Modular forming method of deflector

A deflector and metal tube technology, which is applied in the field of deflectors, can solve problems such as deflector deformation and internal stress, achieve the effects of simplifying processing, solving deformation problems, and improving the performance of later use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following describes the implementation of the present invention in detail with reference to the examples, but they do not constitute a limitation of the present invention, but are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand by illustrating the advantages.

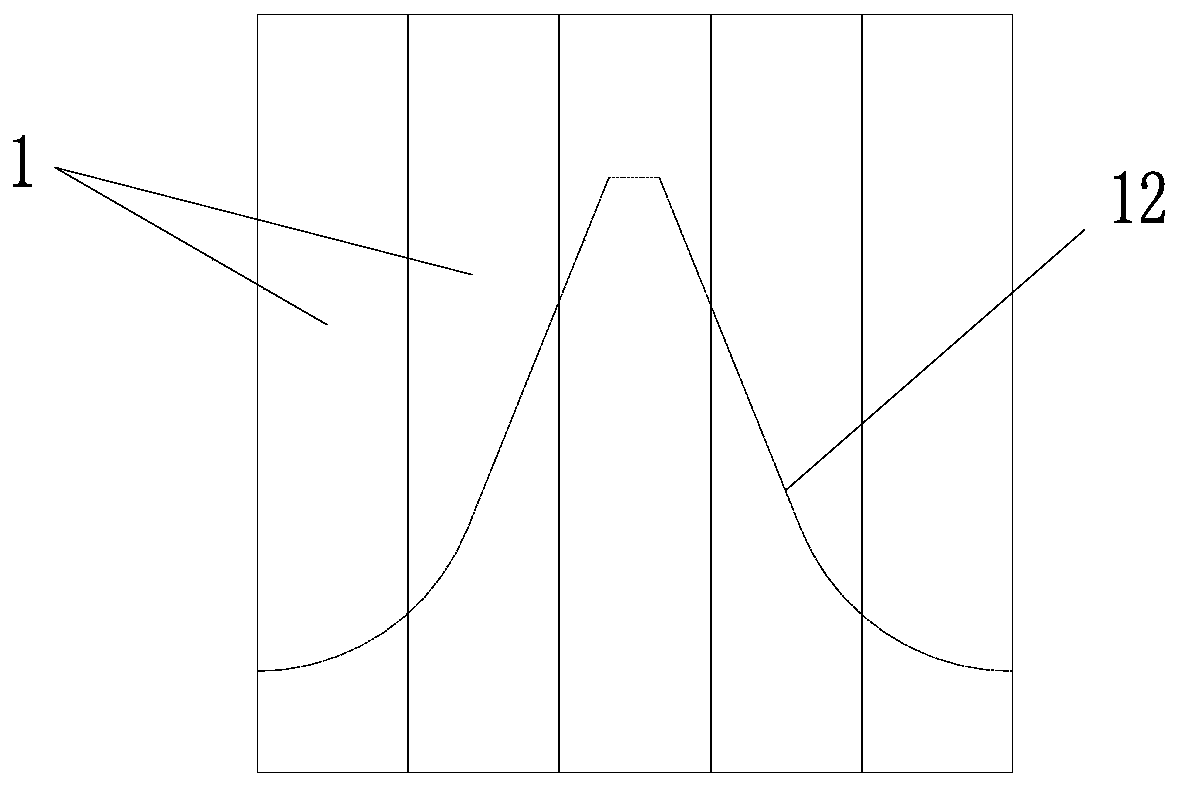

[0032] figure 1 Shown is a schematic diagram of the structure of the main body part of the traditional thin-plate welded deflector. The composition and the deficiencies of the structure have been described in the background art, and will not be repeated here.

