Patents

Literature

36results about How to "Guaranteed assembly clearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

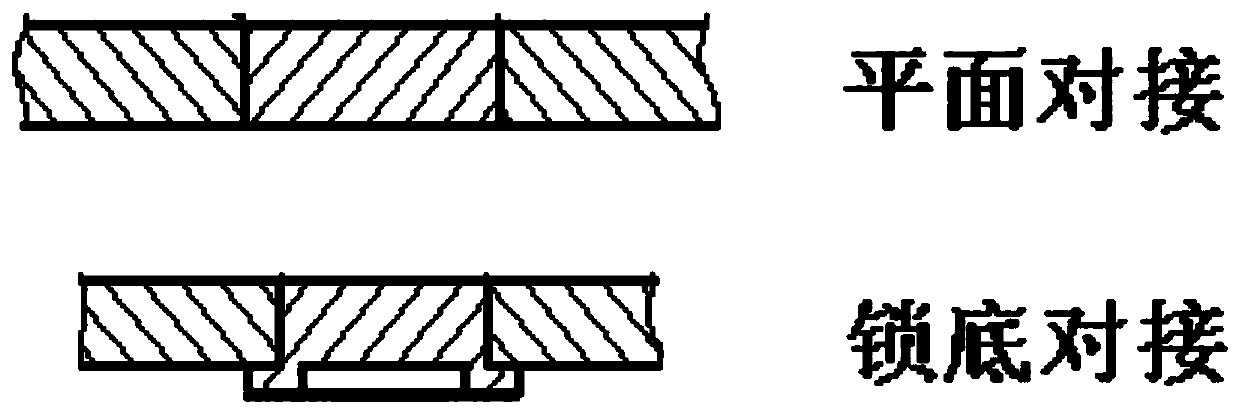

Electron beam welding method applicable to small-diameter flange plates on thin-wall top cover

ActiveCN106670640AIncrease foilPlay full without depressionElectron beam welding apparatusWorkpiece edge portionsButt jointEngineering

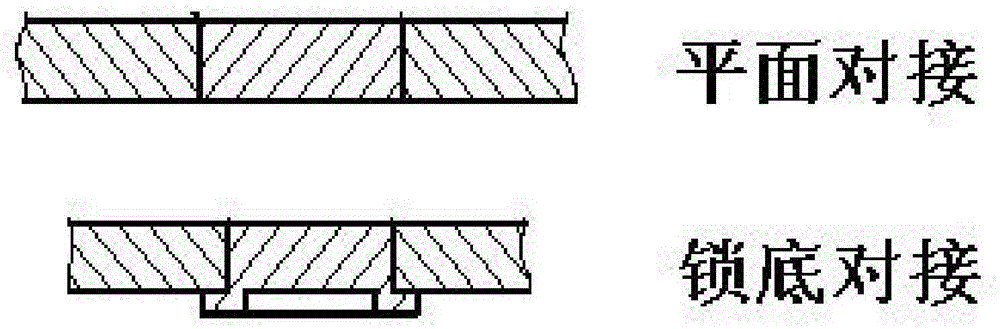

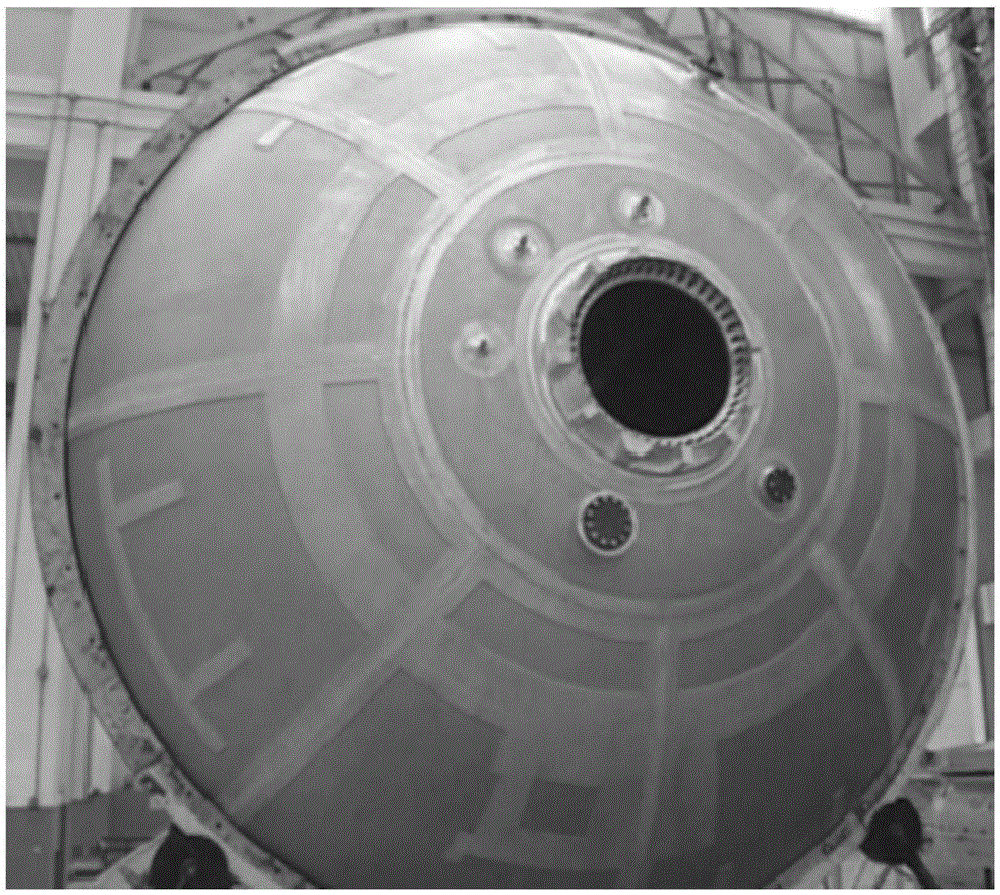

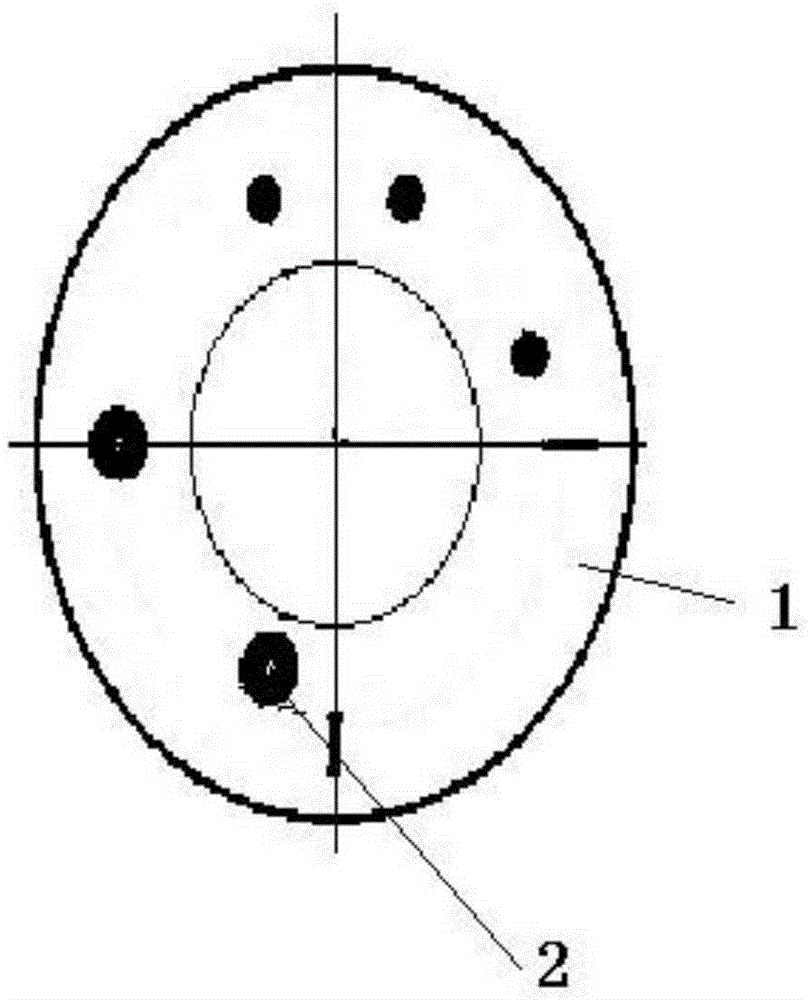

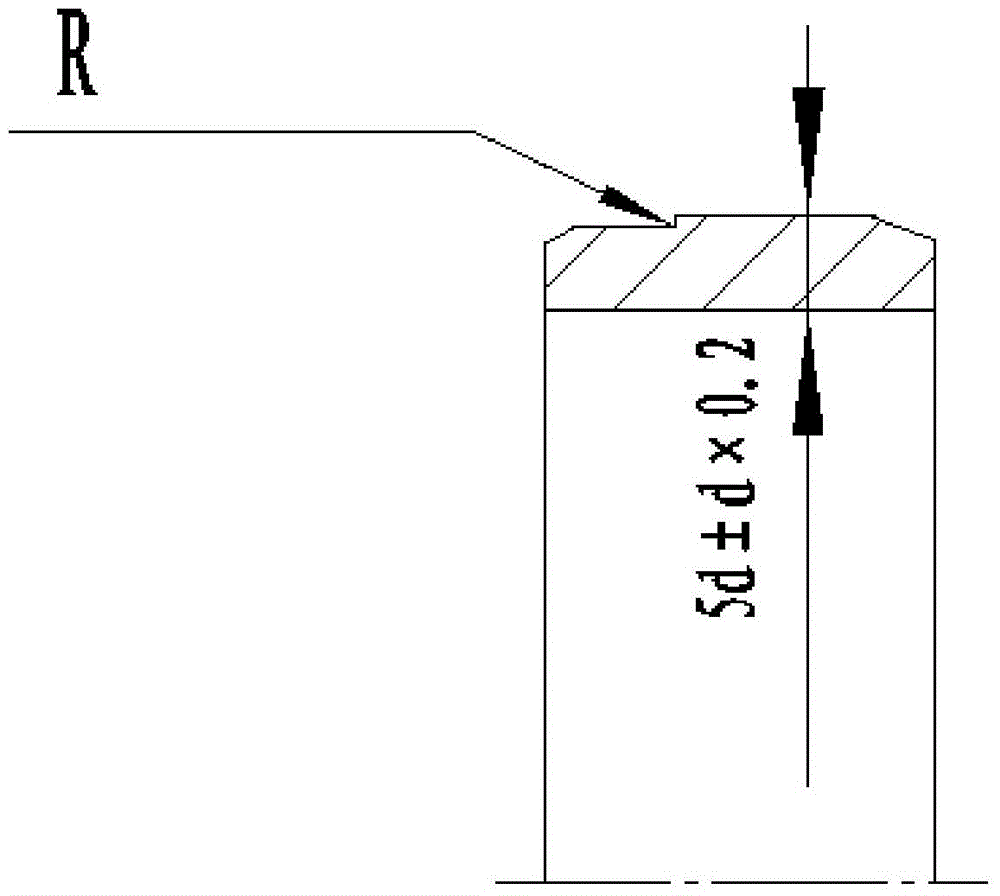

The invention belongs to the technical field of electron beam welding, and particularly relates to an electron beam welding method for multiple small-diameter flange plates at different circumferential positions of a large-size thin-wall space curved face top cover. A flange plate structure applicable to top cover flange plate electron beam welding is designed, a welding joint portion of each flange plate is of a butt joint lock bottom structure, and assembling precision and welding quality are effectively ensured. Meanwhile, according to the hole size in the position, to which each flange plate is assembled and welded, on the top cover, the diameter of the welding face of the corresponding flange plate is adjusted, and it is ensured that the assembling gap between the corresponding flange plate and the top cover meets welding requirements. By using a tool, by the adoption of elastic prestress deformation, welding stress is counteracted, deformation is reduced, electron beam welding for the flange plates distributed at different positions of the space curved face top cover is achieved, and satisfying welding quality is obtained.

Owner:CAPITAL AEROSPACE MACHINERY +1

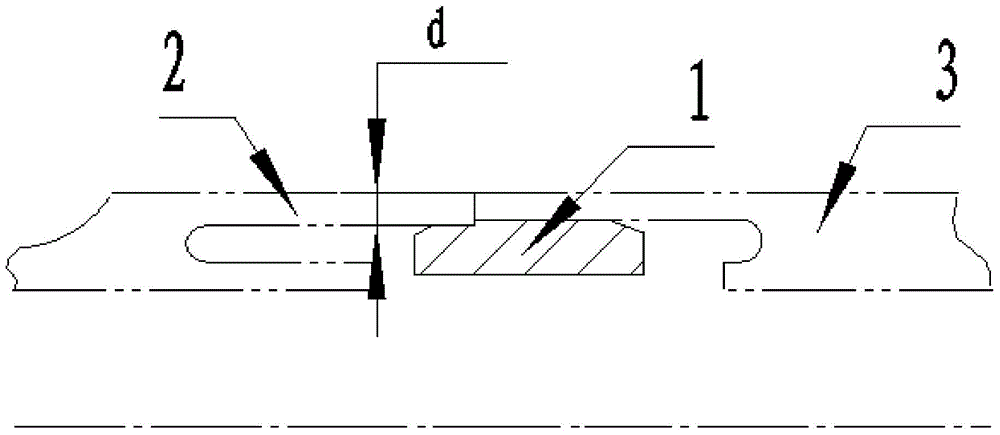

Welding lap joint structure and method for thin-wall pipes

ActiveCN105014293APrecise positioningAvoid the problem that part of the surface of the part cannot be processedWelding/cutting auxillary devicesAuxillary welding devicesButt jointLap joint

The invention discloses a welding lap joint structure and method for thin-wall pipes. The welding lap joint structure and method aim at avoiding limitation of electron beam welding to the structures of welded parts. According to the technical scheme, the welding lap joint structure comprises a supporting bushing ring (1) made of the material the same as that of the welded pipes. The supporting bushing ring (1) is of a two-step-shaped structure. The lap joint portion of the short welded pipe (2) is assembled at the small end of the supporting bushing ring (1). The lap joint portion of the long welded pipe (3) is assembled at the large end of the supporting bushing ring (1). The lap joint portions of the short welded pipe (2) and the long welded pipe (3) are each of an orifice-shaped or groove-shaped structure. The supporting bushing ring (1) can be assembled in the orifice-shaped or groove-shaped structures. The lap joint portions of the short welded pipe (2) and the long welded pipe (3) are flush and end faces are in butt joint in the lap joint process of the supporting bushing ring (1).

Owner:AECC AVIATION POWER CO LTD

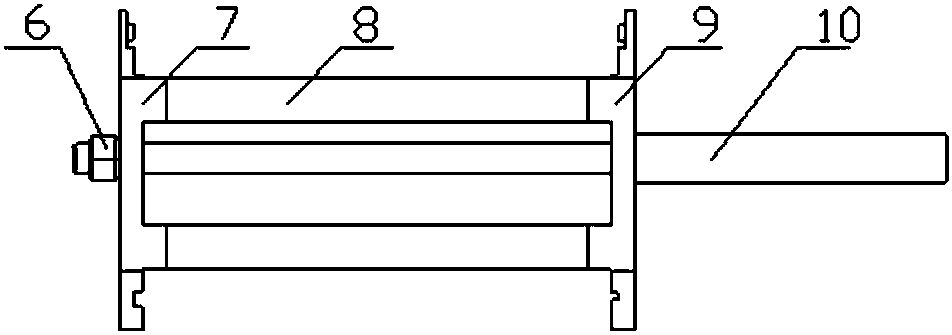

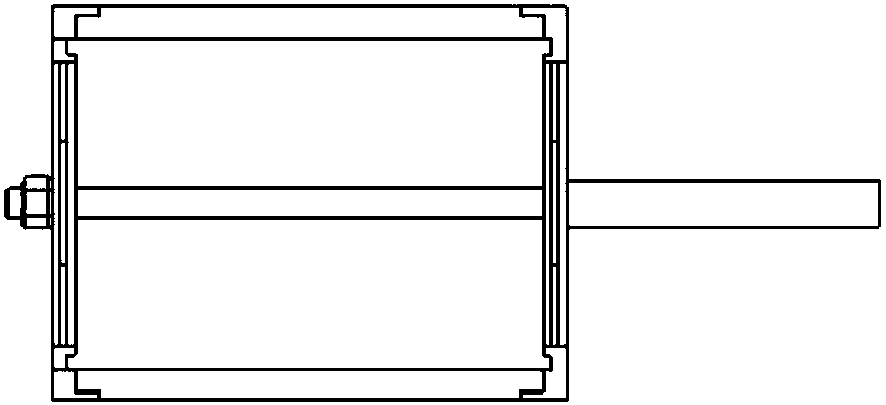

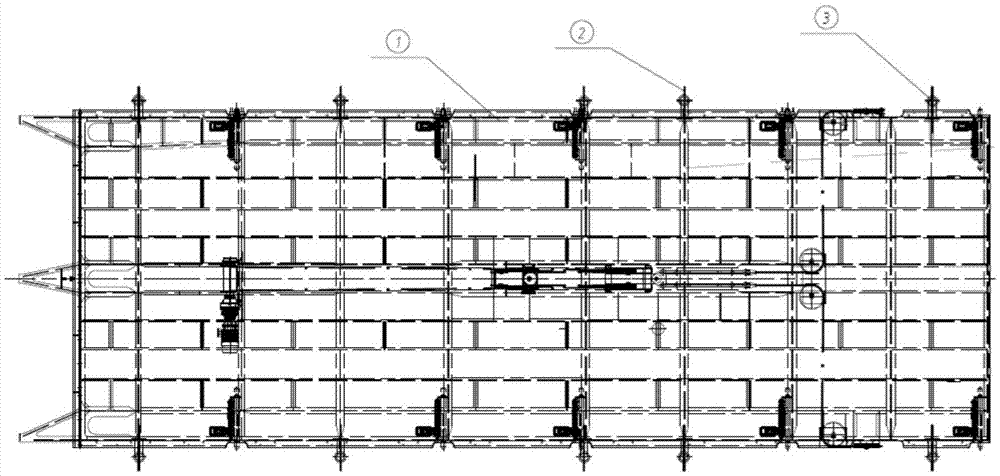

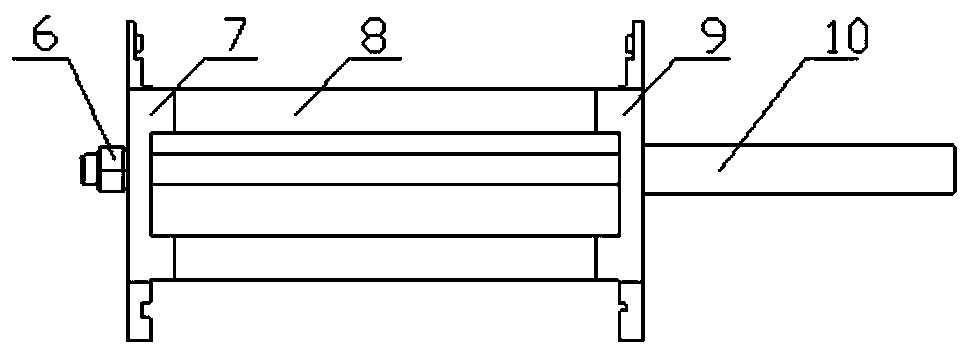

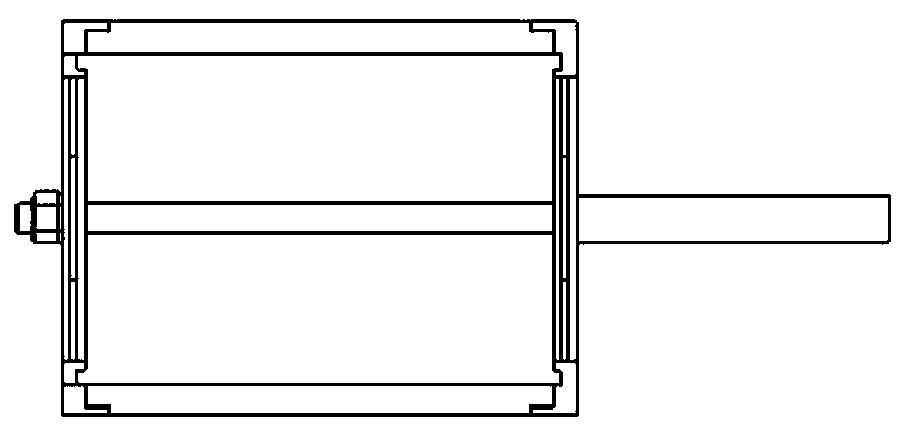

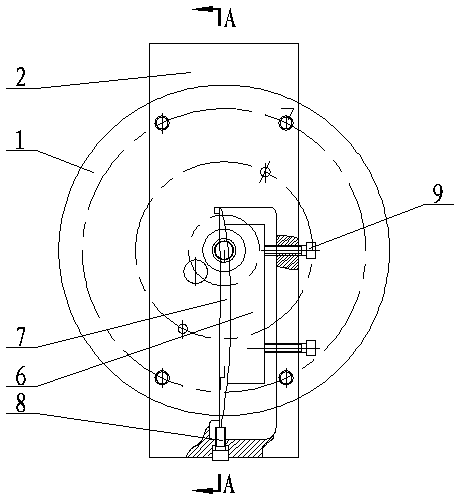

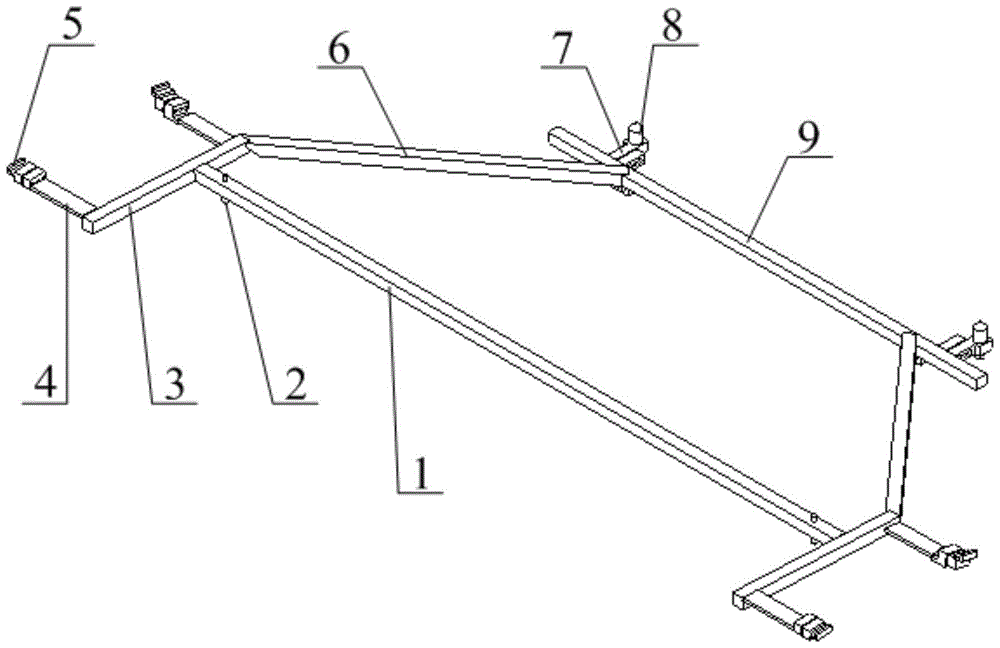

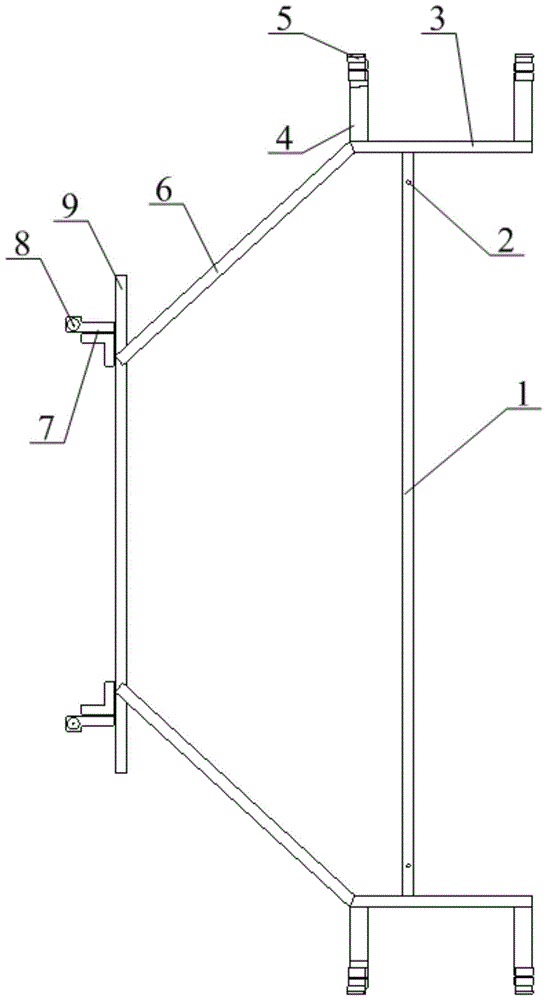

Assembly welding tool of high-precision frame structure

ActiveCN108098222AGuaranteed misalignmentPrevent rotationWelding/cutting auxillary devicesAuxillary welding devicesInterference fitEngineering

