Patents

Literature

167results about How to "Avoid structural deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

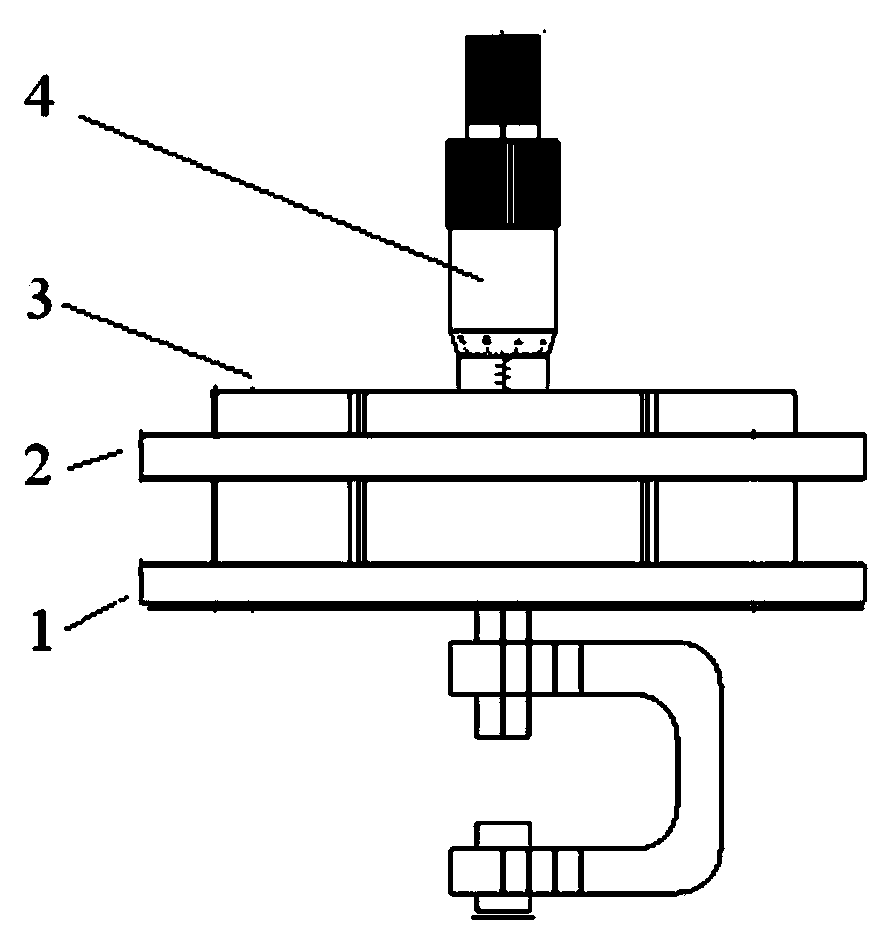

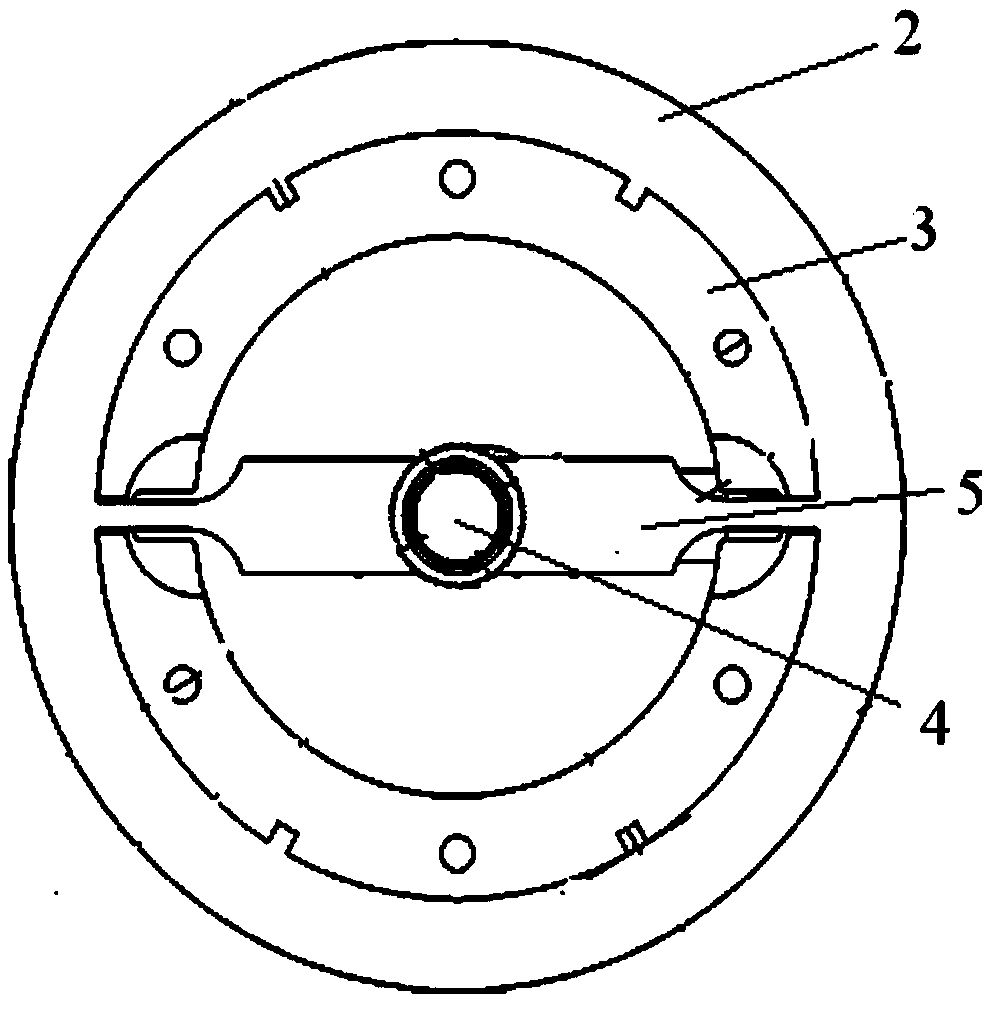

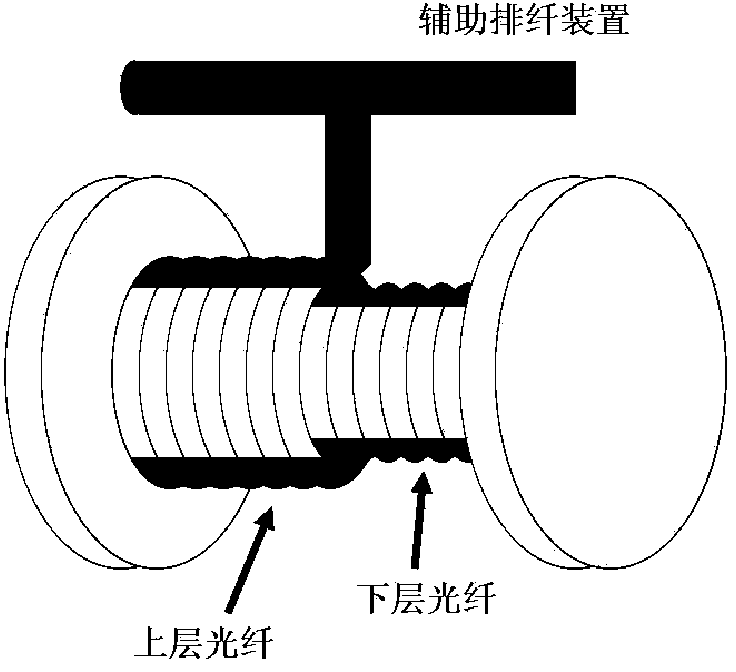

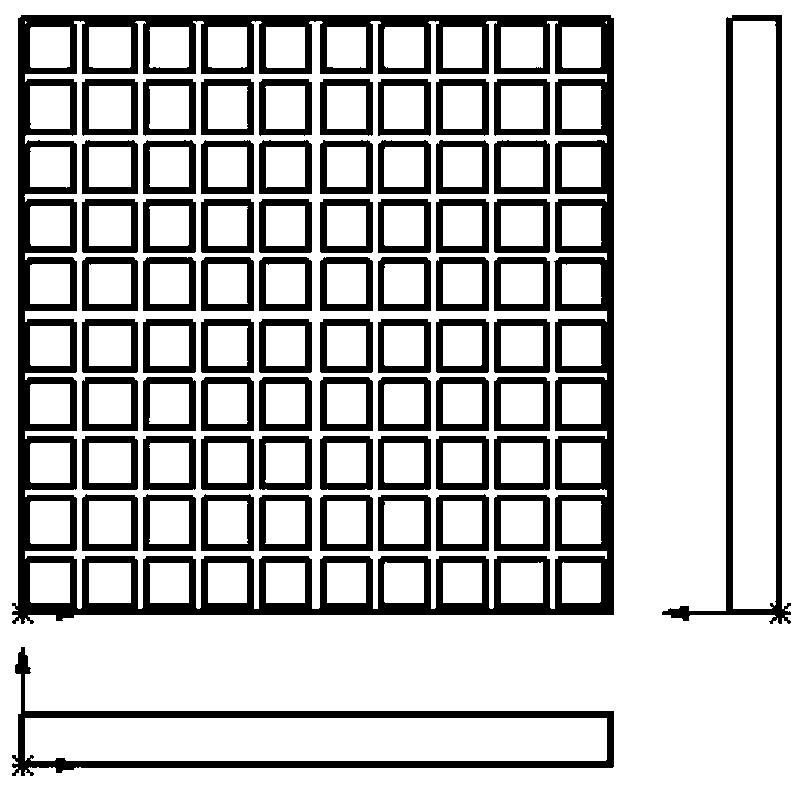

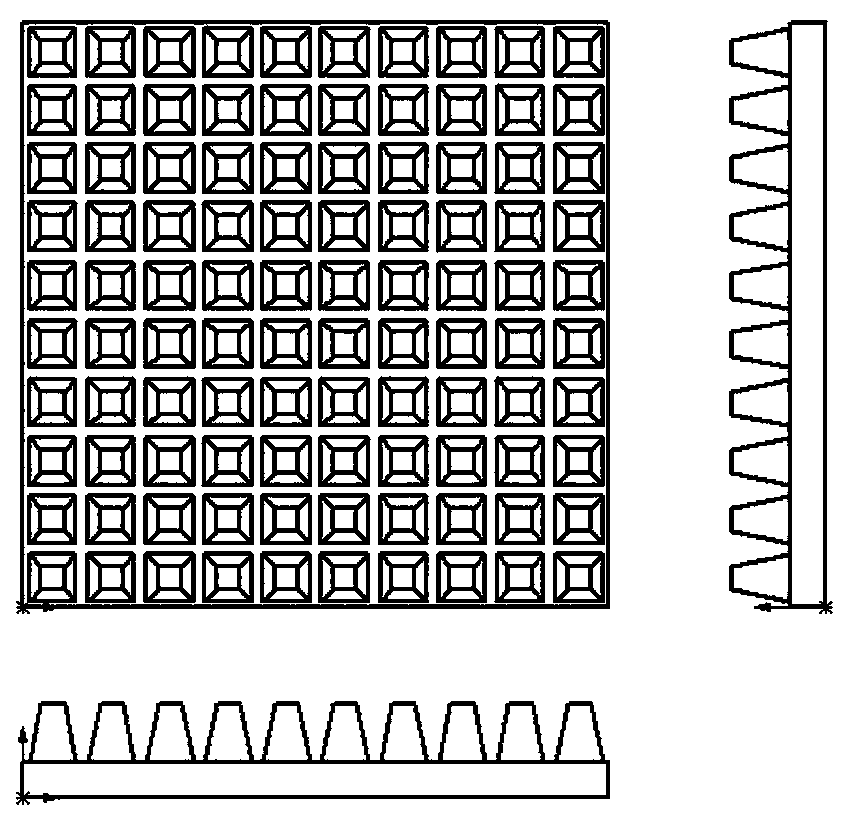

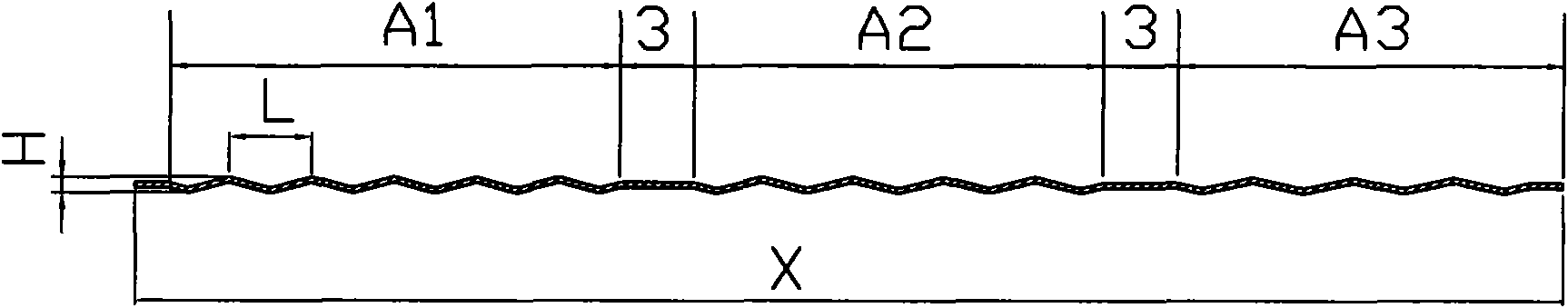

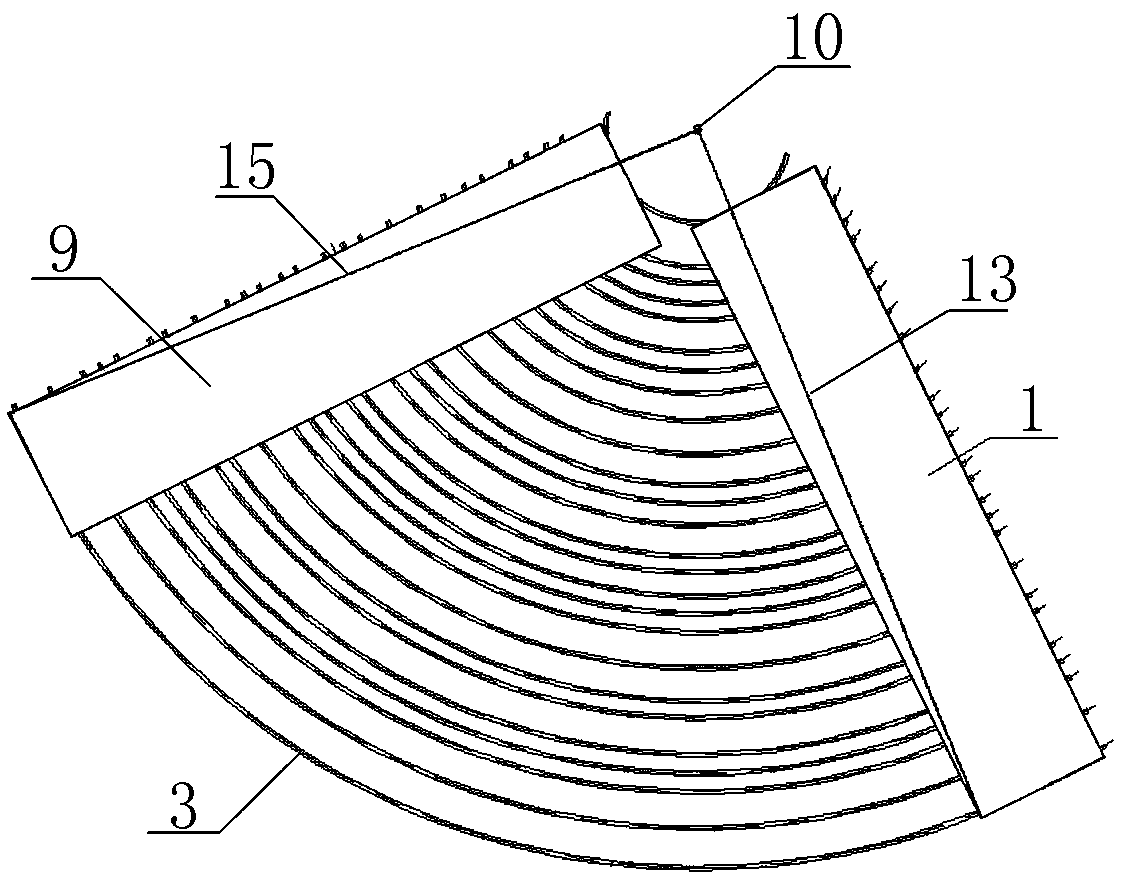

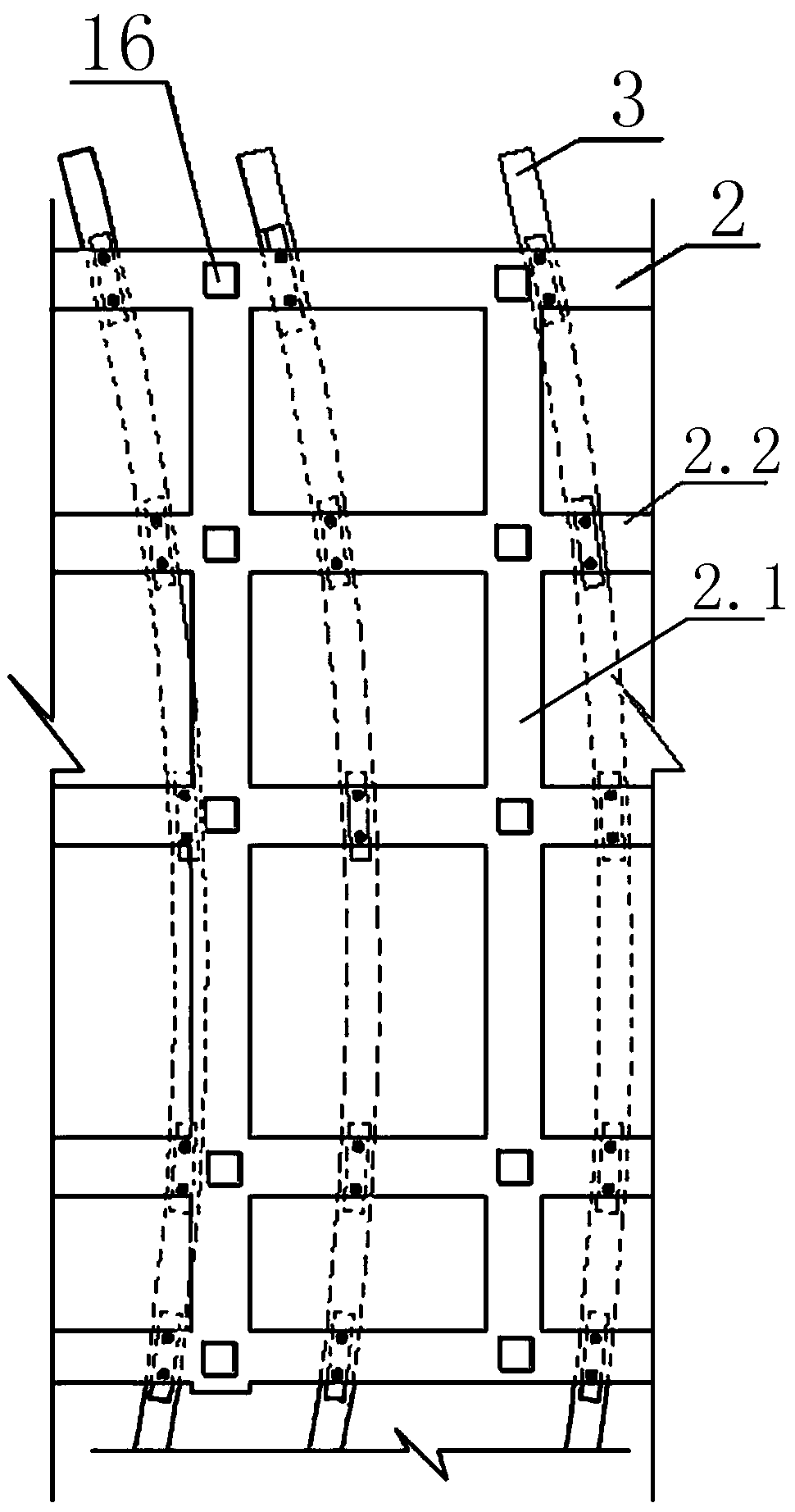

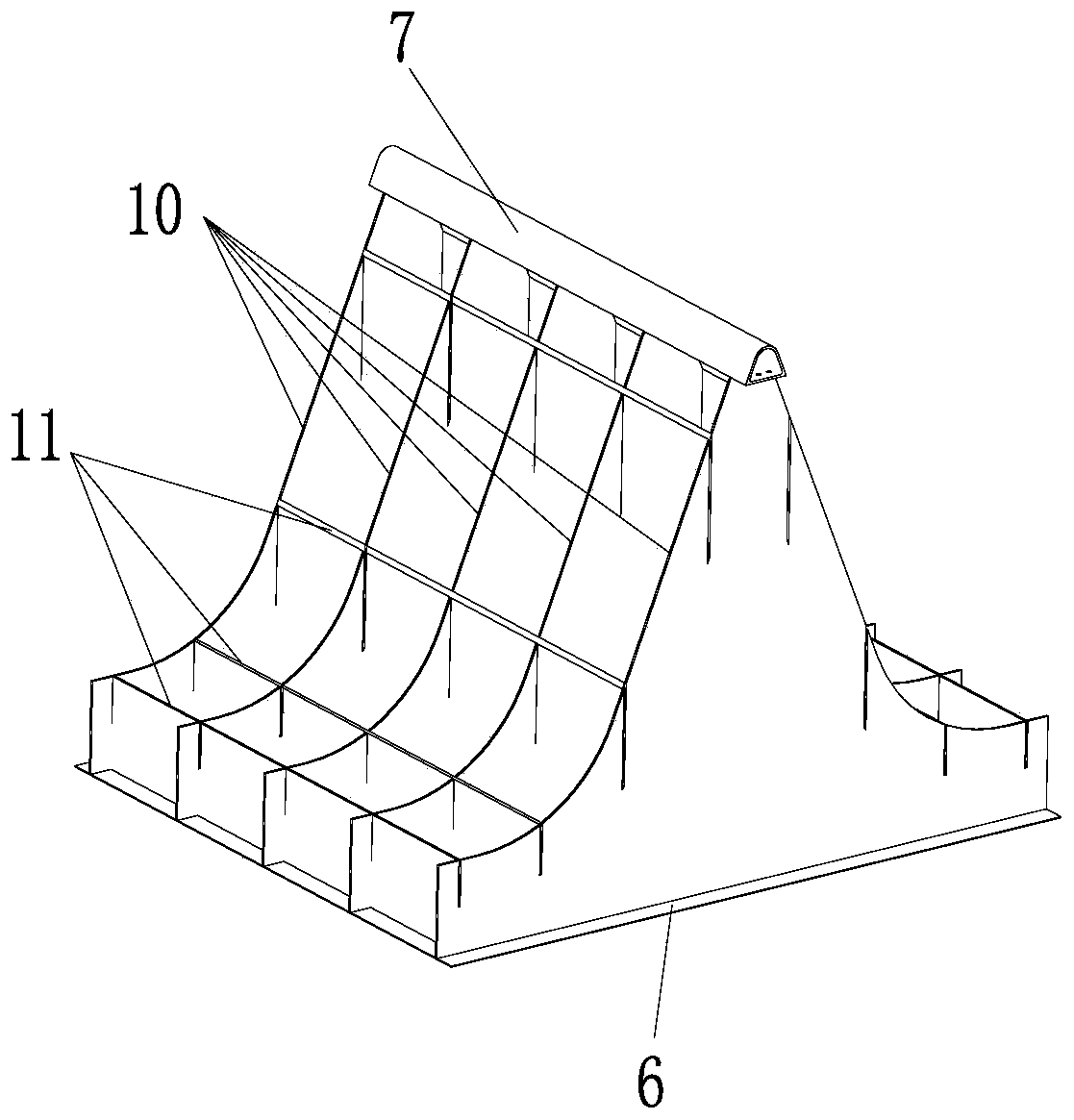

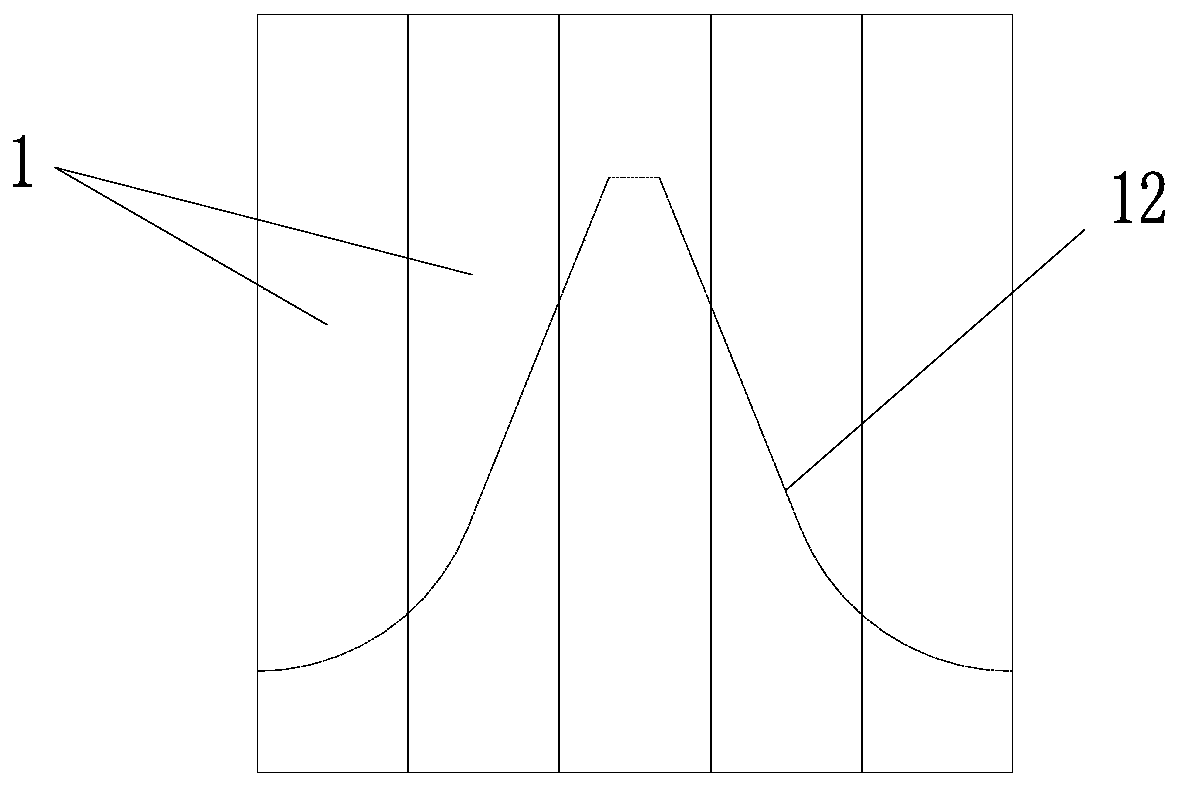

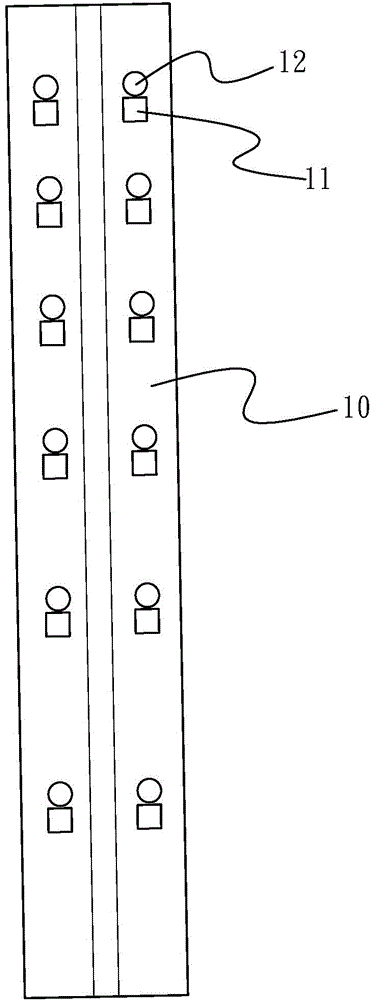

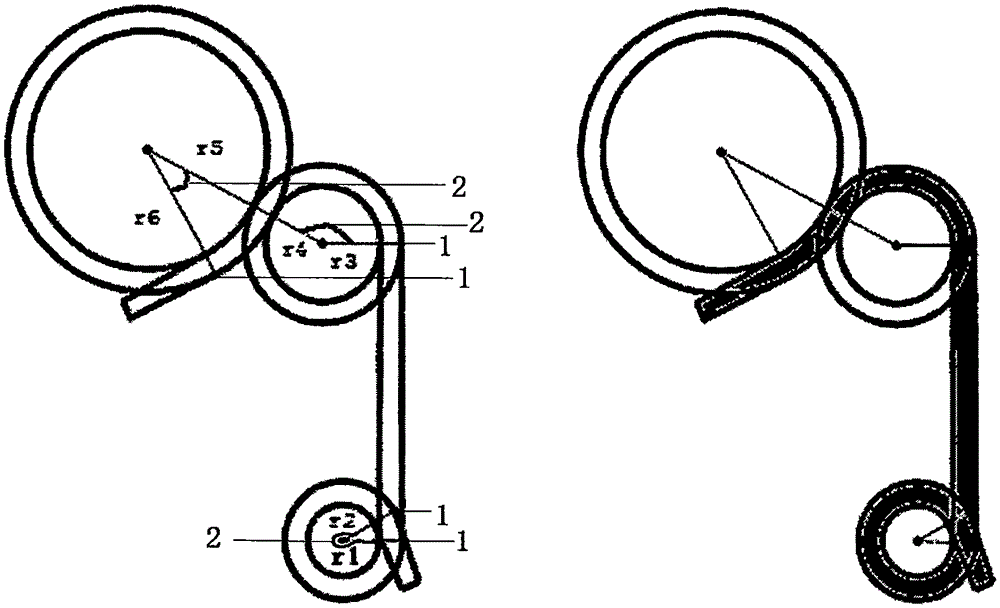

Variable groove width skeleton tool and method for forming fiber rings by utilizing tool

ActiveCN103884354AAvoid structural deformationGuaranteed neat windingMeasurement devicesGroove widthPhotonic crystal

The invention discloses a variable groove width skeleton tool and a method for forming fiber rings by utilizing the tool. The method comprises the following steps of designing a groove-width-adjustable dismountable winding skeleton tool, wherein the groove width can be adjusted to meet the requirements of winding in any integral number of turns according to different diameters of fibers; winding photonic crystal fibers on the dismountable skeleton by using a special winding technology and a low-tension winding technology; curing the photonic crystal fibers to improve the performance level of photonic crystal fiber rings by using a novel gluing curing technology; dismounting the dismountable skeleton tool to obtain formed photonic crystal fiber rings. According to the skeleton tool and the method, a gluing curing process is a glue impregnation curing process, and new adhesive curing conditions, a novel curing adhesive, a novel gluing curing process and stress releasing measures are designed, so that the residual curing stress of the photonic crystal fiber rings and changes in the inner void structure of the photonic crystal fibers are reduced, and the environmental characteristics of the photonic crystal fiber rings are improved.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

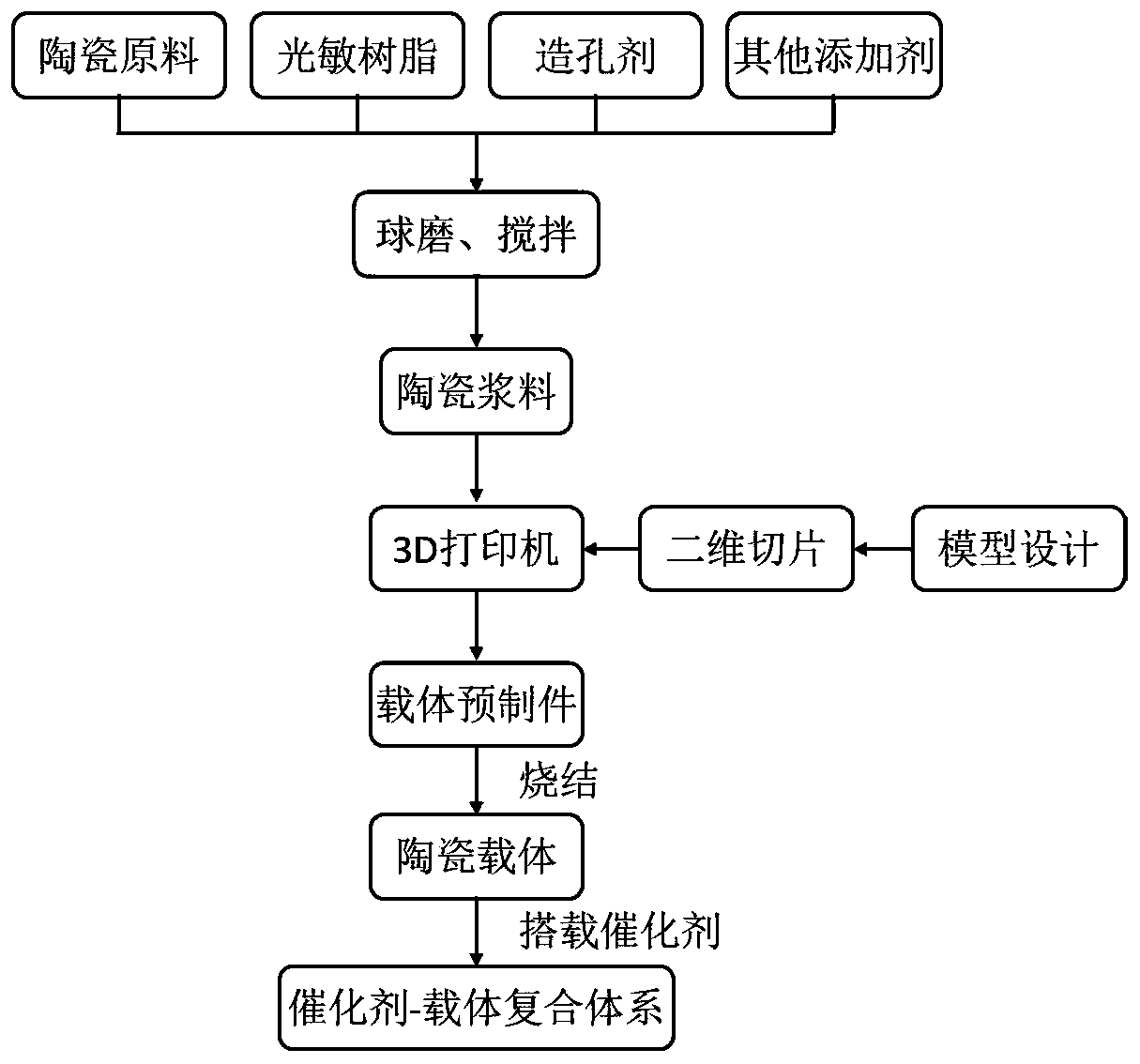

Method for 3D printing of catalyst-carrier system with high specific surface area and high efficiency

ActiveCN110240484AAvoid structural deformationHigh chemistryCatalyst carriersAdditive manufacturing apparatusWorking environmentStructure function

The invention relates to a method for 3D printing of a catalyst-carrier system with a high specific surface area and high efficiency. By adopting a process that ceramic powder or a precursor is independently grinded and dispersed into a light-cured resin, partial high temperatures and partial denaturation caused by collision in the mixing and ball-milling process are effectively avoided; printer parameters are selectively set for prepared slurry, so that the printing thickness of each layer is moderate, and rapid molding can be facilitated; due to a two-section heat preservation process of a ceramic carrier prefabricated part, cross-linking curing and cracking molding time is ensured, and structure deformation after calcining is avoided. Because of the high stability, a ceramic carrier prepared by using the method is applicable to different synthesis methods for carrying catalysts, working environments of the catalysts are not rigorously required, and new ideas are provided for large-scale industrial application of structure-function integrated catalysts.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Enhanced heat transfer fin and production process thereof

ActiveCN101603794AAvoid structural deformationReduce thickness requirementsLaminated elementsEnhanced heat transferEngineering

The invention belongs to the technical field of heat exchangers, which relates to an enhanced heat transfer fin and a production process thereof. The enhanced heat transfer fin comprises a flat and straight substrate, wherein waveform fins which are raised on the flat and straight substrate and form certain angle with the flat and straight substrate are formed on the flat and straight substrate, reversing areas are arranged between a plurality of the waveform fins and divide the waveform fins into a plurality of groups waveform fin areas with different numbers of ripples, the wavelength and the wave amplitude of each waveform fin in each group are equal to each other, the number and the wavelength of the waveform fins of different groups are no equal to each other, and the number of the waveform fins in each group of the waveform fin area decreases in turn in the whole fin length while the wavelength increases in turn. The production process of the enhanced heat transfer fin is to put an aluminum strip on a roll forming machine to form the enhanced heat transfer fin provided with the waveform fins and the flat and straight substrate through one-step rolling. The enhanced heat transfer fin has good heat transfer property and small resistance, and is suitable to serve as a heat transfer fin of an automotive heat exchanger, a water tank radiator, a pressurizing intercooler and a wind cooling type hydraulic oil cooler.

