Assembly type combined formwork system and construction method thereof

A combined formwork and assembly technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problem of high construction cost of aluminum formwork, save the use of pins and reduce construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

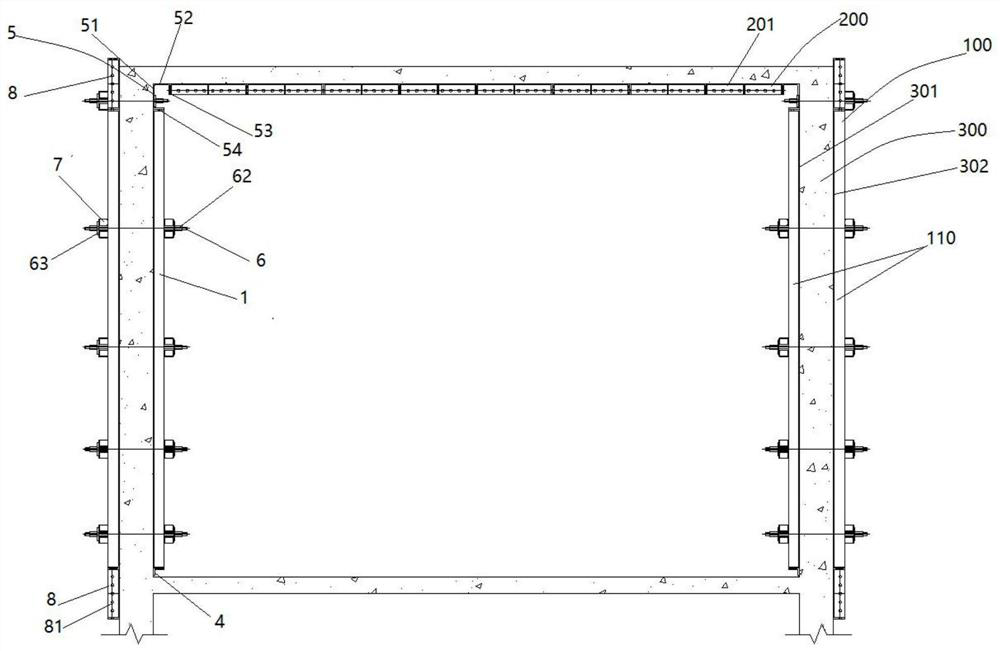

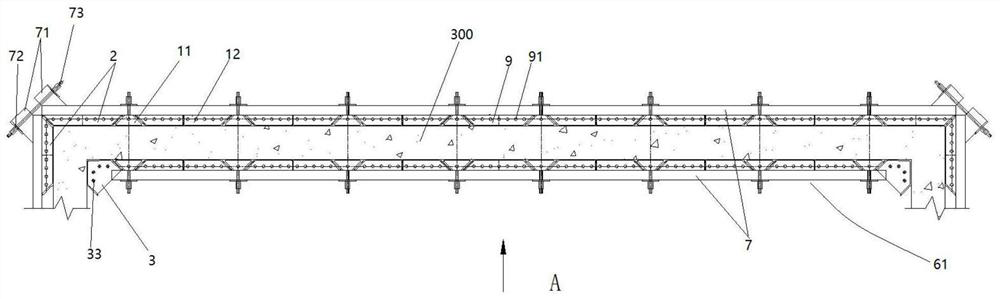

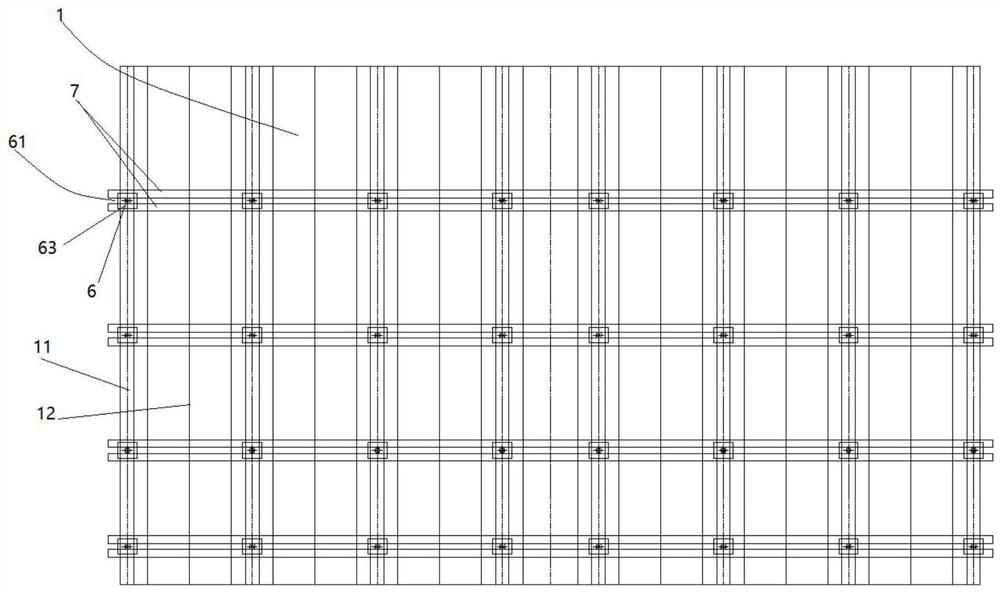

[0060] refer to Figure 1-7 , an assembled combined formwork system according to the present invention, the system includes a wall column formwork unit 100 and a floor formwork unit 200; the floor formwork unit 200 is formed by splicing several floor formwork 201; the wall column The formwork unit 100 includes: four sets of wall stud formwork groups 110, each set of wall stud formwork groups 110 corresponds to a wall 300, each set of wall stud formwork groups 110 includes two vertically spaced wall stud formworks 1, a wall stud formwork 1 corresponds to the inner wall surface 301 of the wall body 300, and another wall stud template 1 corresponds to the outer wall surface 302 of the wall body 300. The wall stud template 1 includes several first vertical Formwork 11 and the second vertical formwork 12, each first vertical formwork 11 surface is provided with several fixing holes 13 at intervals from top to bottom, and the fixing holes 13 on the two wall column formworks 1 are ar...

Embodiment 2

[0084] see Figure 8-12 , the number of connection holes 115 on each of the first connection baffles 114 is four, and the number of connection through holes 125 on each of the second connection baffles 124 is six.

[0085] The number of connection holes 115 on the first connection baffle 114 and the number of connection through holes 125 on the second connection baffle 124 vary, which can be adapted to the assembly of wall stud formworks of different specifications and expand the scope of application.

[0086] The cross-section of the male corner connection formwork 2 is an isosceles trapezoid, one side of the male corner connection formwork 2 is connected to the side of the first vertical formwork 11, and the male corner connection formwork 2 is far away from the bottom corner of the first vertical formwork 11 It abuts against the bottom corners of the adjacent male corner connection templates 2 , the bottom corners of two adjacent male corner connection templates 2 abut agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com