The invention discloses an assembly welding tool of a high-precision frame structure. The assembly welding tool comprises two clamping plates used pairwise, four pressing plates and a pull rod. The four pressing plates are divided into two sets; and the two sets of pressing plates are fixedly connected with wedged blocks on the two clamping plates through an inserting mode, and are positioned on the two sides of the two clamping plates. The middle part of the pull rod and one end of the pull rod are mounted in through holes in the geometric centers of the two clamping plates, and are fastenedthrough nuts; and the pull rod and the through holes of the clamping plates are in interference fit. The other end of the pull rod is positioned out of the clamping plate on the side, and is used forfixedly connecting with a chuck of a vacuum electronic beam welding machine. The assembly welding tool is used for a vacuum electronic beam welding assembly chassis, guarantees the alignment tolerance, controls the welding deformation and the frame rotation, can guarantee the welding line alignment tolerance, constrains a whole frame, and prevents deformation of the frame in the welding process; and meanwhile, the tool enables the frame to rotate, so that all welding lines can be welded under vacuum of the same furnace, and the welding efficiency and quality are improved.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

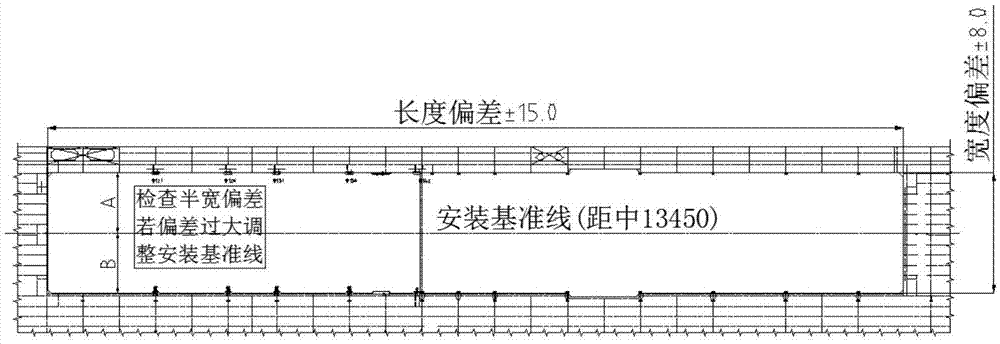

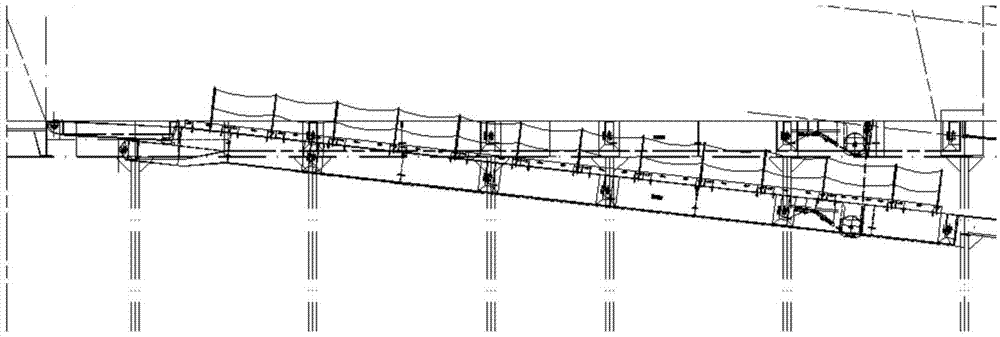

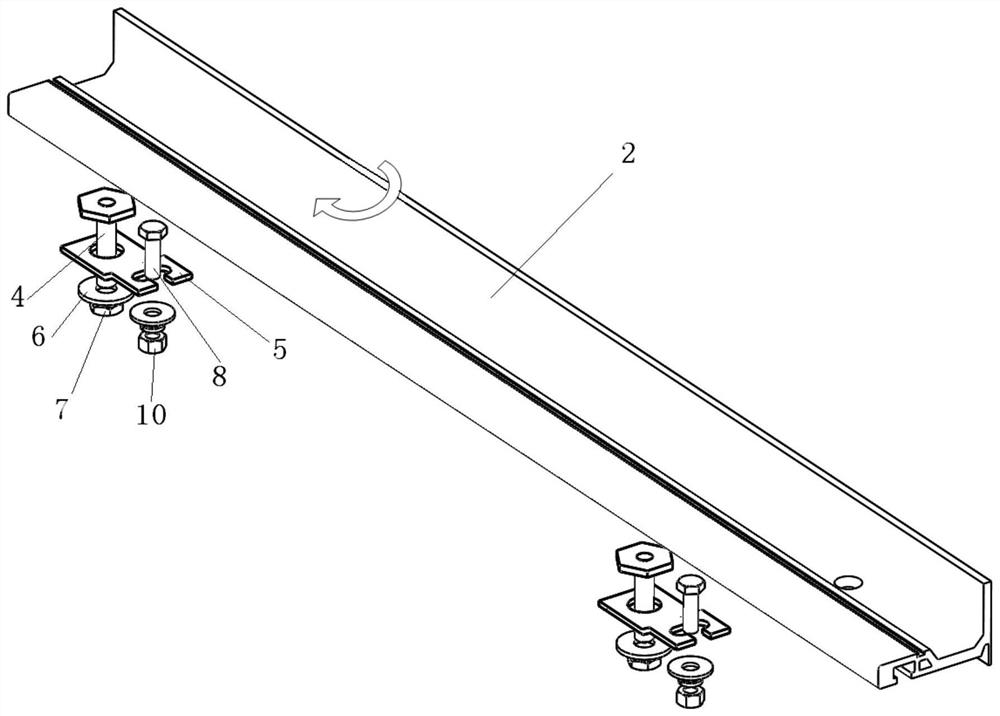

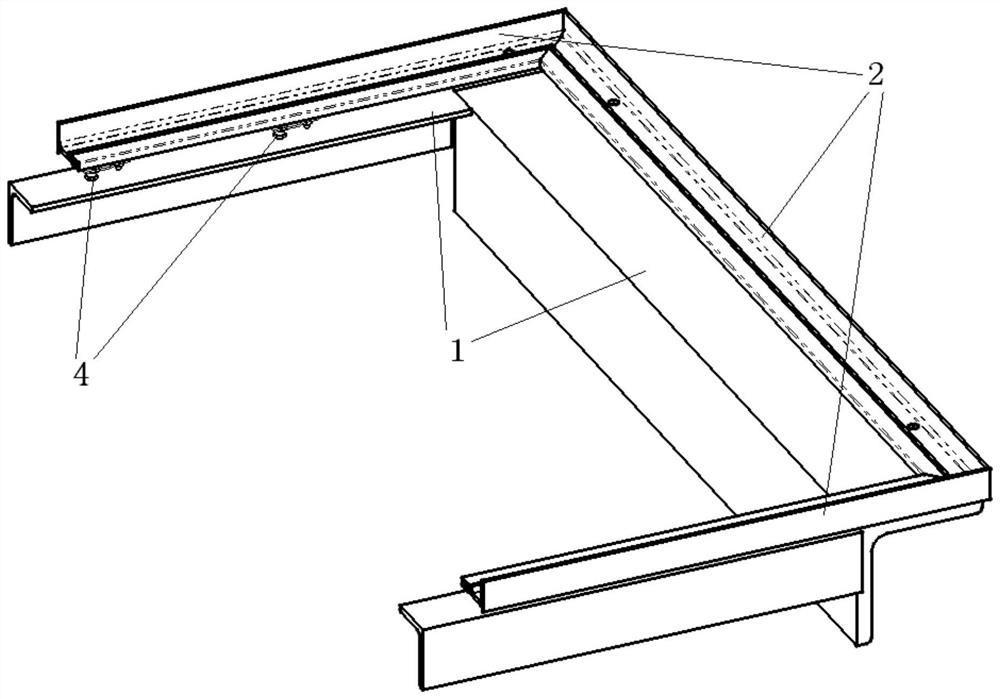

Mounting method for large movable ramp

InactiveCN105438400AAvoid secondary correctionsReduce interchange workVessel partsHull structureEngineering

The invention relates to a mounting method for a large movable ramp. The method comprises the following steps that the movable ramp and a hull structure are measured; a lap joint tool is welded to the movable ramp, and the ramp is in lap joint with an opening of the structure; a centre drawer hinge bracket connected with a hull is assembled; the position of the movable ramp is determined, after other accessories are mounted and positioned, the gap between the ramp and a supporting base is measured, and an adjusting gasket is machined; and the movable ramp is hoisted, a lap joint plate is in lap joint with a round pipe, repair welding is conducted on a blind spot in hinge welding, the ramp is started, and the adjusting gasket is welded. Through the method, the ramp can be mounted with high precision, and the special tool is used so that the lap joint requirement can be met and movable adjustment can be achieved during adjustment. Labor intensity is relieved, and meanwhile mounting quality is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

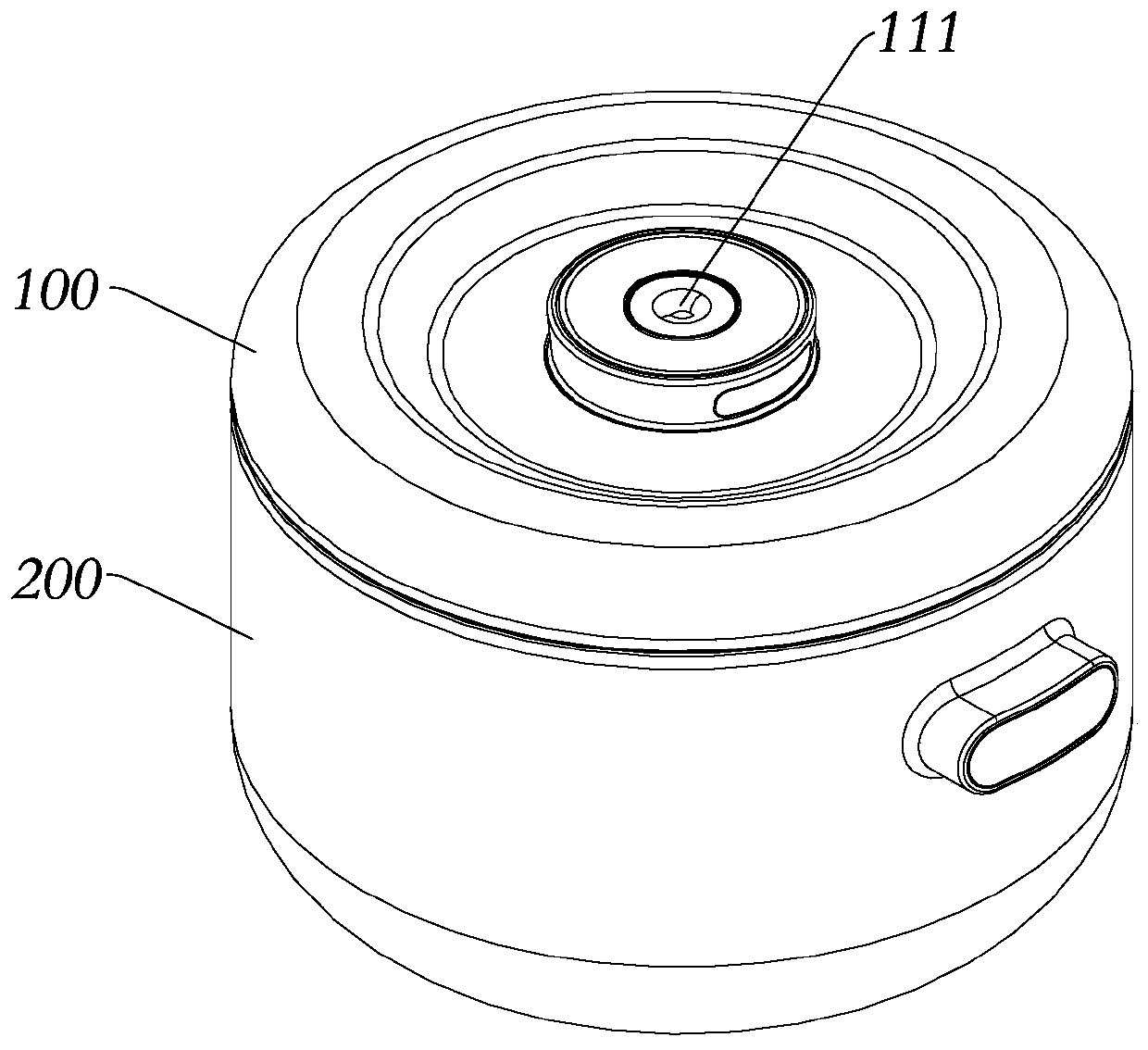

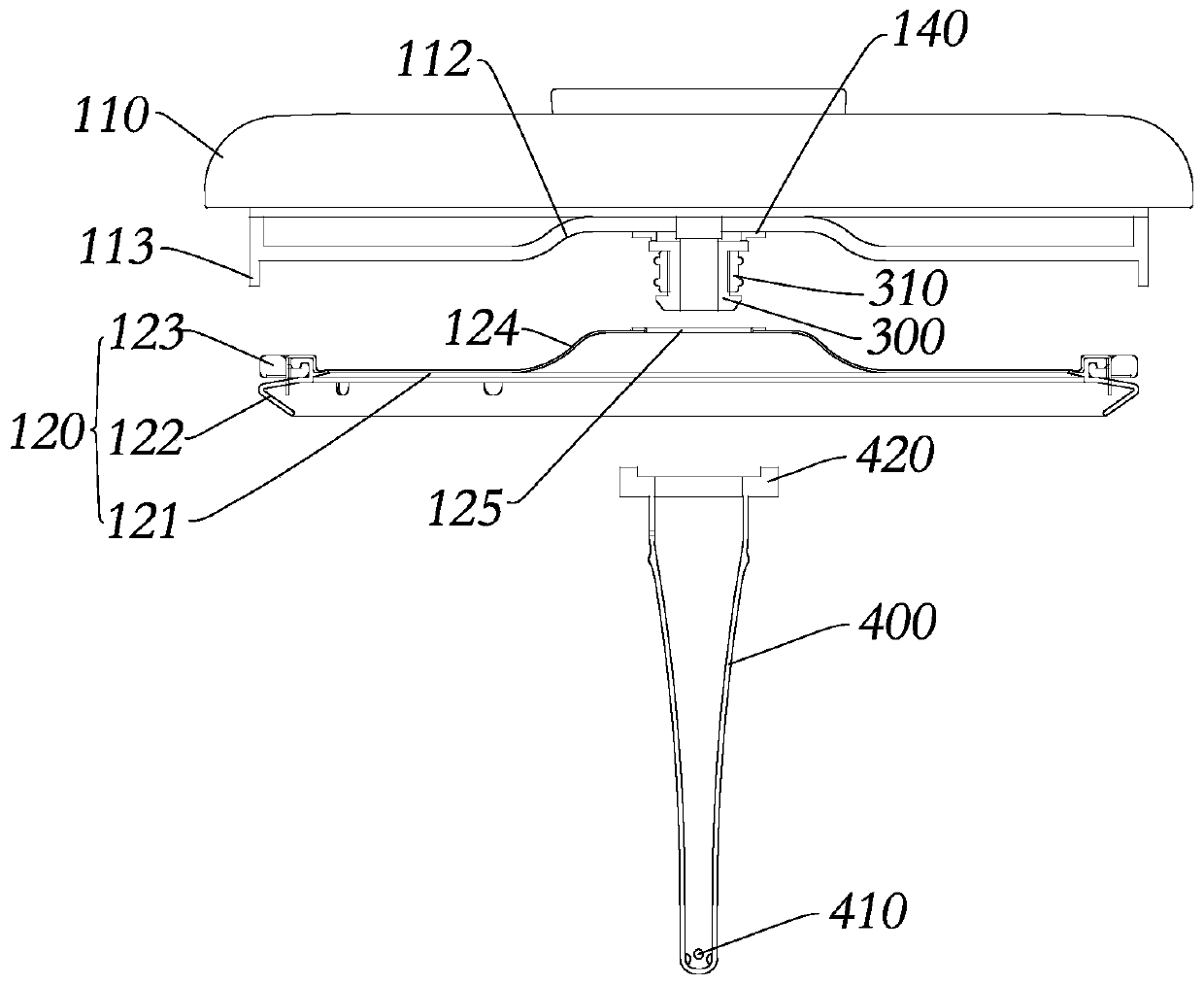

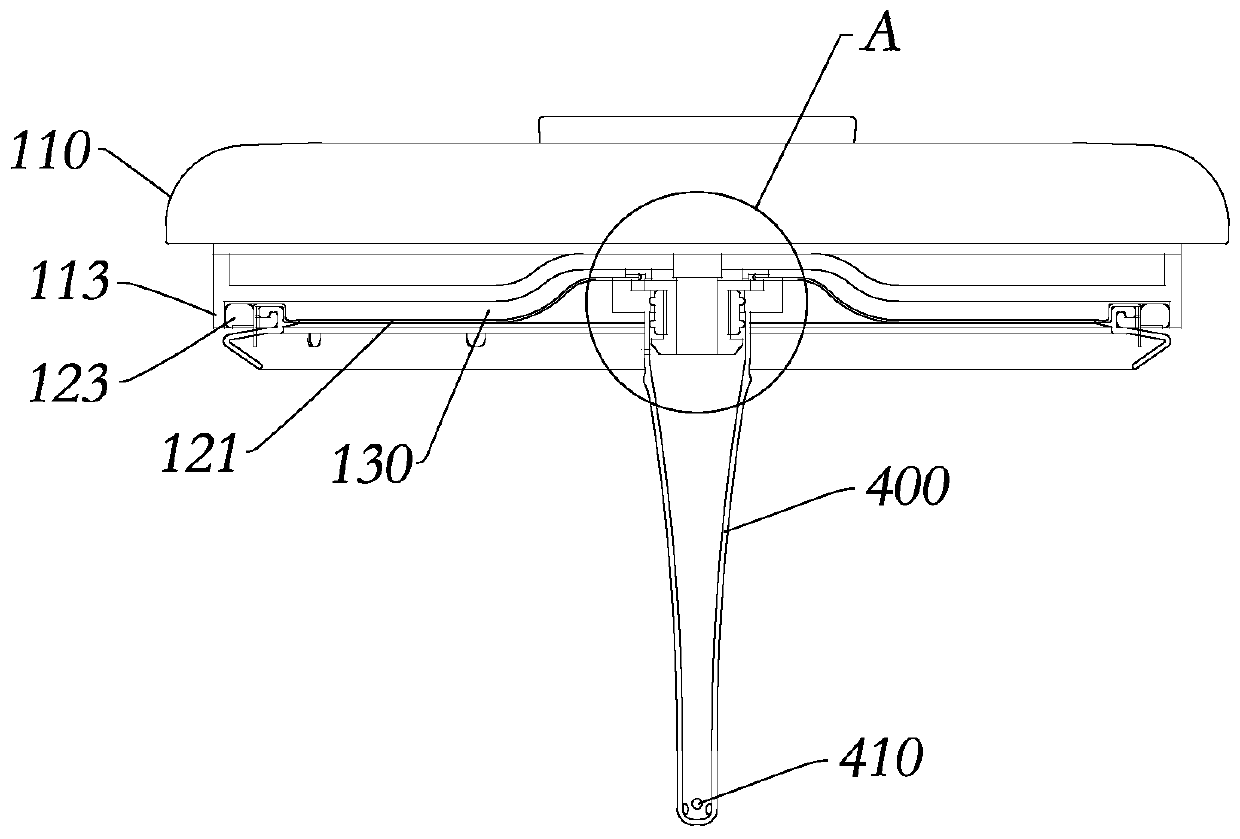

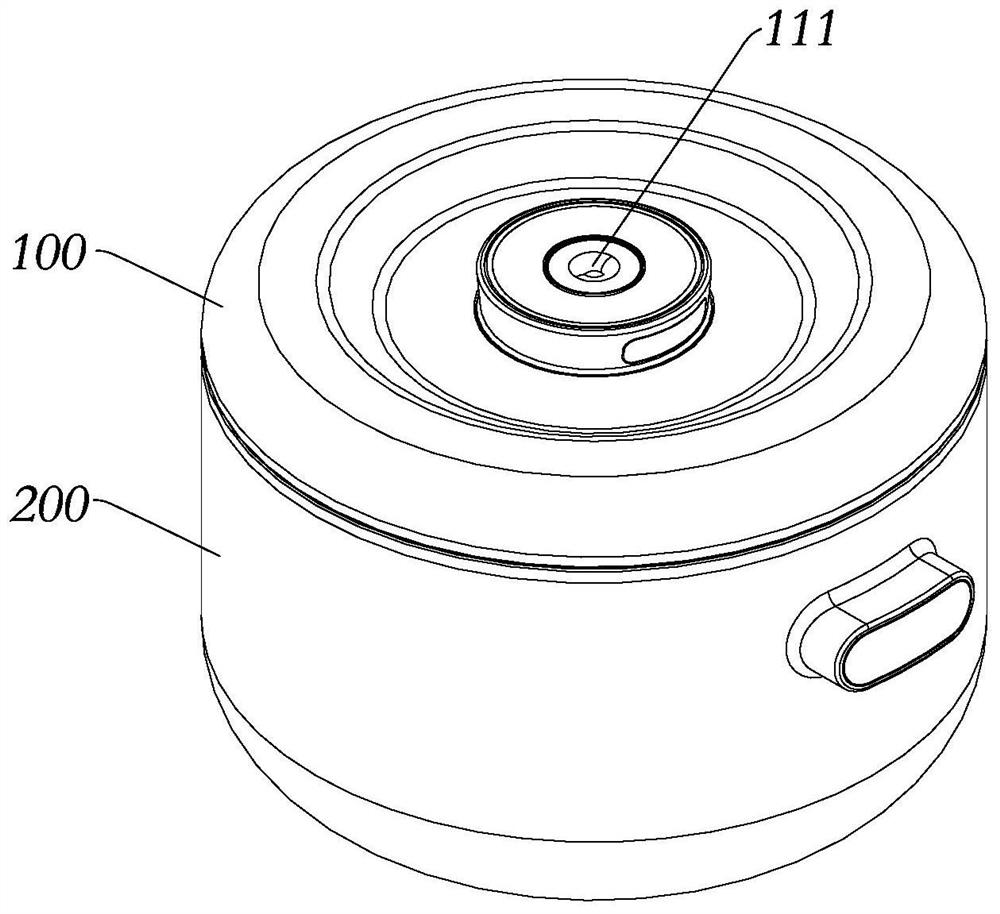

Cooking pan using steam heating, and steam heating type cooking utensil

ActiveCN110338641AExtend your lifeReduce entryBoiling over preventionCooking-vessel lids/coversEngineeringSteam heating

The invention discloses a cooking pan using steam heating, and a steam heating type cooking utensil, belongs to the field of kitchen household appliances, and solves the problem that a pan cover of acooking pan in the prior art is inconvenient to clean. The cooking pan provided by the invention comprises a pan body and a pan cover, wherein the pan cover comprises an outer cover and an inner cover; the outer cover covers the pan edge of the pan body; and the inner cover and the pan body are matched to form a cooking chamber. The cooking pan further comprises a steam guide pipe, wherein a projected air inlet connector is arranged on the inner side of the outer cover and penetrates through the inner cover; and the steam guide pipe can be detachably arranged on the air inlet connector and axially positions the inner cover. The cooking pan provided by the invention adopts the design of the detachable inner cover, so that the inner cover can be conveniently and independently cleaned.