Owner:上海银轮热交换系统有限公司

Alloyed powder for directly printing metal parts in 3D (three-dimensional) manner and preparation method of alloyed powder

ActiveCN104668553ANo lossPrevent solidificationTransportation and packagingMetal-working apparatusStructural deformationMicrosphere

The invention provides alloyed powder for directly printing metal parts in a 3D (three-dimensional) manner. The alloyed powder is characterized in that nanometer aluminum is adhered to the surface of oxide of iron through a layer of thin tin powder to form iron-base alloy microspheres, the grain size of the microspheres is 2-10 micrometers, the sphericity is greater than 95%, and the alloyed powder comprises the following materials in part by weight: 60-70 parts of iron oxide, 30-40 parts of nanometer aluminum and 0.1-0.5 part of tin powder. The alloyed powder can be directly used for printing the metal parts in the 3D manner. When the alloyed powder is used for directly printing the metal parts in the 3D manner, the iron oxide is gradually reduced through aluminum, structure deformation caused by direct fusion molding of metal, cooling crystallization is uniform, the strength of a molded piece is improved by formed aluminum oxide, the porosity of products is reduced, and the compactness is high. The alloyed powder can be used for directly printing the high-precision metal parts which have complication shapes.

Owner:康硕(河南)智能制造有限公司

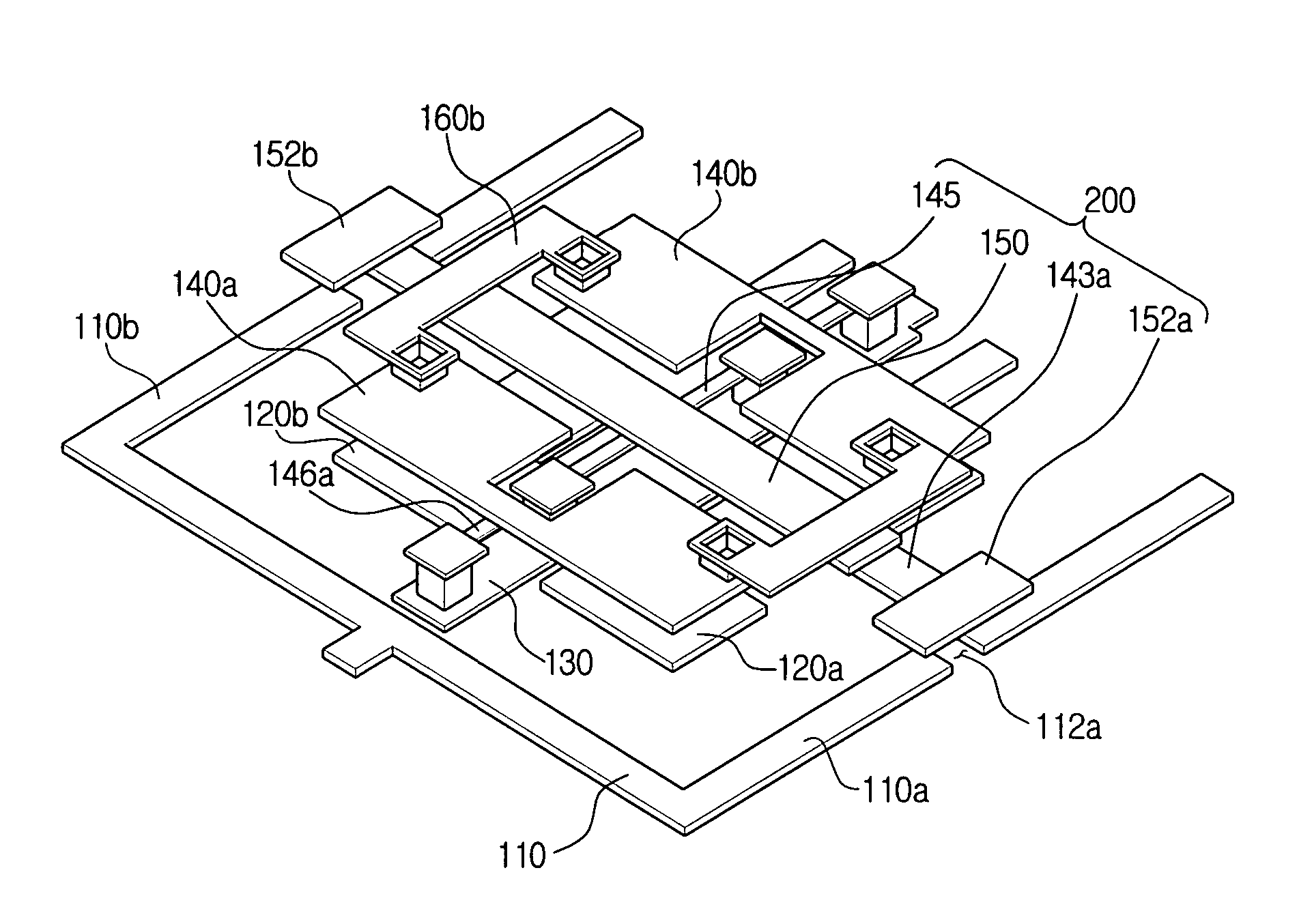

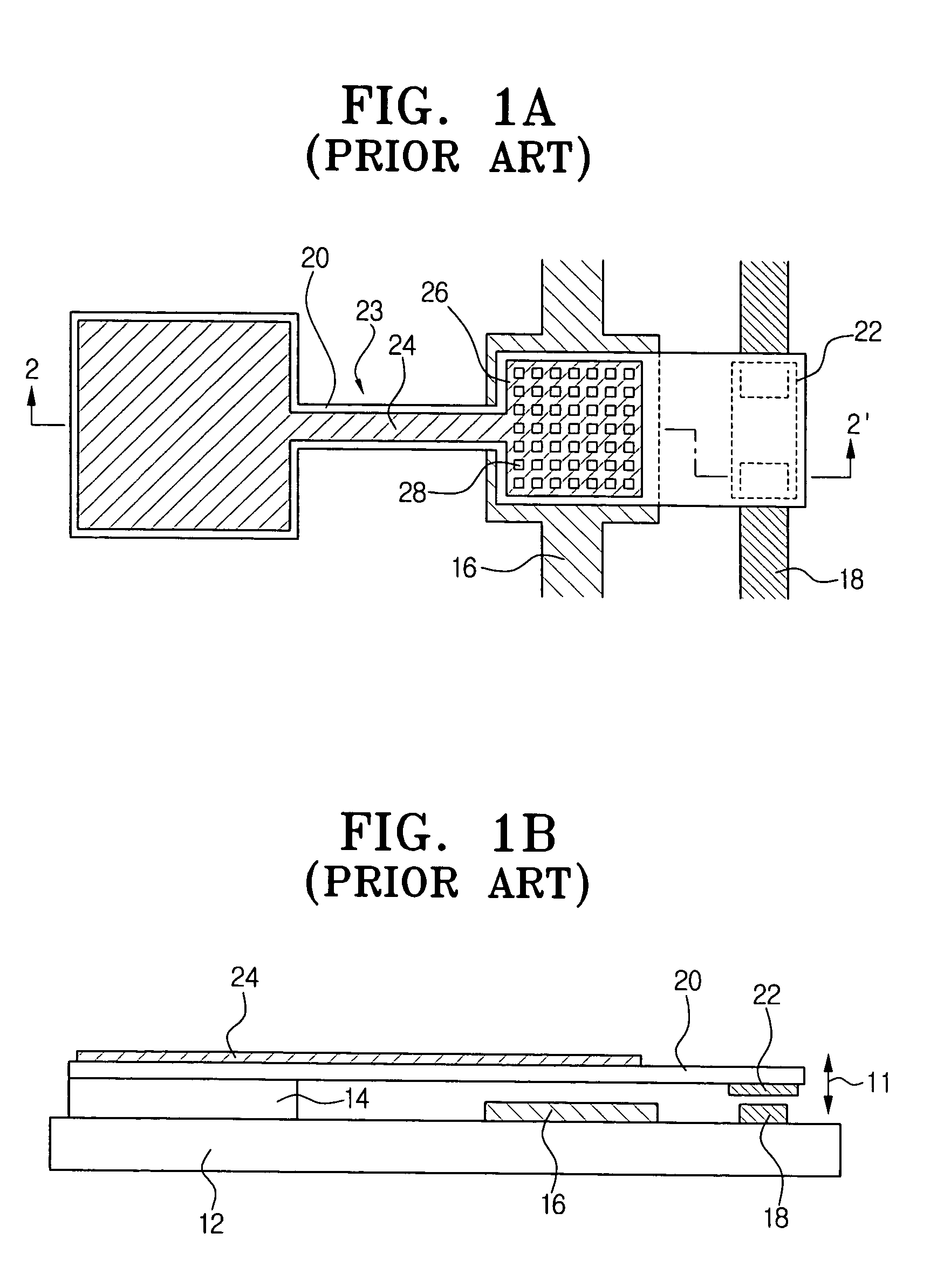

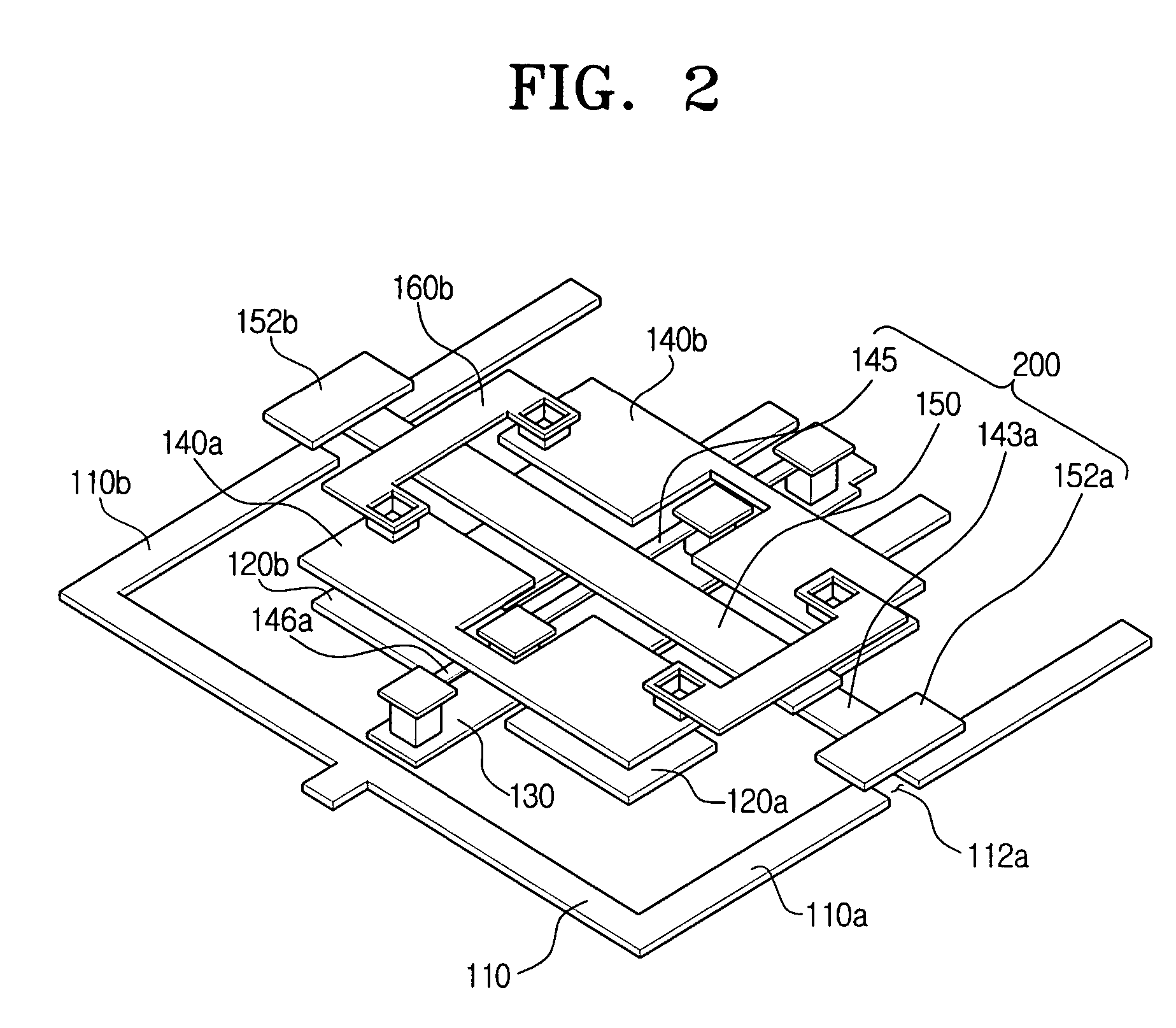

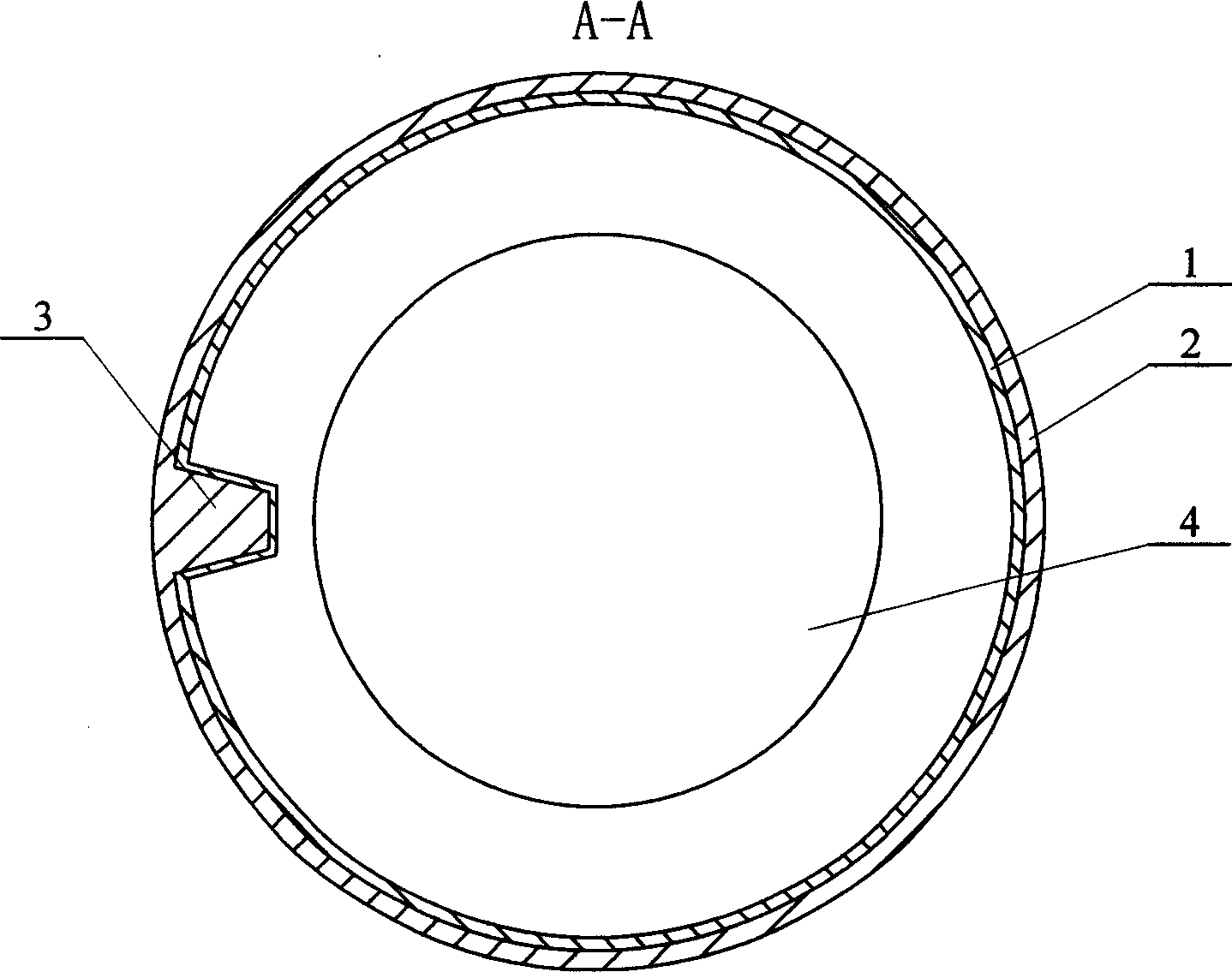

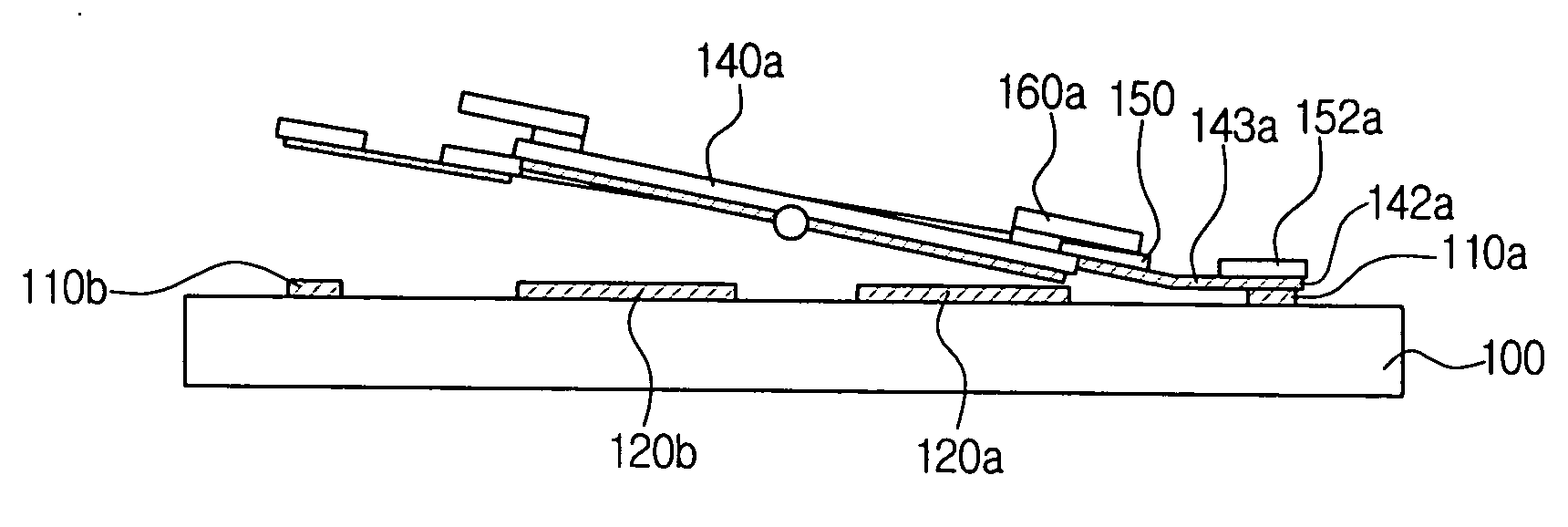

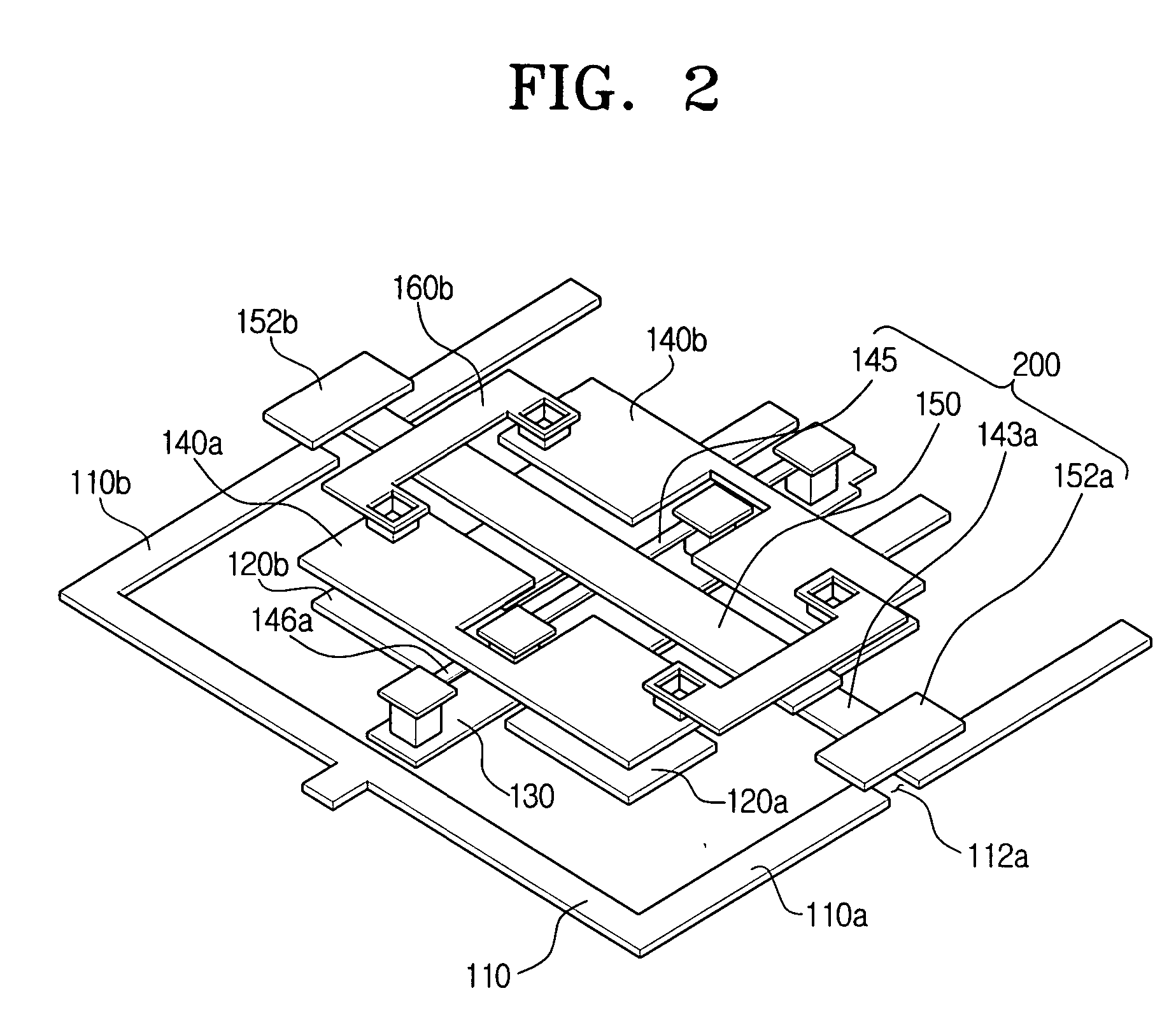

Seesaw-type MEMS switch and method for manufacturing the same

ActiveUS7049904B2Inhibit deteriorationAvoid structural deformationPiezoelectric/electrostriction/magnetostriction machinesElectrostatic/electro-adhesion relaysEngineeringRadio frequency

In a seesaw-type MEMS switch for radio frequency (RF) and a method for manufacturing the same, the seesaw-type MEMS switch for radio frequency (RF) includes a substrate, a transmission line formed on the substrate having a gap therein to provide a circuit open condition, an intermittent part formed a predetermined distance from the substrate, the intermittent part being operable to contact the transmission line on both sides of the gap by performing a seesaw movement about a seesaw movement axis, and a driving part to drive the seesaw movement of the intermittent part in response to a driving signal.