[0033] A method for modularizing a deflector of the present invention comprises the following steps:

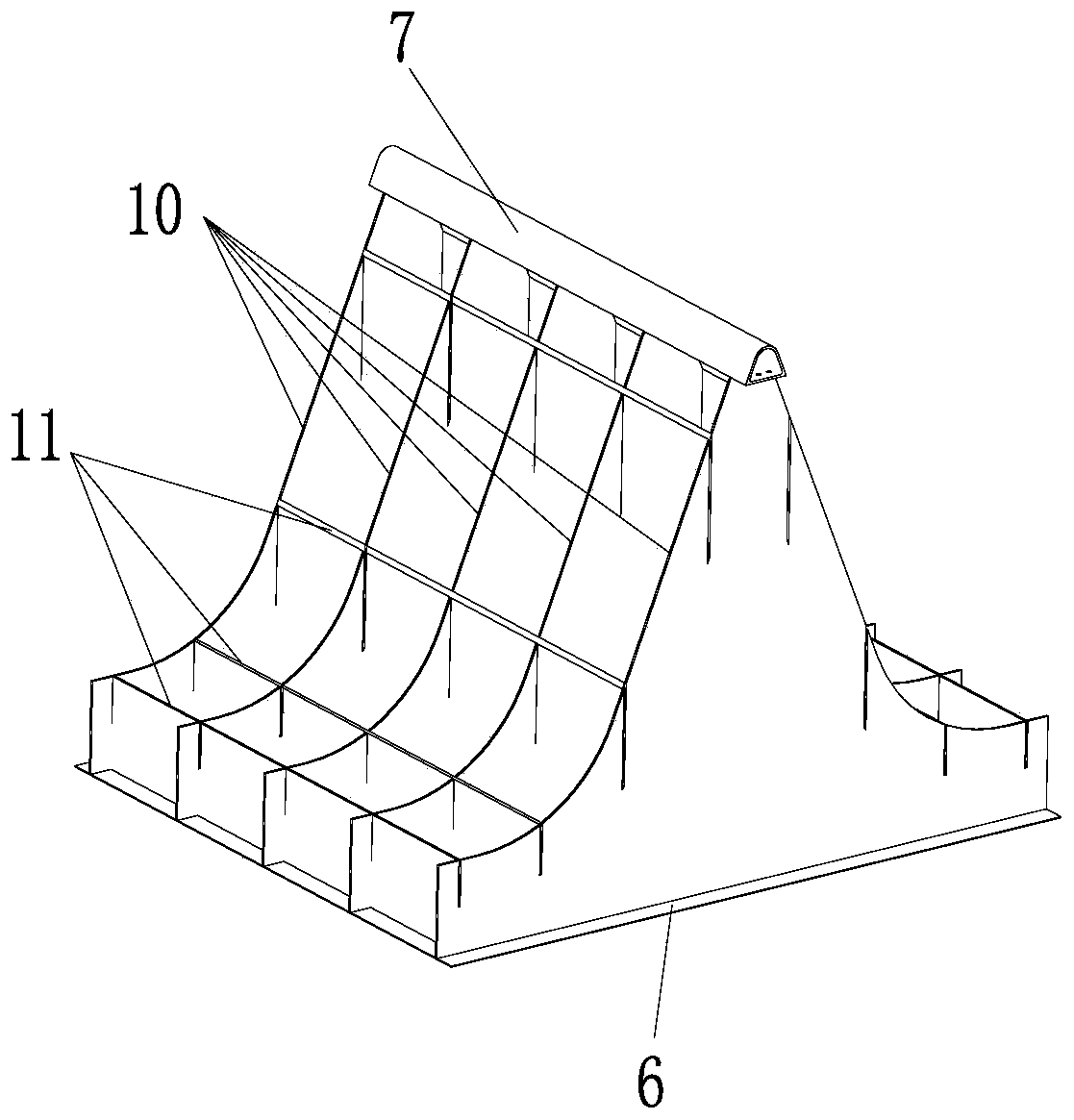

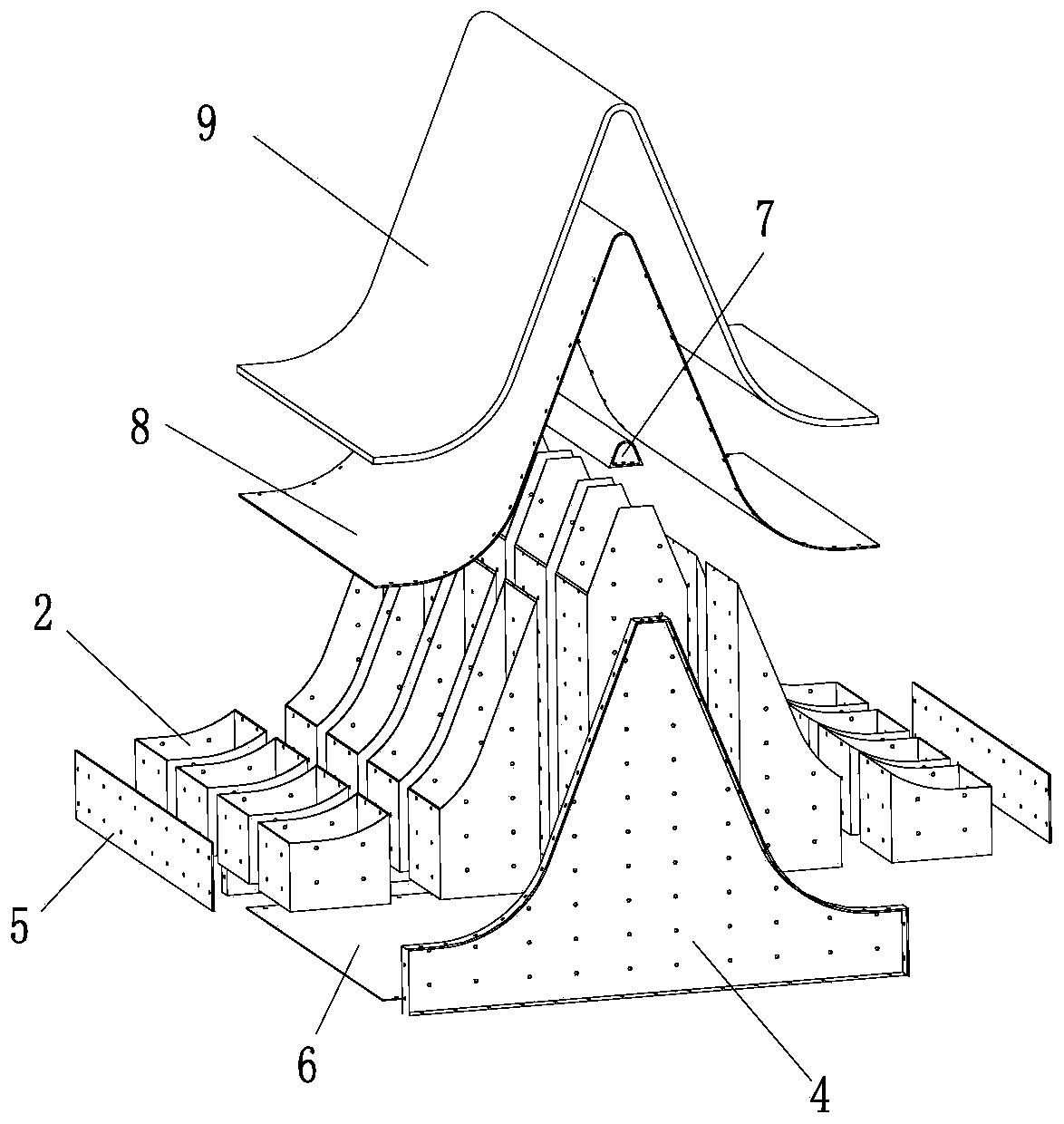

[0034] 1) Forming of the splicing module: according to the deflector (such as figure 2 ), determine the appropriate cross-sectional shape and quantity of the metal tube 1, the cross-sectional shape of the metal tube 1 is a polygon or a circle, and the outer sides of the metal tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com