Steel template system used for subway foundation pit supporting beam

A technology of steel formwork and support beams, which is applied in infrastructure engineering, water conservancy projects, artificial islands, etc., can solve problems such as failure to reach support beams, insufficient support force, easy deformation, etc., to prevent structural deformation, improve quality, Non-deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

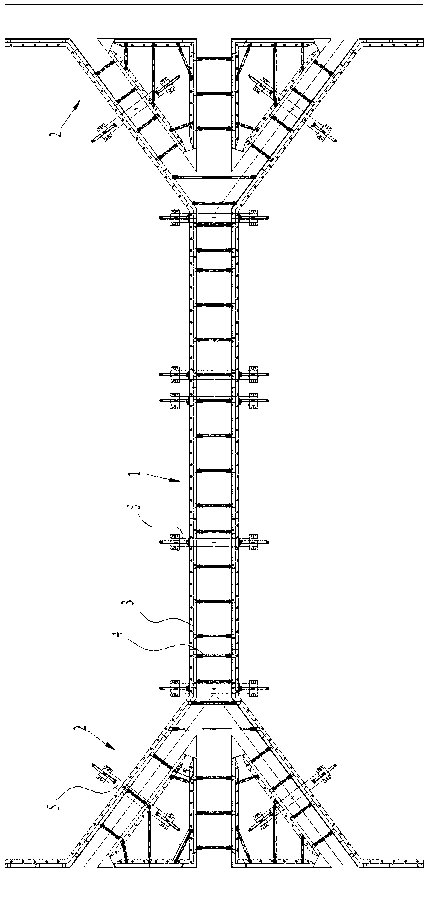

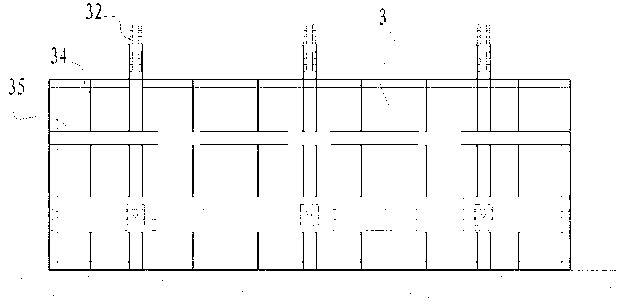

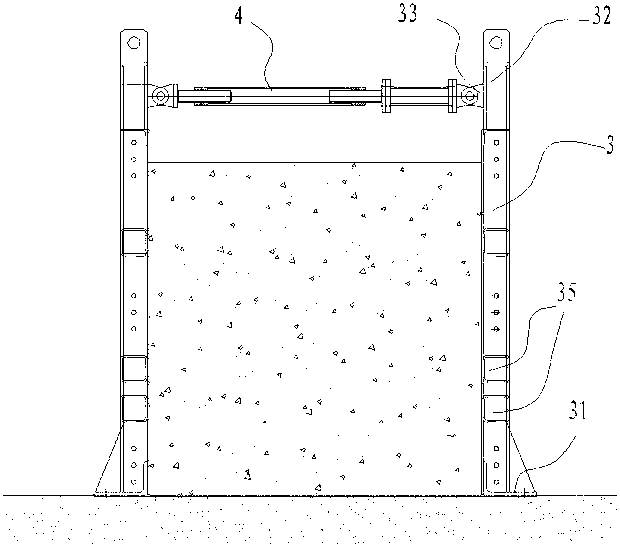

[0021] figure 1 It is a general structure diagram of an embodiment of the steel formwork system used for supporting beams in subway foundation pits according to the present invention. The embodiment of the present invention includes a main beam formwork 1 located in the middle and diagonally braced beam formworks 2 located at both ends. Further, the inclined The supporting beam formwork forms the shape of the head and tail of the Chinese character "米", that is, the steel formwork system of the present invention presents the shape of the Chinese character "米" without the middle horizontal line. Both the main girder formwork and the braced beam formwork are made of steel formwork 3 arranged in parallel and opposed to each other. The bottom of the steel formwork 3 is provided with a foot support 31 that can be locked with the ground. The foot s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com