Owner:SAMSUNG ELECTRONICS CO LTD

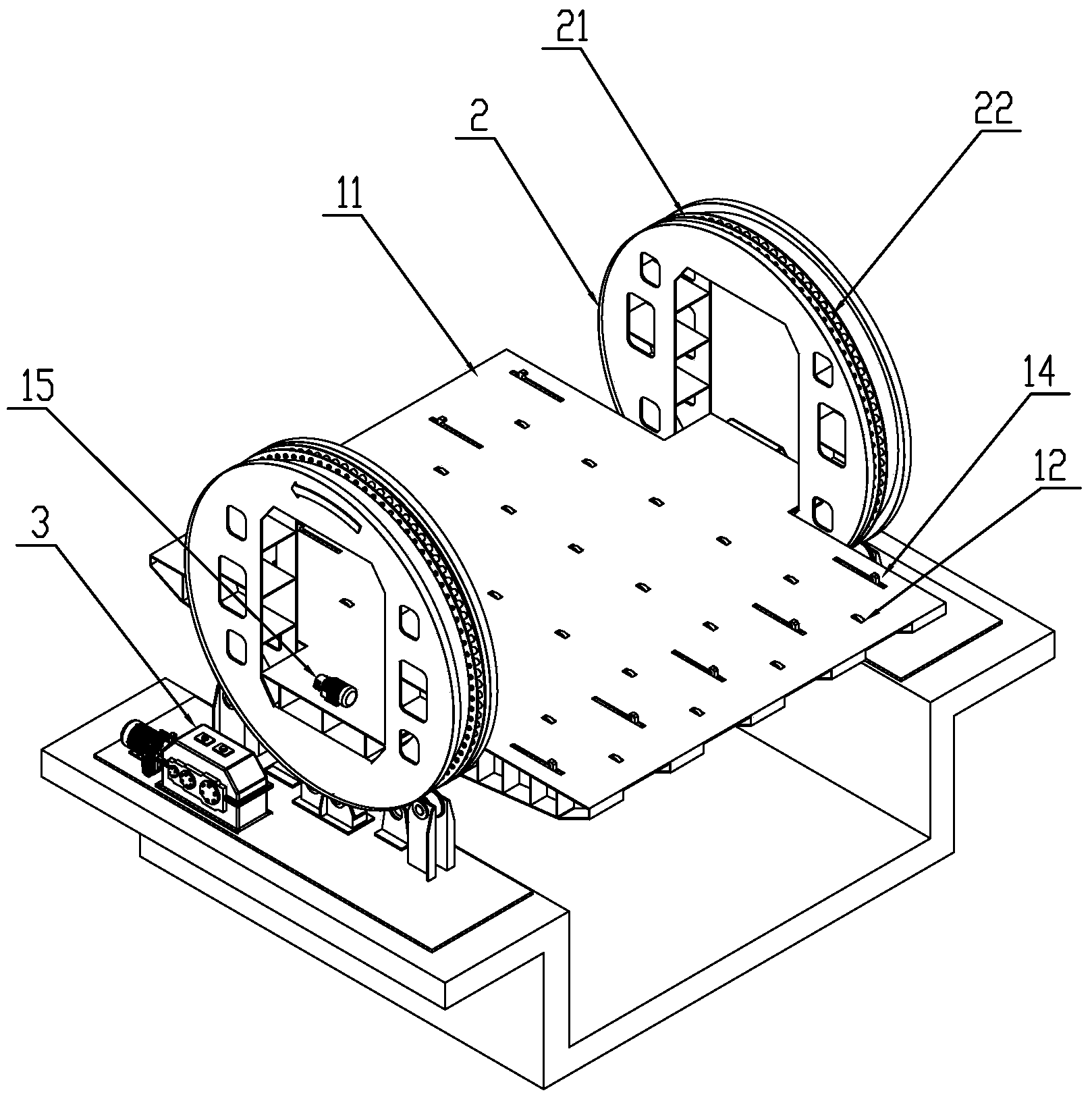

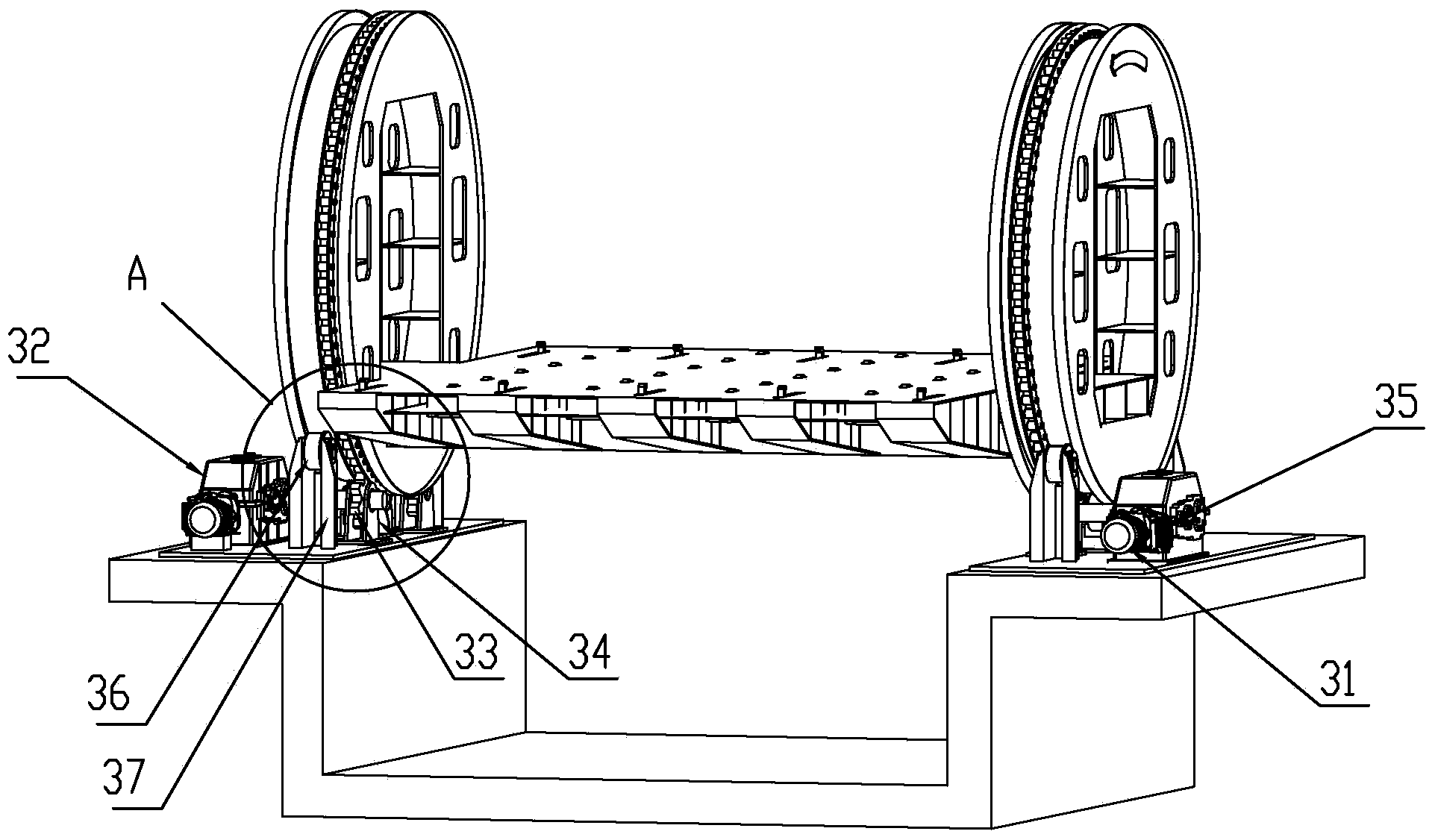

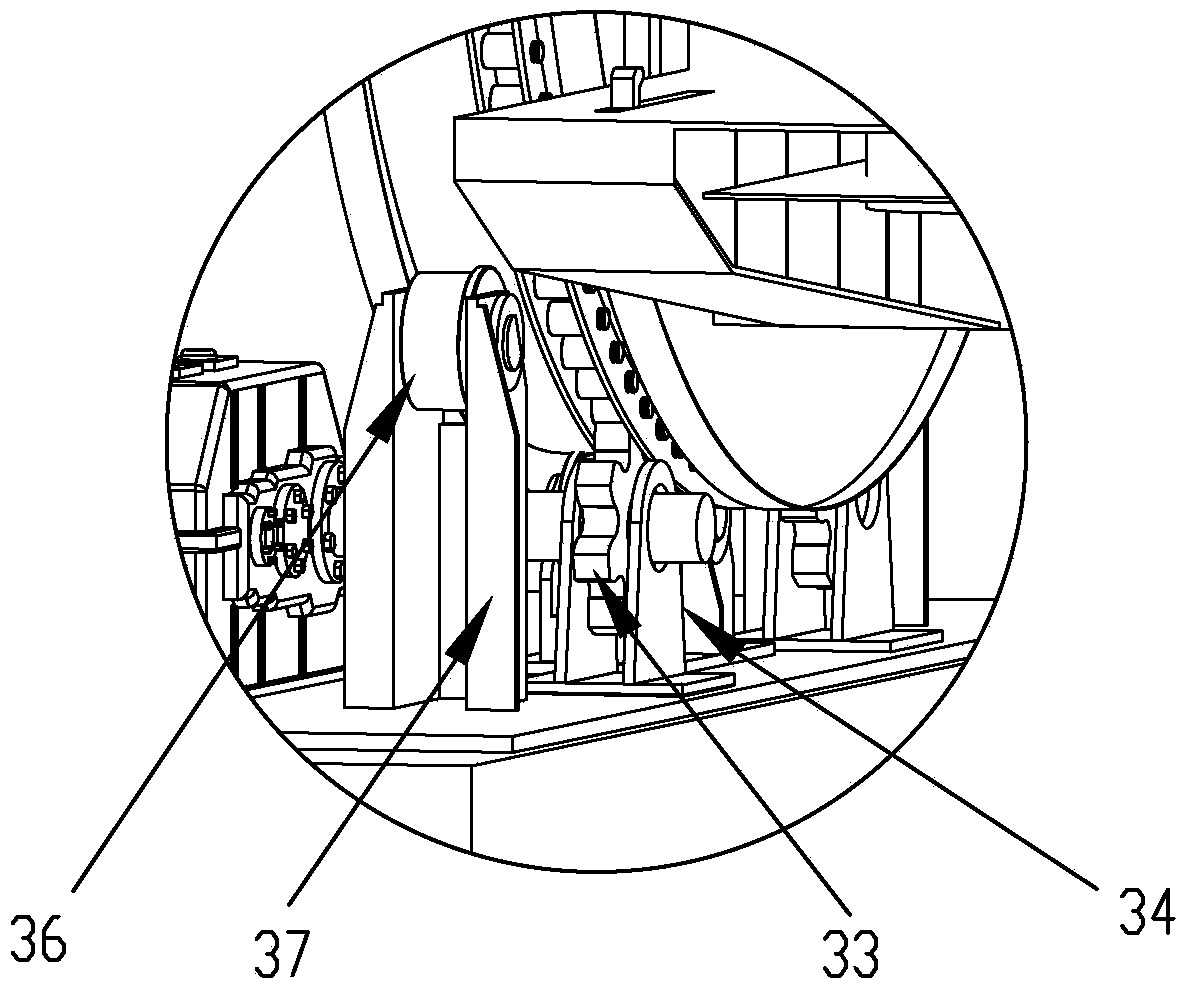

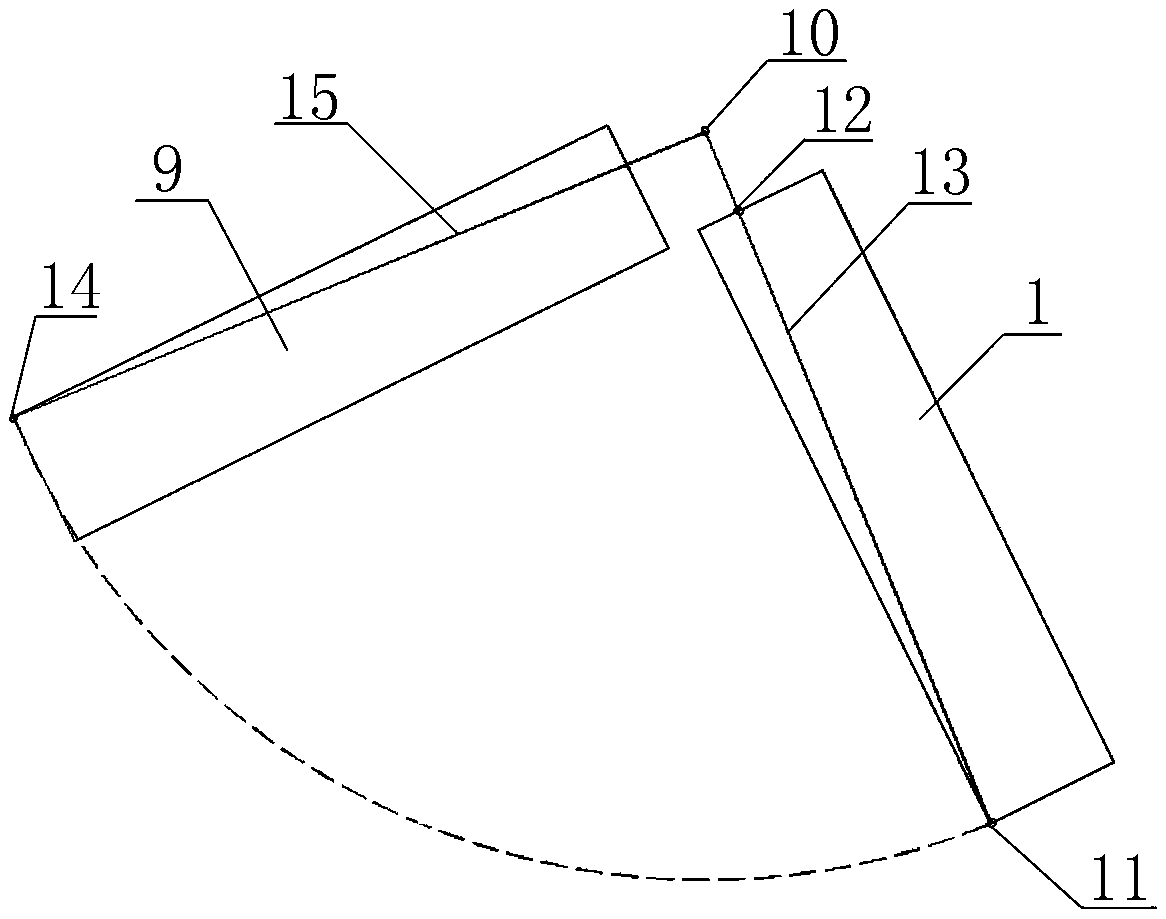

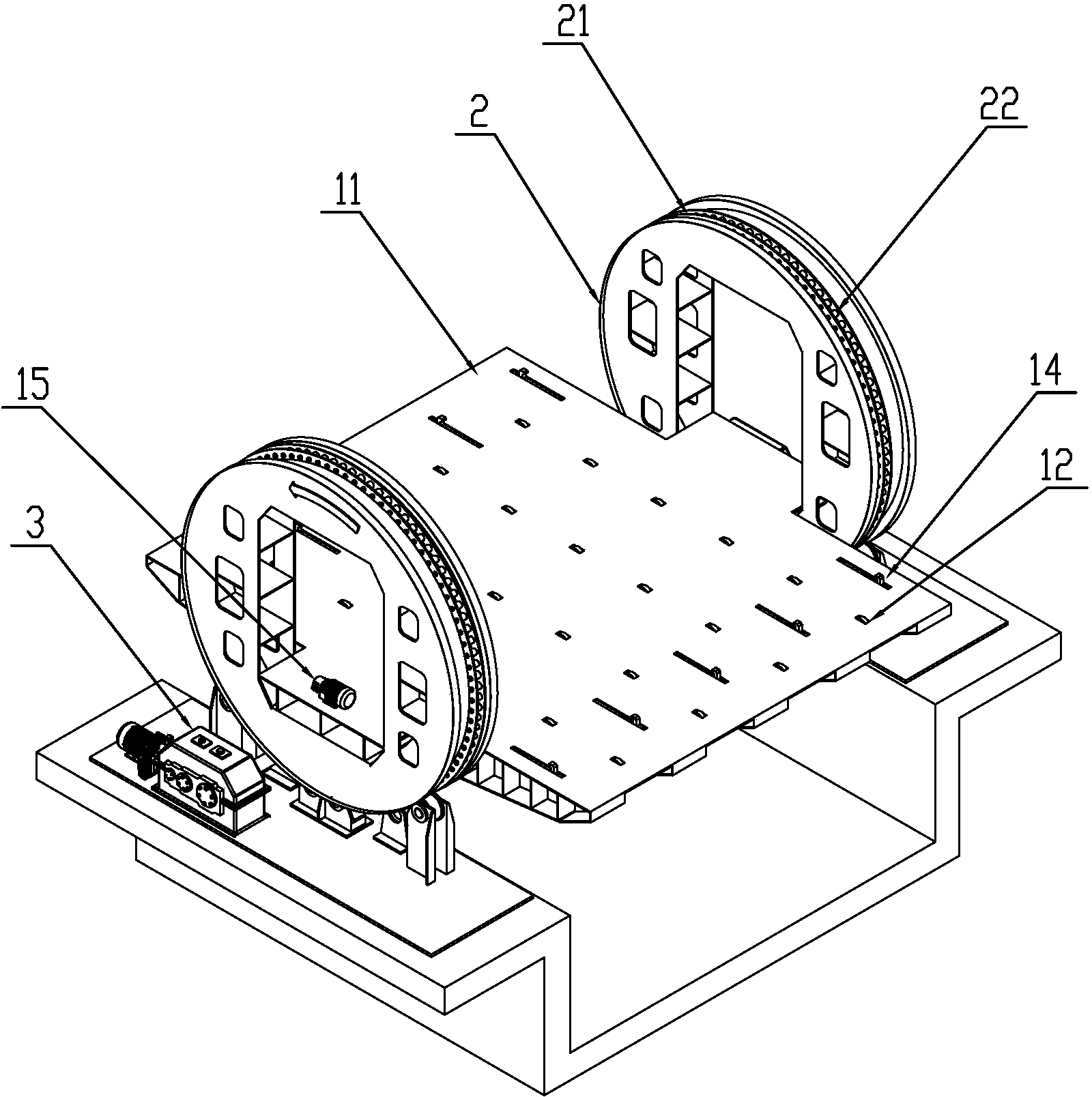

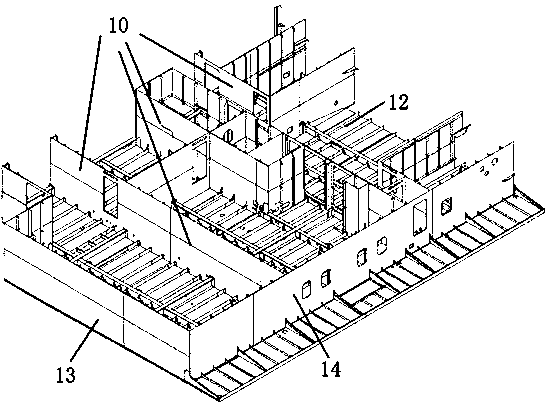

Lift roller based hull block turning equipment during ship construction

ActiveCN103661799AImprove build accuracyReduce secondary transportVessel partsEngineeringMechanical engineering

The invention discloses lift roller based hull block turning equipment during ship construction. The turning equipment comprises a rotary table (11). Two sides of the rotary table (11) are fixed on rotary rings (21) used for overturning respectively. The rotary table (11) comprises an electromagnet adsorption component and a plane attached to a hull block. Each rotary ring (21) rotates together with an outer side driving gear (33). Grooves are formed in the plane, attracted to the hull block, of the rotary table (11) at intervals. Lift roller components (12) are arranged in the grooves. Each lift roller component (12) comprises a track (123) perpendicular to the plane of the rotary table (11). Roller carriers (124) with rollers (121) are arranged in the tracks (123). Lift roller hydraulic oil cylinder components (122) are connected to the lower sides of the roller carriers (124). Rotary shafts of the rollers (121) are connected with roller driving motor components. By the turning equipment, construction cost of the hull block is greatly reduced, and construction efficiency is improved.

Owner:DALIAN SHIPBUILDING IND

Rotary horizontal-moving system of building and construction method of rotary horizontal-moving system

PendingCN110067405ASolve the problem of synchronous rotation and translationSolve the phenomenon of stuck railBuilding repairsLong axisEngineering

The invention discloses a rotary horizontal-moving system of a building and a construction method of the rotary horizontal-moving system. The rotary horizontal-moving system comprises a set of lower slideway beams, a tray beam, a plurality of sets of walking devices and a hydraulic control system, wherein the set of lower slideway beams is arranged on a foundation in a rotary horizontal-moving path area in parallel and at intervals; each lower slideway beam is in an arc shape, and the set of lower slideway beams shares one circle center; the tray beam is connected to the bottom of a building to be horizontally moved in a supporting mode and positioned above the lower slideway beams; the walking devices are arranged between the tray beam and the lower slideway beams respectively and used for jacking and pushing the tray beam; the sets of walking devices are spaced along the long axes of the lower slideway beams, and the walking devices on every two adjacent lower slideway beams are correspondingly arranged. The technical problems that a traditional rotary horizontal-moving method is complex in operation, low in efficiency, low in safety and incapable of moving a building in place ata time are solved.

