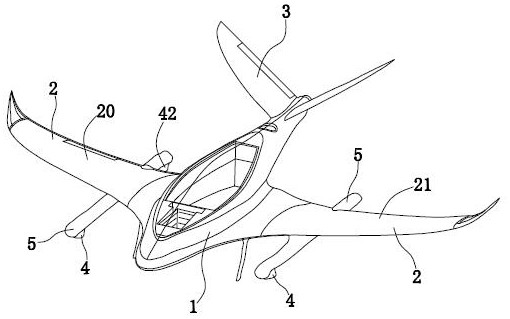

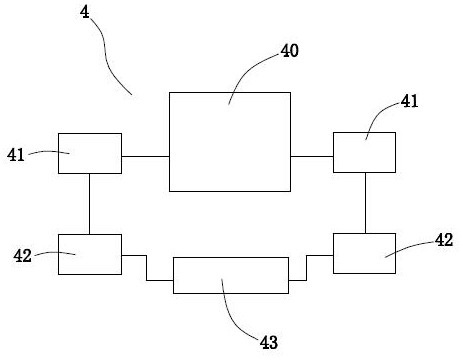

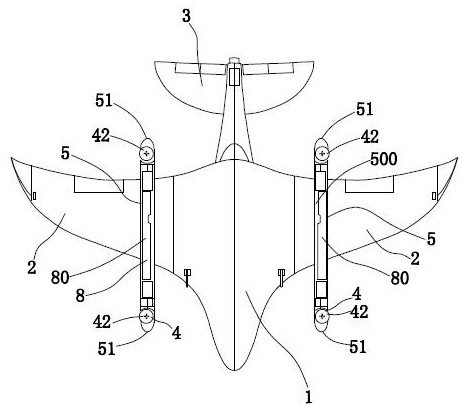

Aircraft provided with low-resistance hanging wall

PendingCN112319774AMounting point reinforcementGuaranteed assembly strengthHeat reducing structuresFlight vehicleFastener

The invention provides an aircraft provided with low-resistance hanging walls, which comprises an aircraft body, wings, an empennage, a power device and at least two hanging walls, the two hanging walls are arranged on the lower surfaces of the wings positioned on two sides of the center line direction of the aircraft body, a left embedding groove is formed in the lower surface of a left wing body, and a right embedding groove is formed in the lower surface of a right wing body; each hanging wall comprises a shell with a lower opening cavity and conical arc cylinders extending out along the two ends of the shell, each shell comprises a shell body part and a windward side shell part arranged at the top of the shell body, the upper half part of each conical arc cylinder is integrally connected with the shell body part, and the lower half part of each conical arc cylinder extends out of the opening of the lower opening cavity of the shell body; one part of the fasteners respectively penetrate through the glass fiber plate and the windward side shell part on the same side of the left wing body and are locked in the lock hole of the left embedding groove, and the other part of the fasteners respectively penetrate through the glass fiber plate and the windward side shell part on the same side of the right wing body and are locked in the lock hole of the right embedding groove. Compared with the prior art, air resistance generated by wall hanging is reduced, and the flight speed is increased.