Owner:JOYOUNG CO LTD

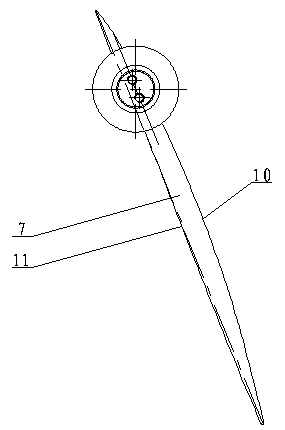

Manufacturing method of blade for centrifugal aeration blower diffuser and positioning tool for same

ActiveCN102658459AGuaranteed line profileAccurate calculation of throat areaPositioning apparatusMetal-working holdersEngineeringMachining

The invention discloses a manufacturing method of a blade for a centrifugal aeration blower diffuser and a positioning tool for the same. The manufacturing method sequentially comprises the following machining procedures of: 1), roughly milling four sides of the blade and a process lug; 2), carrying out finish milling on the molded line of the blade; 3), adopting the positioning tool, carrying out wire-electrode cutting to remove the process lug; 4), grinding the top surface of the blade; 5), adopting the positioning tool, beneficially turning a positioning shaft by a turning lathe and cutting off the end surface of the process lug; 6), trimming and turning an overlap by a bench worker and milling a knuckle radius between two molded lines at two ends of the blade; 7), mounting a turning tool to drill a threaded bottom hole; 8), tapping and removing burrs by the bench worker; and 9), carrying out comprehensive detection. The manufacturing method and the positioning tool have the advantages that the procedures are arranged reasonably, and the machining quality and the machining efficiency can be effectively improved.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

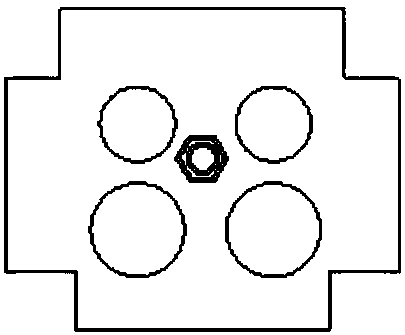

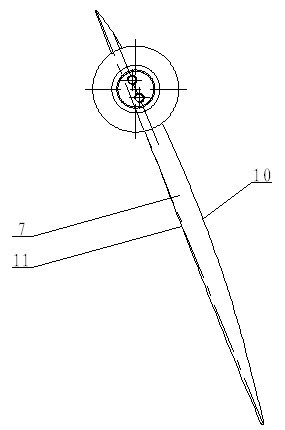

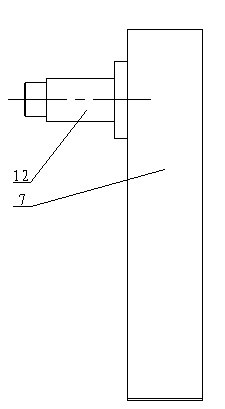

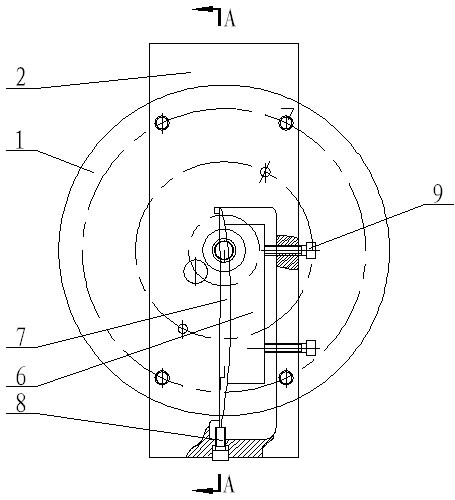

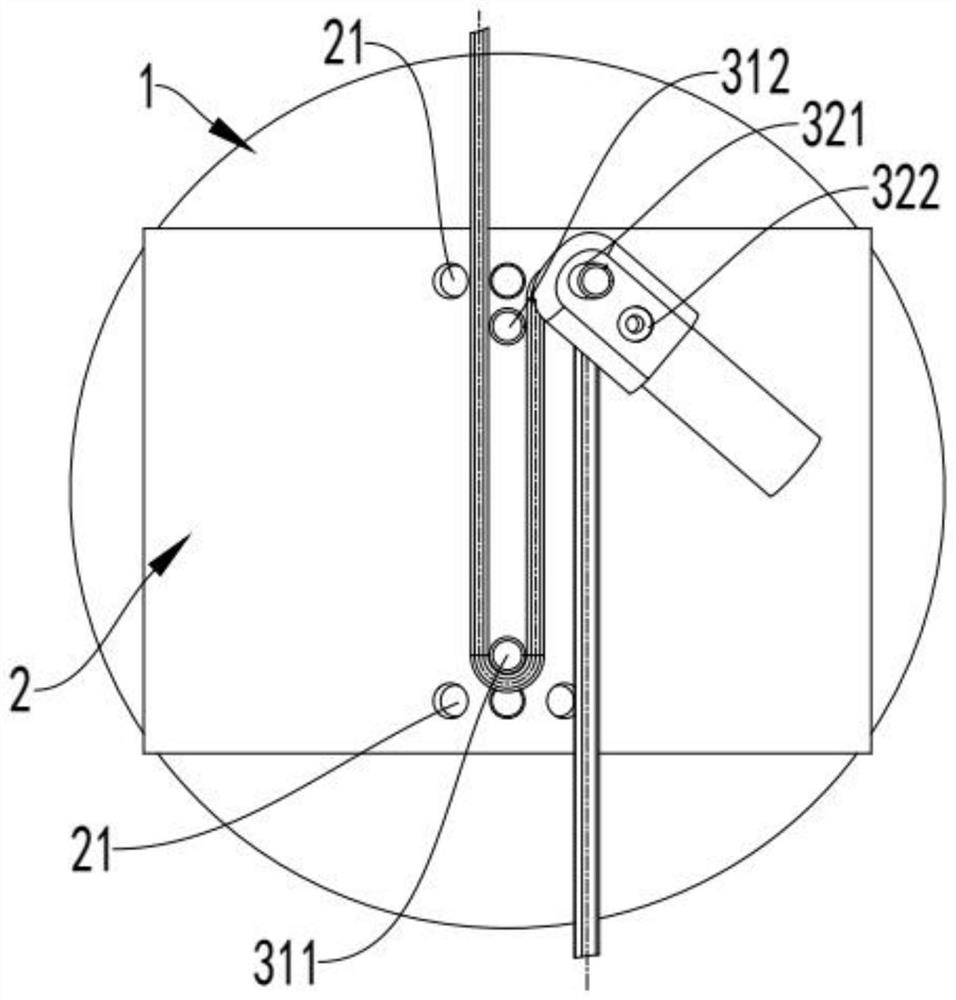

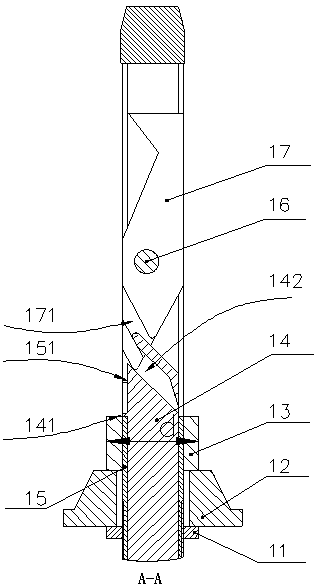

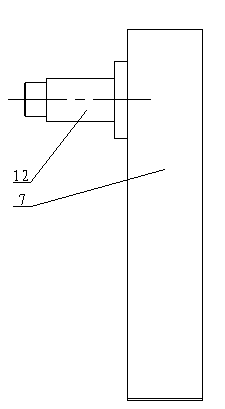

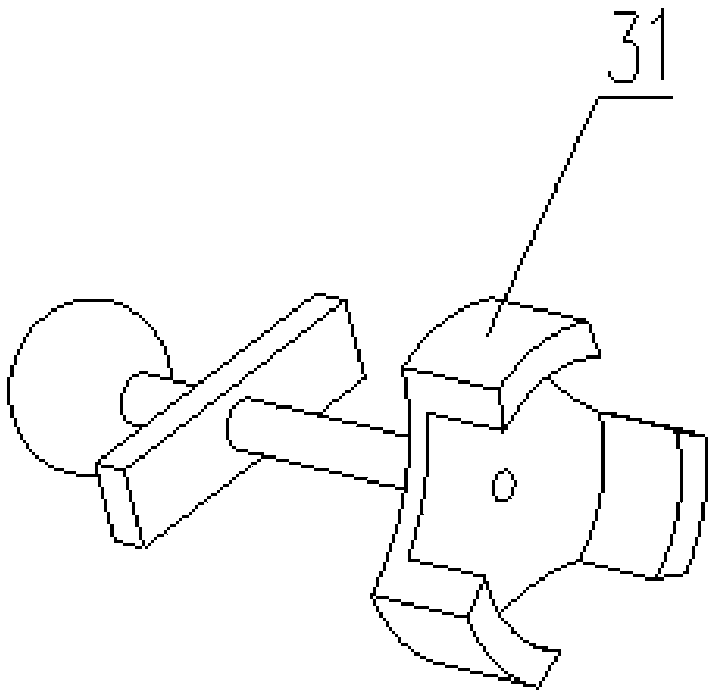

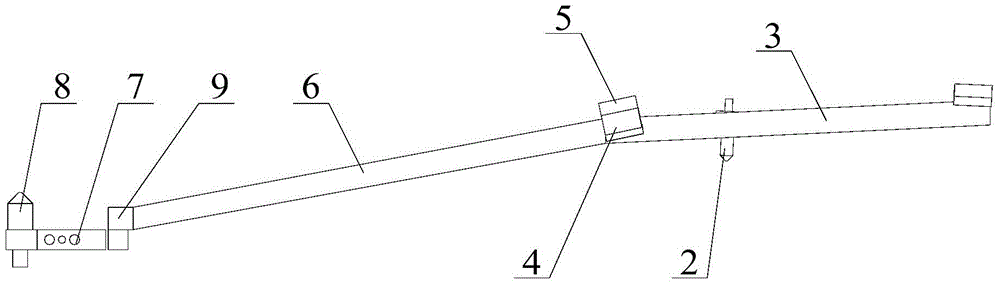

Serpentine spring forming tool for serpentine spring coupler

PendingCN112024670AGuaranteed assembly clearanceCircumferential Array UniformYielding couplingLow internal friction springsPhysicsWrench

The invention discloses a serpentine spring forming tool for a serpentine spring coupler. The serpentine spring forming tool comprises a base, a guide cylinder and a bending structure, wherein the guide cylinder is fixedly arranged on the base; the bending structure is arranged on the guide cylinder; the guide cylinder is provided with symmetrically arranged positioning holes; the bending structure comprises bolts and a bending wrench; the bolts are embedded in the positioning holes; and the bending wrench is also embedded in one positioning hole and rotatably arranged in the positioning hole.According to the serpentine spring forming tool for the serpentine spring coupler, the position relation between the bolts can be better controlled through the positioning holes, so that it is ensured that the assembly clearances are consistent, and the load of a manufactured serpentine spring is balanced; and through the bending structure, it can be ensured that the formed two ends of the springare symmetrical, the circumferential array is uniform, the transition fillet can be smooth, and the stress concentration cannot occur.

Owner:JINGJI TECH JIAXING CO LTD

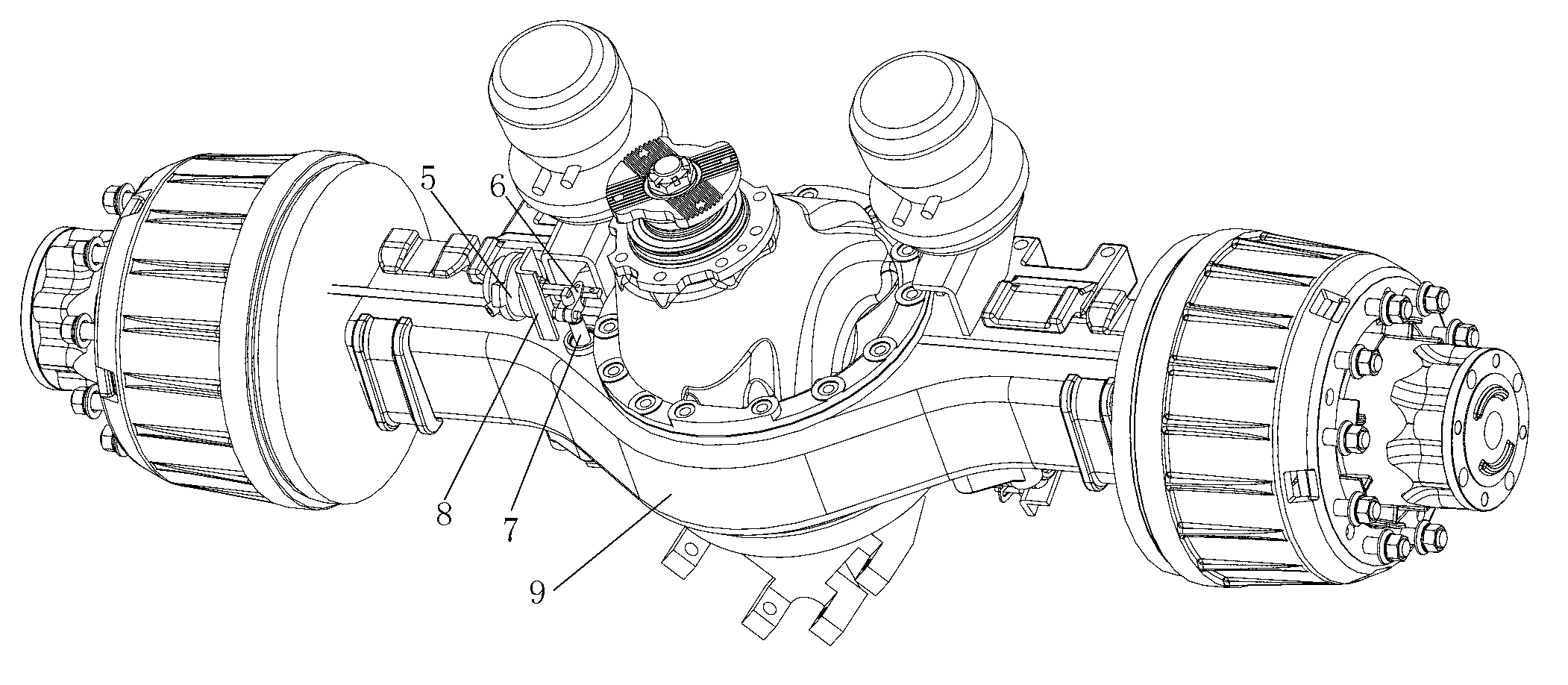

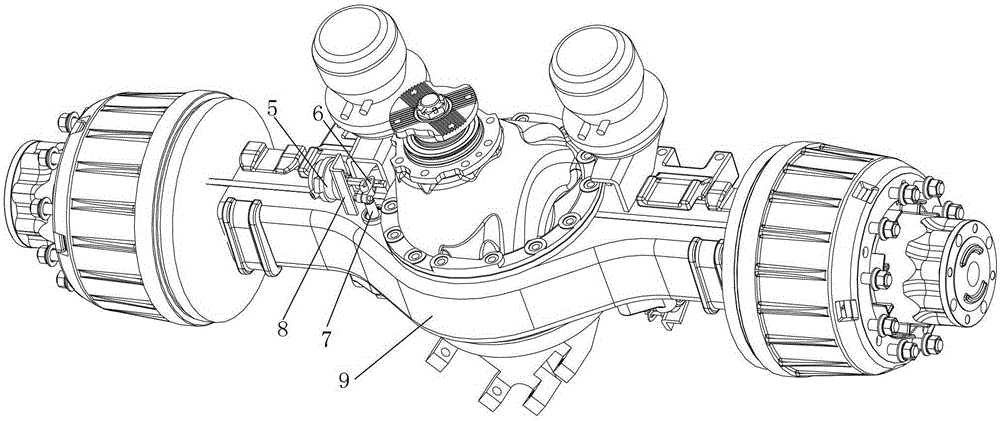

Clearance adjustment device and clearance adjustment method for differential lock

ActiveCN102840319AAchieve regulationGuaranteed assembly clearanceGearing detailsPetroleum engineering

The invention provides a clearance adjustment device for a differential lock. The clearance adjustment device is used for adjusting the clearance between a sliding engaging sleeve and a fixed engaging sleeve of the differential lock, and comprises a dial, a rotating sleeve and a pointer, wherein the dial is matched with the rotating sleeve; the rotating sleeve can be matched with a rotating shaft driving the sliding engaging sleeve to move and can rotate relative to the dial along with the rotation of the rotating shaft; the pointer is fixed on the rotating sleeve and can rotate relative to the dial along with the rotation of the rotating sleeve; and the rotating angle of the pointer can be displayed on the scale of the dial. The invention further provides a clearance adjustment method for the differential lock and a method for adjusting the clearance of the differential lock by utilizing the clearance adjustment device. Through the technical scheme provided by the invention, the clearance between the sliding engaging sleeve and the fixed engaging sleeve of the differential lock can meet the design requirement and be irrelevant to the stroke error of a cylinder, so that the differential lock can work normally.

Owner:SANY AUTOMOBILE MFG CO LTD

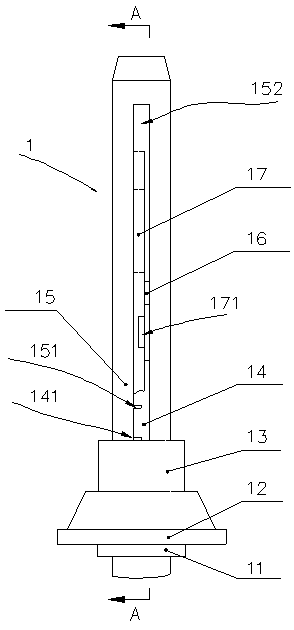

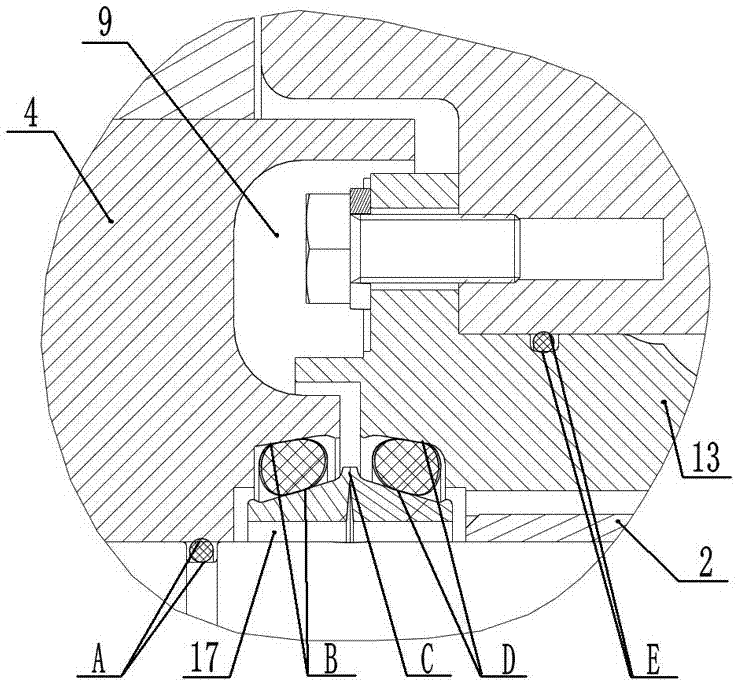

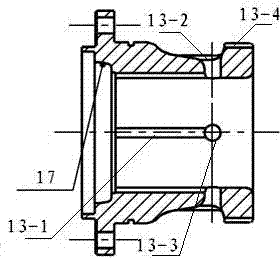

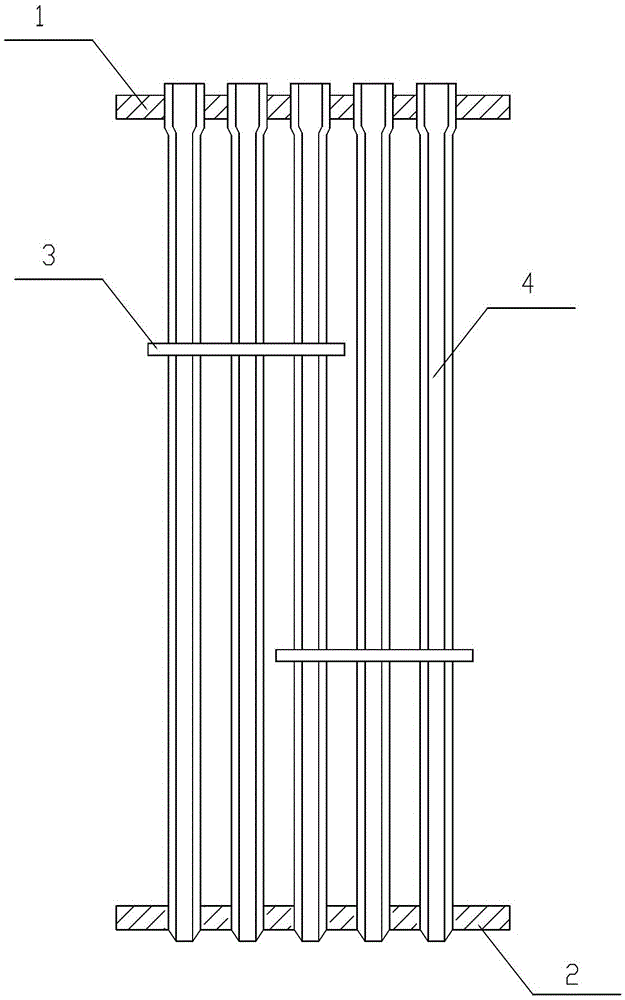

Repair method and device of welding defect of inner hole welding in U-shaped pipe type heat exchanger

PendingCN111408894AImprove maintainabilityFacilitate mass adoptionArc welding apparatusStructural engineeringWeld seam

The invention relates to a repair method and device of a welding defect of inner hole welding in a U-shaped pipe type heat exchanger. The repair method uses a designed repair device to completely remove an inner hole welding line generating the defects, and form a new inner hole welding groove in a pipe plate, an original U-shaped heat exchange pipe is drawn out and replaced with a new U-shaped heat exchange pipe is replaced, and inner hole welding is carried out on the new U-shaped heat exchange pipe and a pipe plate set again, the repair device comprises a height fixing nut, a cushion block,a positioning ring, a push rod, a shaft sleeve, a pin shaft and a cutting blade, according to the repair method and device of the welding defect of inner hole welding in the U-shaped pipe type heat exchanger, the phenomenon that after a defect appears in an inner hole welding line at present, a manner of blocking a pipe hole of a pipe plate is only adopted for repair can be avoided thoroughly, the inner hole welding line maintainability is greatly improved, and the large-scale application of the inner hole welding technology can be greatly promoted.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