Owner:HUAJIANG CONSTR OF CHINA CONSTR FIRST BUILDING GROUP CORP +1

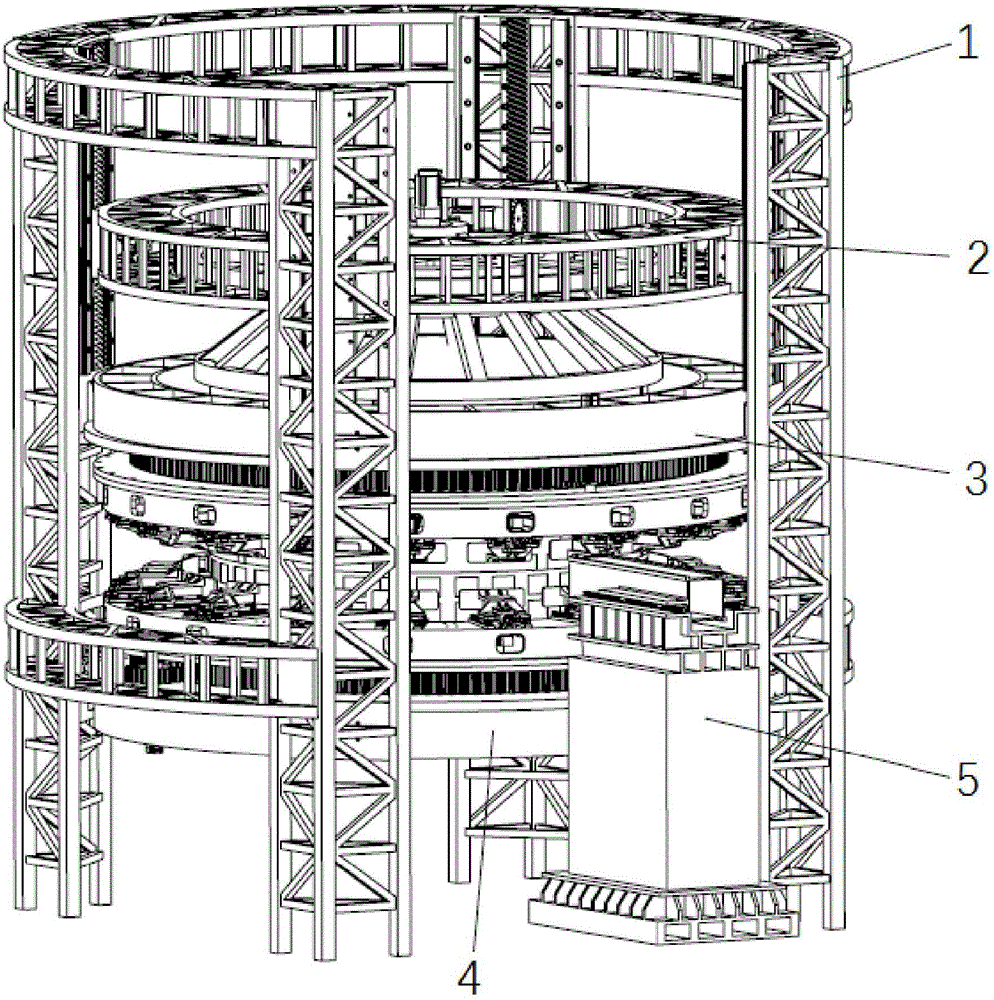

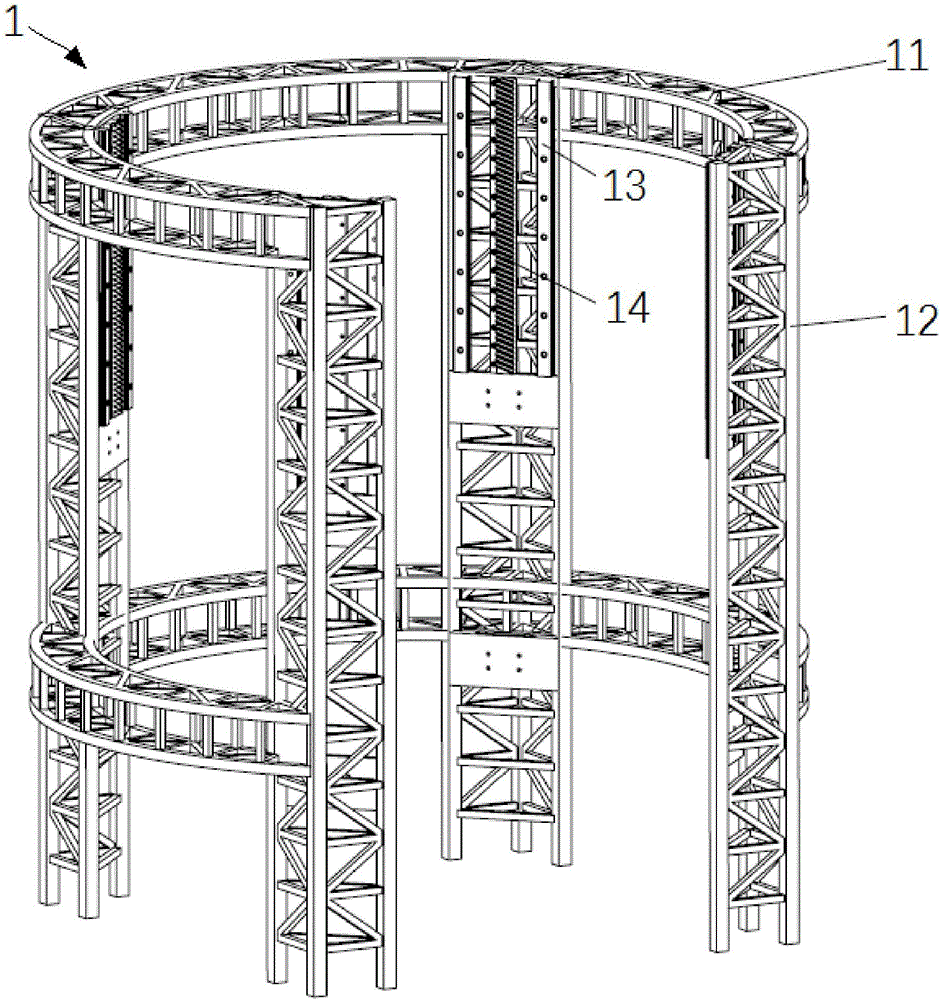

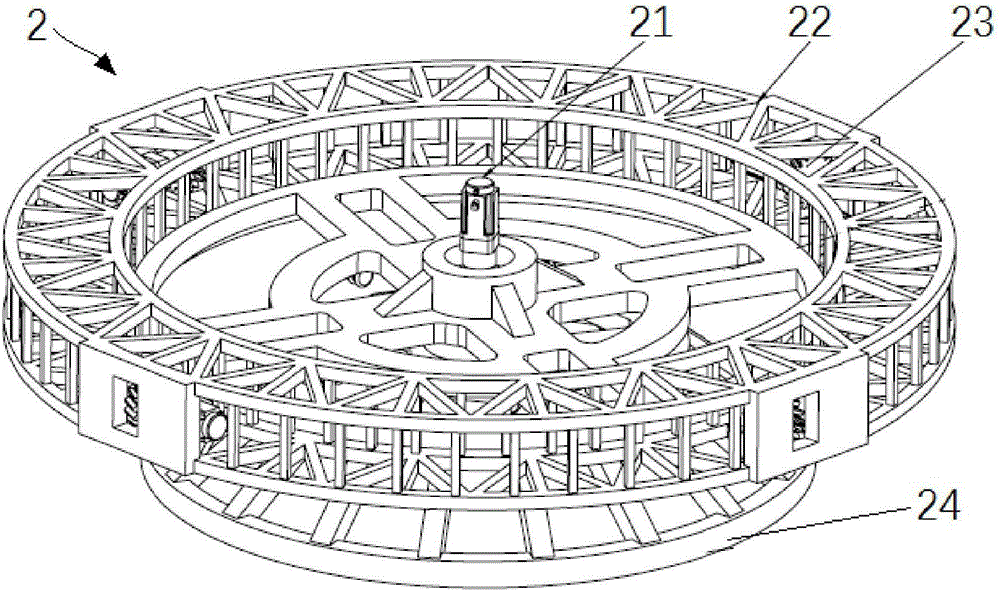

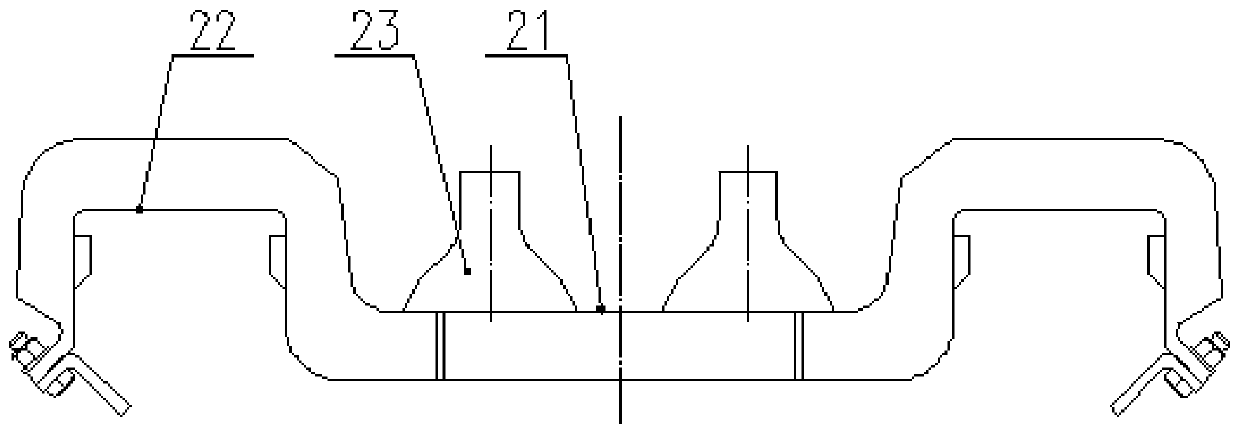

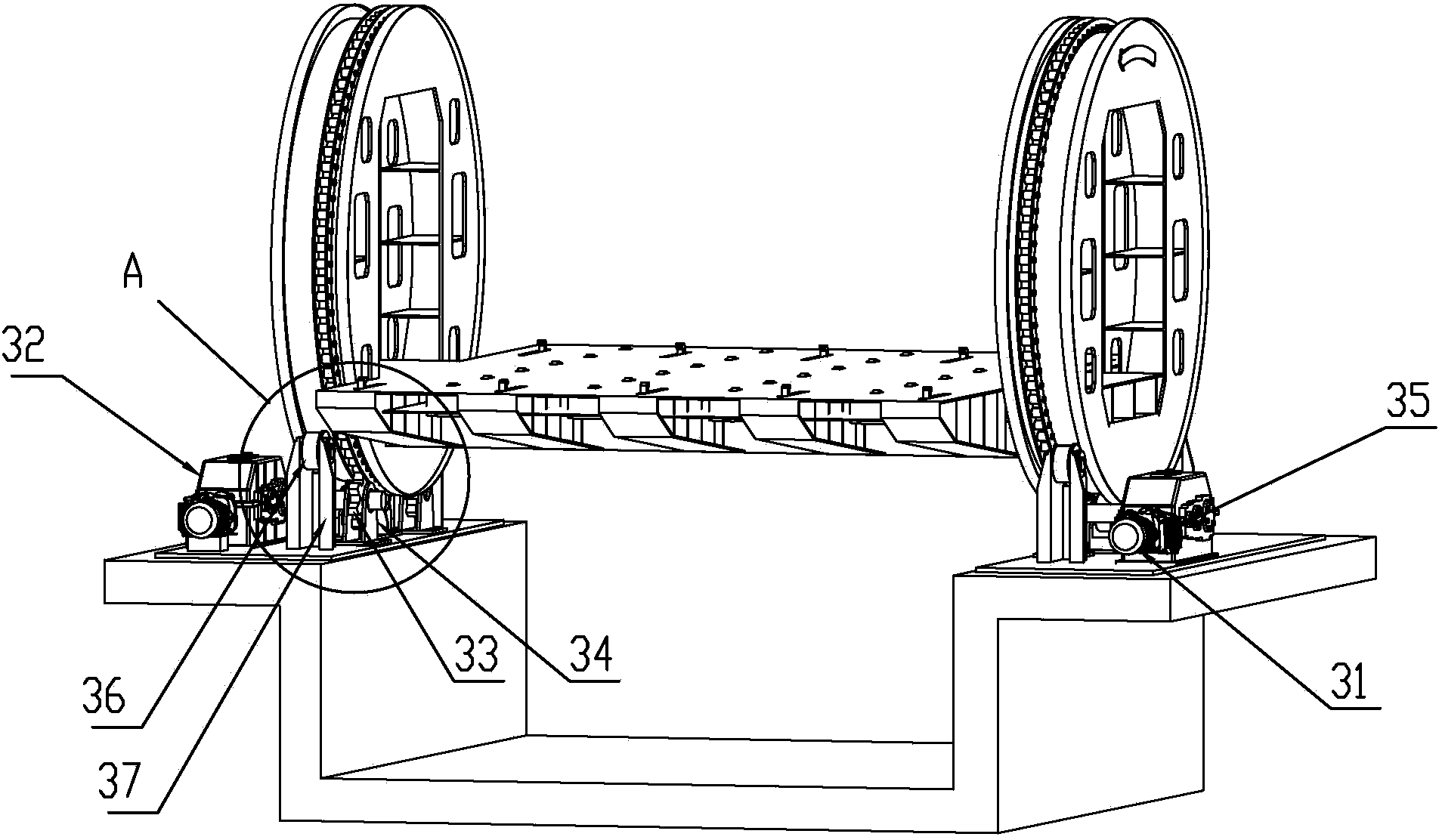

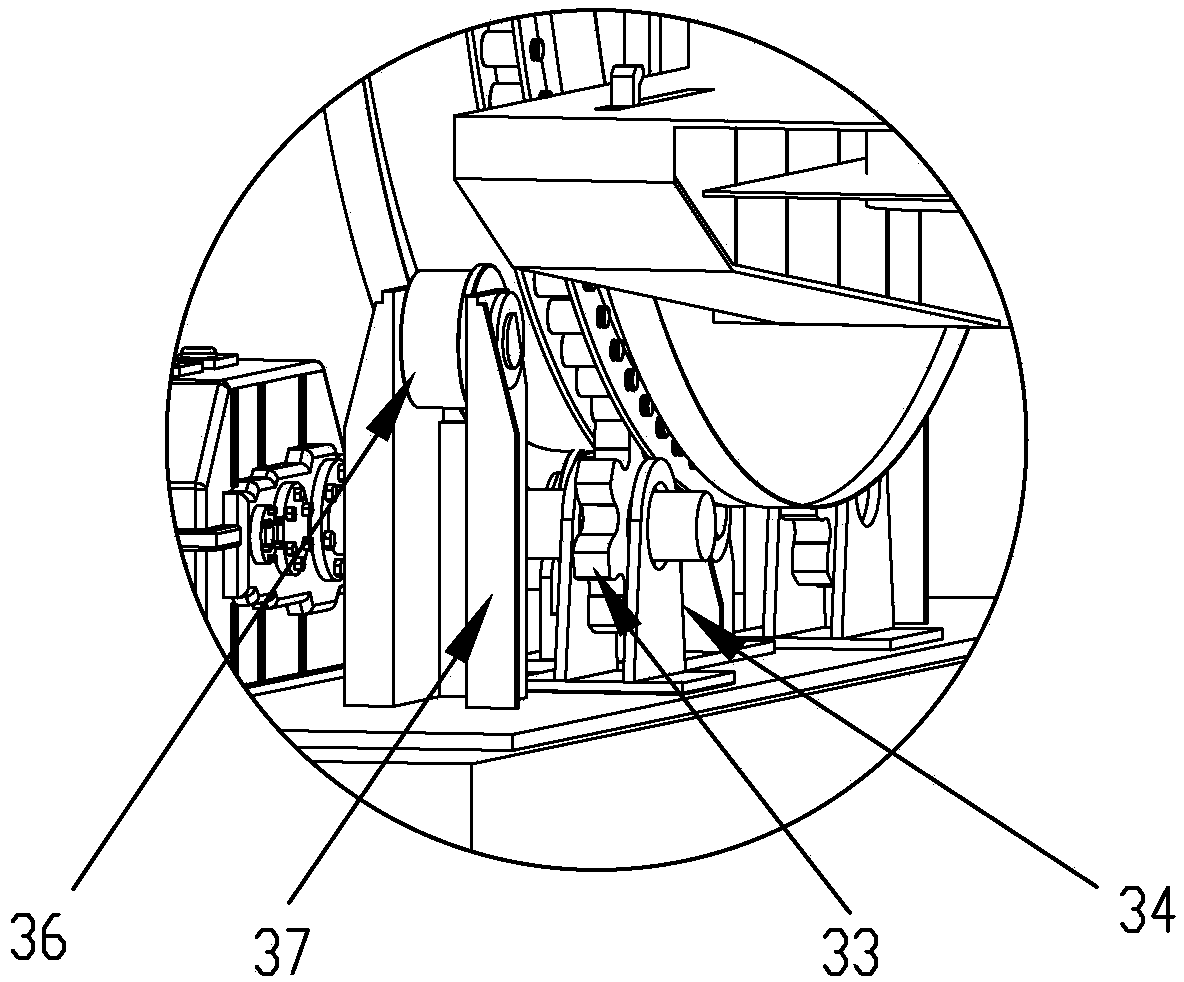

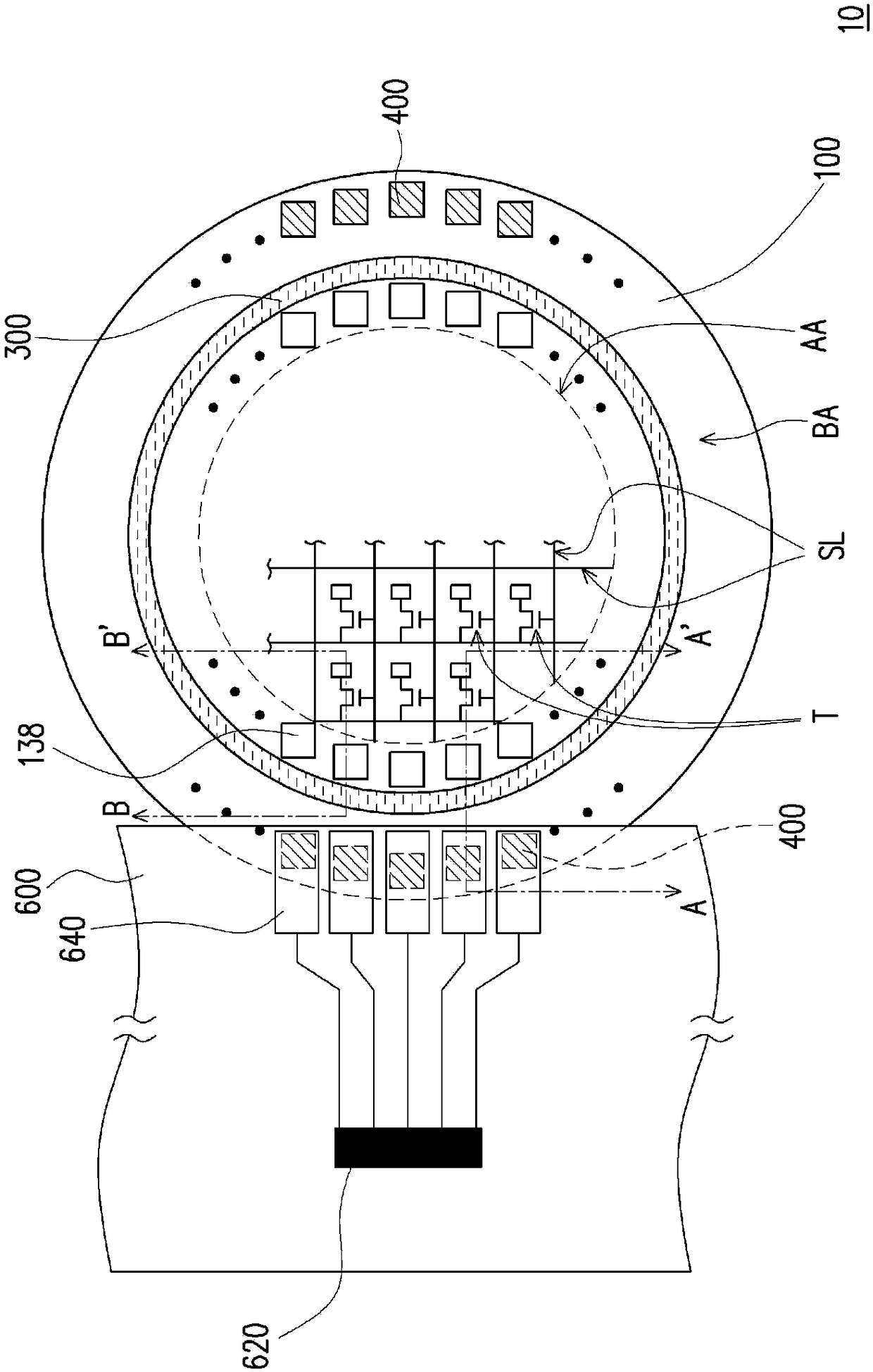

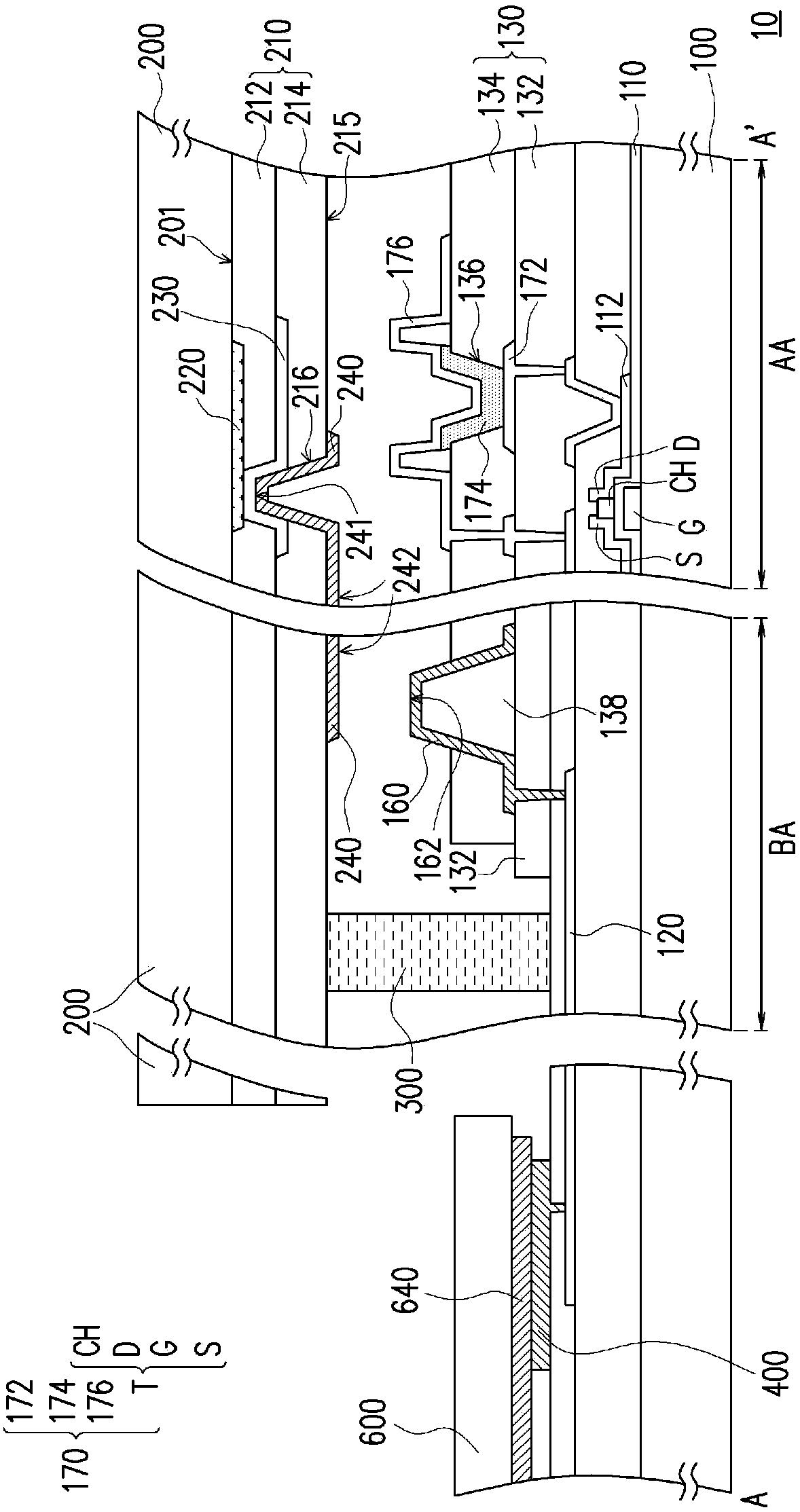

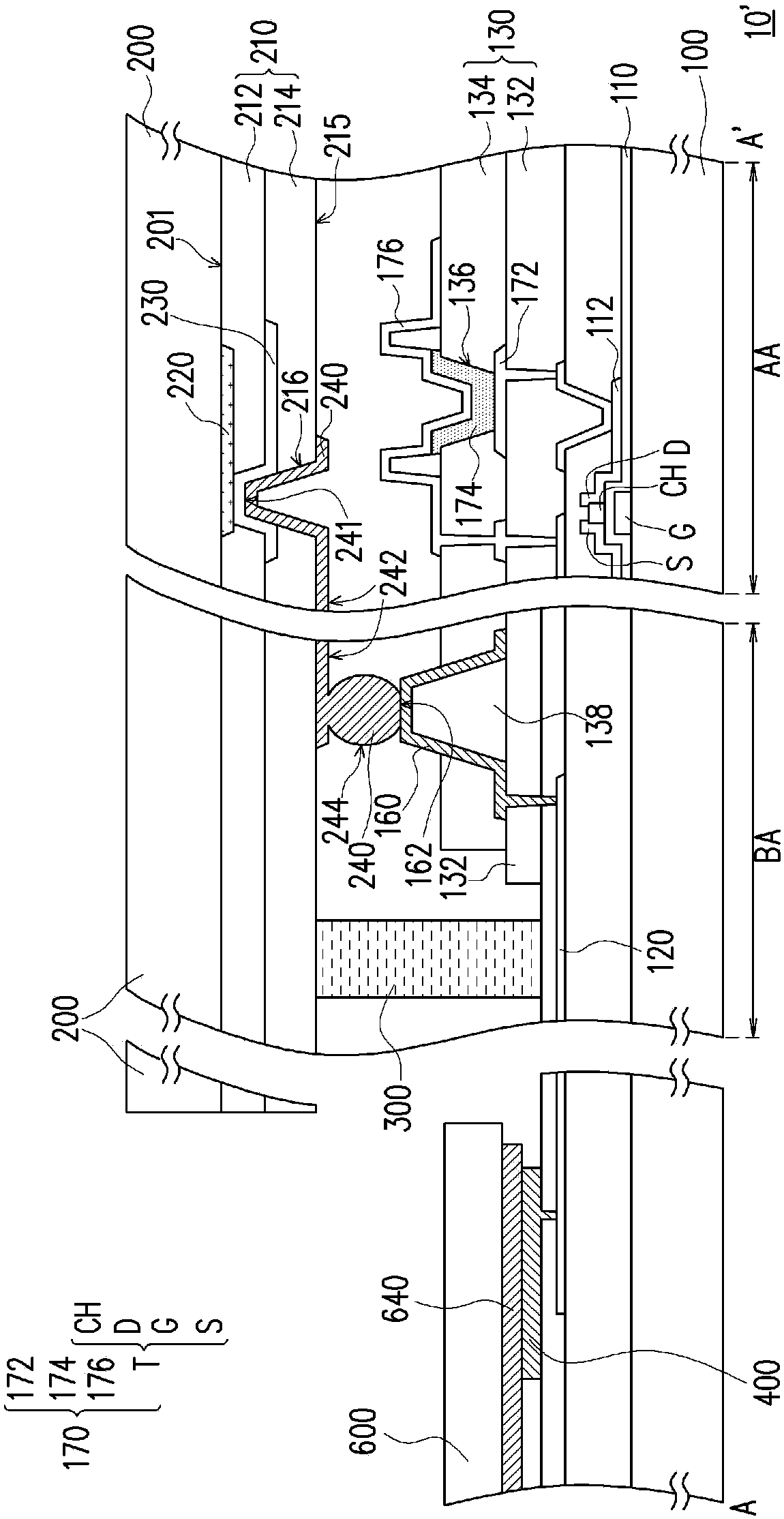

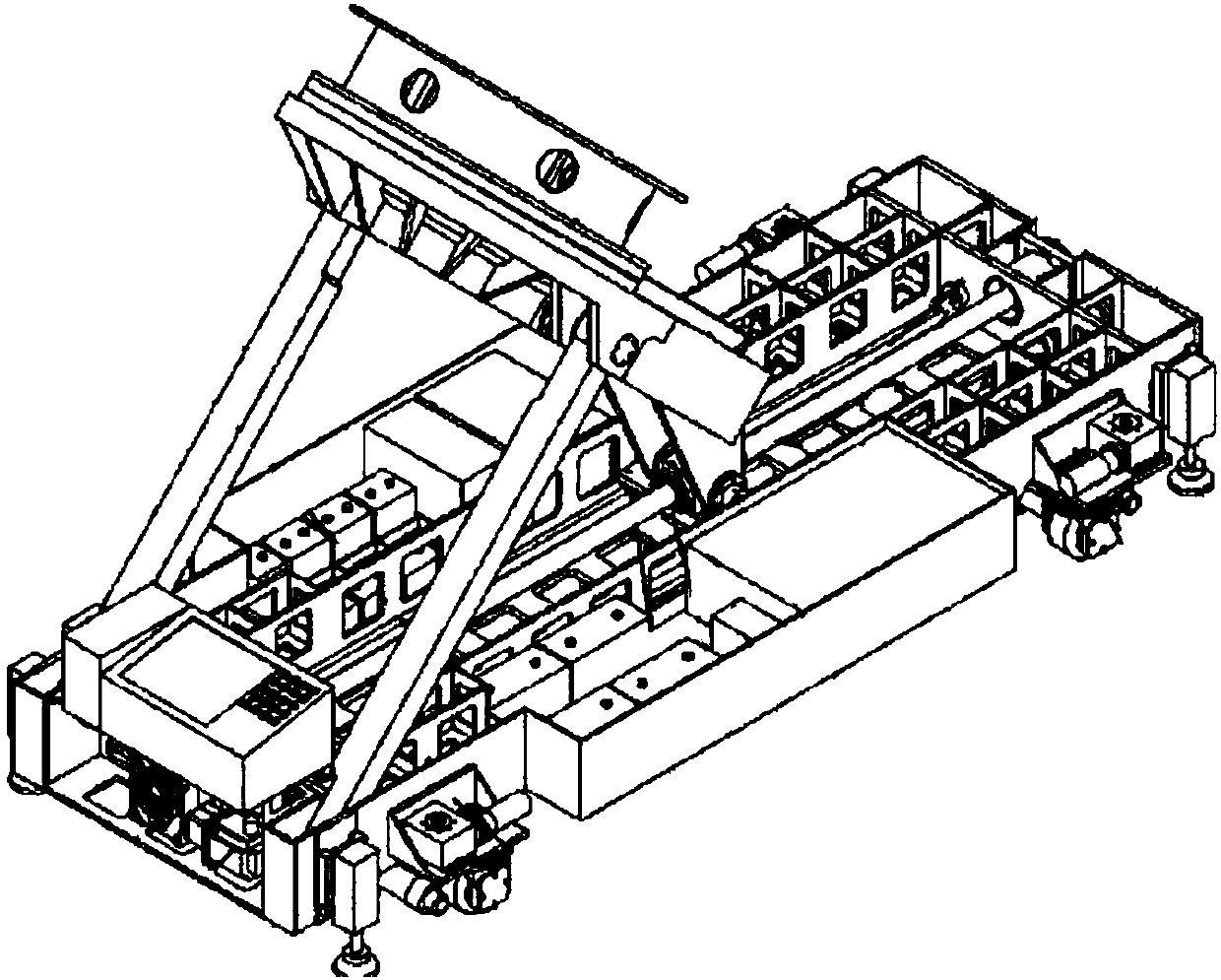

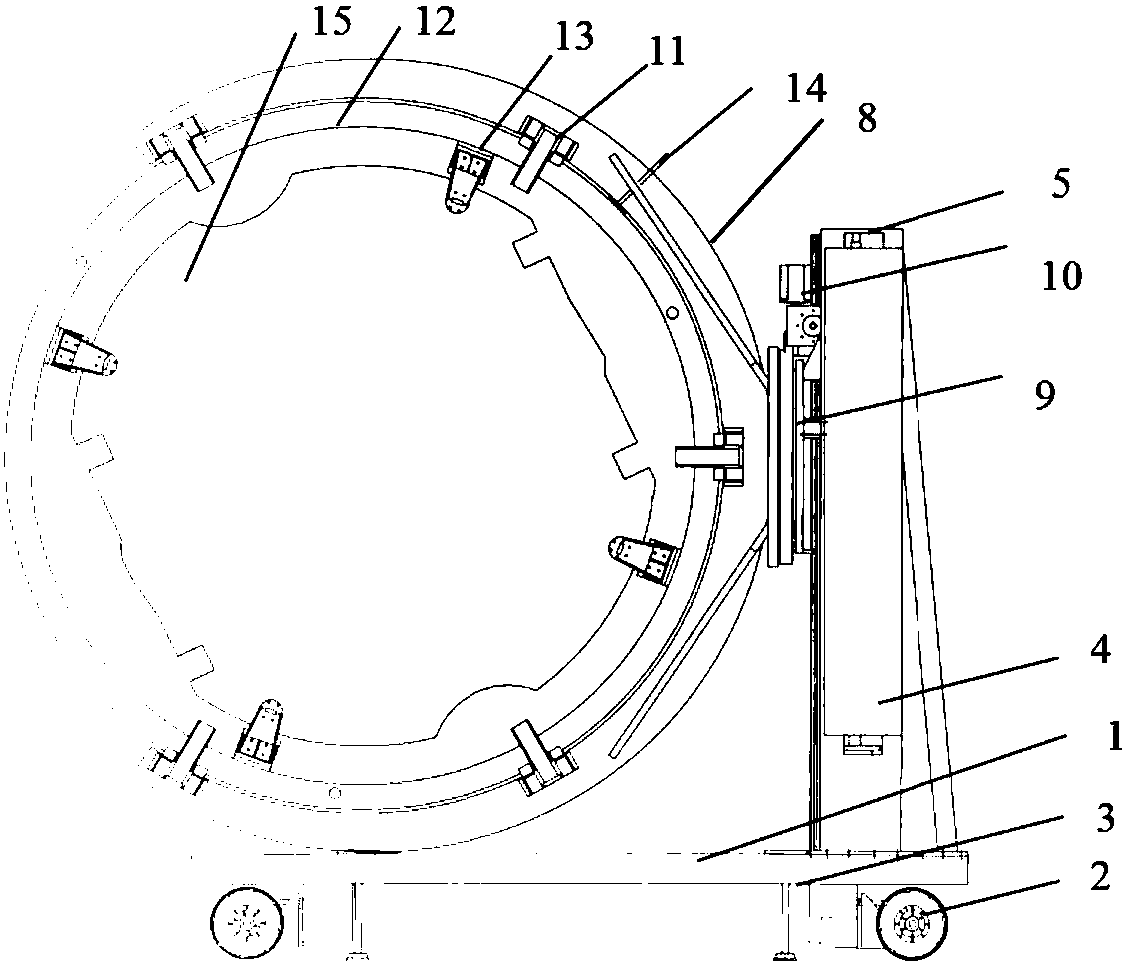

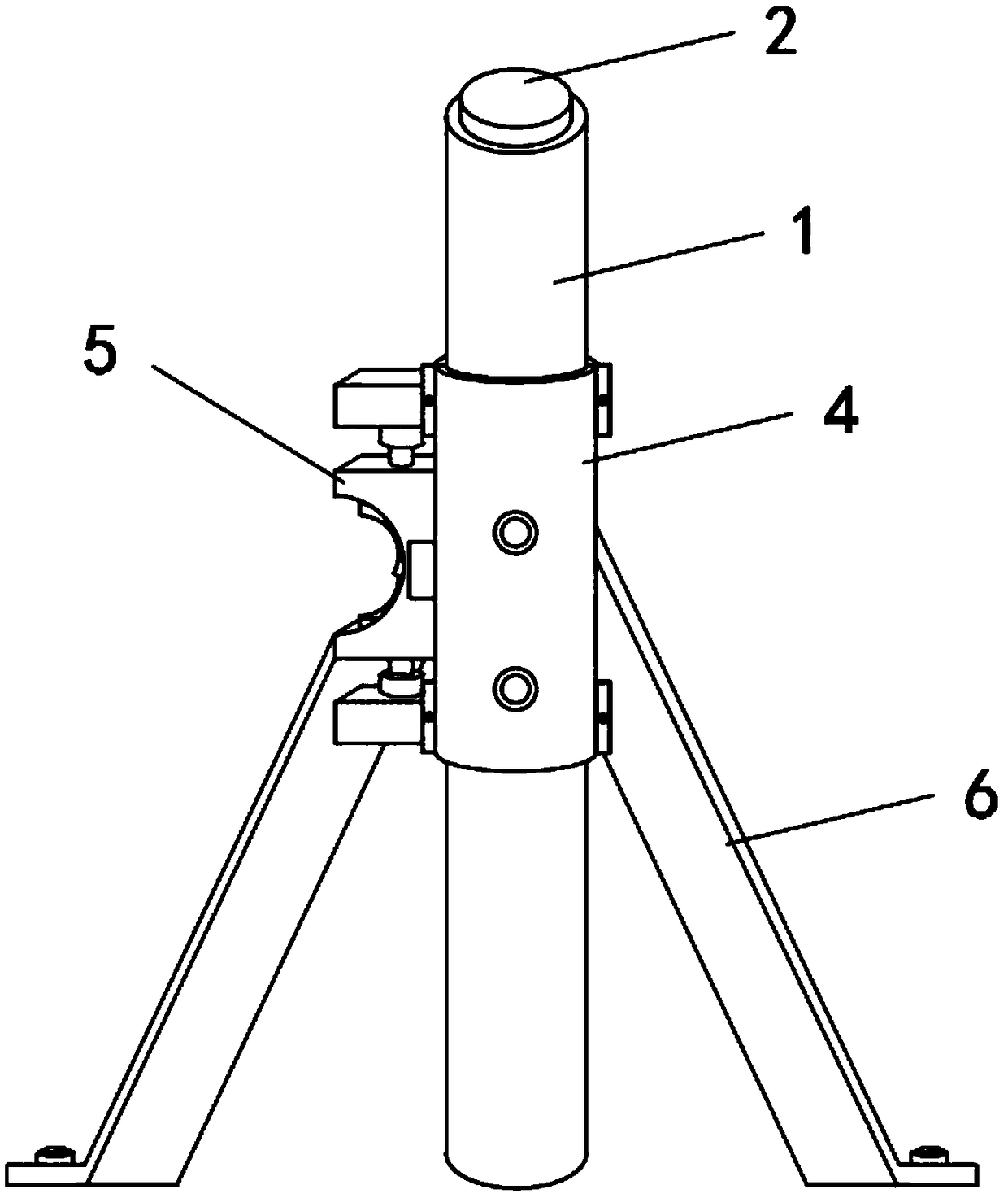

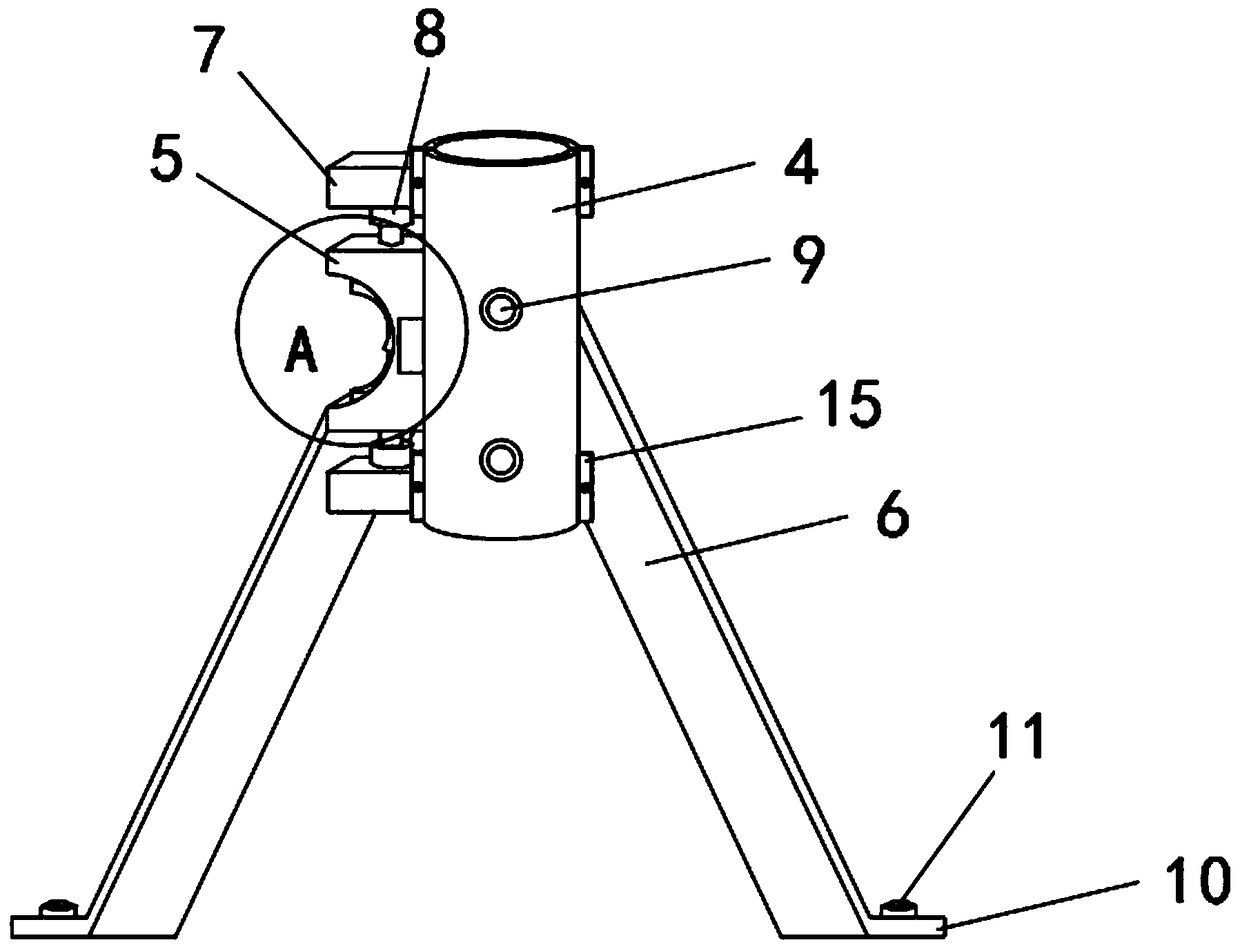

Rotary vertical assembling device for thin-walled barrel-shaped components

ActiveCN106624549AAvoid structural deformationFew influence factors of errorWelding/cutting auxillary devicesAuxillary welding devicesDistortionThin walled

The invention provides a rotary vertical assembling device for thin-walled barrel-shaped components. The rotary vertical assembling device comprises a machine frame, a vertical lifting platform, a mixing and friction welding mechanism, an annular upper outward-pressing clamp and an annular lower outward-pressing clamp. The vertical lifting platform is used for lifting the thin-walled barrel-shaped components. The vertical lifting platform, the annular upper outward-pressing clamp and the annular lower outward-pressing clamp are sequentially arranged in the machine frame in a sliding manner in the vertical direction. The barrel-shaped components are clamped by the annular upper outward-pressing clamp and the annular lower outward-pressing clamp, and the annular upper outward-pressing clamp and the annular lower outward-pressing clamp rotate. The mixing and friction welding mechanism is fixed on one side of the machine frame. The assembling device adopts a vertical clamping and welding way, avoids structural distortion of the thin-walled barrel-shaped components due to self gravity, and reduces the error influence factors during the assembling process; and the clamps are uniformly distributed in the circumferential direction, flexible clamping of the thin-walled barrel-shaped components is realized, the positioning precision is ensured, the clamping and positioning errors are reduced, the automatic degree of the device is high, the stations are concentrated, the occupied area is small, the height can be controlled during the processes of feeding, clamping, welding and discharging, and the assembling efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV

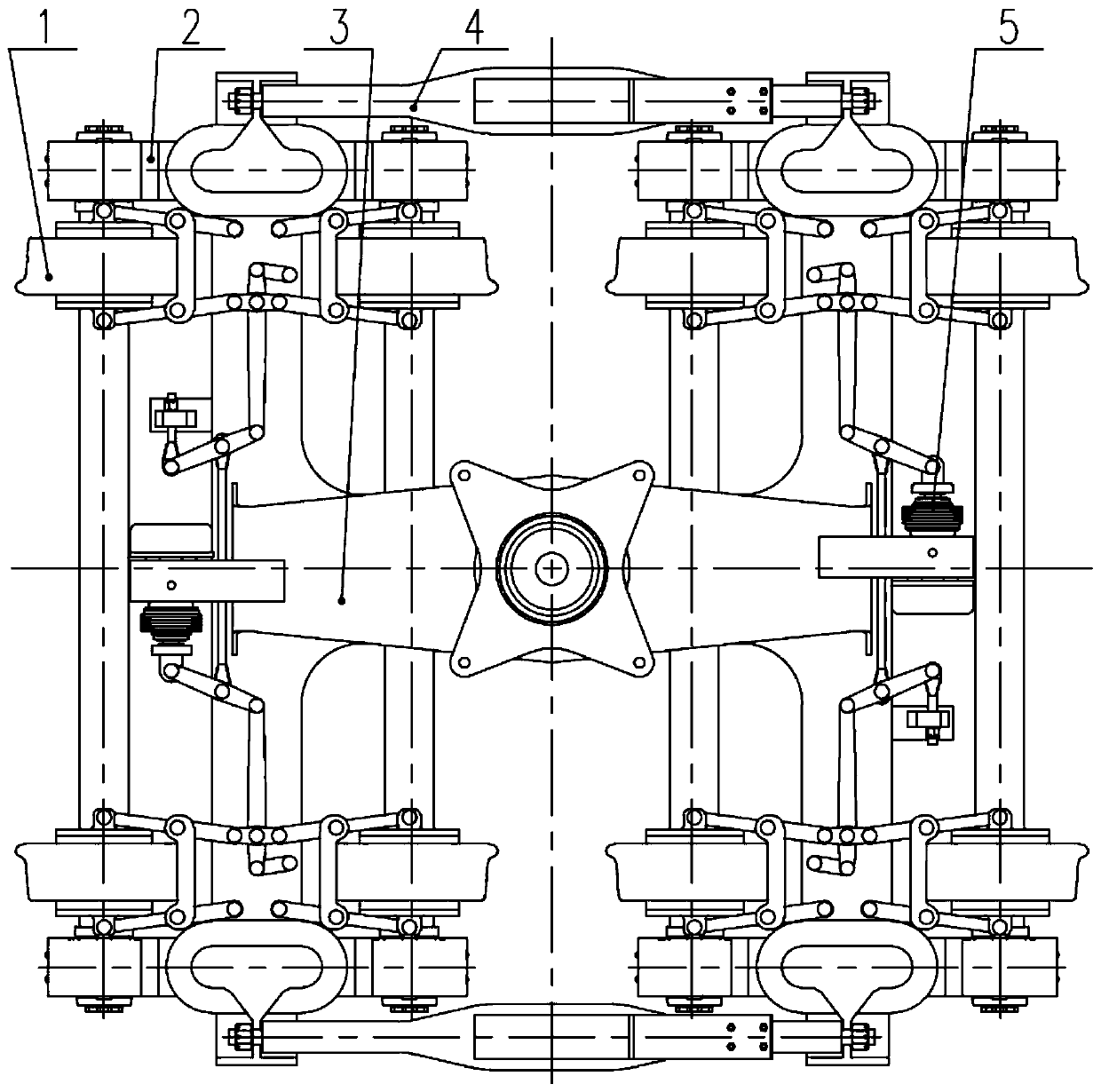

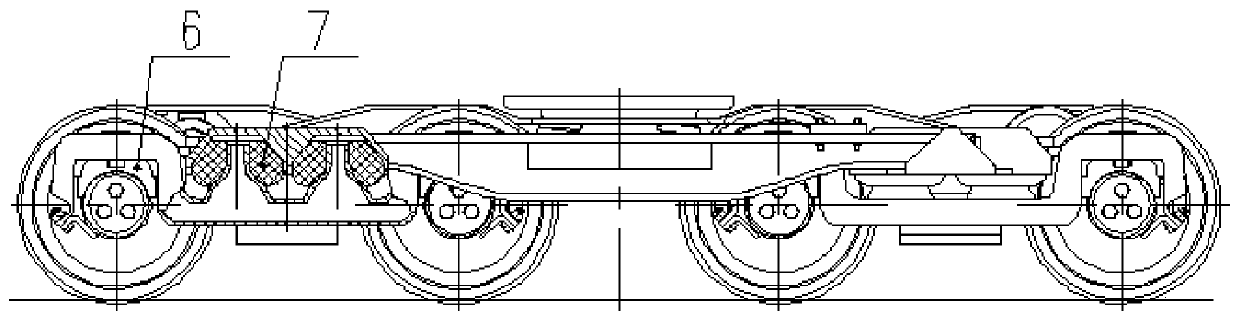

Bogie for railway wagon with integral low bearing surface and railway wagon

InactiveCN110065518ALower the altitudeLower bearing surfaceBogiesBogie-underframe connectionsBogieEngineering

The invention discloses a bogie for a railway wagon with integral low bearing surface and the railway wagon. The bogie comprises side beams and a frame. The frame is composed of a longitudinal beam and two transverse beams, the two transverse beams are symmetrically installed on the longitudinal beam, and the two transverse beams are parallel to each other and perpendicular to the longitudinal beam. The middle part of the longitudinal beam is of a concave structure, and a central disk device is arranged in the concave structure. Axles parallel to the transverse beams are arranged on the two sides of the transverse beams, and the axles positioned on the two sides of the transverse beams are connected together through the side beams. The side beams are of a U-shaped structure with a concavemiddle part, guide frame openings matched with axles are formed in the two ends of the side beams, and spring seats are arranged on the middle parts of the side beams. The frame is supported on the spring seats of the four side beams through four groups of suspension springs.

