Amphibious vehicle mechanical claw device

A technology for mechanical claws and amphibious vehicles, which can be used in amphibious vehicles, manipulators, motor vehicles, etc., and can solve problems such as ineffective, rusty front claws, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

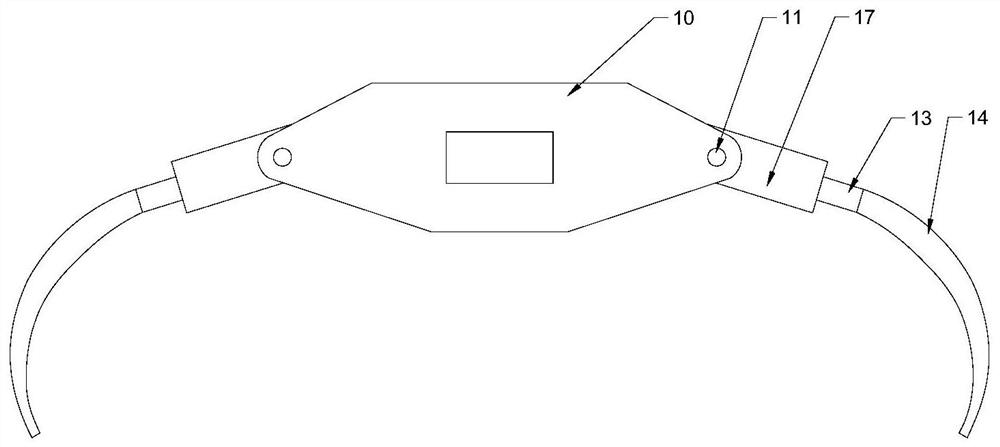

[0024] The technical problem to be solved in this embodiment is that due to the harsh working environment of the mechanical claw device of the amphibious vehicle, the problem that the front claw cannot rotate properly due to long-term contact with muddy water is easy to rust. Dismantling, grinding and derusting treatment, the existing mechanical device is an integral assembly structure, and if there is a problem with one claw of the mechanical claw, it needs to be completely dismantled.

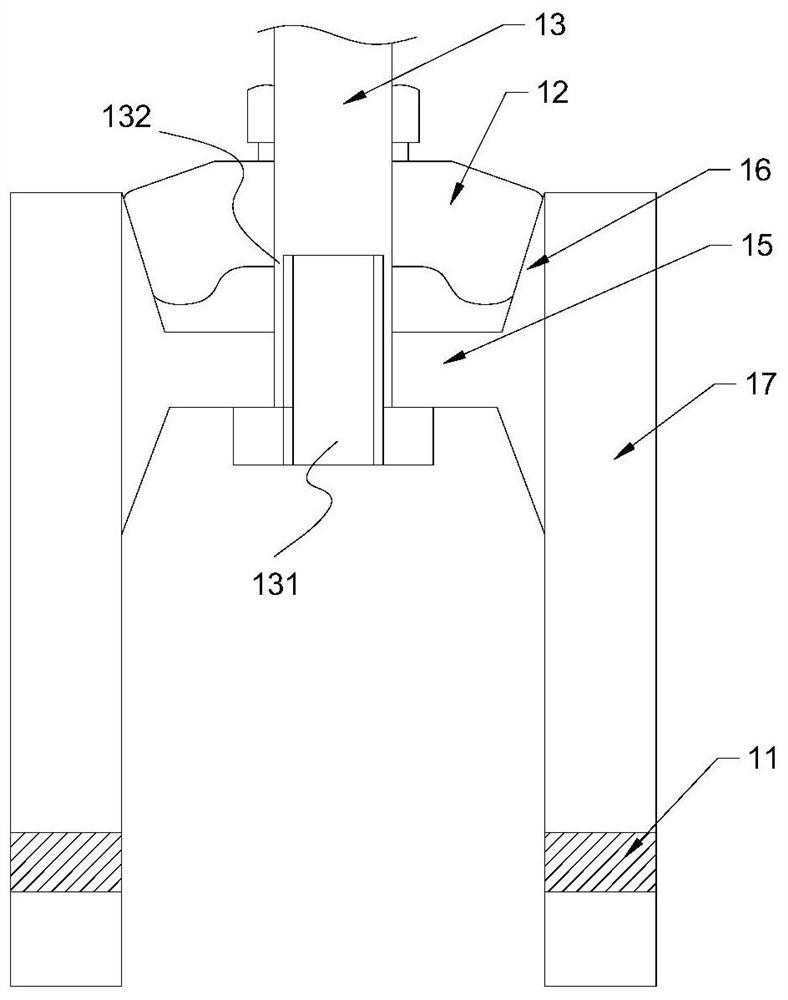

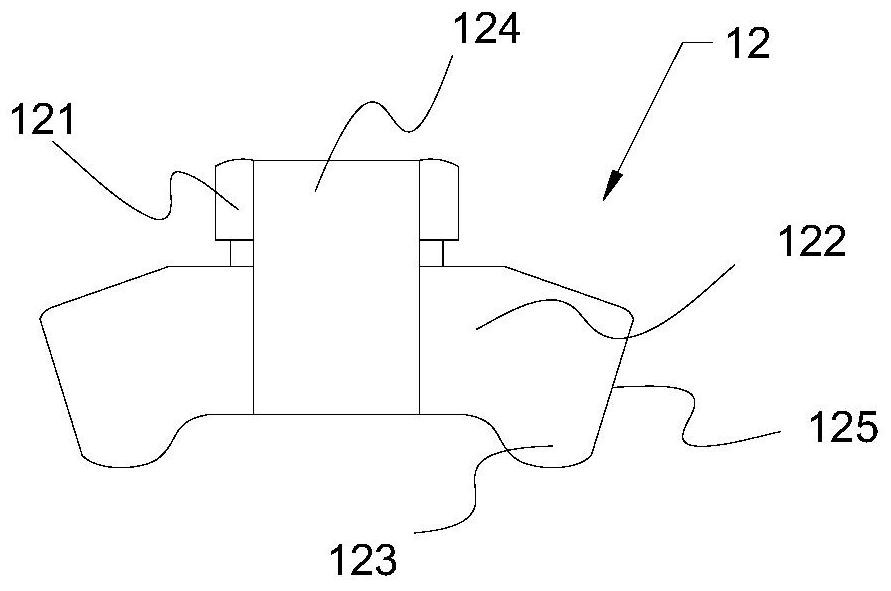

[0025] In order to solve the above technical problems, this embodiment provides a mechanical claw device for an amphibious vehicle, such as figure 1 As shown, it includes a base 10, a connecting shaft 11, and a front paw 14. The bottom of the front paw 14 is fixedly connected with the bottom rod 13 of the claw. 10 on;

[0026] The connecting rocker 17 includes two relatively parallel mounting pieces, and the mounting piece includes a connecting shaft hole for connecting with the base 10; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com