Laser scanner for detecting electronic component

A technology of laser scanners and electronic components, applied in the field of laser scanners, can solve the problems of low manual detection efficiency, lack of detection systems, and increased labor costs of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

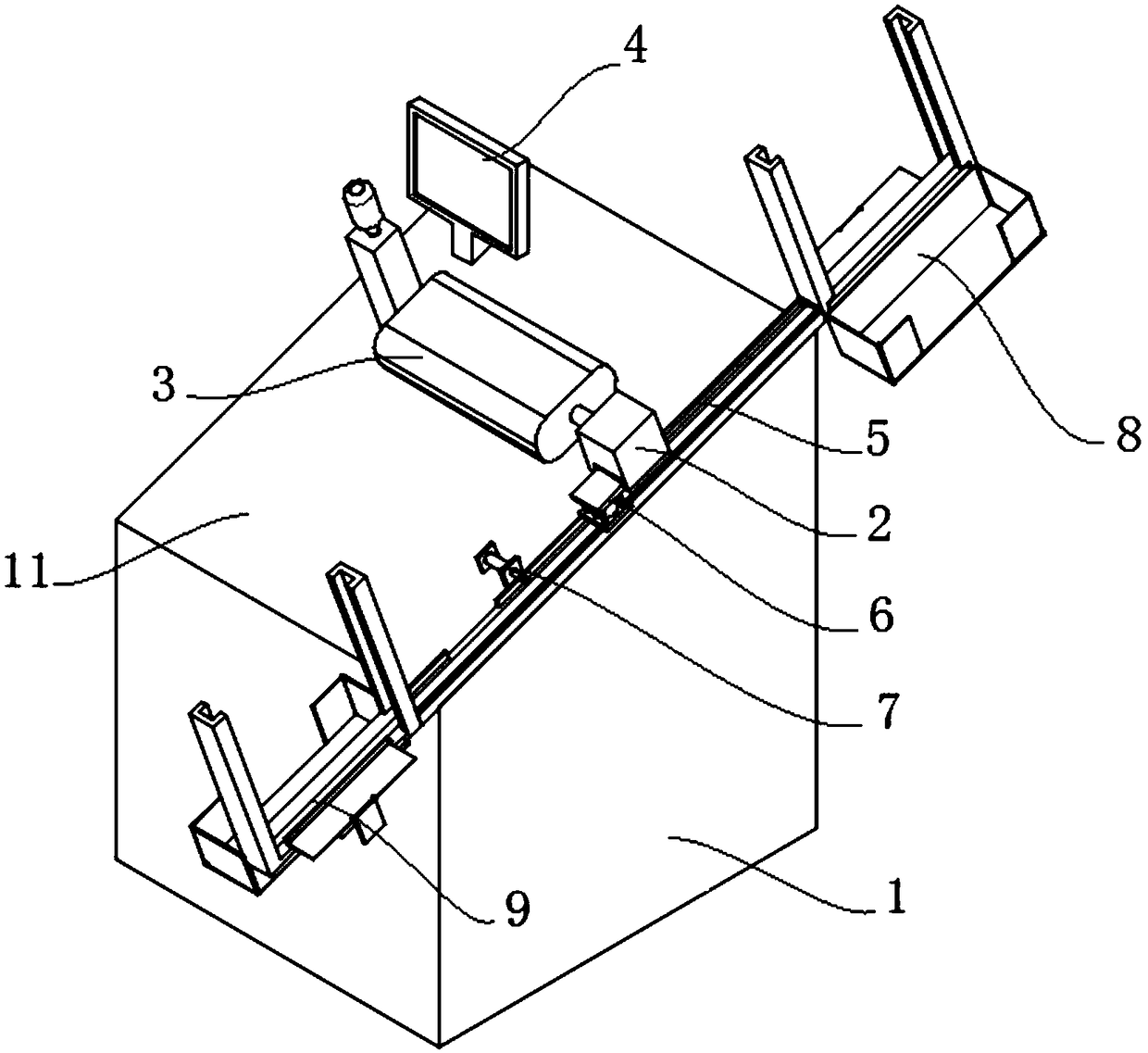

[0020] Such as figure 1 As shown, a laser scanner for electronic component detection in the present invention includes a detection platform 1, a workbench 11 on the top of the detection platform 1 forms an angle of 20 degrees with the ground, and a three-dimensional laser scanner 2, image The information detector 3, the image information display 4, the three-dimensional laser scanner 2 and the image information display 4 are electrically connected to the image information detector 3, and the three-dimensional laser scanner 2 is used to scan the three-dimensional size of the network transformer and whether there are defects on the surface of the network transformer, The image information detector 3 is used to detect the image information collected by the three-dimensional laser scanner 2 , and display unqualified network transformers through the image information display 4 . Workbench 11 is also provided with network transformer slide track 5, the length direction of slide trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com