Owner:CRRC SHANDONG CO LTD

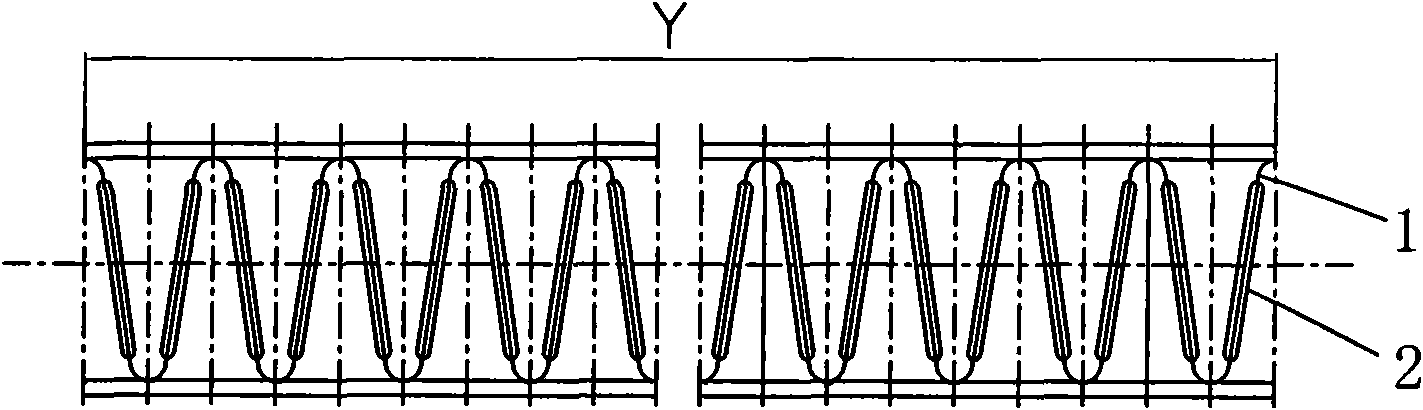

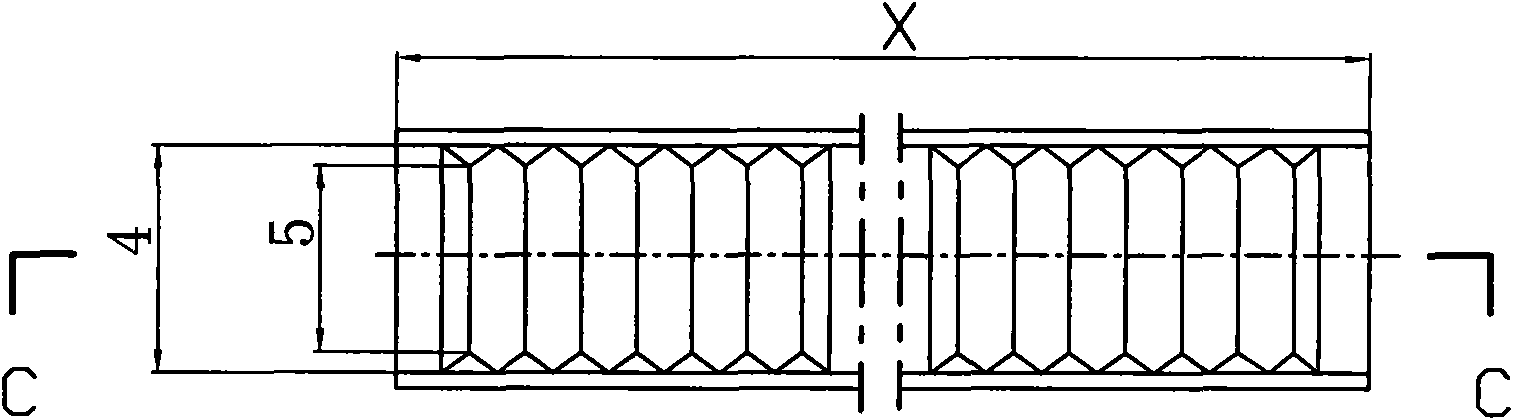

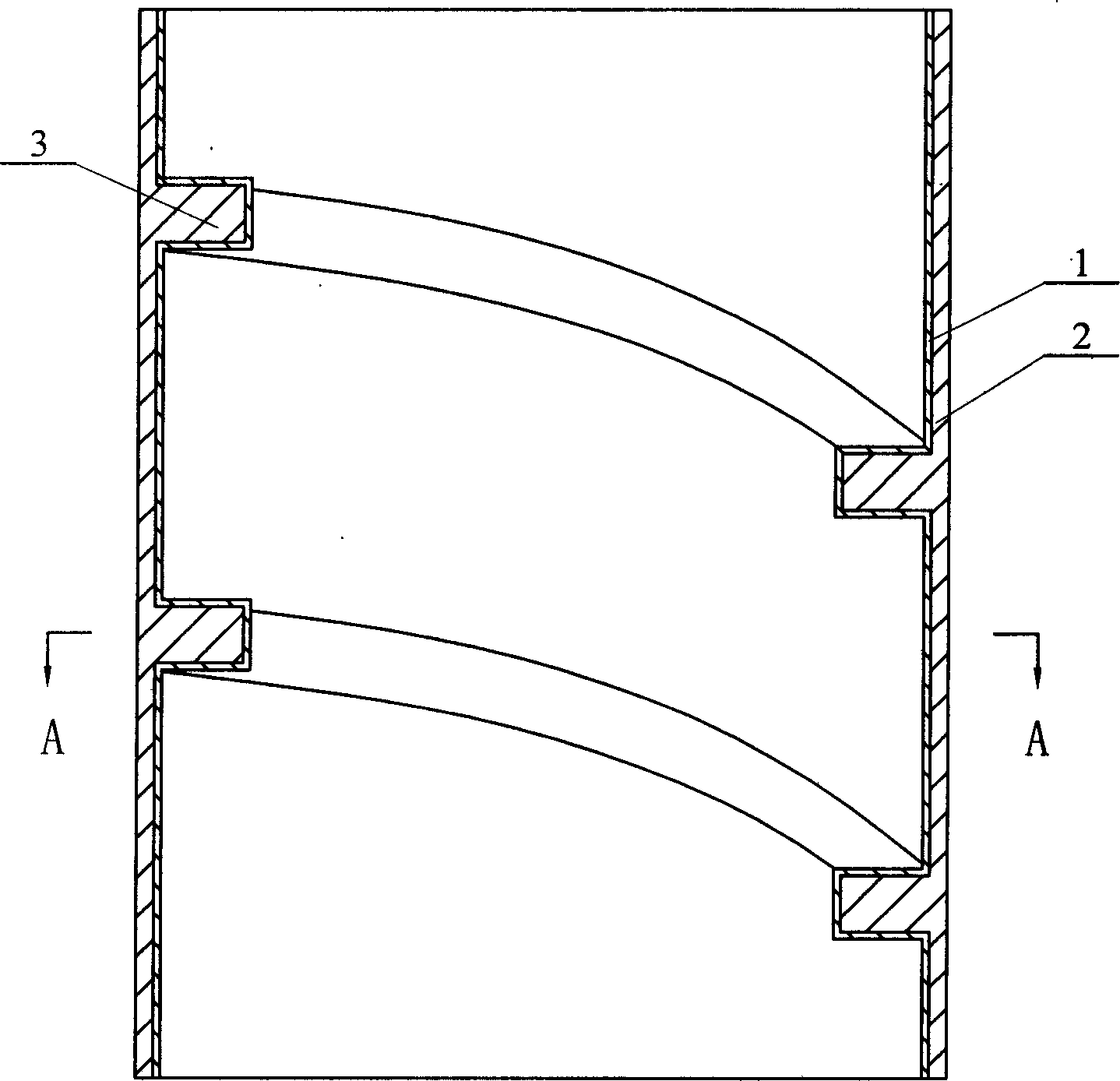

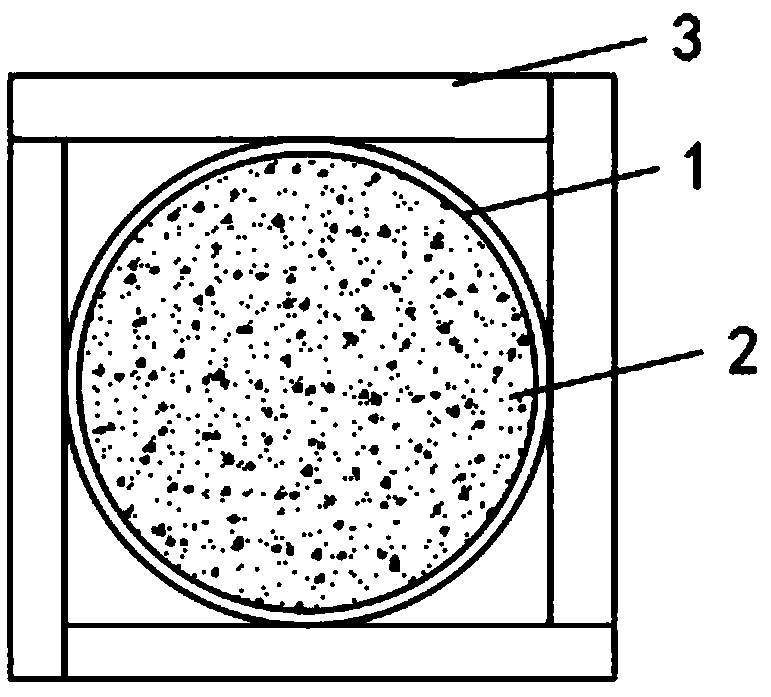

Fiber reinforced plastic cylinder with interior spiral reinforcing bar and method for manufacturing the same

The invention relates to a fiber strengthen plastic cylinder with inner screw strength bar. Wherein, the liner layer (1) has at least one screw groove; the strength bar (3) is fixed inside the groove whose length is at least 1 / 3 of the cylinder length; the outer layer (2) of cylinder is fixed on the outer surface of liner layer (1) and the strength bar (3). The producing method comprises: treating the outer surface of mould; laying and coiling the liner layer (1), cylinder outer layer (2) and the strength bar (3) to be put into solidify furnace to be molded; then treating the outer surface. The invention has short producing time, high efficiency and simple process. And the inventive cylinder has high strength, smooth inner surface without crack, etc.

Owner:HARBIN FRP INST +1

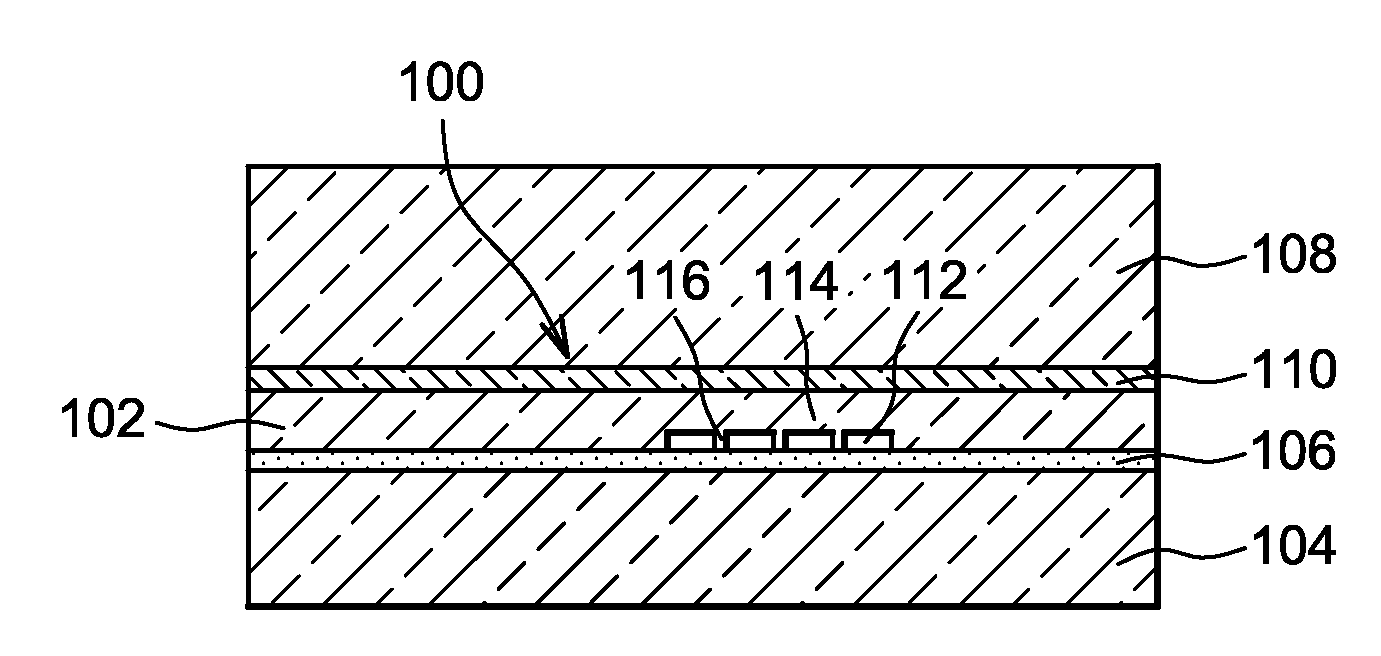

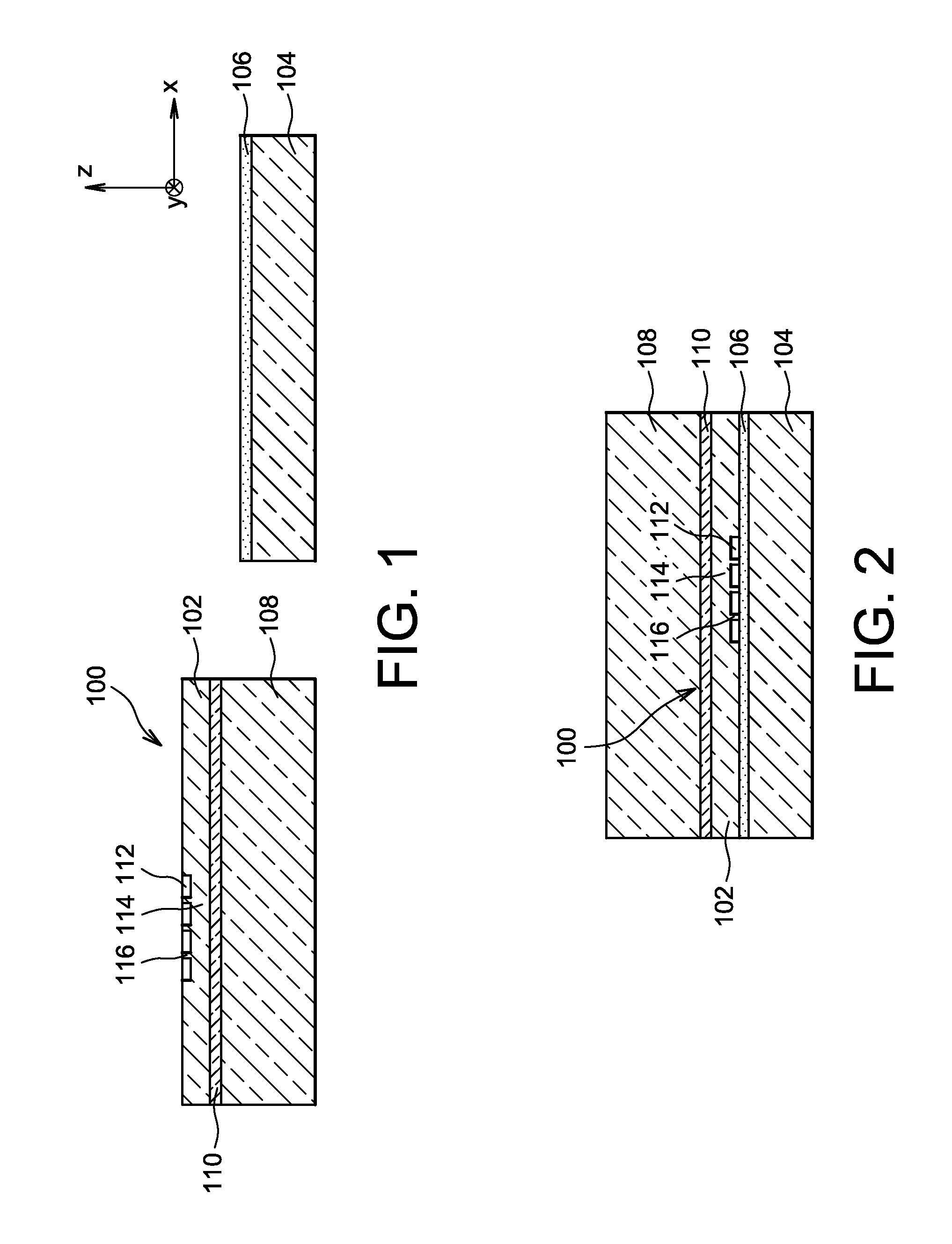

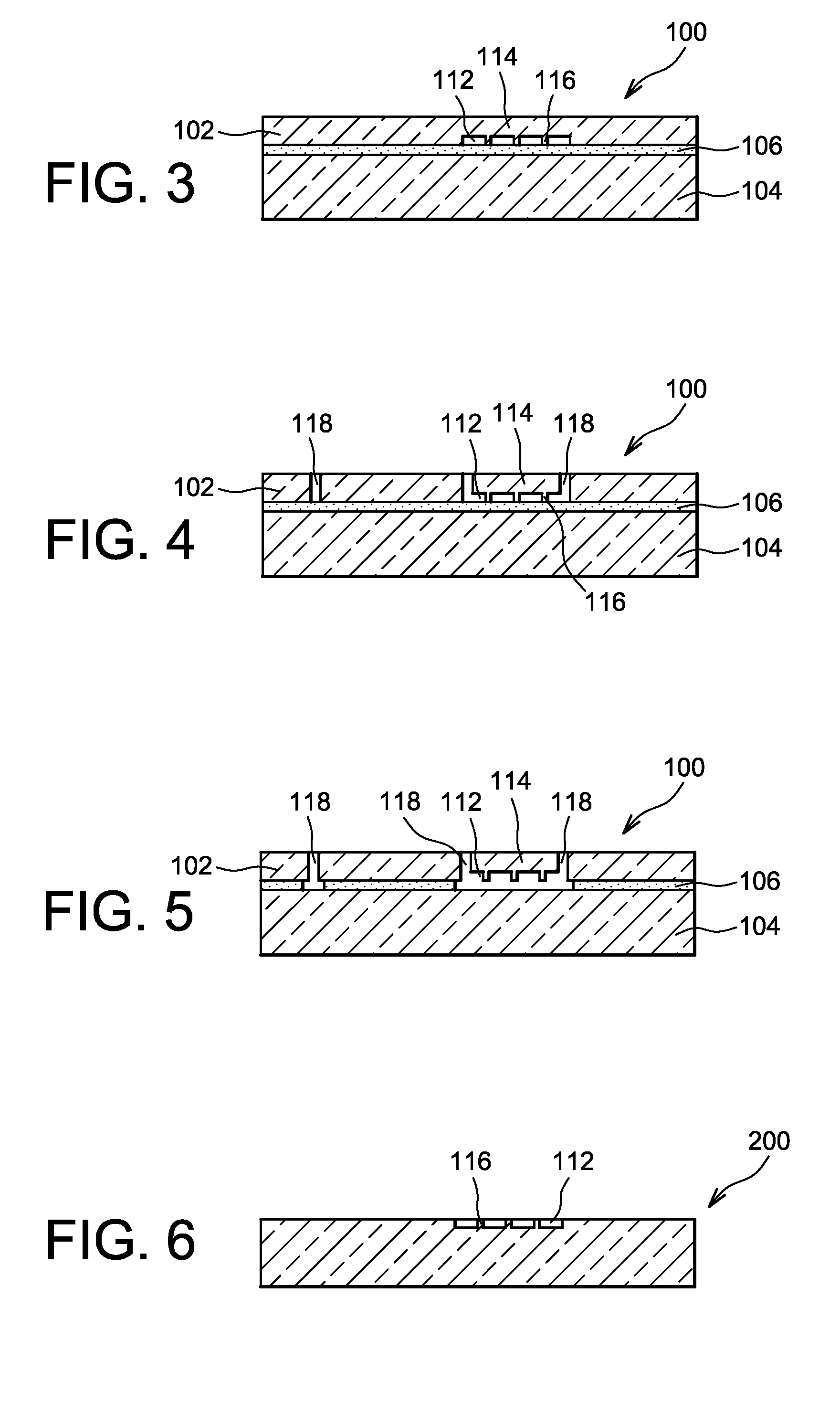

Seesaw-type MEMS switch for radio frequency and method for manufacturing the same

ActiveUS20050012562A1Inhibit deteriorationAvoid structural deformationPiezoelectric/electrostriction/magnetostriction machinesElectrostatic/electro-adhesion relaysRadio frequencyTransmission line

In a seesaw-type MEMS switch for radio frequency (RF) and a method for manufacturing the same, the seesaw-type MEMS switch for radio frequency (RF) includes a substrate, a transmission line formed on the substrate having a gap therein to provide a circuit open condition, an intermittent part formed a predetermined distance from the substrate, the intermittent part being operable to contact the transmission line on both sides of the gap by performing a seesaw movement about a seesaw movement axis, and a driving part to drive the seesaw movement of the intermittent part in response to a driving signal.

Owner:SAMSUNG ELECTRONICS CO LTD

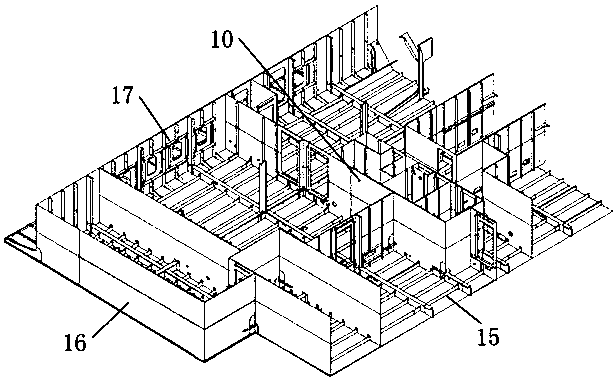

Hull block turning equipment provided with clamping and protecting mechanisms during ship construction

ActiveCN103661800AImprove build accuracyReduce secondary transportVessel partsEngineeringMechanical engineering

The invention discloses hull block turning equipment provided with clamping and protecting mechanisms during ship construction. The hull block turning equipment comprises a rotary table (11). Two sides of the rotary table (11) are fixed on rotary rings (21) used for overturning respectively. The rotary table (11) comprises an electromagnet adsorption component and a plane attached to a hull block. Each rotary ring (21) rotates together with an outer side driving gear (33). Wide slots are formed at the edge, contacting with the hull block, of the rotary table (11). Movable clamping components are arranged in the wide slots. Each movable clamping component comprises a track frame component which is perpendicular to the plane of the rotary platform and moves outwards parallelly to the plane of the rotary platform. Clamping claws are arranged in the track frame components. Each clamping claw is provided with a hydraulic component for moving the claws in two directions. By the hull block turning equipment, construction cost is greatly reduced, and construction efficiency is improved.

Owner:DALIAN SHIPBUILDING IND

Pre-released structure device

ActiveUS20090261431A1Quick releaseGreat freedomTransistorTransducer detailsSecondary layerBiomedical engineering

A pre-released structure device comprising:at least one first stacking, comprising at least one first layer based on at least one first material, arranged against a second stacking comprising at least one second layer based on at least one second material,at least one closed cavity, formed in the first and / or the second stacking, and arranged between a portion of the first stacking forming the pre-released structure and the second stacking,at least one spacer arranged in the cavity and linking the portion of the first stacking to the second stacking.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

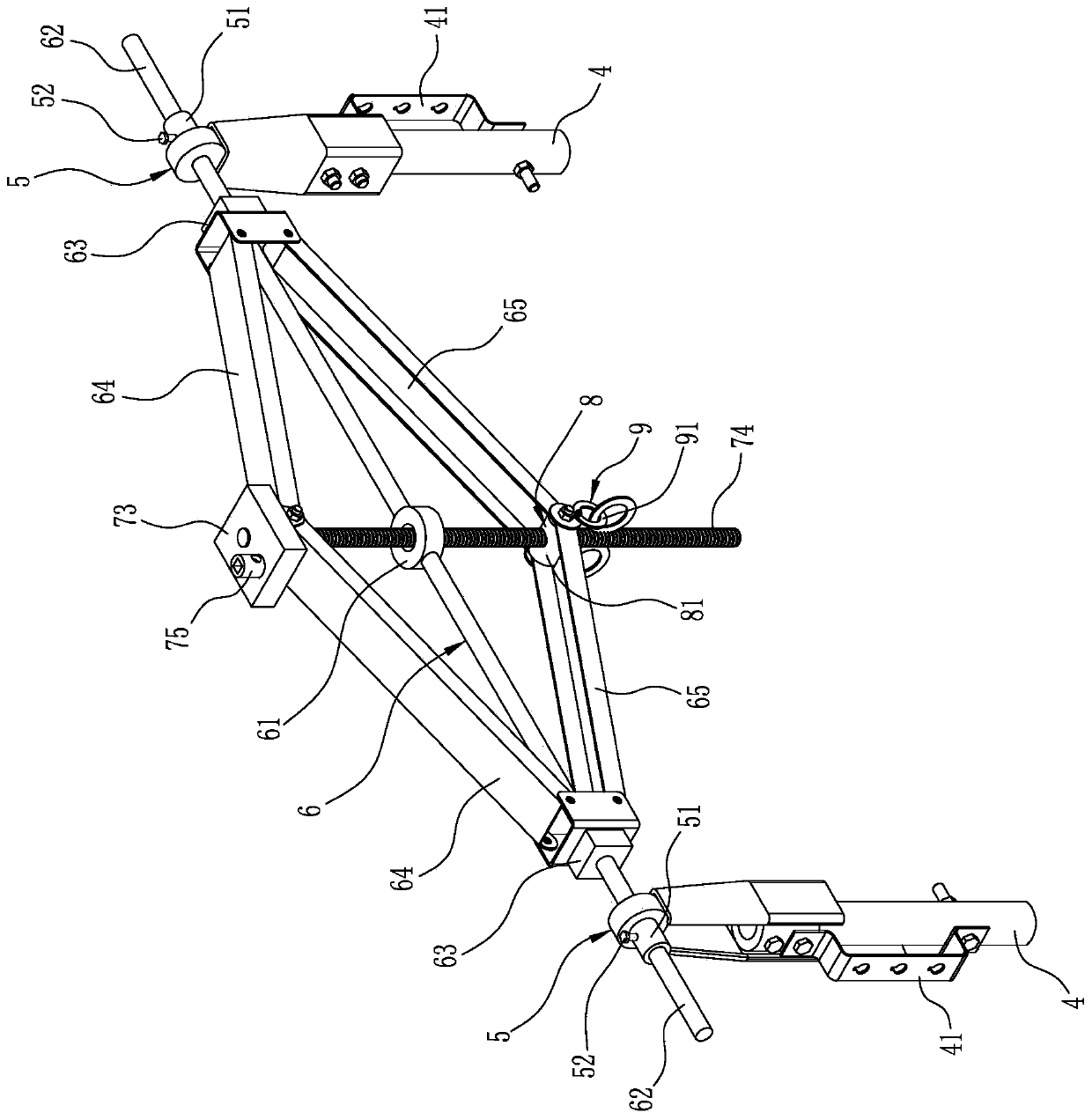

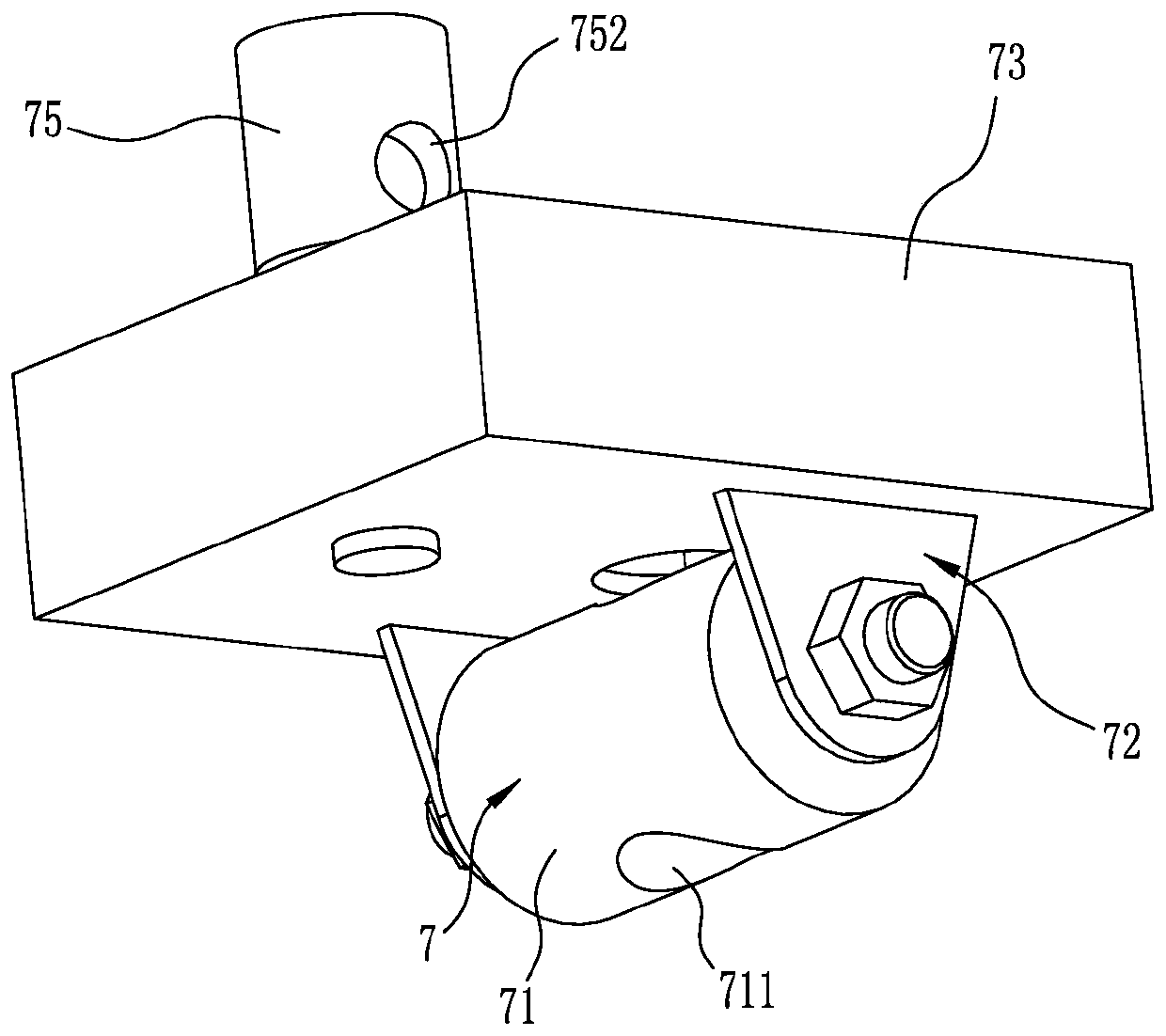

Convenient lifting device for manhole covers

InactiveCN109761174AAvoid structural deformationStable structureLifting devicesHoisting equipmentsWrenchEngineering

The invention discloses a convenient lifting device for manhole covers. The convenient lifting device comprises a lifting base frame; a dragging mechanism and a base frame leveling mechanism are arranged on the lifting base frame; two lifting sliding rails are arranged on the lifting base frame; lifting sliding seats are glidingly mounted on the two lifting sliding rails; lifting vertical arms aremounted on the two lifting sliding seats; a lifting cross beam is mounted at the top ends of the two lifting vertical arms; two connecting rod sliding seats are glidingly mounted on the lifting crossbeam; an upper force application seat is arranged above the two connecting rod sliding seats; upper connecting rods are hinged between the upper force application seat and the two connecting rod sliding seats; a lower force application seat is arranged below the two connecting rod sliding seats; lower connecting rods are hinged between the lower force application seat and the two connecting rod sliding seats; a lifting screw is rotationally mounted on the upper force application seat; a lifting screw sleeve is arranged on the lower force application seat; a control device is mounted on the upper force application seat; and a manhole cover hooking device is mounted on the lower force application seat. According to the convenient lifting device, by the aid of the upper connecting rods and the lower connecting rods, the triangular stable support is formed for the lifting screw and a connecting piece of the lifting screw, the structure is more reliable, driving by the aid of an electric wrench is facilitated, and the lifting efficiency can be improved.

Owner:宋夕杰

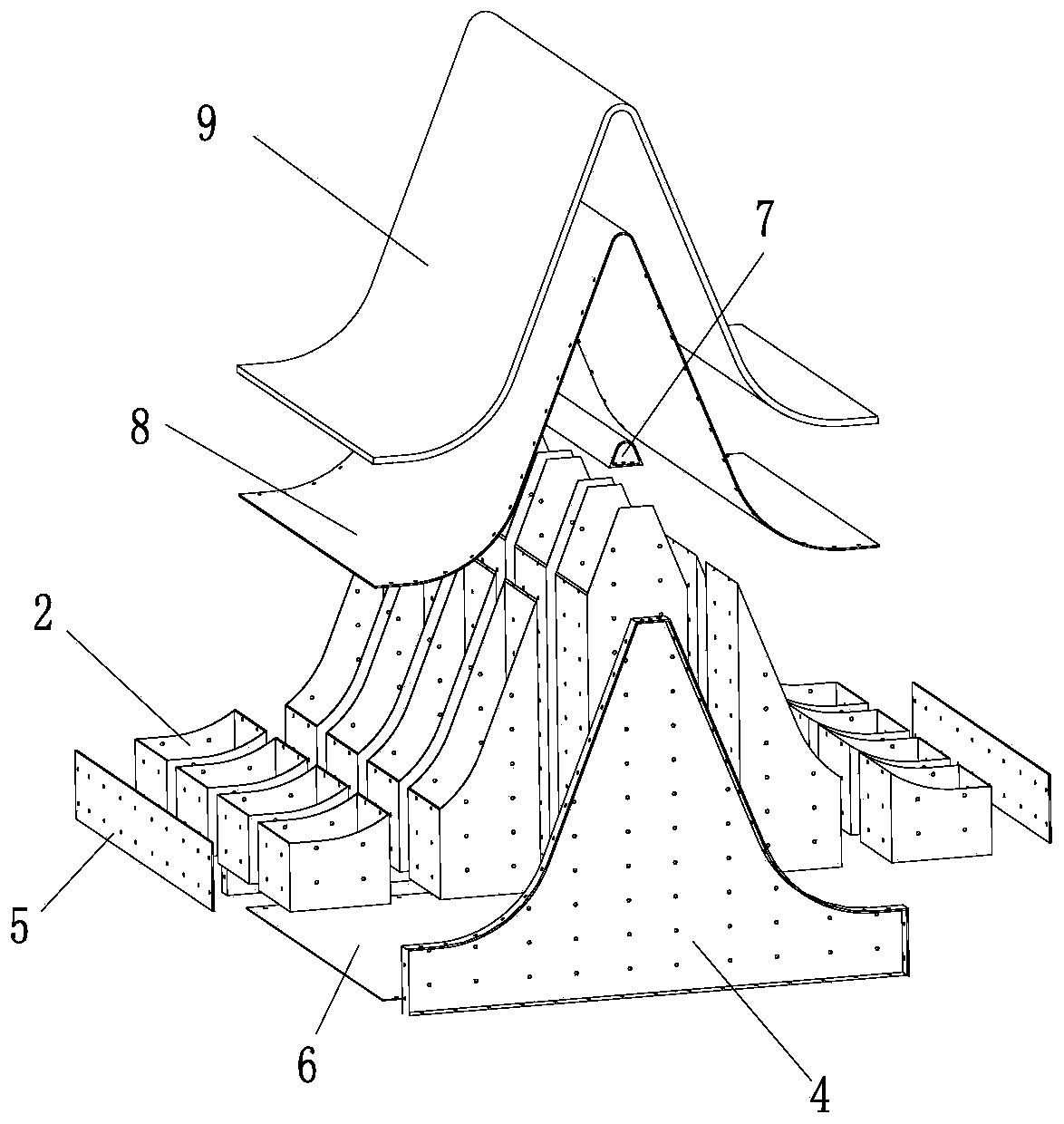

Modular forming method of deflector

ActiveCN110131076AAvoid deformationSolve the deformation problemRocket engine plantsEngineeringInternal stress

The invention discloses a modular forming method of a deflector. The method comprises the first step of forming of a splicing module, the second step of forming of an internal frame, the third step offorming of a peripheral structure, the fourth step of installation of a metal panel, and the fifth step of installation of a non-metal panel. A modularized metal pipe is adopted to construct the internal frame of the deflector for a rocket engine, the internal frame is connected with the metal panel, a bottom plate and a top cone part in a riveted or threaded more to form an integral structure through adapter connection of side plates on the periphery of the internal frame, and finally the non-metal panel and the metal panel are connected together through a bonding method. The problems of deformation and internal stress caused by welding and forming of a metal thin plate adopted in a traditional machining method of the deflector are solved.