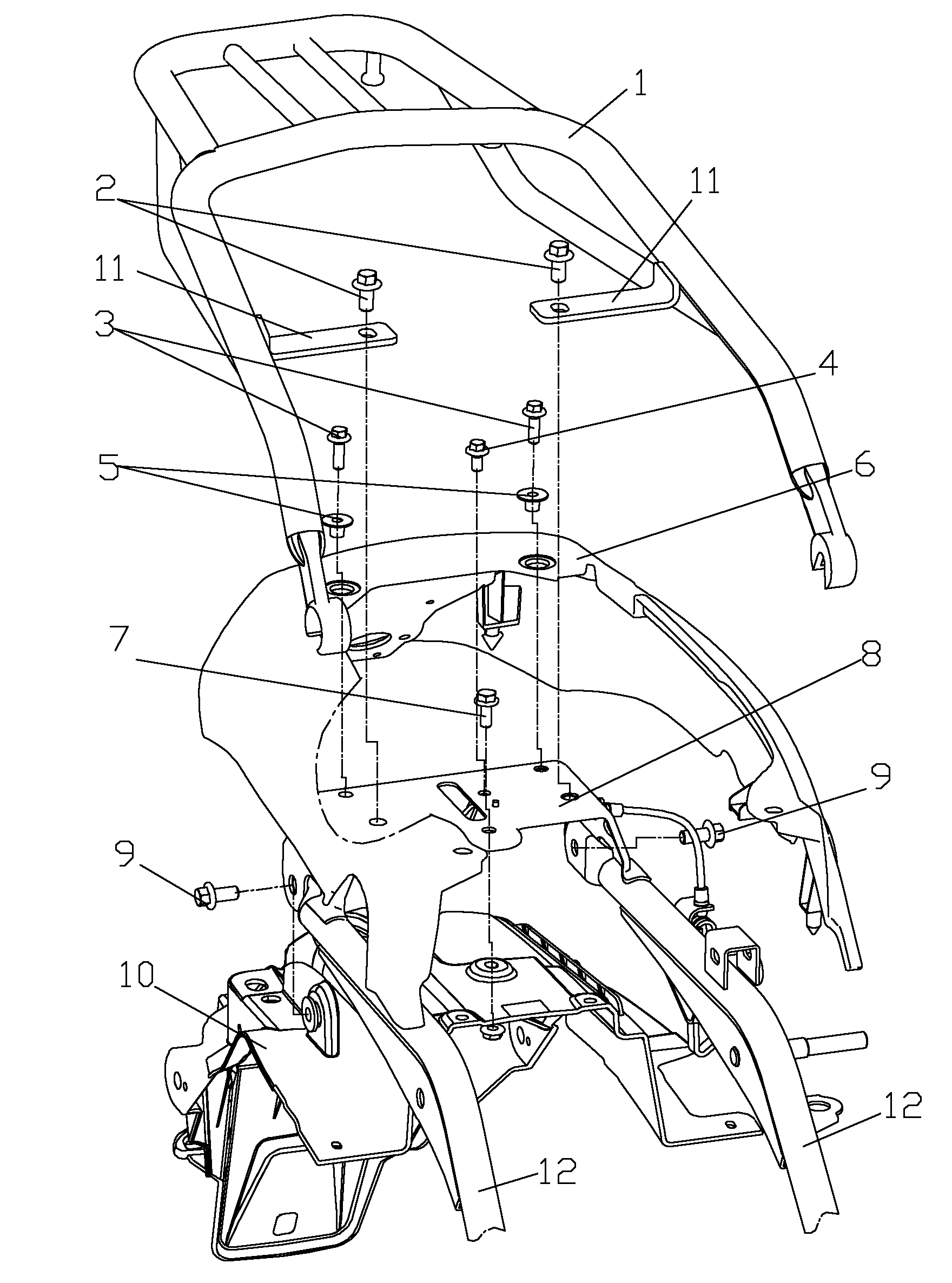

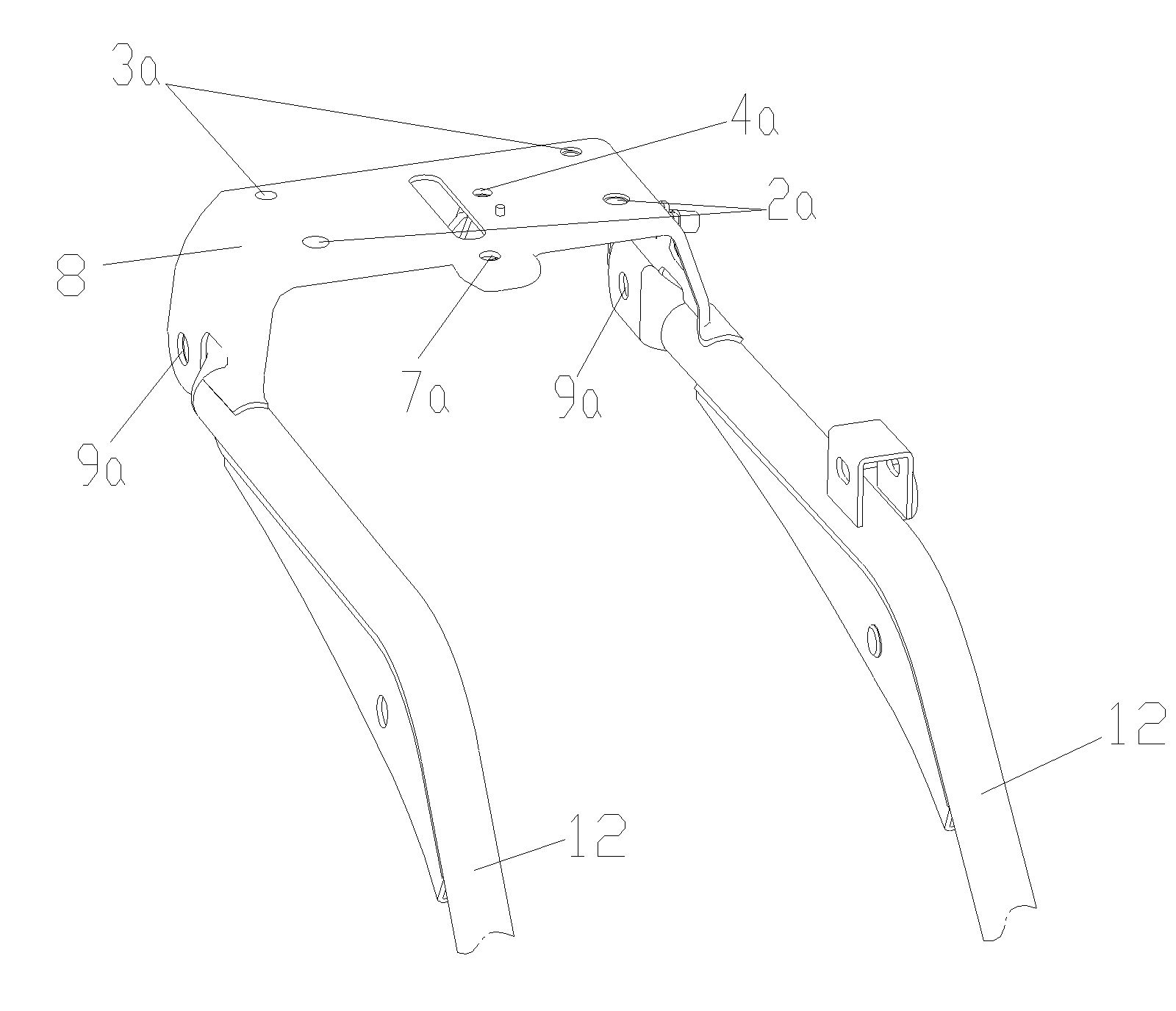

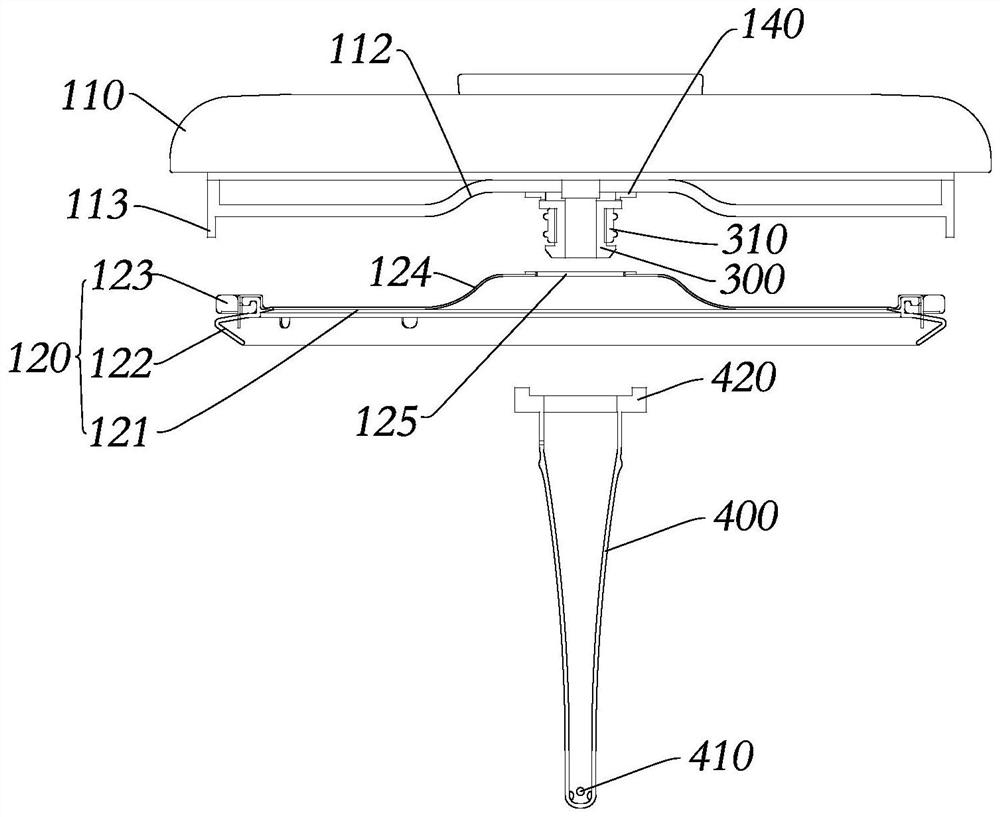

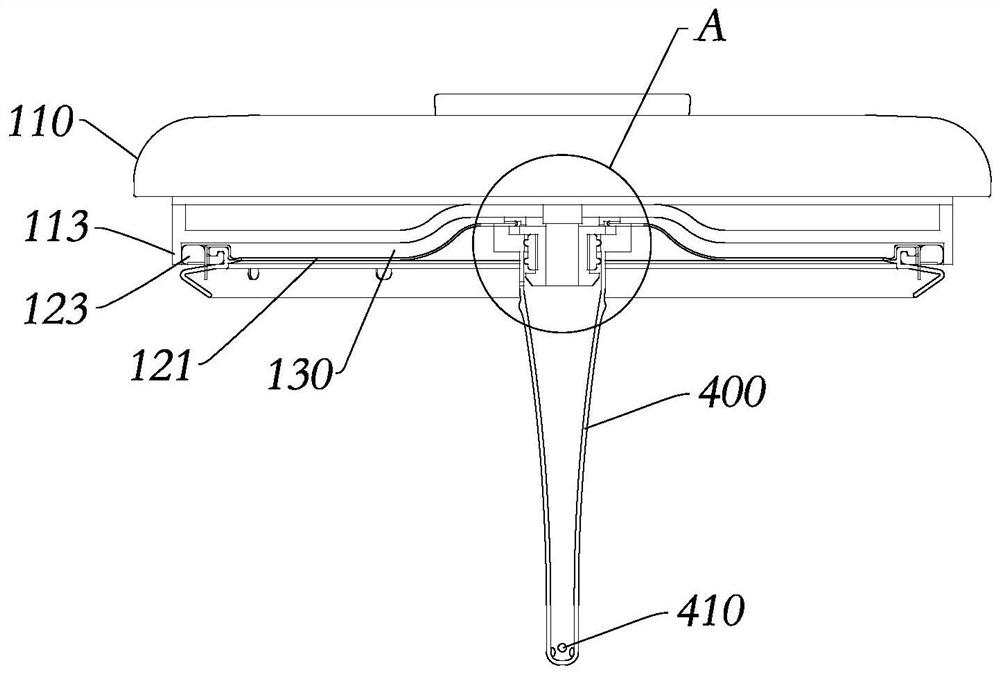

Motorcycle and after-frame assembly thereof

ActiveCN102180212BImproved ability to resist bending momentsImprove loosenessLuggage carriersMotorcyclesVehicle frameEngineering

The invention discloses a motorcycle and an after-frame assembly thereof. The after-frame assembly of the motorcycle comprises a seat cushion loctal base, a rear fender board, a rear carrying rack, a tail cover, frame tail pipes and a connecting plate, wherein two frame tail pipes are parallel along a transverse direction; the connecting plate is laid between the two frame tail pipes and fixedly connected with the two frame tail pipes; and the seat cushion loctal base, the rear fender board, the rear carrying rack and the tail cover are all detachably and fixedly connected with the connectingplate. The after-frame assembly disclosed by the invention realizes the standardized installation of the seat cushion loctal base, the rear fender board, the rear carrying rack and the tail cover, isbeneficial to ensuring the assembling gaps among parts and the installation dimensions among the parts and preventing the interference among the parts and has the characteristics of standardization and high generality; in addition, the after-frame assembly disclosed by the invention has larger size relative to the prior art by adopting a connecting piece structure and has good firmness without deforming the connecting piece when used for a long time, thereby ensuring the integral appearance of the motorcycle.

Owner:CHONGQING LONCIN MOTOR

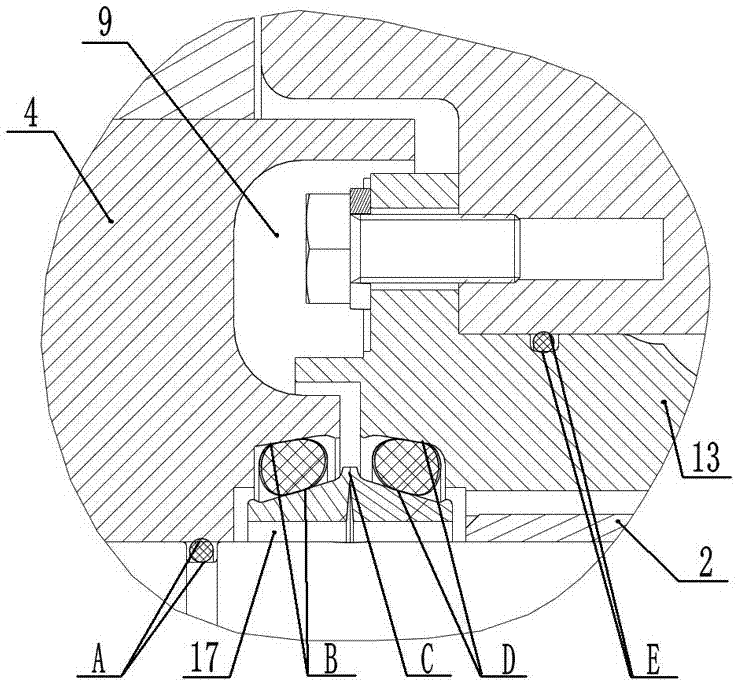

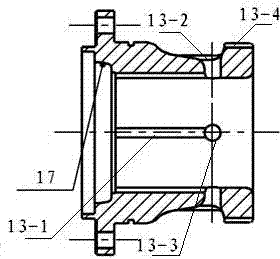

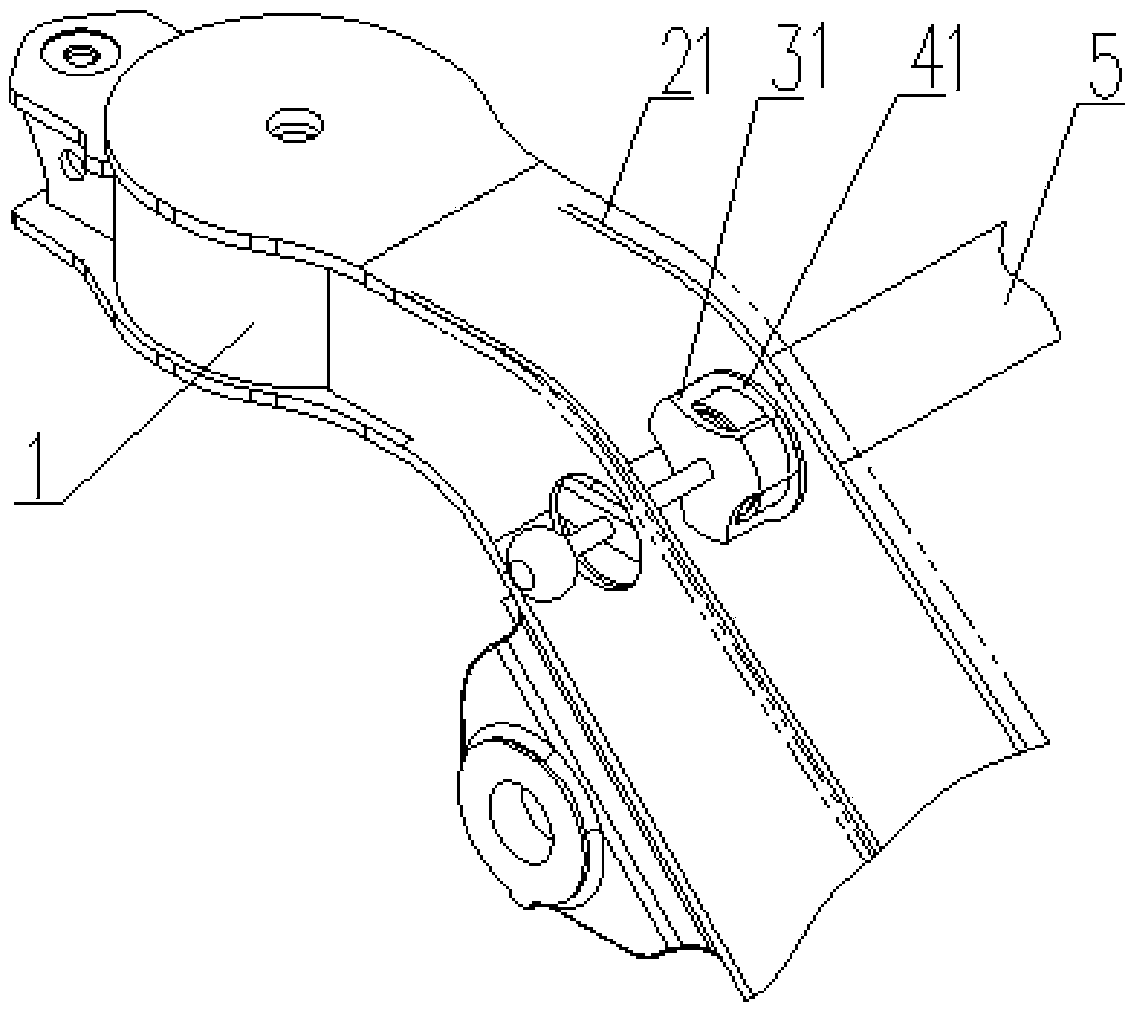

Working device hinging mechanism

InactiveCN106884862ADifficult to enterReduce Adhesive WearBearing componentsPivotal connectionsMechanical engineeringAdhesive wear

The invention provides a working device hinging mechanism, and relates to the technical field of engineering machinery. The working device hinging mechanism comprises a bearing bush, a shaft and an anti-dust ring, wherein a bushing is arranged out of the bearing bush in a sleeving manner; the shaft is arranged in the bearing bush in a penetrating manner; a left floating sealing seat and a right floating sealing seat are respectively connected with the two ends of the shaft in a sleeving manner; a first floating oil sealing cavity is formed in a contact surface between the bushing and the left floating sealing seat; a second floating oil sealing cavity is formed in a contact surface between the bushing and the right left floating sealing seat; the first floating oil sealing cavity and the second floating oil sealing cavity are communicated with the shaft; a floating oil seal is arranged in each floating oil sealing cavity; a concave pit is formed in the inner end surface of each of the left floating sealing seat and the right floating sealing seat; end heads of the bushing are embedded into the concave pits; each embedding gap is a zigzag gap channel; compared with the prior art, the floating oil seals of the working device hinging mechanism form static seal; when the floating oil seals are in contact with each other and are rotated, dynamic end surface seal is formed; small particles do not enter the space between the shaft and a shaft sleeve easily, and an anti-dust effect is good; the adhesive wear and the abrasive wear of a bearing can be reduced; the work reliability of a sliding bearing mechanism can be improved.

Owner:LIUZHOU LIUGONG EXCAVATORS +2

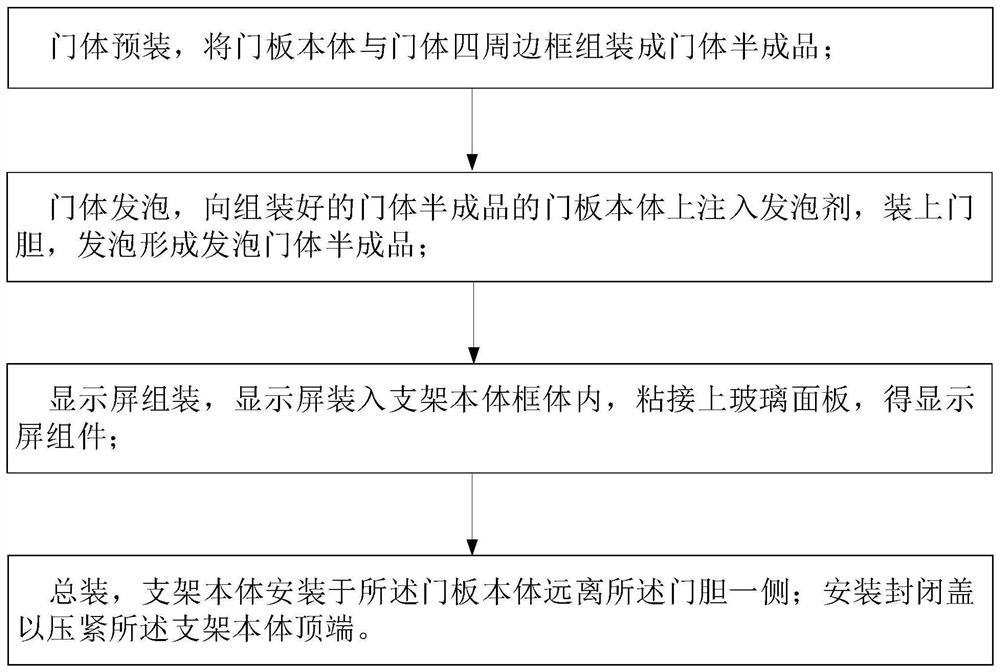

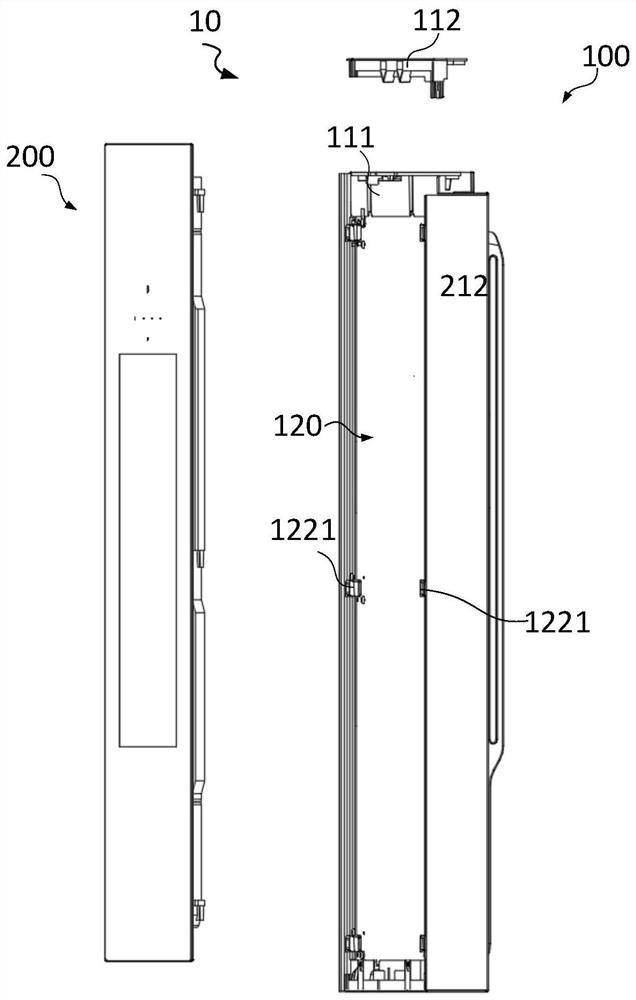

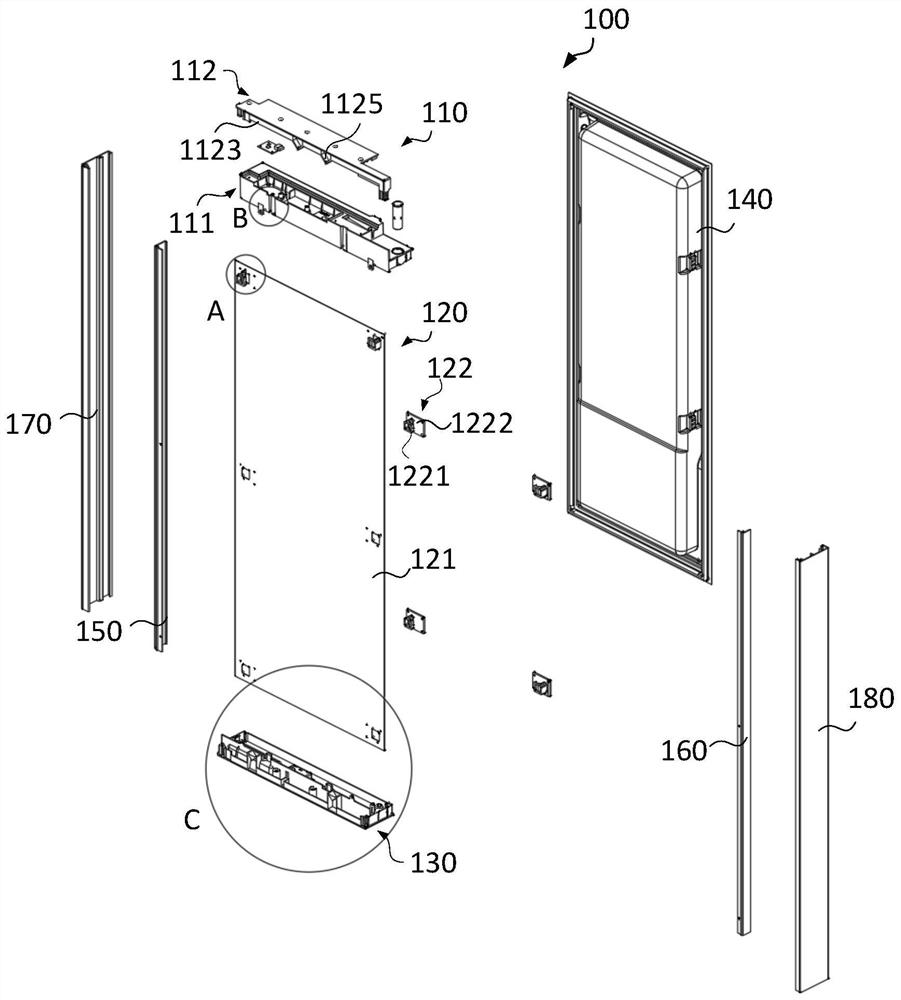

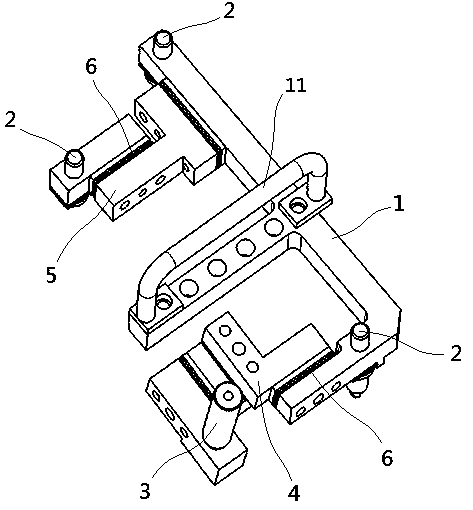

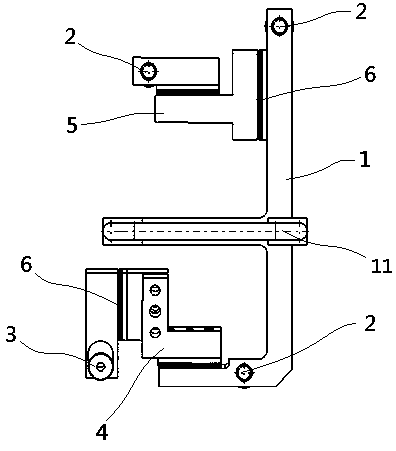

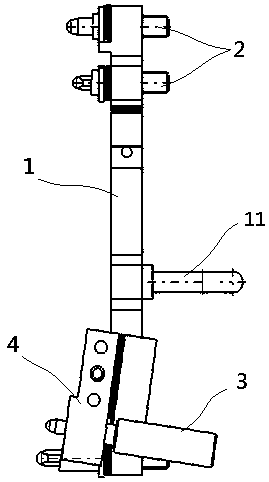

Installation method of door body display screen, refrigerator door body and refrigerator

ActiveCN113446808AQuick installationEasy to installLighting and heating apparatusDomestic refrigeratorsFoaming agentIcebox

The invention provides an installation method of a door body display screen. The installation method comprises the following steps that a door plate body and a door body frame are assembled into a door body semi-finished product; a foaming agent is injected into the door plate body of the door body semi-finished product, and a door liner is installed for foaming; a display screen is arranged in a frame body of a support body and is bonded with a glass panel; the support body is installed on the side, away from the door liner, of the door plate body, and a sealing cover is installed to press the top end of the support body. The invention further provides a refrigerator door body and a refrigerator. According to the installation method, the display screen, the support body and the glass panel are assembled into a display screen assembly, then the support body is assembled on one side of the foaming door body semi-finished product, and finally the sealing cover is installed. Assembling is fast, the support body plays a certain role in protecting the display screen, and the display screen is easy to disassemble.

