A laser full-face tunneling orientation positioning system

A laser system, directional positioning technology, applied in the direction of active optical measurement device, reference line/plane/sector, measurement device, etc., can solve the problems of poor reliability, difficult maintenance, poor practicability, etc., to achieve strong practicability and operability , to ensure the effect of stable reliability and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

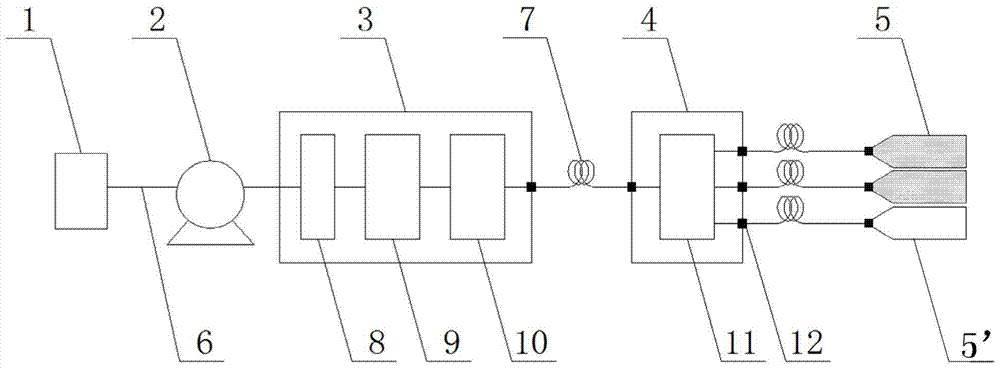

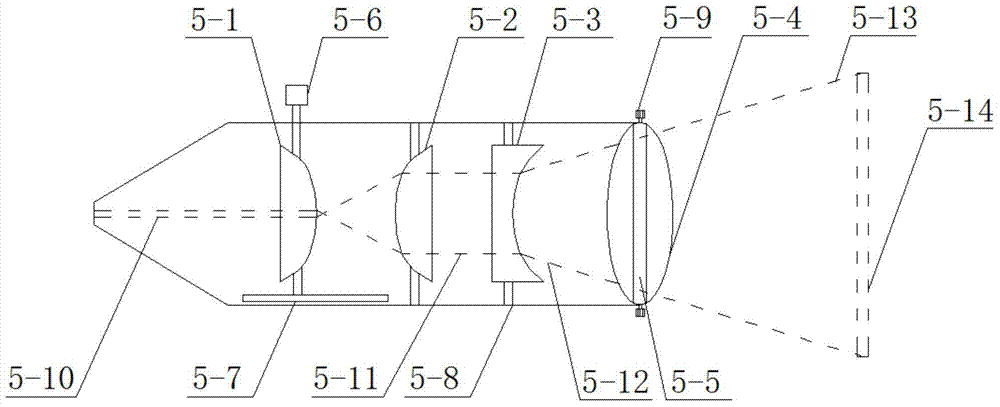

[0029] figure 1 A green laser full-face excavation directional positioning system shown includes: an all-solid-state green laser system 3, a laser beam splitting system 4, two first laser shaping systems 5, a second laser shaping system 5', and a UPS power supply 1. Explosion-proof switch 2, explosion-proof cable 6, optical fiber 7, fiber optic coupler 12; the UPS power supply 1 and the all-solid-state laser system 3 are connected with an explosion-proof cable 6 and provided with an explosion-proof switch 2; the all-solid-state green The optical laser system 3 outputs a bunch of green laser through the optical fiber 7 and enters the laser beam splitting system 4, and the laser beam splitting system 4 outputs three beams of laser light, which are respectively input to two first laser shaping systems 5 and a second laser shaping system through three optical fibers. System 5'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com