Owner:湖北三江航天江北机械工程有限公司

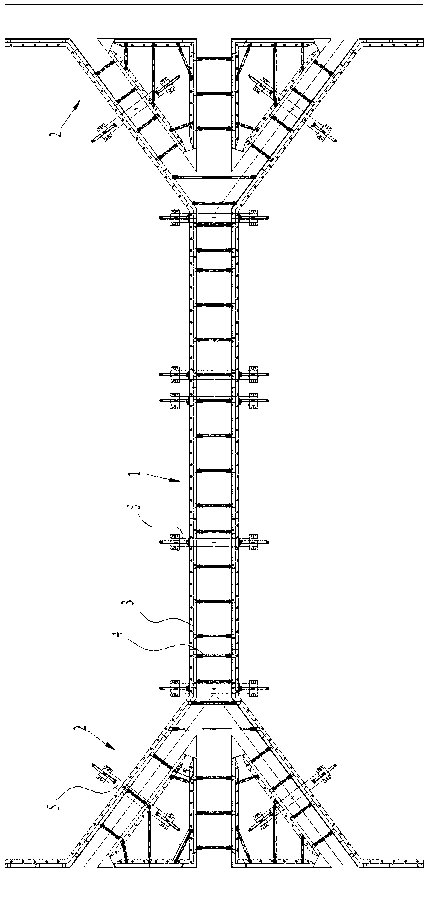

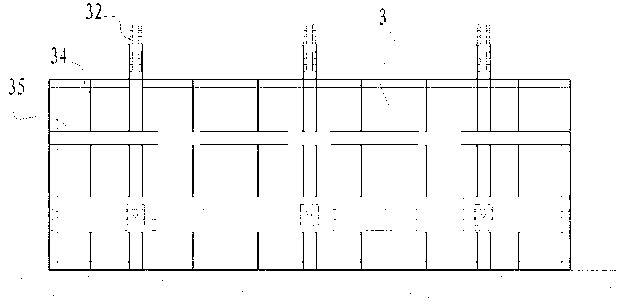

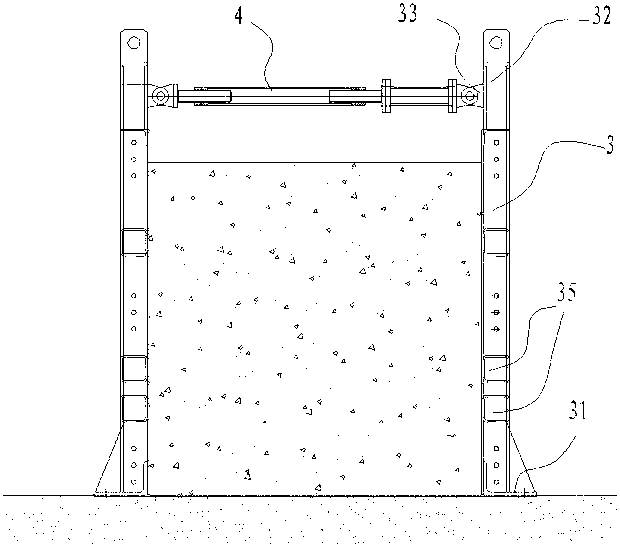

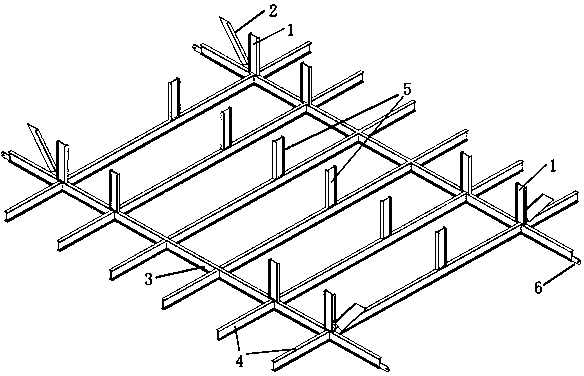

Steel template system used for subway foundation pit supporting beam

ActiveCN103276748AAvoid structural deformationEffective support and fixationArtificial islandsExcavationsStructural deformationBraced frame

The invention discloses a steel template system used for a subway foundation pit supporting beam. The steel template system comprises a main beam template and diagonal bracing beam templates, wherein the main beam template is located in the middle, the diagonal bracing beam templates are located at the two ends, the main beam template and the diagonal bracing beam templates are formed by steel templates in a parallel and opposite mode, the bottoms of the steel templates are provided with foot braces which can be locked with the ground, the oppositely-arranged steel templates are connected and supported through jack screws at the tops of the steel templates, the outer side of each steel template is provided with an outer supporting framework which can support and abut against the steel templates, each outer supporting framework comprises a portal frame and supporting rod assemblies, each portal frame is provided with a portal frame cross beam and stand columns, the supporting rod assemblies are installed on the stand columns and used for supporting the steel templates, each supporting rod assembly comprises a supporting board used for abutting against the steel templates, and a supporting rod used for adjusting the supporting board to move back and forth, each supporting board is connected to the end portion of one supporting rod, and the supporting rods are screws and penetrate through the stand columns and are in threaded connection with the stand columns. By the adoption of the technical scheme, the steel template system is good in integrality, the templates do not deform easily, fixation is firm, the supporting beam is prevented from producing structural deformation when concreted is poured, and assembly and disassembly are rapid and convenient.

Owner:GUANGZHOU JISHI CONSTR GRP +1

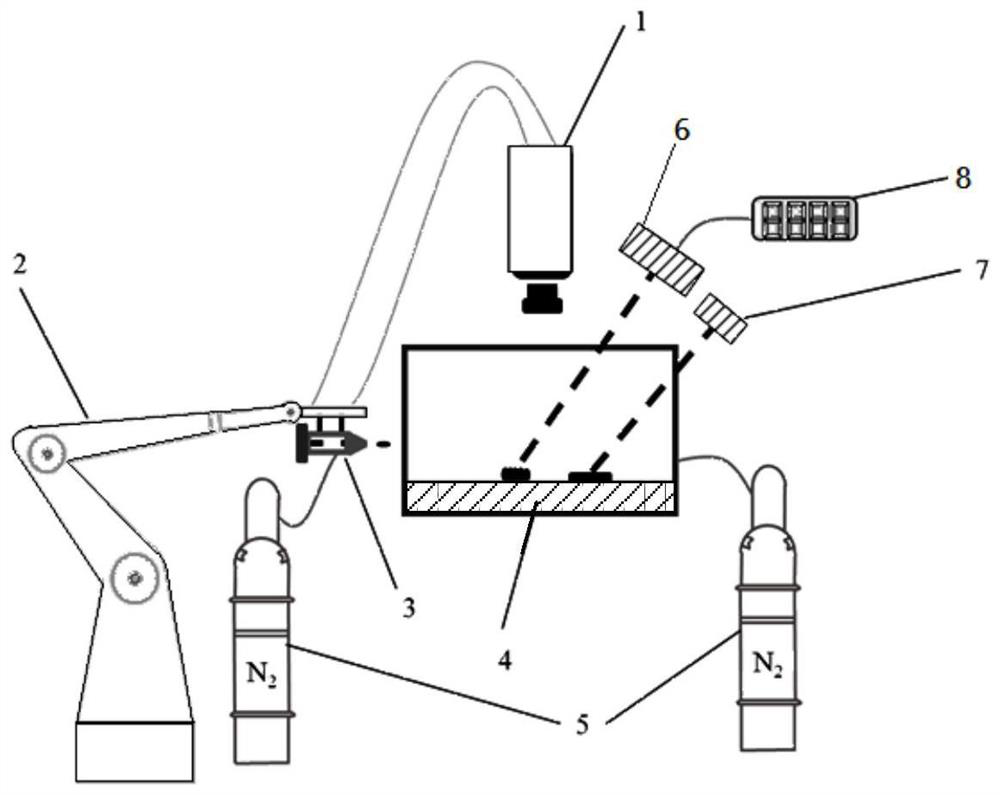

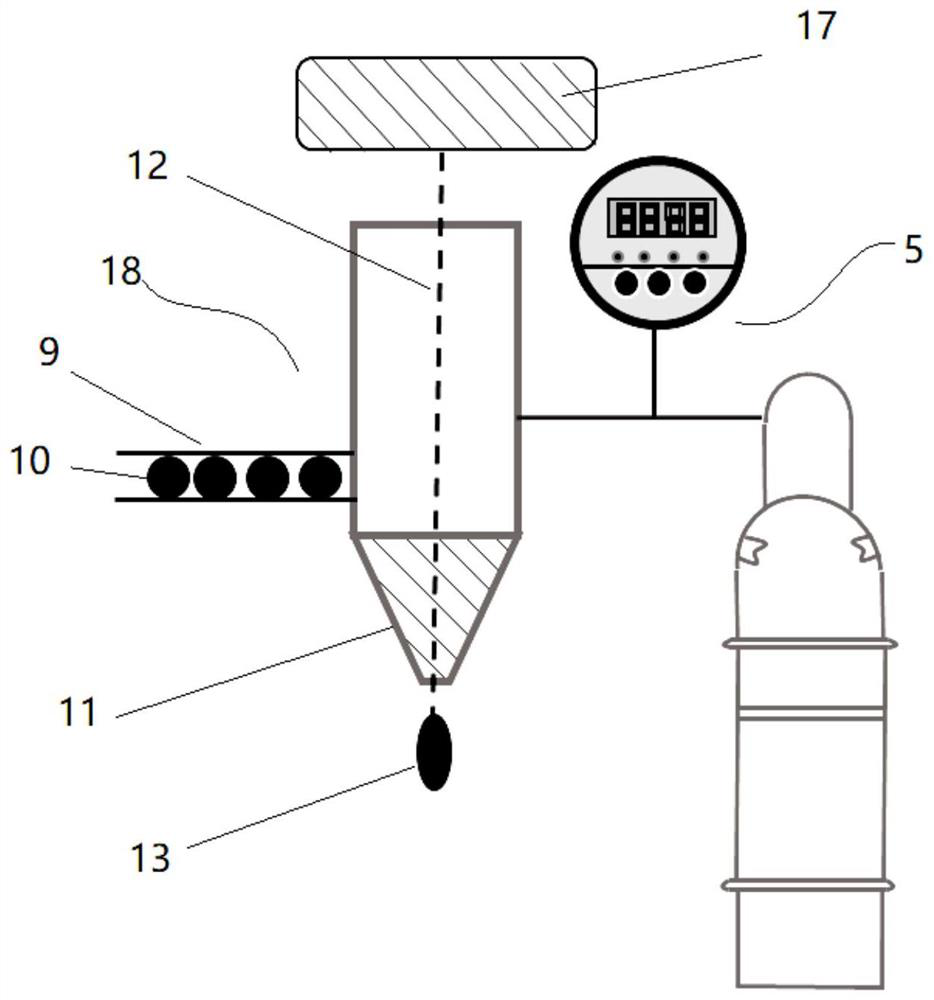

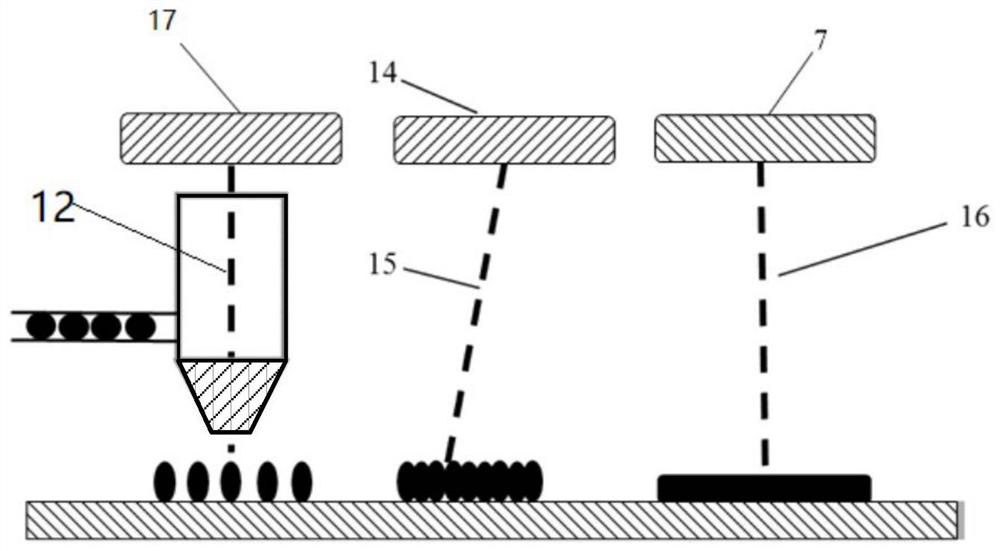

Laser welding-brazing packaging method and device for three-dimensional weld joint

ActiveCN112008178AReduce residual stressWetting and spreadingFinal product manufactureSolder feeding devicesFiller metalConnected device

The invention provides a laser welding-brazing packaging method and device for a three-dimensional weld joint. The method comprises the steps of step S1, carrying out surface treatment on a joint of ato-be-connected device, and selecting low-temperature brazing filler metal with a proper size; step S2, performing in-situ melting on the low-temperature brazing filler metal through laser melting brazing, spraying the molten brazing filler metal to the joint through high-pressure airflow, and completing preliminary connection through an auxiliary wetting and filling method; and step S3, after the brazing filler metal is sprayed, applying a second laser to heat the brazing filler metal again for secondary remelting, conducting heat preservation aftertreatment on the weld joint after a periodof time, and completing metallurgical connection. According to the technical scheme, three heating procedures are adopted to sequentially complete melting, filling, wetting and interface reaction of the brazing filler metal, and rapid low-temperature welding is achieved; and compared with traditional one-time laser welding, the method has the advantages of being more sufficient in wetting and spreading, good in weld joint integrity, high in welding performance and surface quality and low in residual stress.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

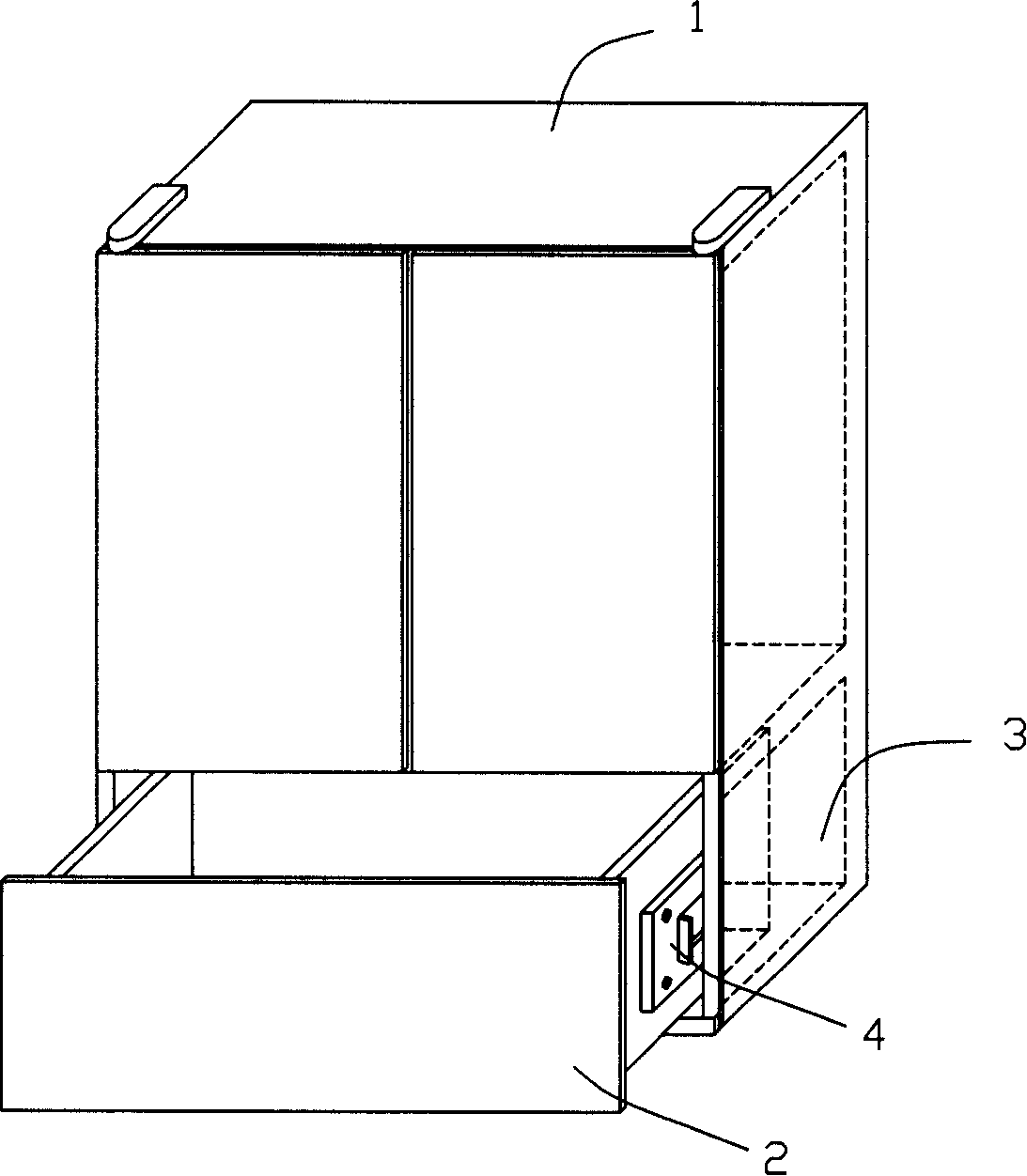

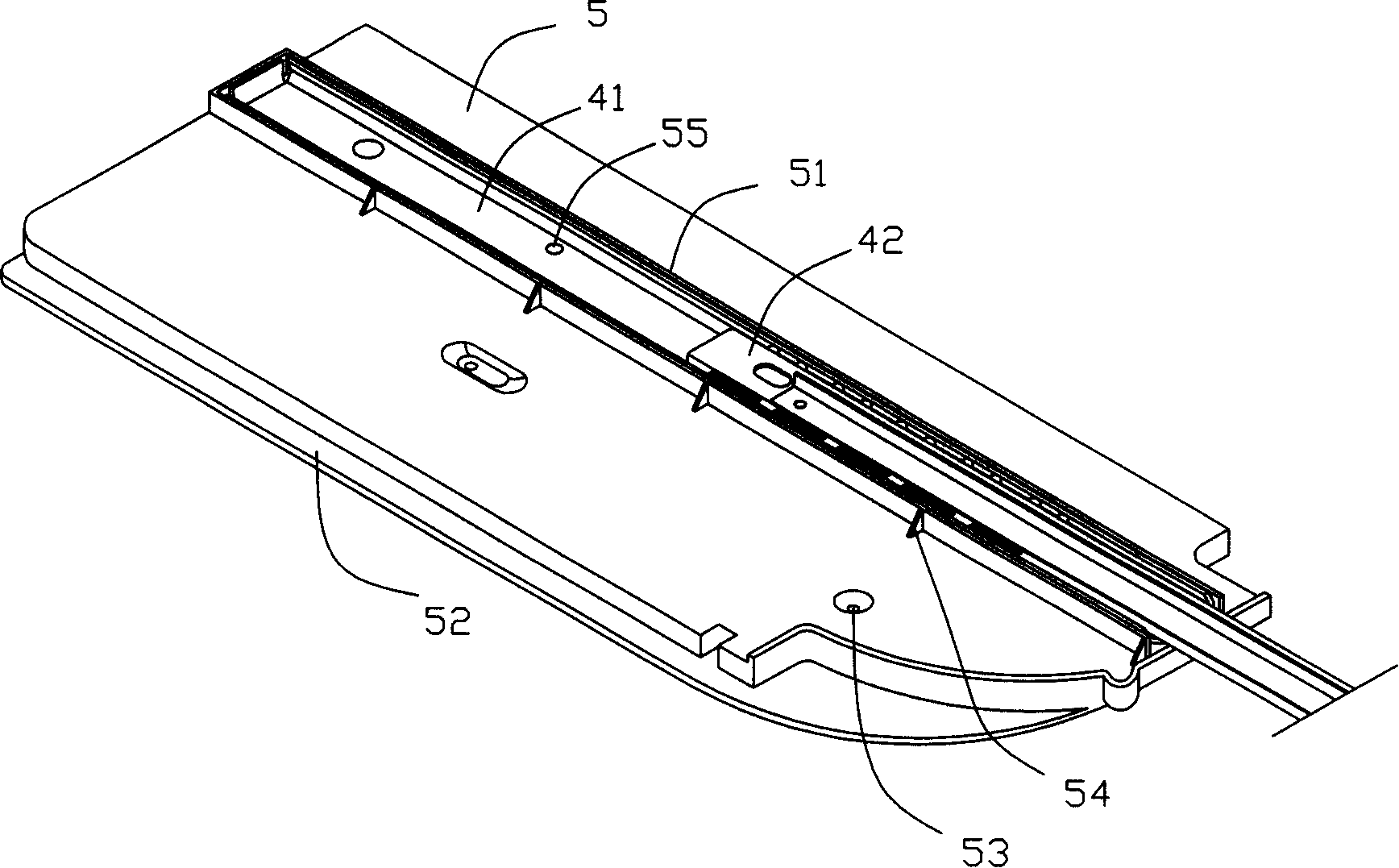

Drawer sliding rail insertion type inner wall mounting mechanism and mounting method thereof

ActiveCN101167615AGuaranteed accuracy requirementsAvoid structural deformationLighting and heating apparatusDrawersEngineeringRefrigerated temperature

The plug-in inner wall installation mechanism of the drawer slide rail and the method thereof in the present invention provide a mechanism for positioning the drawer slide rail on the inner wall of the refrigerator through a plug-in support frame, and the fixing rail of the drawer slide rail Embedded in the support frame and horizontally fixed on the inner side wall together, so as to realize the positioning and support of the drawer slide rail inside the refrigerator. The device realizes the horizontal positioning of the fixed rails on both sides of the drawer by inserting and fastening the support frame on the inner wall, meets the design accuracy requirements between the drawer and the box body, and avoids increasing the drawer’s space due to the positioning deviation of the slide rails. Push and pull resistance.

Owner:HAIER GRP CORP +1

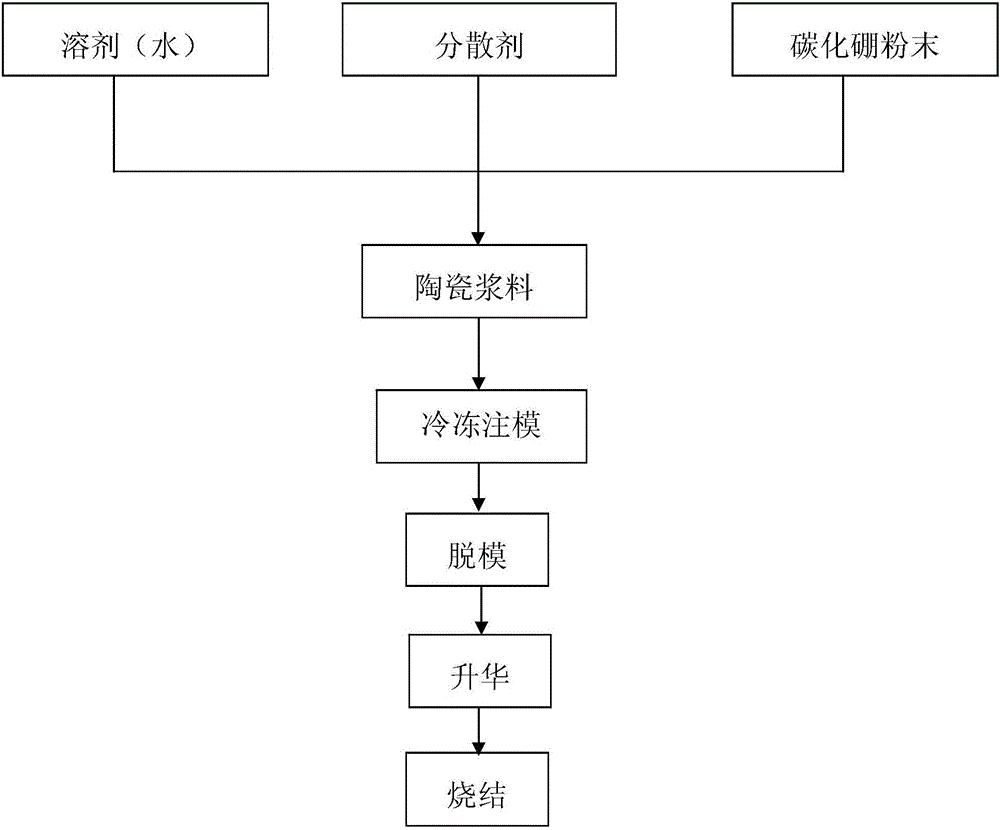

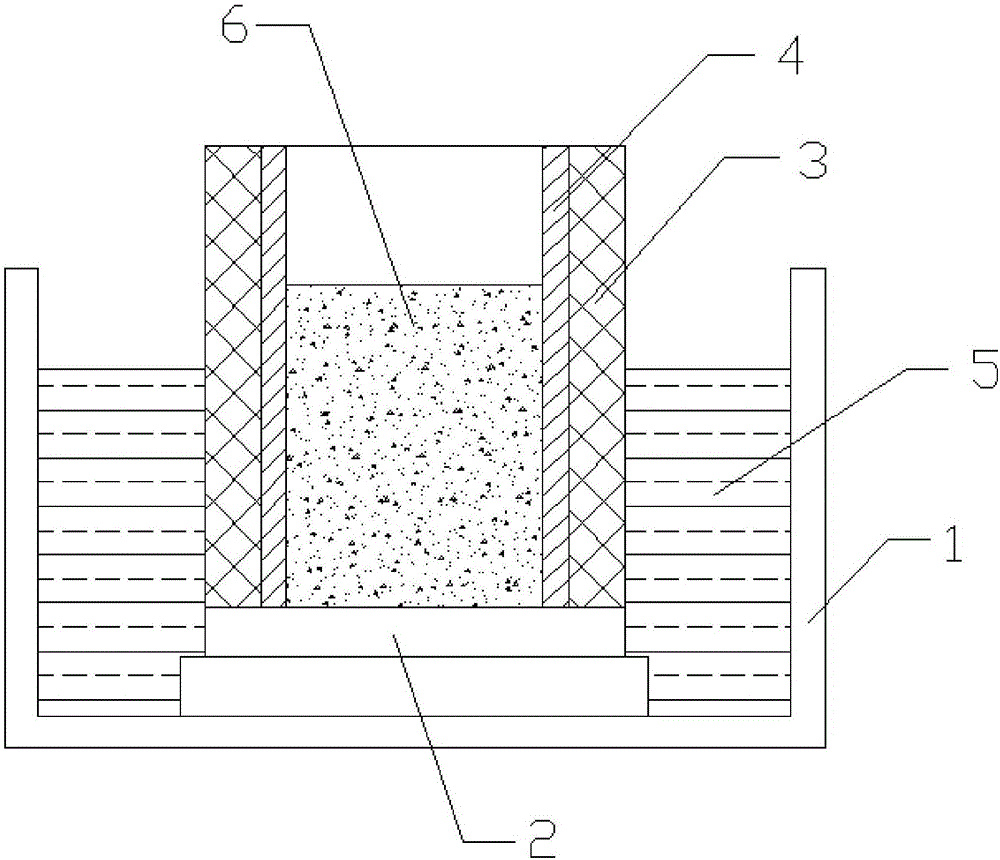

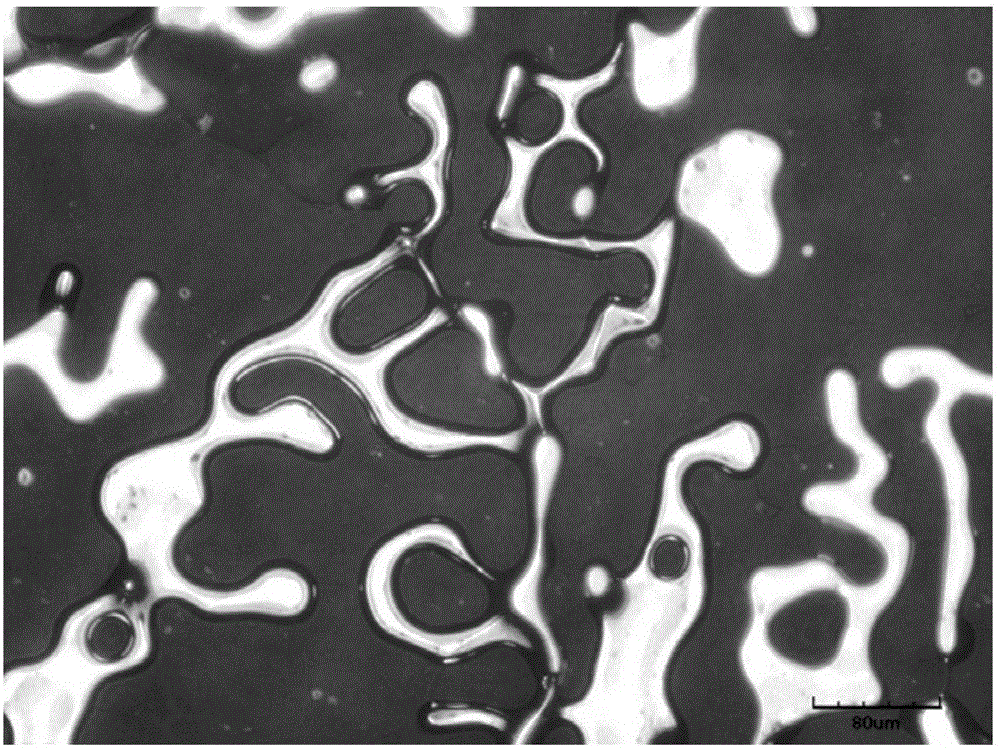

Porous B4C ceramic skeleton and freeze-casting process thereof

ActiveCN106830942AEvenly dispersedWith mechanical strengthAuxillary shaping apparatusCeramicwareAdhesiveFreeze-casting

The invention relates to a porous B4C ceramic skeleton and a freeze-casting process thereof. Porous B4C is a ceramic skeleton of B4C / Al serving as a neutron absorption material, and Al is impregnated in the B4C skeleton through an impregnation method, thereby increasing the B4C ceramic content in the B4C / Al structure and improving the neutron absorption capability. The B4C ceramic skeleton for Al impregnation is prepared through the following steps: taking different B4C particles respectively having particle diameters of 5 mu m, 10 mu m, 20 mu m and 40 mu m, selecting water as freeze-casting solvent, mixing according to mass percents, adding a proper amount of dispersing agent and adhesive, freezing, sublimating to obtain a B4C ceramic body, and sintering at 2000 DEG C. The B4C ceramic skeleton provided by the invention is moderate in strength and high in B4C ceramic content, has a favorable through hole structure, and can tolerate pressure produced in the Al impregnation process; the preparation process is simple; and the increase of the B4C content can greatly improve the neutron absorption efficiency of the B4C / Al.