Owner:FOSHAN VIOMI ELECTRICAL TECH +1

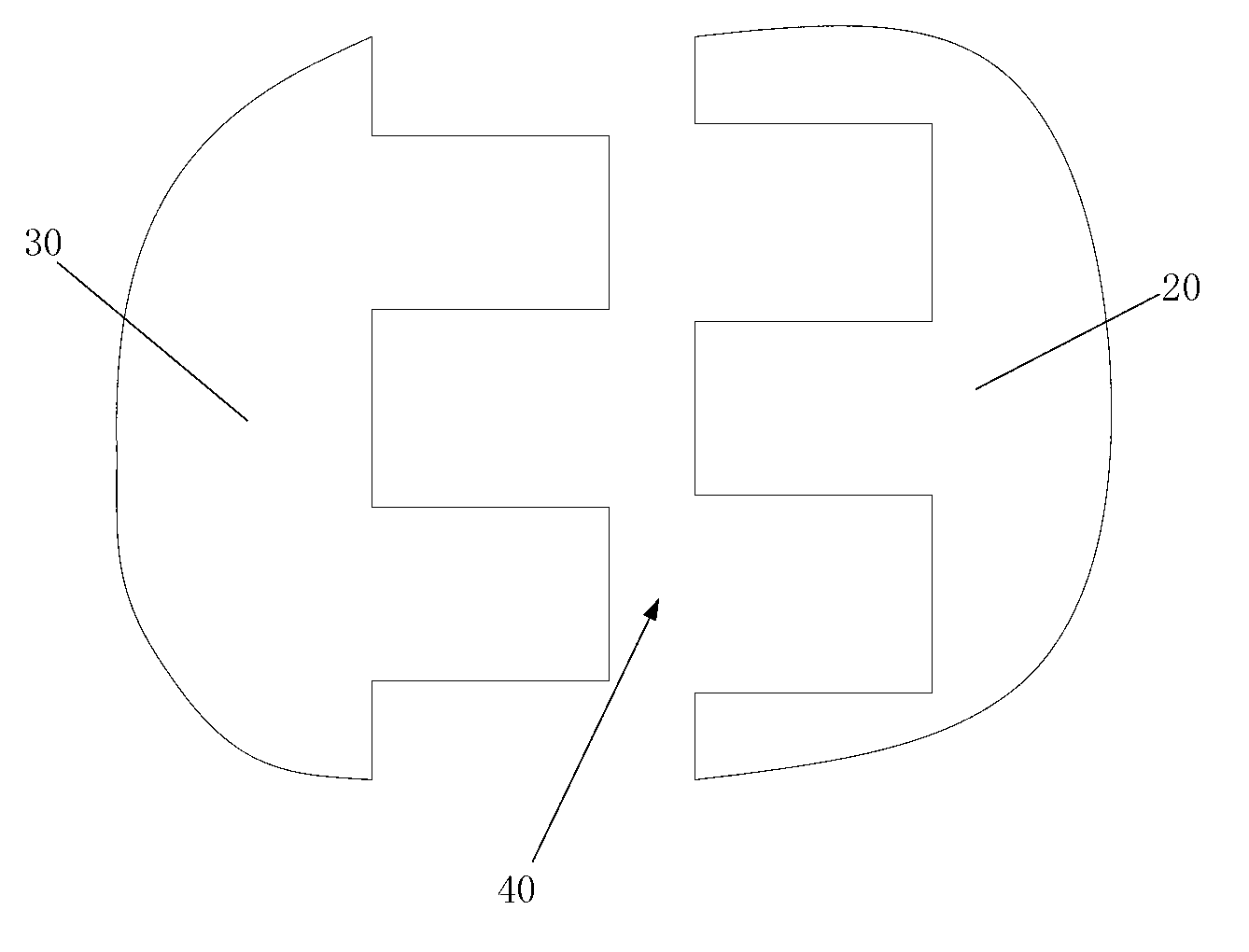

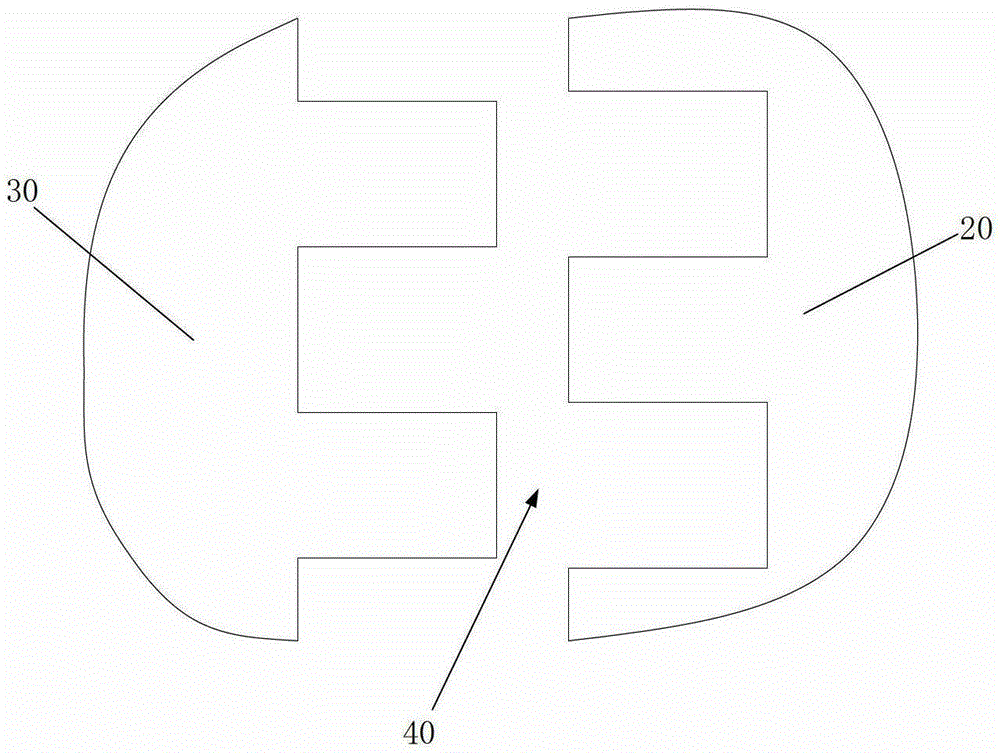

Testing auxiliary tool and testing method for matching clearance of B column cover plates of car doors

InactiveCN107860297AShorten the timeReduce dependenceMechanical clearance measurementsEngineeringFixed position

The invention relates to a testing auxiliary tool and a testing method for a matching clearance of B column cover plates of car doors. The testing auxiliary tool comprises a base, fixed positioning pins and a movable positioning pin, wherein the fixed positioning pins and the movable positioning pin are arranged on the base. The movable positioning pins are pluggable. The testing auxiliary tool matches a positioning hole on B column wind frame reinforcing plates of a front car door and a back car door through the fixed positioning pins and the movable positioning pin, thereby testing whether the matching clearance between the B column cover plates of the front car door and the back front car door is qualified. The base body has an inverse-F-shaped structure. The upper end and the lower endof the inverse-F-shaped structure are respectively provided with a fixed positioning pin. A third fixed positioning pin is arranged at the upper part of the inverse-F-shaped structure through a connecting block II. The movable positioning pin is arranged outside the lower cross bar of the inverse-F-shaped structure through a connecting block I. The testing auxiliary tool and the testing method ensures high consistency of the matching clearance of the B column cover plates of the car doors, and furthermore reduces reworking of the B column cover plates by employees.

Owner:CHERY AUTOMOBILE CO LTD

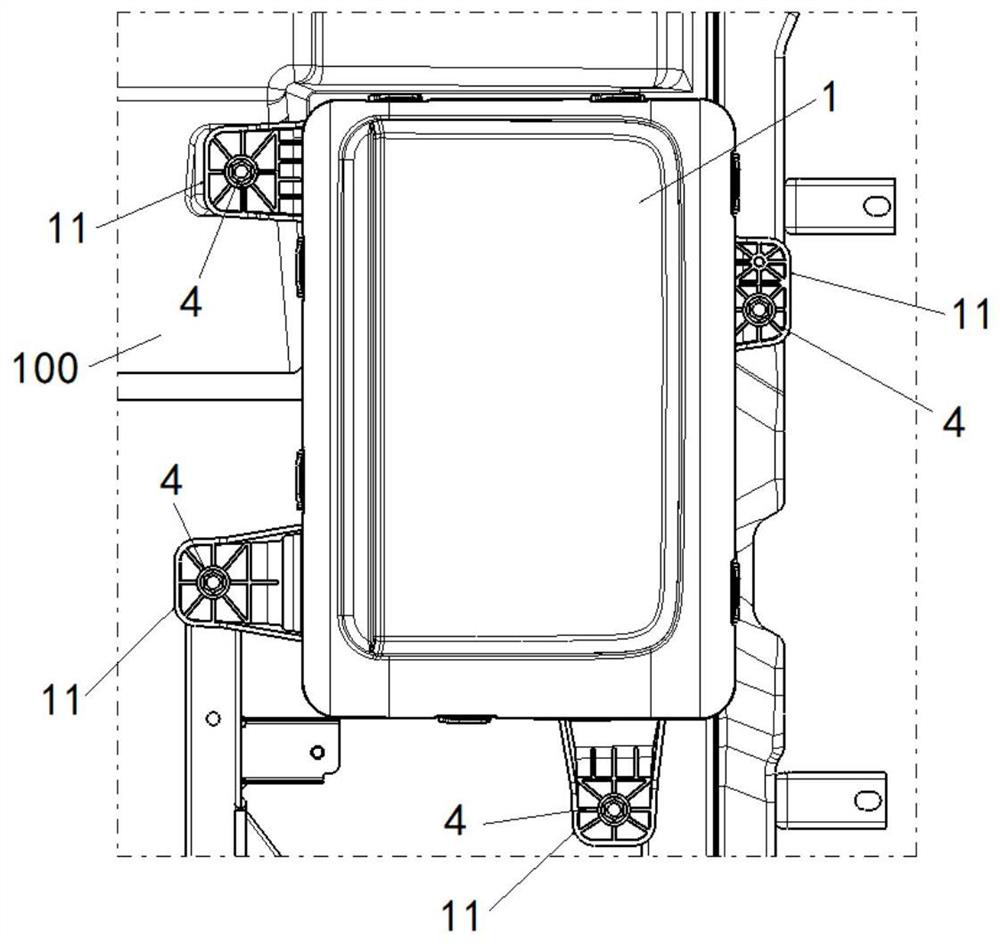

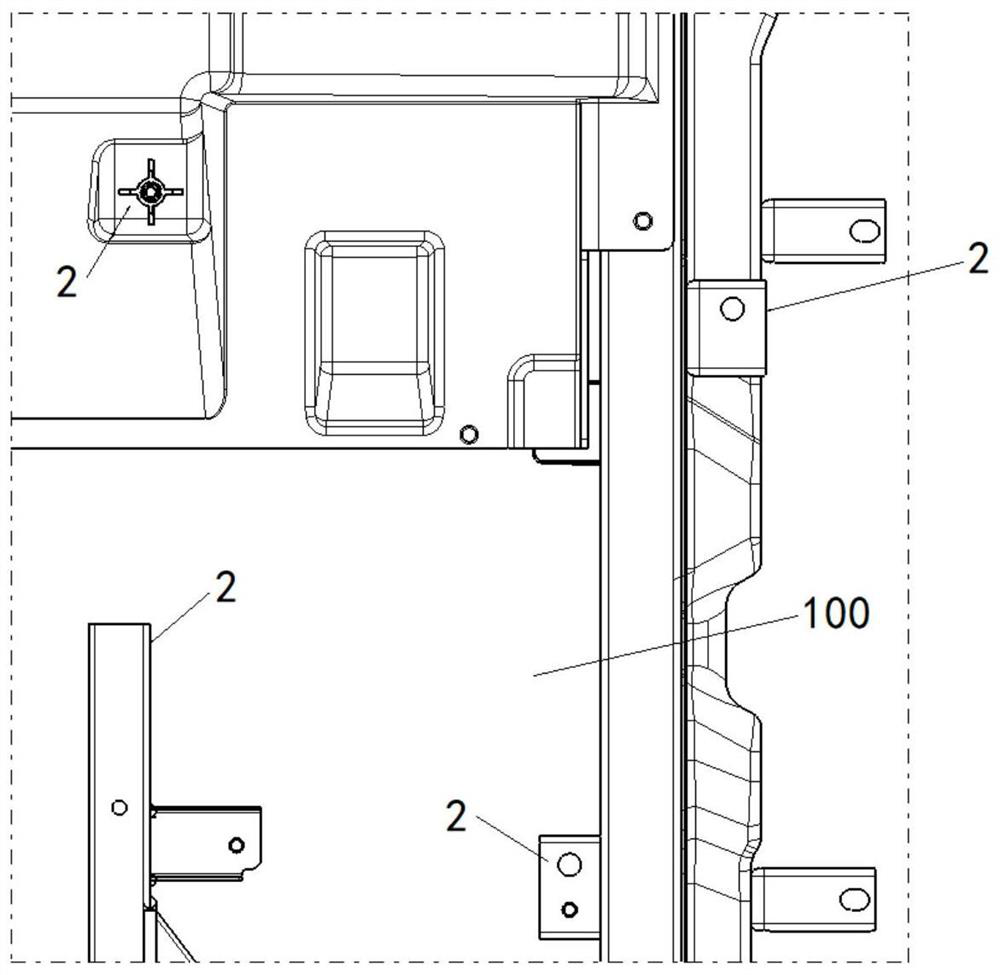

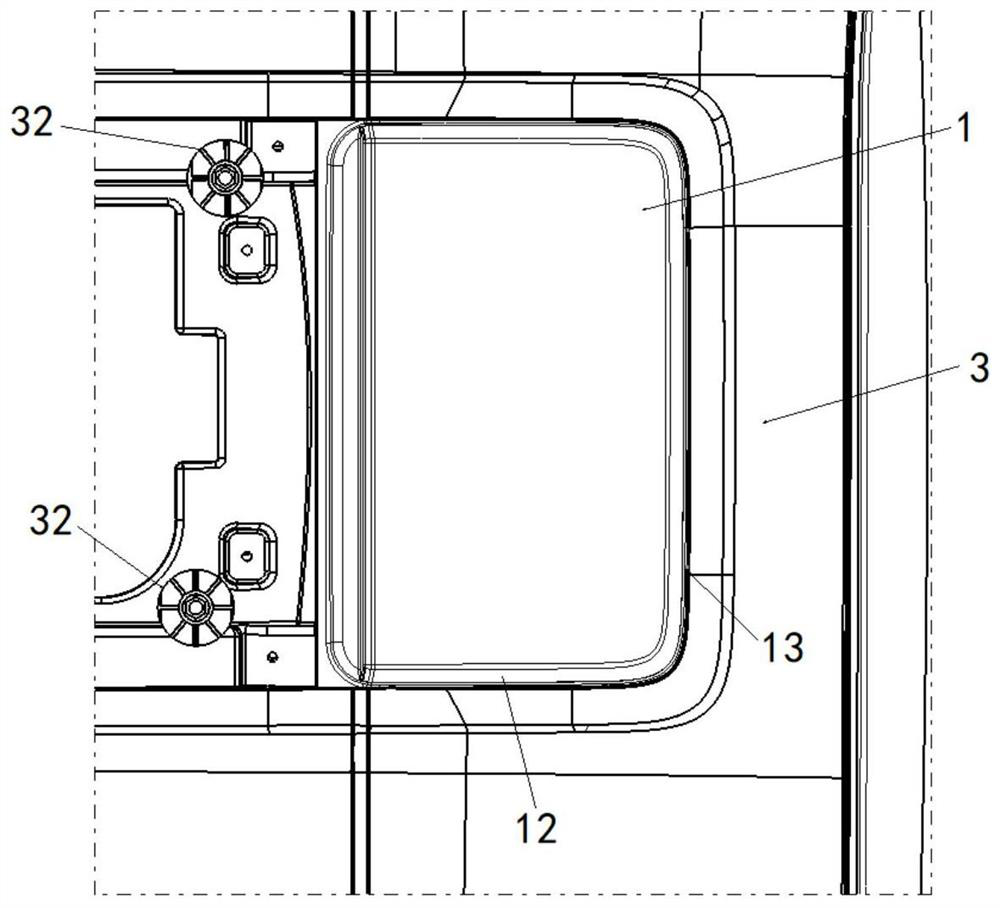

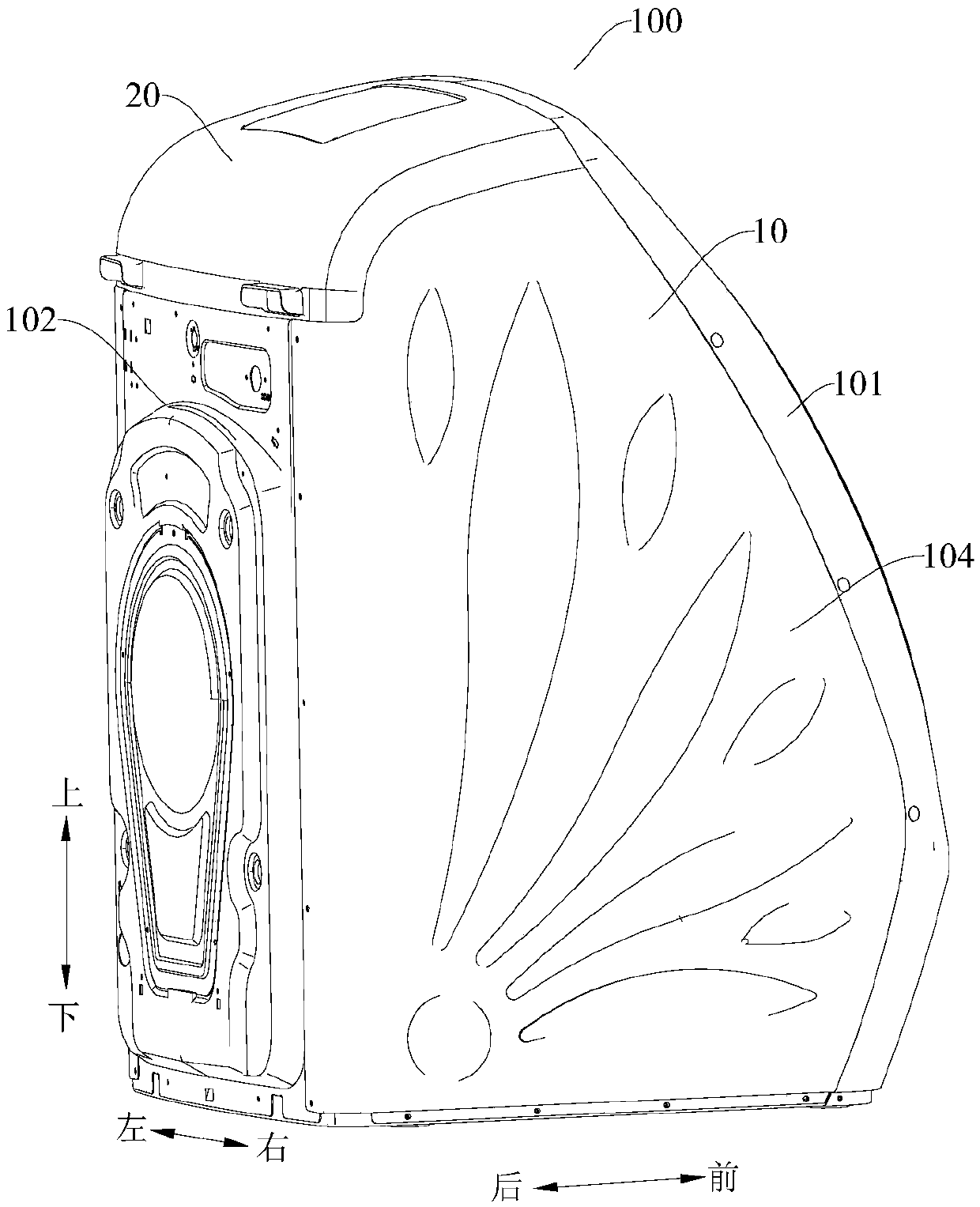

Headlamp mounting structure and headlamp mounting method

ActiveCN111791794AAchieve installationGuaranteed assembly clearanceVehicle headlampsLighting support devicesEngineeringStructural engineering

