A processing method for double-sided thin-walled web parts

A processing method and web technology, applied in the field of mechanical processing, can solve the problems of easy deformation of parts during processing, troubled production lines, low processing efficiency, etc., and achieve the effect of overcoming easy deformation of parts during processing, eliminating secondary correction, and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

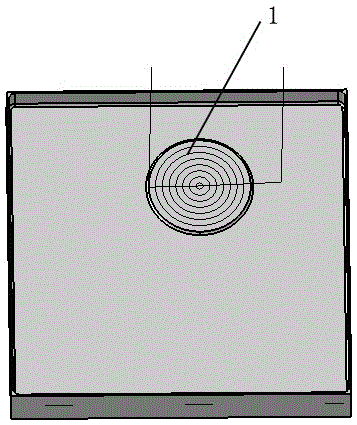

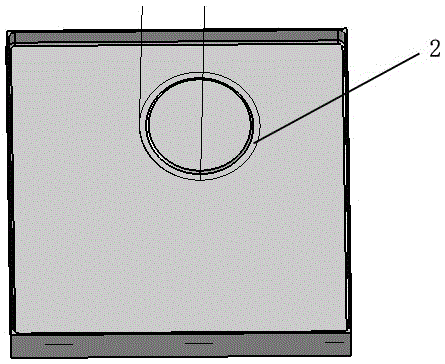

[0020] Such as Figure 1 to Figure 3 As shown, a method for processing double-sided single-boss thin-walled web parts includes the following steps:

[0021] (1) The machining allowance in the axial direction is reserved according to the thickness of the web part, and the principle that the thinner the thickness of the web part is, the more machining allowance is left in the axial direction, usually the axial The machining allowance is controlled at 3mm-5mm;

[0022] (2) Determine the processing parameters of the web parts: select the rated speed of the machine tool for the number of spindle revolutions to be 2500-24000r / min; the depth of cut is determined to be 2-5mm according to the machining allowance of the web parts in the axial direction; The thickness of the web part is determined to be 0.5-5mm; the feed rate of a single tooth is determined to be 0.15-0.18mm / turn (usually calculated as 0.18mm / turn) according to the thickness of the web part and the tool; After the amou...

Embodiment 2

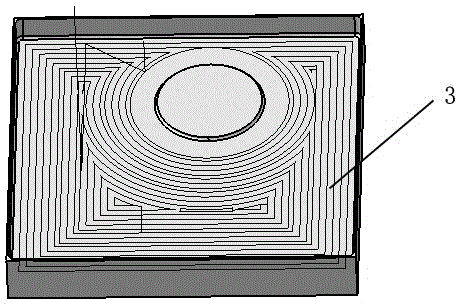

[0027] Such as Figure 4 to Figure 6 Shown, a kind of processing method of double-sided thin-walled web part, comprises the following steps:

[0028] (1) The machining allowance in the axial direction is reserved according to the thickness of the web part, and the principle that the thinner the thickness of the web part is, the more machining allowance is left in the axial direction, usually the axial The machining allowance is controlled at 3mm-5mm;

[0029] (2) Determine the processing parameters of the web parts: select the rated speed of the machine tool for the number of spindle revolutions to be 2500-24000r / min; the depth of cut is determined to be 2-5mm according to the machining allowance of the web parts in the axial direction; The thickness of the web part is determined to be 0.5-5mm; the feed rate of a single tooth is determined to be 0.15-0.18 mm / turn (usually calculated as 0.18mm / turn) according to the thickness of the web part and the tool; After the amount is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com