Owner:镇江纽科利核能新材料科技有限公司 +1

Touch display panel and repairing method thereof

ActiveCN108459777AIncrease film thicknessAvoid failureInput/output processes for data processingComputer scienceRepair method

Owner:AU OPTRONICS CORP

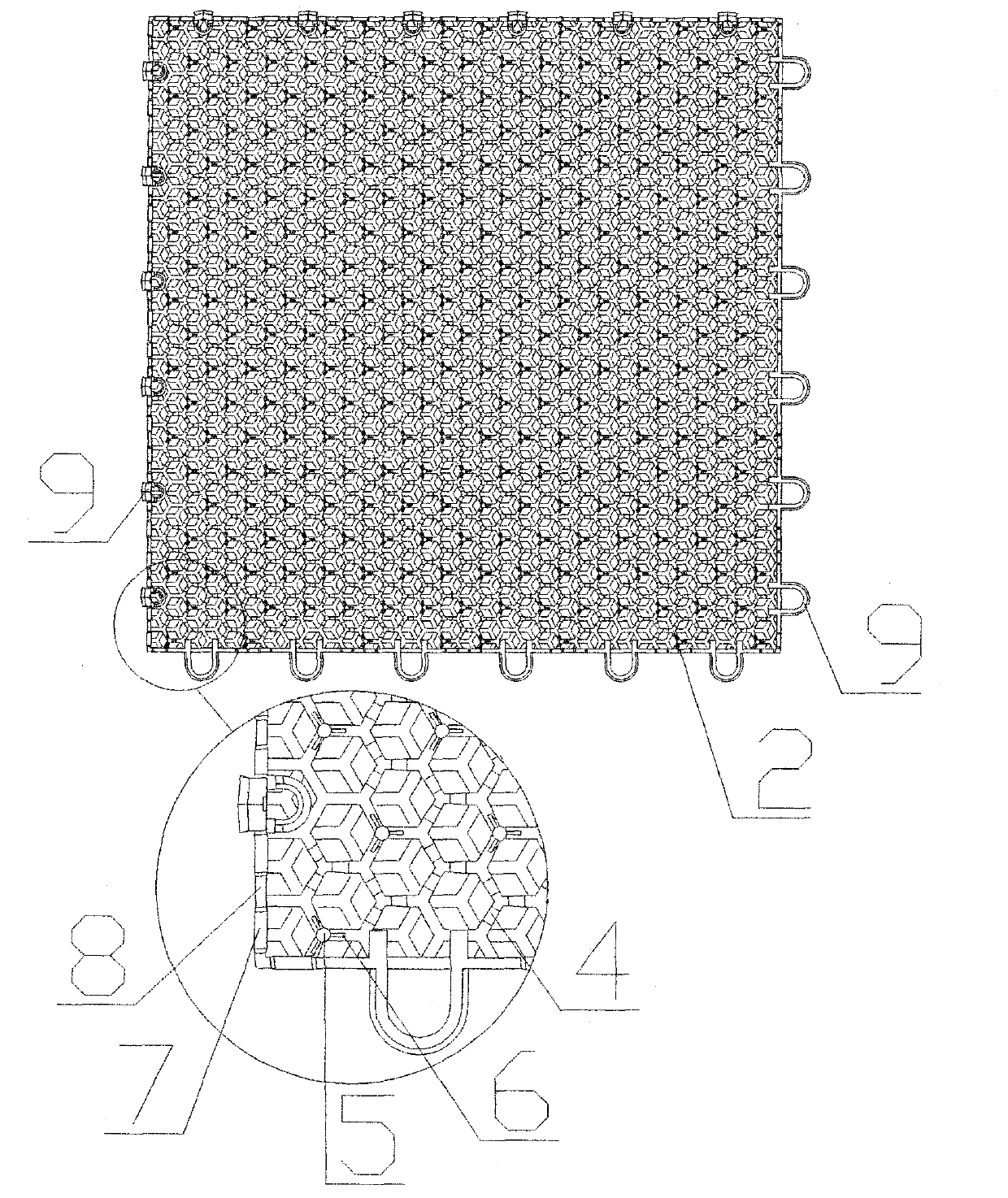

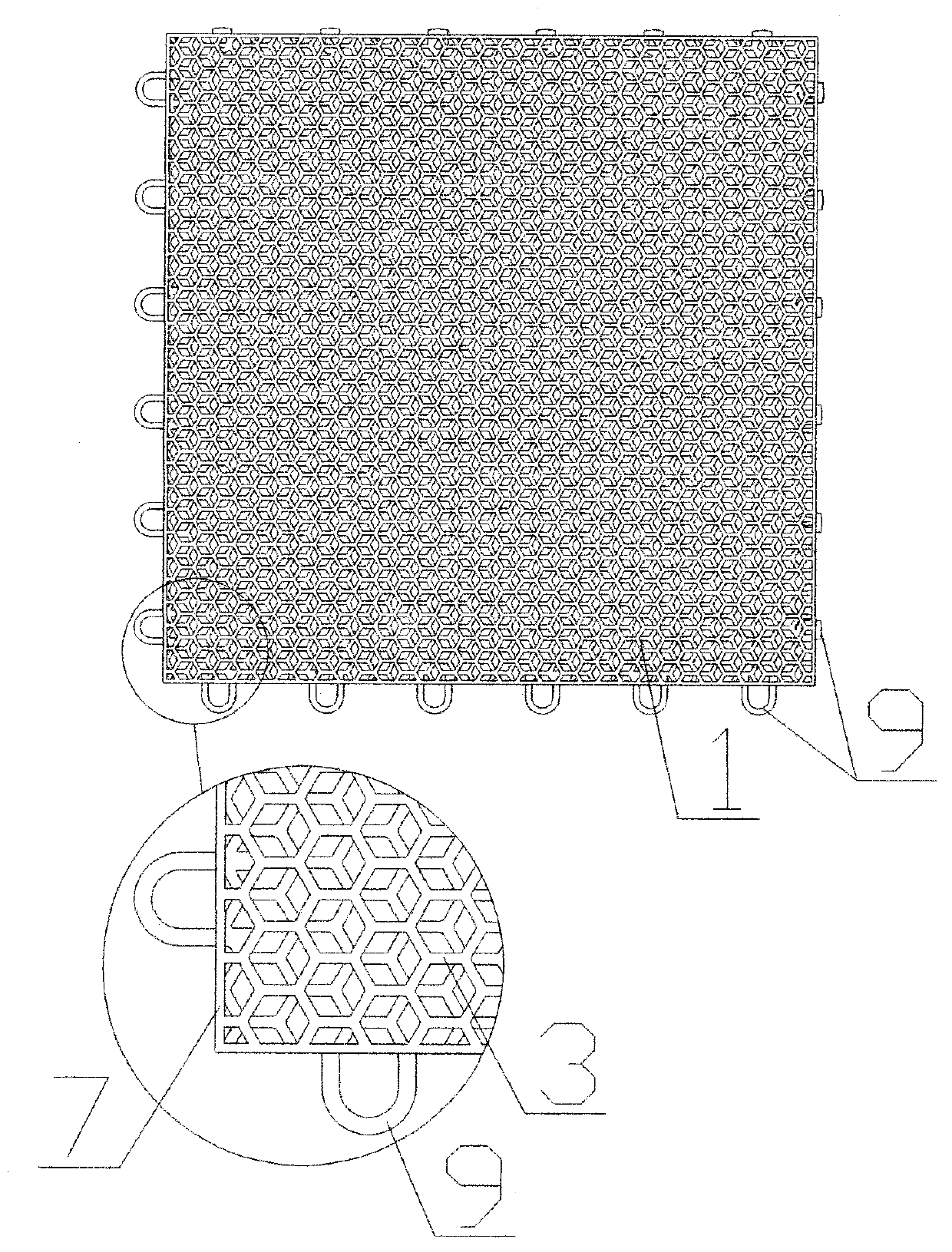

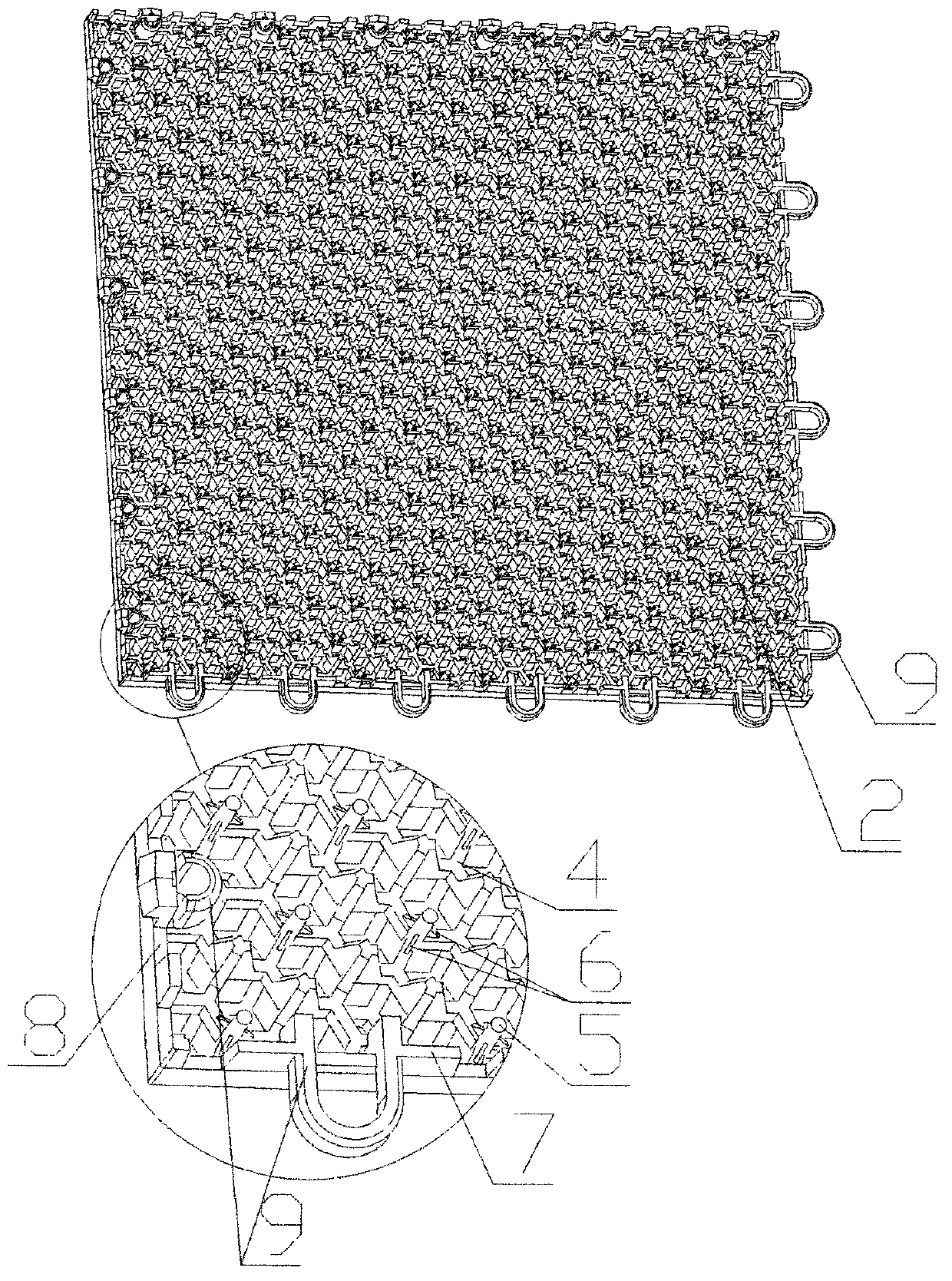

Assembled floor

Owner:余德辉

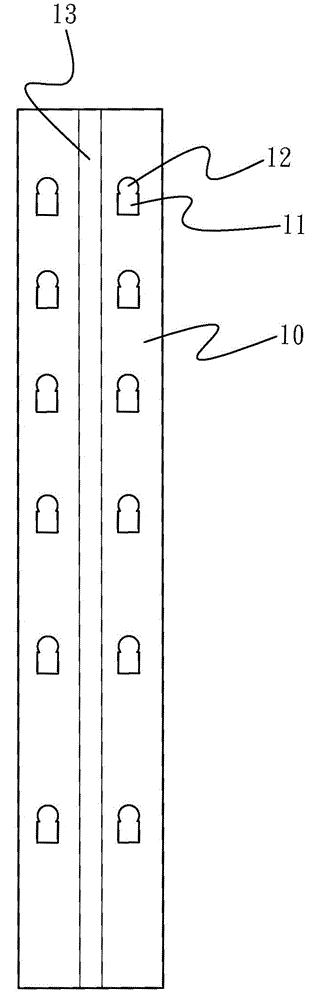

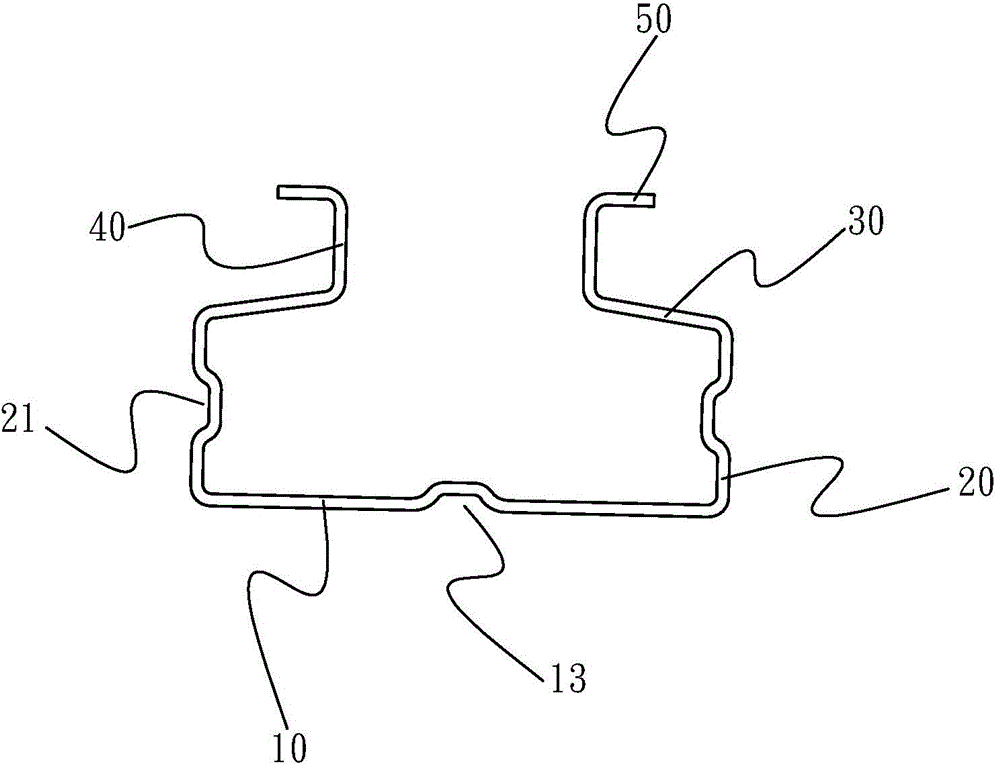

Novel hole-pattern heavy-duty goods shelf stand column and manufacturing method thereof

InactiveCN104590797AIncreased load-bearing capacityImprove structural stabilityStorage devicesEngineeringHeavy duty

The invention provides a novel hole-pattern heavy-duty goods shelf stand column and a manufacturing method of the novel hole-pattern heavy-duty goods shelf stand column and belongs to the technical field of machinery. The novel hole-pattern heavy-duty goods shelf stand column solves the problem that an existing heavy-duty goods shelf stand column is poor in bearing capacity. The novel hole-pattern heavy-duty goods shelf stand column is provided with a stand column body, two oppositely-arranged first connecting parts, two second connecting parts and two clamping parts, wherein the edges of the two sides of the stand column body extend in the same direction to form the two first connecting parts; the sides, away from the stand column body, of the first connecting parts extend to form the two second connecting parts; the sides, away from the stand column body, of the second connecting parts extend in the same direction to form the two clamping parts; the stand column body is provided with at least one column of hook hole group arranged in the vertical direction; the distances between the adjacent hook hole groups gradually decrease from bottom to top; each hook hole group comprises a first hook hole and a second hook hole located over the first hook hole; each clamping part is provided with a column of plug pin holes arranged vertically, and the distances between the adjacent plug pin holes gradually decrease from bottom to top. The novel hole-pattern heavy-duty goods shelf stand column is simple in structure and high in bearing capacity; the manufacturing method is simple in procedure, and the production cost is saved.

Owner:NINGBO CITY XINGUANG SHELF

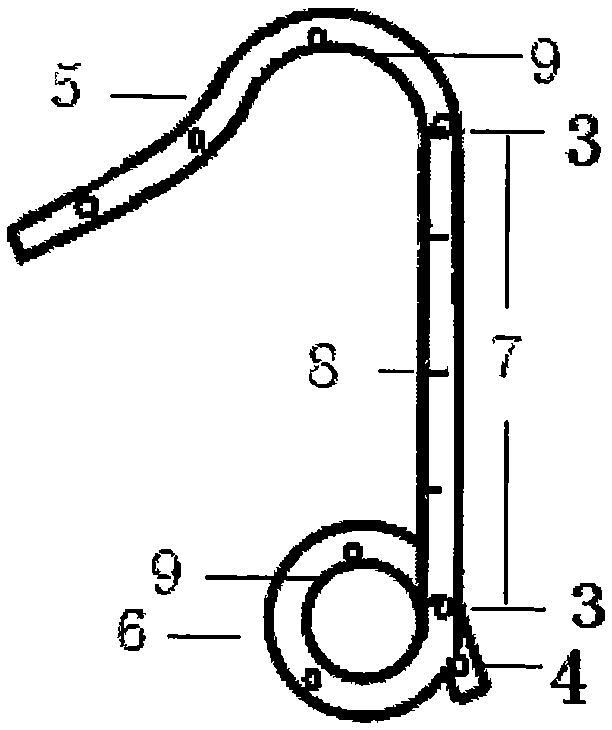

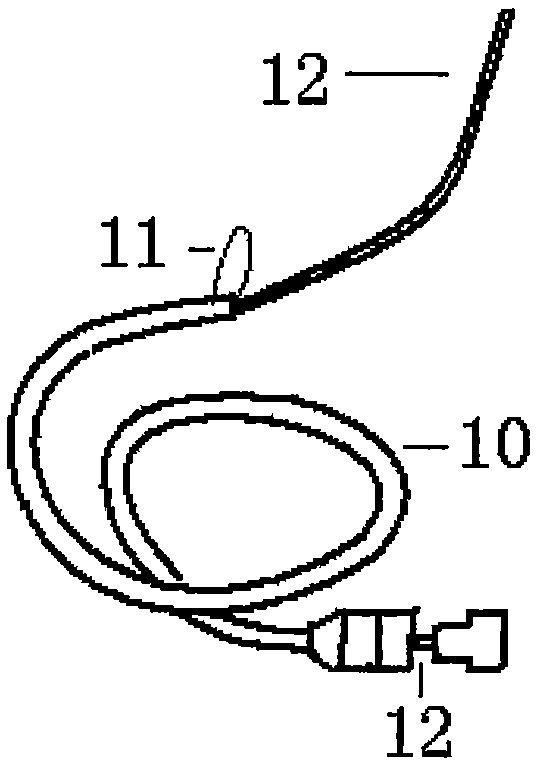

Integrated cobra-shaped biliary stent

The invention provides an integrated cobra-shaped biliary stent comprising a biliary stent body, a stent push pipe, a stent guiding pipe, and a stent protection casing pipe. The stent guiding pipe passes through the stent push pipe and the biliary stent body successively to connect a loop and a through hole pedestal into one. The stent protection casing pipe sleeves the top ends of the biliary stent body and the stent push pipe to protect the stent structure before usage. The biliary stent body is in an oblique S shape, the other end of the biliary stent body is in a shape like alpha, and the middle part of the biliary stent body serves as a drainage segment. Under guidance of a guide wire, the integrated biliary stent can pass through a choledochal duct cut, a T-shaped pipe sinus tract, and a percutaneous transhepatic biliary puncture sinus tract successively and then enters a biliary drainage part in a direct motion manner or can be placed into a biliary drainage part through a duodenoscope in a retrograde motion manner. The stent can fall automatically. Different stent drainage time can be obtained by selecting S-shaped structures with different radians according to clinic demands; and on the basis of the special S-shaped structure of the stent, a phenomenon that pancreatitis is caused because of pressing at a pancreiatic duct opening when the stent is discharged out of the biliary duct can be avoided.

Owner:田明国 +1

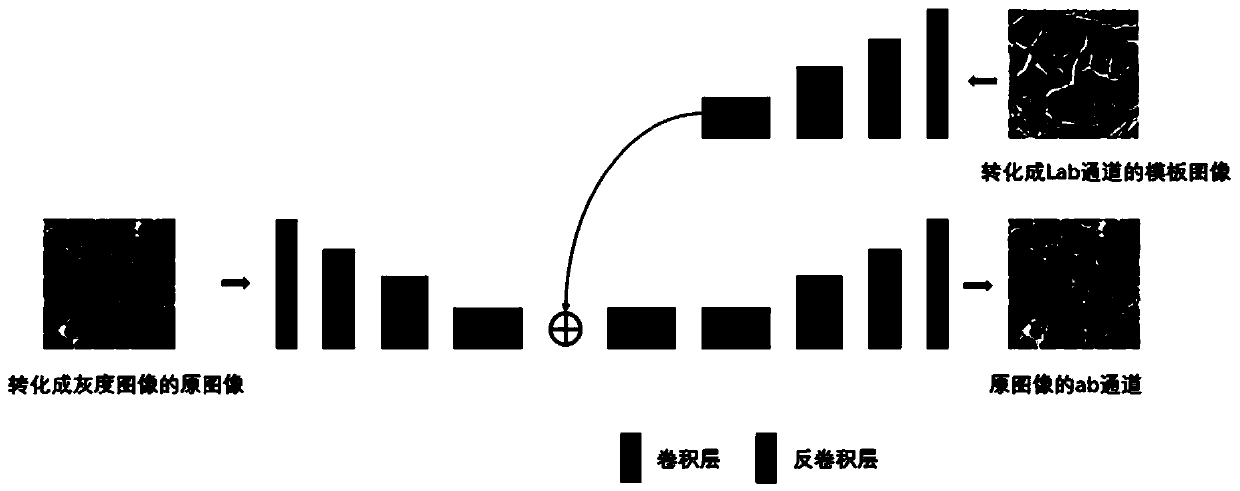

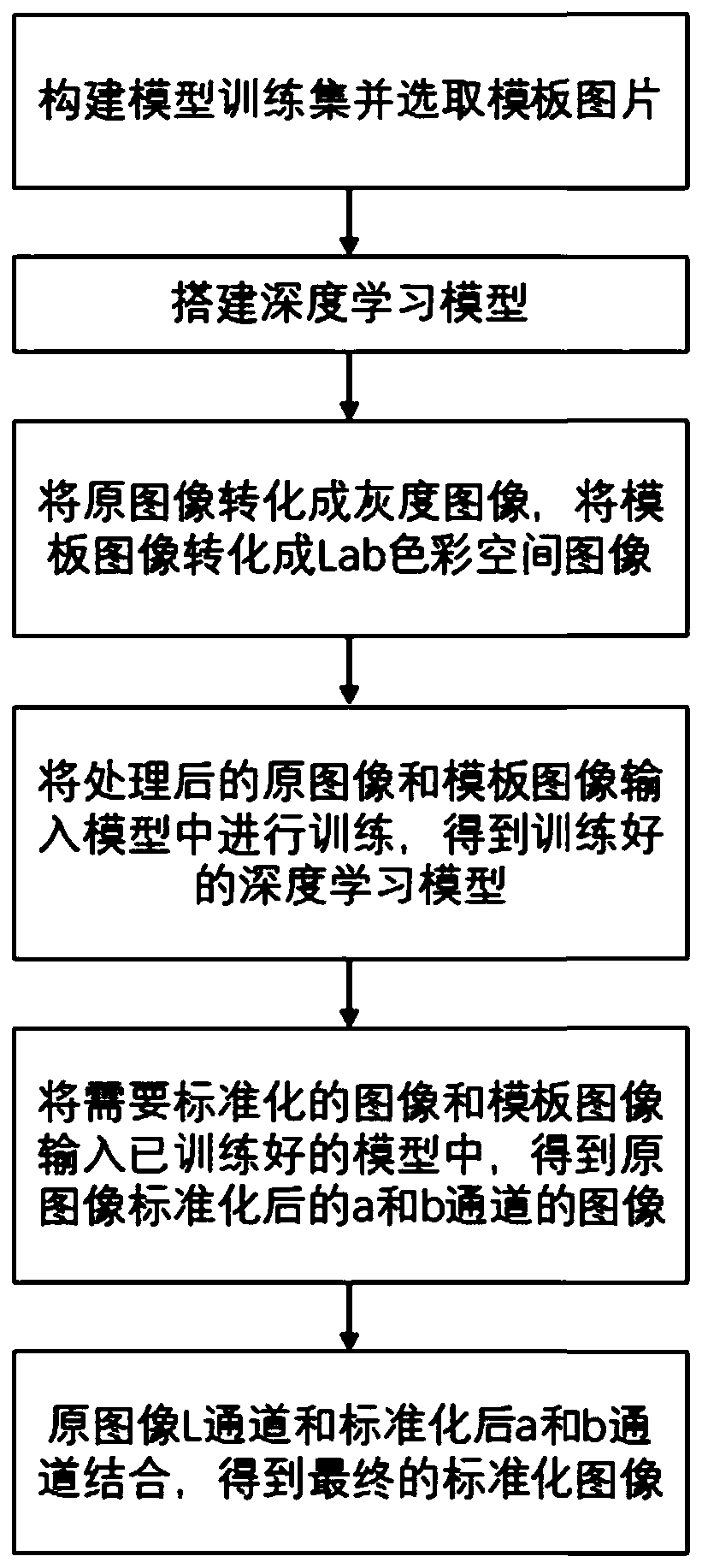

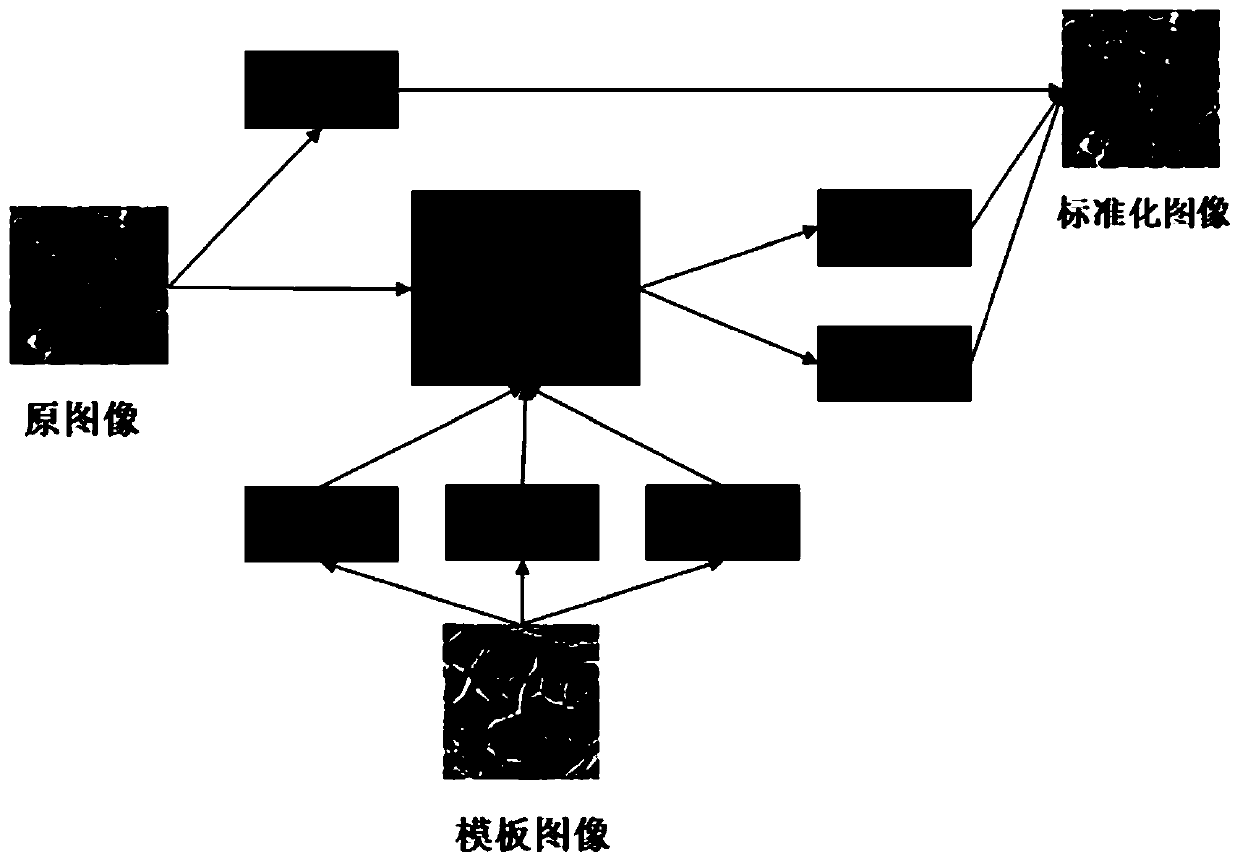

Pathological image color standardization method with invariable structure based on deep learning

ActiveCN111476857AAvoid structural deformation problemsStrong learning abilityImage enhancementImage analysisLab color spaceDeep learning

The invention discloses a pathological image color standardization method with an invariable structure based on deep learning. The method comprises the following steps: constructing a model training set; selecting an image with excellent dyeing quality from the training set as a template image, and taking other images as original images; building a deep learning model; inputting the grayscale image of the original image and the Lab color space image of the template image into a network, and training a deep learning model to obtain standardized a and b channel images; and combining the L channel of the original image with the standardized a and b channels to obtain a standardized RGB channel image. According to the method, a deep learning model is combined with an automatic coloring principle, the color style of an original image is converted into the color style of a template image by utilizing the structure information of a gray level image and the color information of the template image, and color standardization of a pathological image is realized.