Owner:上海元城汽车技术有限公司

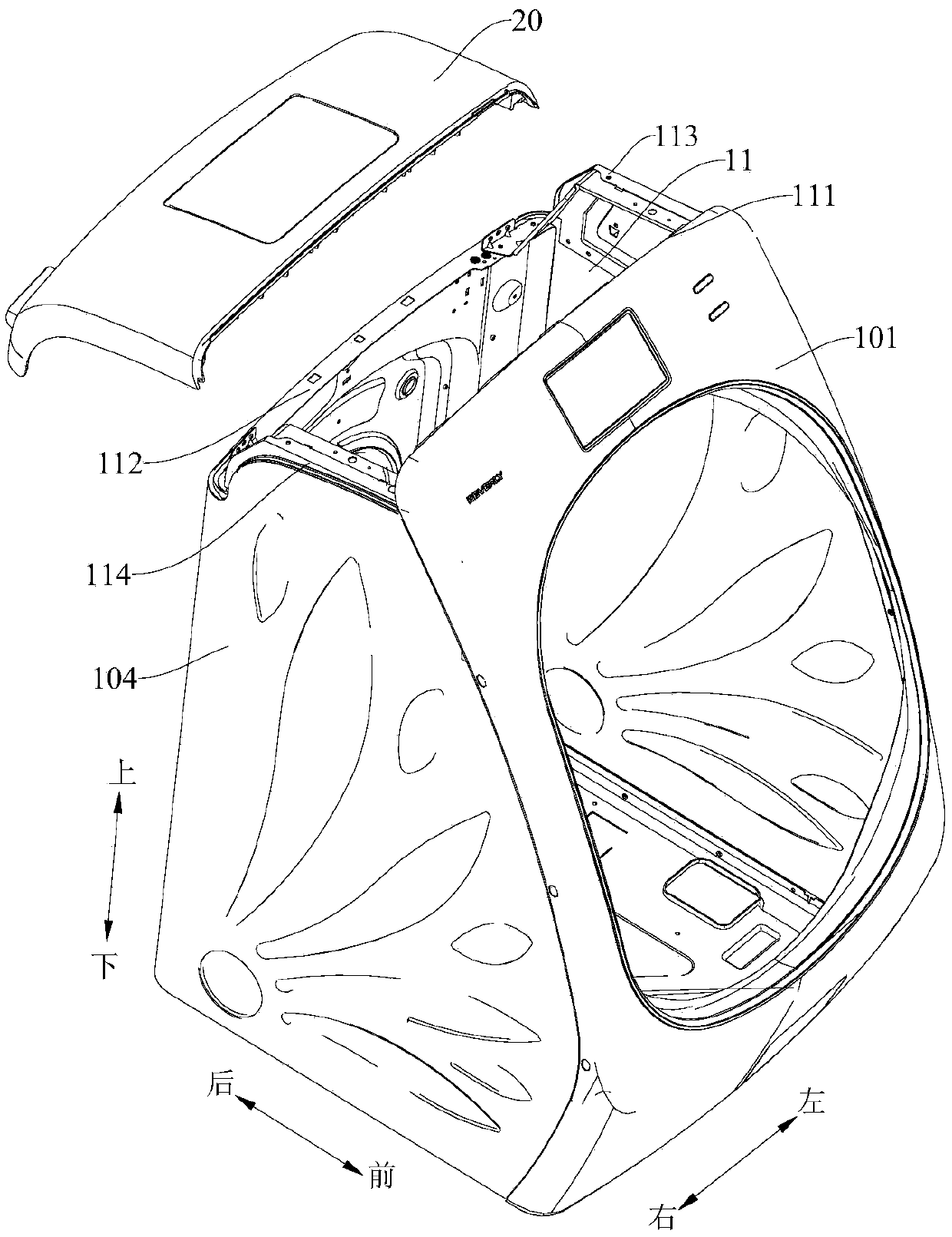

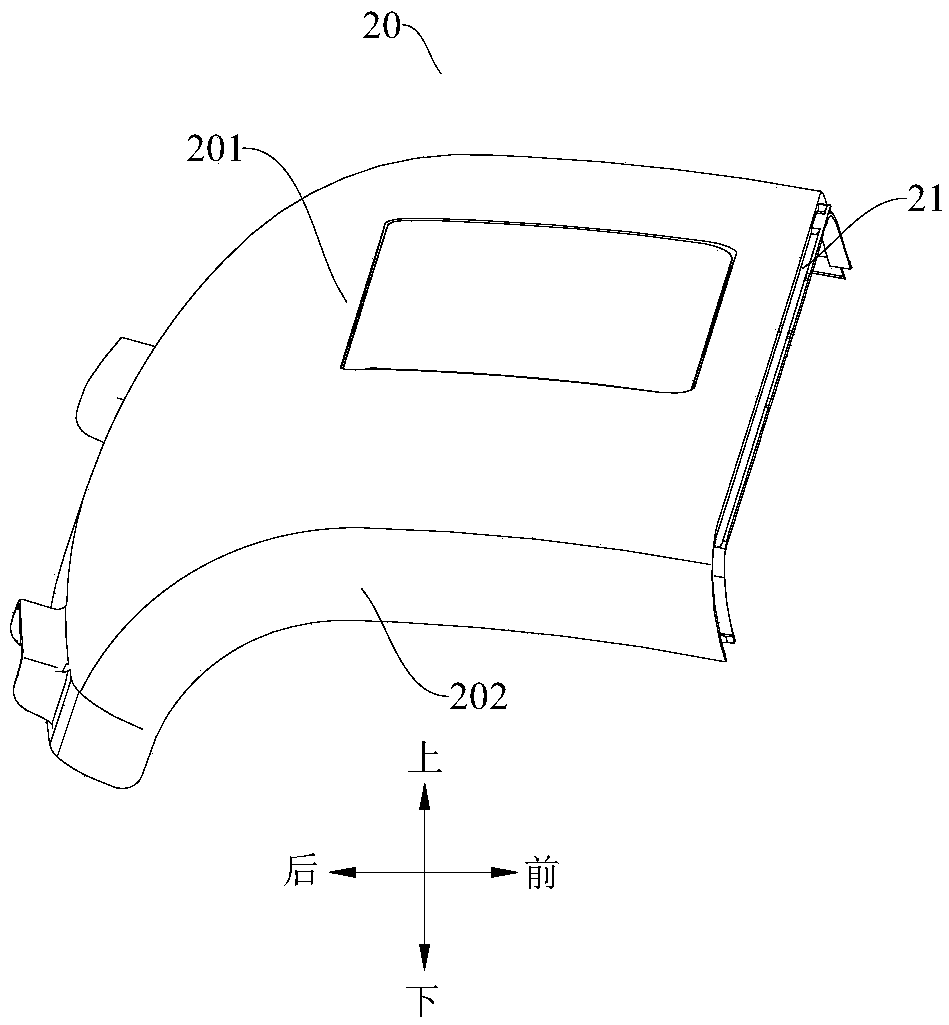

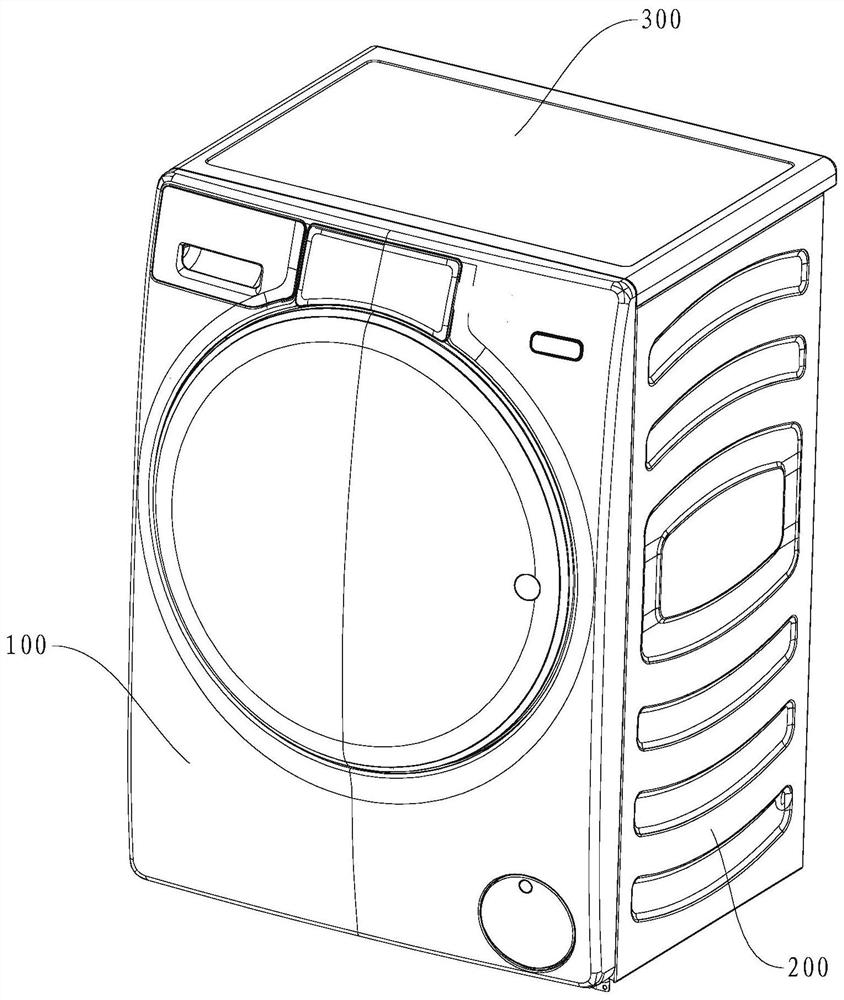

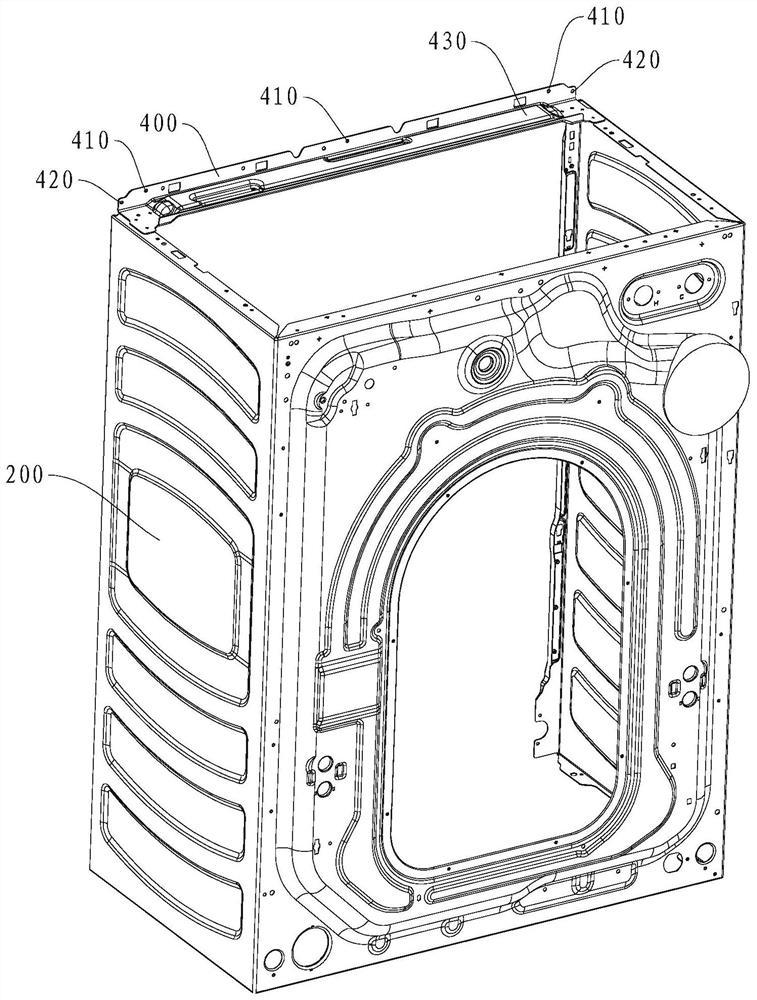

Case assembly and clothes treating apparatus

InactiveCN111155280AEasy to installGuaranteed assembly clearanceOther washing machinesTextiles and paperStructural engineeringMechanical engineering

The invention discloses a case assembly and a clothes treating apparatus. The case assembly comprises a case and a head cover, wherein an opening is formed in the top of the case; and the opening is provided with a front frame, a rear frame, a left frame and a right frame; and the head cover is suitable for being pushed to the top of the case from the rear side of the case and is clamped with at least one of the front frame, the rear frame, the left frame and the right frame. According to the case assembly disclosed by the embodiment of the invention, fixation of the case assembly is achievedthrough clamping the head cover and the frames of the opening in the top of the case; the case assembly is convenient to install; a certain assembly clearance is ensured; the condition that the head cover cannot be arranged in place is avoided; the assembly reliability is ensured; and the case assembly is high in installation strength and good in stability.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

An Electron Beam Welding Method Applicable to Small Diameter Flanges of Thin Wall Roof

ActiveCN106670640BIncrease foilPlay full without depressionElectron beam welding apparatusWorkpiece edge portionsButt jointPre stress

