Washing machine front plate installing structure and washing machine

An installation structure and washing machine technology, which is applied in the field of washing machines, can solve problems such as difficulty in ensuring assembly clearances, many washing machine assembly line processes, and complicated assembly operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

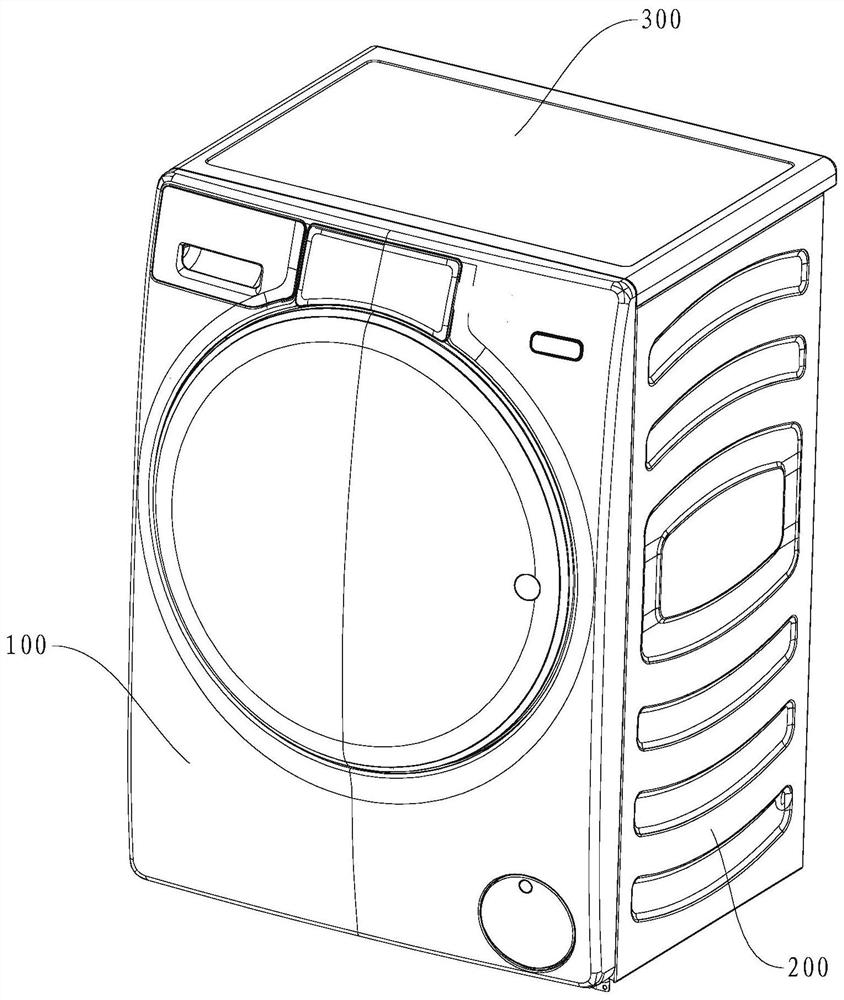

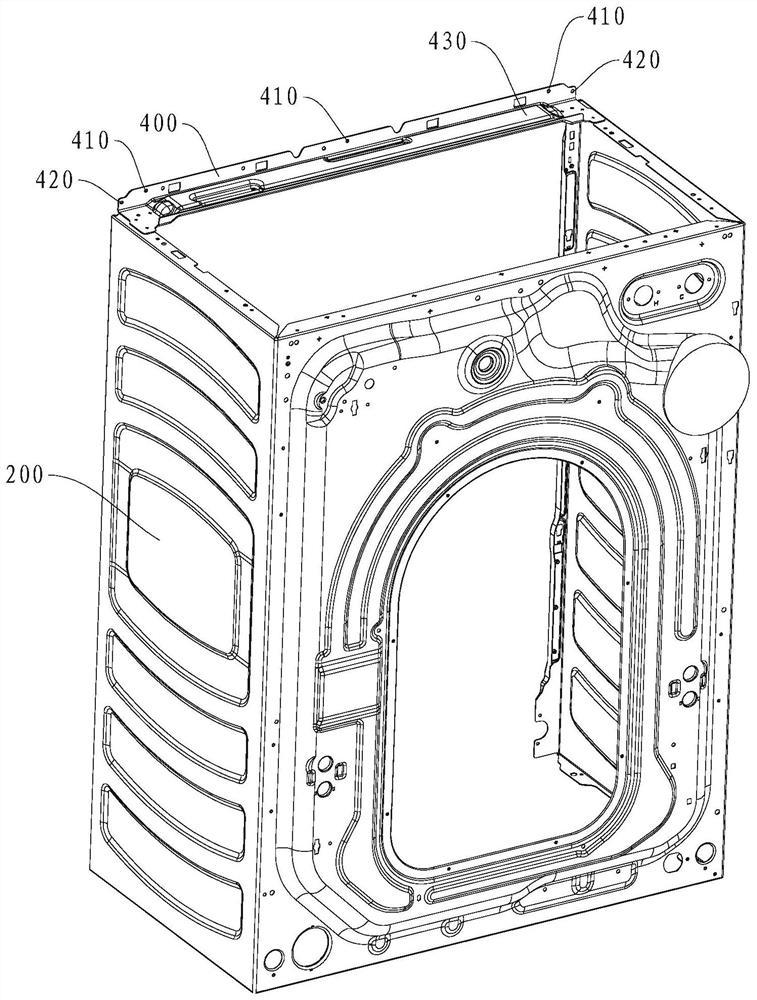

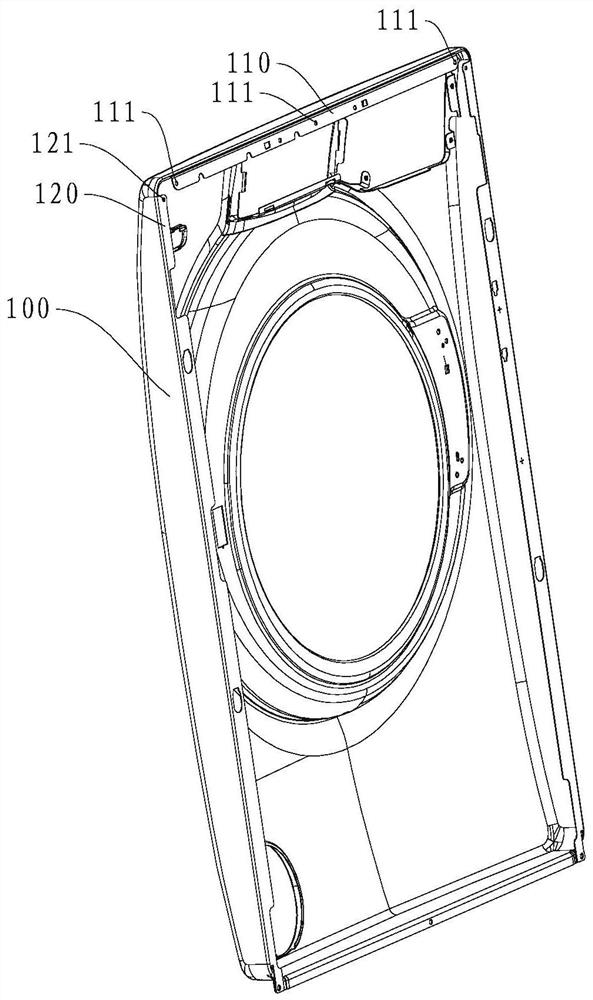

[0028] refer to figure 1 , the front plate installation structure of the washing machine in an embodiment of the present invention, the washing machine includes a cabinet 200 and a table 300 fixed to the cabinet. In this embodiment, preferably, the front end of the box body is an integral front panel 100, and the front panel is an integral sheet metal part. The main control module of the washing machine, such as a display screen and a power supply module, is installed on the front panel 100. The integrated front panel can reduce assembly procedures, improve production efficiency, reduce assembly gaps, and improve product appearance. In another embodiment, the front surface of the cabinet may also include an upper main control panel and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com