A fluidized bed mixing and feeding equipment for coal and biomass

A technology of feeding equipment and fluidized bed, which is applied in the direction of fluidized bed combustion equipment, lighting and heating equipment, combustion equipment, etc., can solve the problems of poor airtightness of pneumatic feeding, high labor intensity, short service life, etc., and avoid secondary Sub-correction, strong automaticity, anti-clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

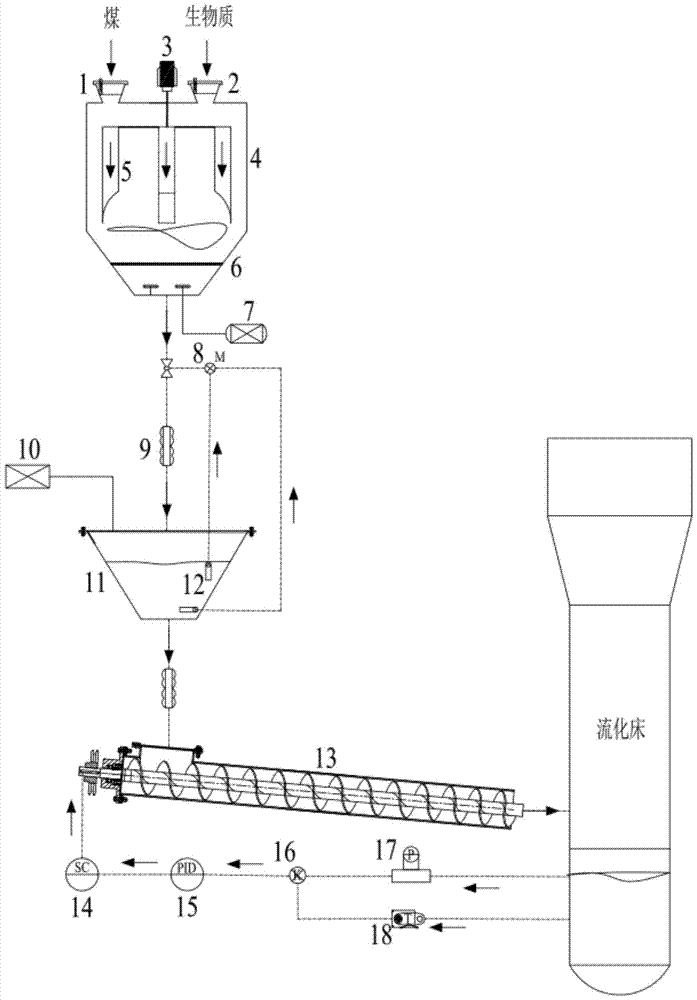

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

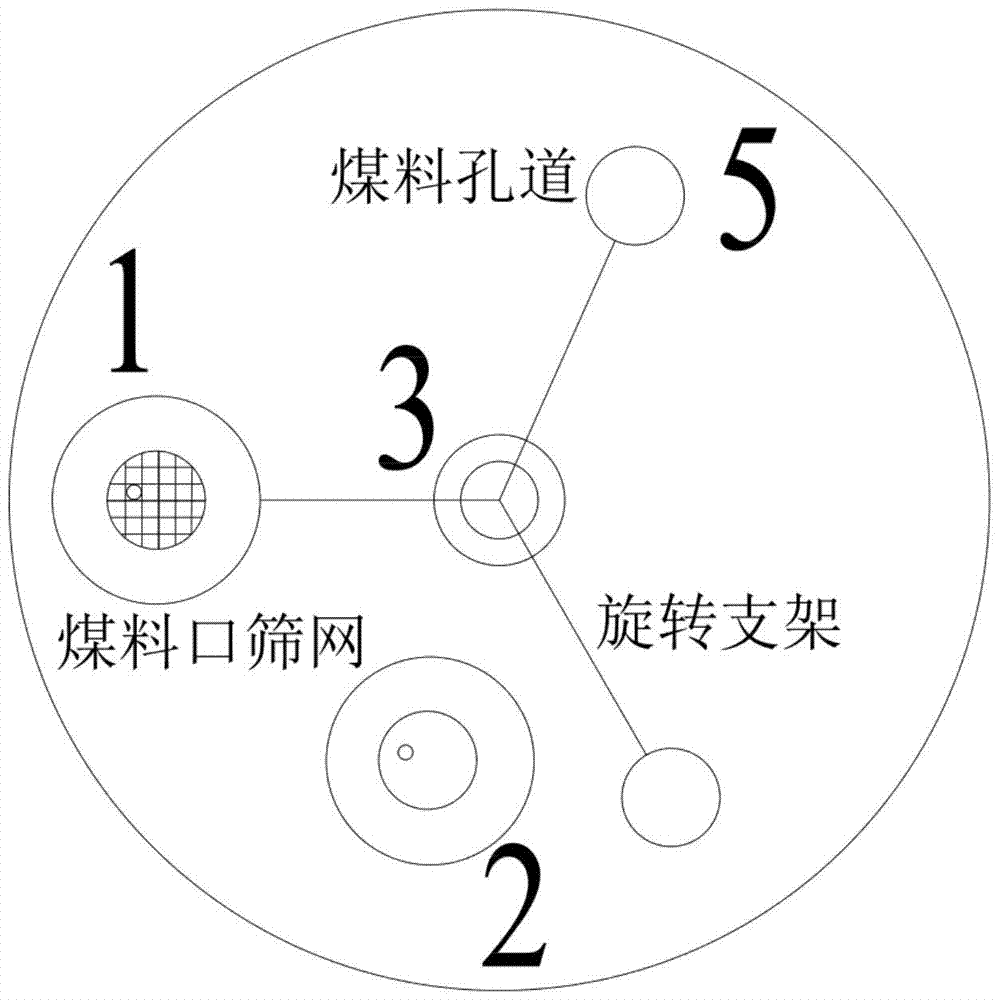

[0031] A coal and biomass fluidized bed mixing and feeding equipment, which mainly adopts "mechanical and air secondary agitation" to ensure the uniform mixing of materials, and uses "balanced breathing" and "three differential speed screw" for continuous feeding, and adopts " Level gauge" and "PID regulator" for automatic control, such as Figure 1-5As shown, it includes a high-level silo 4, an intermediate silo 11, and a fluidized bed. The high-level silo 4 is connected to the intermediate silo 11 through the first flexible connecting pipe 9, and the mixed material is transported into the The intermediate silo 11; and the intermediate silo 11 is connected with the fluidized bed through a screw machine 13; the intermediate silo 11 is connected with the screw machine 13 through a second flexible connecting pipe, and the screw machine 13 is connected with the fluidized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com