Owner:CAPITAL AEROSPACE MACHINERY +1

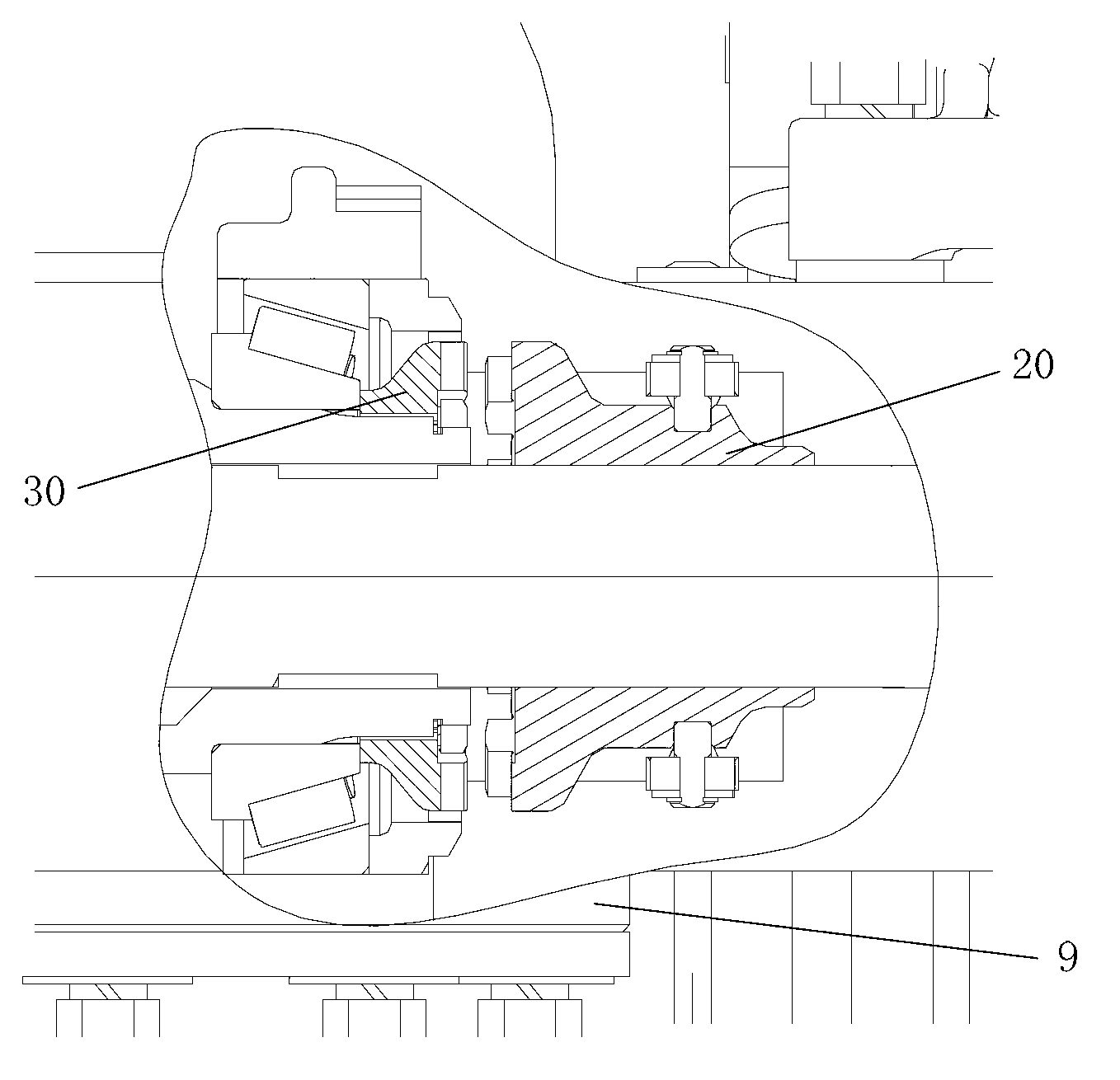

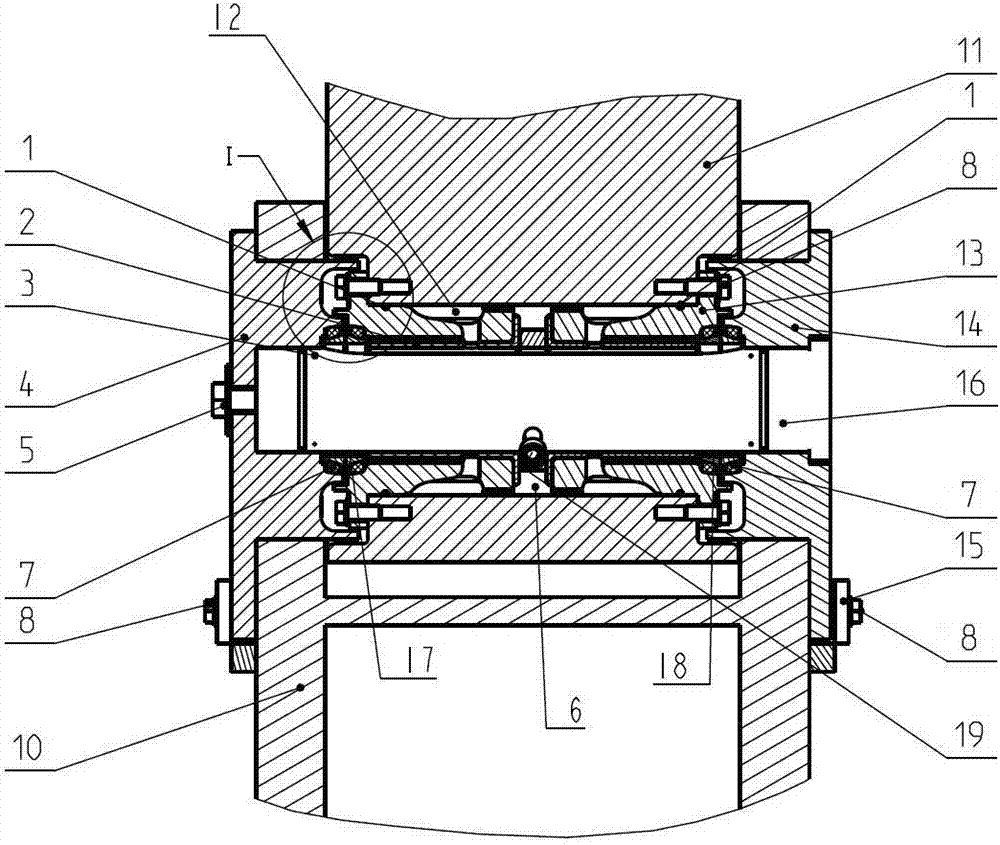

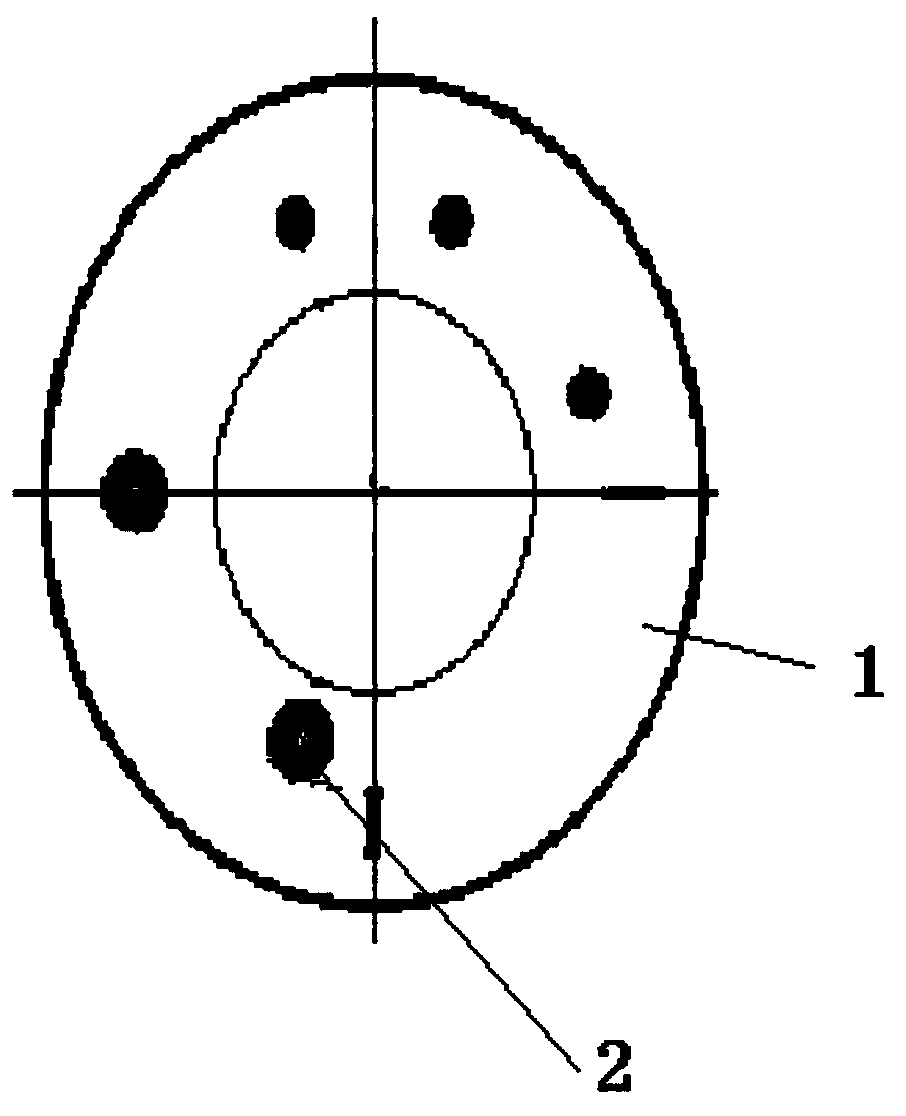

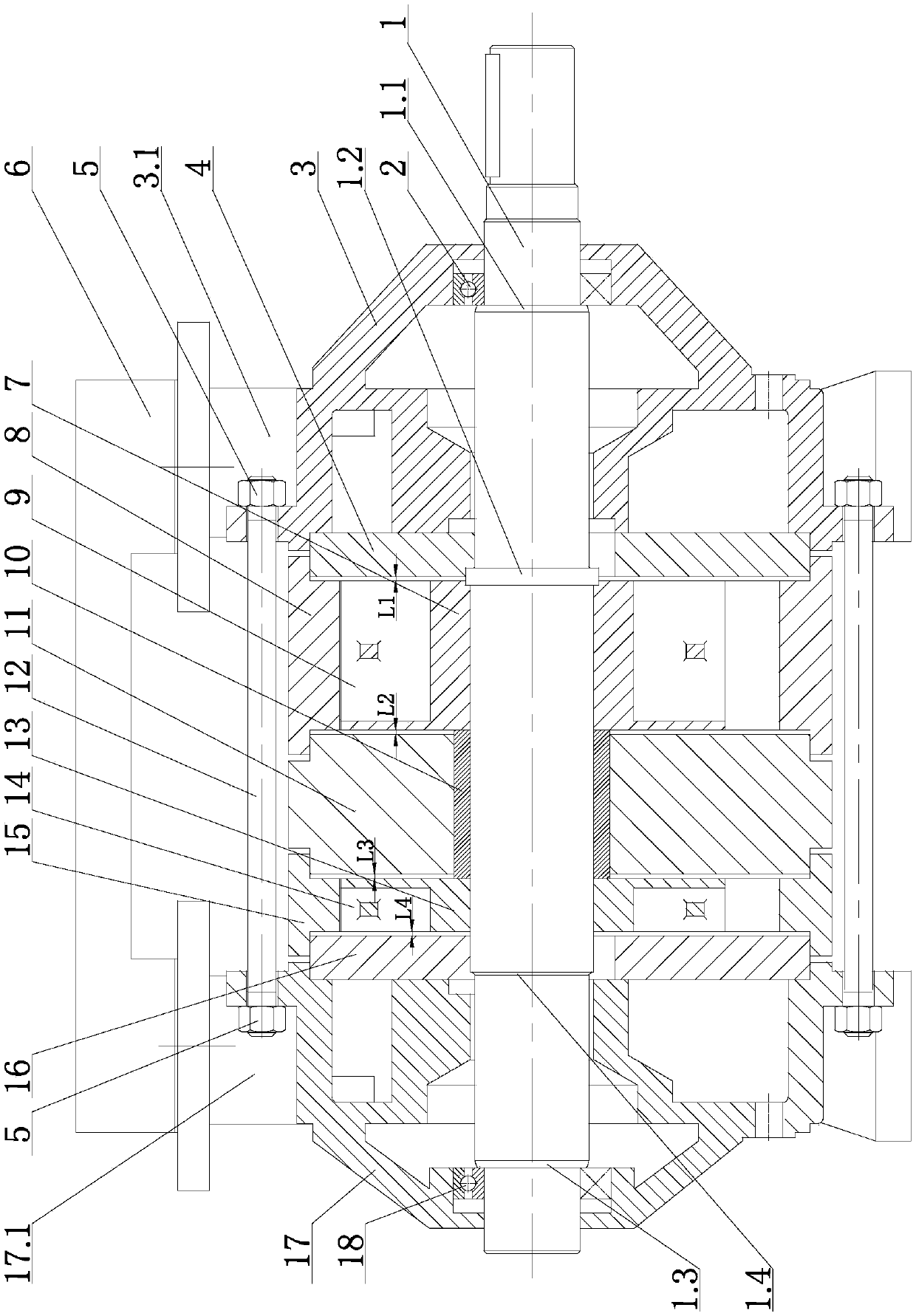

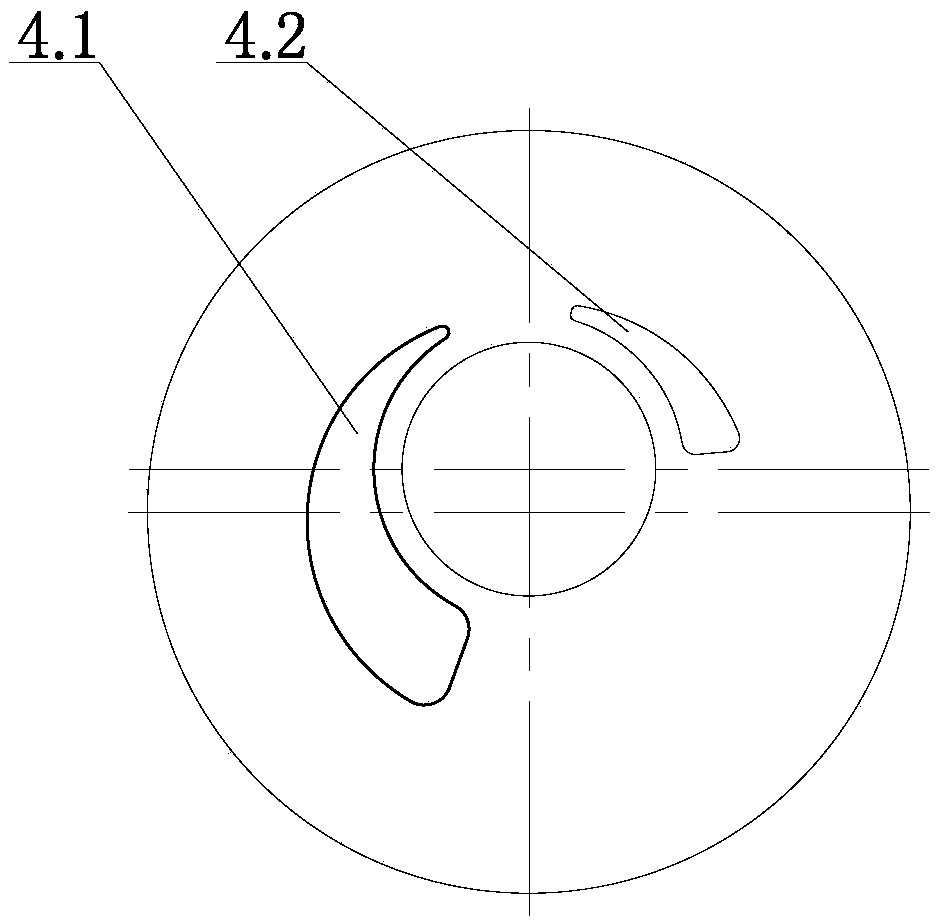

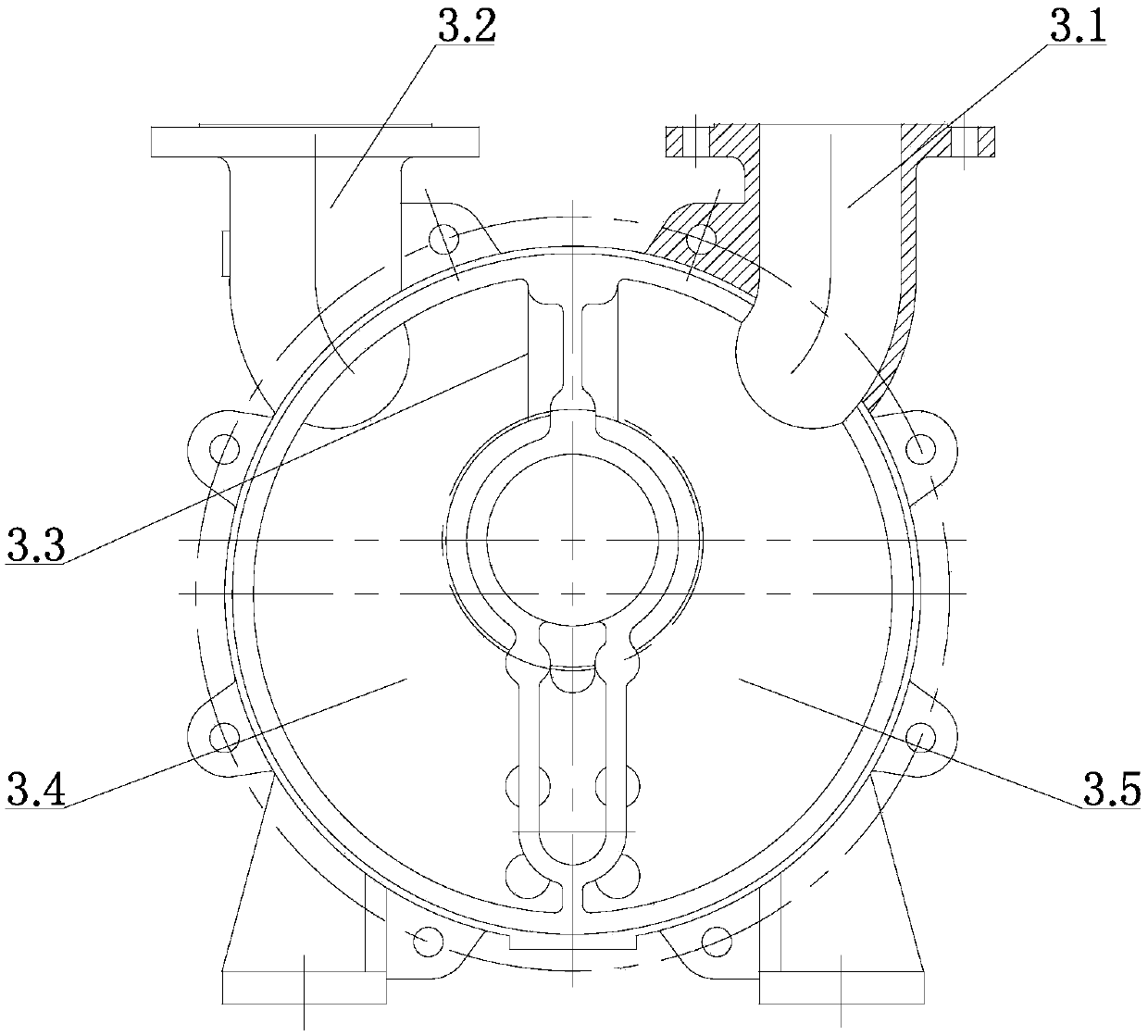

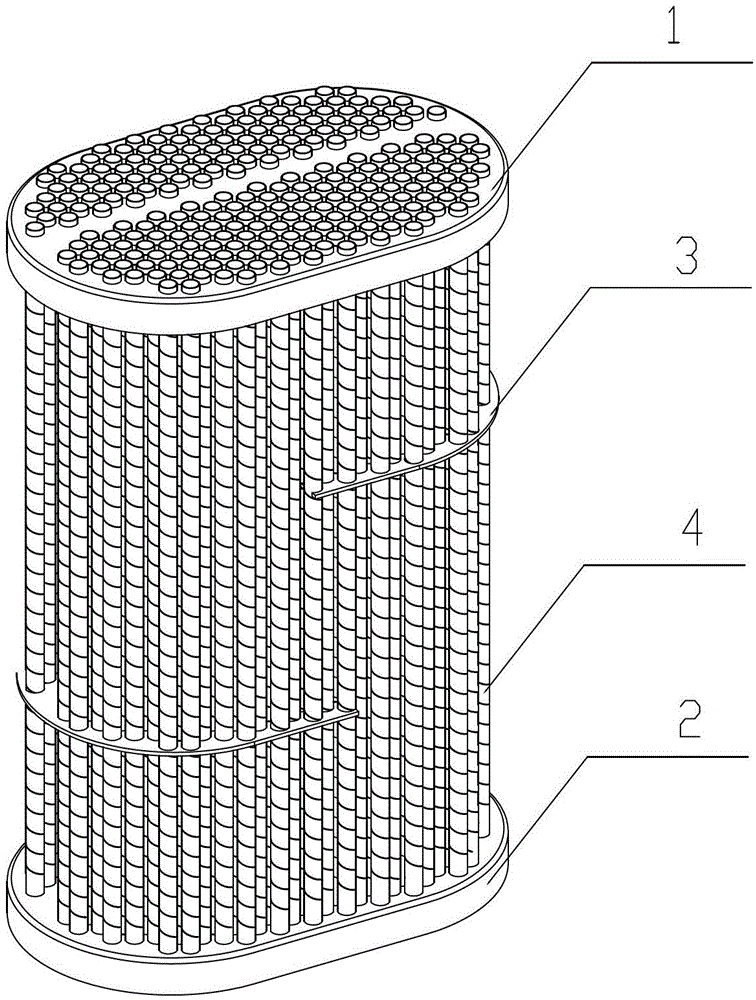

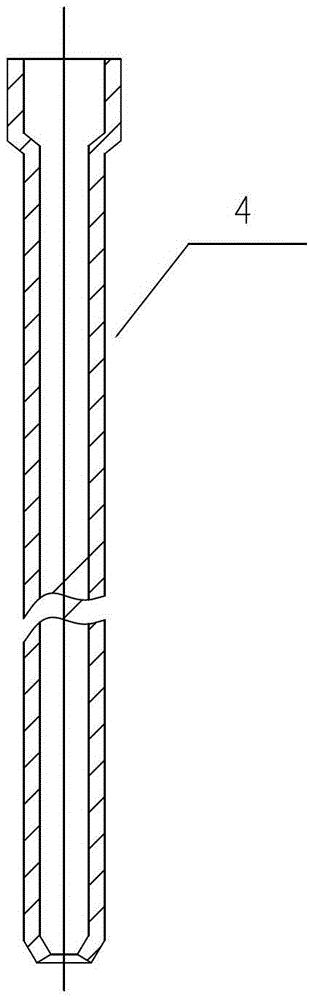

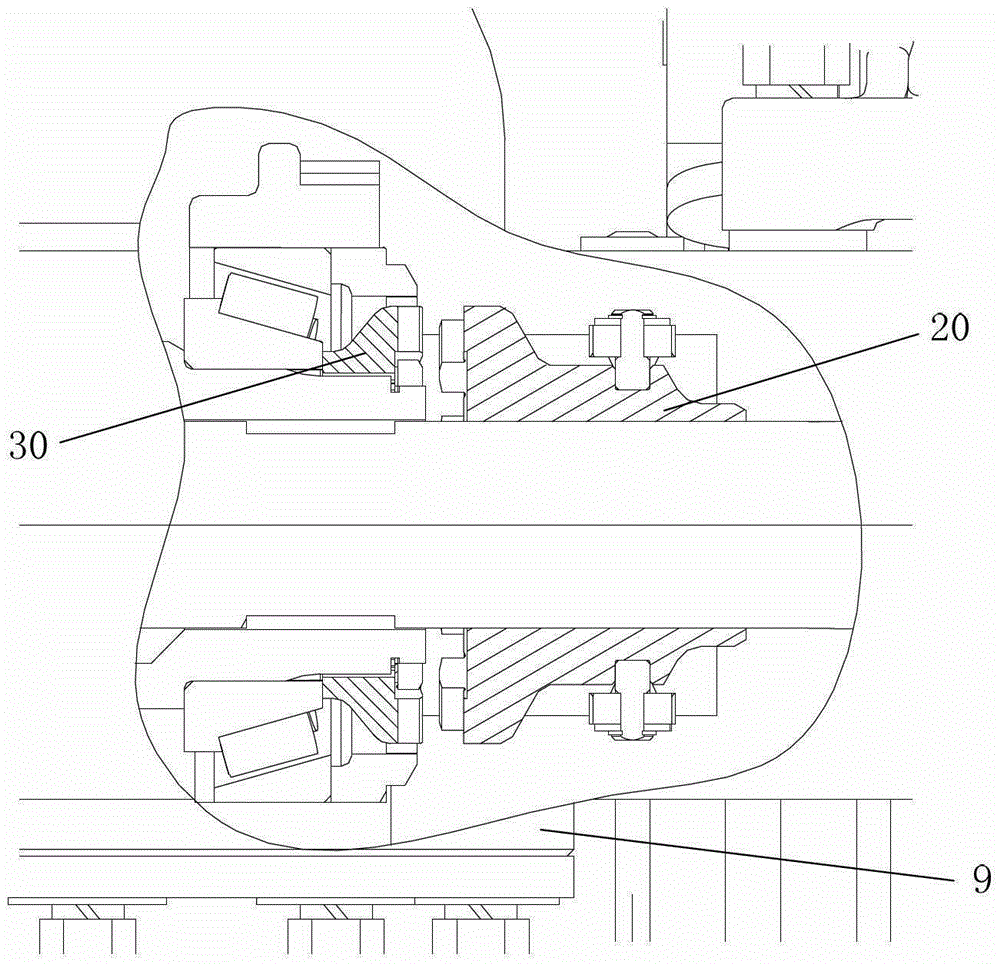

Two-stage liquid ring vacuum pump and assembling method thereof

ActiveCN109667759AGuaranteed assembly clearanceSimplify the assembly processRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsNoise pollutionEngineering

The invention belongs to the field of liquid ring pumps, and particularly relates to a two-stage liquid ring vacuum pump and an assembling method thereof. The two-stage liquid ring vacuum pump is reasonable in structural design, the two-stage liquid ring vacuum pump is provided with two stage compressing chambers, a gas passage is not arranged on a middle wall, the two stage compressing chambers can be communicated directly through an external communication tube, and therefore, in the assembly process, only the numerical values of the gaps L1 and L4 need to be controlled, the gap L2 and the gap L3 are naturally formed by the machining size and do not need to be controlled, so that the assembly clearance is easily ensured, and on the premise that the air extraction amount and the vacuum degree are not affected, the assembly process can be simplified, the assembling efficiency is improved, and the using performance and the safety stability are improved, meanwhile, compared with a traditional two-stage pump, the production noise can be greatly reduced, and the noise pollution can be reduced. According to the method for assembling the two stage liquid ring vacuum pump, the gap L1 and gap L4 can be completely controlled, the assembly precision of the whole pump body is ensured, the assembly process is further simplified, and the assembly efficiency is improved.

Owner:淄博真空设备厂有限公司

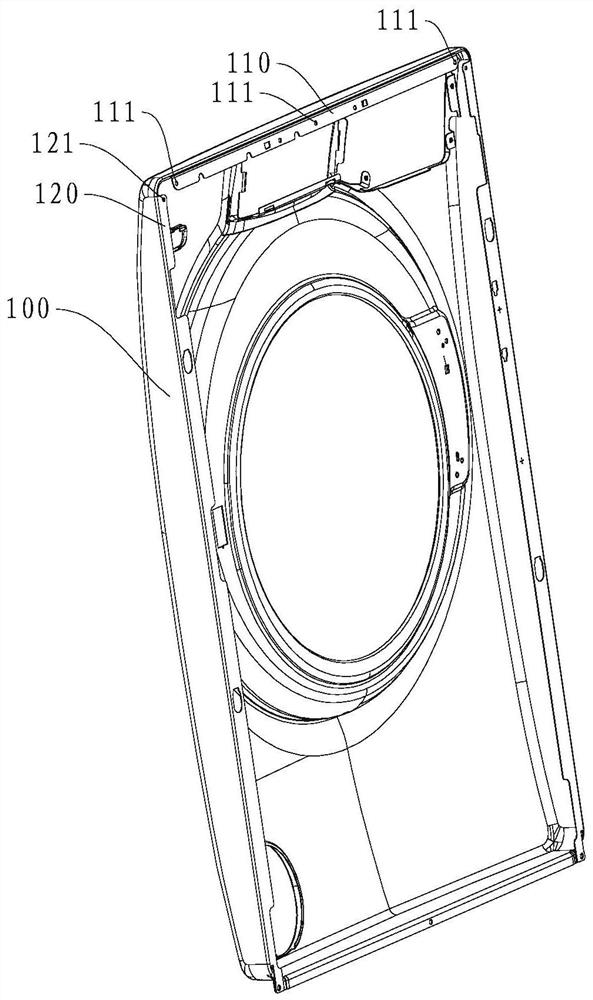

Washing machine front plate installing structure and washing machine

PendingCN111764117AImprove stabilitySimple and fast operationOther washing machinesTextiles and paperLaundry washing machineStructural engineering

The invention discloses a washing machine front plate installing structure and a washing machine. The washing machine comprises a box body and a table top fixed to the box body, the front end face ofthe box body is an integrated front plate, the installing structure comprises a reinforcing part, the reinforcing part is of an L-shaped cross beam structure, the reinforcing part is fixed to a side plate of the box body, a flange is arranged on the side, opposite to the table top, of the front plate, and the front plate is hung on the side edge of the reinforcing part through the flange and fixedly connected with the reinforcing part. According to the washing machine front plate installing structure, the reinforcing part is fixedly connected with the box body, then the front plate is hung onthe side edge of the reinforcing part, finally the front plate and the reinforcing part are fixed, operation is easy and convenient, the reinforcing part can play a certain role in supporting and fixing the front plate, and the stability of the overall structure of the washing machine is enhanced; and by means of the suspension installation mode, the assembly gap is guaranteed, and the assembly strength is guaranteed.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

Cooking pots and steam-heating cooking appliances for steam heating

ActiveCN110338641BExtend your lifeReduce entryBoiling over preventionCooking-vessel lids/coversThermodynamicsMechanical engineering

