Mounting method for large movable ramp

A technology of movable ramps and installation methods, applied in transportation and packaging, ship parts, ships, etc., can solve the problems of difficult control of welding deformation, large stress, penetration of hinge shaft pins, etc., to reduce three-dimensional intersection operations, The effect of preventing welding deformation and avoiding bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The installation method of the large-scale movable ramp of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this.

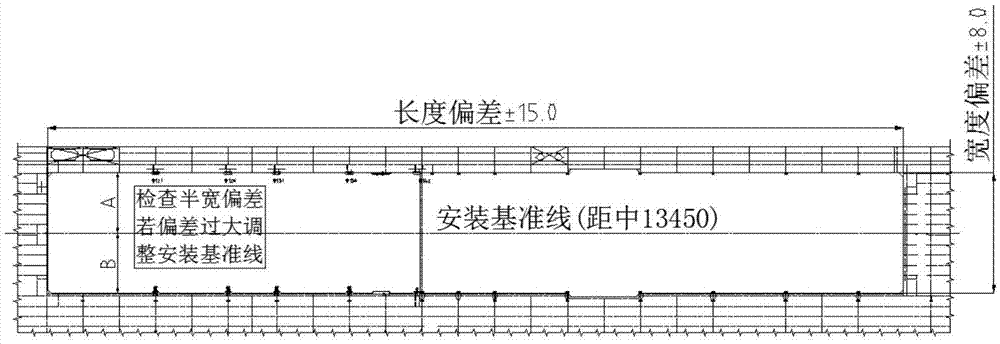

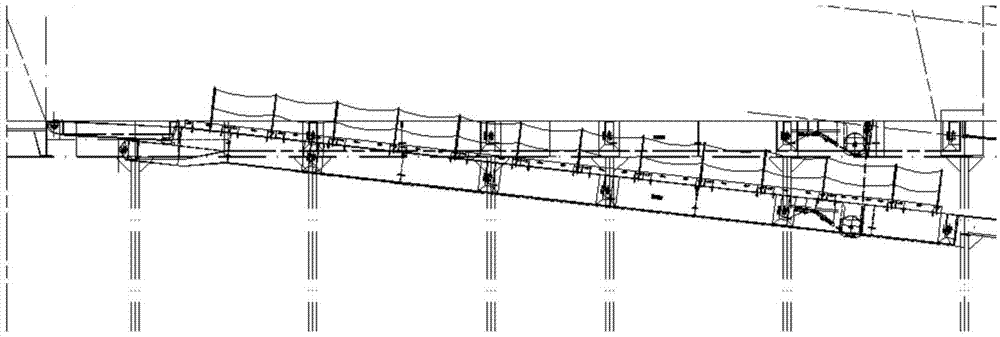

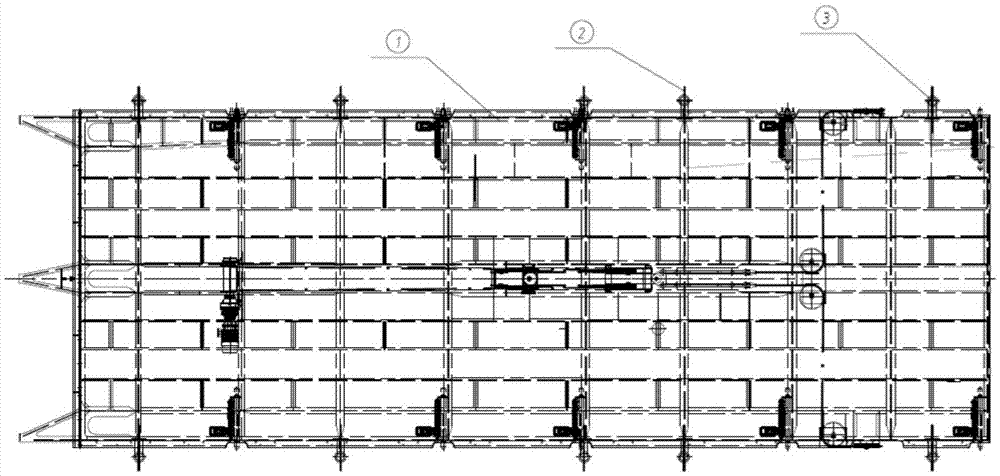

[0030] In the large-scale activity ramp installation method of the present invention, in figure 1 The structural accuracy measurement is carried out under the state. Then retest the accuracy of the active ramp 1 to master the ramp accuracy data. Lap joint tooling 2 is installed, and the movable ramp 1 is hoisted into the opening of the hull structure. The movable ramp hinge 5 is installed and restrained and fixed. Lift the movable ramp 1 and the lap joint tool 2 together in situ, put them on the round pipe 3, carry out the operation in the blind area of the movable ramp, and install the adjusting gasket.

[0031] Specific steps such as Figure 5 as shown, Figure 5 It is a schematic diagram of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com