Owner:深圳市蜉飞科技有限公司

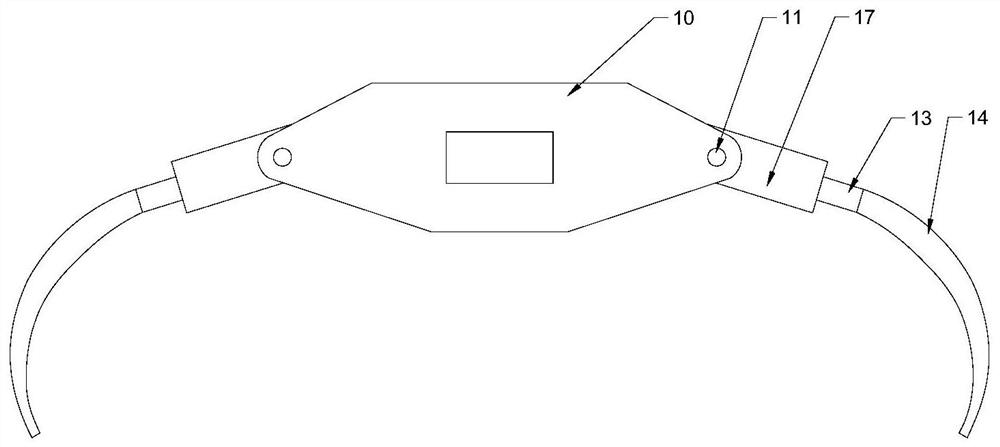

Amphibious vehicle mechanical claw device

PendingCN112476462AGuaranteed assembly strengthAvoids the problem of removing the entire forepaw unitAmphibious vehiclesGripping headsMarine engineeringStructural engineering