Owner:GUANGDONG GENERAL HOSPITAL

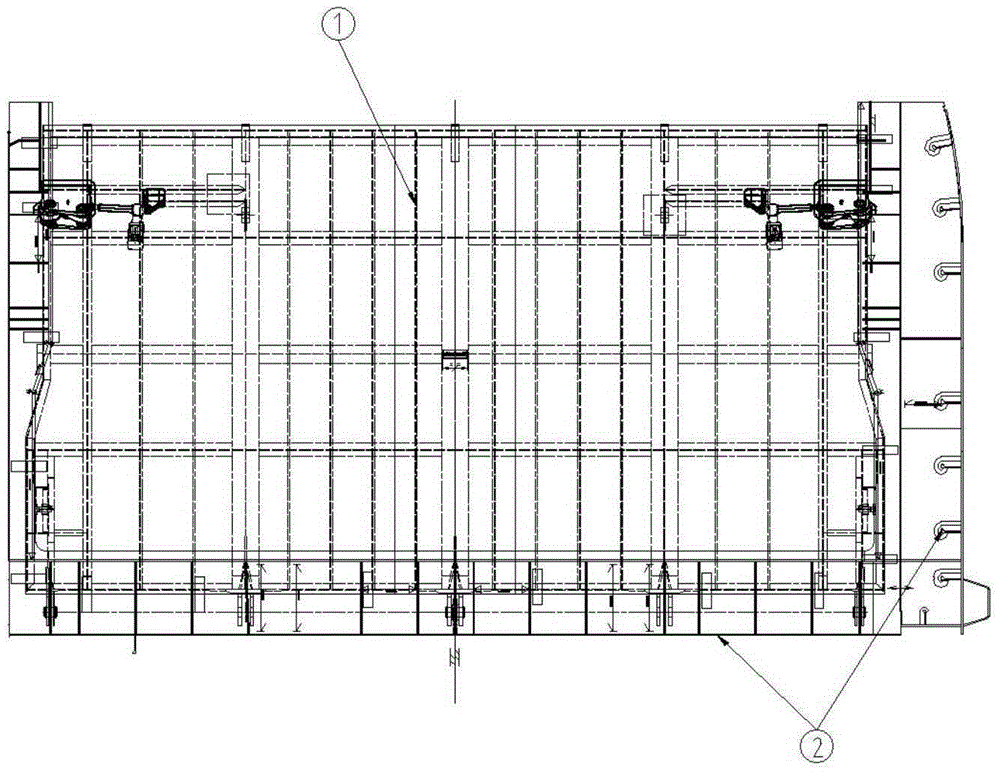

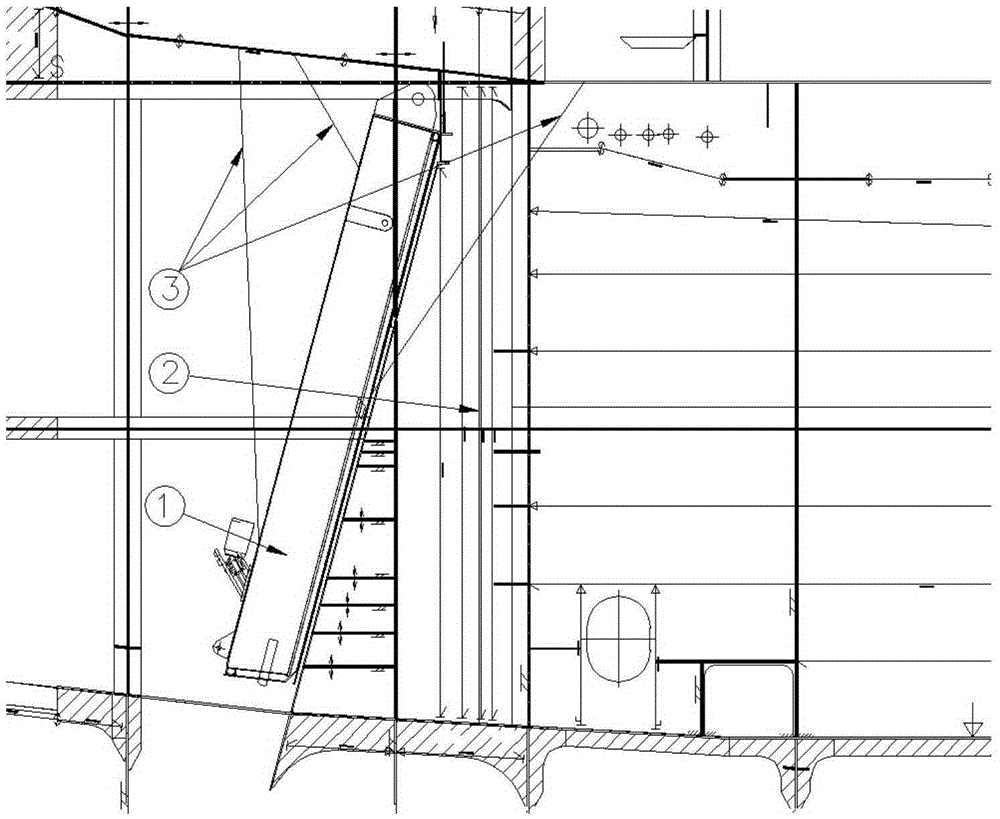

A method for conformal construction of a full-width type structure section of a naval ship

ActiveCN109080769AExpand the scale of constructionAvoid structural deformationVessel partsStructural deformationEngineering

The invention discloses a conformal construction method of a full-width type structure section of a warship, which mainly comprises the inverse construction of a left section and a right section. A left section and a right section are normally lif to a section bracket, and are combined on that section bracket to form a full-width structure section; Fix sectional inner wall panels, sectional outfitting and L-shaped stiffener panels; The steps of hoisting the section bracket with full-width structural segments to the final assembly area. The present invention is a section which can only be constructed in reverse state before, a scheme which can be constructed normally is provided, but also provides a full-width construction option for segments previously constructed only in half-width form,The method also changes the transportation form of the full-width structure segments which can only be transported in reverse state, so that the sections can be transported in a normal state, the structural deformation produced in the process of lifting, turning over, shelving, painting and the like of the sections is avoided, the construction scale of the sections is enlarged, and the pre-outfitting rate of the sectionss is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

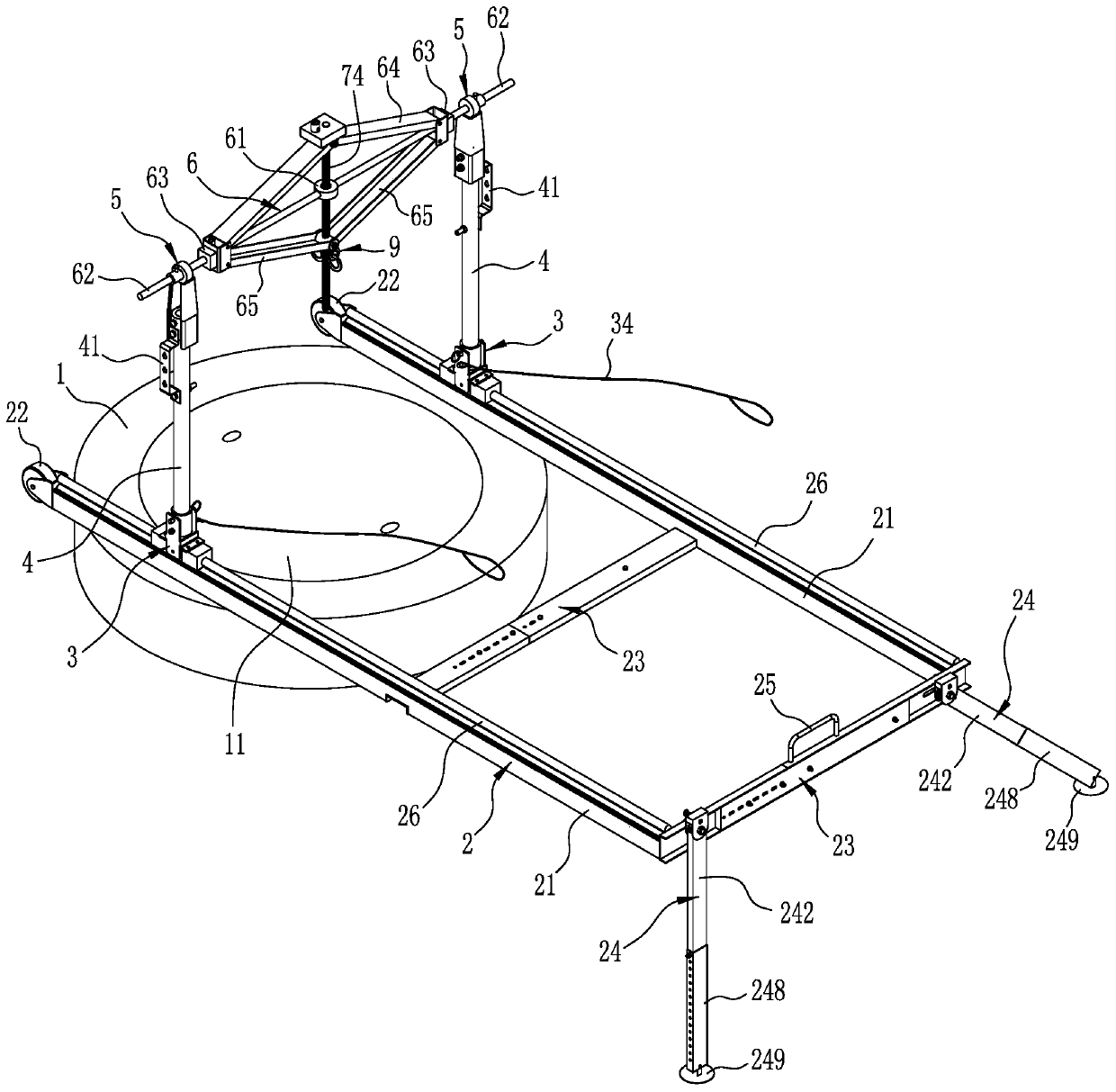

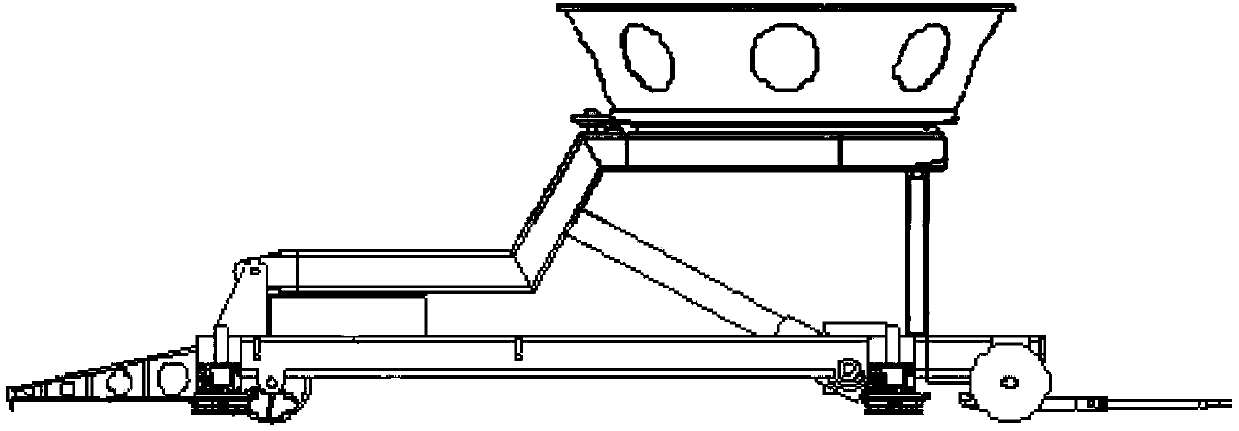

Cantilever type multi-axis turntable for posture adjustment of spacecraft

ActiveCN107775611AOpenabilityMeet assembly needsWork benchesMetal-working hand toolsReachabilityEngineering

The invention discloses a large-span cantilever type triaxial posture adjustment turntable for a spacecraft. The turntable comprises a supporting platform, an omnibearing travelling wheel system, a lifting system, an overturning system and a rotating mechanism, wherein the inner side of a C-type ring of an overturning rack is connected with the outer side of a rotating ring through a roller combination, the inner side of the C-type ring surrounds the outer side of the rotating ring, the rotating ring is adjusted to be in a proper assembling, testing or experimenting state, the spacecraft is locked dead by a locking device of the rotating ring, and then related working items of the spacecraft are carried out. According to the invention, opening assembly requirements of embedded products such as a high-thrust engine and the like as well as products such as narrow space pipes and the like of the spacecraft are met, reachability and convenience of operation are achieved, and the problem ofstructural deformation in the large-span and large-mass load cantilever state is solved.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

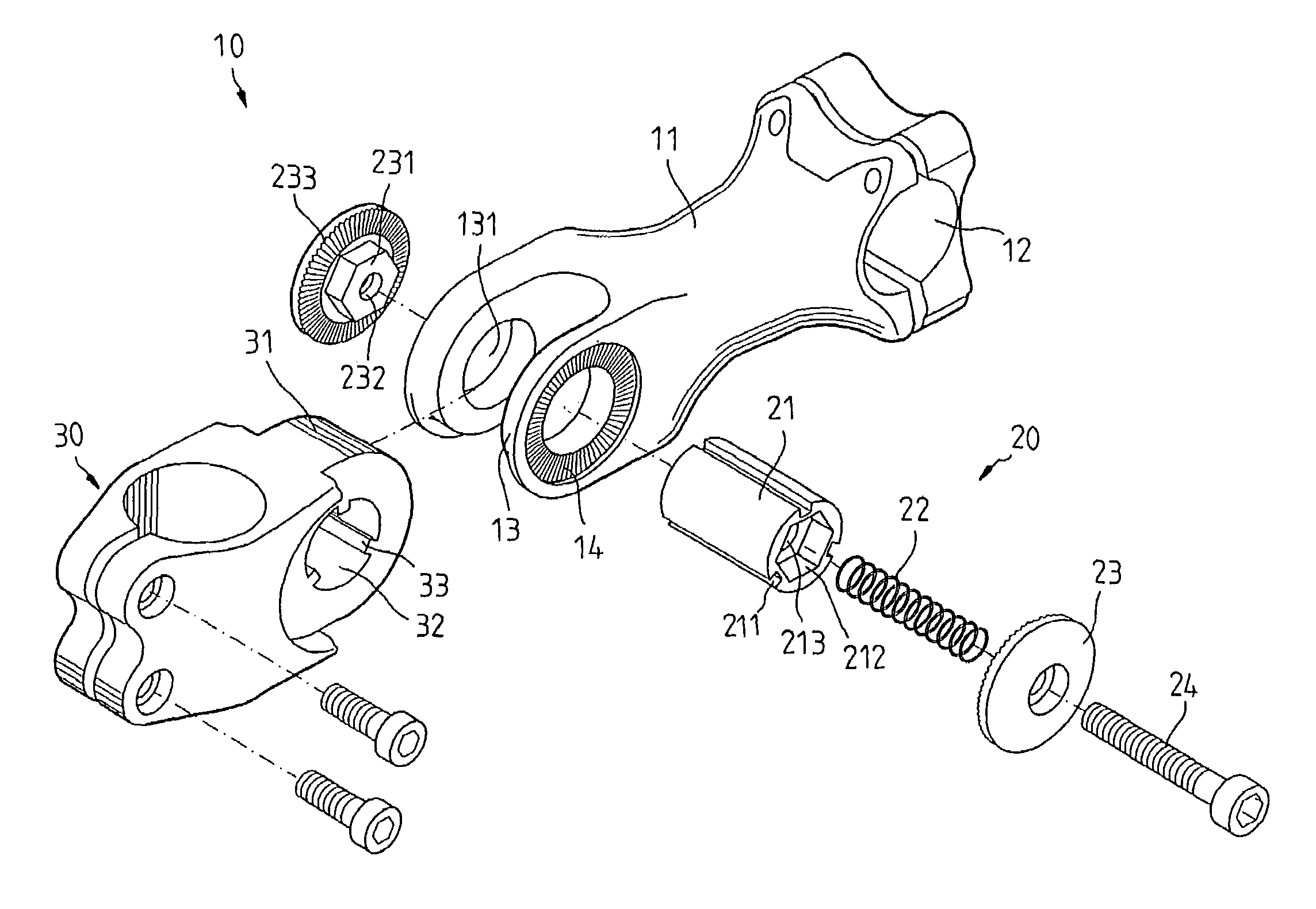

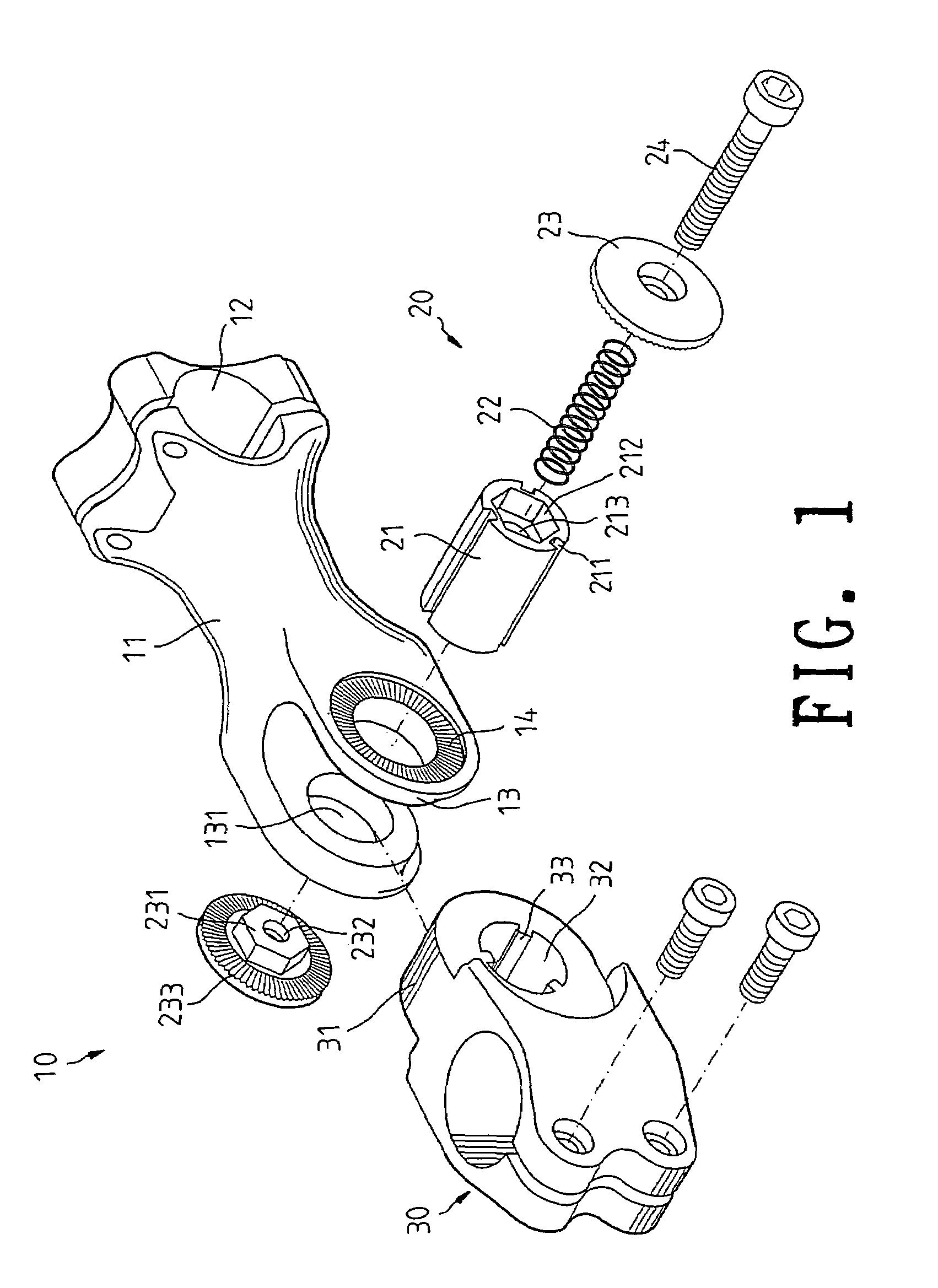

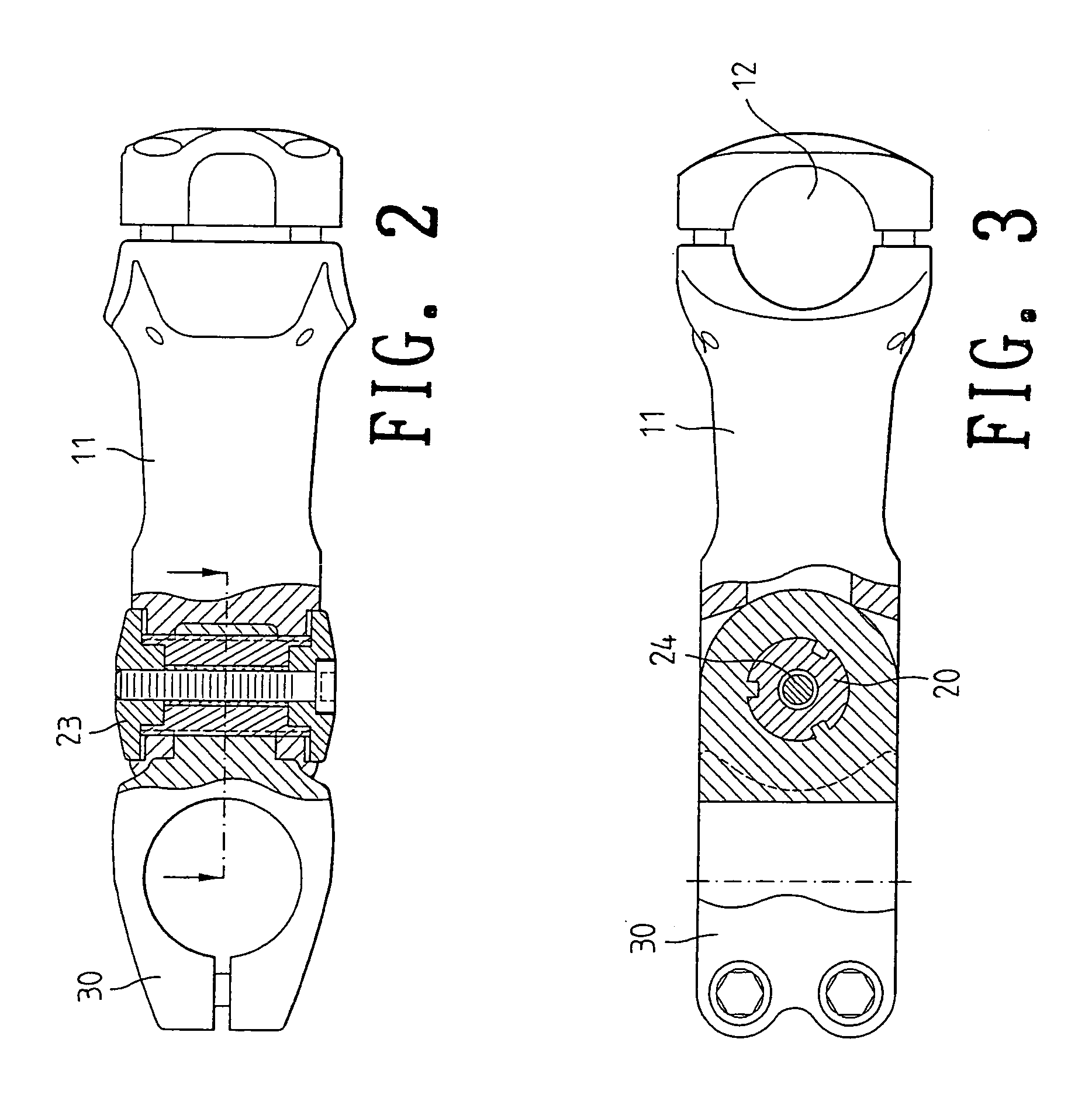

Stand tube of a bicycle

ActiveUS7437970B2Stable structureAvoid structural deformationMechanical apparatusSteering deviceEngineeringMechanical engineering

A stand tube of a bicycle comprises a body; one end of the body formed with a U shape ear; each leg of the U shape ear having a pivotal hole; a head having one end formed with a round portion; the round portion having a transversal penetrating hole; a buckling unit having a pivotal unit; a receiving hole penetrating through the buckling unit; the buckling unit passing through the two pivotal holes and the penetrating hole; two buckles; one surface of the buckle being protruded with a protrusion; and a screw unit received in the receiving hole of the pivotal unit; the teeth of two buckles being then engaged to the teeth portion of the U shape ear and the two protrusion being received into the pivotal hole. By above assembly, the stand tube of a bicycle has a rigid and firm structure.

Owner:CHEN CHAO HU

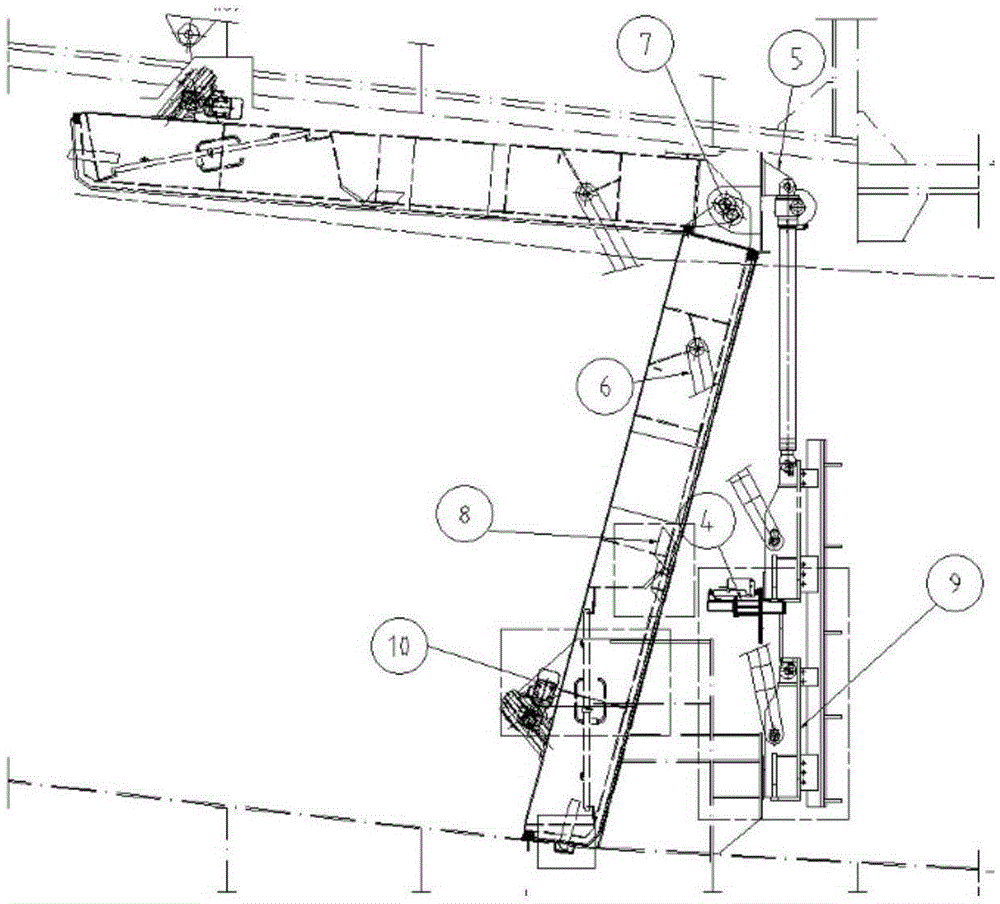

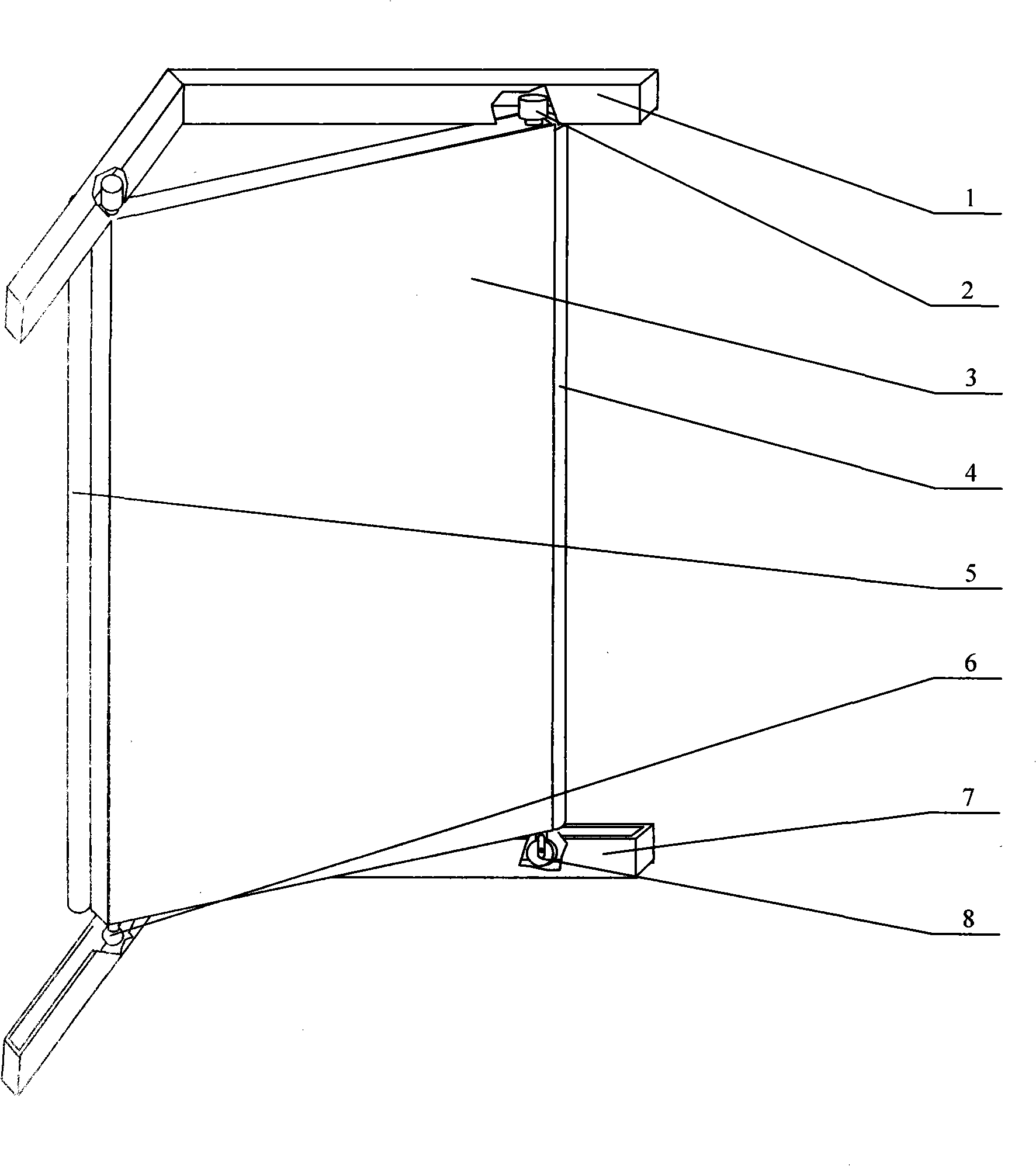

Installation method of large watertight door

ActiveCN105346686APrevent structural deformationSave installation timeWatertight door arrangementsHinge anglePre embedding

The invention relate to an installation method of a large watertight door. The installation method includes the steps that when a section is in a reverse total-assembly, the flatness, the center line and an installation reference line of a block door frame are marked; the watertight door is pre-embedded in the section in a reversely assembled manner to be restrained and fixed and carried by a block to be arranged on a ship; after block carrying and electrowelding submitting are finished, the watertight door is installed, and a hinge, an electric oil cylinder, a locking device and other accessories are located; and finally stainless steel pressing strips are installed. By means of the installation method, the feature of the total-assembly carrying stage of ship building is utilized to the maximum extent, the installation workload of the watertight door is lowered to the minimum, and the installation precision and quality are improved greatly; and by means of the installation method, the labor cost can be lowered greatly, and the influences on installation of the watertight door in different stages of ship building can be avoided.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

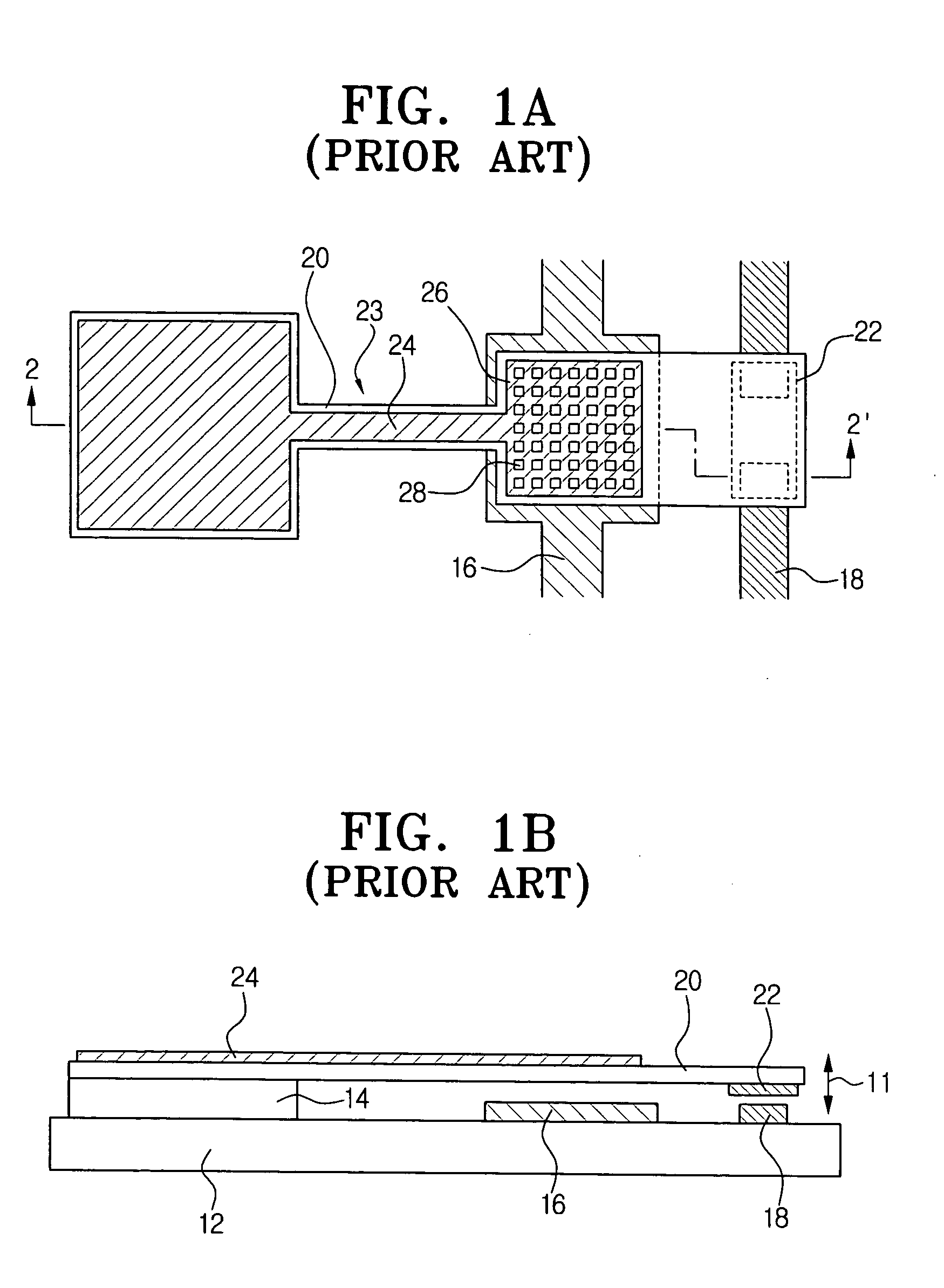

Shaftless edge tangential-rotating door

InactiveCN101571023AUnique way to openSimple structureWing arrangementsStructural deformationRemote control

The invention discloses a shaftless edge tangential-rotating door, which relates to a rotating door without a door shaft. An upper rail 1 corresponds to a ground rail 7. The upper rail and the ground rail are respectively formed by two straight section parts which are respectively provided for the outer side of a door leaf 3 to move tangentially or for the inner side of the door leaf 3 to move horizontally, wherein the two straight section parts keep the identical included angles. The door leaf 3 moves horizontally and slides inwards simultaneously along the upper rail 1 and the ground rail 7, the opening method is unique, the structure is simple, the installation is convenient, the construction cost is low, the opening and the closing are flexible and labor-saving, the load bearing is balanced, the maintenance is facilitated, the structural deformation is avoided, the labor intensity is reduced, the time for installation and work is effectively reduced when the shaftless edge tangential-rotating door is used as a garage door, the civil engineering investment is saved, the wind resistance function is obvious, no external space is occupied, a vehicle can be caused to turn at the same time of leaving, the vehicle line haul hour is saved, and the shaftless edge tangential-rotating door is particularly suitable to be used for a firefighting and redeployment garage. In addition, according to the need, the shaftless edge tangential-rotating door can be additionally provided with an electric device, a remote control device and the functions of preventing thieves, breaking and bullets.

Owner:马利娜

Re-jacking reinforcing structure for post-cast belt cantilever and construction method of structure

PendingCN109457952ASimple processStrong maneuverabilityForms/shuttering/falseworksSteel tubeStress change

The invention discloses a re-jacking reinforcing structure for a post-cast belt cantilever and a construction method of the structure. The structure can solve the problems that since traditional re-jacking modes of post-cast belt cantilever structures most adopt steel pipe scaffolds for supporting, re-jacking cannot be carried out in a rear casting belt area in time or in place after original full-grounded supporting scaffolds are dismantled, correspondingly the stress change of a cantilever end of a beam plate is caused, and even a plate surface is cracked because of uneven settlement of thecantilever beam plate. The structure comprises a PVC pipe, concrete, wood strips and a rotating sleeve, wherein concrete is poured into the PVC pipe; the upper and lower ends of the PVC pipe are fixedthrough the wood strips; the rotating sleeve sleeves the middle of the outer wall of the PVC pipe; a joint is welded to the middle of the side wall of the rotating sleeve, the side wall of the jointis provided with a clamping groove which is used for butting fixation with steel pipes, a power supply is embedded in the outer wall of the joint, and the inner walls of the upper and lower sides of the clamping groove are provided with clamping covers respectively.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com