Owner:JOYOUNG CO LTD

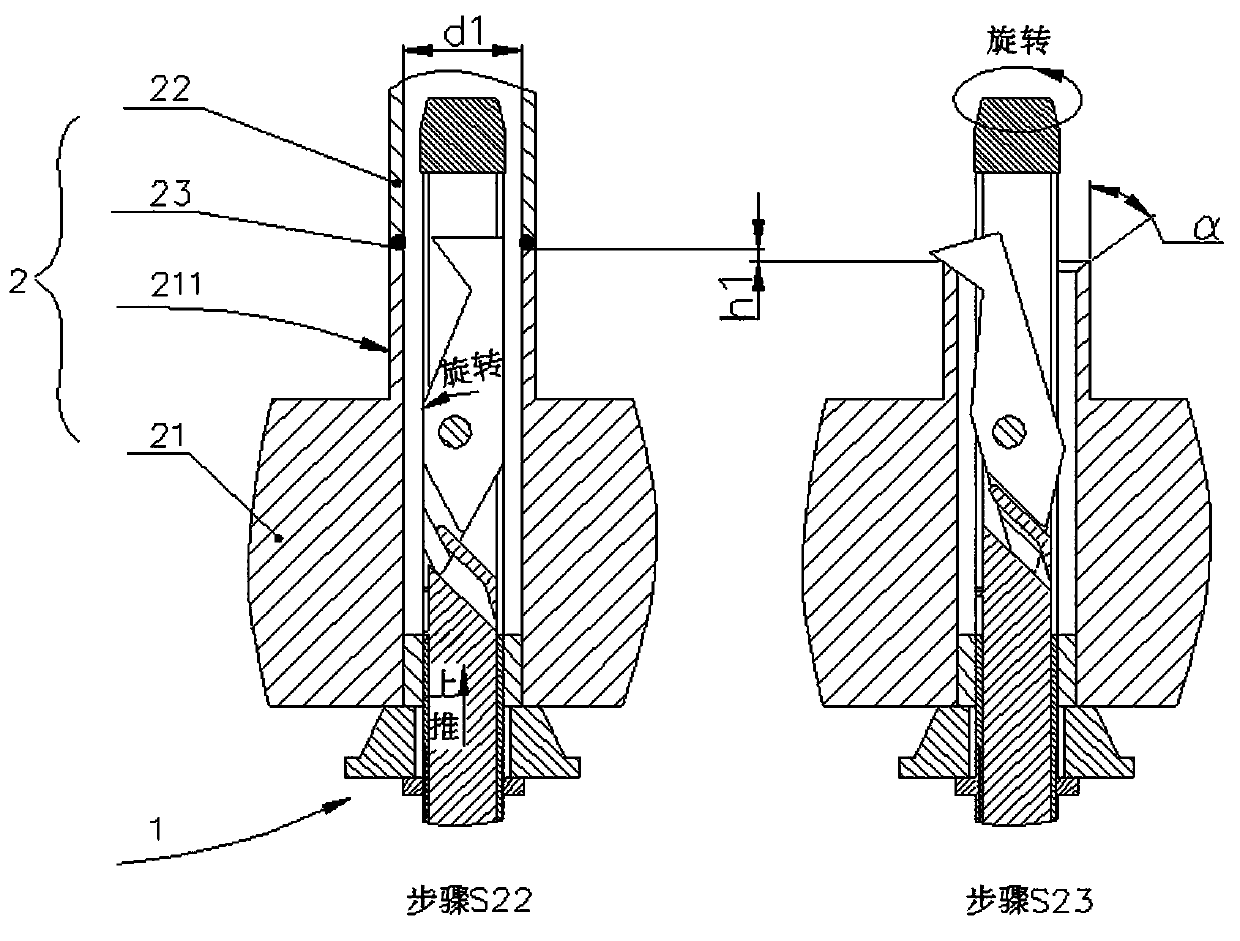

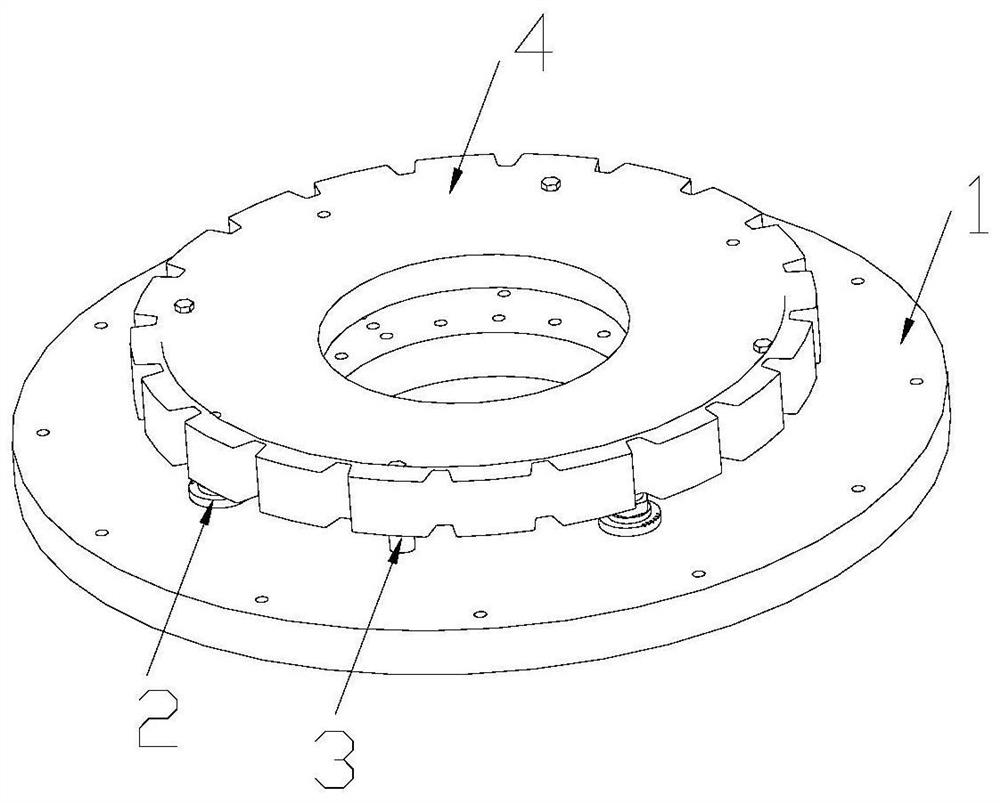

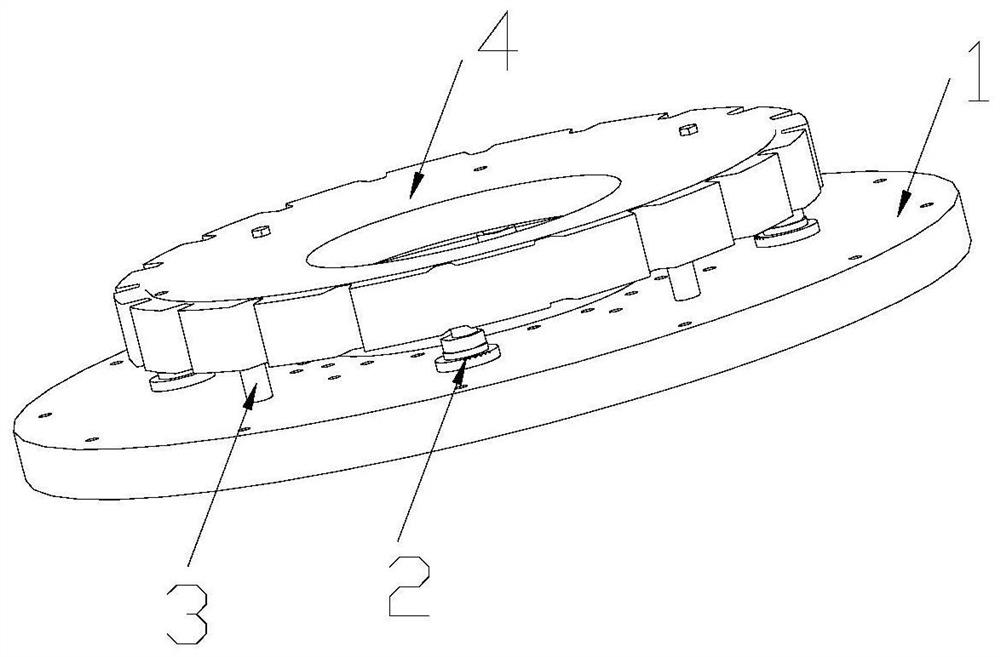

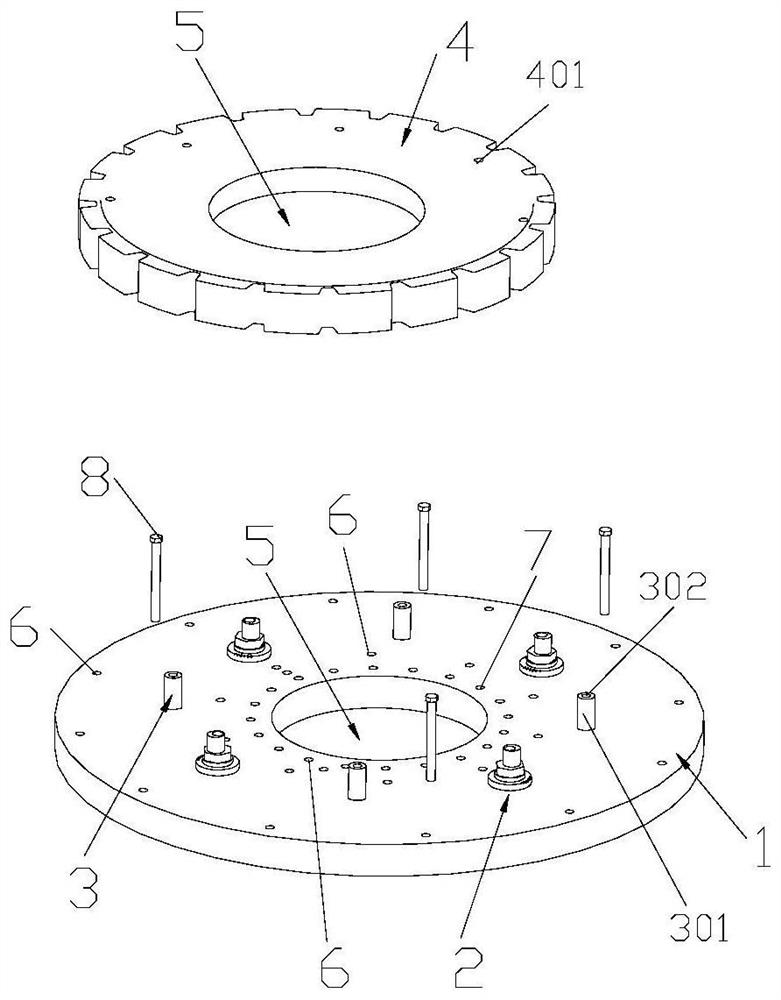

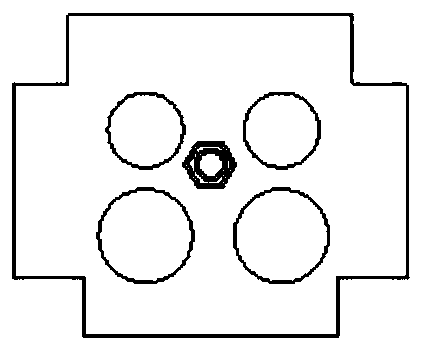

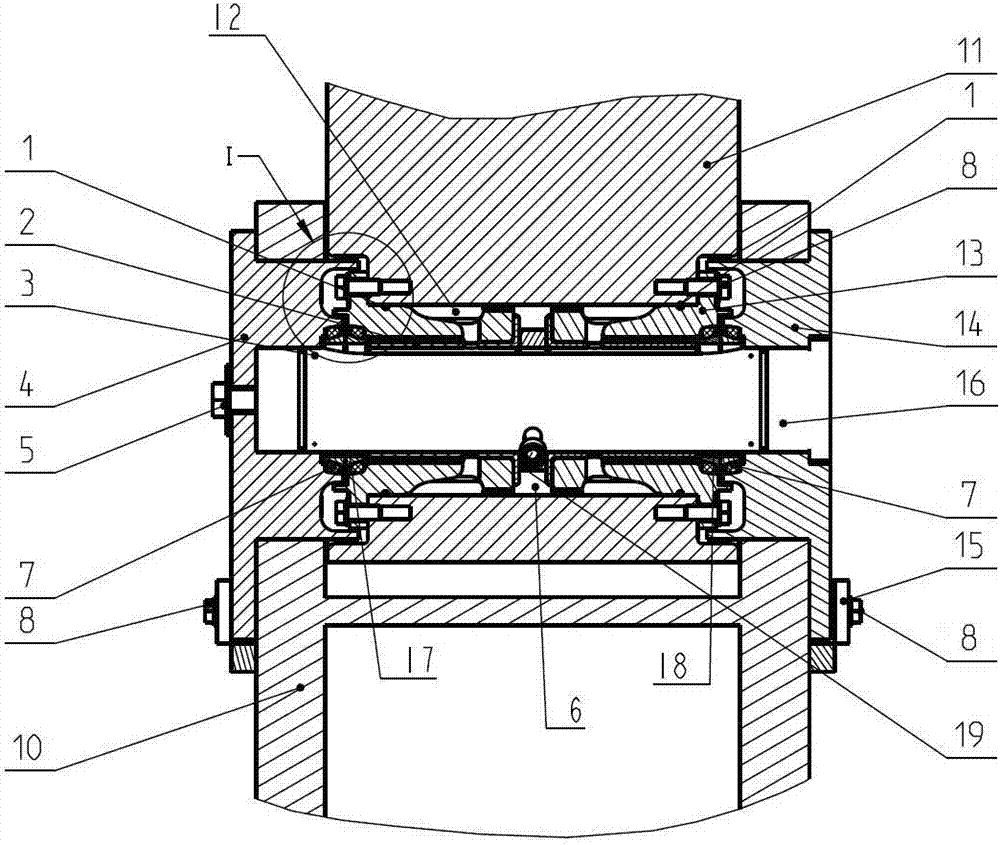

Balance adjusting device of turbofan engine rotor single-stage disc and adjusting method thereof

ActiveCN112097995AGood operabilityReduce operating errorsStatic/dynamic balance measurementEfficient propulsion technologiesEngineeringTurbofan

The invention discloses a balance adjusting device of a turbofan engine rotor single-stage disc and an adjusting method of the balance adjusting device. The device comprises a balance base; an eccentric adjusting assembly which is installed on the balance base, and a supporting assembly which is installed on the balance base; a single-stage disc which is supported above the eccentric adjusting assembly, wherein the distance between the eccentric adjusting assembly and the center of the balance base is adjusted, so the single-stage disc and the balance base are connected into an up-down concentric structure through the supporting assembly. According to the invention, the balance adjustment requirements of the single-machine discs with different diameters can be met, and the technical problems that the unbalance amount of the tool is large, the assembly gap is not easy to guarantee and multiple groups of tools need to be processed in the single-stage disc balance process are solved.

Owner:CHENGDU ENGINE GROUP

A high-precision frame structure assembly welding tool

ActiveCN108098222BGuaranteed misalignmentPrevent rotationWelding/cutting auxillary devicesAuxillary welding devicesInterference fitWeld line

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

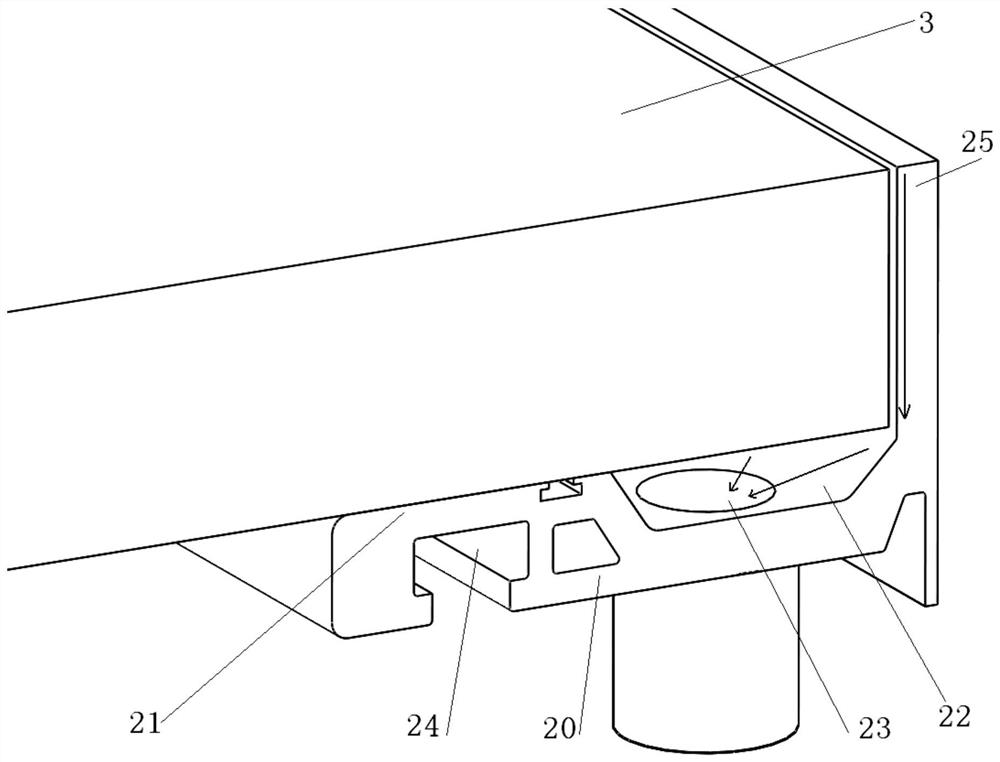

Escalator floor slab support structure and support frame

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

Working device hinging mechanism

InactiveCN106884863ADifficult to enterReduce Adhesive WearBearing componentsPivotal connectionsEngineeringMechanical engineering

The invention provides a working device hinging mechanism, and relates to the technical field of engineering machinery. The working device hinging mechanism comprises a bearing bush, a shaft which is arranged in the bearing bush in a penetrating manner and an anti-dust ring, wherein a bushing is arranged out of the bearing bush in a sleeving manner; a left floating sealing seat and a right floating sealing seat are respectively connected with the two ends of the shaft in a sleeving manner; a first floating oil sealing cavity is formed in a contact surface between the bushing and the left floating sealing seat; a second floating oil sealing cavity is formed in a contact surface between the bushing and the right left floating sealing seat; the first floating oil sealing cavity and the second floating oil sealing cavity are communicated with the shaft; a floating oil seal is arranged in each floating oil sealing cavity; at least one shaft oil channel is formed in the surface of the shaft in a shaft length direction; the shaft oil channel is communicated with the first floating oil sealing cavity; compared with the prior art, the floating oil seals of the working device hinging mechanism form static seal; when the floating oil seals are in contact with each other and are rotated, dynamic end surface seal is formed; small particles do not enter the space between the shaft and a shaft sleeve easily, and an anti-dust effect is very good, so that the adhesive wear and the abrasive wear of a bearing can be reduced; the work reliability of a sliding bearing mechanism can be improved.

Owner:LIUZHOU LIUGONG EXCAVATORS +2

Exhaust gas recirculation (EGR) cooler core body

ActiveCN103104378BWon't fall offGuaranteed assembly clearanceInternal combustion piston enginesNon-fuel substance addition to fuelInterference fitNeck structure

Owner:无锡双翼汽车环保科技有限公司

Manufacturing method of blade for centrifugal aeration blower diffuser and positioning tool for same

ActiveCN102658459BGuaranteed line profileAccurate calculation of throat areaPositioning apparatusMetal-working holdersEngineeringMachining

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

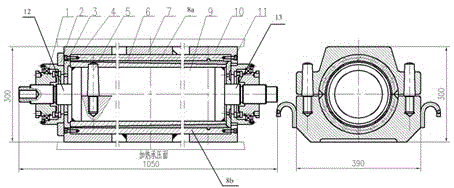

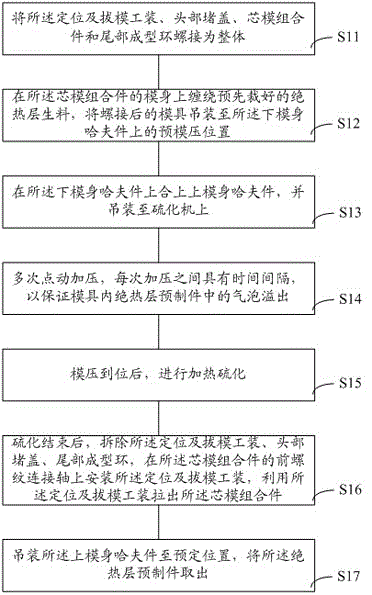

Integral molding die and molding method for engine inner heat insulation layer

An integral molding die for a motor internal insulation layer and a molding process. The die includes the following parts: an upper die body half piece and a lower die body half piece, which cooperate for usage; a mandrel assembly, which comprises a die body, and a front screw thread connection shaft and a rear screw thread connection shaft, welded to the front end and the rear end of the die body; a tail forming ring, which is in screw joint with the rear screw thread connection shaft of the mandrel assembly; a head blanking cap, which is in screw joint with the front screw thread connection shaft of the mandrel assembly; and a positioning and draft tool, which is in screw joint with the front screw thread connection shaft of the mandrel assembly. The invention makes the structure size and precision of an insulation layer preform meet the design requirements, and in the premise of satisfying the structure reliability, the invention reducing the negative quality of thermal protection.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

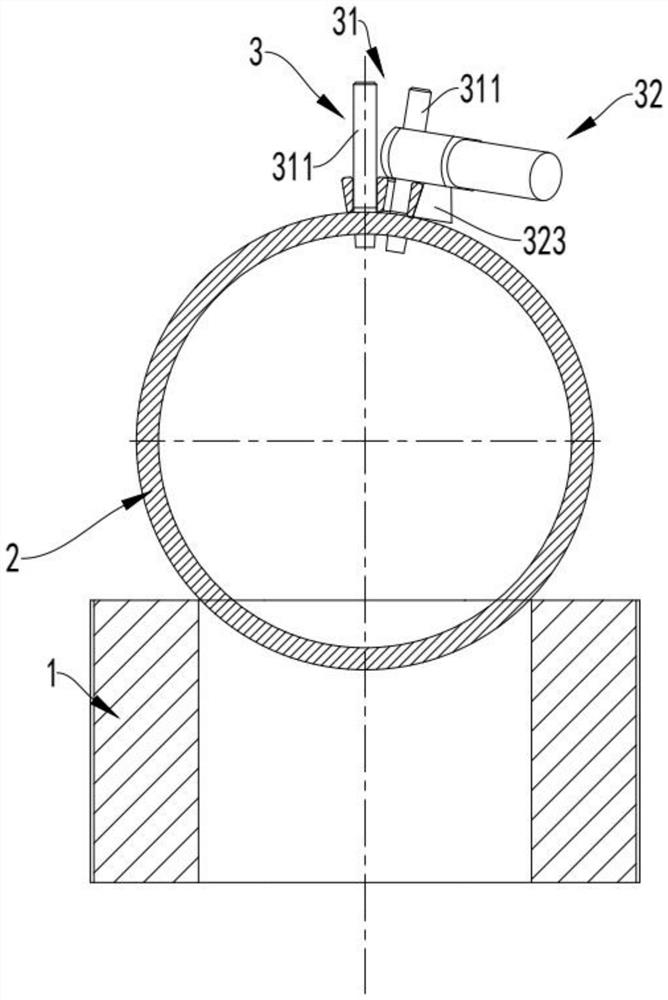

Installation method of ring welding backing plate

ActiveCN107470822BSolve the problem of low efficiency of assembly processQuick implementation of pairingWelding/cutting auxillary devicesAuxillary welding devicesWeld seamEngineering

The invention relates to an installation method for an annular welding base plate. The installation method is achieved through a special tool, it can be ensured that the annular welding base plate is positioned and fixed when the annular welding base plate and a pipe type cross beam are in a concentric state, and welding and assembling operation of the annular welding base plate is completed. By means of the installation method, the problem that a traditional pipe type cross beam and box type side beam assembling process is low in efficiency is solved, assembling of the pipe type cross beam and the box type side beam can be rapidly achieved, and an assembling gap of an annular weld seam is guaranteed. By matching the device positioning hole diameter, the installation method can be widely applied to production of assembling structures of pipe type cross beams with different pipe diameters and box type side beams.

Owner:CRRC NANJING PUZHEN CO LTD

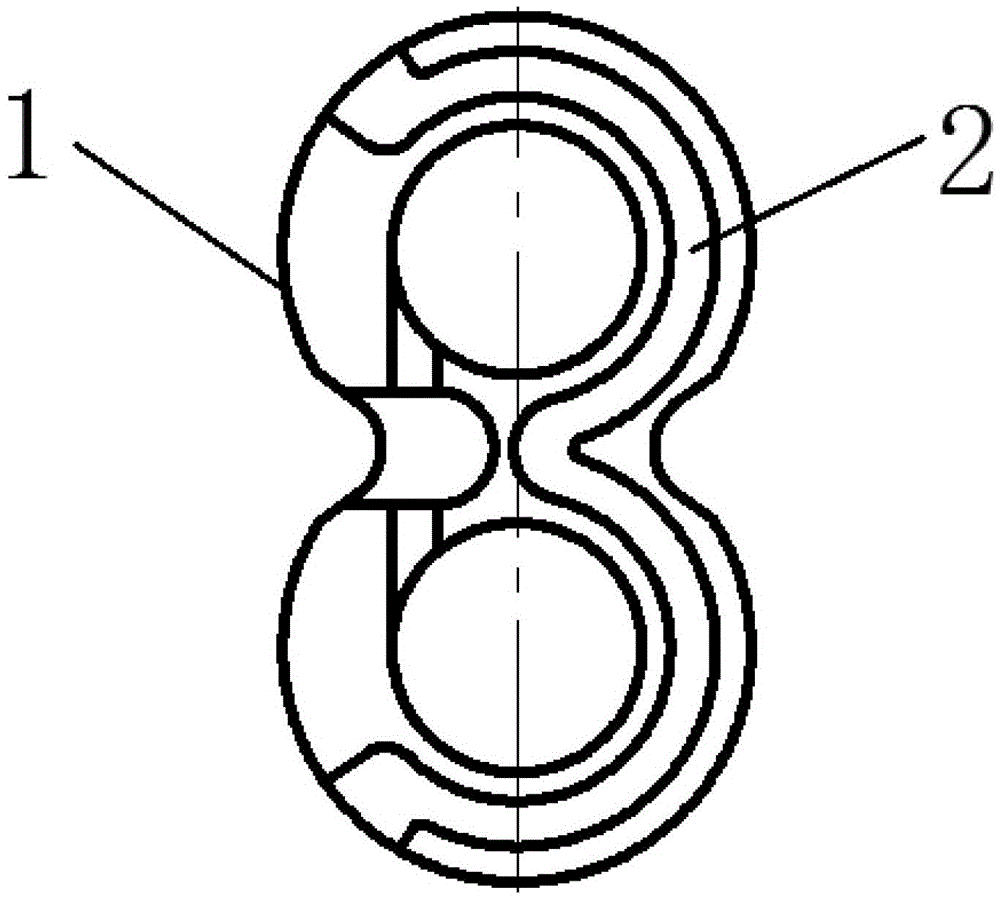

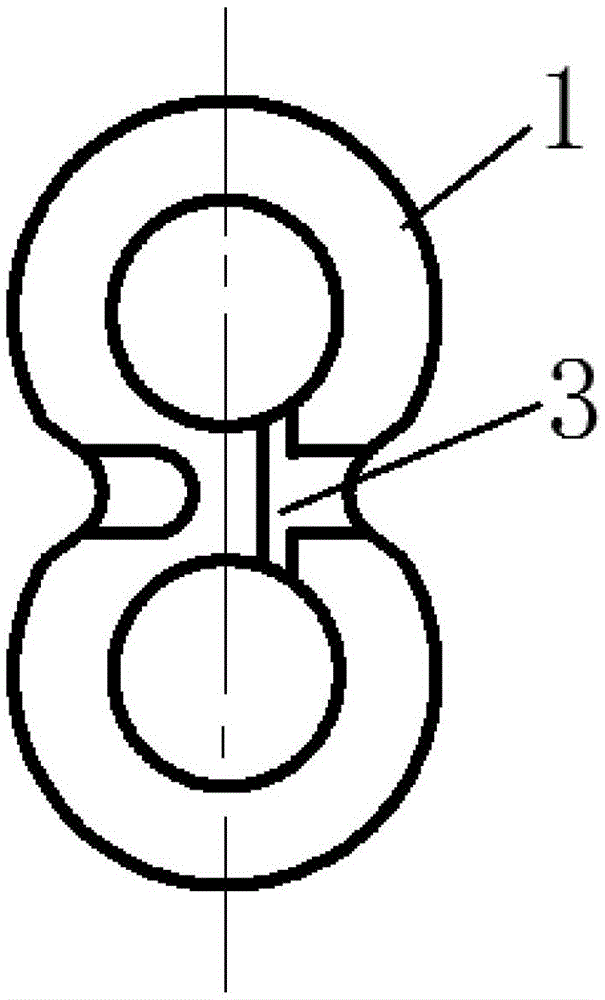

A kind of wear-resistant floating aluminum alloy bearing seat and preparation method

ActiveCN103291762BReduce hardnessImprove wear resistanceBearing unit rigid supportManufacturing technologyWear resistant

The invention provides an anti-abrasion floating aluminum alloy bearing pedestal which comprises a bearing pedestal which is in clearance fit with a gear hole, wherein two symmetric apertures are poured in the bearing pedestal; the whole bearing pedestal is 8-shaped; matched composite linings are arranged on the apertures; a 3-shaped sealing ring slot is arranged in one end face of the bearing pedestal in a sunken manner; an unloading slot is arranged in the other end face of the bearing pedestal. Due to the design of the unloading slot, a phenomenon of oil trapping during the meshing of a gear can be reduced; furthermore, the unloading slot can be used for lubricating the composite linings, so that the abrasion degree is reduced; moreover, due to the design of the end face sealing ring slot, oil in a certain region on the end face of the bearing pedestal can be pressed to push the aluminum alloy bearing pedestal to get close to the end face of the gear, and leakage of the oil pressing end face is prevented; due to an aluminum alloy material for making proportional materials and a technology and a manufacturing technology, the anti-abrasion floating aluminum alloy bearing pedestal is high in abrasion resistance and high in intensity.

Owner:HEFEI AUTOMOBILE OIL PUMP

Differential lock gap adjustment device and differential lock gap adjustment method

ActiveCN102840319BAchieve regulationGuaranteed assembly clearanceGearing detailsPetroleum engineering

The invention provides a differential lock gap adjustment device, which is used for adjusting the gap between a sliding engagement sleeve and a fixed engagement sleeve of a differential lock, comprising a dial, a rotary sleeve and a pointer; the dial is matched with the rotary sleeve, The rotating sleeve can cooperate with the rotating shaft that drives the sliding engagement sleeve to move, and can rotate relative to the dial with the rotation of the rotating shaft; the pointer is fixed on the rotating sleeve and can move with the rotating sleeve The rotation of the pointer rotates relative to the dial, and the rotation angle of the pointer can be displayed on the scale of the dial. The invention also provides a method for adjusting the differential lock clearance and a method for adjusting the differential lock clearance by using the differential lock clearance adjustment device. Through the technical solution provided by the invention, the gap between the sliding engagement sleeve and the fixed engagement sleeve of the differential lock can be guaranteed to meet the design requirements, regardless of the stroke error of the cylinder, so that the differential lock can work normally.

Owner:SANY AUTOMOBILE MFG CO LTD

An engine compartment cover assembly and a fender assembly

InactiveCN104229001BGuaranteed assembly clearanceSimple structureVehiclesNacelleAerospace engineering

The invention discloses an engine compartment cover device, comprising a frame and a first profile block, wherein the frame is matched with the upper contour of the engine compartment, and the lower part of the frame is provided with symmetrical mounting holes for matching with the left and right suspension mounting holes of the engine compartment respectively The upper part of the front end of the frame is provided with symmetrical second positioning pins for matching with the two positioning holes on the engine compartment cover, and there are at least four first profile blocks, which are symmetrically distributed on the frame. On both sides of the hood, the inner surface of the first profile block is attached to the side of the engine compartment cover to control the assembly gap between the engine compartment cover and the fender, and the structure is simple and easy to operate; the invention also discloses a The fender mount of the engine compartment cover mount can simultaneously position the engine compartment cover, the fender and the front door, and ensure the assembly gap between the engine compartment cover and the fender and between the fender and the front door.

Owner:力帆科技(集团)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com