Owner:泰华智业(天津)科技有限责任公司 +1

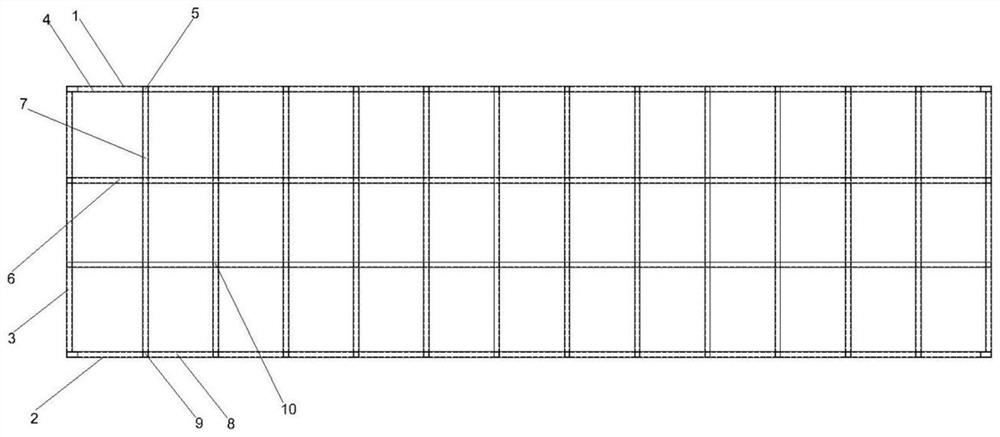

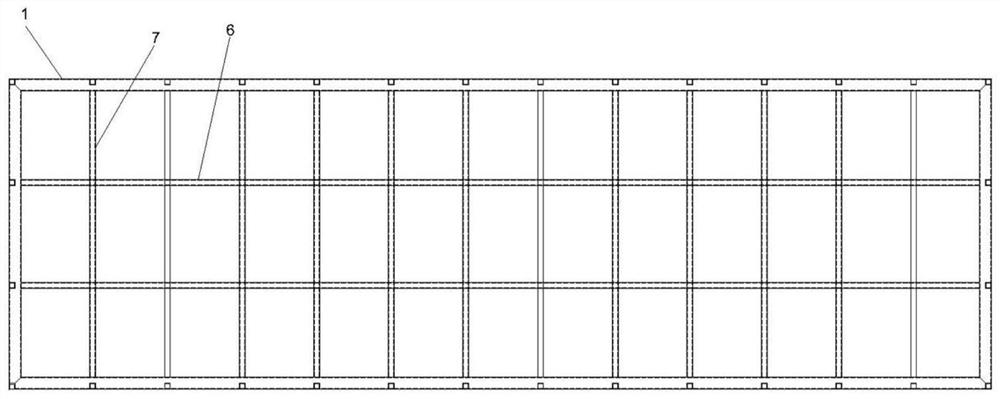

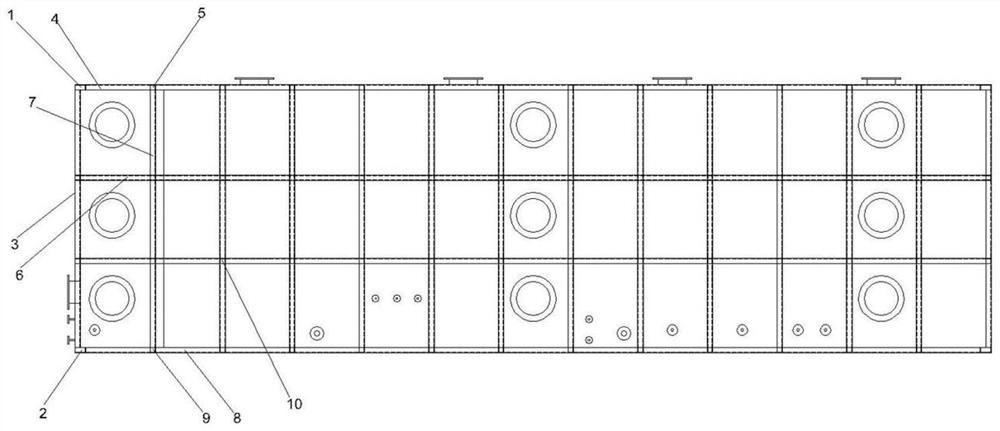

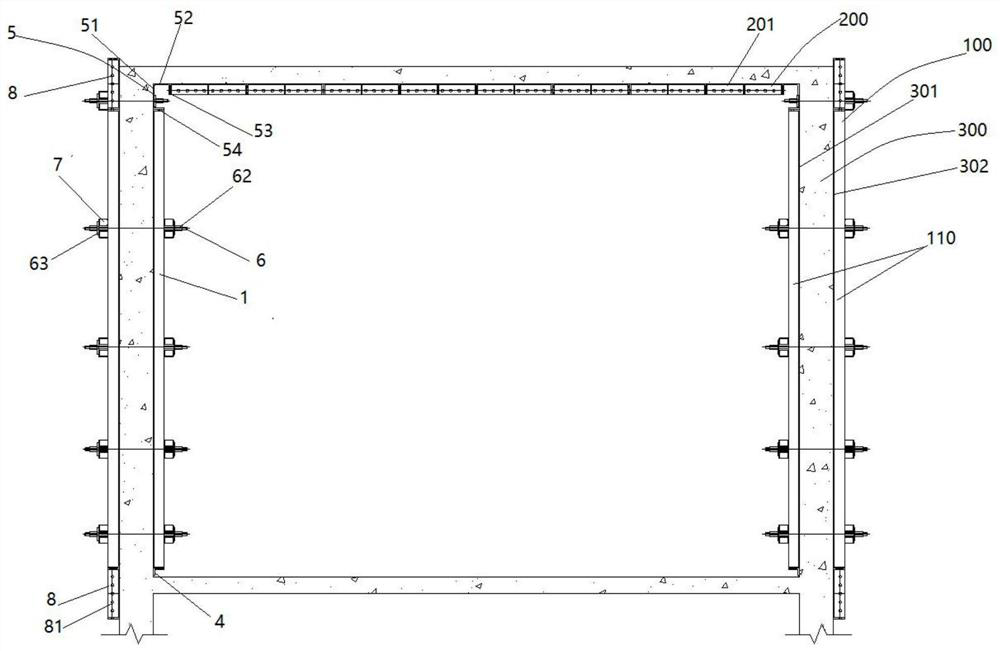

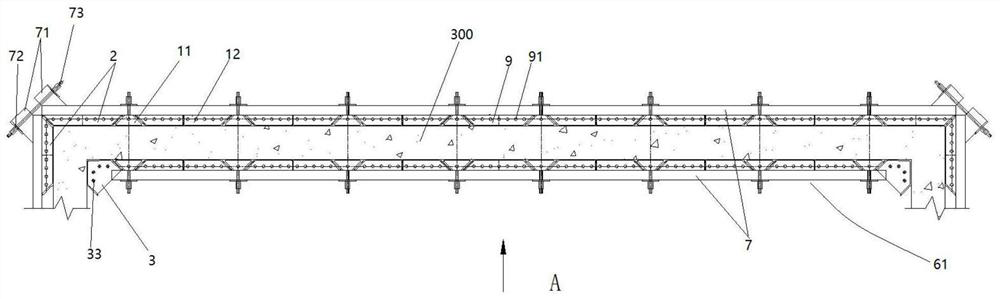

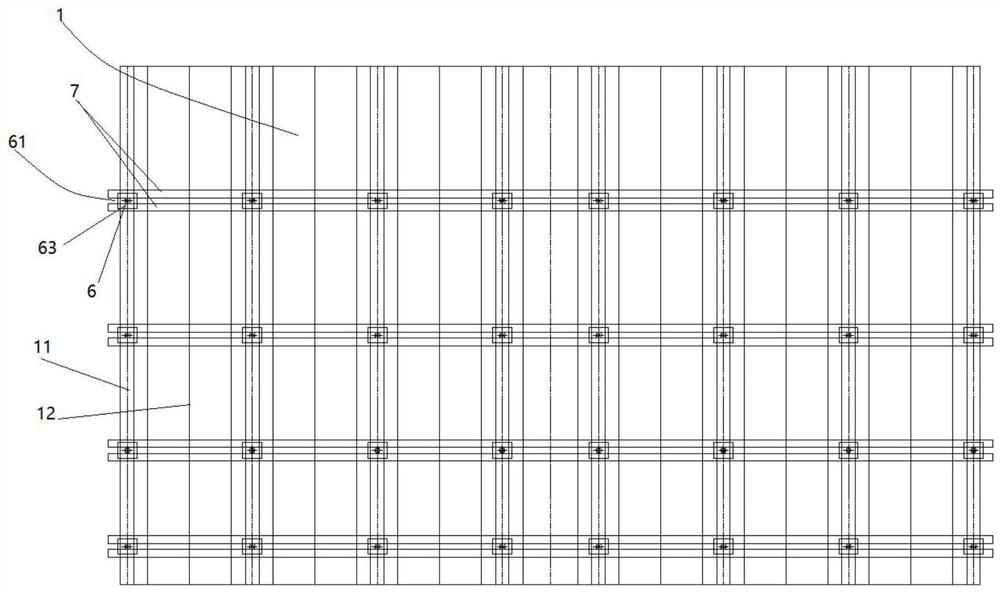

Assembly type combined formwork system and construction method thereof

PendingCN111779260AGuaranteed stiffnessGuaranteed StrengthForms/shuttering/falseworksBuilding material handlingArchitectural engineeringStructural engineering

The invention provides an assembly type combined formwork system and a construction method thereof. The assembly type combined formwork system comprises a wall column formwork unit and a floor formwork unit. The wall column formwork unit comprises four wall column formwork sets. Each wall column formwork set comprises two wall column formworks, each wall column formwork comprises a plurality of first vertical formworks and a plurality of second vertical formworks, and the first vertical formworks and the adjacent second vertical formworks are spliced. Two external corner connecting formworks are attached to form an external corner, and every two wall column formworks are connected through internal corner formworks to form an internal corner. The lower end faces of the wall column formworksare connected with bottom corner aluminum. Internal corner connecting formworks are connected with a floor formwork. multiple opposite-pull screws are inserted into fixing holes, back edges are arranged on the outer surfaces of the wall column formworks, and nuts fasten the opposite-pull screws and the back edges. A plurality of connecting K plates are respectively connected to the upper end surfaces and the lower end surfaces of the wall column formworks. According to the system, the number of used pins is reduced, the assembly cost is reduced, and the wall column formworks are used in cooperation with the opposite-pull screws, the nuts and the back edges, so that the rigidity and strength of the wall column formworks are guaranteed.

Owner:广西汇林达科技有限公司

Assembled structures on lightweight foam concrete components

The object of the invention is to provide an assembling structure arranged on an ALC with high precision while exhibiting high reliability in mounting strength of the unit to be assembled. The assembling structure on the ALC unit comprises: an outer wall panel (12) as the ALC unit buried with a reinforcement frame (2) with a metal slice (3) and an outer substrate piece (52), wherein a self-flapping screw (4) screwed from the side of the outer wall substrate piece (52) is screwed into the metal slice (3), therefore the outer wall substrate piece (52) is assembled on the outer wall panel (12) and an outer wall decoration plate (53) is adhered on the surface of the outer wall substrate piece (52) by an adhesive.

Owner:SEKISUI CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com